lecture 3.pptx

- Количество слайдов: 23

Lecture 3 Hydrodynamic enhanced oil recovery methods

Lecture 3 Hydrodynamic enhanced oil recovery methods

Hydrodynamic EOR methods are applied at the third and fourth stages of development of the production facilities; the secondary methods of oil production the most economical methods of enhanced oil recovery.

Hydrodynamic EOR methods are applied at the third and fourth stages of development of the production facilities; the secondary methods of oil production the most economical methods of enhanced oil recovery.

Hydrodynamic EOR methods are divided into: 1. The filtration flow direction change; 2. The cyclic flooding; 3. The forced fluid withdrawal. Their combined application should be defined as a combined non-stationary flooding, because all these methods are based on the non-stationary fluid filtration.

Hydrodynamic EOR methods are divided into: 1. The filtration flow direction change; 2. The cyclic flooding; 3. The forced fluid withdrawal. Their combined application should be defined as a combined non-stationary flooding, because all these methods are based on the non-stationary fluid filtration.

Filtration flows’ direction changing considers that water injection to the injection wells of the production facility periodically changes. As a result, the filtration flows direction changing occurs.

Filtration flows’ direction changing considers that water injection to the injection wells of the production facility periodically changes. As a result, the filtration flows direction changing occurs.

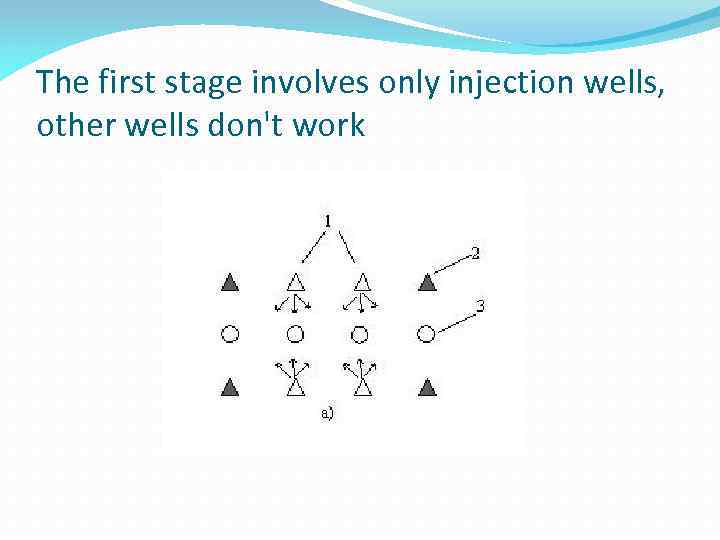

The first stage involves only injection wells, other wells don't work

The first stage involves only injection wells, other wells don't work

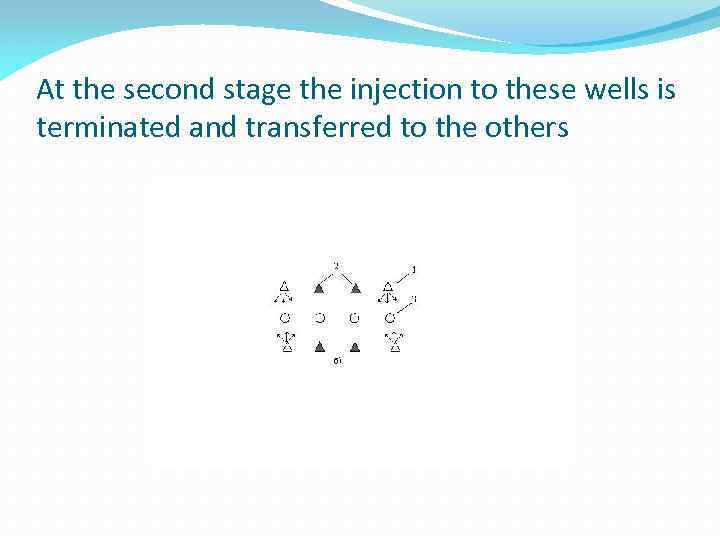

At the second stage the injection to these wells is terminated and transferred to the others

At the second stage the injection to these wells is terminated and transferred to the others

As a result, the filtration flows direction changing occurs. 1. The method is producible it requires only a small power reserve of the pumping stations and active flooding system. For this method 2. There are used cross-cutting rows, the combination of edge water flooding and circle water flooding. The application of this method allows to maintain the achieved oil production rate, to reduce the current water cut level and to increase the sweep flooding

As a result, the filtration flows direction changing occurs. 1. The method is producible it requires only a small power reserve of the pumping stations and active flooding system. For this method 2. There are used cross-cutting rows, the combination of edge water flooding and circle water flooding. The application of this method allows to maintain the achieved oil production rate, to reduce the current water cut level and to increase the sweep flooding

The application of the filtration flows’ direction changing method allows to: maintain the achieved oil production rate; reduce the current water cut level; increase the sweep flooding.

The application of the filtration flows’ direction changing method allows to: maintain the achieved oil production rate; reduce the current water cut level; increase the sweep flooding.

Forced fluid withdrawal (FFW) considers gradual increase of producing wells output. The essence of a method consists in: the creating of high pressure differentials by depression increasing, hence, there is the reduction of bottomhole pressure of the producing wells and increasing of the injection wells. The residual bypassed oil, oil lenses, dead end and stagnant zones, low-permeability interlayers are involved into development of heterogeneous high-watered formations.

Forced fluid withdrawal (FFW) considers gradual increase of producing wells output. The essence of a method consists in: the creating of high pressure differentials by depression increasing, hence, there is the reduction of bottomhole pressure of the producing wells and increasing of the injection wells. The residual bypassed oil, oil lenses, dead end and stagnant zones, low-permeability interlayers are involved into development of heterogeneous high-watered formations.

The conditions of method application: 1) Output water cut is not less than 90 -95% (The beginning of the closing stage of the development); 2) High coefficients of wells’ effectiveness at the beginning of the field operation; 3) The reservoir is stable under the conditions of bottomhole pressure decrease (it is not destructed), the injection pressure shouldn’t exceed rock’s breakdown point; 4) the casing string is non-fault, water cross flows are absent from the neighboring horizons; 5) The flow capacity of the production system is enough to apply forced fluid withdrawal.

The conditions of method application: 1) Output water cut is not less than 90 -95% (The beginning of the closing stage of the development); 2) High coefficients of wells’ effectiveness at the beginning of the field operation; 3) The reservoir is stable under the conditions of bottomhole pressure decrease (it is not destructed), the injection pressure shouldn’t exceed rock’s breakdown point; 4) the casing string is non-fault, water cross flows are absent from the neighboring horizons; 5) The flow capacity of the production system is enough to apply forced fluid withdrawal.

For the application of the FFW it is recommended to: collect and analyze the information about the well production activity: 1. the liquid and oil production rates, 2. water cut factor, 3. bottom-hole pressures of producing and injection wells, 4. the composition of the salts in the injected water

For the application of the FFW it is recommended to: collect and analyze the information about the well production activity: 1. the liquid and oil production rates, 2. water cut factor, 3. bottom-hole pressures of producing and injection wells, 4. the composition of the salts in the injected water

Technically, FFW is fulfilled by: the use of electric pumps with more supply, sucker-rod pumps operating at full load

Technically, FFW is fulfilled by: the use of electric pumps with more supply, sucker-rod pumps operating at full load

The main criteria of cyclic water flooding implementation: 1) the presence of stratified-heterogeneous by permeability or fractured-porous hydrophilic reservoirs; 2) high residual oil-saturation of low-permeability interlayers; 3) technical-technological ability to create pressure fluctuations of high amplitude that can reach 0, 5 -0, 7 from the average pressure differential between the injection and producing wells.

The main criteria of cyclic water flooding implementation: 1) the presence of stratified-heterogeneous by permeability or fractured-porous hydrophilic reservoirs; 2) high residual oil-saturation of low-permeability interlayers; 3) technical-technological ability to create pressure fluctuations of high amplitude that can reach 0, 5 -0, 7 from the average pressure differential between the injection and producing wells.

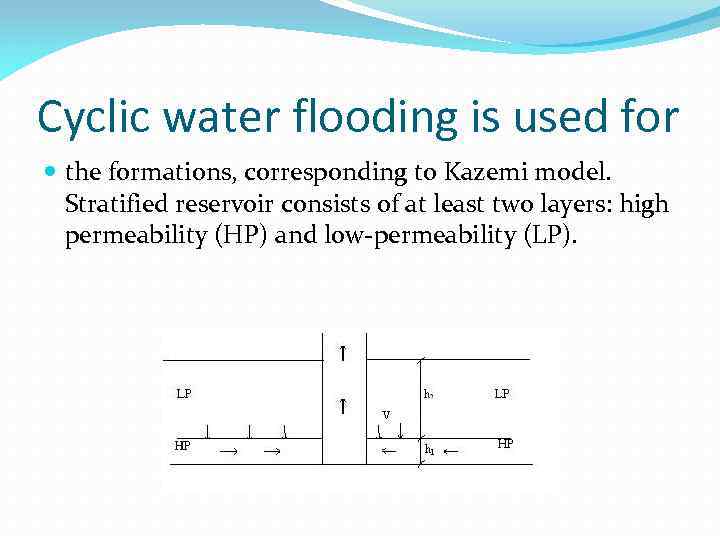

Cyclic water flooding is used for the formations, corresponding to Kazemi model. Stratified reservoir consists of at least two layers: high permeability (HP) and low-permeability (LP).

Cyclic water flooding is used for the formations, corresponding to Kazemi model. Stratified reservoir consists of at least two layers: high permeability (HP) and low-permeability (LP).

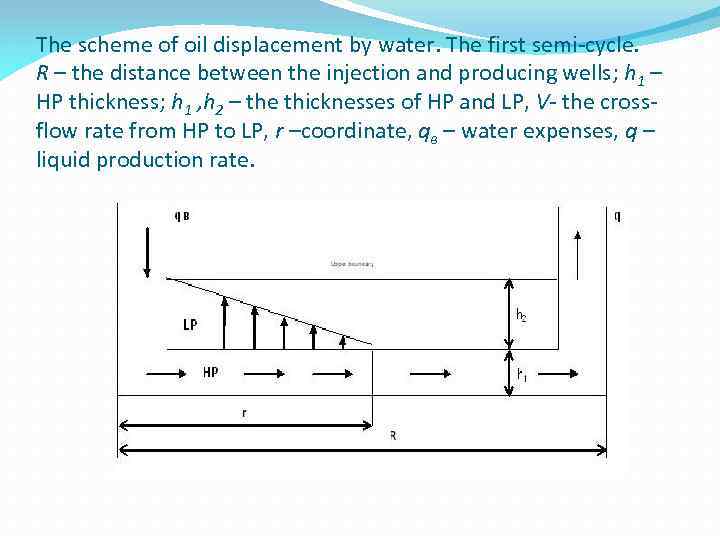

The scheme of oil displacement by water. The first semi-cycle. R – the distance between the injection and producing wells; h 1 – HP thickness; h 1 , h 2 – the thicknesses of HP and LP, V- the crossflow rate from HP to LP, r –coordinate, qв – water expenses, q – liquid production rate.

The scheme of oil displacement by water. The first semi-cycle. R – the distance between the injection and producing wells; h 1 – HP thickness; h 1 , h 2 – the thicknesses of HP and LP, V- the crossflow rate from HP to LP, r –coordinate, qв – water expenses, q – liquid production rate.

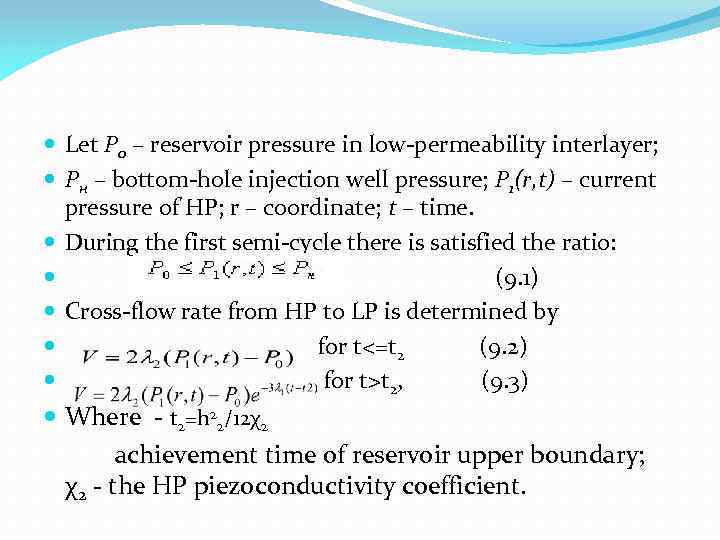

Let Р 0 – reservoir pressure in low-permeability interlayer; Рн – bottom-hole injection well pressure; Р 1(r, t) – current pressure of HP; r – coordinate; t – time. During the first semi-cycle there is satisfied the ratio: (9. 1) Cross-flow rate from HP to LP is determined by for t<=t 2 (9. 2) for t>t 2, (9. 3) Where - t 2=h 22/12χ2 achievement time of reservoir upper boundary; χ2 - the HP piezoconductivity coefficient.

Let Р 0 – reservoir pressure in low-permeability interlayer; Рн – bottom-hole injection well pressure; Р 1(r, t) – current pressure of HP; r – coordinate; t – time. During the first semi-cycle there is satisfied the ratio: (9. 1) Cross-flow rate from HP to LP is determined by for t<=t 2 (9. 2) for t>t 2, (9. 3) Where - t 2=h 22/12χ2 achievement time of reservoir upper boundary; χ2 - the HP piezoconductivity coefficient.

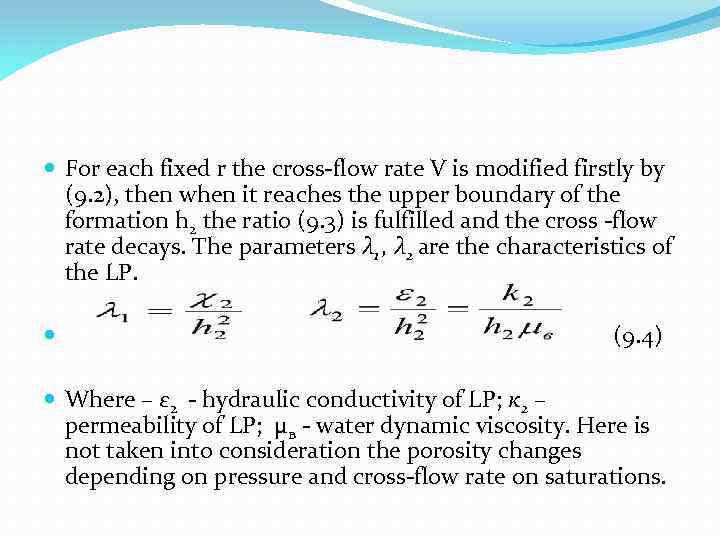

For each fixed r the cross-flow rate V is modified firstly by (9. 2), then when it reaches the upper boundary of the formation h 2 the ratio (9. 3) is fulfilled and the cross -flow rate decays. The parameters λ 1 , λ 2 are the characteristics of the LP. (9. 4) Where – ε 2 - hydraulic conductivity of LP; к 2 – permeability of LP; μв - water dynamic viscosity. Here is not taken into consideration the porosity changes depending on pressure and cross-flow rate on saturations.

For each fixed r the cross-flow rate V is modified firstly by (9. 2), then when it reaches the upper boundary of the formation h 2 the ratio (9. 3) is fulfilled and the cross -flow rate decays. The parameters λ 1 , λ 2 are the characteristics of the LP. (9. 4) Where – ε 2 - hydraulic conductivity of LP; к 2 – permeability of LP; μв - water dynamic viscosity. Here is not taken into consideration the porosity changes depending on pressure and cross-flow rate on saturations.

At cyclic flooding each of the producing and injection wells operates in the periodic pressure changing drive (withdrawal, consumption).

At cyclic flooding each of the producing and injection wells operates in the periodic pressure changing drive (withdrawal, consumption).

Combined non-stationary water flooding: includes the use of the changing of the filtration flow direction technology if there is a hydrodynamic connection between the inter-layers of different permeability, that is, the possibility of combined implementation of two technologies: changing of the filtration flow direction and cyclic flooding.

Combined non-stationary water flooding: includes the use of the changing of the filtration flow direction technology if there is a hydrodynamic connection between the inter-layers of different permeability, that is, the possibility of combined implementation of two technologies: changing of the filtration flow direction and cyclic flooding.

In this case, the reservoir sweep coefficient increases as due to the increase of the drainage area, and due to the flow of oil from the low-permeability reservoirs. Because the fluid flow increases, the replacement of the pumping equipment by more productive, which is chosen in accordance with the increased wells’ productivity factor is necessary.

In this case, the reservoir sweep coefficient increases as due to the increase of the drainage area, and due to the flow of oil from the low-permeability reservoirs. Because the fluid flow increases, the replacement of the pumping equipment by more productive, which is chosen in accordance with the increased wells’ productivity factor is necessary.

But the ECP (electrical centrifugal pump) replacement with more supply in this case is not the method of FFW because the water cut is not close to critical, and production facility is the on the second or third stage of development.

But the ECP (electrical centrifugal pump) replacement with more supply in this case is not the method of FFW because the water cut is not close to critical, and production facility is the on the second or third stage of development.

Combined non-stationary water flooding is possible only in hydrodynamically connected inter-layers.

Combined non-stationary water flooding is possible only in hydrodynamically connected inter-layers.

Thank for your attention!!!

Thank for your attention!!!