ec6945798094817bf13699aca8b54141.ppt

- Количество слайдов: 47

Lesson 4: Design Cycle Description Prof. Olivier de Weck 4 -1

Lesson 4: Design Cycle Description Prof. Olivier de Weck 4 -1

Themes Addressed 4 -2

Themes Addressed 4 -2

Lesson 4: Design Cycle Description Prof. Olivier de Weck 4 -3

Lesson 4: Design Cycle Description Prof. Olivier de Weck 4 -3

Lesson Outline • • • Typical attributes of design engineer Basic steps of design process Waterfall vs. spiral processes Examples from industry & government Other important considerations Bottom line: – Value of conceptual design – Value of prototyping & iterating 4 -4

Lesson Outline • • • Typical attributes of design engineer Basic steps of design process Waterfall vs. spiral processes Examples from industry & government Other important considerations Bottom line: – Value of conceptual design – Value of prototyping & iterating 4 -4

Typical Attributes of Design Engineer “The scientist seeks to understand what is; the engineer seeks to create what never was” —Theodor von Kármán 4 -5

Typical Attributes of Design Engineer “The scientist seeks to understand what is; the engineer seeks to create what never was” —Theodor von Kármán 4 -5

An engineer should be able to. . . • • • Determine quickly how things work Determine what customers want Create concept Use abstractions/math models to improve concept Build or create prototype version Quantitatively & robustly test prototype to improve concept & predict performance • Determine whether customer value & enterprise value are aligned (i. e. , does it make “business sense”? ) • Communicate all of above to various audiences 4 -6

An engineer should be able to. . . • • • Determine quickly how things work Determine what customers want Create concept Use abstractions/math models to improve concept Build or create prototype version Quantitatively & robustly test prototype to improve concept & predict performance • Determine whether customer value & enterprise value are aligned (i. e. , does it make “business sense”? ) • Communicate all of above to various audiences 4 -6

Engineering Abilities • Much of engineer’s abilities require domainspecific knowledge & experience • Several require systems thinking & statistical thinking • All require teamwork, leadership & societal awareness 4 -7

Engineering Abilities • Much of engineer’s abilities require domainspecific knowledge & experience • Several require systems thinking & statistical thinking • All require teamwork, leadership & societal awareness 4 -7

Boeing’s “Desired Attributes of an Engineer” • Good understanding of engineering science fundamentals – Mathematics (including statistics) – Physical & life sciences – Information technology (far more than “computer literacy”) • Good understanding of design & manufacturing processes (i. e. , understands engineering) • A multidisciplinary systems perspective Complete list can be found on Boeing Web site: http: //www. boeing. com/educationrelations/attributes. html 4 -8

Boeing’s “Desired Attributes of an Engineer” • Good understanding of engineering science fundamentals – Mathematics (including statistics) – Physical & life sciences – Information technology (far more than “computer literacy”) • Good understanding of design & manufacturing processes (i. e. , understands engineering) • A multidisciplinary systems perspective Complete list can be found on Boeing Web site: http: //www. boeing. com/educationrelations/attributes. html 4 -8

Boeing’s “Desired Attributes of an Engineer” (cont. ) • Basic understanding of context in which engineering is practiced – – Economics (including business practice) History Environment Customer & societal needs • Good communication skills – – Written Oral Graphic Listening 4 -9

Boeing’s “Desired Attributes of an Engineer” (cont. ) • Basic understanding of context in which engineering is practiced – – Economics (including business practice) History Environment Customer & societal needs • Good communication skills – – Written Oral Graphic Listening 4 -9

Boeing’s “Desired Attributes of an Engineer” (cont. ) • High ethical standards • Ability to think critically & creatively, independently & cooperatively • Flexibility: ability & self-confidence to adapt to rapid or major change • Curiosity & desire to learn for life • Profound understanding of importance of teamwork 4 -10

Boeing’s “Desired Attributes of an Engineer” (cont. ) • High ethical standards • Ability to think critically & creatively, independently & cooperatively • Flexibility: ability & self-confidence to adapt to rapid or major change • Curiosity & desire to learn for life • Profound understanding of importance of teamwork 4 -10

Boeing’s “Desired Attributes of an Engineer” (cont. ) • List, begun in 1994, of basic, durable attributes into which can be mapped specific skills reflecting diversity of overall engineering environment in which engineers in professional practice operate • Current version of list can be viewed on Boeing Web site (http: //www. boeing. com. educationrelations/attributes. html) as basic message to those seeking advice from company on topic • Contents also included in part in ABET EC 2000 (http: //www. abet. org). ABET criteria are used to assess engineering education programs, including abilities for systems thinking, communications & teamwork, as well as technical skills in math & physics 4 -11

Boeing’s “Desired Attributes of an Engineer” (cont. ) • List, begun in 1994, of basic, durable attributes into which can be mapped specific skills reflecting diversity of overall engineering environment in which engineers in professional practice operate • Current version of list can be viewed on Boeing Web site (http: //www. boeing. com. educationrelations/attributes. html) as basic message to those seeking advice from company on topic • Contents also included in part in ABET EC 2000 (http: //www. abet. org). ABET criteria are used to assess engineering education programs, including abilities for systems thinking, communications & teamwork, as well as technical skills in math & physics 4 -11

Design Process • In addition to individual skills, engineers need to have common understanding of process • For example, an orchestra must have the following for process of making music: – Group of highly skilled musicians – AND conductor – AND score/notes 4 -12

Design Process • In addition to individual skills, engineers need to have common understanding of process • For example, an orchestra must have the following for process of making music: – Group of highly skilled musicians – AND conductor – AND score/notes 4 -12

Basic Steps of Design Process • Basic design steps • Design & objective space • Typical design phases 4 -13

Basic Steps of Design Process • Basic design steps • Design & objective space • Typical design phases 4 -13

Basic Design Steps 1. Define requirements 2. Create/choose concept 3. Perform design 4. Analyze system 5. Build prototype 6. Test prototype 7. Accept final design 4 -14

Basic Design Steps 1. Define requirements 2. Create/choose concept 3. Perform design 4. Analyze system 5. Build prototype 6. Test prototype 7. Accept final design 4 -14

Basic Design Steps (cont. ) Flying wing Biplane PM SG-8 Monoplane Delta dart 4 -15

Basic Design Steps (cont. ) Flying wing Biplane PM SG-8 Monoplane Delta dart 4 -15

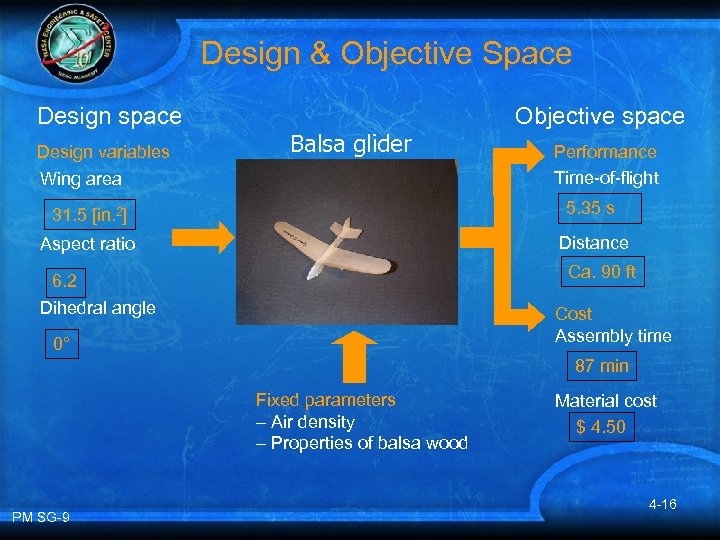

Design & Objective Space Design space Design variables Wing area Balsa glider Objective space Performance Time-of-flight 31. 5 [in. 2] 5. 35 s Aspect ratio Distance Ca. 90 ft 6. 2 Dihedral angle Cost Assembly time 0° 87 min Fixed parameters – Air density – Properties of balsa wood PM SG-9 Material cost $ 4. 50 4 -16

Design & Objective Space Design space Design variables Wing area Balsa glider Objective space Performance Time-of-flight 31. 5 [in. 2] 5. 35 s Aspect ratio Distance Ca. 90 ft 6. 2 Dihedral angle Cost Assembly time 0° 87 min Fixed parameters – Air density – Properties of balsa wood PM SG-9 Material cost $ 4. 50 4 -16

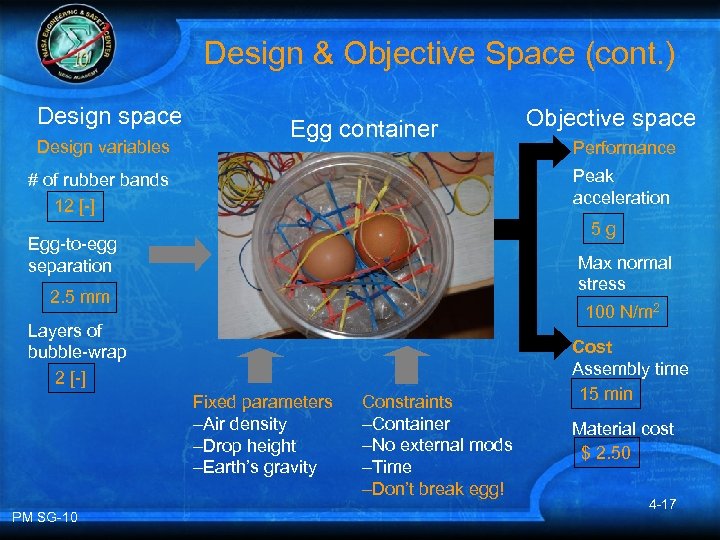

Design & Objective Space (cont. ) Design space Design variables Egg container Performance Peak acceleration # of rubber bands 12 [-] 5 g Egg-to-egg separation Max normal stress 2. 5 mm 100 N/m 2 Layers of bubble-wrap 2 [-] Fixed parameters –Air density –Drop height –Earth’s gravity PM SG-10 Objective space Constraints –Container –No external mods –Time –Don’t break egg! Cost Assembly time 15 min Material cost $ 2. 50 4 -17

Design & Objective Space (cont. ) Design space Design variables Egg container Performance Peak acceleration # of rubber bands 12 [-] 5 g Egg-to-egg separation Max normal stress 2. 5 mm 100 N/m 2 Layers of bubble-wrap 2 [-] Fixed parameters –Air density –Drop height –Earth’s gravity PM SG-10 Objective space Constraints –Container –No external mods –Time –Don’t break egg! Cost Assembly time 15 min Material cost $ 2. 50 4 -17

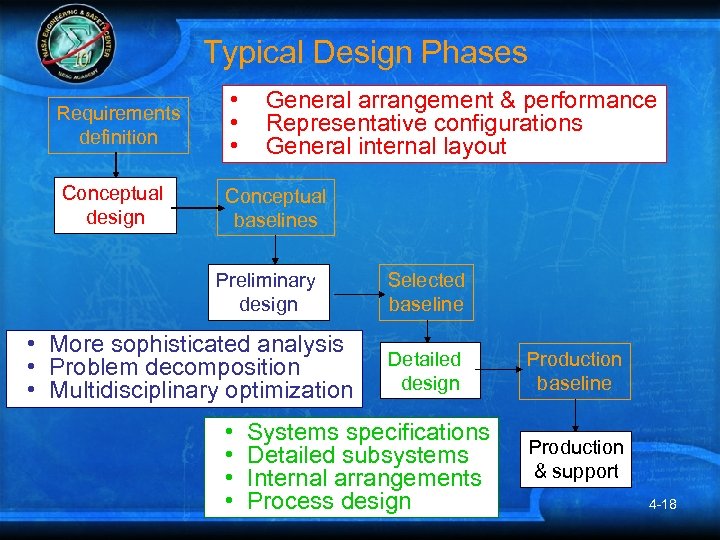

Typical Design Phases Requirements definition • • • Conceptual design Conceptual baselines General arrangement & performance Representative configurations General internal layout Preliminary design • More sophisticated analysis • Problem decomposition • Multidisciplinary optimization • • Selected baseline Detailed design Systems specifications Detailed subsystems Internal arrangements Process design Production baseline Production & support 4 -18

Typical Design Phases Requirements definition • • • Conceptual design Conceptual baselines General arrangement & performance Representative configurations General internal layout Preliminary design • More sophisticated analysis • Problem decomposition • Multidisciplinary optimization • • Selected baseline Detailed design Systems specifications Detailed subsystems Internal arrangements Process design Production baseline Production & support 4 -18

Waterfall vs. Spiral Process • Phased vs. spiral preliminary design processes • Stage gate preliminary design process • Spiral preliminary design process 4 -19

Waterfall vs. Spiral Process • Phased vs. spiral preliminary design processes • Stage gate preliminary design process • Spiral preliminary design process 4 -19

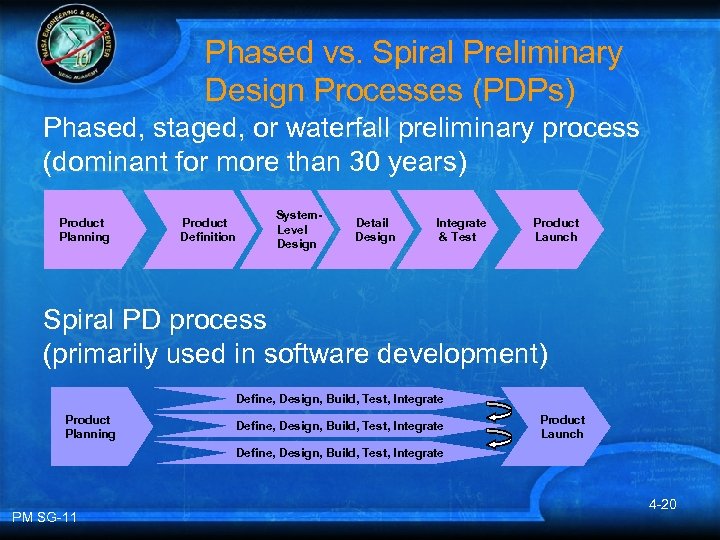

Phased vs. Spiral Preliminary Design Processes (PDPs) Phased, staged, or waterfall preliminary process (dominant for more than 30 years) Product Planning Product Definition System. Level Design Detail Design Integrate & Test Product Launch Spiral PD process (primarily used in software development) Define, Design, Build, Test, Integrate Product Planning Define, Design, Build, Test, Integrate Product Launch Define, Design, Build, Test, Integrate PM SG-11 4 -20

Phased vs. Spiral Preliminary Design Processes (PDPs) Phased, staged, or waterfall preliminary process (dominant for more than 30 years) Product Planning Product Definition System. Level Design Detail Design Integrate & Test Product Launch Spiral PD process (primarily used in software development) Define, Design, Build, Test, Integrate Product Planning Define, Design, Build, Test, Integrate Product Launch Define, Design, Build, Test, Integrate PM SG-11 4 -20

Phased vs. Spiral Preliminary Design Processes (PDPs) (cont. ) • Process design questions: – How many spirals should be planned? – Which phases should be in each spiral? – When should gate reviews be conducted? 4 -21

Phased vs. Spiral Preliminary Design Processes (PDPs) (cont. ) • Process design questions: – How many spirals should be planned? – Which phases should be in each spiral? – When should gate reviews be conducted? 4 -21

Stage Gate Preliminary Design Process Reviews Planning Concept design System-level design Detailed design Cross-phase iterations (unplanned) Integration & test Within-phase iterations (planned) Release Reference: Cooper, Robert. Winning at New Products: Accelerating the Process from Idea to Launch, Third Edition (New York: Basic Books, 2001). PM SG-12 4 -22

Stage Gate Preliminary Design Process Reviews Planning Concept design System-level design Detailed design Cross-phase iterations (unplanned) Integration & test Within-phase iterations (planned) Release Reference: Cooper, Robert. Winning at New Products: Accelerating the Process from Idea to Launch, Third Edition (New York: Basic Books, 2001). PM SG-12 4 -22

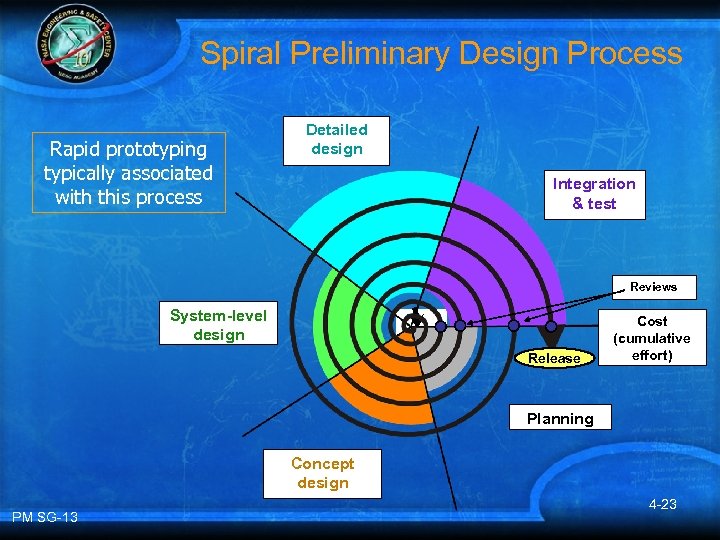

Spiral Preliminary Design Process Rapid prototyping typically associated with this process Detailed design Integration & test Reviews System-level design Release Cost (cumulative effort) Planning Concept design PM SG-13 4 -23

Spiral Preliminary Design Process Rapid prototyping typically associated with this process Detailed design Integration & test Reviews System-level design Release Cost (cumulative effort) Planning Concept design PM SG-13 4 -23

Spiral Preliminary Design Process (cont. ) Reviews Planning Concept design System-level design Detailed design Integration & test Release Slides on PDPs courtesy of Prof. Steve Eppinger PM SG-14 Time 4 -24

Spiral Preliminary Design Process (cont. ) Reviews Planning Concept design System-level design Detailed design Integration & test Release Slides on PDPs courtesy of Prof. Steve Eppinger PM SG-14 Time 4 -24

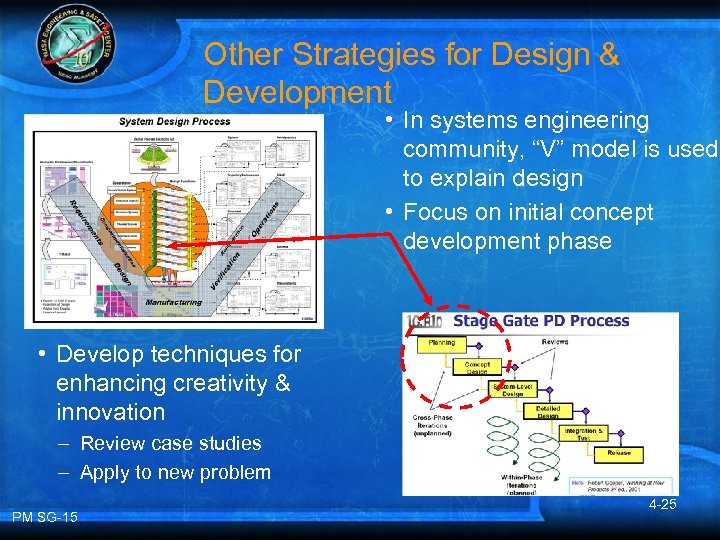

Other Strategies for Design & Development • In systems engineering community, “V” model is used to explain design • Focus on initial concept development phase • Develop techniques for enhancing creativity & innovation – Review case studies – Apply to new problem PM SG-15 4 -25

Other Strategies for Design & Development • In systems engineering community, “V” model is used to explain design • Focus on initial concept development phase • Develop techniques for enhancing creativity & innovation – Review case studies – Apply to new problem PM SG-15 4 -25

Examples from Industry & Government • NASA project lifecycle • BP projects common major process • Turbine blade development process • Xerox multifunction office machines • Xerox time-to-market (TTM) process • Extreme Programming (XP) 4 -26

Examples from Industry & Government • NASA project lifecycle • BP projects common major process • Turbine blade development process • Xerox multifunction office machines • Xerox time-to-market (TTM) process • Extreme Programming (XP) 4 -26

NASA Project Lifecycle See NASA Systems Engineering Handbook, NASA/SP-2007 -6105 Rev 1 PM SG-16 4 -27

NASA Project Lifecycle See NASA Systems Engineering Handbook, NASA/SP-2007 -6105 Rev 1 PM SG-16 4 -27

BP Projects Common Major Process * APPRAISE Gate SELECT DSP Cost/schedule estimating & risk analysis Cost/ schedule controls e. PROJECTS use Gate DSP DEFINE Gate DSP Develop Base Estimate & Risk Analysis Refine Base Estimate & Risk Analysis Set-up FEL Cost/Schedule Controls Set-up Execute Stage Cost/ Schedule Controls OPERATE Manage Execute Stage Cost/ Schedule Controls Manage Operate Cost/Schedule Controls Reconcile & Feedback to e. PROJECTS at each stage based on Project size & scope plan Estimate Range Controls Estimate Range Out of Control In Control AFE Image reprinted with permission of Prof. Olivier de Weck, MIT PM SG-17 Gate DSP Manage FEL Cost/Schedule Controls Plan Execute Stage Cost/ Schedule Controls Gate DSP Complete Base Estimate & Risk Analysis Plan FEL Cost/Schedule Controls EXECUTE AFE 4 -28

BP Projects Common Major Process * APPRAISE Gate SELECT DSP Cost/schedule estimating & risk analysis Cost/ schedule controls e. PROJECTS use Gate DSP DEFINE Gate DSP Develop Base Estimate & Risk Analysis Refine Base Estimate & Risk Analysis Set-up FEL Cost/Schedule Controls Set-up Execute Stage Cost/ Schedule Controls OPERATE Manage Execute Stage Cost/ Schedule Controls Manage Operate Cost/Schedule Controls Reconcile & Feedback to e. PROJECTS at each stage based on Project size & scope plan Estimate Range Controls Estimate Range Out of Control In Control AFE Image reprinted with permission of Prof. Olivier de Weck, MIT PM SG-17 Gate DSP Manage FEL Cost/Schedule Controls Plan Execute Stage Cost/ Schedule Controls Gate DSP Complete Base Estimate & Risk Analysis Plan FEL Cost/Schedule Controls EXECUTE AFE 4 -28

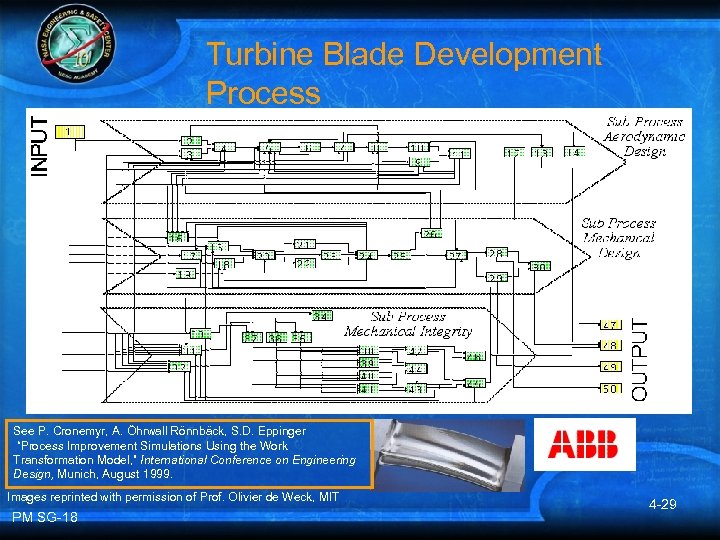

Turbine Blade Development Process See P. Cronemyr, A. Öhrwall Rönnbäck, S. D. Eppinger “Process Improvement Simulations Using the Work Transformation Model, ” International Conference on Engineering Design, Munich, August 1999. Images reprinted with permission of Prof. Olivier de Weck, MIT PM SG-18 4 -29

Turbine Blade Development Process See P. Cronemyr, A. Öhrwall Rönnbäck, S. D. Eppinger “Process Improvement Simulations Using the Work Transformation Model, ” International Conference on Engineering Design, Munich, August 1999. Images reprinted with permission of Prof. Olivier de Weck, MIT PM SG-18 4 -29

Xerox Multifunction Office Machines • Hardware (DC 460 -ST) & software (Endeavor) • Large company & steady platform (variant) products • Iterations – TTM process technically stage gate, but, has some important exceptions • Software subprocess • Internal experiments & waivers • Risk: Emphasis on controlling schedule 4 -30

Xerox Multifunction Office Machines • Hardware (DC 460 -ST) & software (Endeavor) • Large company & steady platform (variant) products • Iterations – TTM process technically stage gate, but, has some important exceptions • Software subprocess • Internal experiments & waivers • Risk: Emphasis on controlling schedule 4 -30

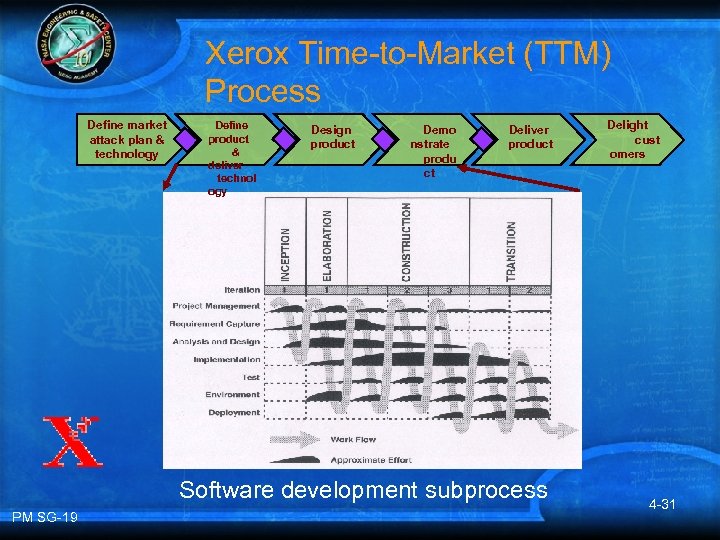

Xerox Time-to-Market (TTM) Process Define market attack plan & technology Define product & deliver technol ogy Design product Demo nstrate produ ct Deliver product Software development subprocess PM SG-19 Delight cust omers 4 -31

Xerox Time-to-Market (TTM) Process Define market attack plan & technology Define product & deliver technol ogy Design product Demo nstrate produ ct Deliver product Software development subprocess PM SG-19 Delight cust omers 4 -31

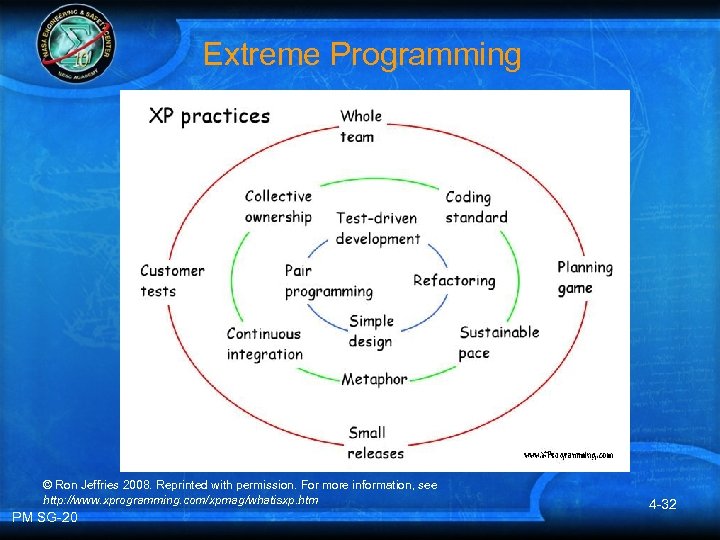

Extreme Programming © Ron Jeffries 2008. Reprinted with permission. For more information, see http: //www. xprogramming. com/xpmag/whatisxp. htm PM SG-20 4 -32

Extreme Programming © Ron Jeffries 2008. Reprinted with permission. For more information, see http: //www. xprogramming. com/xpmag/whatisxp. htm PM SG-20 4 -32

Key Similarities Between PDPs • • • Attempt to meet customer needs Discrete phases of development Iteration in some form Existence of reviews or gates Attempt to control development risks 4 -33

Key Similarities Between PDPs • • • Attempt to meet customer needs Discrete phases of development Iteration in some form Existence of reviews or gates Attempt to control development risks 4 -33

Key Differences Between PDPs • • • Names & number of development phases Type of iterations Type of review Customer interface points Product complexity Risks addressed 4 -34

Key Differences Between PDPs • • • Names & number of development phases Type of iterations Type of review Customer interface points Product complexity Risks addressed 4 -34

Identification of Key Risks Risk Profile Category of risk Technical/ Performance Market/ User Budget Schedule 1 2 3 Low (Coord. /Variation) 4 High (Unk-unks/chaotic) Level of risk PM SG-21 5 4 -35

Identification of Key Risks Risk Profile Category of risk Technical/ Performance Market/ User Budget Schedule 1 2 3 Low (Coord. /Variation) 4 High (Unk-unks/chaotic) Level of risk PM SG-21 5 4 -35

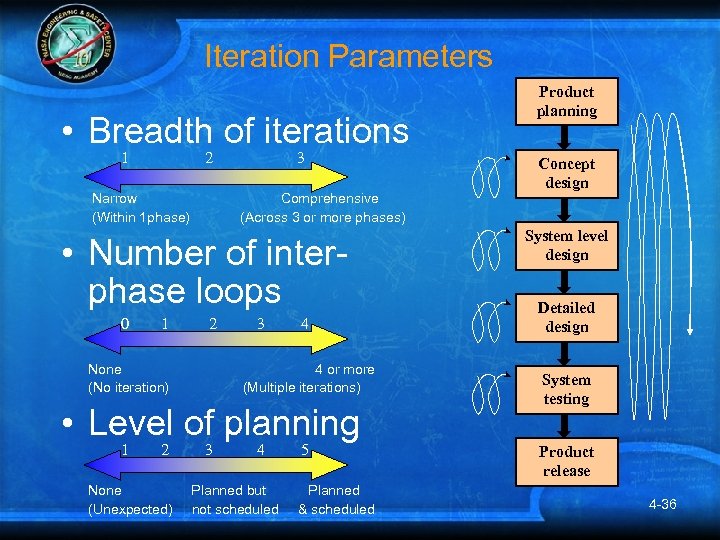

Iteration Parameters • Breadth of iterations 1 2 Narrow (Within 1 phase) 3 Comprehensive (Across 3 or more phases) • Number of interphase loops 0 1 2 None (No iteration) 3 4 4 or more (Multiple iterations) • Level of planning 1 2 None (Unexpected) 3 4 Planned but not scheduled 5 Planned & scheduled Product planning Concept design System level design Detailed design System testing Product release 4 -36

Iteration Parameters • Breadth of iterations 1 2 Narrow (Within 1 phase) 3 Comprehensive (Across 3 or more phases) • Number of interphase loops 0 1 2 None (No iteration) 3 4 4 or more (Multiple iterations) • Level of planning 1 2 None (Unexpected) 3 4 Planned but not scheduled 5 Planned & scheduled Product planning Concept design System level design Detailed design System testing Product release 4 -36

Review/Gate Parameters • Rigidity 1 2 3 Action stage 4 5 Deliverables Final standard (Rigid criteria) Phase check (Less rigid criteria) • Frequency 1 2 Frequent (After each phase) 3 4 Format of stage gate Review /OK? Yes 5 Sporadic (After 3 or more phases) No Outputs Next stage 4 -37

Review/Gate Parameters • Rigidity 1 2 3 Action stage 4 5 Deliverables Final standard (Rigid criteria) Phase check (Less rigid criteria) • Frequency 1 2 Frequent (After each phase) 3 4 Format of stage gate Review /OK? Yes 5 Sporadic (After 3 or more phases) No Outputs Next stage 4 -37

Parameterized Theoretical PDPs Parameter Waterfall/ Stage -gate Design to Sched/Budget Evolutionary prototyping Start End 3 Spiral Breadth Risk 1 # of interphase loops 0 Unspecified 0 2 3 5 Rigidity Review gates 2 Planning Iterations 1 1 2 3 3 5 Frequency 1 2 2 1 Unspecified Profile of key Manages tech risks risk well Manages sched. /budget risk well Unspec ified Manages market risk well 3 Unspecified but many Manages market risk well 4 -38

Parameterized Theoretical PDPs Parameter Waterfall/ Stage -gate Design to Sched/Budget Evolutionary prototyping Start End 3 Spiral Breadth Risk 1 # of interphase loops 0 Unspecified 0 2 3 5 Rigidity Review gates 2 Planning Iterations 1 1 2 3 3 5 Frequency 1 2 2 1 Unspecified Profile of key Manages tech risks risk well Manages sched. /budget risk well Unspec ified Manages market risk well 3 Unspecified but many Manages market risk well 4 -38

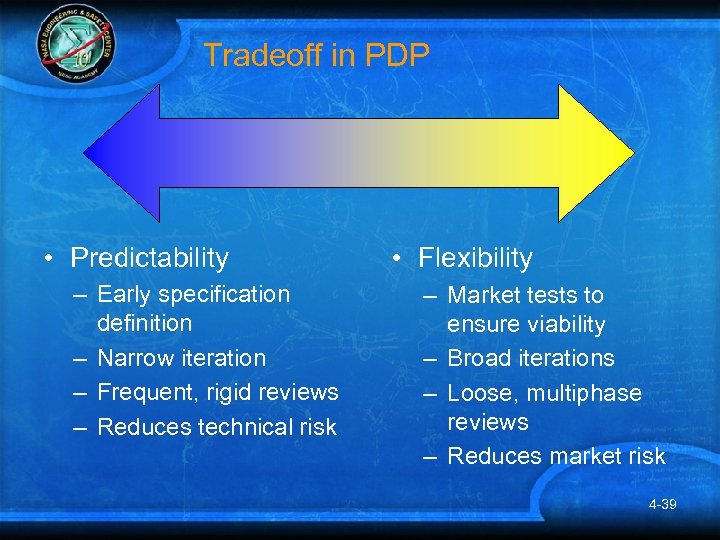

Tradeoff in PDP • Predictability – Early specification definition – Narrow iteration – Frequent, rigid reviews – Reduces technical risk • Flexibility – Market tests to ensure viability – Broad iterations – Loose, multiphase reviews – Reduces market risk 4 -39

Tradeoff in PDP • Predictability – Early specification definition – Narrow iteration – Frequent, rigid reviews – Reduces technical risk • Flexibility – Market tests to ensure viability – Broad iterations – Loose, multiphase reviews – Reduces market risk 4 -39

Other Considerations • • Tradeoffs in product development Design for manufacturing Hierarchy Complexity 4 -40

Other Considerations • • Tradeoffs in product development Design for manufacturing Hierarchy Complexity 4 -40

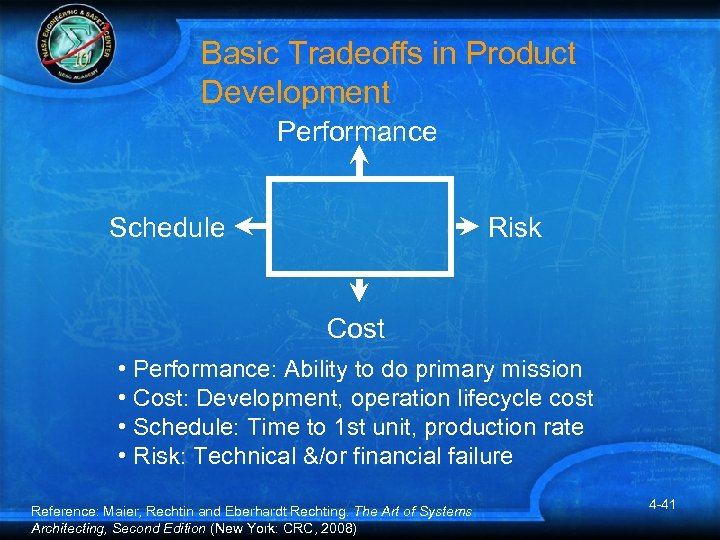

Basic Tradeoffs in Product Development Performance Schedule Risk Cost • Performance: Ability to do primary mission • Cost: Development, operation lifecycle cost • Schedule: Time to 1 st unit, production rate • Risk: Technical &/or financial failure Reference: Maier, Rechtin and Eberhardt Rechting. The Art of Systems Architecting, Second Edition (New York: CRC, 2008) 4 -41

Basic Tradeoffs in Product Development Performance Schedule Risk Cost • Performance: Ability to do primary mission • Cost: Development, operation lifecycle cost • Schedule: Time to 1 st unit, production rate • Risk: Technical &/or financial failure Reference: Maier, Rechtin and Eberhardt Rechting. The Art of Systems Architecting, Second Edition (New York: CRC, 2008) 4 -41

Design for Manufacturing: F/A-18 Aircraft F/A-18 manufacturing breakdown PM SG-22 Image reprinted with permission of Prof. Olivier de Weck, MIT 4 -42

Design for Manufacturing: F/A-18 Aircraft F/A-18 manufacturing breakdown PM SG-22 Image reprinted with permission of Prof. Olivier de Weck, MIT 4 -42

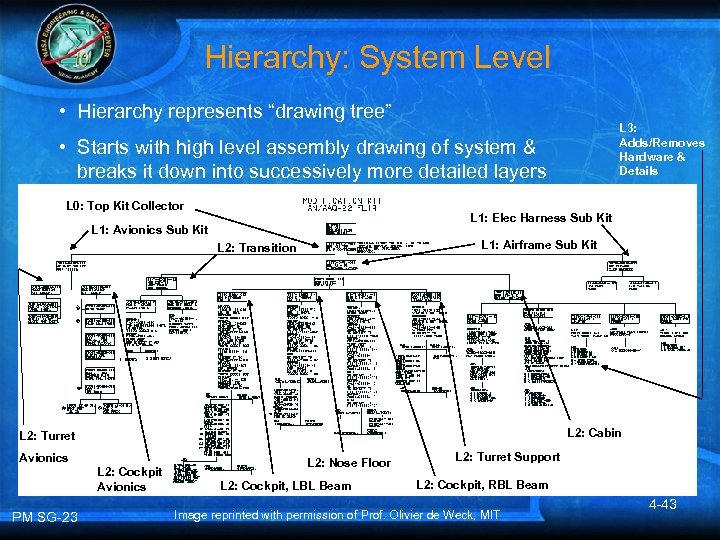

Hierarchy: System Level • Hierarchy represents “drawing tree” L 3: Adds/Removes Hardware & Details • Starts with high level assembly drawing of system & breaks it down into successively more detailed layers L 0: Top Kit Collector L 1: Elec Harness Sub Kit L 1: Avionics Sub Kit L 1: Airframe Sub Kit L 2: Transition L 2: Cabin L 2: Turret Avionics L 2: Cockpit Avionics PM SG-23 L 2: Nose Floor L 2: Cockpit, LBL Beam L 2: Turret Support L 2: Cockpit, RBL Beam Image reprinted with permission of Prof. Olivier de Weck, MIT 4 -43

Hierarchy: System Level • Hierarchy represents “drawing tree” L 3: Adds/Removes Hardware & Details • Starts with high level assembly drawing of system & breaks it down into successively more detailed layers L 0: Top Kit Collector L 1: Elec Harness Sub Kit L 1: Avionics Sub Kit L 1: Airframe Sub Kit L 2: Transition L 2: Cabin L 2: Turret Avionics L 2: Cockpit Avionics PM SG-23 L 2: Nose Floor L 2: Cockpit, LBL Beam L 2: Turret Support L 2: Cockpit, RBL Beam Image reprinted with permission of Prof. Olivier de Weck, MIT 4 -43

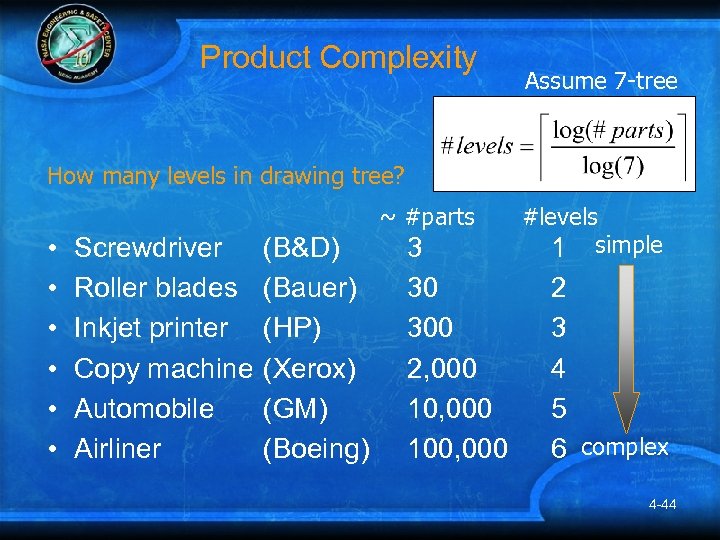

Product Complexity Assume 7 -tree How many levels in drawing tree? ~ #parts • • • Screwdriver Roller blades Inkjet printer Copy machine Automobile Airliner (B&D) (Bauer) (HP) (Xerox) (GM) (Boeing) 3 30 300 2, 000 100, 000 #levels 1 simple 2 3 4 5 6 complex 4 -44

Product Complexity Assume 7 -tree How many levels in drawing tree? ~ #parts • • • Screwdriver Roller blades Inkjet printer Copy machine Automobile Airliner (B&D) (Bauer) (HP) (Xerox) (GM) (Boeing) 3 30 300 2, 000 100, 000 #levels 1 simple 2 3 4 5 6 complex 4 -44

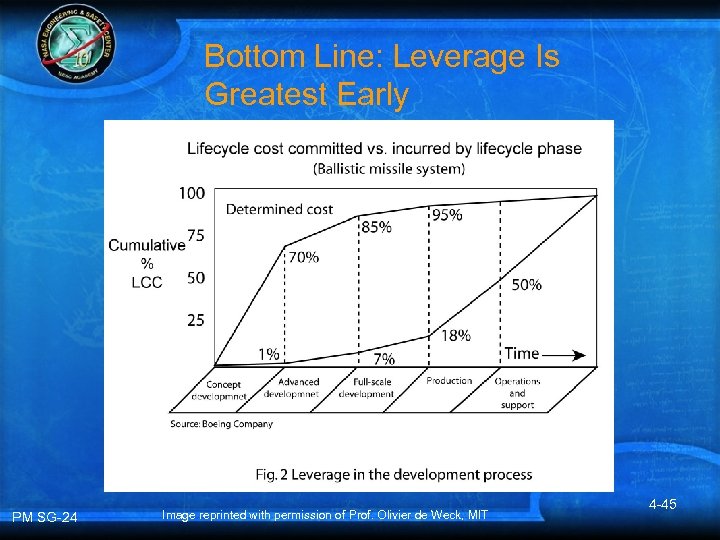

Bottom Line: Leverage Is Greatest Early PM SG-24 Image reprinted with permission of Prof. Olivier de Weck, MIT 4 -45

Bottom Line: Leverage Is Greatest Early PM SG-24 Image reprinted with permission of Prof. Olivier de Weck, MIT 4 -45

Summary • • • Designing is most important activity engineers do There must be common process, or there is chaos Waterfall (phase-gate) vs. spiral continuum Hybrid forms in many real organizations PDP design driven by dominant risks – – technical market schedule budget 4 -46

Summary • • • Designing is most important activity engineers do There must be common process, or there is chaos Waterfall (phase-gate) vs. spiral continuum Hybrid forms in many real organizations PDP design driven by dominant risks – – technical market schedule budget 4 -46

Summary (cont. ) • Key distinguishers/PDP design factors – Iterations: breadth, number, planned/unplanned – Review gates: rigidity (rigor), frequency • Most important points for this class: – Spend enough time on conceptual design! – Spirals that include (cheap) prototyping & testing are valuable 4 -47

Summary (cont. ) • Key distinguishers/PDP design factors – Iterations: breadth, number, planned/unplanned – Review gates: rigidity (rigor), frequency • Most important points for this class: – Spend enough time on conceptual design! – Spirals that include (cheap) prototyping & testing are valuable 4 -47