07db4980d6874ea2eff00f796a372bb3.ppt

- Количество слайдов: 20

Lightweight Machine Gun and Ammunition: The “Clean Slate” Approach NDIA Joint Service Small Arms Symposium May 2004 Kori Spiegel Joint Service Small Arms Program (973) 724 -7944 kspiegel@pica. army. mil

Lightweight Machine Gun and Ammunition: The “Clean Slate” Approach NDIA Joint Service Small Arms Symposium May 2004 Kori Spiegel Joint Service Small Arms Program (973) 724 -7944 kspiegel@pica. army. mil

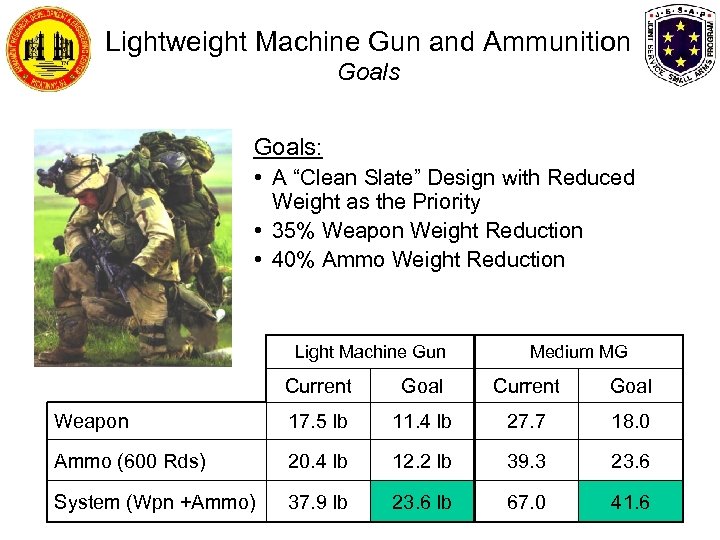

Lightweight Machine Gun and Ammunition Goals: • A “Clean Slate” Design with Reduced Weight as the Priority • 35% Weapon Weight Reduction • 40% Ammo Weight Reduction Light Machine Gun Medium MG Current Goal Weapon 17. 5 lb 11. 4 lb 27. 7 18. 0 Ammo (600 Rds) 20. 4 lb 12. 2 lb 39. 3 23. 6 System (Wpn +Ammo) 37. 9 lb 23. 6 lb 67. 0 41. 6

Lightweight Machine Gun and Ammunition Goals: • A “Clean Slate” Design with Reduced Weight as the Priority • 35% Weapon Weight Reduction • 40% Ammo Weight Reduction Light Machine Gun Medium MG Current Goal Weapon 17. 5 lb 11. 4 lb 27. 7 18. 0 Ammo (600 Rds) 20. 4 lb 12. 2 lb 39. 3 23. 6 System (Wpn +Ammo) 37. 9 lb 23. 6 lb 67. 0 41. 6

Requirements Ammunition Weapon External Interfaces

Requirements Ammunition Weapon External Interfaces

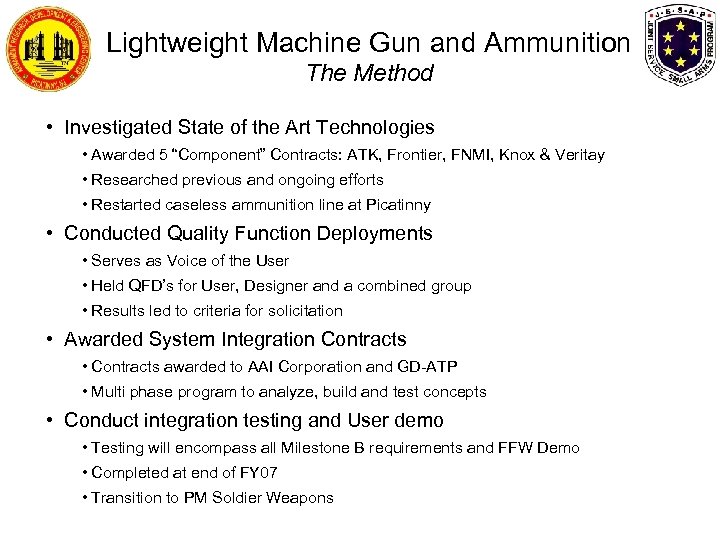

Lightweight Machine Gun and Ammunition The Method • Investigated State of the Art Technologies • Awarded 5 “Component” Contracts: ATK, Frontier, FNMI, Knox & Veritay • Researched previous and ongoing efforts • Restarted caseless ammunition line at Picatinny • Conducted Quality Function Deployments • Serves as Voice of the User • Held QFD’s for User, Designer and a combined group • Results led to criteria for solicitation • Awarded System Integration Contracts • Contracts awarded to AAI Corporation and GD-ATP • Multi phase program to analyze, build and test concepts • Conduct integration testing and User demo • Testing will encompass all Milestone B requirements and FFW Demo • Completed at end of FY 07 • Transition to PM Soldier Weapons

Lightweight Machine Gun and Ammunition The Method • Investigated State of the Art Technologies • Awarded 5 “Component” Contracts: ATK, Frontier, FNMI, Knox & Veritay • Researched previous and ongoing efforts • Restarted caseless ammunition line at Picatinny • Conducted Quality Function Deployments • Serves as Voice of the User • Held QFD’s for User, Designer and a combined group • Results led to criteria for solicitation • Awarded System Integration Contracts • Contracts awarded to AAI Corporation and GD-ATP • Multi phase program to analyze, build and test concepts • Conduct integration testing and User demo • Testing will encompass all Milestone B requirements and FFW Demo • Completed at end of FY 07 • Transition to PM Soldier Weapons

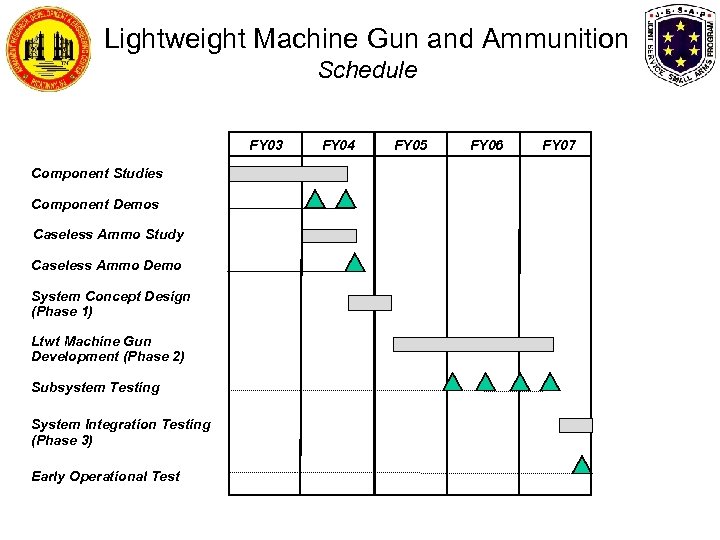

Lightweight Machine Gun and Ammunition Schedule FY 03 Component Studies Component Demos Caseless Ammo Study Caseless Ammo Demo System Concept Design (Phase 1) Ltwt Machine Gun Development (Phase 2) Subsystem Testing System Integration Testing (Phase 3) Early Operational Test FY 04 FY 05 FY 06 FY 07

Lightweight Machine Gun and Ammunition Schedule FY 03 Component Studies Component Demos Caseless Ammo Study Caseless Ammo Demo System Concept Design (Phase 1) Ltwt Machine Gun Development (Phase 2) Subsystem Testing System Integration Testing (Phase 3) Early Operational Test FY 04 FY 05 FY 06 FY 07

Lightweight Machine Gun and Ammunition AAI Team

Lightweight Machine Gun and Ammunition AAI Team

Lightweight Machine Gun and Ammunition AAI – Key Features • Achieves weight reduction objective – Ammunition – Weapon • Simplified weapon action • Extensive use of composites • Spiral development approach Light Machine Gun Medium Machine Gun

Lightweight Machine Gun and Ammunition AAI – Key Features • Achieves weight reduction objective – Ammunition – Weapon • Simplified weapon action • Extensive use of composites • Spiral development approach Light Machine Gun Medium Machine Gun

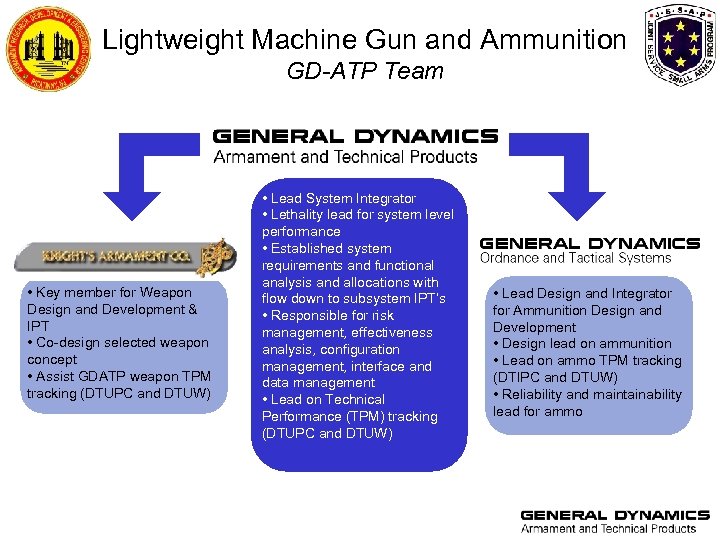

Lightweight Machine Gun and Ammunition GD-ATP Team • Key member for Weapon Design and Development & IPT • Co-design selected weapon concept • Assist GDATP weapon TPM tracking (DTUPC and DTUW) • Lead System Integrator • Lethality lead for system level performance • Established system requirements and functional analysis and allocations with flow down to subsystem IPT’s • Responsible for risk management, effectiveness analysis, configuration management, interface and data management • Lead on Technical Performance (TPM) tracking (DTUPC and DTUW) • Lead Design and Integrator for Ammunition Design and Development • Design lead on ammunition • Lead on ammo TPM tracking (DTIPC and DTUW) • Reliability and maintainability lead for ammo

Lightweight Machine Gun and Ammunition GD-ATP Team • Key member for Weapon Design and Development & IPT • Co-design selected weapon concept • Assist GDATP weapon TPM tracking (DTUPC and DTUW) • Lead System Integrator • Lethality lead for system level performance • Established system requirements and functional analysis and allocations with flow down to subsystem IPT’s • Responsible for risk management, effectiveness analysis, configuration management, interface and data management • Lead on Technical Performance (TPM) tracking (DTUPC and DTUW) • Lead Design and Integrator for Ammunition Design and Development • Design lead on ammunition • Lead on ammo TPM tracking (DTIPC and DTUW) • Reliability and maintainability lead for ammo

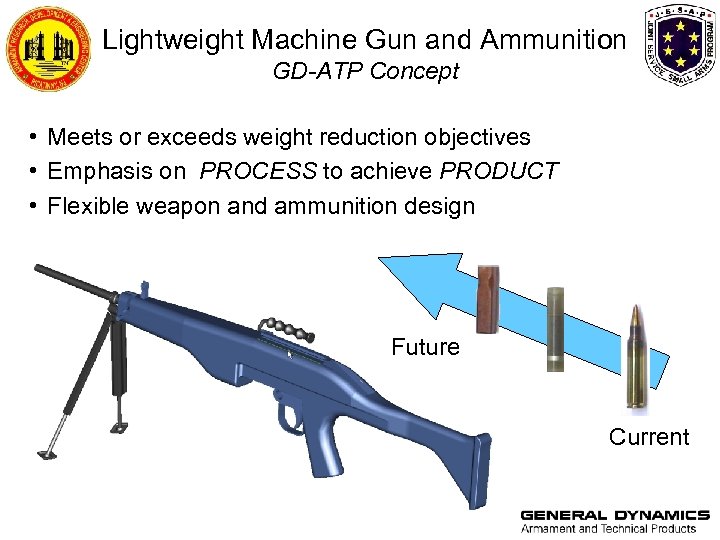

Lightweight Machine Gun and Ammunition GD-ATP Concept • Meets or exceeds weight reduction objectives • Emphasis on PROCESS to achieve PRODUCT • Flexible weapon and ammunition design Future Current

Lightweight Machine Gun and Ammunition GD-ATP Concept • Meets or exceeds weight reduction objectives • Emphasis on PROCESS to achieve PRODUCT • Flexible weapon and ammunition design Future Current

Caseless Ammunition Capability Demonstration Patricia M. O’Reilly Chief, Energetic and Organic Materials Laboratory Branch Energetics and Warheads Division Energetics, Warheads, and Environmental Technology Directorate Armaments Engineering and Technology Center US Army Armament Research Development Engineering Center NDIA Small Arms Symposium & Exhibition May 12, 2004 Las Vegas, Nevada

Caseless Ammunition Capability Demonstration Patricia M. O’Reilly Chief, Energetic and Organic Materials Laboratory Branch Energetics and Warheads Division Energetics, Warheads, and Environmental Technology Directorate Armaments Engineering and Technology Center US Army Armament Research Development Engineering Center NDIA Small Arms Symposium & Exhibition May 12, 2004 Las Vegas, Nevada

Caseless Ammunition Capability Demonstration • Objective – To develop and demonstrate an in-house capability and core competency to manufacture Caseless Ammunition prototypes in support of the Lightweight Machine Gun and Ammunition Science & Technology Objective – Deliver Caseless Ammunition for a live-fire/ballistic demonstration Establish ARDEC with a World Class Caseless Ammunition Capability

Caseless Ammunition Capability Demonstration • Objective – To develop and demonstrate an in-house capability and core competency to manufacture Caseless Ammunition prototypes in support of the Lightweight Machine Gun and Ammunition Science & Technology Objective – Deliver Caseless Ammunition for a live-fire/ballistic demonstration Establish ARDEC with a World Class Caseless Ammunition Capability

Caseless Ammunition Capability Demonstration • Why Caseless Ammunition? – – Lightweight Force Multiplier Decreased Logistics Burden High Ignition Temperature Propellant (HITP) provides improved propellant characteristics & energetic behavior – High level interest – Push the State of the Art – A Technology that fits the “clean slate” approach

Caseless Ammunition Capability Demonstration • Why Caseless Ammunition? – – Lightweight Force Multiplier Decreased Logistics Burden High Ignition Temperature Propellant (HITP) provides improved propellant characteristics & energetic behavior – High level interest – Push the State of the Art – A Technology that fits the “clean slate” approach

Caseless Ammunition Capability Demonstration • Background – Previous work performed under Advanced Combat Rifle (ACR) Program nearly 15 years ago – Technology Development funded by US (ARDEC) and Germany to Heckler & Koch (H&K)/Dynamit Nobel (DNAG) – Successful Demonstration of Caseless Ammunition Rifle System – Technology Licensed & Transferred to the US at ARDEC

Caseless Ammunition Capability Demonstration • Background – Previous work performed under Advanced Combat Rifle (ACR) Program nearly 15 years ago – Technology Development funded by US (ARDEC) and Germany to Heckler & Koch (H&K)/Dynamit Nobel (DNAG) – Successful Demonstration of Caseless Ammunition Rifle System – Technology Licensed & Transferred to the US at ARDEC

Caseless Ammunition Capability Demonstration • Why ARDEC In-house Effort? – Original Caseless Ammunition prototype manufacturing capability exists/retained – Risk of Technology being lost - Loss of expertise – Develop and maintain expertise/competency area – Provides new hires hands-on experience – Development of cutting edge technology

Caseless Ammunition Capability Demonstration • Why ARDEC In-house Effort? – Original Caseless Ammunition prototype manufacturing capability exists/retained – Risk of Technology being lost - Loss of expertise – Develop and maintain expertise/competency area – Provides new hires hands-on experience – Development of cutting edge technology

Caseless Ammunition Capability Demonstration • Technical Approach – Determine Feasibility • Identify and address technical challenges/potential risk areas – Near term & long term • Material needs and source suppliers - availability • Assess equipment condition • Costs – Determined viability Organizational Commitment – Re-establish capability and prototyping process utilizing existing technology – Validation of In-house Caseless Ammunition capability for 5. 56 mm

Caseless Ammunition Capability Demonstration • Technical Approach – Determine Feasibility • Identify and address technical challenges/potential risk areas – Near term & long term • Material needs and source suppliers - availability • Assess equipment condition • Costs – Determined viability Organizational Commitment – Re-establish capability and prototyping process utilizing existing technology – Validation of In-house Caseless Ammunition capability for 5. 56 mm

Caseless Ammunition Capability Demonstration • Status of Progress – Accomplishments • • • Materials, supplies and services obtained Maintenance and service equipment – test and manufacturing SOPs and Manufacturing Process procedures Baseline Formulation Selected First HITP mix manufactured Pressing Study completed

Caseless Ammunition Capability Demonstration • Status of Progress – Accomplishments • • • Materials, supplies and services obtained Maintenance and service equipment – test and manufacturing SOPs and Manufacturing Process procedures Baseline Formulation Selected First HITP mix manufactured Pressing Study completed

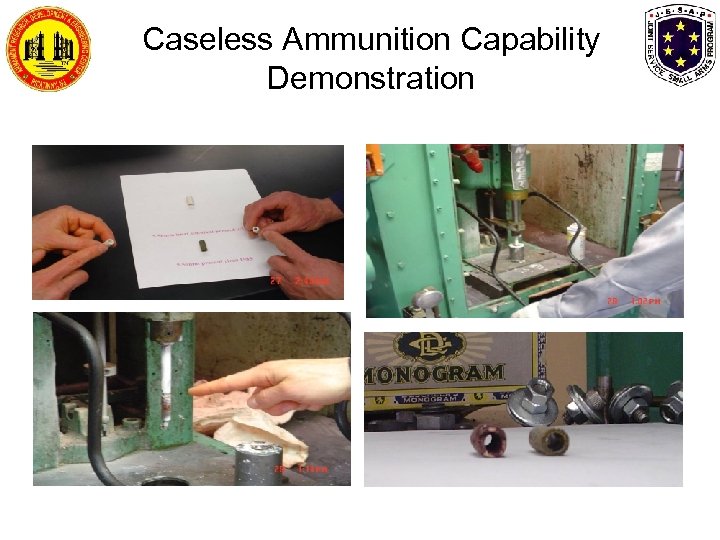

Caseless Ammunition Capability Demonstration

Caseless Ammunition Capability Demonstration

Caseless Ammunition Capability Demonstration • Status of Progress – Next Steps • Select initial charge weights • Manufacture initial quantity of prototypes – – Charge Weight Determination (Ballistic Evaluation) Evaluate results and select next charge weight(s) Characterization Implementation of any processing improvements • Interior Ballistic Modeling • Manufacture second HITP mix and qty of prototypes – Charge weight(s) verification (Ballistic Evaluation) – Evaluate results and determine optimal charge weight • Manufacture HITP for Demonstration Quantity – Small qty of prototypes for charge wt and ballistic performance validation – Manufacture demonstration qty • Deliver Demonstration quantity - June ‘ 04

Caseless Ammunition Capability Demonstration • Status of Progress – Next Steps • Select initial charge weights • Manufacture initial quantity of prototypes – – Charge Weight Determination (Ballistic Evaluation) Evaluate results and select next charge weight(s) Characterization Implementation of any processing improvements • Interior Ballistic Modeling • Manufacture second HITP mix and qty of prototypes – Charge weight(s) verification (Ballistic Evaluation) – Evaluate results and determine optimal charge weight • Manufacture HITP for Demonstration Quantity – Small qty of prototypes for charge wt and ballistic performance validation – Manufacture demonstration qty • Deliver Demonstration quantity - June ‘ 04

Caseless Ammunition Capability Demonstration • Technical Challenges – Long term availability and identification of source suppliers – Material replacements – Environmentally friendly alternatives/ manufacturing processes for constituents • Summary – Validation of the in-house capability proceeding – Efforts focused to bring Caseless Ammunition Capability/Technology to a sufficient maturation level • Acknowledgements – JSAAP Office – PPP – Entire Caseless Ammunition IPT

Caseless Ammunition Capability Demonstration • Technical Challenges – Long term availability and identification of source suppliers – Material replacements – Environmentally friendly alternatives/ manufacturing processes for constituents • Summary – Validation of the in-house capability proceeding – Efforts focused to bring Caseless Ammunition Capability/Technology to a sufficient maturation level • Acknowledgements – JSAAP Office – PPP – Entire Caseless Ammunition IPT

Lightweight Machine Gun and Ammunition Summary • By using “Clean Slate”, program goals are feasible • Program progressing successfully • Close partnering between Government & Industry Comments/Questions?

Lightweight Machine Gun and Ammunition Summary • By using “Clean Slate”, program goals are feasible • Program progressing successfully • Close partnering between Government & Industry Comments/Questions?