b7b3ca7ce2fffd50d45ff5439fbfb5b1.ppt

- Количество слайдов: 19

Lecture Outline 5 Manufacturing Systems (Production and Operations Management)

Lecture Outline 5 Manufacturing Systems (Production and Operations Management)

Production of Tangible Goods • such a business has three types of inventory: raw materials, work-in-process, and finished goods • Use of computers in manufacturing is widespread

Production of Tangible Goods • such a business has three types of inventory: raw materials, work-in-process, and finished goods • Use of computers in manufacturing is widespread

Computers in Manufacturing • Computer-aided design (CAD) • Computer-aided engineering (CAE) – 3 -D representation of car engine on screen – Simulation of engine’s performance – Performance data gathered • Automated control of production machines – Computer control of sawing patterns – Computer control of industrial robots

Computers in Manufacturing • Computer-aided design (CAD) • Computer-aided engineering (CAE) – 3 -D representation of car engine on screen – Simulation of engine’s performance – Performance data gathered • Automated control of production machines – Computer control of sawing patterns – Computer control of industrial robots

Production Planning & Control *L • Raw materials acquisition (when, how much) • Machine and worker requirements • Detailed production schedules • Gathering evaluation statistics – Sensors, scanners, shop floor terminals – Quality control – Comparing performance data to plans • Cost accounting for mfg. goods

Production Planning & Control *L • Raw materials acquisition (when, how much) • Machine and worker requirements • Detailed production schedules • Gathering evaluation statistics – Sensors, scanners, shop floor terminals – Quality control – Comparing performance data to plans • Cost accounting for mfg. goods

In More Detail *MC • Master Production Schedule – Based on - accepted sales orders • Sales forecast • Current finished goods inventory • Lists #units to be produced each week

In More Detail *MC • Master Production Schedule – Based on - accepted sales orders • Sales forecast • Current finished goods inventory • Lists #units to be produced each week

Bill of Materials *L • A list of raw materials needed to produce one unit of finished product and the quantity of each material • Material Requirements Planning (MRP) – With the MPS and BOM, a system can produce time-phased purchase orders for raw materials (main output of MRP)

Bill of Materials *L • A list of raw materials needed to produce one unit of finished product and the quantity of each material • Material Requirements Planning (MRP) – With the MPS and BOM, a system can produce time-phased purchase orders for raw materials (main output of MRP)

Capacity Requirements Planning *L • What MRP is to materials required • CRP is to machines time and worker time required • What the bill of materials is to MRP, the Route Sheet is to CRP - shows sequence of required operations and the standard time allowed for each operation (usually person + machine)

Capacity Requirements Planning *L • What MRP is to materials required • CRP is to machines time and worker time required • What the bill of materials is to MRP, the Route Sheet is to CRP - shows sequence of required operations and the standard time allowed for each operation (usually person + machine)

Capacity *L • How much machine time and worker time do we have? – May need to rent more floor space and / or machines – May need to hire temp workers • CRP generates a detailed production schedule • It releases manufacturing orders to the production floor

Capacity *L • How much machine time and worker time do we have? – May need to rent more floor space and / or machines – May need to hire temp workers • CRP generates a detailed production schedule • It releases manufacturing orders to the production floor

Manufacturing Resource Planning (MRPII) *L • Composed of: – – – Master Production Schedule (tactical) MRP (tactical / operational) CRP (tactical / operational) Shop floor control (operational / tactical) Quality control (operational / tactical) Cost allocation (material, labour, overhead) to finished goods – a comprehensive, integrated way of managing manufacturing

Manufacturing Resource Planning (MRPII) *L • Composed of: – – – Master Production Schedule (tactical) MRP (tactical / operational) CRP (tactical / operational) Shop floor control (operational / tactical) Quality control (operational / tactical) Cost allocation (material, labour, overhead) to finished goods – a comprehensive, integrated way of managing manufacturing

Inventory Control *MC • In manufacturing, we have: – Raw materials inventory – Work-in-process inventory – Finished goods inventory • Systems keep track of quantities and costs of each

Inventory Control *MC • In manufacturing, we have: – Raw materials inventory – Work-in-process inventory – Finished goods inventory • Systems keep track of quantities and costs of each

Just-In-Time (JIT) Manufacturing *MC Raw materials arrive just when they are needed on the production floor • Minimizes inventory • Requires complex information systems (operational) • May have vendor managed inventory (supplier’s computers tap into our inv. systems)

Just-In-Time (JIT) Manufacturing *MC Raw materials arrive just when they are needed on the production floor • Minimizes inventory • Requires complex information systems (operational) • May have vendor managed inventory (supplier’s computers tap into our inv. systems)

Computers in Manufacturing SUMMARY: - computer support in manufacturing extensive - we’re concerned with supporting information systems (not drafting or machine control) - Many operational / tactical systems

Computers in Manufacturing SUMMARY: - computer support in manufacturing extensive - we’re concerned with supporting information systems (not drafting or machine control) - Many operational / tactical systems

Operational & Tactical Systems • • Master Production Scheduling system Material requirements planning system Capacity requirements planning system Detailed Production Schedule Shop floor control (comp. to schedule) Quality control (comp. to quality standards) Cost accounting; inventory control Put together in MRP II (Mfg Resource Planning)

Operational & Tactical Systems • • Master Production Scheduling system Material requirements planning system Capacity requirements planning system Detailed Production Schedule Shop floor control (comp. to schedule) Quality control (comp. to quality standards) Cost accounting; inventory control Put together in MRP II (Mfg Resource Planning)

IT Considerations in Mfg. *L • Large databases designed for varied and quick retrieval • Data capture in variety of ways (incl. sensors, measurement devices, scanning) • Connectivity throughout production facilities • Both operational and tactical (eg. Shop floor control) • Integration with system outside mfg.

IT Considerations in Mfg. *L • Large databases designed for varied and quick retrieval • Data capture in variety of ways (incl. sensors, measurement devices, scanning) • Connectivity throughout production facilities • Both operational and tactical (eg. Shop floor control) • Integration with system outside mfg.

Strategic Manufacturing Systems *X • Assist top management with – Selecting a plant site – Building a new plant – Designing and laying out a production facility – Assessing technologies to be used in production processes • May use both internal and external data

Strategic Manufacturing Systems *X • Assist top management with – Selecting a plant site – Building a new plant – Designing and laying out a production facility – Assessing technologies to be used in production processes • May use both internal and external data

Supply Chain Management Software (SCM) *MC • Supply chain: flow of materials, services and information from suppliers of merchandise and raw materials through to the organization’s customers – Now: supply network • Supply chain management: processes and procedures used to ensure the delivery of goods and services to customers at the lowest cost while providing highest value to the customers

Supply Chain Management Software (SCM) *MC • Supply chain: flow of materials, services and information from suppliers of merchandise and raw materials through to the organization’s customers – Now: supply network • Supply chain management: processes and procedures used to ensure the delivery of goods and services to customers at the lowest cost while providing highest value to the customers

SCM (cont’d) • suppliers are gaining access to an organization’s production planning schedules to assure an ability to fulfill orders • producing organization is opening its systems to the customer to allow the customer to view inventory and production levels before placing orders

SCM (cont’d) • suppliers are gaining access to an organization’s production planning schedules to assure an ability to fulfill orders • producing organization is opening its systems to the customer to allow the customer to view inventory and production levels before placing orders

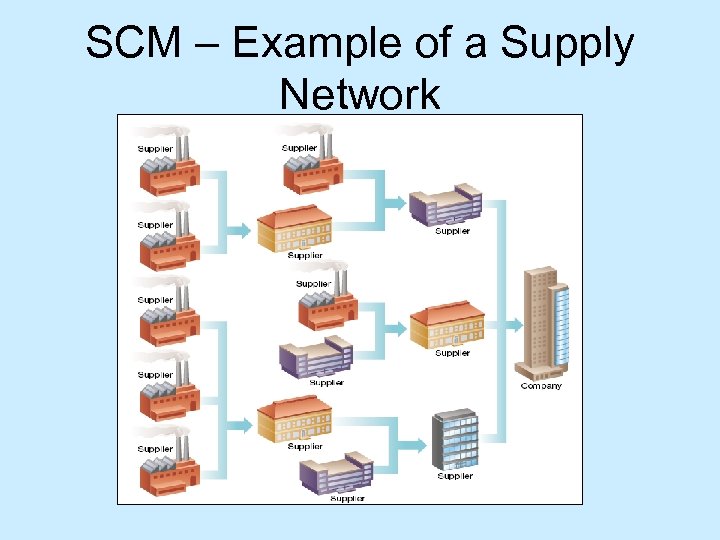

SCM – Example of a Supply Network

SCM – Example of a Supply Network

Dell Computers’ SCM system • Dell uses Ariba SCM to automate its purchasing process • SCM system is connected to its broad supplier network • System provides Dell with data to id inefficiencies within its supply network; and to negotiate key contracts for goods and services

Dell Computers’ SCM system • Dell uses Ariba SCM to automate its purchasing process • SCM system is connected to its broad supplier network • System provides Dell with data to id inefficiencies within its supply network; and to negotiate key contracts for goods and services