b71d2a78d767c49e677bd69c6d058b7d.ppt

- Количество слайдов: 22

Lear Supplier Development 5 S and Visual Management Implementation

Lear Supplier Development 5 S and Visual Management Implementation

Introduction • Lear Supplier Development – Develop a relationship for flawless launch – My experience with 5 S • Sourced Program Suppliers – New to Lear – 5 S implementation at your facility – Familiarity with 5 S 2

Introduction • Lear Supplier Development – Develop a relationship for flawless launch – My experience with 5 S • Sourced Program Suppliers – New to Lear – 5 S implementation at your facility – Familiarity with 5 S 2

Why is 5 S important to Lear? • Commitment within Lear’s own plants • Role out to supplier base • Another efficiency “tool” in the tool box – Open the lead to eliminating additional waste – Relatively easy to implement • Limited Lear resources • Commitment to developing “World Class” Suppliers 3

Why is 5 S important to Lear? • Commitment within Lear’s own plants • Role out to supplier base • Another efficiency “tool” in the tool box – Open the lead to eliminating additional waste – Relatively easy to implement • Limited Lear resources • Commitment to developing “World Class” Suppliers 3

Overview of the 5 S System • Abbreviated Japanese words – – – Seiri Seiton Seison Seiketsu Shituke • Philosophy or system that focuses on – Effectively organizing the work place – Standardizing work procedures – Eliminating waste 4

Overview of the 5 S System • Abbreviated Japanese words – – – Seiri Seiton Seison Seiketsu Shituke • Philosophy or system that focuses on – Effectively organizing the work place – Standardizing work procedures – Eliminating waste 4

Poor Workplace Organization Means Waste • Unneeded inventory incurs extra inventoryrelated expenses • Extra manpower is needed to manage the growing inventory • Greater amounts of stocked items become obsolete due to design changes, limited shelf life, etc. 5

Poor Workplace Organization Means Waste • Unneeded inventory incurs extra inventoryrelated expenses • Extra manpower is needed to manage the growing inventory • Greater amounts of stocked items become obsolete due to design changes, limited shelf life, etc. 5

Poor Workplace Organization Means Waste • Quality defects result from unneeded inprocess inventory and machine breakdowns • Unneeded equipment poses a daily obstacle to production activities • The presence of unneeded items makes designing factory/office layouts more difficult 6

Poor Workplace Organization Means Waste • Quality defects result from unneeded inprocess inventory and machine breakdowns • Unneeded equipment poses a daily obstacle to production activities • The presence of unneeded items makes designing factory/office layouts more difficult 6

Major Benefits of 5 S • Tangible measurables – – – Case study examples Reduces downtime Improves efficiency and productivity Improves delivery times and assists in reducing costs Improves safety / Reduces accidents 7

Major Benefits of 5 S • Tangible measurables – – – Case study examples Reduces downtime Improves efficiency and productivity Improves delivery times and assists in reducing costs Improves safety / Reduces accidents 7

Major Benefits of 5 S • Intangible measurables – Enhances operational control of processes – Improves product quality – Creates a positive work environment – First impressions • Customers • Employees “You never get a second chance to create a first impression. ” 8

Major Benefits of 5 S • Intangible measurables – Enhances operational control of processes – Improves product quality – Creates a positive work environment – First impressions • Customers • Employees “You never get a second chance to create a first impression. ” 8

First Impression: Plant Main Aisle 9

First Impression: Plant Main Aisle 9

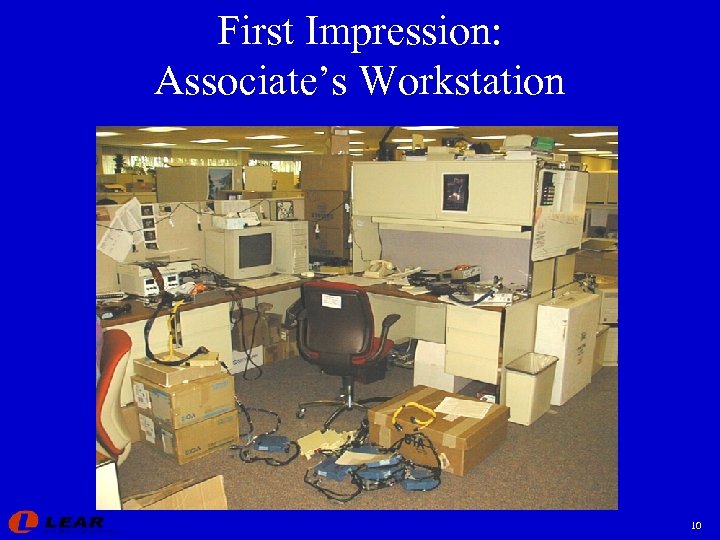

First Impression: Associate’s Workstation 10

First Impression: Associate’s Workstation 10

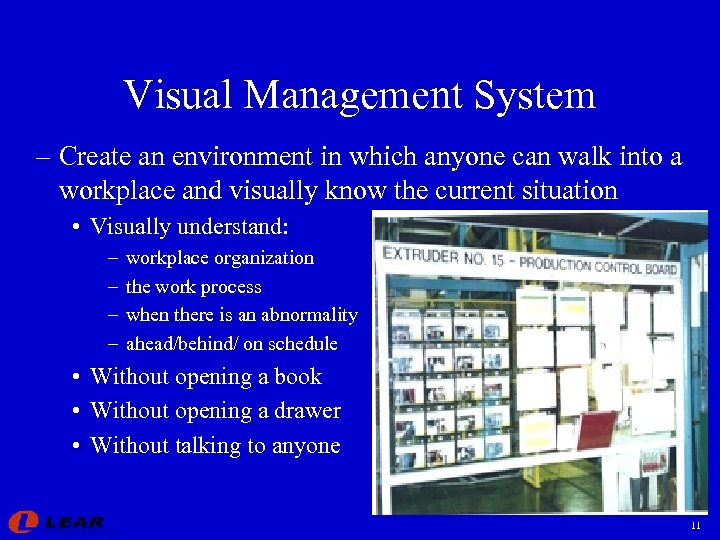

Visual Management System – Create an environment in which anyone can walk into a workplace and visually know the current situation • Visually understand: – – workplace organization the work process when there is an abnormality ahead/behind/ on schedule • Without opening a book • Without opening a drawer • Without talking to anyone 11

Visual Management System – Create an environment in which anyone can walk into a workplace and visually know the current situation • Visually understand: – – workplace organization the work process when there is an abnormality ahead/behind/ on schedule • Without opening a book • Without opening a drawer • Without talking to anyone 11

Visual Management: Major Benefits • Controls inventory levels • Controls lot sizes • Reduces space by better organization / utilization • Reduces energy (manual or mechanical) • Promotes quality 13

Visual Management: Major Benefits • Controls inventory levels • Controls lot sizes • Reduces space by better organization / utilization • Reduces energy (manual or mechanical) • Promotes quality 13

5 S Workplace Organization The Foundation of the Visual Workplace • Sort - Eliminate what is not needed • Straighten - A place for everything and everything in its place • Shine - Cleaning and looking for ways to keep it clean • Standardize - Maintain and monitor the first 3 S’s • Sustain- Stick to the rules 14

5 S Workplace Organization The Foundation of the Visual Workplace • Sort - Eliminate what is not needed • Straighten - A place for everything and everything in its place • Shine - Cleaning and looking for ways to keep it clean • Standardize - Maintain and monitor the first 3 S’s • Sustain- Stick to the rules 14

DIVIDE ITEMS INTO TWO CATEGORIES: RED TAG STRATEGY RED TAG Category 1. Raw material 2. In-process stock 3. Semi-finished goods 4. Finished goods 5. Equipment 6. Dies and jigs 7. Tools and supplies 8. Measuring devices 9. Documents 10. Other Item name and number Quantity Reason Disposal by: Disposal method: Posting date: Units $ Value 1. Not needed 6. Other 2. Defective 3. Not needed soon 4. Scrap material 5. Use unknown Department/Business Unit/Product Center 1. Discard 2. Return 3. Move to red-tag storage site 4. Move to separate storage site 5. Other Disposal date: Disposal complete (signature ) ATTACH TO ALL UNNECESSARY ITEMS SORT CATEGORIZE NECESSARY ITEMS: * RARELY USED * OCCASIONALLY USED * FREQUENTLY USED NECESSARY UNNECESSARY DISCARD UNNECESSARY ITEMS

DIVIDE ITEMS INTO TWO CATEGORIES: RED TAG STRATEGY RED TAG Category 1. Raw material 2. In-process stock 3. Semi-finished goods 4. Finished goods 5. Equipment 6. Dies and jigs 7. Tools and supplies 8. Measuring devices 9. Documents 10. Other Item name and number Quantity Reason Disposal by: Disposal method: Posting date: Units $ Value 1. Not needed 6. Other 2. Defective 3. Not needed soon 4. Scrap material 5. Use unknown Department/Business Unit/Product Center 1. Discard 2. Return 3. Move to red-tag storage site 4. Move to separate storage site 5. Other Disposal date: Disposal complete (signature ) ATTACH TO ALL UNNECESSARY ITEMS SORT CATEGORIZE NECESSARY ITEMS: * RARELY USED * OCCASIONALLY USED * FREQUENTLY USED NECESSARY UNNECESSARY DISCARD UNNECESSARY ITEMS

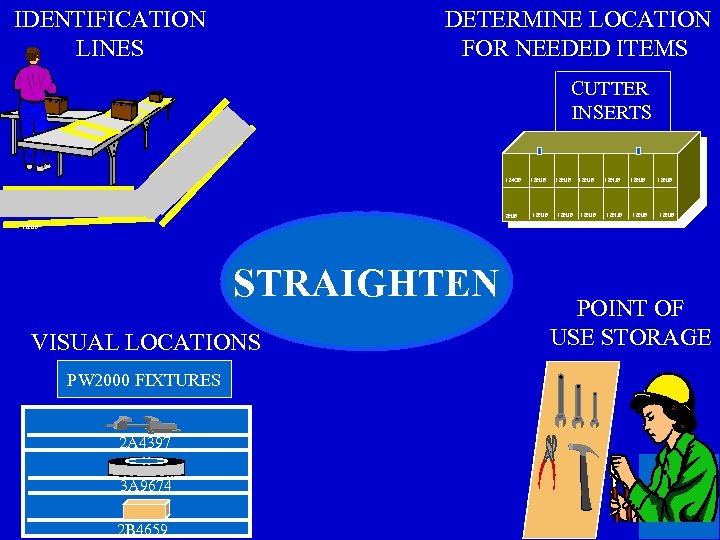

IDENTIFICATION LINES DETERMINE LOCATION FOR NEEDED ITEMS CUTTER INSERTS 124 GF 2 HJF 12 HJF 12 HJF 12 HJF 12 HJF STRAIGHTEN VISUAL LOCATIONS PW 2000 FIXTURES 2 A 4397 3 A 9674 2 B 4659 POINT OF USE STORAGE

IDENTIFICATION LINES DETERMINE LOCATION FOR NEEDED ITEMS CUTTER INSERTS 124 GF 2 HJF 12 HJF 12 HJF 12 HJF 12 HJF STRAIGHTEN VISUAL LOCATIONS PW 2000 FIXTURES 2 A 4397 3 A 9674 2 B 4659 POINT OF USE STORAGE

BUILD PRIDE IN WORK AREAS SHINE ELIMINATE DIRT SWEEP BUILD VALUE IN EQUIPMENT CLEANING AS A FORM OF INSPECTION CLEAN 17

BUILD PRIDE IN WORK AREAS SHINE ELIMINATE DIRT SWEEP BUILD VALUE IN EQUIPMENT CLEANING AS A FORM OF INSPECTION CLEAN 17

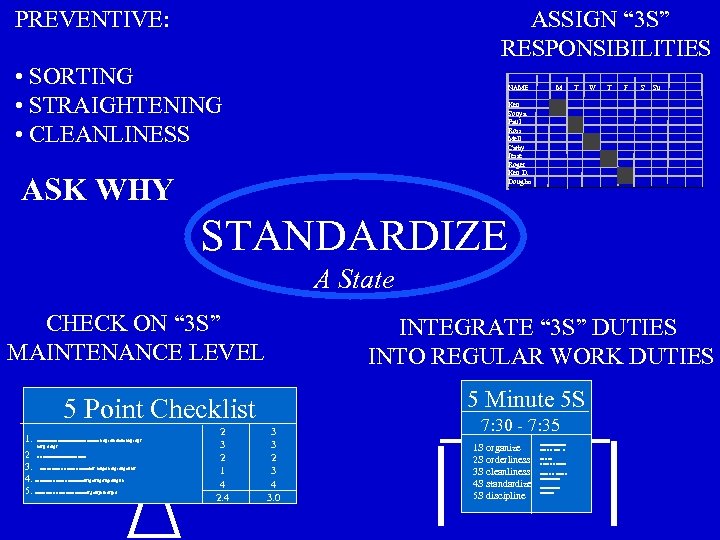

PREVENTIVE: ASSIGN “ 3 S” RESPONSIBILITIES • SORTING • STRAIGHTENING • CLEANLINESS NAME M T W T F S Su Ken Sonya Paul Ross Mell Cathy Jesse Roger Ken D. Douglas ASK WHY STANDARDIZE A State CHECK ON “ 3 S” MAINTENANCE LEVEL INTEGRATE “ 3 S” DUTIES INTO REGULAR WORK DUTIES 5 Minute 5 S 5 Point Checklist 1. xxxxxxxxxxxxxxcx lsdfj sdlk dkdie ldslj sdlj f lsdflj sldkj f 2 3. 4. 5. x x xxxxxxxxx xxxx x xxxxxlsdf lsdkjei lsdkj sdl ldf xx xxxxxxxsdlfkj sdflkj sflkjsdflkj flk xxxxx x x xxxxxsdf, j sdlfjk flsdf ljsd 2 3 2 1 4 2. 4 3 3 2 3 4 3. 0 7: 30 - 7: 35 1 S organize 2 S orderliness 3 S cleanliness 4 S standardize 5 S discipline xxxxxxx xxx x xxx x x xxxxxxxxxxx

PREVENTIVE: ASSIGN “ 3 S” RESPONSIBILITIES • SORTING • STRAIGHTENING • CLEANLINESS NAME M T W T F S Su Ken Sonya Paul Ross Mell Cathy Jesse Roger Ken D. Douglas ASK WHY STANDARDIZE A State CHECK ON “ 3 S” MAINTENANCE LEVEL INTEGRATE “ 3 S” DUTIES INTO REGULAR WORK DUTIES 5 Minute 5 S 5 Point Checklist 1. xxxxxxxxxxxxxxcx lsdfj sdlk dkdie ldslj sdlj f lsdflj sldkj f 2 3. 4. 5. x x xxxxxxxxx xxxx x xxxxxlsdf lsdkjei lsdkj sdl ldf xx xxxxxxxsdlfkj sdflkj sflkjsdflkj flk xxxxx x x xxxxxsdf, j sdlfjk flsdf ljsd 2 3 2 1 4 2. 4 3 3 2 3 4 3. 0 7: 30 - 7: 35 1 S organize 2 S orderliness 3 S cleanliness 4 S standardize 5 S discipline xxxxxxx xxx x xxx x x xxxxxxxxxxx

MANAGERS COMMITTED TO 5 S PROPER TRAINING 5 S asdfsdfs sdf dsfsdfsdfsfdsdfsdf SUSTAIN CORRECT PROCEDURES BECOME A HABIT “BUY-IN” FROM ALL WORKERS 19

MANAGERS COMMITTED TO 5 S PROPER TRAINING 5 S asdfsdfs sdf dsfsdfsdfsfdsdfsdf SUSTAIN CORRECT PROCEDURES BECOME A HABIT “BUY-IN” FROM ALL WORKERS 19

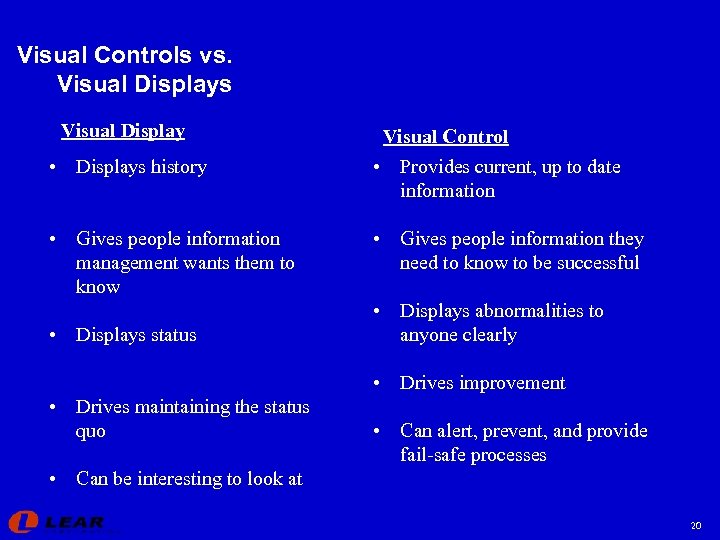

Visual Controls vs. Visual Displays Visual Display Visual Control • Displays history • Provides current, up to date information • Gives people information management wants them to know • Gives people information they need to know to be successful • Displays status • Displays abnormalities to anyone clearly • Drives improvement • Drives maintaining the status quo • Can alert, prevent, and provide fail-safe processes • Can be interesting to look at 20

Visual Controls vs. Visual Displays Visual Display Visual Control • Displays history • Provides current, up to date information • Gives people information management wants them to know • Gives people information they need to know to be successful • Displays status • Displays abnormalities to anyone clearly • Drives improvement • Drives maintaining the status quo • Can alert, prevent, and provide fail-safe processes • Can be interesting to look at 20

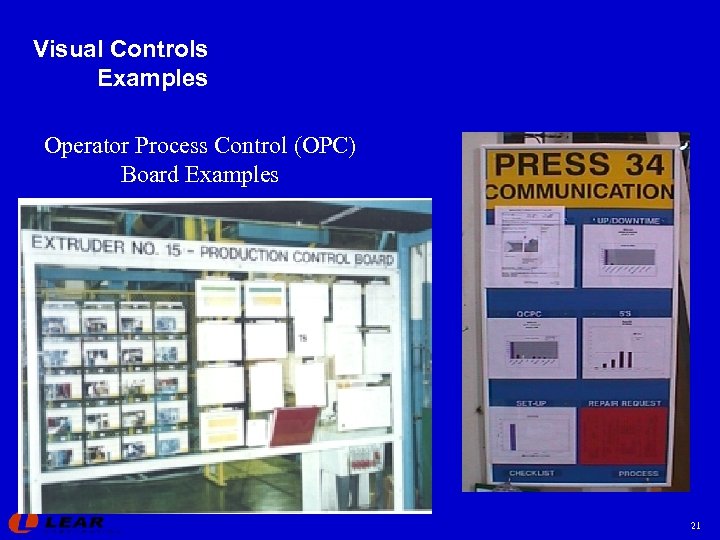

Visual Controls Examples Operator Process Control (OPC) Board Examples 21

Visual Controls Examples Operator Process Control (OPC) Board Examples 21

Implementation Key Points • • Publicly announce the start of the program Obtain top level support in the organization Involve all levels of employees Assign a champion(s) to lead 5 S team – Not only quality 22

Implementation Key Points • • Publicly announce the start of the program Obtain top level support in the organization Involve all levels of employees Assign a champion(s) to lead 5 S team – Not only quality 22

Implementation Key Points • Standardize formats, design and theme of visuals • Disseminate information on progress • Photograph or video tape current look • Include in current process – i. e. , work order system, p. m. system 23

Implementation Key Points • Standardize formats, design and theme of visuals • Disseminate information on progress • Photograph or video tape current look • Include in current process – i. e. , work order system, p. m. system 23