c9a196c9a5e65fe887856fe24237af50.ppt

- Количество слайдов: 38

Lecture 13. 0 Chemical Mechanical Polishing

Lecture 13. 0 Chemical Mechanical Polishing

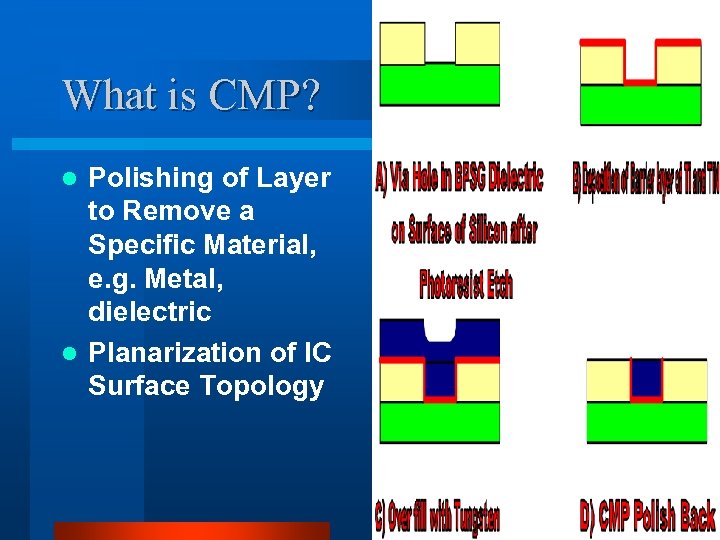

What is CMP? Polishing of Layer to Remove a Specific Material, e. g. Metal, dielectric l Planarization of IC Surface Topology l

What is CMP? Polishing of Layer to Remove a Specific Material, e. g. Metal, dielectric l Planarization of IC Surface Topology l

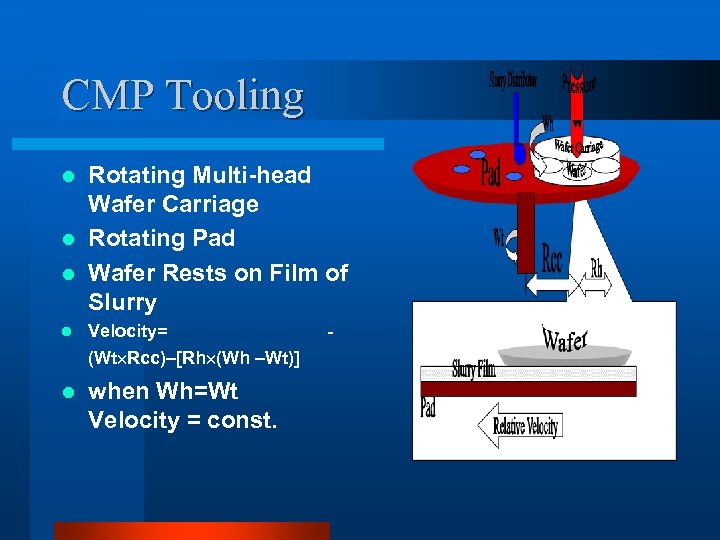

CMP Tooling Rotating Multi-head Wafer Carriage l Rotating Pad l Wafer Rests on Film of Slurry l l Velocity= (Wt Rcc)–[Rh (Wh –Wt)] l when Wh=Wt Velocity = const. -

CMP Tooling Rotating Multi-head Wafer Carriage l Rotating Pad l Wafer Rests on Film of Slurry l l Velocity= (Wt Rcc)–[Rh (Wh –Wt)] l when Wh=Wt Velocity = const. -

Slurry l Aqueous Chemical Mixture – Material to be removed is soluble in liquid – Material to be removed reacts to form an oxide layer which is abraded by abrasive l Abrasive – 5 -20% wgt of ~200± 50 nm particles • Narrow PSD, high purity(<100 ppm) • Fumed particle = fractal aggregates of spherical primary particles (15 -30 nm)

Slurry l Aqueous Chemical Mixture – Material to be removed is soluble in liquid – Material to be removed reacts to form an oxide layer which is abraded by abrasive l Abrasive – 5 -20% wgt of ~200± 50 nm particles • Narrow PSD, high purity(<100 ppm) • Fumed particle = fractal aggregates of spherical primary particles (15 -30 nm)

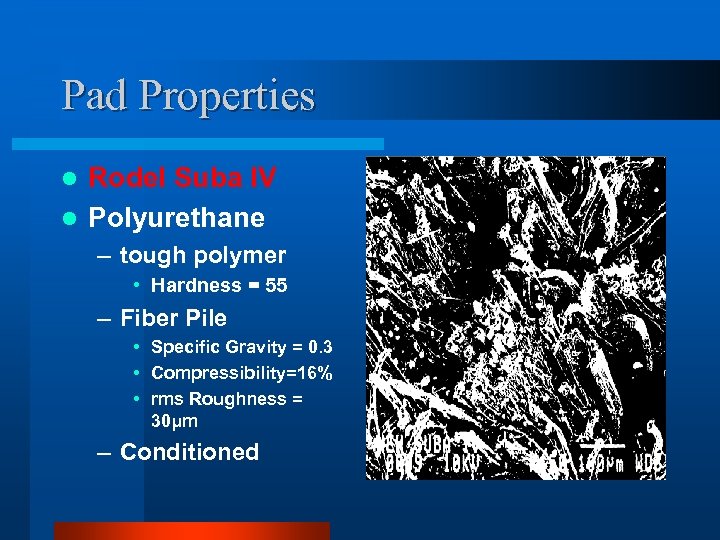

Pad Properties Rodel Suba IV l Polyurethane l – tough polymer • Hardness = 55 – Fiber Pile • Specific Gravity = 0. 3 • Compressibility=16% • rms Roughness = 30μm – Conditioned

Pad Properties Rodel Suba IV l Polyurethane l – tough polymer • Hardness = 55 – Fiber Pile • Specific Gravity = 0. 3 • Compressibility=16% • rms Roughness = 30μm – Conditioned

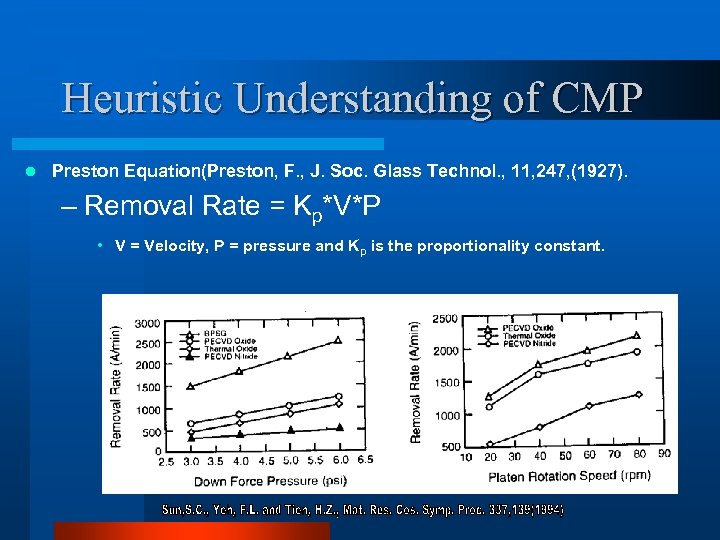

Heuristic Understanding of CMP l Preston Equation(Preston, F. , J. Soc. Glass Technol. , 11, 247, (1927). – Removal Rate = Kp*V*P • V = Velocity, P = pressure and Kp is the proportionality constant.

Heuristic Understanding of CMP l Preston Equation(Preston, F. , J. Soc. Glass Technol. , 11, 247, (1927). – Removal Rate = Kp*V*P • V = Velocity, P = pressure and Kp is the proportionality constant.

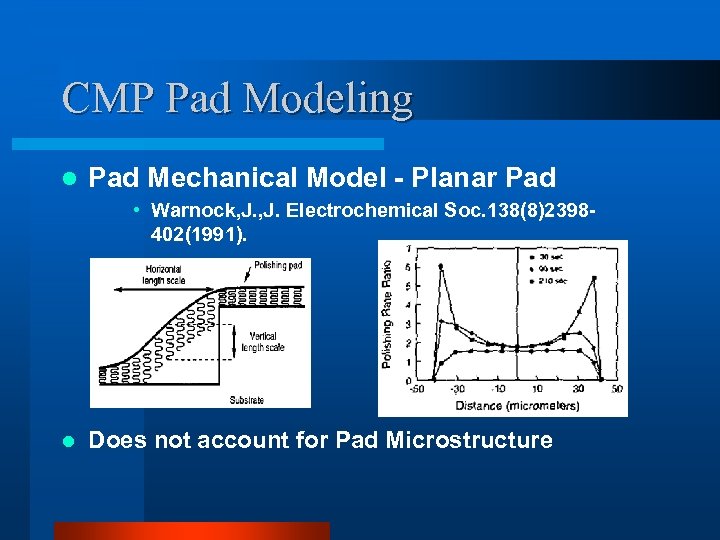

CMP Pad Modeling l Pad Mechanical Model - Planar Pad • Warnock, J. Electrochemical Soc. 138(8)2398402(1991). l Does not account for Pad Microstructure

CMP Pad Modeling l Pad Mechanical Model - Planar Pad • Warnock, J. Electrochemical Soc. 138(8)2398402(1991). l Does not account for Pad Microstructure

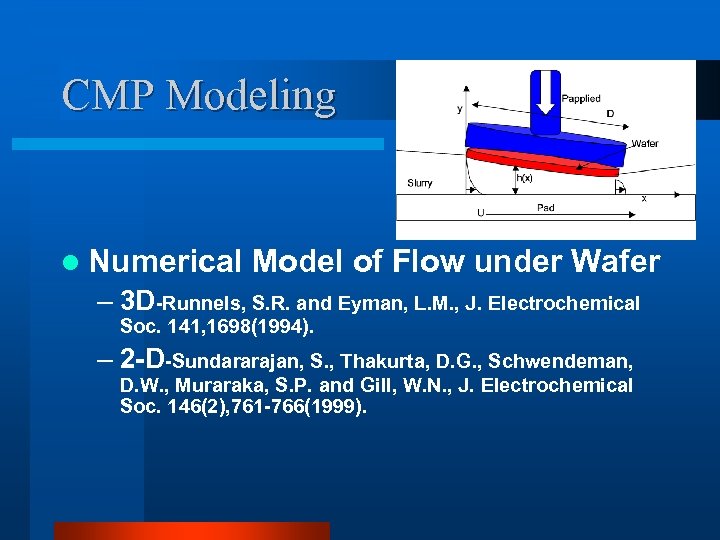

CMP Modeling l Numerical Model of Flow under Wafer – 3 D-Runnels, S. R. and Eyman, L. M. , J. Electrochemical Soc. 141, 1698(1994). – 2 -D-Sundararajan, S. , Thakurta, D. G. , Schwendeman, D. W. , Muraraka, S. P. and Gill, W. N. , J. Electrochemical Soc. 146(2), 761 -766(1999).

CMP Modeling l Numerical Model of Flow under Wafer – 3 D-Runnels, S. R. and Eyman, L. M. , J. Electrochemical Soc. 141, 1698(1994). – 2 -D-Sundararajan, S. , Thakurta, D. G. , Schwendeman, D. W. , Muraraka, S. P. and Gill, W. N. , J. Electrochemical Soc. 146(2), 761 -766(1999).

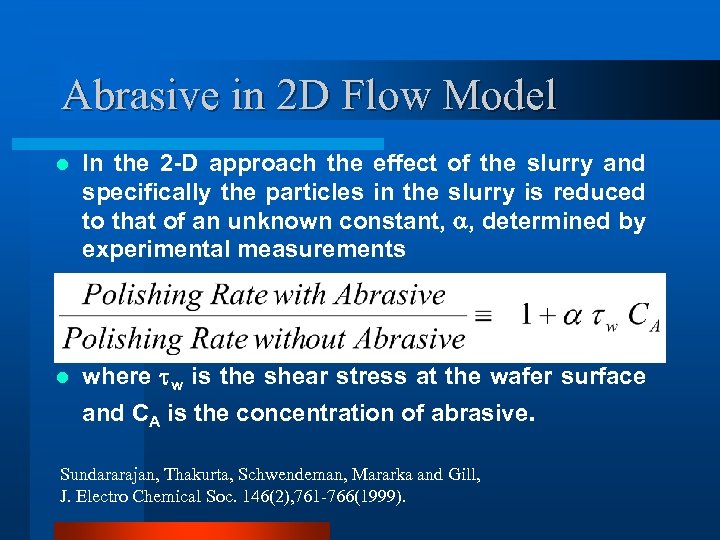

Abrasive in 2 D Flow Model l In the 2 -D approach the effect of the slurry and specifically the particles in the slurry is reduced to that of an unknown constant, , determined by experimental measurements l where w is the shear stress at the wafer surface and CA is the concentration of abrasive. Sundararajan, Thakurta, Schwendeman, Mararka and Gill, J. Electro Chemical Soc. 146(2), 761 -766(1999).

Abrasive in 2 D Flow Model l In the 2 -D approach the effect of the slurry and specifically the particles in the slurry is reduced to that of an unknown constant, , determined by experimental measurements l where w is the shear stress at the wafer surface and CA is the concentration of abrasive. Sundararajan, Thakurta, Schwendeman, Mararka and Gill, J. Electro Chemical Soc. 146(2), 761 -766(1999).

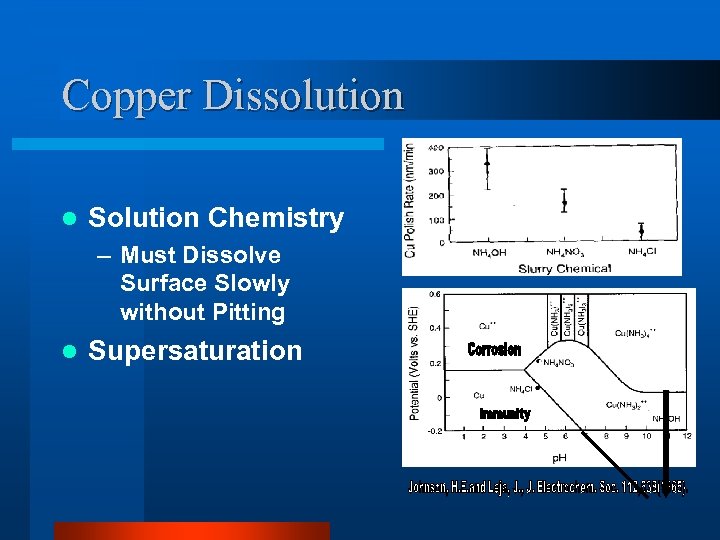

Copper Dissolution l Solution Chemistry – Must Dissolve Surface Slowly without Pitting l Supersaturation

Copper Dissolution l Solution Chemistry – Must Dissolve Surface Slowly without Pitting l Supersaturation

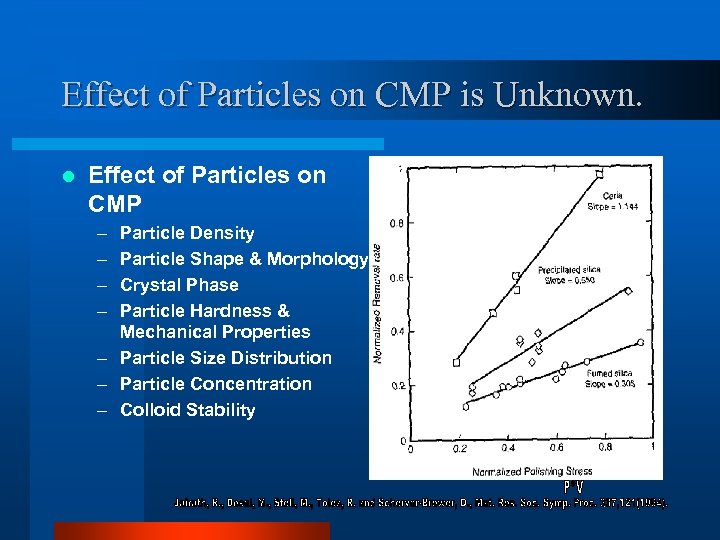

Effect of Particles on CMP is Unknown. l Effect of Particles on CMP – – Particle Density Particle Shape & Morphology Crystal Phase Particle Hardness & Mechanical Properties – Particle Size Distribution – Particle Concentration – Colloid Stability

Effect of Particles on CMP is Unknown. l Effect of Particles on CMP – – Particle Density Particle Shape & Morphology Crystal Phase Particle Hardness & Mechanical Properties – Particle Size Distribution – Particle Concentration – Colloid Stability

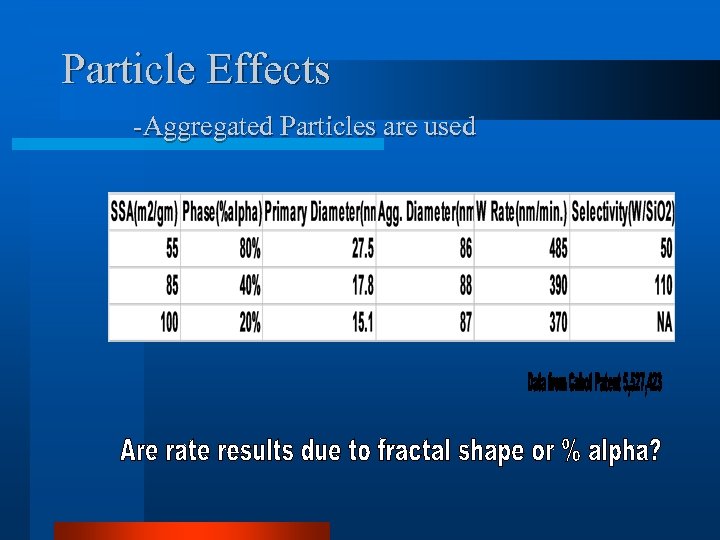

Particle Effects -Aggregated Particles are used

Particle Effects -Aggregated Particles are used

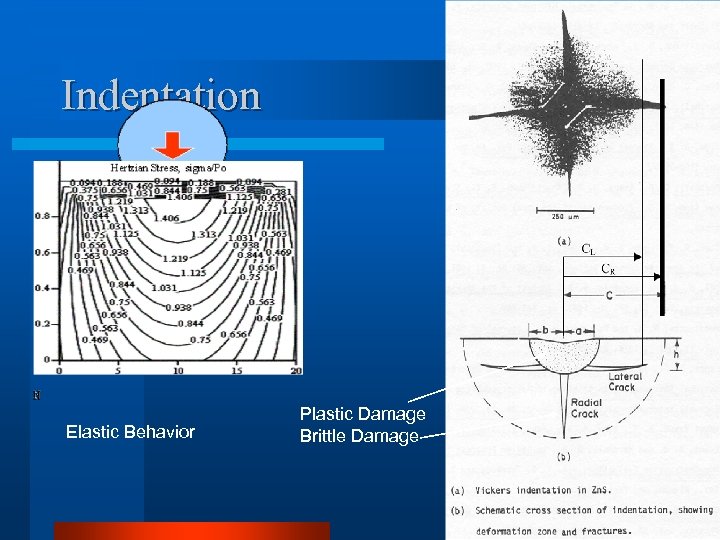

Indentation Elastic Behavior Plastic Damage Brittle Damage

Indentation Elastic Behavior Plastic Damage Brittle Damage

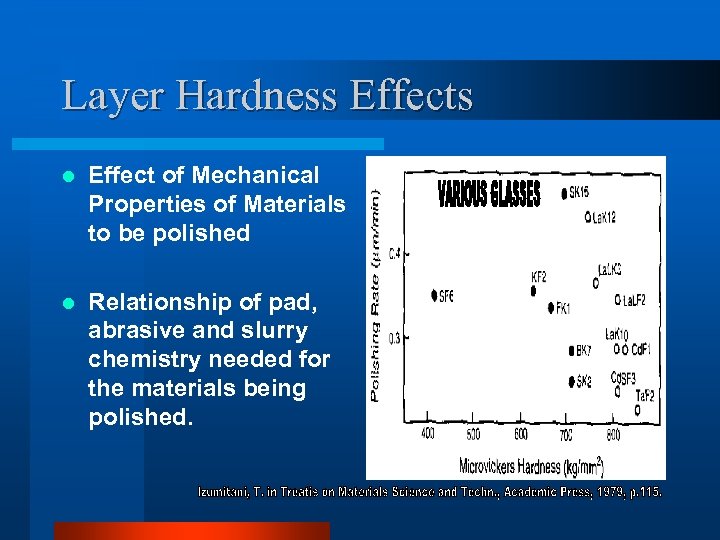

Layer Hardness Effects l Effect of Mechanical Properties of Materials to be polished l Relationship of pad, abrasive and slurry chemistry needed for the materials being polished.

Layer Hardness Effects l Effect of Mechanical Properties of Materials to be polished l Relationship of pad, abrasive and slurry chemistry needed for the materials being polished.

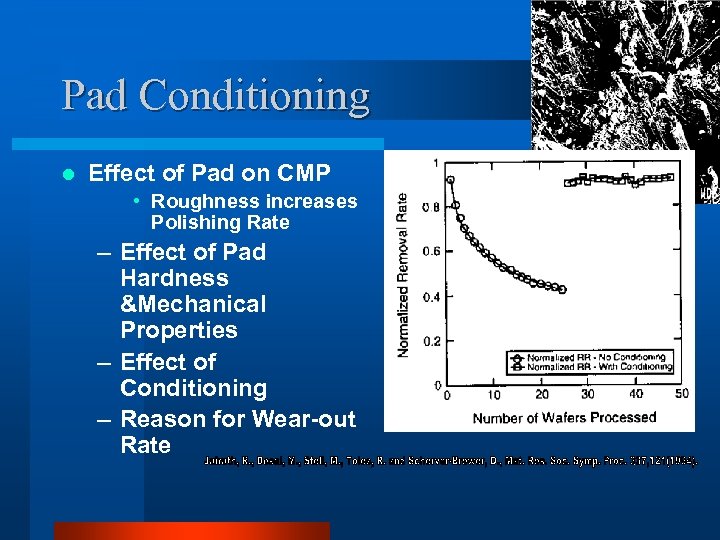

Pad Conditioning l Effect of Pad on CMP • Roughness increases Polishing Rate – Effect of Pad Hardness &Mechanical Properties – Effect of Conditioning – Reason for Wear-out Rate

Pad Conditioning l Effect of Pad on CMP • Roughness increases Polishing Rate – Effect of Pad Hardness &Mechanical Properties – Effect of Conditioning – Reason for Wear-out Rate

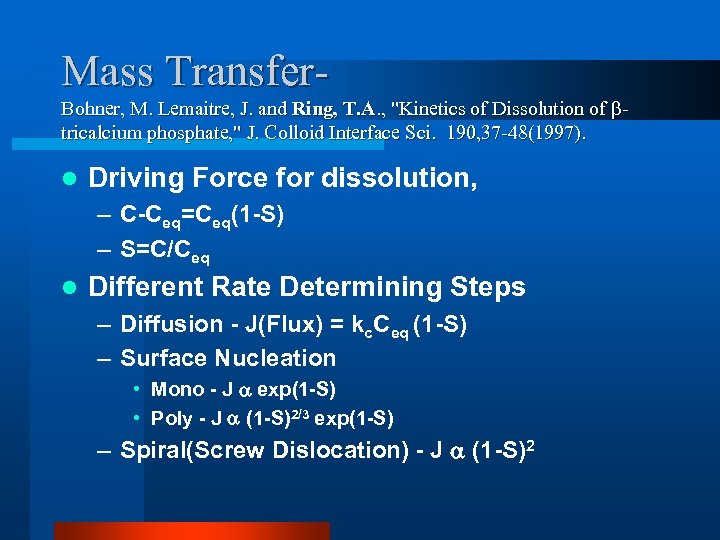

Mass Transfer- Bohner, M. Lemaitre, J. and Ring, T. A. , "Kinetics of Dissolution of tricalcium phosphate, " J. Colloid Interface Sci. 190, 37 -48(1997). l Driving Force for dissolution, – C-Ceq=Ceq(1 -S) – S=C/Ceq l Different Rate Determining Steps – Diffusion - J(Flux) = kc. Ceq (1 -S) – Surface Nucleation • Mono - J exp(1 -S) • Poly - J (1 -S)2/3 exp(1 -S) – Spiral(Screw Dislocation) - J (1 -S)2

Mass Transfer- Bohner, M. Lemaitre, J. and Ring, T. A. , "Kinetics of Dissolution of tricalcium phosphate, " J. Colloid Interface Sci. 190, 37 -48(1997). l Driving Force for dissolution, – C-Ceq=Ceq(1 -S) – S=C/Ceq l Different Rate Determining Steps – Diffusion - J(Flux) = kc. Ceq (1 -S) – Surface Nucleation • Mono - J exp(1 -S) • Poly - J (1 -S)2/3 exp(1 -S) – Spiral(Screw Dislocation) - J (1 -S)2

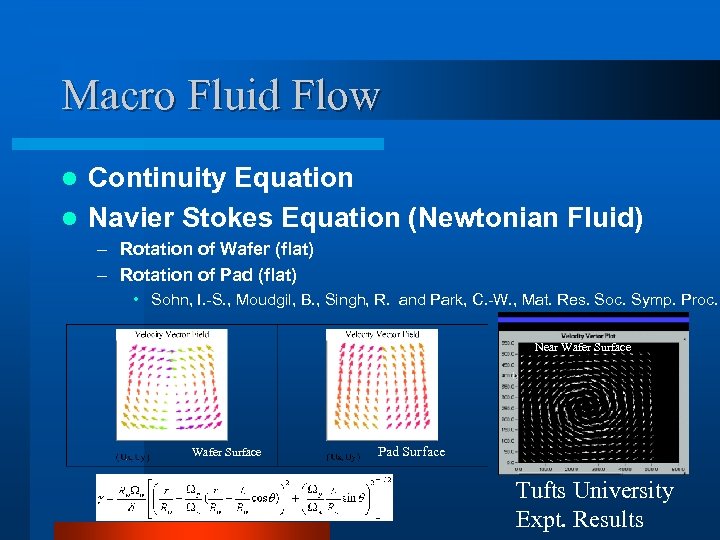

Macro Fluid Flow Continuity Equation l Navier Stokes Equation (Newtonian Fluid) l – Rotation of Wafer (flat) – Rotation of Pad (flat) • Sohn, I. -S. , Moudgil, B. , Singh, R. and Park, C. -W. , Mat. Res. Soc. Symp. Proc. Near Wafer Surface Pad Surface Tufts University Expt. Results

Macro Fluid Flow Continuity Equation l Navier Stokes Equation (Newtonian Fluid) l – Rotation of Wafer (flat) – Rotation of Pad (flat) • Sohn, I. -S. , Moudgil, B. , Singh, R. and Park, C. -W. , Mat. Res. Soc. Symp. Proc. Near Wafer Surface Pad Surface Tufts University Expt. Results

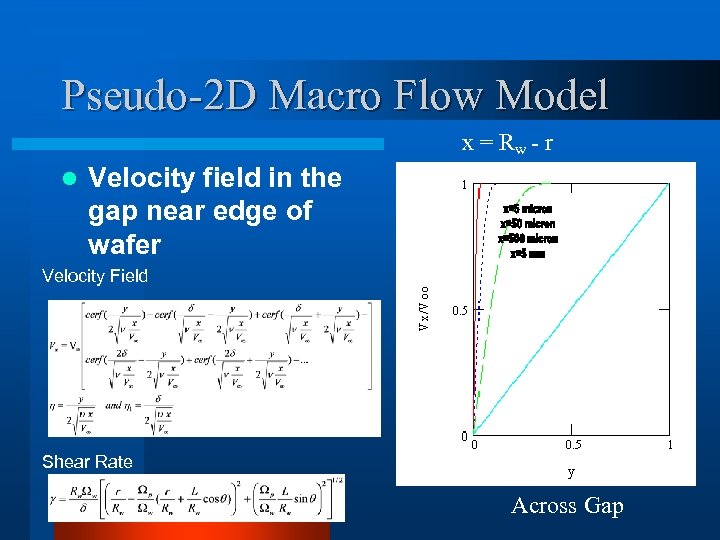

Pseudo-2 D Macro Flow Model x = Rw - r l Velocity field in the gap near edge of wafer Velocity Field Shear Rate Across Gap

Pseudo-2 D Macro Flow Model x = Rw - r l Velocity field in the gap near edge of wafer Velocity Field Shear Rate Across Gap

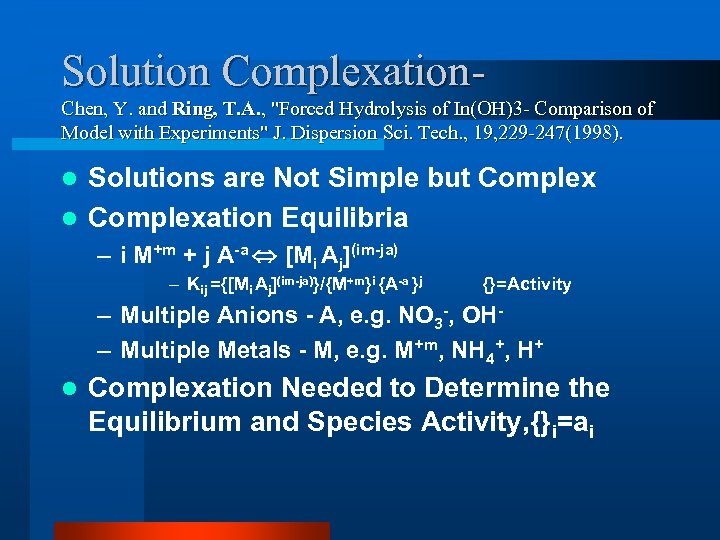

Solution Complexation. Chen, Y. and Ring, T. A. , "Forced Hydrolysis of In(OH)3 - Comparison of Model with Experiments" J. Dispersion Sci. Tech. , 19, 229 -247(1998). Solutions are Not Simple but Complex l Complexation Equilibria l – i M+m + j A-a [Mi Aj](im-ja) – Kij ={[Mi Aj](im-ja)}/{M+m}i {A-a }j {}=Activity – Multiple Anions - A, e. g. NO 3 -, OH– Multiple Metals - M, e. g. M+m, NH 4+, H+ l Complexation Needed to Determine the Equilibrium and Species Activity, {}i=ai

Solution Complexation. Chen, Y. and Ring, T. A. , "Forced Hydrolysis of In(OH)3 - Comparison of Model with Experiments" J. Dispersion Sci. Tech. , 19, 229 -247(1998). Solutions are Not Simple but Complex l Complexation Equilibria l – i M+m + j A-a [Mi Aj](im-ja) – Kij ={[Mi Aj](im-ja)}/{M+m}i {A-a }j {}=Activity – Multiple Anions - A, e. g. NO 3 -, OH– Multiple Metals - M, e. g. M+m, NH 4+, H+ l Complexation Needed to Determine the Equilibrium and Species Activity, {}i=ai

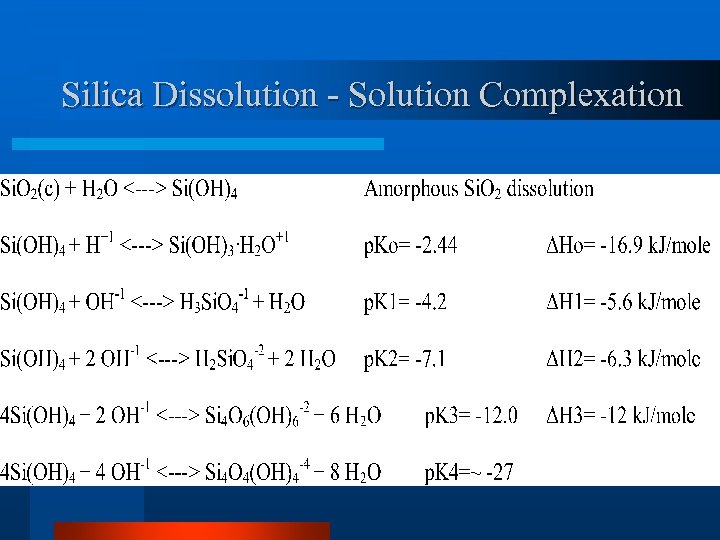

Silica Dissolution - Solution Complexation

Silica Dissolution - Solution Complexation

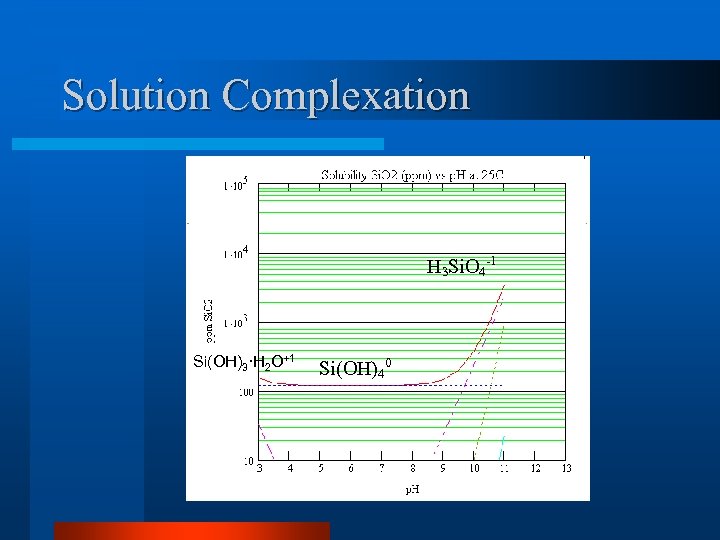

Solution Complexation H 3 Si. O 4 -1 Si(OH)3·H 2 O+1 Si(OH)40

Solution Complexation H 3 Si. O 4 -1 Si(OH)3·H 2 O+1 Si(OH)40

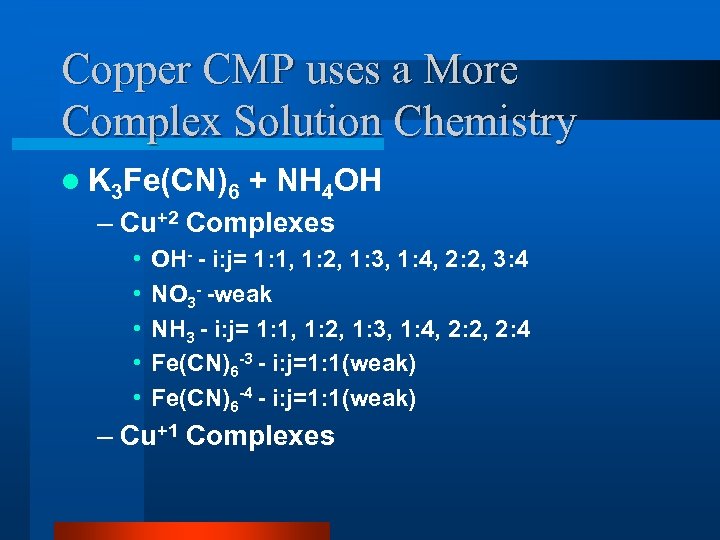

Copper CMP uses a More Complex Solution Chemistry l K 3 Fe(CN)6 + NH 4 OH – Cu+2 Complexes • • • OH- - i: j= 1: 1, 1: 2, 1: 3, 1: 4, 2: 2, 3: 4 NO 3 - -weak NH 3 - i: j= 1: 1, 1: 2, 1: 3, 1: 4, 2: 2, 2: 4 Fe(CN)6 -3 - i: j=1: 1(weak) Fe(CN)6 -4 - i: j=1: 1(weak) – Cu+1 Complexes

Copper CMP uses a More Complex Solution Chemistry l K 3 Fe(CN)6 + NH 4 OH – Cu+2 Complexes • • • OH- - i: j= 1: 1, 1: 2, 1: 3, 1: 4, 2: 2, 3: 4 NO 3 - -weak NH 3 - i: j= 1: 1, 1: 2, 1: 3, 1: 4, 2: 2, 2: 4 Fe(CN)6 -3 - i: j=1: 1(weak) Fe(CN)6 -4 - i: j=1: 1(weak) – Cu+1 Complexes

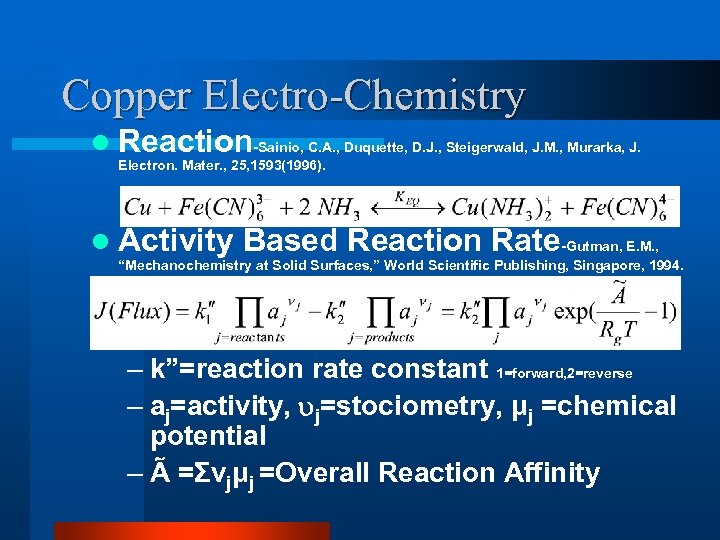

Copper Electro-Chemistry l Reaction-Sainio, C. A. , Duquette, D. J. , Steigerwald, J. M. , Murarka, J. Electron. Mater. , 25, 1593(1996). l Activity Based Reaction Rate-Gutman, E. M. , “Mechanochemistry at Solid Surfaces, ” World Scientific Publishing, Singapore, 1994. – k”=reaction rate constant 1=forward, 2=reverse – aj=activity, j=stociometry, μj =chemical potential – Ã =Σνjμj =Overall Reaction Affinity

Copper Electro-Chemistry l Reaction-Sainio, C. A. , Duquette, D. J. , Steigerwald, J. M. , Murarka, J. Electron. Mater. , 25, 1593(1996). l Activity Based Reaction Rate-Gutman, E. M. , “Mechanochemistry at Solid Surfaces, ” World Scientific Publishing, Singapore, 1994. – k”=reaction rate constant 1=forward, 2=reverse – aj=activity, j=stociometry, μj =chemical potential – Ã =Σνjμj =Overall Reaction Affinity

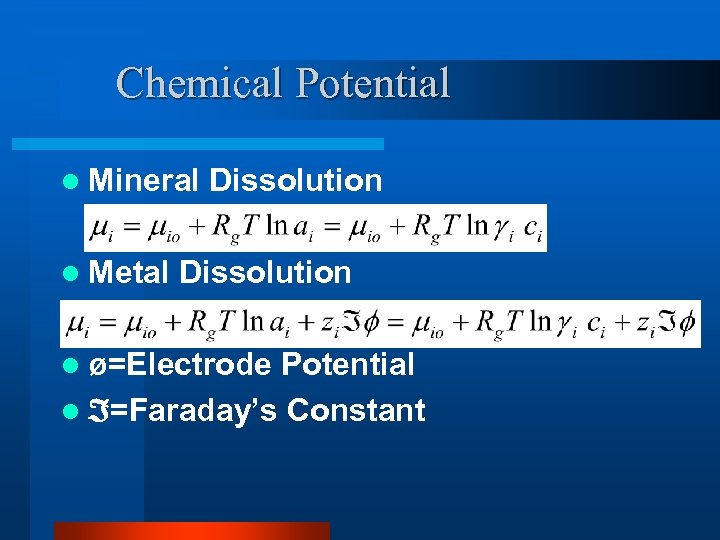

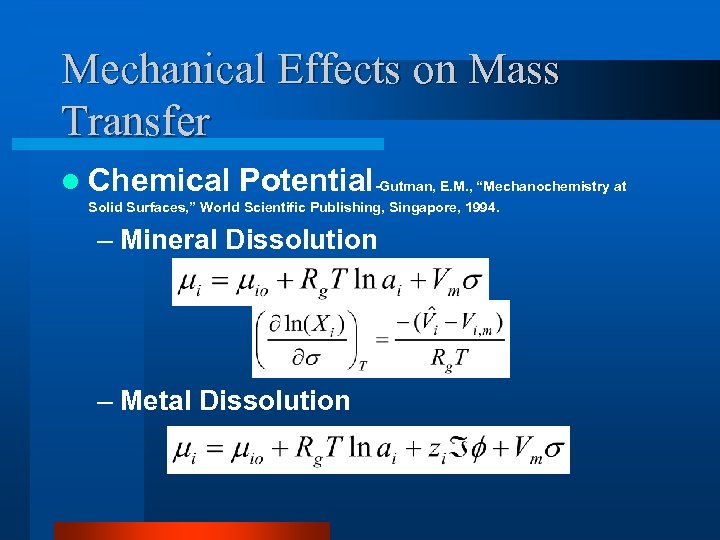

Chemical Potential l Mineral l Metal Dissolution l ø=Electrode Potential l =Faraday’s Constant

Chemical Potential l Mineral l Metal Dissolution l ø=Electrode Potential l =Faraday’s Constant

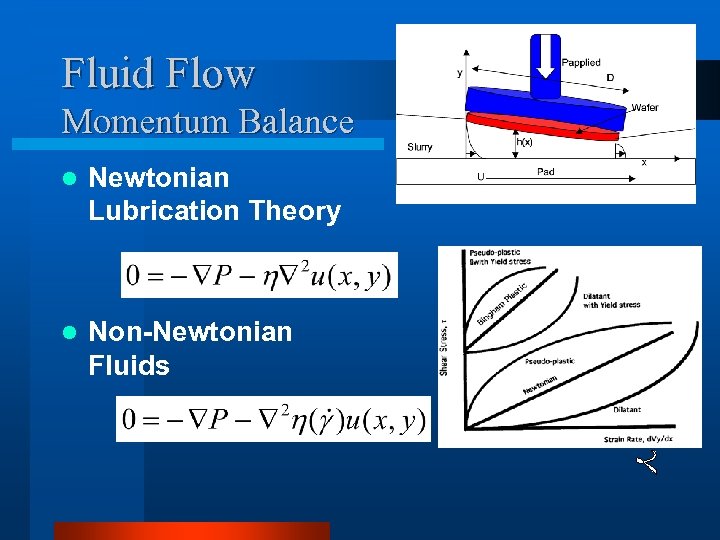

Fluid Flow Momentum Balance l Newtonian Lubrication Theory l Non-Newtonian Fluids

Fluid Flow Momentum Balance l Newtonian Lubrication Theory l Non-Newtonian Fluids

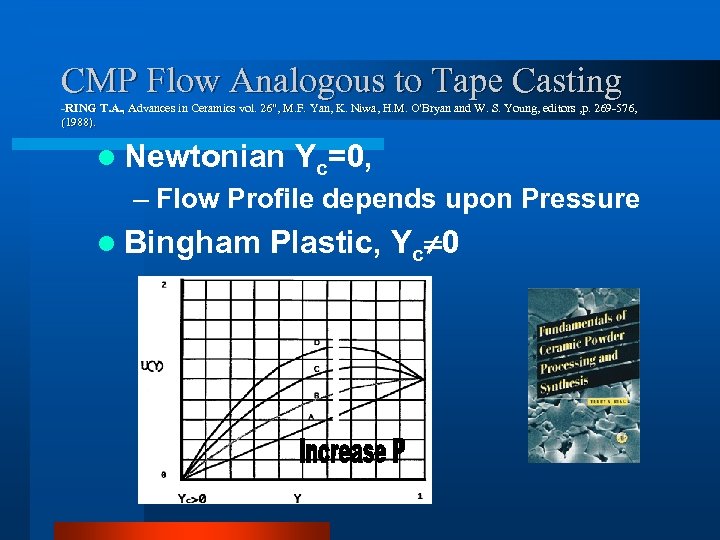

CMP Flow Analogous to Tape Casting -RING T. A. , Advances in Ceramics vol. 26", M. F. Yan, K. Niwa, H. M. O'Bryan and W. S. Young, editors , p. 269 -576, Yan, Niwa, (1988). l Newtonian Yc=0, – Flow Profile depends upon Pressure l Bingham Plastic, Yc 0

CMP Flow Analogous to Tape Casting -RING T. A. , Advances in Ceramics vol. 26", M. F. Yan, K. Niwa, H. M. O'Bryan and W. S. Young, editors , p. 269 -576, Yan, Niwa, (1988). l Newtonian Yc=0, – Flow Profile depends upon Pressure l Bingham Plastic, Yc 0

Wall Shear Rate, w l Product of – Viscosity at wall shear stress – Velocity Gradient at wall

Wall Shear Rate, w l Product of – Viscosity at wall shear stress – Velocity Gradient at wall

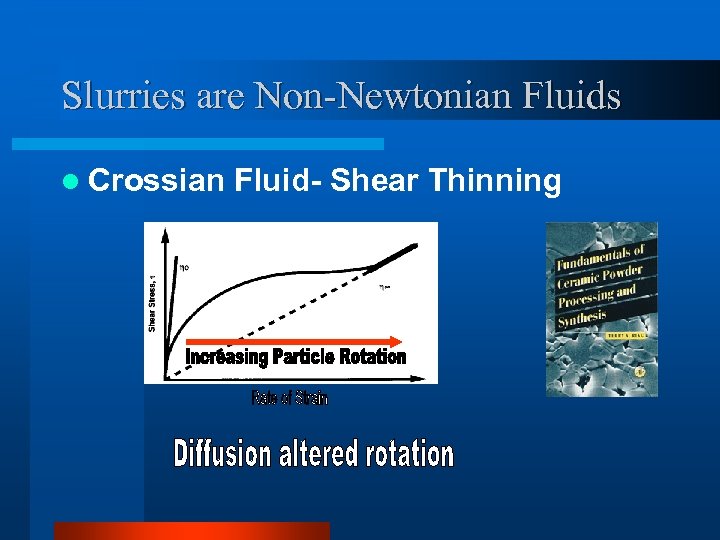

Slurries are Non-Newtonian Fluids l Crossian Fluid- Shear Thinning

Slurries are Non-Newtonian Fluids l Crossian Fluid- Shear Thinning

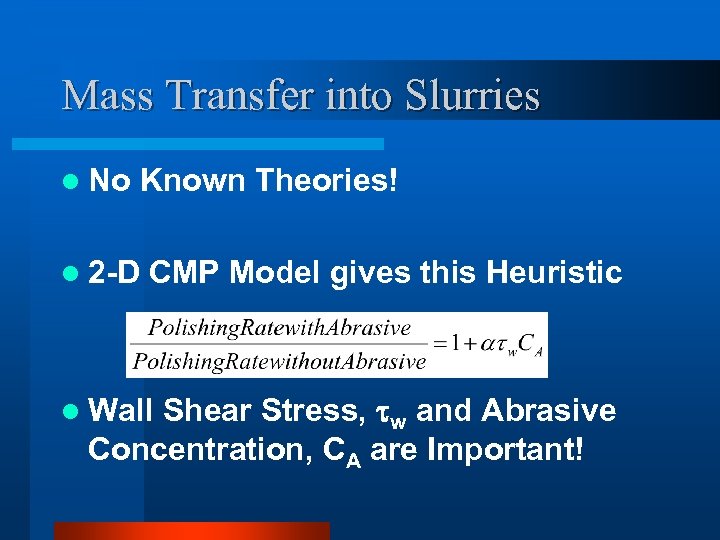

Mass Transfer into Slurries l No Known Theories! l 2 -D CMP Model gives this Heuristic Shear Stress, w and Abrasive Concentration, CA are Important! l Wall

Mass Transfer into Slurries l No Known Theories! l 2 -D CMP Model gives this Heuristic Shear Stress, w and Abrasive Concentration, CA are Important! l Wall

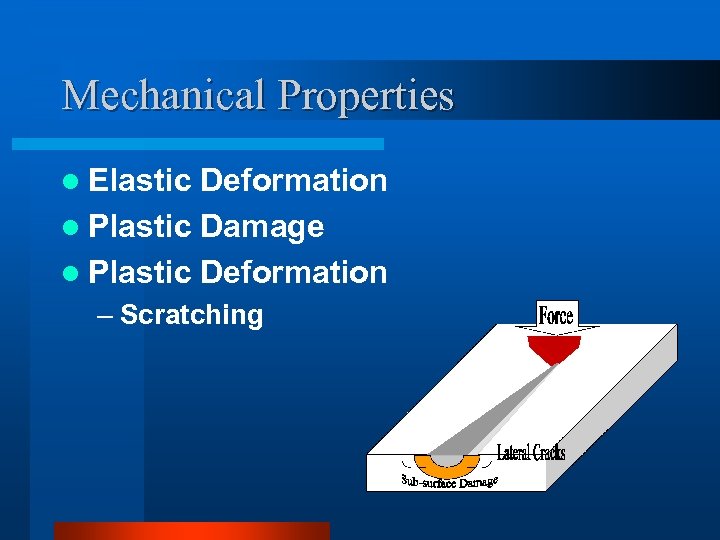

Mechanical Properties l Elastic Deformation l Plastic Damage l Plastic Deformation – Scratching

Mechanical Properties l Elastic Deformation l Plastic Damage l Plastic Deformation – Scratching

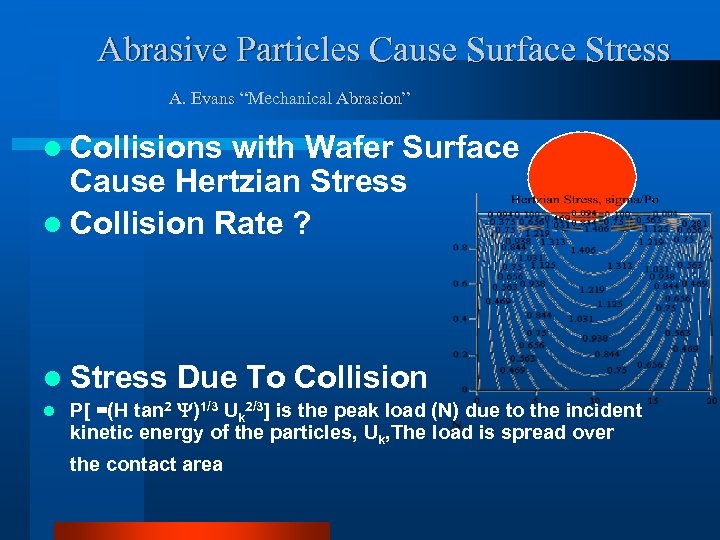

Abrasive Particles Cause Surface Stress A. Evans “Mechanical Abrasion” l Collisions with Wafer Surface Cause Hertzian Stress l Collision Rate ? l Stress l Due To Collision P[ =(H tan 2 )1/3 Uk 2/3] is the peak load (N) due to the incident kinetic energy of the particles, Uk, The load is spread over the contact area

Abrasive Particles Cause Surface Stress A. Evans “Mechanical Abrasion” l Collisions with Wafer Surface Cause Hertzian Stress l Collision Rate ? l Stress l Due To Collision P[ =(H tan 2 )1/3 Uk 2/3] is the peak load (N) due to the incident kinetic energy of the particles, Uk, The load is spread over the contact area

Mechanical Effects on Mass Transfer l Chemical Potential-Gutman, E. M. , “Mechanochemistry at Solid Surfaces, ” World Scientific Publishing, Singapore, 1994. – Mineral Dissolution – Metal Dissolution

Mechanical Effects on Mass Transfer l Chemical Potential-Gutman, E. M. , “Mechanochemistry at Solid Surfaces, ” World Scientific Publishing, Singapore, 1994. – Mineral Dissolution – Metal Dissolution

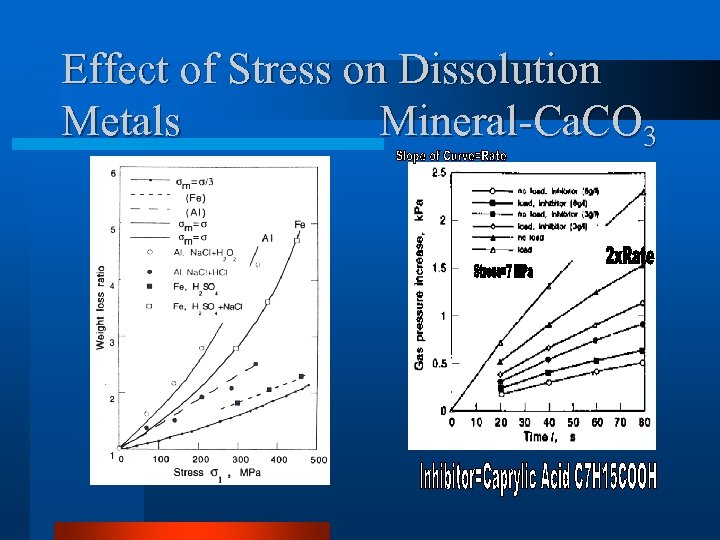

Effect of Stress on Dissolution Metals Mineral-Ca. CO 3

Effect of Stress on Dissolution Metals Mineral-Ca. CO 3

Mechano-Chemical Effect – Effect on Chemical Potential of solid – Effect of Activity of Solid l As a result, Dissolution Rate of Metal and Mineral are Enhanced by Stress.

Mechano-Chemical Effect – Effect on Chemical Potential of solid – Effect of Activity of Solid l As a result, Dissolution Rate of Metal and Mineral are Enhanced by Stress.

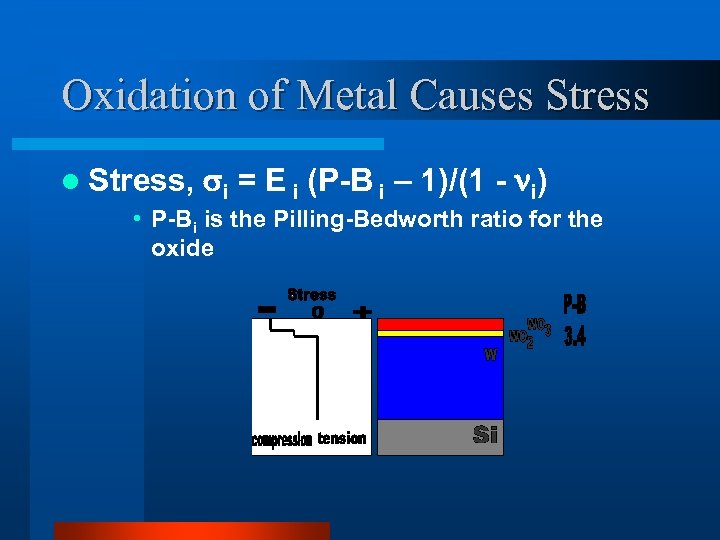

Oxidation of Metal Causes Stress l Stress, i = E i (P-B i – 1)/(1 - i) • P-Bi is the Pilling-Bedworth ratio for the oxide

Oxidation of Metal Causes Stress l Stress, i = E i (P-B i – 1)/(1 - i) • P-Bi is the Pilling-Bedworth ratio for the oxide

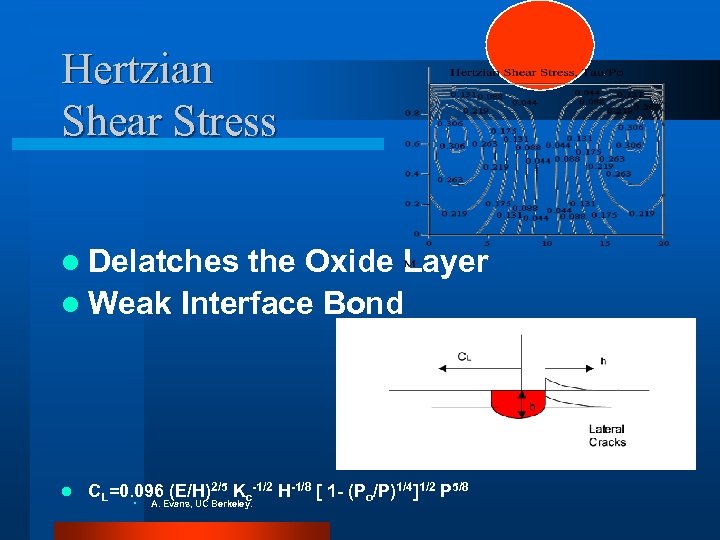

Hertzian Shear Stress l Delatches the Oxide Layer l Weak Interface Bond l CL=0. 096 (E/H)2/5 Kc-1/2 H-1/8 [ 1 - (Po/P)1/4]1/2 P 5/8 • A. Evans, UC Berkeley.

Hertzian Shear Stress l Delatches the Oxide Layer l Weak Interface Bond l CL=0. 096 (E/H)2/5 Kc-1/2 H-1/8 [ 1 - (Po/P)1/4]1/2 P 5/8 • A. Evans, UC Berkeley.

CMP Problems l Defectivity – WIWNU – Dishing and Erosion – Line Erosion – Scratching

CMP Problems l Defectivity – WIWNU – Dishing and Erosion – Line Erosion – Scratching

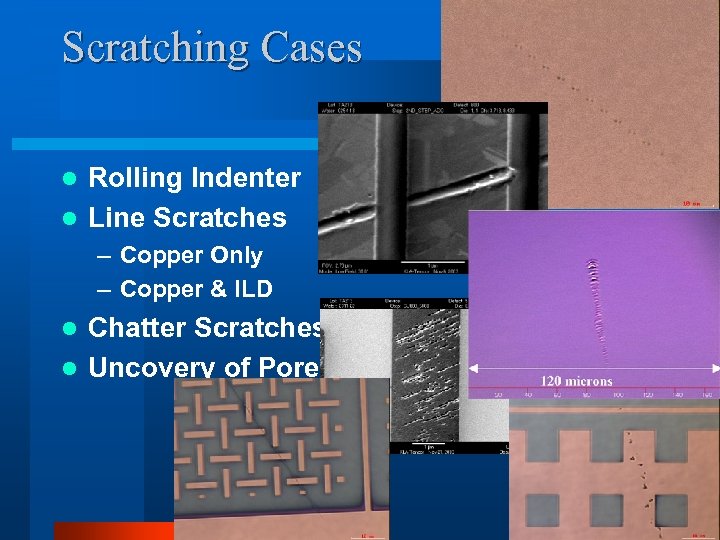

Scratching Cases Rolling Indenter l Line Scratches l – Copper Only – Copper & ILD Chatter Scratches l Uncovery of Pores l

Scratching Cases Rolling Indenter l Line Scratches l – Copper Only – Copper & ILD Chatter Scratches l Uncovery of Pores l