12145e91d9eb3d5f18e0c1c5c6c17231.ppt

- Количество слайдов: 28

Lecture LOs a) Appreciate the (complexity) course, in general. . b) Get some ideas what the course is all about.

Lecture LOs a) Appreciate the (complexity) course, in general. . b) Get some ideas what the course is all about.

2 Groups. Build paper jet planes. Let’s see which one people like more.

2 Groups. Build paper jet planes. Let’s see which one people like more.

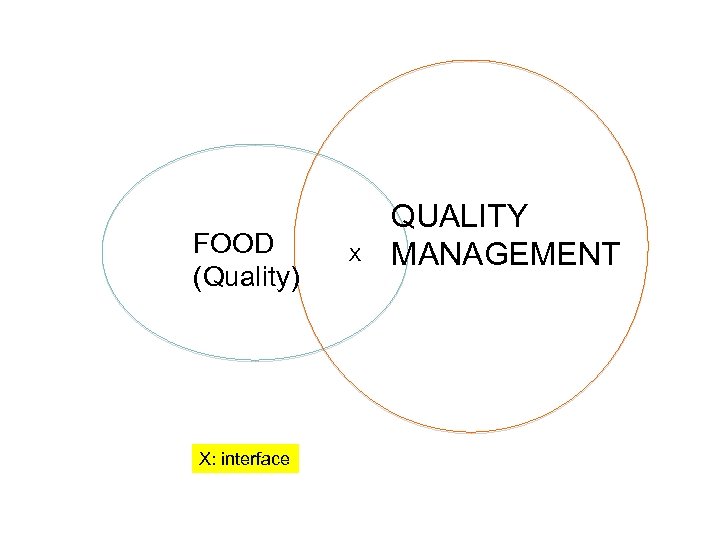

FOOD (Quality) X: interface X QUALITY MANAGEMENT

FOOD (Quality) X: interface X QUALITY MANAGEMENT

That’s easy, I can give. I want…

That’s easy, I can give. I want…

That’s easy, I can give. I want…

That’s easy, I can give. I want…

I want… Mee too. That’s easy, I can give. Mee too.

I want… Mee too. That’s easy, I can give. Mee too.

How do we manage the quality? How do we assure, control the quality?

How do we manage the quality? How do we assure, control the quality?

We need specifications • criteria- in writing- goal Get help from Standard And/Or Food Acts/Regulation (look at instant noodles e. g. )

We need specifications • criteria- in writing- goal Get help from Standard And/Or Food Acts/Regulation (look at instant noodles e. g. )

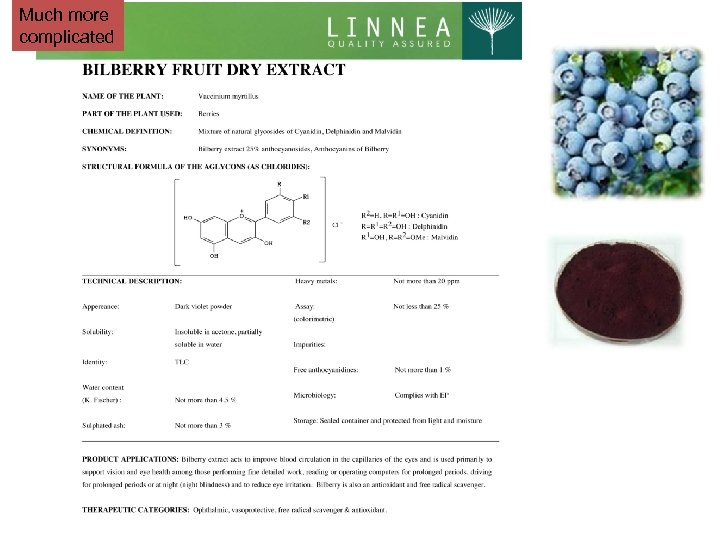

Much more complicated

Much more complicated

Finished product specification (after lengthy processes of new product development) According to latest research, this is good and will satisfy

Finished product specification (after lengthy processes of new product development) According to latest research, this is good and will satisfy

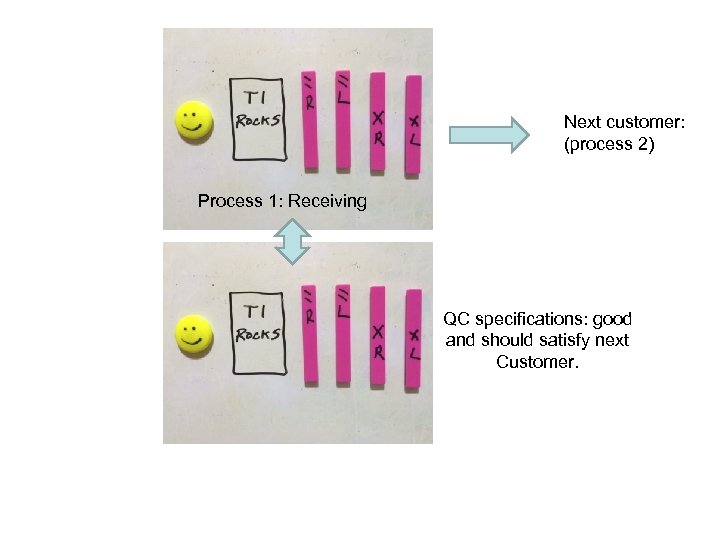

Next customer: (process 2) Process 1: Receiving QC specifications: good and should satisfy next Customer.

Next customer: (process 2) Process 1: Receiving QC specifications: good and should satisfy next Customer.

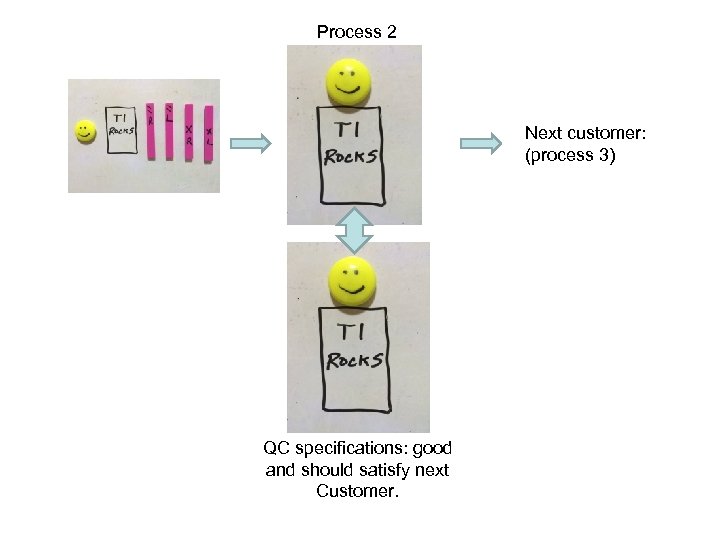

Process 2 Next customer: (process 3) QC specifications: good and should satisfy next Customer.

Process 2 Next customer: (process 3) QC specifications: good and should satisfy next Customer.

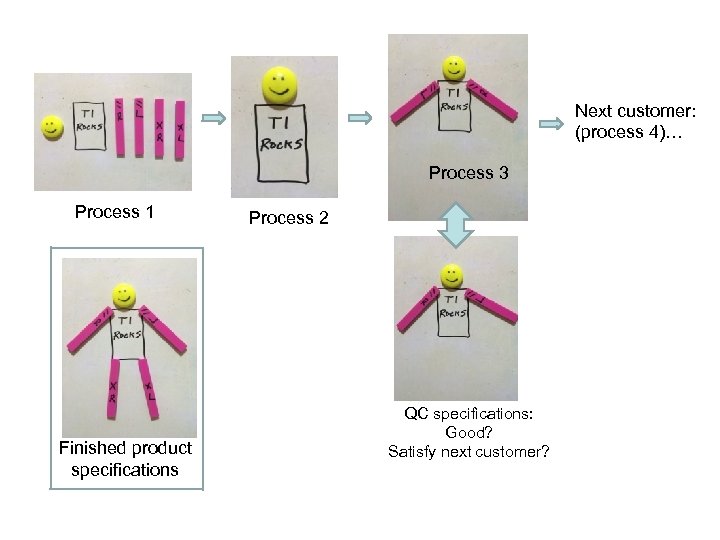

Next customer: (process 4)… Process 3 Process 1 Finished product specifications Process 2 QC specifications: Good? Satisfy next customer?

Next customer: (process 4)… Process 3 Process 1 Finished product specifications Process 2 QC specifications: Good? Satisfy next customer?

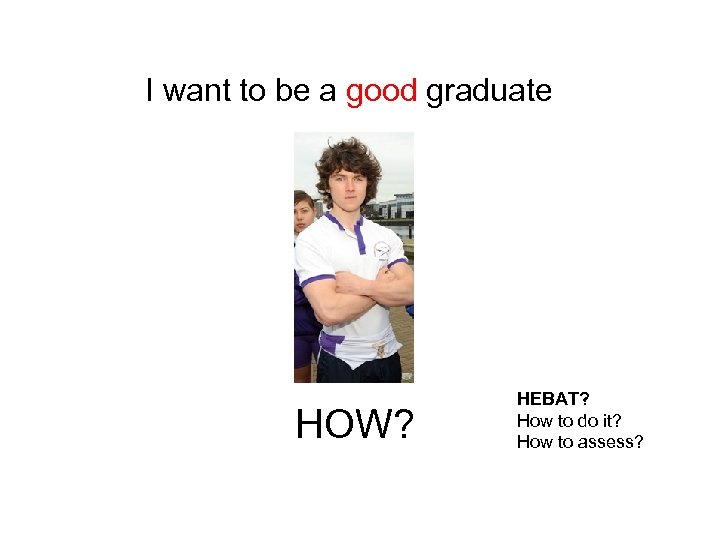

I want to be a good graduate HOW? HEBAT? How to do it? How to assess?

I want to be a good graduate HOW? HEBAT? How to do it? How to assess?

I want to produce high quality burger HOW?

I want to produce high quality burger HOW?

Important courses that help; (a) Statistics and process control (b) Food processing (c) Food Analysis (mostly Chemical) (d) Management + Food Quality Management

Important courses that help; (a) Statistics and process control (b) Food processing (c) Food Analysis (mostly Chemical) (d) Management + Food Quality Management

Other very relevant references; Tamime, A. Y. Milk processing and quality management, Wiley-Blackwell (certain case study) Inteaz Alli. Food Quality Assurance; Principles and practices, CRC Press (overview) Debby L. Newslow. The ISO 9000 Quality System; Application in Food and Technology, Wiley-Interscience Food Act 1983 and Standards from SIRIM

Other very relevant references; Tamime, A. Y. Milk processing and quality management, Wiley-Blackwell (certain case study) Inteaz Alli. Food Quality Assurance; Principles and practices, CRC Press (overview) Debby L. Newslow. The ISO 9000 Quality System; Application in Food and Technology, Wiley-Interscience Food Act 1983 and Standards from SIRIM

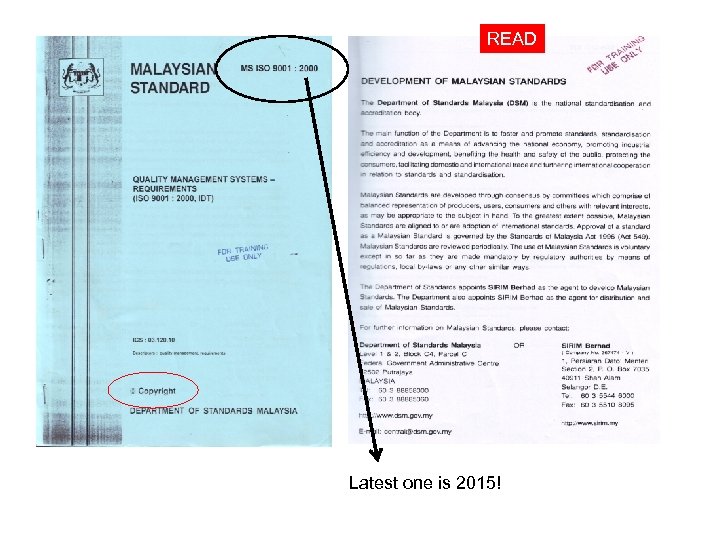

READ Latest one is 2015!

READ Latest one is 2015!

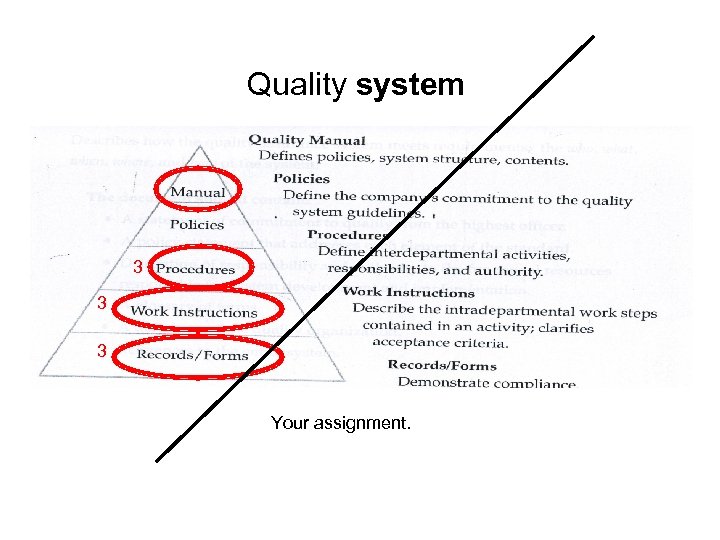

Quality system 3 3 3 Your assignment.

Quality system 3 3 3 Your assignment.

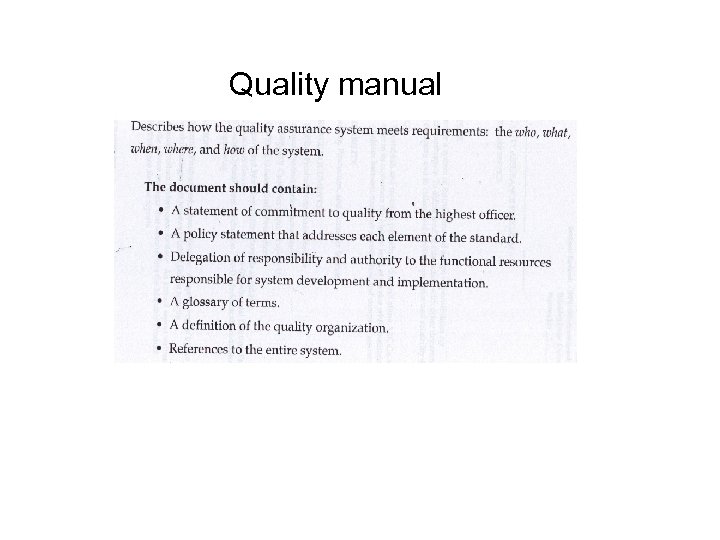

Quality manual

Quality manual

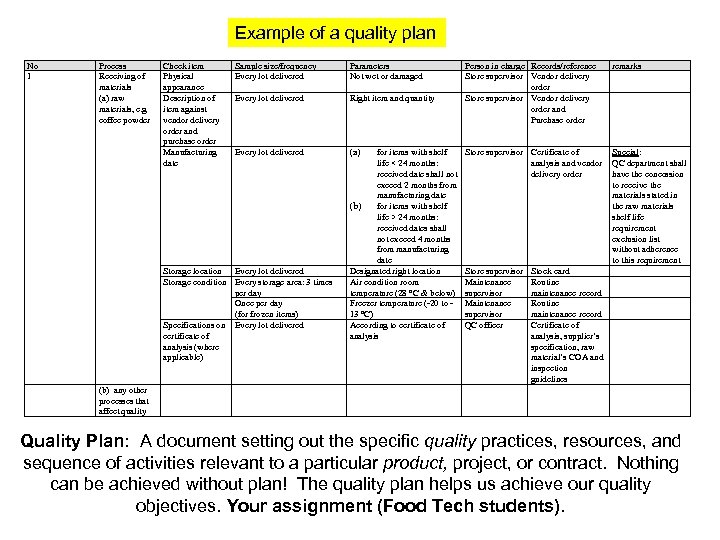

Example of a quality plan No 1 Process Receiving of materials (a) raw materials, e. g coffee powder Check item Physical appearance Description of item against vendor delivery order and purchase order Manufacturing date Sample size/frequency Every lot delivered Parameters Not wet or damaged Every lot delivered Right item and quantity Every lot delivered (a) Storage location Every lot delivered Storage condition Every storage area: 3 times per day Once per day (for frozen items) Specifications on Every lot delivered certificate of analysis (where applicable) for items with shelf life < 24 months: received date shall not exceed 2 months from manufacturing date (b) for items with shelf life > 24 months: received dates shall not exceed 4 months from manufacturing date Designated right location Air condition room temperature (28 C & below) Freezer temperature (-20 to 13 C) According to certificate of analysis Person in charge Records/reference Store supervisor Vendor delivery order and Purchase order remarks Store supervisor Certificate of analysis and vendor delivery order Special: QC department shall have the concession to receive the materials stated in the raw materials shelf life requirement exclusion list without adherence to this requirement Store supervisor Maintenance supervisor QC officer Stock card Routine maintenance record Certificate of analysis, supplier’s specification, raw material’s COA and inspection guidelines (b) any other processes that affect quality Quality Plan: A document setting out the specific quality practices, resources, and sequence of activities relevant to a particular product, project, or contract. Nothing can be achieved without plan! The quality plan helps us achieve our quality objectives. Your assignment (Food Tech students).

Example of a quality plan No 1 Process Receiving of materials (a) raw materials, e. g coffee powder Check item Physical appearance Description of item against vendor delivery order and purchase order Manufacturing date Sample size/frequency Every lot delivered Parameters Not wet or damaged Every lot delivered Right item and quantity Every lot delivered (a) Storage location Every lot delivered Storage condition Every storage area: 3 times per day Once per day (for frozen items) Specifications on Every lot delivered certificate of analysis (where applicable) for items with shelf life < 24 months: received date shall not exceed 2 months from manufacturing date (b) for items with shelf life > 24 months: received dates shall not exceed 4 months from manufacturing date Designated right location Air condition room temperature (28 C & below) Freezer temperature (-20 to 13 C) According to certificate of analysis Person in charge Records/reference Store supervisor Vendor delivery order and Purchase order remarks Store supervisor Certificate of analysis and vendor delivery order Special: QC department shall have the concession to receive the materials stated in the raw materials shelf life requirement exclusion list without adherence to this requirement Store supervisor Maintenance supervisor QC officer Stock card Routine maintenance record Certificate of analysis, supplier’s specification, raw material’s COA and inspection guidelines (b) any other processes that affect quality Quality Plan: A document setting out the specific quality practices, resources, and sequence of activities relevant to a particular product, project, or contract. Nothing can be achieved without plan! The quality plan helps us achieve our quality objectives. Your assignment (Food Tech students).

Reminder: Assignment/coursework Form a team of 4 -5. Decide on types of operation/organization/product and draw a flowchart. Develop a quality plan. I will select interview session with certain groups, so do well. Dateline: week 8.

Reminder: Assignment/coursework Form a team of 4 -5. Decide on types of operation/organization/product and draw a flowchart. Develop a quality plan. I will select interview session with certain groups, so do well. Dateline: week 8.