686e0d291c637d3d4986601c571529b8.ppt

- Количество слайдов: 44

Lecture slides to accompany Basics of Engineering Economy by Leland Blank and Anthony Tarquin Chapter 11 Estimating Costs Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 1 © 2008, Mc. Graw-Hill All rights reserved

Chapter 11 – Estimating Costs PURPOSE TOPICS Learn to make cost estimates Learn how to allocate indirect costs Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 2 • Cost estimation approaches • Unit method • Cost index method • Cost-capacity relations • Factor method • Learning curve relation • Indirect cost allocation © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 1 – Making Cost Estimates TYPES OF COSTS TO ESTIMATE Ø Direct – labor, machine and material costs -- Estimate in detail to extent possible ØIndirect – support functions, management, warranty, legal, taxes -- Estimate using standard rates and factors Technology, automation, human labor costs q Have caused indirect costs to be a much larger percentage of total project or system cost q Require that more accurate methods of indirect cost estimation be applied Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 3 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 1 – Making Cost Estimates Direct cost examples • Physical assets • Maintenance and operating costs (M&O) • Materials • Direct human labor (costs and benefits) • Scrapped and reworked product • Direct supervision of personnel Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 4 Indirect cost examples • • • Utilities IT systems and networks Purchasing Management Taxes Legal functions Warranty and guarantees Quality assurance Accounting functions Marketing and publicity © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 1 – Making Cost Estimates Questions that can guide direct cost estimation ü What components of cost must be estimated? Labor, materials, assets, M&O, training, etc. ü What estimation approach is best to use? Design-to-cost or bottom-up approach is common ü What level of estimation accuracy is needed? Design stage uses order-of-magnitude for ± 20% accuracy; detailed design requires accuracy in ± 5% range ü What estimation techniques are best to use? Tables, software, unit, index, factor, cost-capacity, learning curve, expert opinion, comparison, etc. Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 5 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 1 – Components to Estimate What components of cost must be estimated? • Depends upon complexity of project or system • Some common components that need estimates Asset first costs, plus delivery and installation costs (P) Direct labor costs Direct material costs Annual operating costs (AOC) – also called M&O for maintenance and operating costs • Many tabular and software systems are available R. S. Means NASA Marshall and Swift US Dept. of Labor Mc. Graw-Hill Construction Environmental Protection Int’l Project Estimating (software) Agency Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 6 © 2008, Mc. Graw-Hill All rights reserved

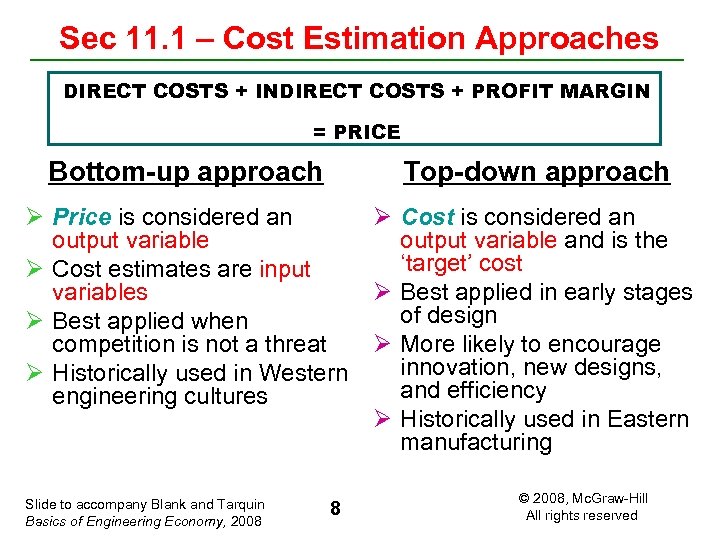

Sec 11. 1 – Cost Estimation Approaches What estimation approach is better to use? Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 7 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 1 – Cost Estimation Approaches DIRECT COSTS + INDIRECT COSTS + PROFIT MARGIN = PRICE Bottom-up approach Top-down approach Ø Price is considered an output variable Ø Cost estimates are input variables Ø Best applied when competition is not a threat Ø Historically used in Western engineering cultures Ø Cost is considered an output variable and is the ‘target’ cost Ø Best applied in early stages of design Ø More likely to encourage innovation, new designs, and efficiency Ø Historically used in Eastern manufacturing Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 8 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 1 – Accuracy of Estimates What level of estimation accuracy is needed? q No estimate can be exact q Must be reasonable and accurate enough to support a reliable economic analysis £ In preliminary design phase v Estimates are considered ‘first cuts’ v Order-of-magnitude estimates in the ± 20% range ¥ However, in detailed design phase v Accuracy must support analysis for ‘go-no go’ decision v Estimates expected to be in ± 5% range Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 9 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 1 – Accuracy of Estimates Accuracy vs. time spent in making estimates Situation: Construction of a building Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 10 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 1 – Estimation Techniques What estimation techniques are best to use? Preliminary design phase estimators: ü Unit cost method – very preliminary and very popular ü Cost index method – bases present cost estimates on past cost experiences; inflation adjusted ü Cost-estimating relationships (CER) v Factor method v Cost-capacity equations v Learning curve These are all discussed on slides that follow Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 11 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 1 – Estimation Techniques What estimation techniques are best to use? Detailed design phase estimators: ü Various software packages and tabulated handbooks v These include timely data bases with indexes and factors specific to an industrial sector ü Other useful methods in any design phase: v Expert opinion v Comparison with known installations v Past experience in the field Note: Estimates outside the ± 15% or 20% range are not reliable; don’t use them as the design process continues Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 12 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 2 – Unit Method • • Used commonly by estimators and in daily life Provides very preliminary estimates Cost factors must be updated to remain timely Equation for total cost CT is simply CT = unit cost factor × number of units = U×N Example: New house construction costs average U = $250 per square foot in specific city. Cost of N = 2, 400 ft 2 house CT = 250 × 2, 400 = $600, 000 Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 13 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 2 – Unit Method - Example Unit cost factors can be used to develop a preliminary cost estimate for a multi-component system • Table below shows 5 resources with U and N values • Preliminary cost estimate is sum of U×N terms Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 14 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 3 – Cost Index Method • Index is ratio of cost today to cost in past • Indicates change in cost over time; therefore, considers impact of inflation • Index is dimensionless • CPI (Consumer Price Index) is a good example • Equation for total cost CT is Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 15 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 3 – Cost Index Method – Example • Construction project cost $3. 4 million 5 years ago • Skilled labor cost component then was 25% or $850, 000 • Skilled labor index then was 3496; Same index this month is 4038 • Total cost estimate now CT = 850, 000(4038/3496) = $981, 780 q Jump forward in time - assume actual cost for skilled labor is reported as $1 million when construction is complete q Solve for It for index value that should have been used It = I 0 × (CT/C 0 ) = 3496(1, 000/850, 000) = 4113 Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 16 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 3 – Cost Index Method • Excellent cost indexes are maintained in areas such as construction, chemical and mechanical industries – Updated monthly and annually; many include regionalized and international project indexes – Indexes in these areas are often subdivided into smaller components and can be used in preliminary, as well as more detailed design phases • Examples are: – Chemical Engineering Plant Cost Index – Mc. Graw-Hill Construction Index – Marshall & Swift Equipment Cost Index Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 17 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 4 – Cost Estimating Relationships (CER) Ø Generically different approach than index method Ø Use equations to estimate cost based on design variables Ø Example design variables: ü Size ü Speed ü Capacity ü Weight ü Mileage ü Thrust Ø Some CER models: ü Cost-capacity ü Factor ü Learning curve Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 18 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 4 – Cost-Capacity Equations Also called power law and sizing model Exponent defines relation between 2 capacities If x = 1, relationship is linear Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 19 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 4 – Cost-Capacity Equations • If x > 1, larger capacities will cost more than a linear cost relation (diseconomies of scale) • If x < 1, larger capacities will cost less than a linear cost relation (economies of scale) • Usually, 0 < x ≤ 1 (economy of scale predicted) • If x is not tabulated or estimable, use x = 0. 6 q Called six-tenth model q Historically used in chemical processing industry • Example data sources of x values: ü Chemical Engineer’s Handbook ü Plant Design and Economics ü UN Food and Agriculture Organization (fishery industry) Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 20 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 4 – Cost-Capacity Equations Sample exponent values for equipment and plants Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 21 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 4 – Cost-Capacity Equations - Example In year 2000, aerobic digester equipment with flow rate of 0. 5 MGD (million gallons per day) was installed at a cost of $1. 7 million Estimate cost for 2. 0 MGD x = 0. 14 from table for 0. 2 – 40 MGD aerobic digester Q 2 = 2. 0 MGD Q 1 = 0. 5 MGD C 1 = $1. 7 million C 2 = 1. 7 million (2. 0/0. 5)0. 14 = $2. 06 million Note: There is good economy of scale since x << 1. 0 Capacity is 4 x larger, but estimated cost increases by only 21% Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 22 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 4 – Cost-Capacity Equations ■ Cost-capacity exponents do not change with time; no cost indexing is included ■ Multiply by cost index (It/I 0) to adjust for time and obtain estimate of current cost (i. e. , in constant-value dollars) Example: Estimate cost of aerobic digester if cost index has increased from 131 in 2000 to 225 this year C 2 = 1. 7 million (2. 0/0. 5)0. 14(225/131) = $3. 545 million Note: Time adjustment caused cost estimate to increase 108% from $1. 7 million in year 2000 Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 23 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 5 – Factor Method o Factor method estimates total plant costs for processing industries o Concept and factors first developed by Hans Lang o Multiply total first cost of major equipment by h, an overall cost factor or a sum of several cost factors which relate to major components or stages of the plant Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 24 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 5 – Factor Method ■ Using a cost factor for each major cost component, such as construction, maintenance, labor, indirect costs, h is ■ i = 1, …, n are the components ■ To estimate total plant cost: Ø Determine estimated total cost of capital equipment Ø Define major components Ø Find their cost factors for the type of plant being developed Ø Multiply equipment cost by h to estimate CT Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 25 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 5 – Factor Method - Example First cost of all equipment is P = $273, 000 Major components and cost factors Component Installation of hardware Cost factor 0. 49 Construction Indirect costs 0. 53 0. 21 h = 1 + 0. 49 +0. 53 + 0. 21 = 2. 23 CT = 2. 23(273, 000) = $608, 790 Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 26 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 5 – Factor Method Ø If cost components are not defined in early design stages, use h = 4 to estimate total plant cost Ø If indirect costs are separately estimated based on total direct costs of the plant: v h does not include indirect cost component v separate indirect cost factor f. I is inserted Note: Be sure to understand the basis for the factors before calculating CT Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 27 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 6 – Learning Curve • Based on often observed fact that completion time of repetitive tasks decreases at an approximate constant rate every time production is doubled • Developed primarily for repetitive task manufacturing and process industries; yet, it works in a much broader set of environments • Model estimates time to complete Nth unit, not cost and not total or average completion time • For example, if reduction is 10%, learning rate is 90% Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 28 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 6 – Learning Curve • Plots as straight line on log-log graph • Learning curve slope s is defined as Example: Plot TN for rate of 90% and T 1 = 60 minutes Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 29 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 6 – Learning Curve Take log of TN to obtain straight line equation log TN = log T 1 + s log N Total cost of N units is cost per unit c times sum of T 1 through TN time estimates CT = c(T 1 + T 2 + … + TN) Learning curve time estimates are best for smaller lots up to ~200 units Usually, large quantity lots do not experience continued learning, so completion time does not decrease according to the doubling assumption in this model Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 30 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 6 – Learning Curve - Example T 1 = 200 hours Learning rate = 80% Lot size is 25 Cost = $50 per hour Learning curve slope: s = log 0. 8/log 2 = - 0. 0969/0. 301 = - 0. 322 Estimated cost of unit 1: C 1 = 50(200) = $10, 000 Estimated time to complete 5 th unit: T 5 = T 1 × Ns = 200(5)-0. 322 = 119. 1 hours Estimated cost of unit 5: C 1 = 50(119. 1) = $5, 955 Total time to complete entire lot: Sum T 1 to T 25 = 2461. 4 hours Estimated cost of lot of 25 units: C 1 = 50(2461. 4) = $123, 070 Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 31 Cost reduced by ~40% in first 5 units © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 7 – Indirect Cost (IC) Estimation • Indirect costs are not directly associated with a specific product or process • Also called overhead costs • Indirect cost examples (activities and departments) Planning and scheduling General maintenance Human resources Taxes Legal Supervision Quality and inspection Safety Security and the list goes on… • Indirect costs are usually allocated to primary producing departments quarterly, semiannually, and annually Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 32 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 7 – Indirect Cost (IC) Estimation • Different industries and corporations use various methods to estimate and to allocate indirect costs • Three methods to estimate are: v Factor method – Apply factor implicitly to direct cost estimates; Lang Factors and the factor method are examples v Traditional method - Establish rates using direct cost bases and allocate IC to using departments v ABC method – Establish rates on selected activities (not direct cost centers) and allocate IC to using departments Note: Never forget to include indirect costs in economic analysis as they are usually a significant percentage of total cost Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 33 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 7 – Indirect Cost Estimation Traditional Method Standard IC rates are based on something traceable Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 34 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 7 – Indirect Cost Estimation Traditional Method ü A blanket rate is calculated on only one basis, e. g. , cost of materials ü Applying a blanket rate to all departments or processes can over-allocate IC to lower-value-adding departments ü Apply different rates to various departments, processes or systems when the bases should be different ü Using the appropriate basis and rate is called productive hour rate method Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 35 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 7 – Indirect Cost Estimation Traditional Method - Example MAKE/BUY DECISION WITH INDIRECT COST ALLOCATION Buy: AW = $-1. 5 million per year Make: P = $-2 million S = $50, 000 n = 10 years MARR = 15% • Direct costs of $800, 000 per year are detailed below • Indirect cost rates are established by department cont → Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 36 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 7 – Indirect Cost Estimation Traditional Method - Example INDIRECT COST ALLOCATION FOR MAKE ALTERNATIVE Dept A: Basis is -- Direct labor hours Dept B: Basis is -- Machine hours Dept C: Basis is -- Direct labor hours 25, 000(10) = $250, 000 25, 000(5) = $125, 000 10, 000(15) = $150, 000 ECONOMIC COMPARISON AT MARR = 15% AOCmake = direct labor + direct materials + indirect allocation = 500, 000 + 300, 000 + 525, 000 = $1, 325, 000 AWmake = - 2 M(A/P, 15%, 10) + 50, 000(A/F, 15%, 10) - 1. 325 M = $-1. 721 M Conclusion: Cheaper to purchase outside (buy alternative) AWbuy = $-1. 5 M Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 37 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 7 – Indirect Cost (IC) Estimation Activity-Based Costing (ABC) Method Ø Historically, direct labor Ø Some products may was 35 -50% of total cost; appear profitable, but are now it is 5 -15% not when indirect costs are more realistically Ø ICs make up 35 -50% of allocated cost Ø Automation, more efficient Ø ABC method uses the following to allocate IC: systems, etc. require better IC tracking and Activities allocation Cost drivers Ø ABC method replaces or These are not direct cost supplements traditional bases as used in method in many traditional rates industries Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 38 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 7 – Indirect Cost Estimation ABC Method q Activities are support departments or functions ¬ Purchasing ¬ Quality ¬ Safety ¬ Security ¬ Engineering Legal Accounting Management Personnel (Human Resources) q Cost drivers represent events, usually expressed in volumes ¬ Number of purchase orders ¬ Number of reworks ¬ Cost of engineering changes ¬ Number of software activations ¬ Number of machine setups Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 39 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 7 – Indirect Cost Estimation ABC Method Steps for implementation and Example: allocation of ABC ü Purchasing department is an IC cost center 1. Identify each activity and its total cost ü Purchasing is the activity ü Number of purchase orders 2. Identify cost drivers and their volume measures is the cost driver ü ABC rate for IC allocation to 3. Calculate overhead rate for each activity using departments is: 4. Use rate to allocate to cost $ per purchase order initiated centers (departments, products, processes) Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 40 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 7 – Indirect Cost Estimation o Traditional method is easier to set up and use o Traditional method is usually better when making cost estimates o ABC is more accurate when process is in operation o ABC is more costly, but provides more information for cost analysis and decision making o Traditional and ABC methods complement each other Ø Traditional is good for cost estimation and allocation Ø ABC is better for cost tracking and cost control Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 41 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 7 – Indirect Cost Estimation ABC Method - Example cont → ABC ALLOCATION OF ANNUAL TRAVEL COSTS TO PLANTS Activity: Travel ABC allocation rate Cost driver: travel voucher 500, 000/500 Total cost of travel: $500, 000 = $1, 000 per voucher Total volume of vouchers: 500 Number of vouchers submitted from 4 plants for 5 product lines Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 42 © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 7 – Indirect Cost Estimation ABC Method - Example 1. 2. 3. 4. Activity and its total cost: travel for $500, 000 Cost drivers and volumes: Vouchers and table entries Allocation rate: $1, 000 per voucher Allocate $500, 000: Allocated amounts are (Table value) x 1, 000 Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 43 Plant in Paris ABC allocation $ 75, 000 Florence 140, 000 Hamburg 145, 000 Athens 140, 000 cont → © 2008, Mc. Graw-Hill All rights reserved

Sec 11. 7 – Indirect Cost Estimation ABC Method - Example Travel was previously allocated on basis of number of employees with following results Traditional rate = 500, 000/29, 100 = $17. 28/employee Comparison shows that allocations for all plants (except Hamburg) are significantly different Number of vouchers is a more realistic basis for travel cost allocation Slide to accompany Blank and Tarquin Basics of Engineering Economy, 2008 44 © 2008, Mc. Graw-Hill All rights reserved

686e0d291c637d3d4986601c571529b8.ppt