f456ee78e6b97f5579216cc7e23b6cb5.ppt

- Количество слайдов: 31

Li. CAS Linear Collider Alignement and Survey Li. CAS Warsaw University Applied Geodesy Group 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 1

Li. CAS Linear Collider Alignement and Survey Li. CAS Warsaw University Applied Geodesy Group 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 1

Overview n What is Li. CAS n n n Li. CAS group members and collaborators Progress since last meeting (11. 03. 05) n n The ILC survey problem The RTRS concept The Li. CAS measurement principles FSI LSM Prototype Production Plan for the next 6 months 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 2

Overview n What is Li. CAS n n n Li. CAS group members and collaborators Progress since last meeting (11. 03. 05) n n The ILC survey problem The RTRS concept The Li. CAS measurement principles FSI LSM Prototype Production Plan for the next 6 months 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 2

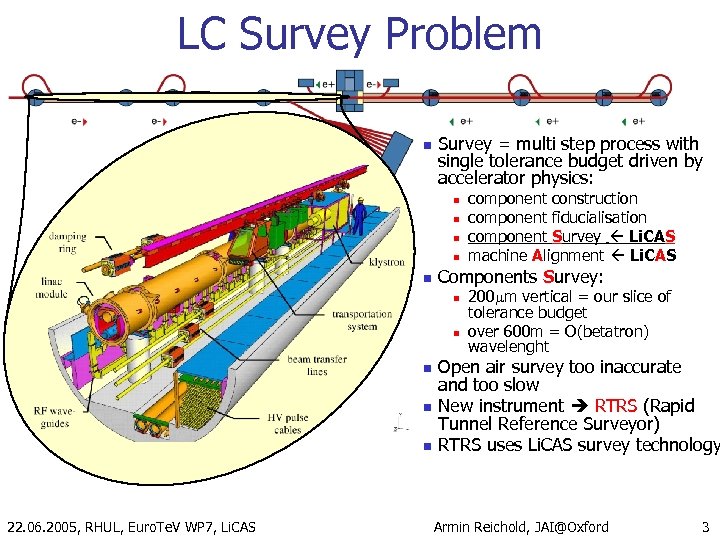

LC Survey Problem n Survey = multi step process with single tolerance budget driven by accelerator physics: n n n Components Survey: n n n 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS component construction component fiducialisation component Survey Li. CAS machine Alignment Li. CAS 200 mm vertical = our slice of tolerance budget over 600 m = O(betatron) wavelenght Open air survey too inaccurate and too slow New instrument RTRS (Rapid Tunnel Reference Surveyor) RTRS uses Li. CAS survey technology Armin Reichold, JAI@Oxford 3

LC Survey Problem n Survey = multi step process with single tolerance budget driven by accelerator physics: n n n Components Survey: n n n 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS component construction component fiducialisation component Survey Li. CAS machine Alignment Li. CAS 200 mm vertical = our slice of tolerance budget over 600 m = O(betatron) wavelenght Open air survey too inaccurate and too slow New instrument RTRS (Rapid Tunnel Reference Surveyor) RTRS uses Li. CAS survey technology Armin Reichold, JAI@Oxford 3

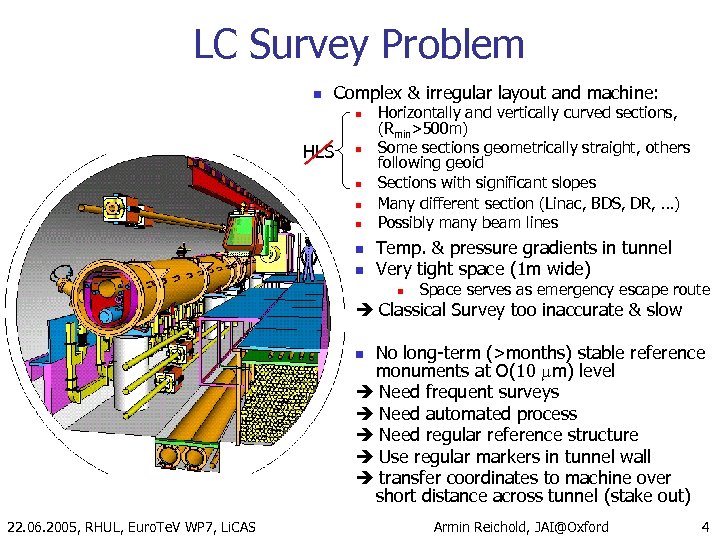

LC Survey Problem n Complex & irregular layout and machine: n HLS n n n Horizontally and vertically curved sections, (Rmin>500 m) Some sections geometrically straight, others following geoid Sections with significant slopes Many different section (Linac, BDS, DR, …) Possibly many beam lines Temp. & pressure gradients in tunnel Very tight space (1 m wide) n Space serves as emergency escape route Classical Survey too inaccurate & slow No long-term (>months) stable reference monuments at O(10 mm) level Need frequent surveys Need automated process Need regular reference structure Use regular markers in tunnel wall transfer coordinates to machine over short distance across tunnel (stake out) n 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 4

LC Survey Problem n Complex & irregular layout and machine: n HLS n n n Horizontally and vertically curved sections, (Rmin>500 m) Some sections geometrically straight, others following geoid Sections with significant slopes Many different section (Linac, BDS, DR, …) Possibly many beam lines Temp. & pressure gradients in tunnel Very tight space (1 m wide) n Space serves as emergency escape route Classical Survey too inaccurate & slow No long-term (>months) stable reference monuments at O(10 mm) level Need frequent surveys Need automated process Need regular reference structure Use regular markers in tunnel wall transfer coordinates to machine over short distance across tunnel (stake out) n 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 4

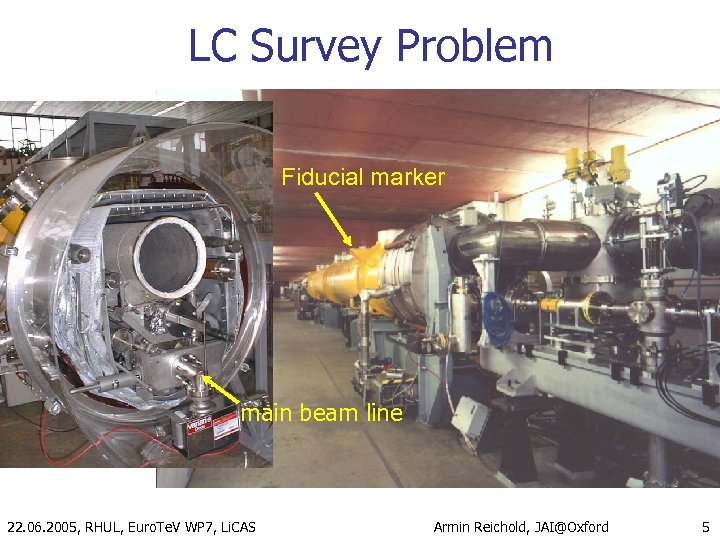

LC Survey Problem Fiducial marker main beam line 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 5

LC Survey Problem Fiducial marker main beam line 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 5

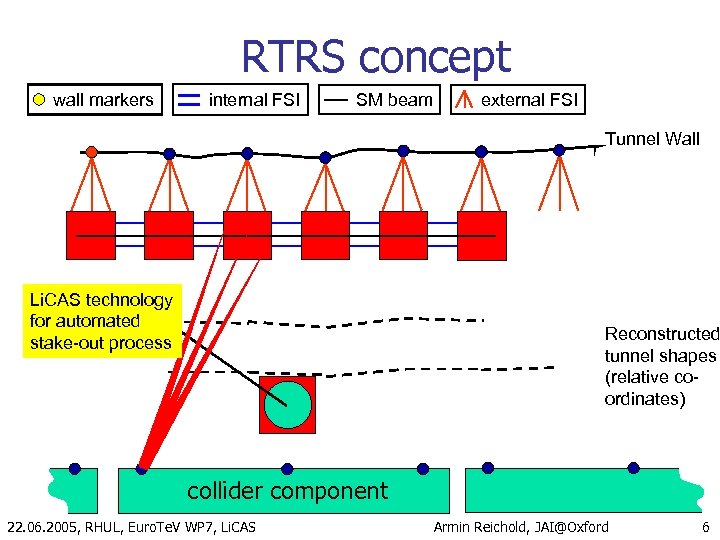

RTRS concept wall markers internal FSI SM beam external FSI Tunnel Wall Li. CAS technology for automated stake-out process Reconstructed tunnel shapes (relative coordinates) collider component 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 6

RTRS concept wall markers internal FSI SM beam external FSI Tunnel Wall Li. CAS technology for automated stake-out process Reconstructed tunnel shapes (relative coordinates) collider component 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 6

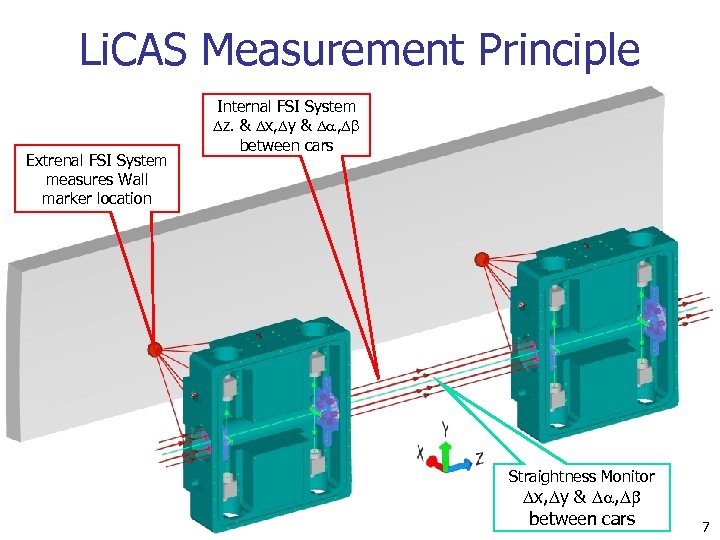

Li. CAS Measurement Principle Extrenal FSI System measures Wall marker location Internal FSI System Dz. & Dx, Dy & Da, Db between cars Straightness Monitor Dx, Dy & Da, Db between cars 7

Li. CAS Measurement Principle Extrenal FSI System measures Wall marker location Internal FSI System Dz. & Dx, Dy & Da, Db between cars Straightness Monitor Dx, Dy & Da, Db between cars 7

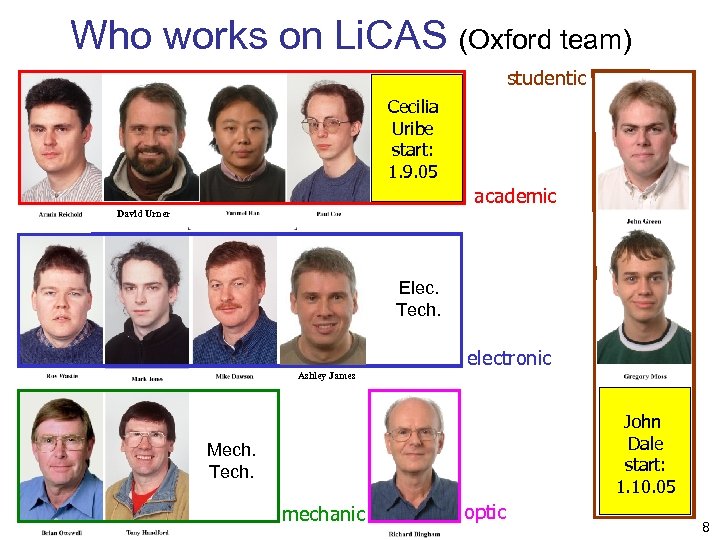

Who works on Li. CAS (Oxford team) studentic Cecilia Uribe start: 1. 9. 05 academic David Urner Elec. Tech. electronic Ashley James John Dale start: 1. 10. 05 Mech. Tech. mechanic optic 8

Who works on Li. CAS (Oxford team) studentic Cecilia Uribe start: 1. 9. 05 academic David Urner Elec. Tech. electronic Ashley James John Dale start: 1. 10. 05 Mech. Tech. mechanic optic 8

Collaborators • Johannes Prenting • Markus Schloesser • Ernst-Otto Saemann • Daniel Kaempnter Oxford: Alumni David Howell Edward Botcherby Brtek Szczygiel student Thomas Zlosnik Simon Wilshin Chris Glassman Gregorz Grzelak 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford Robert Apsimon Peter Baker Ken Chuang 9

Collaborators • Johannes Prenting • Markus Schloesser • Ernst-Otto Saemann • Daniel Kaempnter Oxford: Alumni David Howell Edward Botcherby Brtek Szczygiel student Thomas Zlosnik Simon Wilshin Chris Glassman Gregorz Grzelak 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford Robert Apsimon Peter Baker Ken Chuang 9

News since the last meeting (11. 03. 2005)? 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 10

News since the last meeting (11. 03. 2005)? 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 10

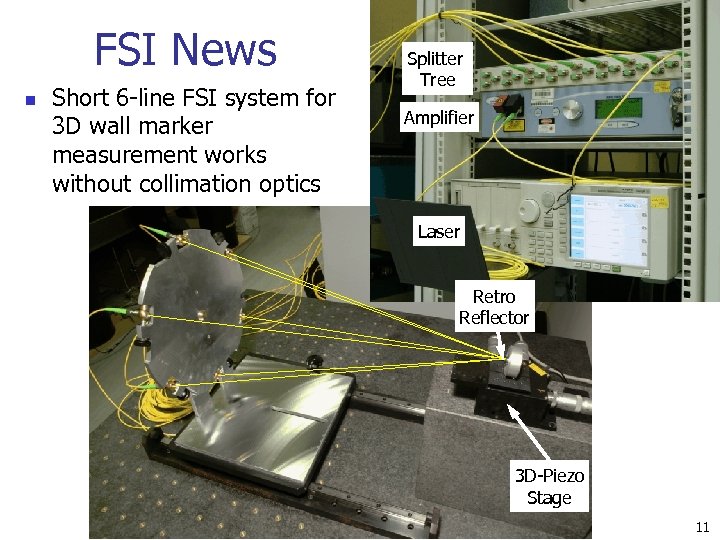

FSI News n Short 6 -line FSI system for 3 D wall marker measurement works without collimation optics Splitter Tree Amplifier Laser Retro Reflector 3 D-Piezo Stage 11

FSI News n Short 6 -line FSI system for 3 D wall marker measurement works without collimation optics Splitter Tree Amplifier Laser Retro Reflector 3 D-Piezo Stage 11

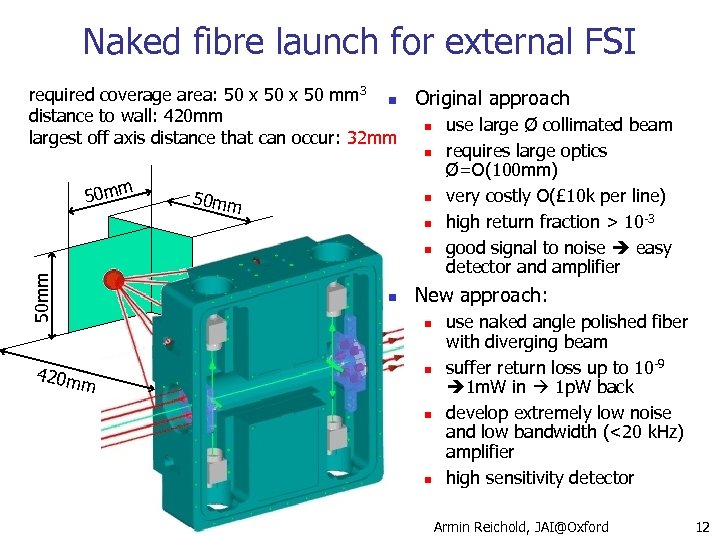

Naked fibre launch for external FSI 50 mm required coverage area: 50 x 50 mm 3 n Original approach distance to wall: 420 mm n use large Ø collimated beam largest off axis distance that can occur: 32 mm n requires large optics Ø=O(100 mm) n very costly O(£ 10 k per line) 50 mm -3 n high return fraction > 10 n good signal to noise easy detector and amplifier n New approach: 420 m n n n use naked angle polished fiber with diverging beam suffer return loss up to 10 -9 1 m. W in 1 p. W back develop extremely low noise and low bandwidth (<20 k. Hz) amplifier high sensitivity detector Armin Reichold, JAI@Oxford 12

Naked fibre launch for external FSI 50 mm required coverage area: 50 x 50 mm 3 n Original approach distance to wall: 420 mm n use large Ø collimated beam largest off axis distance that can occur: 32 mm n requires large optics Ø=O(100 mm) n very costly O(£ 10 k per line) 50 mm -3 n high return fraction > 10 n good signal to noise easy detector and amplifier n New approach: 420 m n n n use naked angle polished fiber with diverging beam suffer return loss up to 10 -9 1 m. W in 1 p. W back develop extremely low noise and low bandwidth (<20 k. Hz) amplifier high sensitivity detector Armin Reichold, JAI@Oxford 12

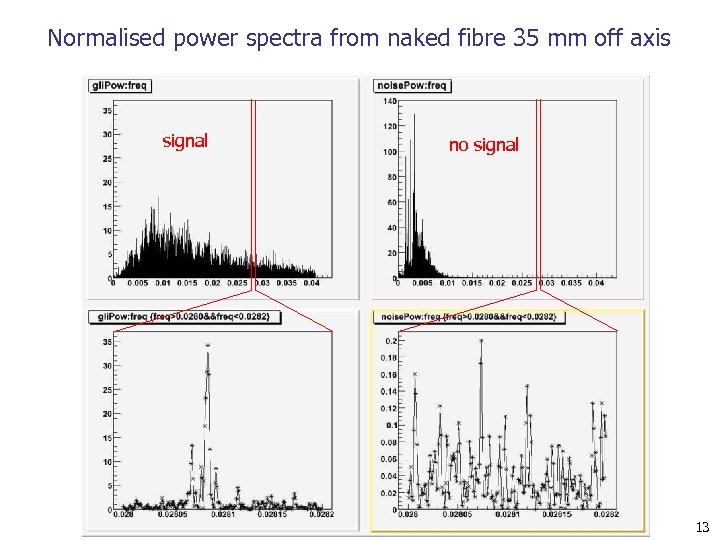

Normalised power spectra from naked fibre 35 mm off axis signal no signal 13

Normalised power spectra from naked fibre 35 mm off axis signal no signal 13

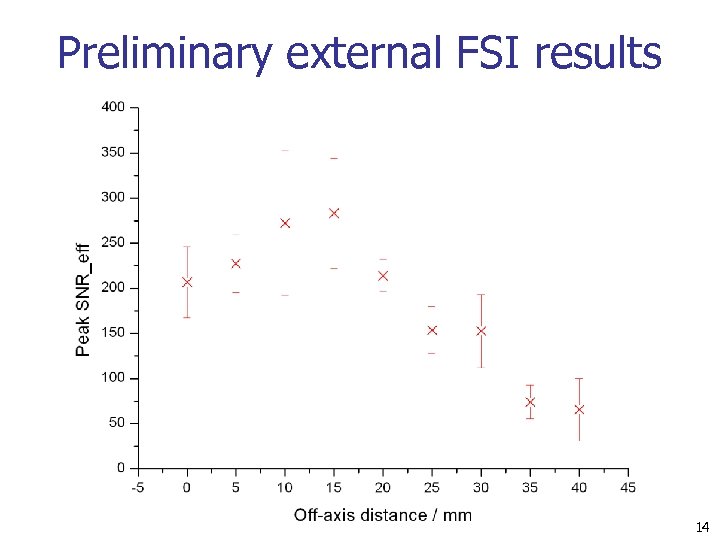

Preliminary external FSI results 14

Preliminary external FSI results 14

Preliminary conclusion on external FSI n n n Signal clearly visible stray light problem not too dramatic Fourier analysis extremely powerful need more work on accuracy and influence of analysis details need to study large statistical samples need to check tilt angles of retro reflectors 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 15

Preliminary conclusion on external FSI n n n Signal clearly visible stray light problem not too dramatic Fourier analysis extremely powerful need more work on accuracy and influence of analysis details need to study large statistical samples need to check tilt angles of retro reflectors 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 15

More news about FSI systems n n n Internal FSI collimators preliminary ok (first one glued 2 weeks ago) Needs more repeatability work to check thermal behaviour New set of questions about optimum reference interferometer length n n n observed differrences between use of long and short reference interferometer appear to need reference length O(5 m) to resolve variations in tuning speed designing folded & evacuated reference interferom. now 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 16

More news about FSI systems n n n Internal FSI collimators preliminary ok (first one glued 2 weeks ago) Needs more repeatability work to check thermal behaviour New set of questions about optimum reference interferometer length n n n observed differrences between use of long and short reference interferometer appear to need reference length O(5 m) to resolve variations in tuning speed designing folded & evacuated reference interferom. now 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 16

More news about FSI n Completed Masters Projects: n calibration of external FSI system n n n displace retro reflector with high precision 3 D motion stage while measuring position with FSI lines O(20 position) obtain origins of FSI lines via consistency fitting very good numerical algorithms for geometrical reconstruction can also obtain some parameters of stage metric multiple distance measurements with single FSI line n n studied minimal resolvable length differences down to 100 mm simulated up to 5 distances in one line 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 17

More news about FSI n Completed Masters Projects: n calibration of external FSI system n n n displace retro reflector with high precision 3 D motion stage while measuring position with FSI lines O(20 position) obtain origins of FSI lines via consistency fitting very good numerical algorithms for geometrical reconstruction can also obtain some parameters of stage metric multiple distance measurements with single FSI line n n studied minimal resolvable length differences down to 100 mm simulated up to 5 distances in one line 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 17

LSM 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 18

LSM 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 18

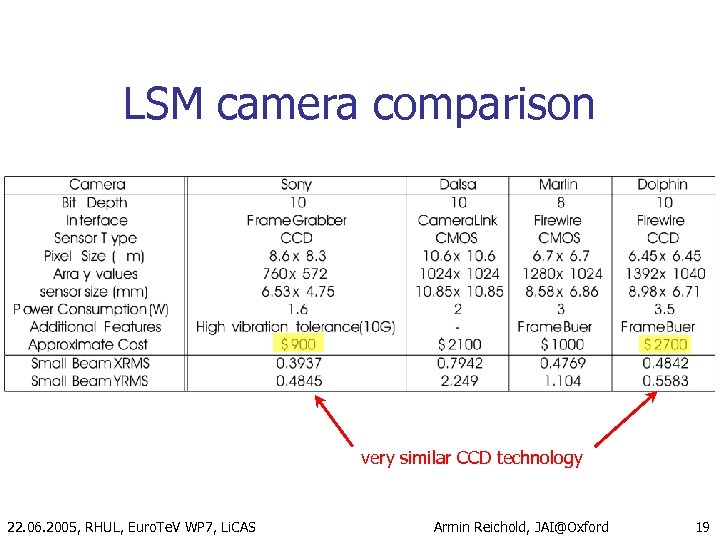

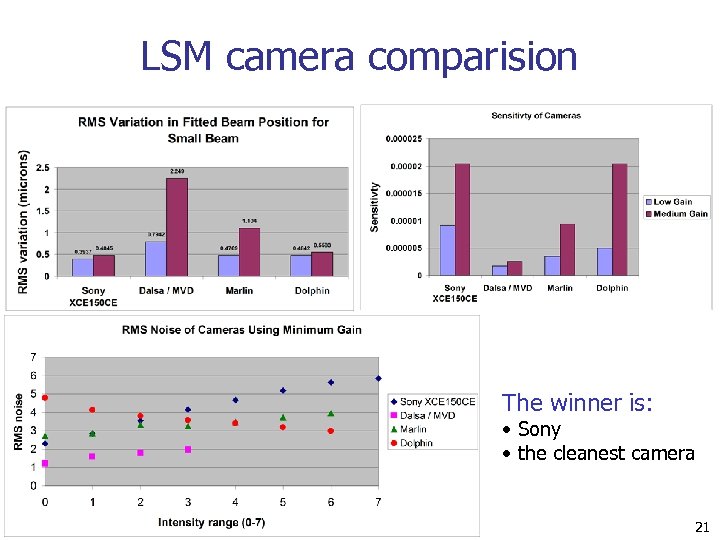

LSM camera comparison very similar CCD technology 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 19

LSM camera comparison very similar CCD technology 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 19

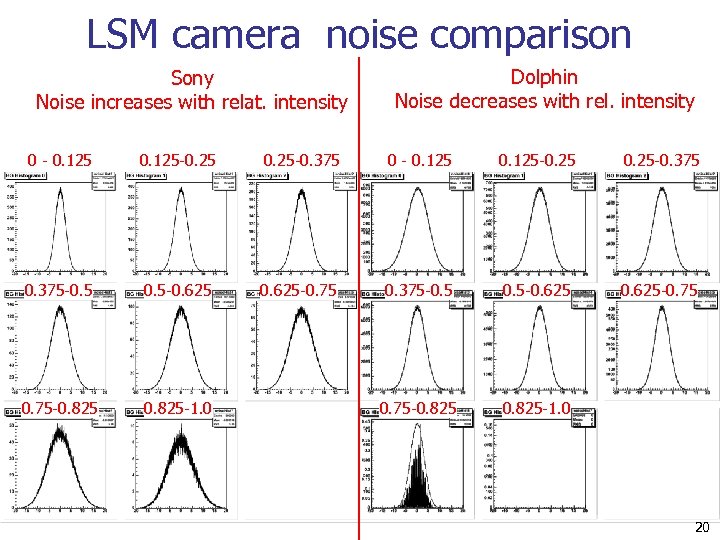

LSM camera noise comparison Sony Noise increases with relat. intensity Dolphin Noise decreases with rel. intensity 0 - 0. 125 -0. 25 -0. 375 -0. 5 -0. 625 -0. 75 -0. 825 -1. 0 20

LSM camera noise comparison Sony Noise increases with relat. intensity Dolphin Noise decreases with rel. intensity 0 - 0. 125 -0. 25 -0. 375 -0. 5 -0. 625 -0. 75 -0. 825 -1. 0 20

LSM camera comparision The winner is: • Sony • the cleanest camera 21

LSM camera comparision The winner is: • Sony • the cleanest camera 21

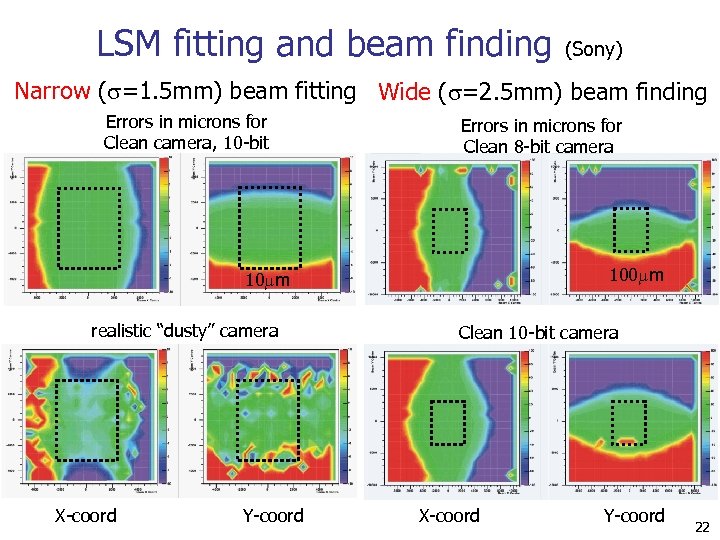

LSM fitting and beam finding (Sony) Narrow (s=1. 5 mm) beam fitting Wide (s=2. 5 mm) beam finding Errors in microns for Clean camera, 10 -bit Errors in microns for Clean 8 -bit camera 100 mm 10 mm realistic “dusty” camera X-coord Y-coord Clean 10 -bit camera X-coord Y-coord 22

LSM fitting and beam finding (Sony) Narrow (s=1. 5 mm) beam fitting Wide (s=2. 5 mm) beam finding Errors in microns for Clean camera, 10 -bit Errors in microns for Clean 8 -bit camera 100 mm 10 mm realistic “dusty” camera X-coord Y-coord Clean 10 -bit camera X-coord Y-coord 22

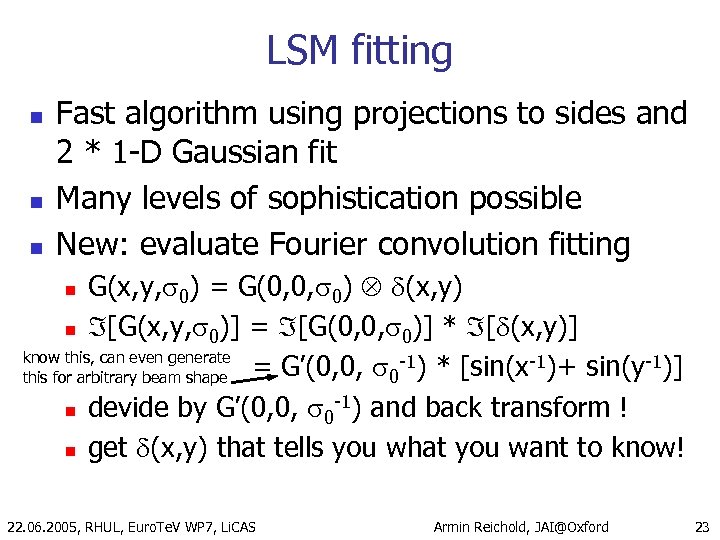

LSM fitting n n n Fast algorithm using projections to sides and 2 * 1 -D Gaussian fit Many levels of sophistication possible New: evaluate Fourier convolution fitting G(x, y, s 0) = G(0, 0, s 0) d(x, y) n [G(x, y, s 0)] = [G(0, 0, s 0)] * [d(x, y)] know this, can even generate = G’(0, 0, s 0 -1) * [sin(x-1)+ sin(y-1)] this for arbitrary beam shape -1 n devide by G’(0, 0, s 0 ) and back transform ! n get d(x, y) that tells you what you want to know! n 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 23

LSM fitting n n n Fast algorithm using projections to sides and 2 * 1 -D Gaussian fit Many levels of sophistication possible New: evaluate Fourier convolution fitting G(x, y, s 0) = G(0, 0, s 0) d(x, y) n [G(x, y, s 0)] = [G(0, 0, s 0)] * [d(x, y)] know this, can even generate = G’(0, 0, s 0 -1) * [sin(x-1)+ sin(y-1)] this for arbitrary beam shape -1 n devide by G’(0, 0, s 0 ) and back transform ! n get d(x, y) that tells you what you want to know! n 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 23

Prototype Production 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 24

Prototype Production 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 24

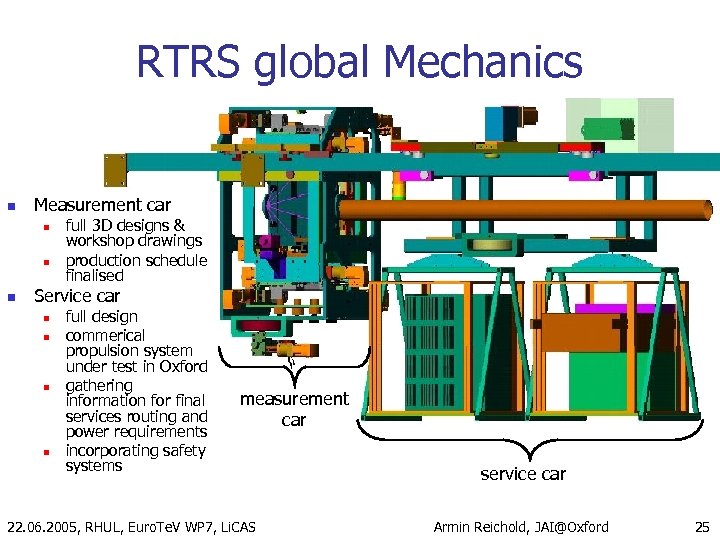

RTRS global Mechanics n Measurement car n n n full 3 D designs & workshop drawings production schedule finalised Service car n n full design commerical propulsion system under test in Oxford gathering information for final services routing and power requirements incorporating safety systems measurement car 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS service car Armin Reichold, JAI@Oxford 25

RTRS global Mechanics n Measurement car n n n full 3 D designs & workshop drawings production schedule finalised Service car n n full design commerical propulsion system under test in Oxford gathering information for final services routing and power requirements incorporating safety systems measurement car 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS service car Armin Reichold, JAI@Oxford 25

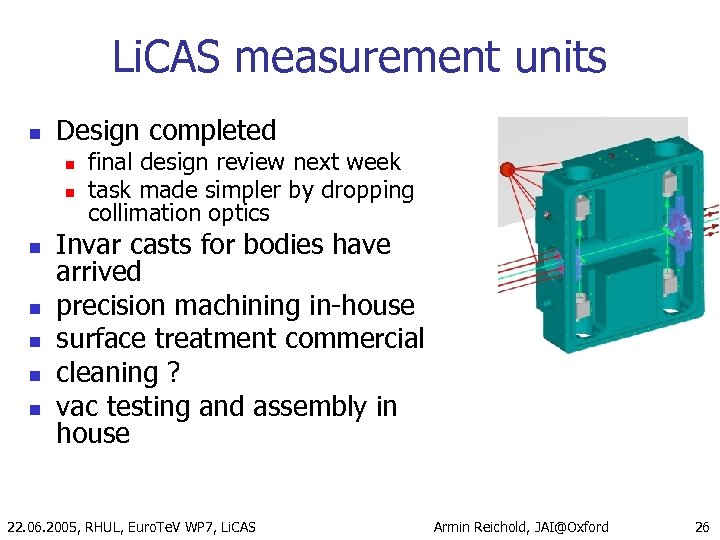

Li. CAS measurement units n Design completed n n n n final design review next week task made simpler by dropping collimation optics Invar casts for bodies have arrived precision machining in-house surface treatment commercial cleaning ? vac testing and assembly in house 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 26

Li. CAS measurement units n Design completed n n n n final design review next week task made simpler by dropping collimation optics Invar casts for bodies have arrived precision machining in-house surface treatment commercial cleaning ? vac testing and assembly in house 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 26

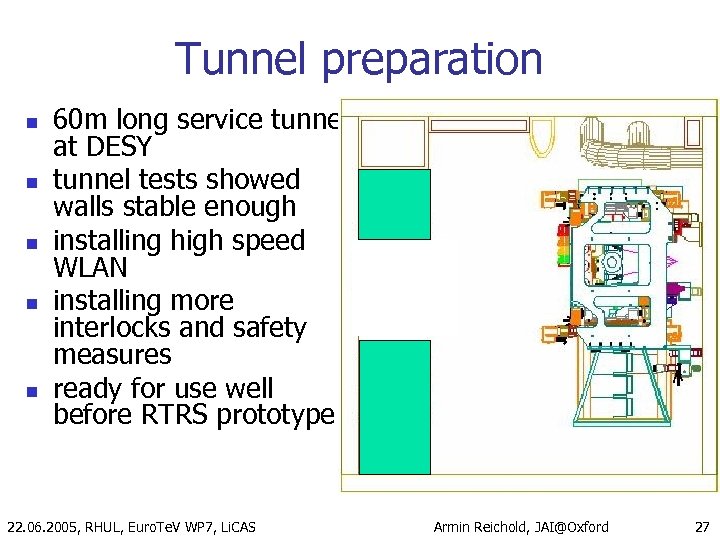

Tunnel preparation n n 60 m long service tunnel at DESY tunnel tests showed walls stable enough installing high speed WLAN installing more interlocks and safety measures ready for use well before RTRS prototype 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 27

Tunnel preparation n n 60 m long service tunnel at DESY tunnel tests showed walls stable enough installing high speed WLAN installing more interlocks and safety measures ready for use well before RTRS prototype 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 27

DAQ and Electronics n Final custom ADC board n n n Final cutom photodetector & amplifier board: n n n pre-series boards being equipped with parts now green light for serial production in 3 weeks Trigger and Clock distribution system n n n single channel performance tests passed nearing completion of firmware O(1 month) first design completed test prototype in 2 months DAQ software: n n lab system in C++ to replace initial Lab. View this month lab system is prototype for train system DAQ and main control 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 28

DAQ and Electronics n Final custom ADC board n n n Final cutom photodetector & amplifier board: n n n pre-series boards being equipped with parts now green light for serial production in 3 weeks Trigger and Clock distribution system n n n single channel performance tests passed nearing completion of firmware O(1 month) first design completed test prototype in 2 months DAQ software: n n lab system in C++ to replace initial Lab. View this month lab system is prototype for train system DAQ and main control 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 28

What do we do next Up to autumn 2005 n Completion of FSI and LSM and global analysis codes n Production of Electronics n Construction of 3 -car prototype components n Partial assembly of inner systems at Oxford n Sub-system calibrations n Installation in DESY test tunnel = 1. Nov. 05 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 29

What do we do next Up to autumn 2005 n Completion of FSI and LSM and global analysis codes n Production of Electronics n Construction of 3 -car prototype components n Partial assembly of inner systems at Oxford n Sub-system calibrations n Installation in DESY test tunnel = 1. Nov. 05 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 29

What do we do next Up to Spring 2006 n Operate prototype at DESY n n n commissioning many calibration programs on full train multiple test surveys of tunnel tuning of operation and analysis algorithms study of systematic errors Up to Spring 2007 n In Oxford n n Improvements of component calibration programs & hardware Design of second generation instrument for X-FEL n n much smaller fits into X-FEL tunnel and maybe ATF-2 much simpler reduce from R&D to production functionality 6 cars Design stake out instrument 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 30

What do we do next Up to Spring 2006 n Operate prototype at DESY n n n commissioning many calibration programs on full train multiple test surveys of tunnel tuning of operation and analysis algorithms study of systematic errors Up to Spring 2007 n In Oxford n n Improvements of component calibration programs & hardware Design of second generation instrument for X-FEL n n much smaller fits into X-FEL tunnel and maybe ATF-2 much simpler reduce from R&D to production functionality 6 cars Design stake out instrument 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 30

What do we do next Up to Spring 2008 n Operate improved first prototype at DESY n Construct second prototype * n Operate second prototype in X-FEL * n Construct stake out instrument * n Operate stake out instrument in X-FEL * *(needs additional funding) 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 31

What do we do next Up to Spring 2008 n Operate improved first prototype at DESY n Construct second prototype * n Operate second prototype in X-FEL * n Construct stake out instrument * n Operate stake out instrument in X-FEL * *(needs additional funding) 22. 06. 2005, RHUL, Euro. Te. V WP 7, Li. CAS Armin Reichold, JAI@Oxford 31