6640d53792002fd74d26b7e254cc2770.ppt

- Количество слайдов: 49

LED Light Emitting Diode

LED Light Emitting Diode

Contents 1. History 2. Application 3. Epitaxy 4. Fabrication 5. Packaging 6. OLED 7. Future

Contents 1. History 2. Application 3. Epitaxy 4. Fabrication 5. Packaging 6. OLED 7. Future

The history of lighting and LED In ancient times , there were no lamps, so people could only use fire for lighting.

The history of lighting and LED In ancient times , there were no lamps, so people could only use fire for lighting.

People stepped into the world of light. The first generation of lighting kerosene lamp candle

People stepped into the world of light. The first generation of lighting kerosene lamp candle

Incandescent lamps were widely used because of the extensive application of electricity. The second generation of lighting incandescent lamps

Incandescent lamps were widely used because of the extensive application of electricity. The second generation of lighting incandescent lamps

Now, fluorescent lamps are the most widely used. The third generation of lighting fluorescent lamps compact fluorescent lamp

Now, fluorescent lamps are the most widely used. The third generation of lighting fluorescent lamps compact fluorescent lamp

LED is the fourth generation of lighting.

LED is the fourth generation of lighting.

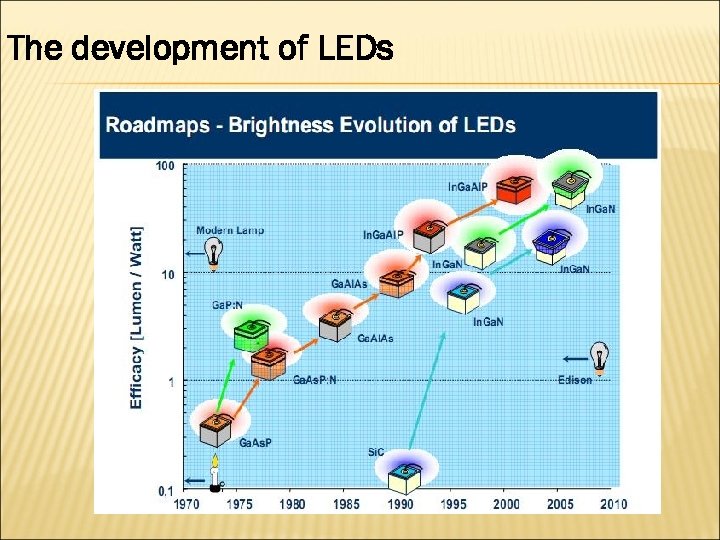

The development of LEDs

The development of LEDs

THE APPLICATION OF LED signal lights

THE APPLICATION OF LED signal lights

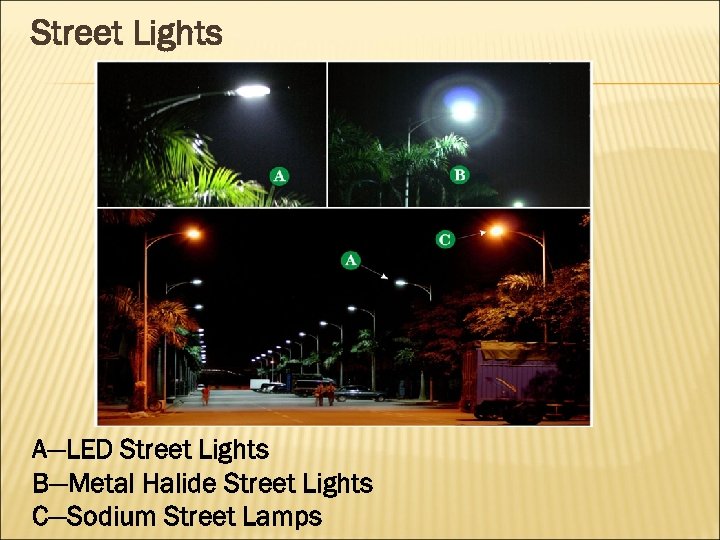

Street Lights A—LED Street Lights B—Metal Halide Street Lights C—Sodium Street Lamps

Street Lights A—LED Street Lights B—Metal Halide Street Lights C—Sodium Street Lamps

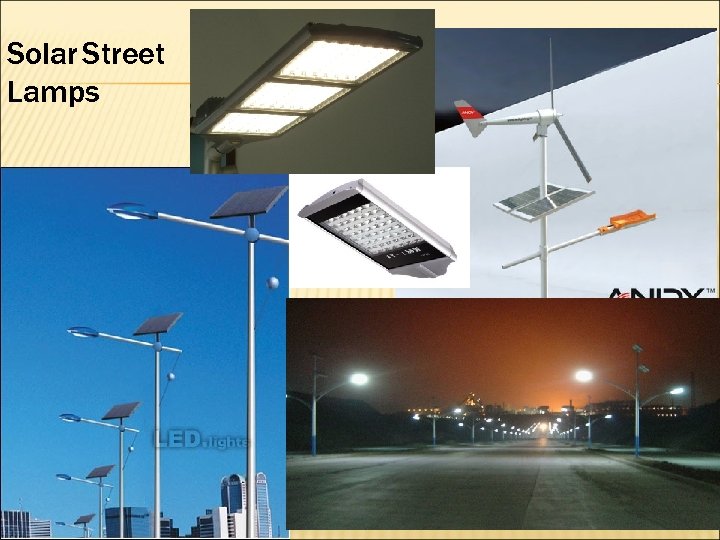

Solar Street Lamps

Solar Street Lamps

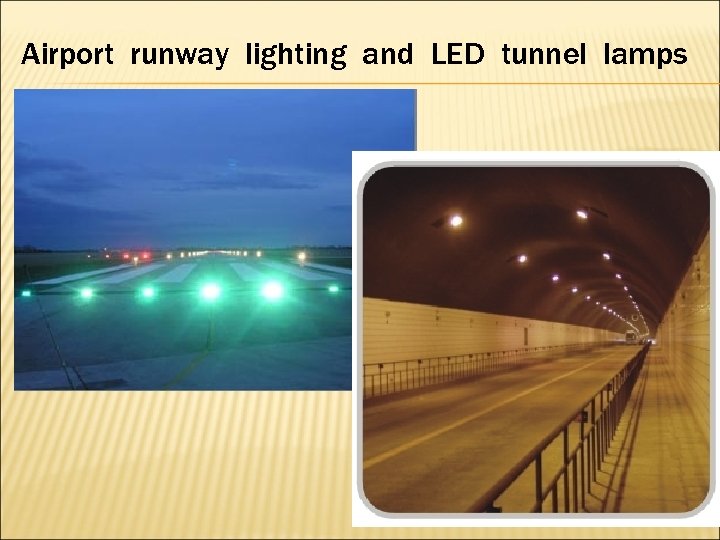

Airport runway lighting and LED tunnel lamps

Airport runway lighting and LED tunnel lamps

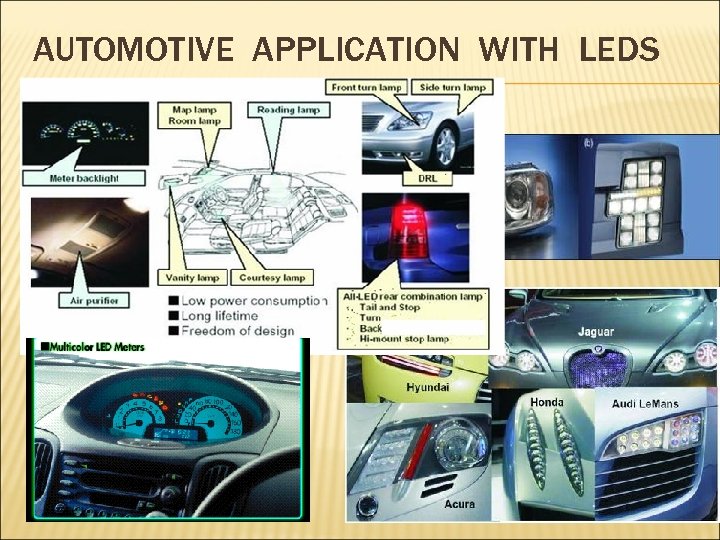

AUTOMOTIVE APPLICATION WITH LEDS

AUTOMOTIVE APPLICATION WITH LEDS

LED interior lighting

LED interior lighting

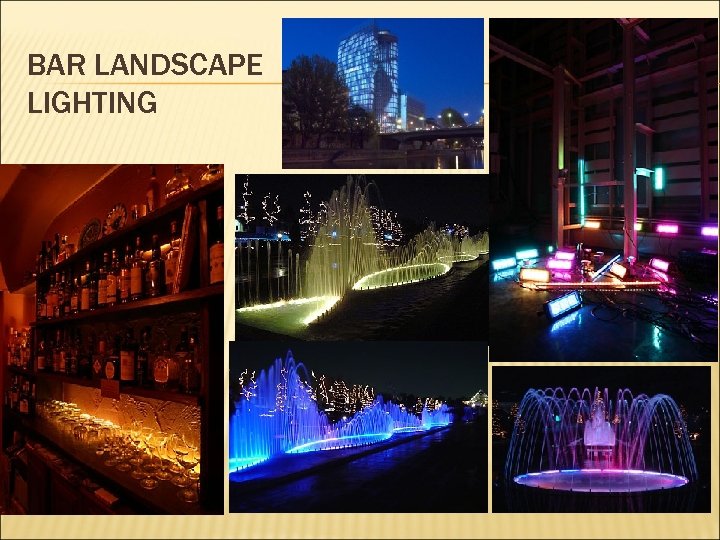

BAR LANDSCAPE LIGHTING

BAR LANDSCAPE LIGHTING

Mobile Application With LEDs

Mobile Application With LEDs

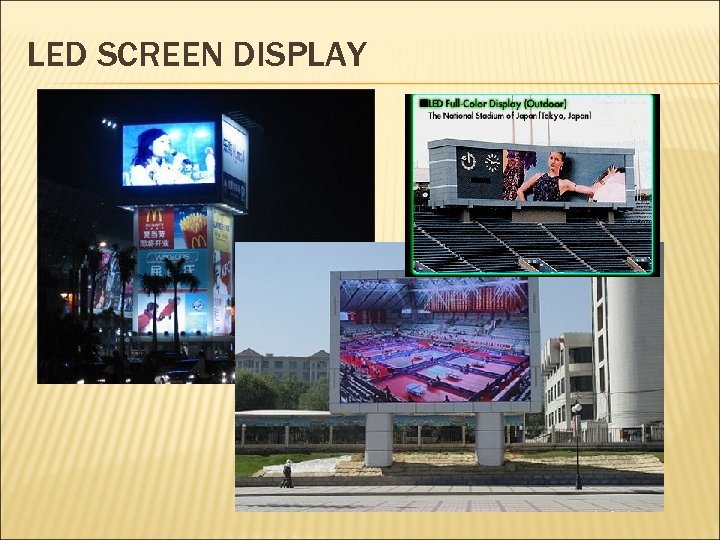

LED SCREEN DISPLAY

LED SCREEN DISPLAY

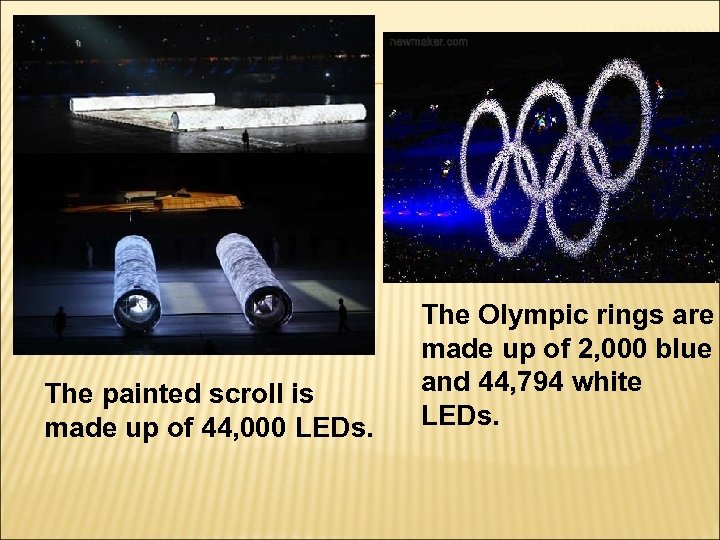

The painted scroll is made up of 44, 000 LEDs. The Olympic rings are made up of 2, 000 blue and 44, 794 white LEDs.

The painted scroll is made up of 44, 000 LEDs. The Olympic rings are made up of 2, 000 blue and 44, 794 white LEDs.

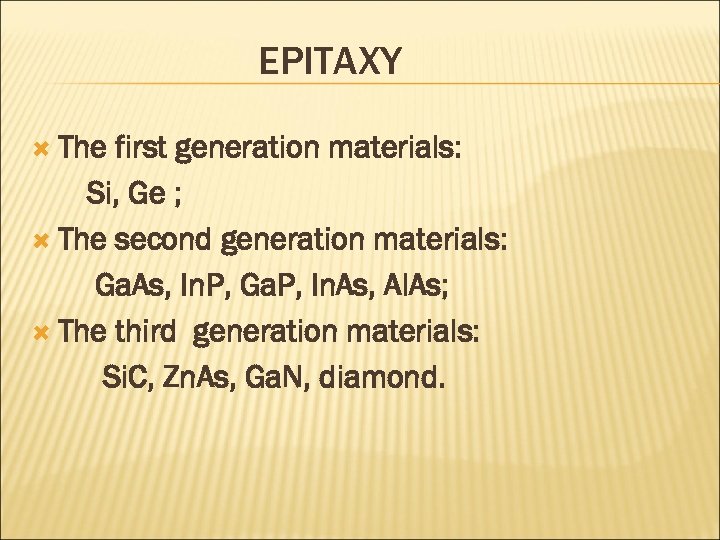

EPITAXY The first generation materials: Si, Ge ; The second generation materials: Ga. As, In. P, Ga. P, In. As, Al. As; The third generation materials: Si. C, Zn. As, Ga. N, diamond.

EPITAXY The first generation materials: Si, Ge ; The second generation materials: Ga. As, In. P, Ga. P, In. As, Al. As; The third generation materials: Si. C, Zn. As, Ga. N, diamond.

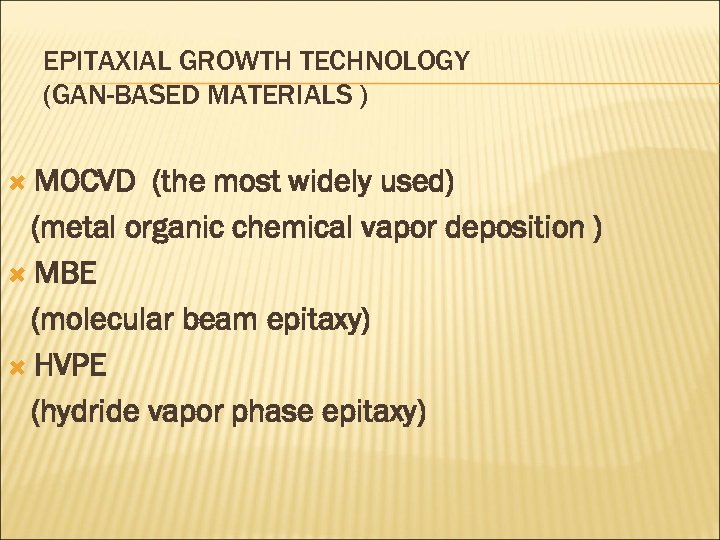

EPITAXIAL GROWTH TECHNOLOGY (GAN-BASED MATERIALS ) MOCVD (the most widely used) (metal organic chemical vapor deposition ) MBE (molecular beam epitaxy) HVPE (hydride vapor phase epitaxy)

EPITAXIAL GROWTH TECHNOLOGY (GAN-BASED MATERIALS ) MOCVD (the most widely used) (metal organic chemical vapor deposition ) MBE (molecular beam epitaxy) HVPE (hydride vapor phase epitaxy)

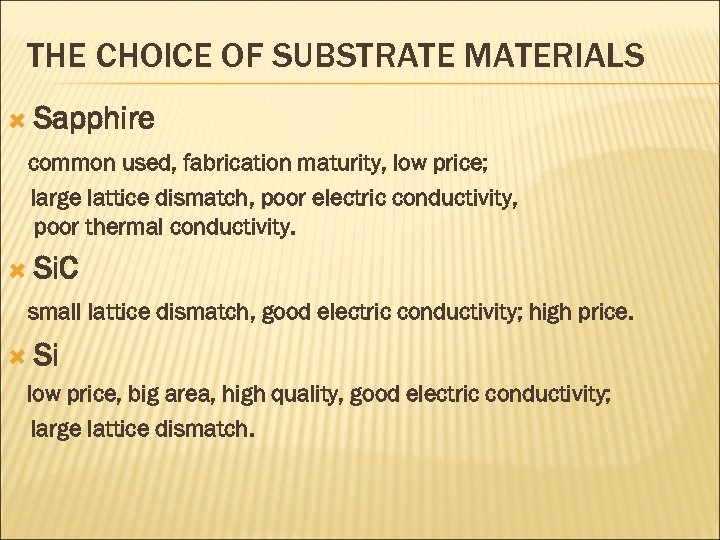

THE CHOICE OF SUBSTRATE MATERIALS Sapphire common used, fabrication maturity, low price; large lattice dismatch, poor electric conductivity, poor thermal conductivity. Si. C small lattice dismatch, good electric conductivity; high price. Si low price, big area, high quality, good electric conductivity; large lattice dismatch.

THE CHOICE OF SUBSTRATE MATERIALS Sapphire common used, fabrication maturity, low price; large lattice dismatch, poor electric conductivity, poor thermal conductivity. Si. C small lattice dismatch, good electric conductivity; high price. Si low price, big area, high quality, good electric conductivity; large lattice dismatch.

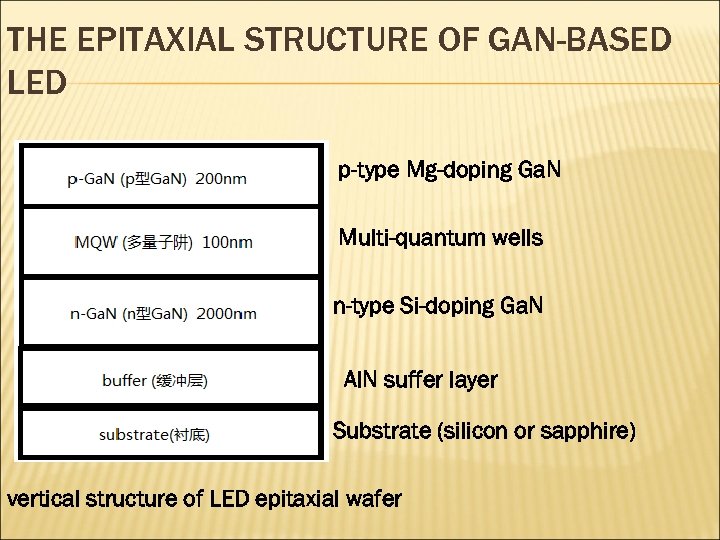

THE EPITAXIAL STRUCTURE OF GAN-BASED LED p-type Mg-doping Ga. N Multi-quantum wells n-type Si-doping Ga. N Al. N suffer layer Substrate (silicon or sapphire) vertical structure of LED epitaxial wafer

THE EPITAXIAL STRUCTURE OF GAN-BASED LED p-type Mg-doping Ga. N Multi-quantum wells n-type Si-doping Ga. N Al. N suffer layer Substrate (silicon or sapphire) vertical structure of LED epitaxial wafer

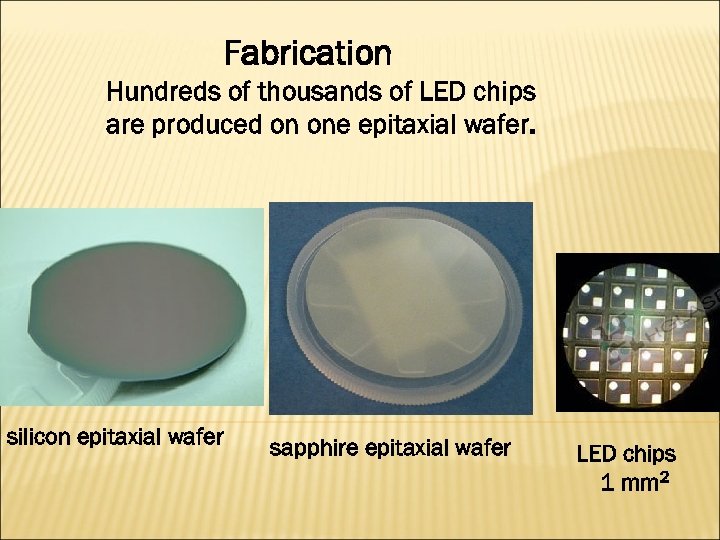

Fabrication Hundreds of thousands of LED chips are produced on one epitaxial wafer. silicon epitaxial wafer sapphire epitaxial wafer LED chips 1 mm 2

Fabrication Hundreds of thousands of LED chips are produced on one epitaxial wafer. silicon epitaxial wafer sapphire epitaxial wafer LED chips 1 mm 2

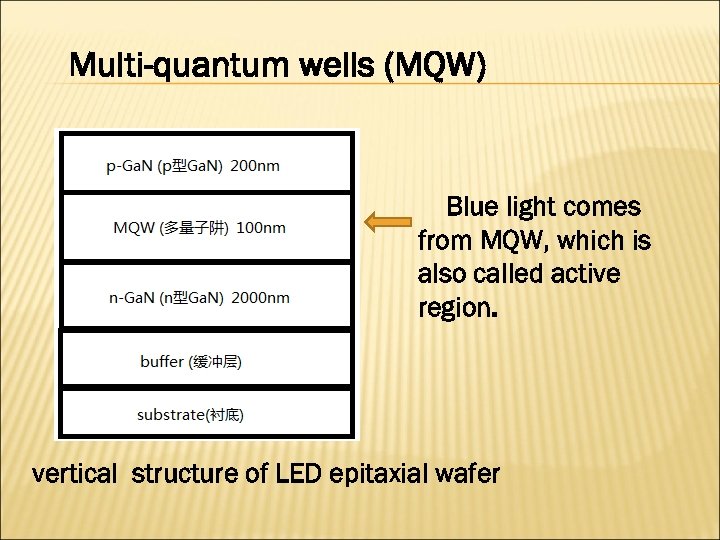

Multi-quantum wells (MQW) Blue light comes from MQW, which is also called active region. vertical structure of LED epitaxial wafer

Multi-quantum wells (MQW) Blue light comes from MQW, which is also called active region. vertical structure of LED epitaxial wafer

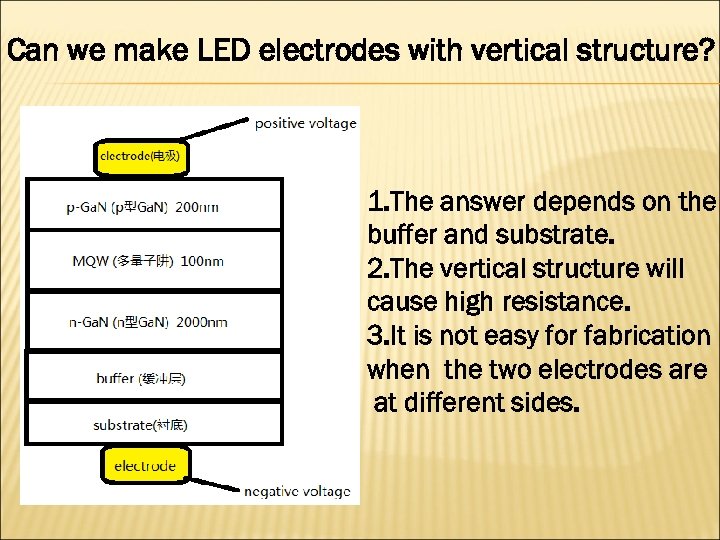

Can we make LED electrodes with vertical structure? 1. The answer depends on the buffer and substrate. 2. The vertical structure will cause high resistance. 3. It is not easy for fabrication when the two electrodes are at different sides.

Can we make LED electrodes with vertical structure? 1. The answer depends on the buffer and substrate. 2. The vertical structure will cause high resistance. 3. It is not easy for fabrication when the two electrodes are at different sides.

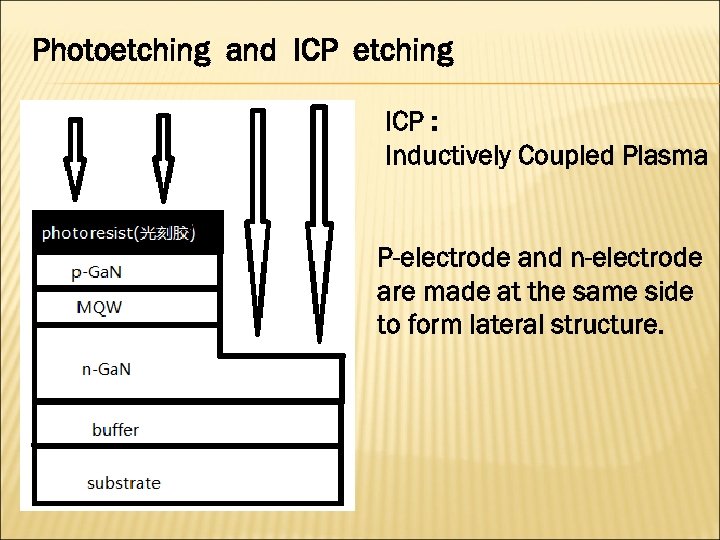

Photoetching and ICP etching ICP : Inductively Coupled Plasma P-electrode and n-electrode are made at the same side to form lateral structure.

Photoetching and ICP etching ICP : Inductively Coupled Plasma P-electrode and n-electrode are made at the same side to form lateral structure.

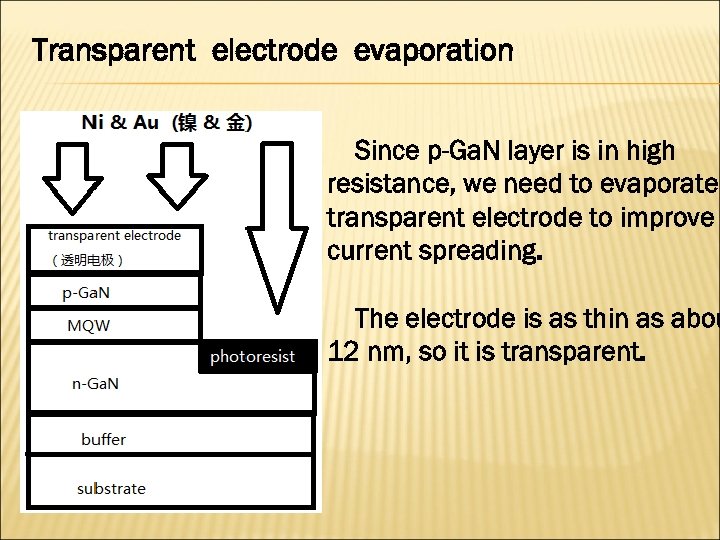

Transparent electrode evaporation Since p-Ga. N layer is in high resistance, we need to evaporate transparent electrode to improve current spreading. The electrode is as thin as abou 12 nm, so it is transparent.

Transparent electrode evaporation Since p-Ga. N layer is in high resistance, we need to evaporate transparent electrode to improve current spreading. The electrode is as thin as abou 12 nm, so it is transparent.

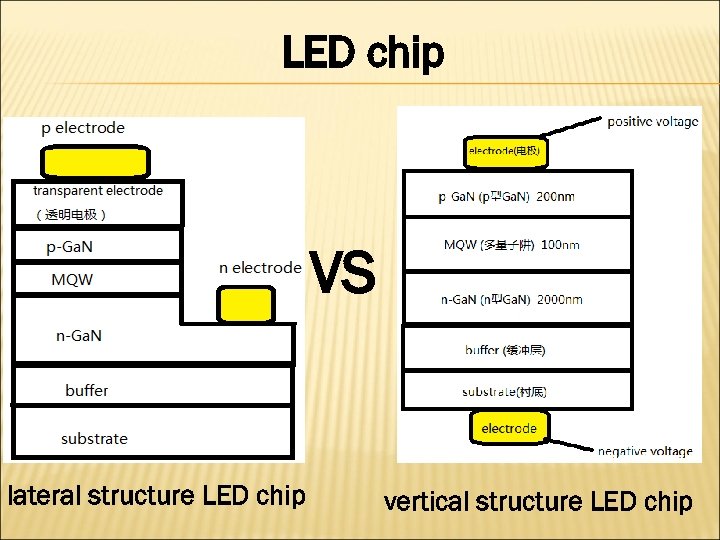

LED chip VS lateral structure LED chip vertical structure LED chip

LED chip VS lateral structure LED chip vertical structure LED chip

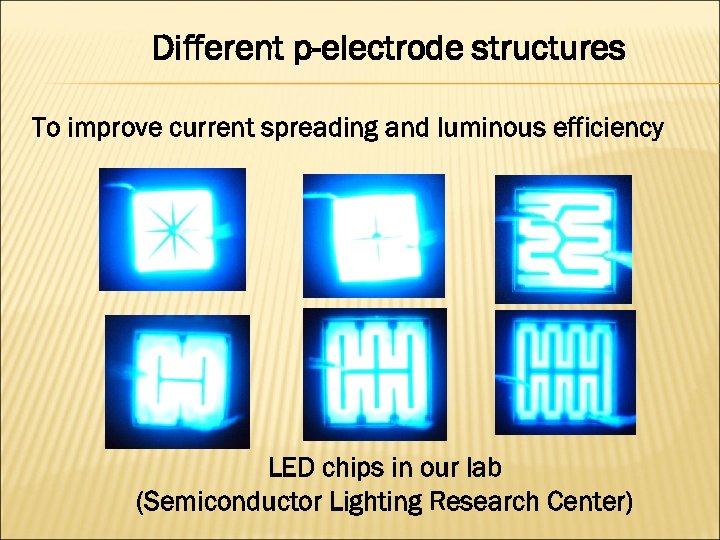

Different p-electrode structures To improve current spreading and luminous efficiency LED chips in our lab (Semiconductor Lighting Research Center)

Different p-electrode structures To improve current spreading and luminous efficiency LED chips in our lab (Semiconductor Lighting Research Center)

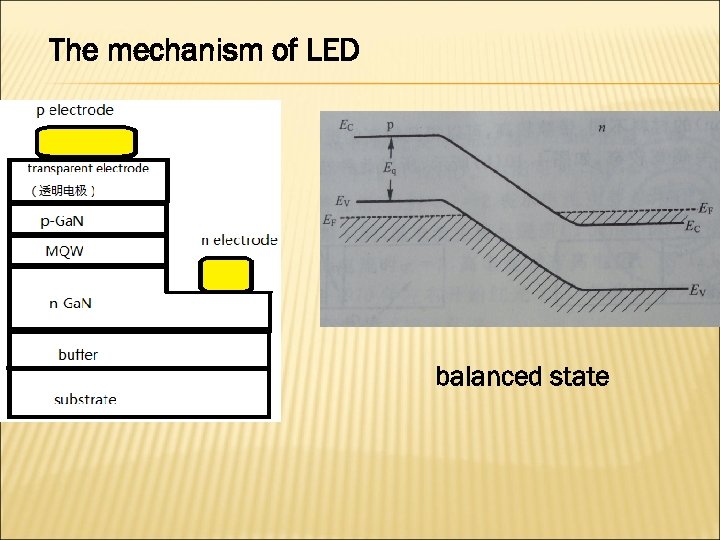

The mechanism of LED balanced state

The mechanism of LED balanced state

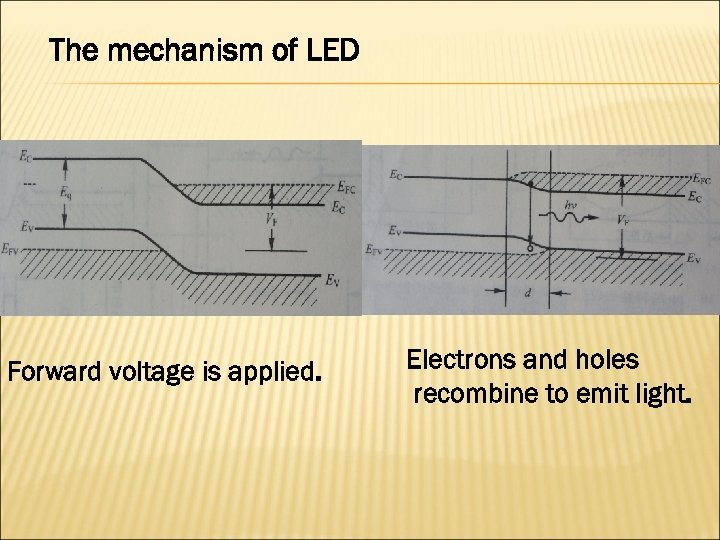

The mechanism of LED Forward voltage is applied. Electrons and holes recombine to emit light.

The mechanism of LED Forward voltage is applied. Electrons and holes recombine to emit light.

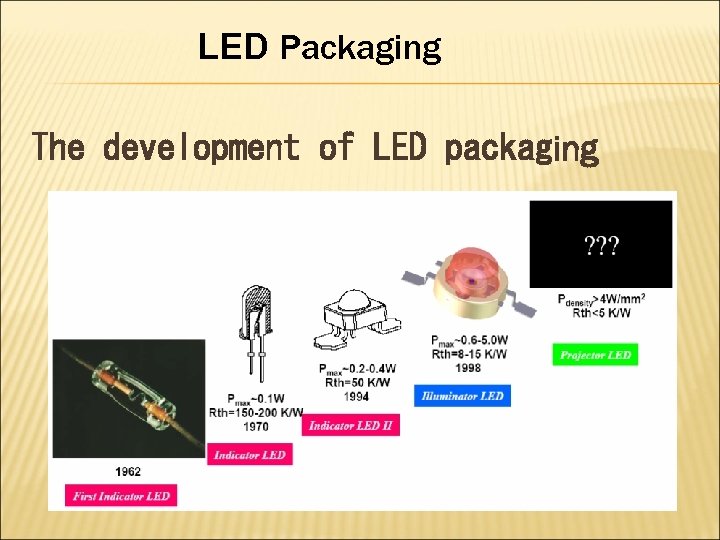

LED Packaging The development of LED packaging

LED Packaging The development of LED packaging

Purpose for packaging l l l To get the input signal To protect the LED chips To get the output of visible light

Purpose for packaging l l l To get the input signal To protect the LED chips To get the output of visible light

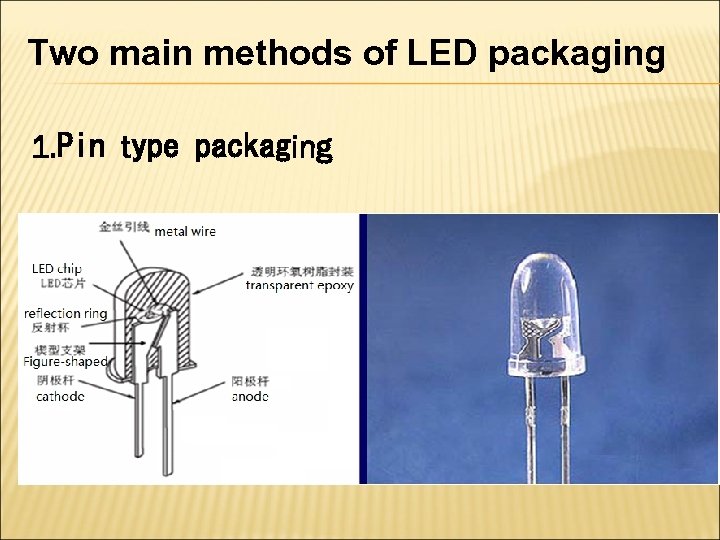

Two main methods of LED packaging 1. Pin type packaging

Two main methods of LED packaging 1. Pin type packaging

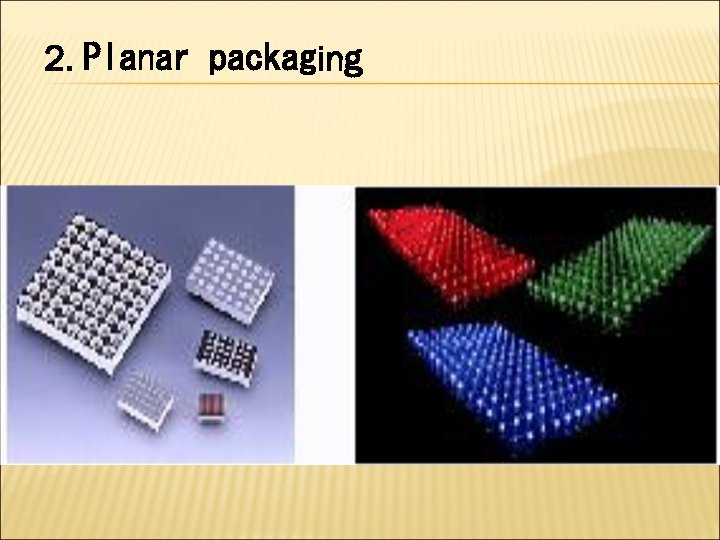

2. Planar packaging

2. Planar packaging

HOW TO MAKE WHITE LED? LED is single color, such as red, yellow, green, blue and so on. However, white is mixed color. We need to mix colors to make white LED.

HOW TO MAKE WHITE LED? LED is single color, such as red, yellow, green, blue and so on. However, white is mixed color. We need to mix colors to make white LED.

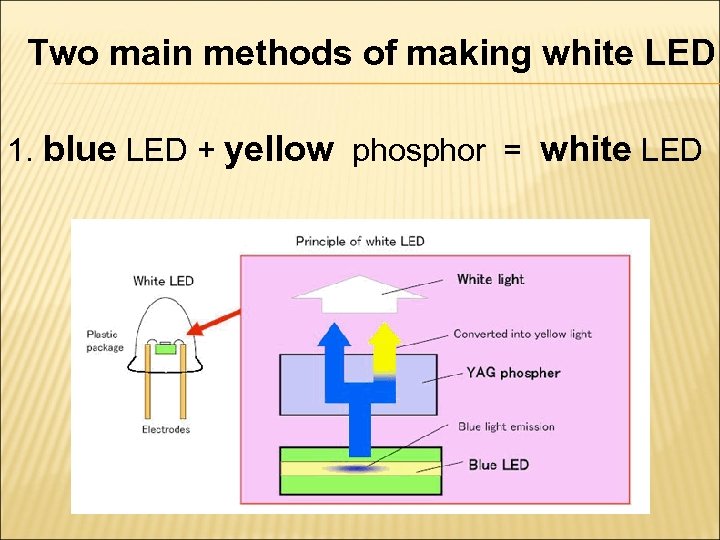

Two main methods of making white LED 1. blue LED + yellow phosphor = white LED

Two main methods of making white LED 1. blue LED + yellow phosphor = white LED

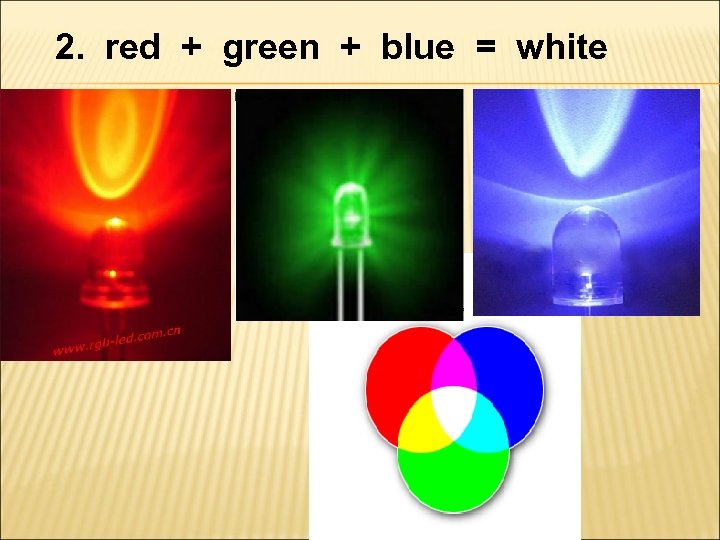

2. red + green + blue = white

2. red + green + blue = white

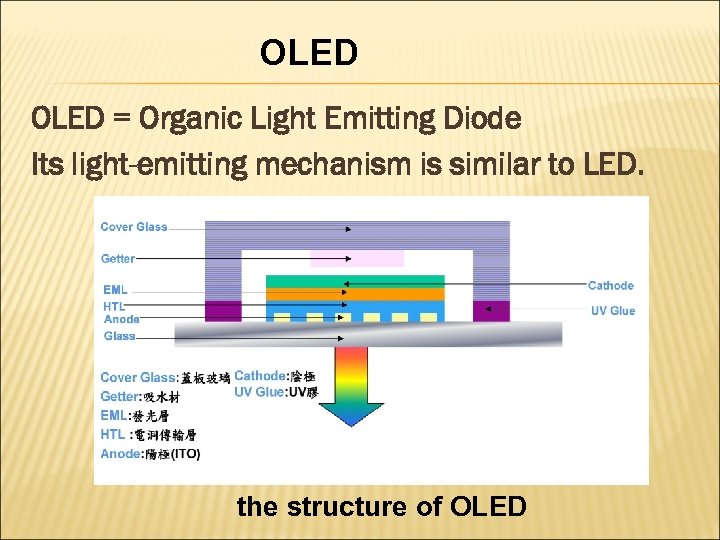

OLED = Organic Light Emitting Diode Its light-emitting mechanism is similar to LED. the structure of OLED

OLED = Organic Light Emitting Diode Its light-emitting mechanism is similar to LED. the structure of OLED

Classification According to light-emitting materials : Small molecular OLED: Alq 3 Polymer OLED (PLED):PPV, MEH-PPV According to display models : Passive Matrix(PM-OLED) : Acitive Matrix (AM-OLED): TFT FOLED: Flexible OLED

Classification According to light-emitting materials : Small molecular OLED: Alq 3 Polymer OLED (PLED):PPV, MEH-PPV According to display models : Passive Matrix(PM-OLED) : Acitive Matrix (AM-OLED): TFT FOLED: Flexible OLED

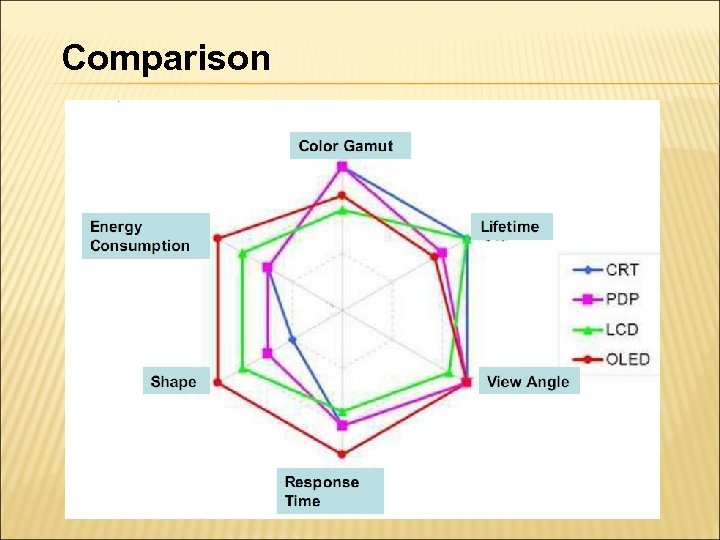

Comparison

Comparison

Advantages u u u Thickness can be less than 1 mm. Simple process; Low cost(30~40%of LCD). Self-luminous; Highly efficient and kind to environment. Low drive voltage and low power consumption. Microsecond response time(1000 times)and wide view angle(>170°). High brightness(100~14000 cd/m 2 ), wide temperature range(-30~80 ℃)

Advantages u u u Thickness can be less than 1 mm. Simple process; Low cost(30~40%of LCD). Self-luminous; Highly efficient and kind to environment. Low drive voltage and low power consumption. Microsecond response time(1000 times)and wide view angle(>170°). High brightness(100~14000 cd/m 2 ), wide temperature range(-30~80 ℃)

Disadvantages u u Life is usually only 5, 000 hours, less than that of LCD at least 1 million hours. Color purity is not enough to show bright and rich color. Large-size OLED panel production has very low yield(<30%), compared with LCD’s(>99%). High patent fees.

Disadvantages u u Life is usually only 5, 000 hours, less than that of LCD at least 1 million hours. Color purity is not enough to show bright and rich color. Large-size OLED panel production has very low yield(<30%), compared with LCD’s(>99%). High patent fees.

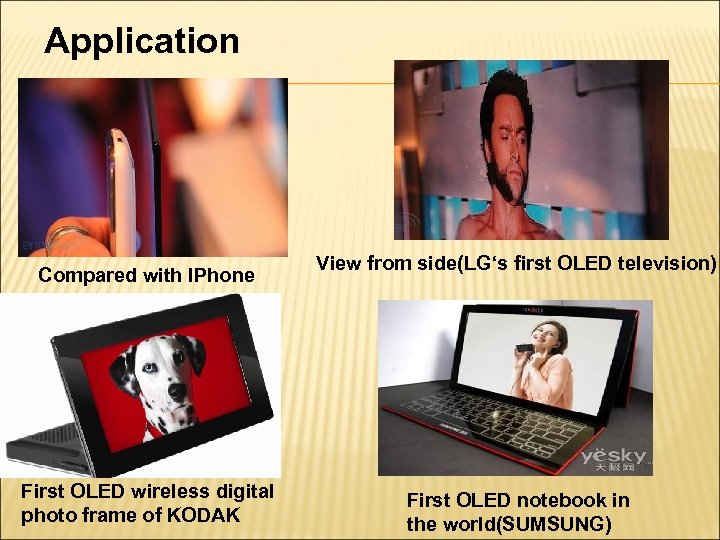

Application Compared with IPhone First OLED wireless digital photo frame of KODAK View from side(LG‘s first OLED television) First OLED notebook in the world(SUMSUNG)

Application Compared with IPhone First OLED wireless digital photo frame of KODAK View from side(LG‘s first OLED television) First OLED notebook in the world(SUMSUNG)

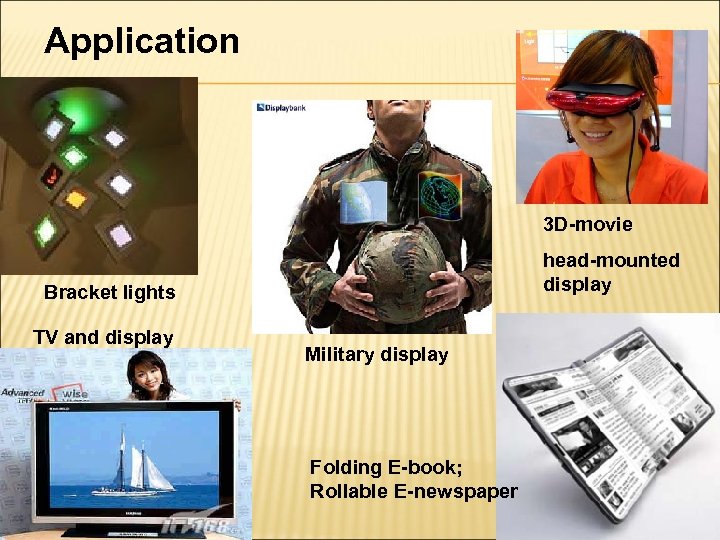

Application 3 D-movie head-mounted display Bracket lights TV and display Military display Folding E-book; Rollable E-newspaper

Application 3 D-movie head-mounted display Bracket lights TV and display Military display Folding E-book; Rollable E-newspaper

The future of LED I’M CUTE! My name is LED. Firstly, I am smaller. Secondly,I need less power. Thirdly,I enjoy longer life. At the same time,you can call me energy saving lamp. It’s last but not the least, I’m a faddish girl.

The future of LED I’M CUTE! My name is LED. Firstly, I am smaller. Secondly,I need less power. Thirdly,I enjoy longer life. At the same time,you can call me energy saving lamp. It’s last but not the least, I’m a faddish girl.

My weakness When it comes to my weakness, my price is too high. And then, my luminous flux is low. Stroboscopic phenomenon. Strong stimulation.

My weakness When it comes to my weakness, my price is too high. And then, my luminous flux is low. Stroboscopic phenomenon. Strong stimulation.

My future is bright! With the development of technology and the reduction of cost, I will be the most popular in the world!

My future is bright! With the development of technology and the reduction of cost, I will be the most popular in the world!

Thank You

Thank You