Lection_3.ppt

- Количество слайдов: 25

Lection 3 “Inventory Concept” 1. Definition of Inventory 2. Types of Inventory 3. Basic Inventory Management

Lection 3 “Inventory Concept” 1. Definition of Inventory 2. Types of Inventory 3. Basic Inventory Management

• 1. Definition of Inventory • Inventory is a list/record for goods and materials, held available in stock by a business • Is a large and costly investment. • Better management of corporate inventories can improve cash flow and return on investment

• 1. Definition of Inventory • Inventory is a list/record for goods and materials, held available in stock by a business • Is a large and costly investment. • Better management of corporate inventories can improve cash flow and return on investment

• c) Commodity rates – Apply when a large quantity of a product is shipped between two locations on a regular basis – These rate are published on a point-to-point basis without regard to product classification

• c) Commodity rates – Apply when a large quantity of a product is shipped between two locations on a regular basis – These rate are published on a point-to-point basis without regard to product classification

• Inventory serves 5 purposes – It enables the firm to achieve economies of scale – It balances supply and demand – It enables specialization in manufacturing – It provides protection from uncertainties in demand order cycle – It acts as a buffer between critical interfaces within the channel of distribution

• Inventory serves 5 purposes – It enables the firm to achieve economies of scale – It balances supply and demand – It enables specialization in manufacturing – It provides protection from uncertainties in demand order cycle – It acts as a buffer between critical interfaces within the channel of distribution

• 1. Economies of scale – Inventory is required to realized the economies of scale in purchasing, transportation or manufacturing – Example: ordering large quantities of raw materials/ finished goods inventory allows the manufacturer to take advantage of the per unit price reductions associated with the volume purchases. – Purchased materials have a lower transportation cost per unit if ordered in large volumes because less handling is required.

• 1. Economies of scale – Inventory is required to realized the economies of scale in purchasing, transportation or manufacturing – Example: ordering large quantities of raw materials/ finished goods inventory allows the manufacturer to take advantage of the per unit price reductions associated with the volume purchases. – Purchased materials have a lower transportation cost per unit if ordered in large volumes because less handling is required.

2. Balancing Supply and Demand for Seasonal Inventories – Seasonal supply or demand may make it necessary for a firm to hold inventory – Example: Boxed Chocolate sales increase during Mother’s Day – Demand for a product may be relatively stable throughout the year, but raw materials may be available only at certain times during the year (e. g. producer of canned fruits and vegetables) this makes necessary to manufacture finished products in excess of current demand hold in inventory

2. Balancing Supply and Demand for Seasonal Inventories – Seasonal supply or demand may make it necessary for a firm to hold inventory – Example: Boxed Chocolate sales increase during Mother’s Day – Demand for a product may be relatively stable throughout the year, but raw materials may be available only at certain times during the year (e. g. producer of canned fruits and vegetables) this makes necessary to manufacture finished products in excess of current demand hold in inventory

3. Specialization – Inventory makes it possible for each of a firm’s plants to specialize in the products that it manufactures – The finished product can be shipped to field warehouses where they are mixed to fill customer order – The specialization by facility is known as Focused Factories

3. Specialization – Inventory makes it possible for each of a firm’s plants to specialize in the products that it manufactures – The finished product can be shipped to field warehouses where they are mixed to fill customer order – The specialization by facility is known as Focused Factories

4. Protection from Uncertainties and Order Cycle – Inventory is held to prevent a stock-out in the case of variability in demand or variability in the replenishment cycle – example: price increase, supply shortage and to maintain a source of supply

4. Protection from Uncertainties and Order Cycle – Inventory is held to prevent a stock-out in the case of variability in demand or variability in the replenishment cycle – example: price increase, supply shortage and to maintain a source of supply

5. Inventory as a Buffer – Inventory is held throughout the supply chain to act as a buffer for the following critical interfaces: • • • Supplier – procurement (purchasing) Procurement – production Production – marketing Marketing – distribution Distribution – intermediary Intermediary – consumer/user

5. Inventory as a Buffer – Inventory is held throughout the supply chain to act as a buffer for the following critical interfaces: • • • Supplier – procurement (purchasing) Procurement – production Production – marketing Marketing – distribution Distribution – intermediary Intermediary – consumer/user

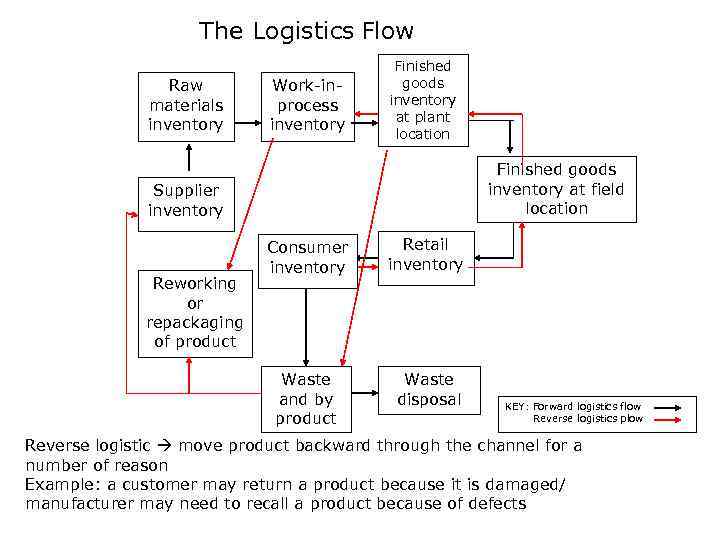

The Logistics Flow Raw materials inventory Work-inprocess inventory Finished goods inventory at plant location Finished goods inventory at field location Supplier inventory Retail inventory Waste and by product Reworking or repackaging of product Consumer inventory Waste disposal KEY: Forward logistics flow Reverse logistics plow Reverse logistic move product backward through the channel for a number of reason Example: a customer may return a product because it is damaged/ manufacturer may need to recall a product because of defects

The Logistics Flow Raw materials inventory Work-inprocess inventory Finished goods inventory at plant location Finished goods inventory at field location Supplier inventory Retail inventory Waste and by product Reworking or repackaging of product Consumer inventory Waste disposal KEY: Forward logistics flow Reverse logistics plow Reverse logistic move product backward through the channel for a number of reason Example: a customer may return a product because it is damaged/ manufacturer may need to recall a product because of defects

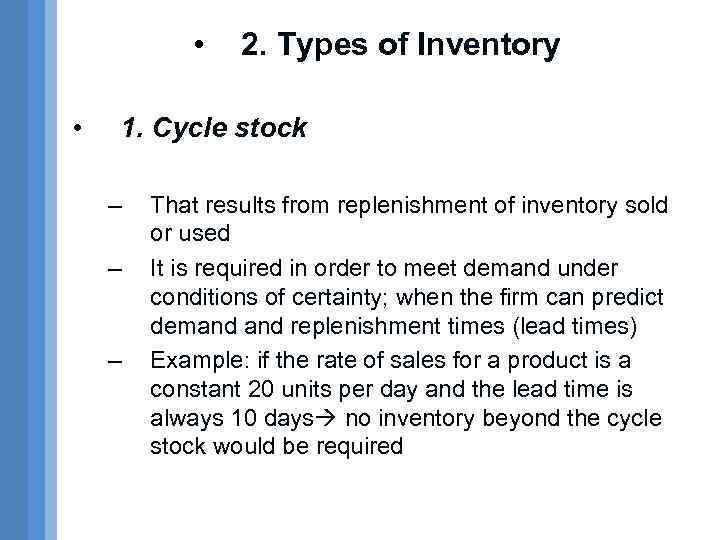

• • 2. Types of Inventory 1. Cycle stock – – – That results from replenishment of inventory sold or used It is required in order to meet demand under conditions of certainty; when the firm can predict demand replenishment times (lead times) Example: if the rate of sales for a product is a constant 20 units per day and the lead time is always 10 days no inventory beyond the cycle stock would be required

• • 2. Types of Inventory 1. Cycle stock – – – That results from replenishment of inventory sold or used It is required in order to meet demand under conditions of certainty; when the firm can predict demand replenishment times (lead times) Example: if the rate of sales for a product is a constant 20 units per day and the lead time is always 10 days no inventory beyond the cycle stock would be required

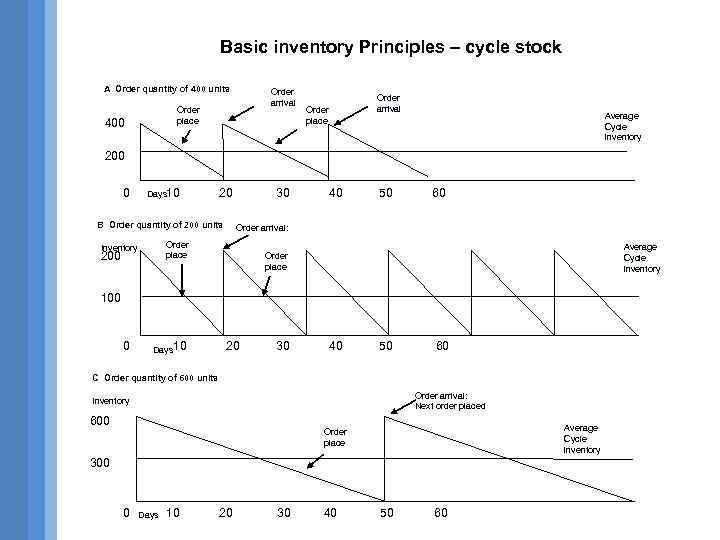

Basic inventory Principles – cycle stock A Order quantity of 400 units Inventory Order arrival Order place 400 Order arrival Order place Average Cycle inventory 200 0 Days 10 20 B Order quantity of 200 units 30 200 50 60 Order arrival: Order place Inventory 40 Average Cycle inventory Order place 100 0 Days 10 20 30 40 50 60 C Order quantity of 600 units Order arrival: Next order placed Inventory 600 Average Cycle inventory Order place 300 0 Days 10 20 30 40 50 60

Basic inventory Principles – cycle stock A Order quantity of 400 units Inventory Order arrival Order place 400 Order arrival Order place Average Cycle inventory 200 0 Days 10 20 B Order quantity of 200 units 30 200 50 60 Order arrival: Order place Inventory 40 Average Cycle inventory Order place 100 0 Days 10 20 30 40 50 60 C Order quantity of 600 units Order arrival: Next order placed Inventory 600 Average Cycle inventory Order place 300 0 Days 10 20 30 40 50 60

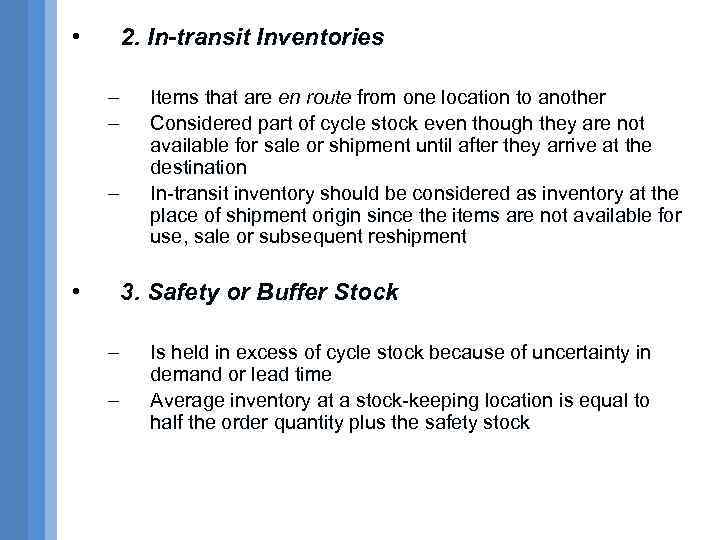

• 2. In-transit Inventories – – – • Items that are en route from one location to another Considered part of cycle stock even though they are not available for sale or shipment until after they arrive at the destination In-transit inventory should be considered as inventory at the place of shipment origin since the items are not available for use, sale or subsequent reshipment 3. Safety or Buffer Stock – – Is held in excess of cycle stock because of uncertainty in demand or lead time Average inventory at a stock-keeping location is equal to half the order quantity plus the safety stock

• 2. In-transit Inventories – – – • Items that are en route from one location to another Considered part of cycle stock even though they are not available for sale or shipment until after they arrive at the destination In-transit inventory should be considered as inventory at the place of shipment origin since the items are not available for use, sale or subsequent reshipment 3. Safety or Buffer Stock – – Is held in excess of cycle stock because of uncertainty in demand or lead time Average inventory at a stock-keeping location is equal to half the order quantity plus the safety stock

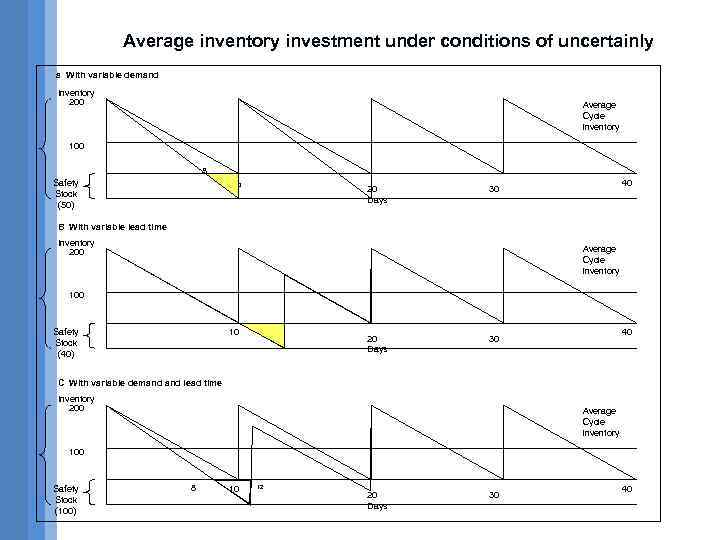

Average inventory investment under conditions of uncertainly a With variable demand Inventory 200 Average Cycle inventory 100 8 Safety Stock (50) 10 20 Days 40 30 B With variable lead time Inventory 200 Average Cycle inventory 100 Safety Stock (40) 12 10 20 Days 40 30 C With variable demand lead time Inventory 200 Average Cycle inventory 100 Safety Stock (100) 8 10 12 20 Days 30 40

Average inventory investment under conditions of uncertainly a With variable demand Inventory 200 Average Cycle inventory 100 8 Safety Stock (50) 10 20 Days 40 30 B With variable lead time Inventory 200 Average Cycle inventory 100 Safety Stock (40) 12 10 20 Days 40 30 C With variable demand lead time Inventory 200 Average Cycle inventory 100 Safety Stock (100) 8 10 12 20 Days 30 40

• 4. Speculative Stock – – • Is inventory held for reason other than satisfying current demand. Example: materials may be purchased in volumes larger than necessary in order to receive quantity discount, because of a forecasted price increase or materials shortage or to protect against the possibility of a strike. 5. Seasonal Stock – – Is a form of speculative stock that involves the accumulation of inventory before a seasonal periods begins Example: agricultural product, fashion industry and seasonal items

• 4. Speculative Stock – – • Is inventory held for reason other than satisfying current demand. Example: materials may be purchased in volumes larger than necessary in order to receive quantity discount, because of a forecasted price increase or materials shortage or to protect against the possibility of a strike. 5. Seasonal Stock – – Is a form of speculative stock that involves the accumulation of inventory before a seasonal periods begins Example: agricultural product, fashion industry and seasonal items

• 6. Dead Stock – Refers to items for which no demand has been registered for some specified period of time – Might be obsolete throughout a company or only at one stock-keeping location

• 6. Dead Stock – Refers to items for which no demand has been registered for some specified period of time – Might be obsolete throughout a company or only at one stock-keeping location

• 3. Basic Inventory Management • Measures of Inventory Management Effectiveness – The key measure of effective inventory management is the impact that inventory has on corporate profitability – Effective inventory management can improve profitability by lowering costs or supporting increased sale – Better inventory management can increase the ability to control and predict how inventory investment will change in response to management policy

• 3. Basic Inventory Management • Measures of Inventory Management Effectiveness – The key measure of effective inventory management is the impact that inventory has on corporate profitability – Effective inventory management can improve profitability by lowering costs or supporting increased sale – Better inventory management can increase the ability to control and predict how inventory investment will change in response to management policy

Inventory Turnover – Measured as: • • Annual dollar sales volume Average dollar inventory investment – A higher number is preferred, indicating that inventory moves through the firm’s operation quickly, rather than being held for an extensive period – Example: annual sales = 500, 000 valued at cost and an average inventory investment of 100, 000 would have a turnover of five times.

Inventory Turnover – Measured as: • • Annual dollar sales volume Average dollar inventory investment – A higher number is preferred, indicating that inventory moves through the firm’s operation quickly, rather than being held for an extensive period – Example: annual sales = 500, 000 valued at cost and an average inventory investment of 100, 000 would have a turnover of five times.

Fill Rate – A logistics measure of inventory effectiveness at meeting demands – Is a common measure of the customer service performance of inventory – Low inventory level can reduce fill rates, hurting customer service and creating loss sales – Increased sales are often possible if high levels of inventory lead to better-in-stock availability and more consistent service level – Example: Fill rate = 96% 4% of requested unit were unavailable when ordered by the customer

Fill Rate – A logistics measure of inventory effectiveness at meeting demands – Is a common measure of the customer service performance of inventory – Low inventory level can reduce fill rates, hurting customer service and creating loss sales – Increased sales are often possible if high levels of inventory lead to better-in-stock availability and more consistent service level – Example: Fill rate = 96% 4% of requested unit were unavailable when ordered by the customer

Impact of Demand Patterns on Inventory Management • Pull versus Push Systems – Pull System If a company waits to produce until customer demand it (customer demand ‘pull’ the inventory) – Push System if a firm produces to forecast or anticipated sales to customers (the firm is pushing its inventory into the market in anticipation of sales)

Impact of Demand Patterns on Inventory Management • Pull versus Push Systems – Pull System If a company waits to produce until customer demand it (customer demand ‘pull’ the inventory) – Push System if a firm produces to forecast or anticipated sales to customers (the firm is pushing its inventory into the market in anticipation of sales)

Inventory Management Under Conditions of Certainty • The components of ordering costs • Replenishment policy under condition of certainty requires the balancing of ordering costs against inventory carrying costs • Example: a policy of ordering large quantities infrequently may result in inventory carrying costs in excess of the savings in ordering costs

Inventory Management Under Conditions of Certainty • The components of ordering costs • Replenishment policy under condition of certainty requires the balancing of ordering costs against inventory carrying costs • Example: a policy of ordering large quantities infrequently may result in inventory carrying costs in excess of the savings in ordering costs

• Ordering costs for products purchased from an outside supplier include; – – • The cost of transmitting the order The cost of receiving the product The cost of placing it in storage The cost of processing the invoice for payment In restocking its own field warehouses, ordering costs include; – The cost of transmitting and processing the inventory transfer – The cost of handling cost – The cost of receiving the product – The cost of documentation

• Ordering costs for products purchased from an outside supplier include; – – • The cost of transmitting the order The cost of receiving the product The cost of placing it in storage The cost of processing the invoice for payment In restocking its own field warehouses, ordering costs include; – The cost of transmitting and processing the inventory transfer – The cost of handling cost – The cost of receiving the product – The cost of documentation

• Economic Order Quantity • The best policy by minimizing the total of inventory carrying costs and ordering costs • The EOQ is a concept which determines the optimal order quantity on the basis of ordering and carrying costs • When incremental ordering costs equal incremental carrying costs, the most economic order quantity exists

• Economic Order Quantity • The best policy by minimizing the total of inventory carrying costs and ordering costs • The EOQ is a concept which determines the optimal order quantity on the basis of ordering and carrying costs • When incremental ordering costs equal incremental carrying costs, the most economic order quantity exists

• Two questions seem appropriate in reference to the example of the previous diagram • Should we place order for 200, 400, or 600 units, or some other quality? • What is the impact on inventory if orders are place at 10, 20, or 30 -day intervals, or some other time period? Assuming constant demand lead time, sale of 20 units per day, and 240 working days per year, annual sales will be 4, 800 units. If orders are place every 10 days, 24 orders off 200 units will be placed. With a 20 -day order interval, 12 orders of 400 units are required. If the average inventory is 100, 200, and 300 units, respectively. Which of these policies would be best?

• Two questions seem appropriate in reference to the example of the previous diagram • Should we place order for 200, 400, or 600 units, or some other quality? • What is the impact on inventory if orders are place at 10, 20, or 30 -day intervals, or some other time period? Assuming constant demand lead time, sale of 20 units per day, and 240 working days per year, annual sales will be 4, 800 units. If orders are place every 10 days, 24 orders off 200 units will be placed. With a 20 -day order interval, 12 orders of 400 units are required. If the average inventory is 100, 200, and 300 units, respectively. Which of these policies would be best?

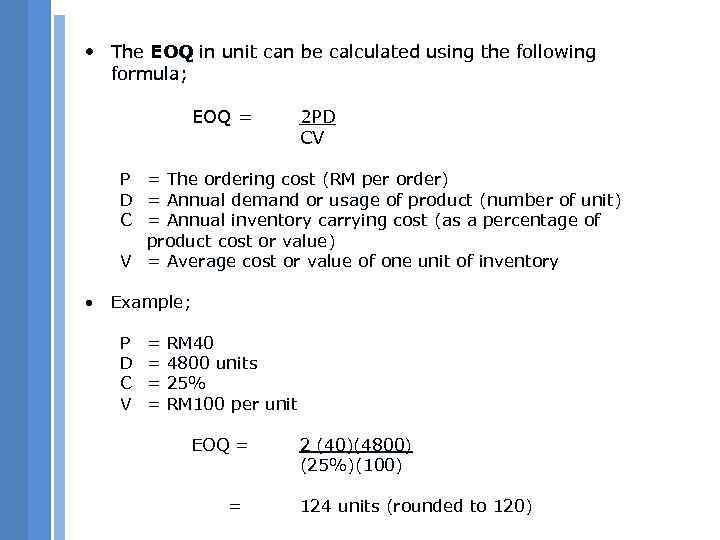

• The EOQ in unit can be calculated using the following formula; EOQ = 2 PD CV P = The ordering cost (RM per order) D = Annual demand or usage of product (number of unit) C = Annual inventory carrying cost (as a percentage of product cost or value) V = Average cost or value of one unit of inventory • Example; P D C V = = RM 40 4800 units 25% RM 100 per unit EOQ = = 2 (40)(4800) (25%)(100) 124 units (rounded to 120)

• The EOQ in unit can be calculated using the following formula; EOQ = 2 PD CV P = The ordering cost (RM per order) D = Annual demand or usage of product (number of unit) C = Annual inventory carrying cost (as a percentage of product cost or value) V = Average cost or value of one unit of inventory • Example; P D C V = = RM 40 4800 units 25% RM 100 per unit EOQ = = 2 (40)(4800) (25%)(100) 124 units (rounded to 120)