Lecture 7: Machining Tool Life: Wear and Failure Faculty of Mechanical Engineering- Technion Israel Institute of Technology ©

Lecture 7: Machining Tool Life: Wear and Failure Faculty of Mechanical Engineering- Technion Israel Institute of Technology ©

Tool Life: Wear and Failure • Cutting tools subjected to – – High forces High temperatures Sliding of the chip along the rake face Sliding of the tool along the freshly cut surface • Induce tool wear – – Tool life Surface quality Dimensional accuracy Economics of cutting operations • Two types of wear – Flank and crater wear

Tool Life: Wear and Failure • Cutting tools subjected to – – High forces High temperatures Sliding of the chip along the rake face Sliding of the tool along the freshly cut surface • Induce tool wear – – Tool life Surface quality Dimensional accuracy Economics of cutting operations • Two types of wear – Flank and crater wear

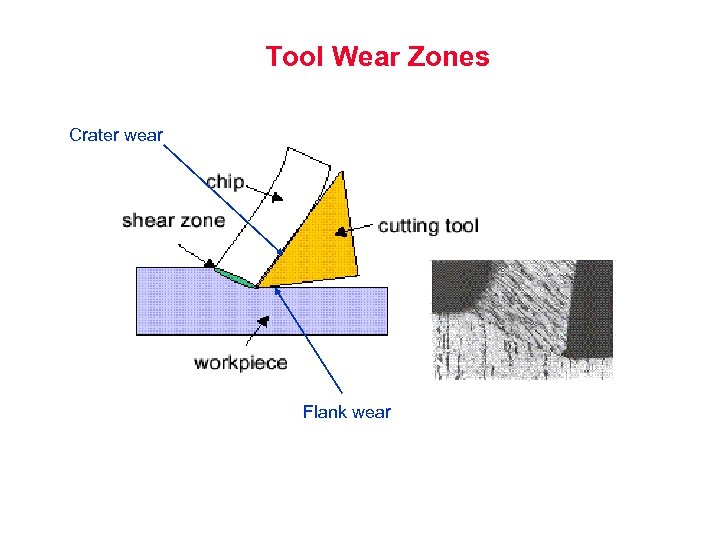

Tool Wear Zones Crater wear Flank wear

Tool Wear Zones Crater wear Flank wear

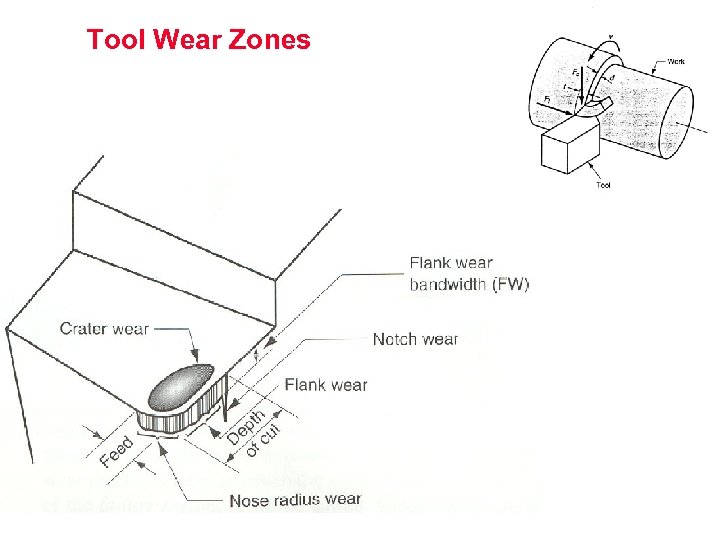

Tool Wear Zones

Tool Wear Zones

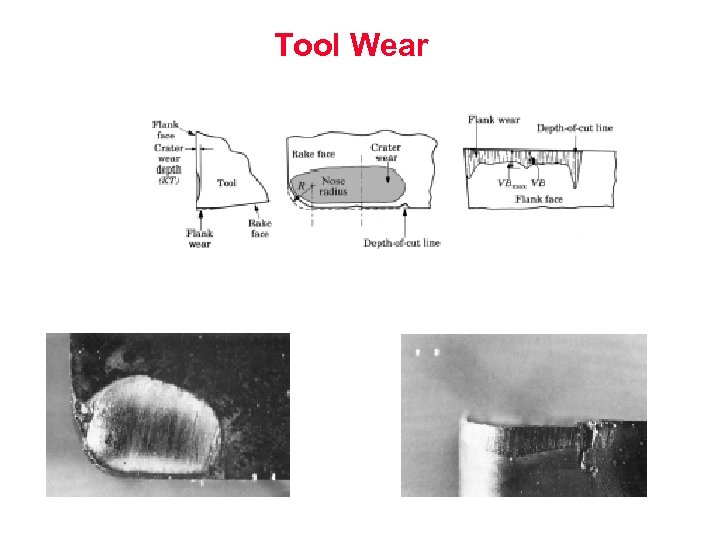

Tool Wear

Tool Wear

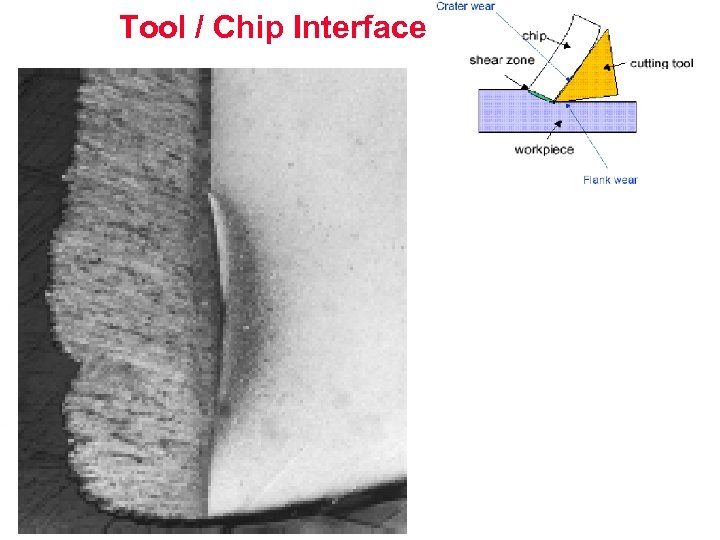

Tool / Chip Interface

Tool / Chip Interface

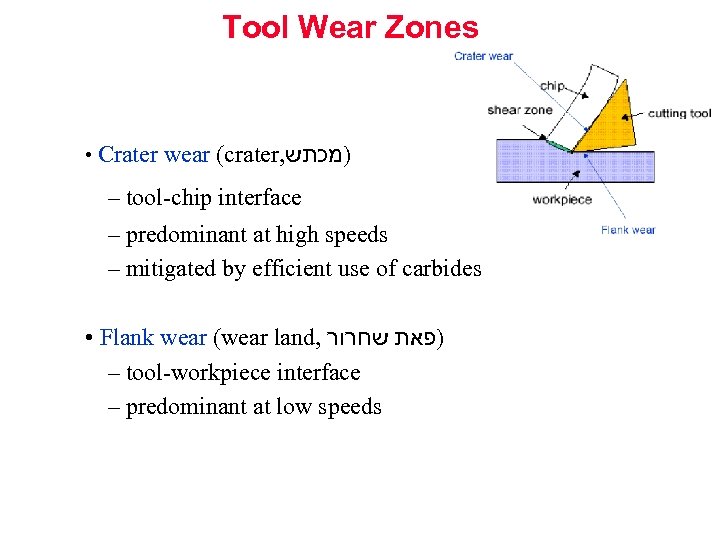

Tool Wear Zones • Crater wear (crater, )מכתש – tool-chip interface – predominant at high speeds – mitigated by efficient use of carbides • Flank wear (wear land, )פאת שחרור – tool-workpiece interface – predominant at low speeds

Tool Wear Zones • Crater wear (crater, )מכתש – tool-chip interface – predominant at high speeds – mitigated by efficient use of carbides • Flank wear (wear land, )פאת שחרור – tool-workpiece interface – predominant at low speeds

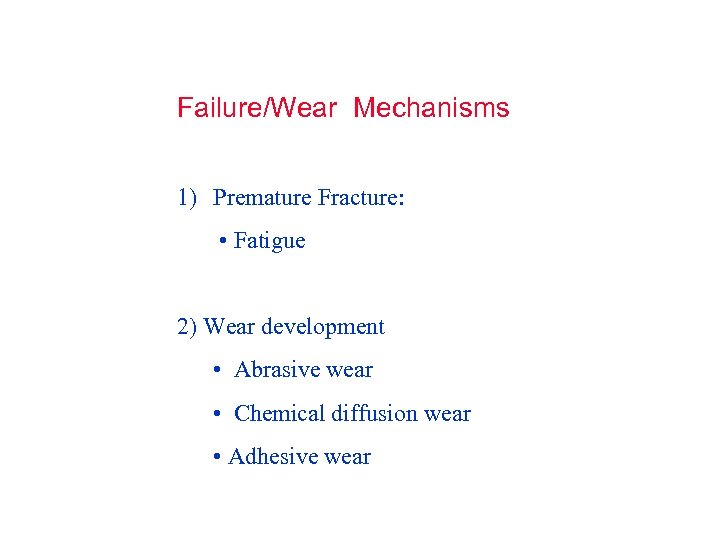

Failure/Wear Mechanisms 1) Premature Fracture: • Fatigue 2) Wear development • Abrasive wear • Chemical diffusion wear • Adhesive wear

Failure/Wear Mechanisms 1) Premature Fracture: • Fatigue 2) Wear development • Abrasive wear • Chemical diffusion wear • Adhesive wear

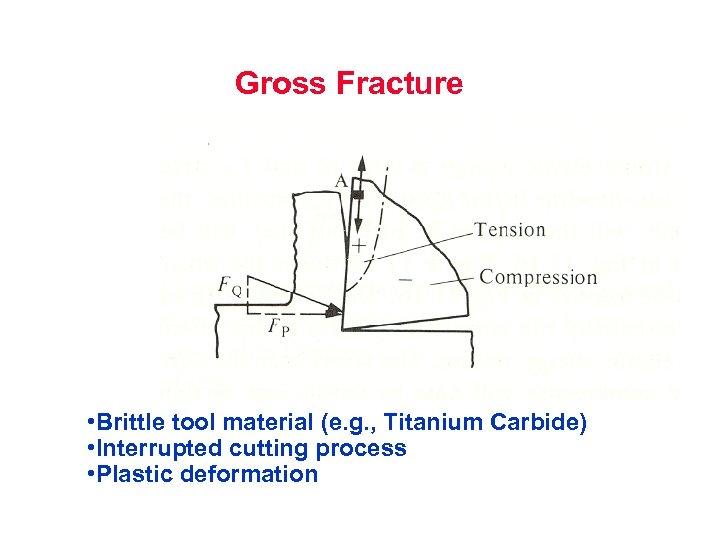

Gross Fracture • Brittle tool material (e. g. , Titanium Carbide) • Interrupted cutting process • Plastic deformation

Gross Fracture • Brittle tool material (e. g. , Titanium Carbide) • Interrupted cutting process • Plastic deformation

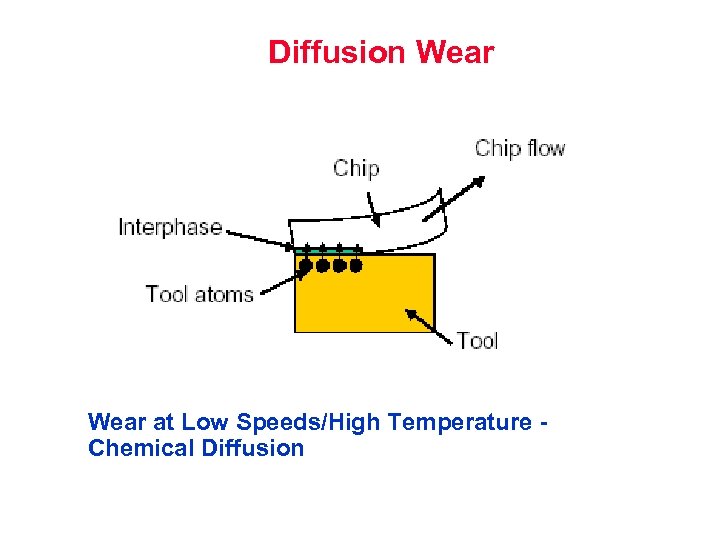

Diffusion Wear at Low Speeds/High Temperature Chemical Diffusion

Diffusion Wear at Low Speeds/High Temperature Chemical Diffusion

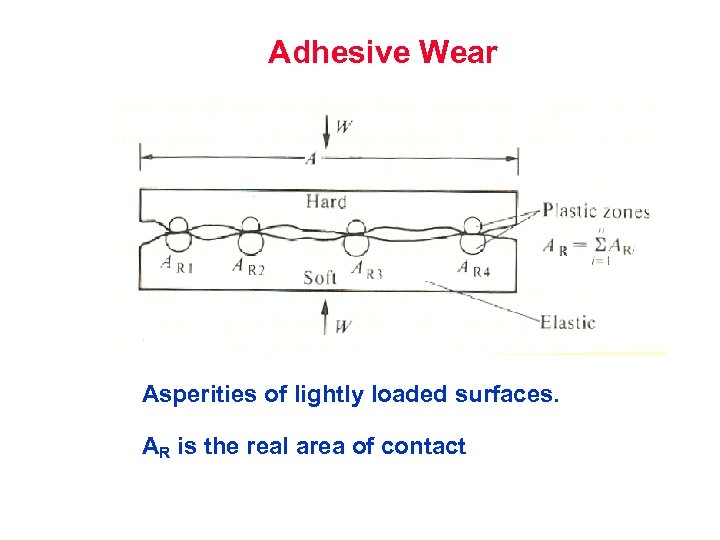

Adhesive Wear Asperities of lightly loaded surfaces. AR is the real area of contact

Adhesive Wear Asperities of lightly loaded surfaces. AR is the real area of contact

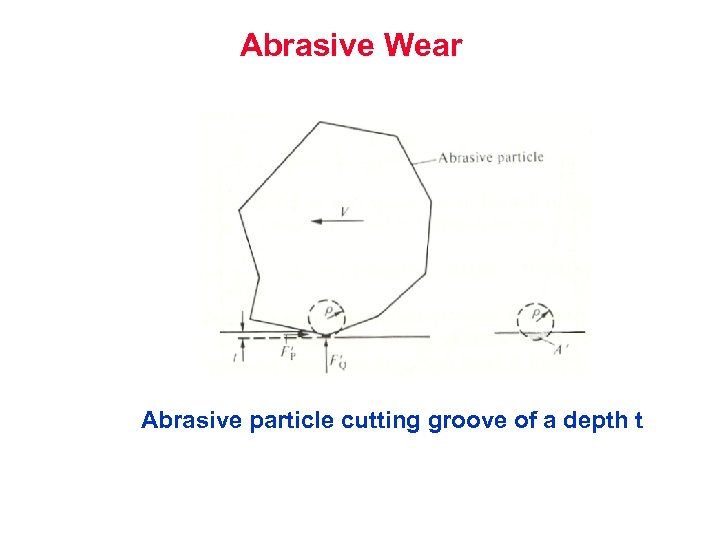

Abrasive Wear Abrasive particle cutting groove of a depth t

Abrasive Wear Abrasive particle cutting groove of a depth t

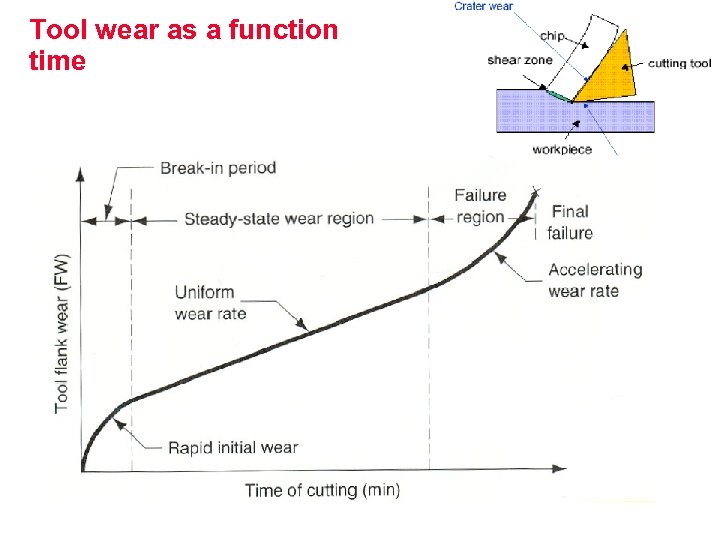

Tool wear as a function time

Tool wear as a function time

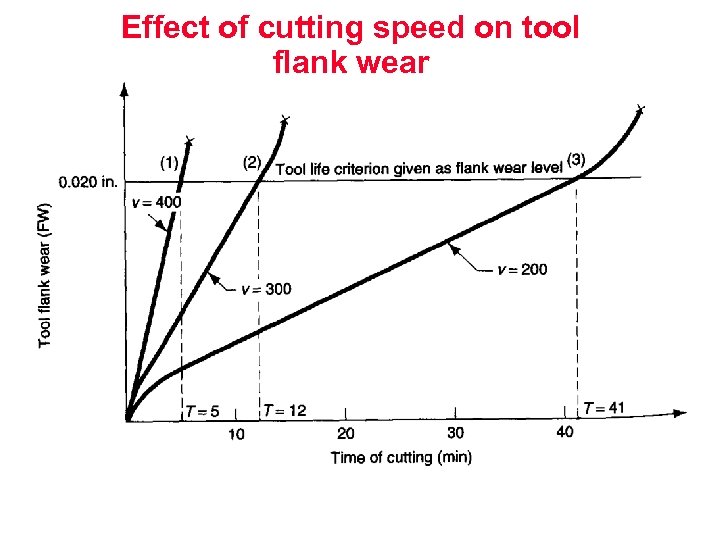

Effect of cutting speed on tool flank wear

Effect of cutting speed on tool flank wear

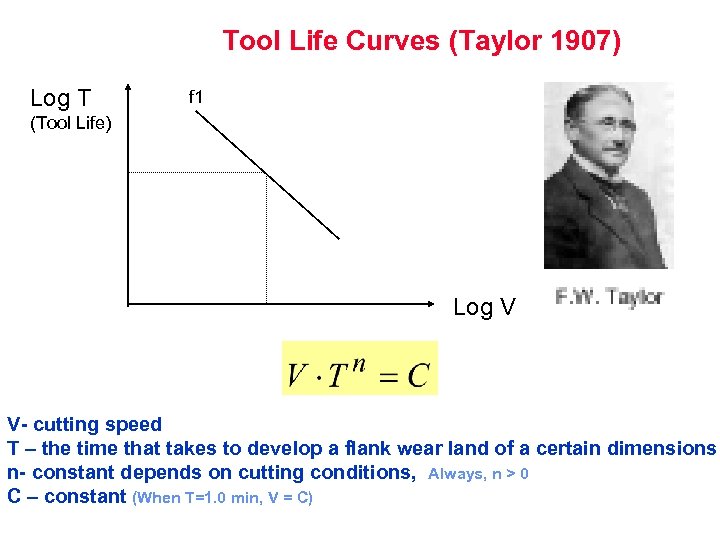

Tool Life Curves (Taylor 1907) Log T f 1 (Tool Life) Log V V- cutting speed T – the time that takes to develop a flank wear land of a certain dimensions n- constant depends on cutting conditions, Always, n > 0 C – constant (When T=1. 0 min, V = C)

Tool Life Curves (Taylor 1907) Log T f 1 (Tool Life) Log V V- cutting speed T – the time that takes to develop a flank wear land of a certain dimensions n- constant depends on cutting conditions, Always, n > 0 C – constant (When T=1. 0 min, V = C)

Taylor’s Equation for Tool Life • VTn = C • Tool-life curve –Log-log curve –T = (C/V)1/n C –Log. T = 1/n log. C – 1/n log. V Tool-life curves for a variety of cutting-tool materials. The negative inverse of the slope of these curves is the exponent n in the Taylor tool-life equations and C is the cutting speed at T = 1 min.

Taylor’s Equation for Tool Life • VTn = C • Tool-life curve –Log-log curve –T = (C/V)1/n C –Log. T = 1/n log. C – 1/n log. V Tool-life curves for a variety of cutting-tool materials. The negative inverse of the slope of these curves is the exponent n in the Taylor tool-life equations and C is the cutting speed at T = 1 min.

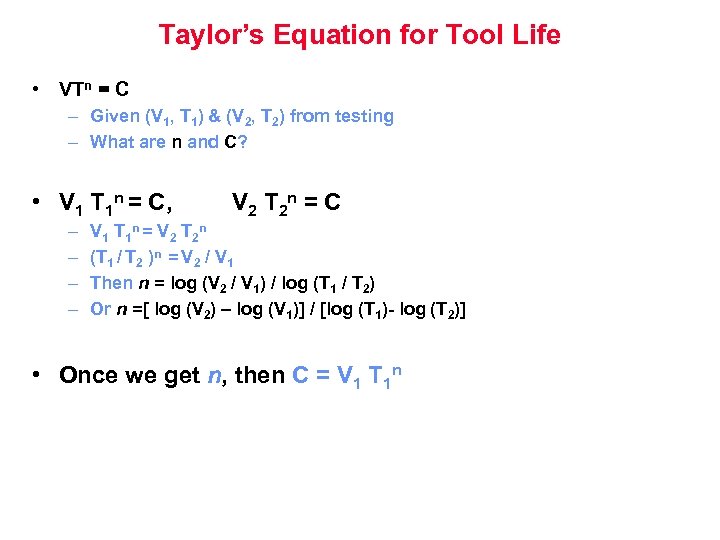

Taylor’s Equation for Tool Life • VTn = C – Given (V 1, T 1) & (V 2, T 2) from testing – What are n and C? • V 1 T 1 n = C, – – V 2 T 2 n = C V 1 T 1 n = V 2 T 2 n (T 1 / T 2 )n = V 2 / V 1 Then n = log (V 2 / V 1) / log (T 1 / T 2) Or n =[ log (V 2) – log (V 1)] / [log (T 1)- log (T 2)] • Once we get n, then C = V 1 T 1 n

Taylor’s Equation for Tool Life • VTn = C – Given (V 1, T 1) & (V 2, T 2) from testing – What are n and C? • V 1 T 1 n = C, – – V 2 T 2 n = C V 1 T 1 n = V 2 T 2 n (T 1 / T 2 )n = V 2 / V 1 Then n = log (V 2 / V 1) / log (T 1 / T 2) Or n =[ log (V 2) – log (V 1)] / [log (T 1)- log (T 2)] • Once we get n, then C = V 1 T 1 n

![n =[ log (V 2) – log (V 1)] / [log (T 1)- log n =[ log (V 2) – log (V 1)] / [log (T 1)- log](https://present5.com/presentation/815285505ce78768fce7efb7d0ef9ff9/image-18.jpg) n =[ log (V 2) – log (V 1)] / [log (T 1)- log (T 2)] T 2 T 1 C V 2 V 1

n =[ log (V 2) – log (V 1)] / [log (T 1)- log (T 2)] T 2 T 1 C V 2 V 1

![[log (T 1)- log (T 2)] n =[ log (V 2) – log (V [log (T 1)- log (T 2)] n =[ log (V 2) – log (V](https://present5.com/presentation/815285505ce78768fce7efb7d0ef9ff9/image-19.jpg) [log (T 1)- log (T 2)] n =[ log (V 2) – log (V 1)] / [log (T 1)- log (T 2)] [log (V 2) – log (V 1)] C

[log (T 1)- log (T 2)] n =[ log (V 2) – log (V 1)] / [log (T 1)- log (T 2)] [log (V 2) – log (V 1)] C