790701bb09a4054f03fe52a3ec5803f0.ppt

- Количество слайдов: 132

Lean Toolkit The fundamental principles of lean production for businesses involved in the edible and amenity horticulture supply chains within Wales.

Lean Toolkit The fundamental principles of lean production for businesses involved in the edible and amenity horticulture supply chains within Wales.

Lean Toolkit Produced by …… Dr Toni Whitehead is a Business Analyst who provides Research, Analysis & Evaluation and Programme Management services to clients across a number of sectors. Toni’s background is in Procurement, Change Management and Supply Chain Management. She has a Masters degree in Lean Supply Chain Management and a Ph. D in Lean Supply Chains and Regional Economic Development from Cardiff University. Dr Donna Samuel is also a Business Analyst and heads up the S A Partners Lean Academy. Donna started her career in manufacturing but moved into the higher education sector where she accumulated over twenty years of graduate and post graduate teaching. She has considerable research experience in the areas of lean, business and process improvement, purchasing and supply chain management. Donna has a Masters degree in Business Administration (MBA) and doctorate. Her Ph. D study focused on the range of factors impacting on the diffusion (or spread) of lean in the UK over the past three decades. Andy Brunskill is a Principle Management Consultant who works with clients on a global basis in a number of sectors, helping them to deliver significant and sustainable improvements across their businesses. For over 20 years, S A Partners has been a leading Lean enterprise excellence consultancy. Their Head Office is in Caerphilly, South Wales. Consultants operate on a global basis. The team are delighted to work with Horticulture Wales on this important project.

Lean Toolkit Produced by …… Dr Toni Whitehead is a Business Analyst who provides Research, Analysis & Evaluation and Programme Management services to clients across a number of sectors. Toni’s background is in Procurement, Change Management and Supply Chain Management. She has a Masters degree in Lean Supply Chain Management and a Ph. D in Lean Supply Chains and Regional Economic Development from Cardiff University. Dr Donna Samuel is also a Business Analyst and heads up the S A Partners Lean Academy. Donna started her career in manufacturing but moved into the higher education sector where she accumulated over twenty years of graduate and post graduate teaching. She has considerable research experience in the areas of lean, business and process improvement, purchasing and supply chain management. Donna has a Masters degree in Business Administration (MBA) and doctorate. Her Ph. D study focused on the range of factors impacting on the diffusion (or spread) of lean in the UK over the past three decades. Andy Brunskill is a Principle Management Consultant who works with clients on a global basis in a number of sectors, helping them to deliver significant and sustainable improvements across their businesses. For over 20 years, S A Partners has been a leading Lean enterprise excellence consultancy. Their Head Office is in Caerphilly, South Wales. Consultants operate on a global basis. The team are delighted to work with Horticulture Wales on this important project.

Contents Introduction What is Lean? Case Studies Lean Philosophy and Concepts Lean Tools and Techniques Glossary of Terms, Tools and Techniques Useful Links and Resources References/Bibliography

Contents Introduction What is Lean? Case Studies Lean Philosophy and Concepts Lean Tools and Techniques Glossary of Terms, Tools and Techniques Useful Links and Resources References/Bibliography

Introduction The purpose of this section is to provide an introduction to the toolkit

Introduction The purpose of this section is to provide an introduction to the toolkit

Introduction - Index Introduction A Simple Growing Process or Value Stream Purpose of Toolkit Audience for Toolkit How Toolkit can/should be used Case Studies within Toolkit

Introduction - Index Introduction A Simple Growing Process or Value Stream Purpose of Toolkit Audience for Toolkit How Toolkit can/should be used Case Studies within Toolkit

Introduction Horticulture Wales provides focused, expert support to businesses involved in both edible and amenity horticulture supply chains within Wales. Their aim is to enhance the efficiency of these businesses and supply chains. The horticulture sector is facing a number of challenges: Characteristics of edible versus amenity horticulture and the differences in price and flexibility Increased demand market dynamics for product variety, uniqueness, freshness (e. g. mixed salad leaves, speciality vine tomatoes etc. ) Increasing customer expectations with regard to quality, cost, speed and adherence of delivery Increased competition and the need for 24/7 or 365 day availability. With these in mind, Horticulture Wales have identified a need to develop a Lean toolkit. Lean Thinking is a globally recognised approach used to deliver value through continuous improvement, efficiencies and operational excellence across an organisation (and its supply chain). Whilst Lean started in the automotive sector horticulture shares many characteristics, for example, repetitive routine activities that produce a quality homogeneous product.

Introduction Horticulture Wales provides focused, expert support to businesses involved in both edible and amenity horticulture supply chains within Wales. Their aim is to enhance the efficiency of these businesses and supply chains. The horticulture sector is facing a number of challenges: Characteristics of edible versus amenity horticulture and the differences in price and flexibility Increased demand market dynamics for product variety, uniqueness, freshness (e. g. mixed salad leaves, speciality vine tomatoes etc. ) Increasing customer expectations with regard to quality, cost, speed and adherence of delivery Increased competition and the need for 24/7 or 365 day availability. With these in mind, Horticulture Wales have identified a need to develop a Lean toolkit. Lean Thinking is a globally recognised approach used to deliver value through continuous improvement, efficiencies and operational excellence across an organisation (and its supply chain). Whilst Lean started in the automotive sector horticulture shares many characteristics, for example, repetitive routine activities that produce a quality homogeneous product.

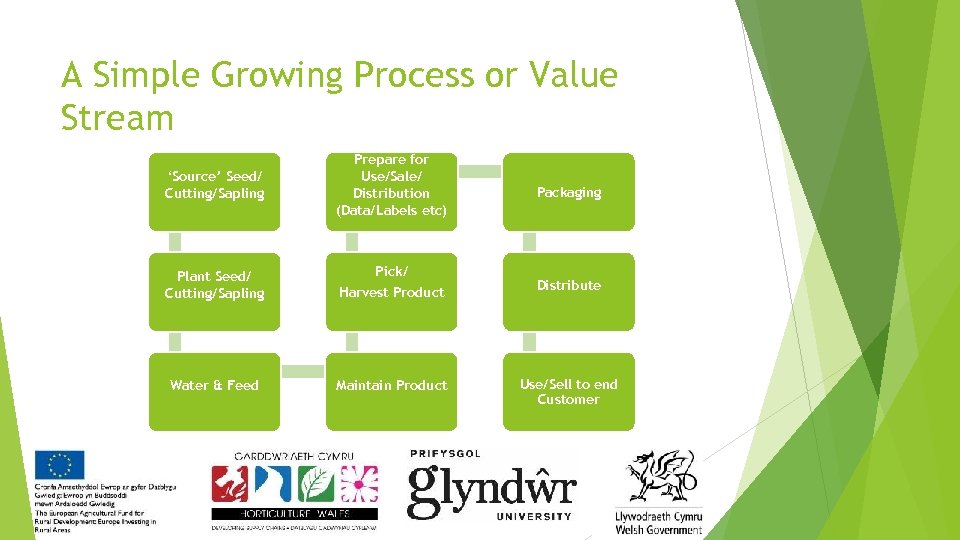

A Simple Growing Process or Value Stream ‘Source’ Seed/ Cutting/Sapling Prepare for Use/Sale/ Distribution (Data/Labels etc) Pick/ Plant Seed/ Cutting/Sapling Harvest Product Water & Feed Maintain Product Packaging Distribute Use/Sell to end Customer

A Simple Growing Process or Value Stream ‘Source’ Seed/ Cutting/Sapling Prepare for Use/Sale/ Distribution (Data/Labels etc) Pick/ Plant Seed/ Cutting/Sapling Harvest Product Water & Feed Maintain Product Packaging Distribute Use/Sell to end Customer

Purpose of Toolkit To raise awareness of Lean approaches amongst the horticultural community in Wales. This toolkit has been designed to introduce Lean as a practical and useful approach to help users make a difference to everyday working lives in relation to: Improved operational efficiency Improved cost, quality and delivery to meet customer needs A more flexible and motivated workforce that can adjust to surges in demand It is anticipated that growers will see value in the toolkit and its relevance to their business, especially with the practical examples and case studies. Lean has the potential to deliver transformational change and ongoing continuous improvements, but these take long term focus and commitment.

Purpose of Toolkit To raise awareness of Lean approaches amongst the horticultural community in Wales. This toolkit has been designed to introduce Lean as a practical and useful approach to help users make a difference to everyday working lives in relation to: Improved operational efficiency Improved cost, quality and delivery to meet customer needs A more flexible and motivated workforce that can adjust to surges in demand It is anticipated that growers will see value in the toolkit and its relevance to their business, especially with the practical examples and case studies. Lean has the potential to deliver transformational change and ongoing continuous improvements, but these take long term focus and commitment.

Audience for Toolkit Businesses involved in both edible and amenity horticulture supply chains within Wales. These can include: Independent growers Nurseries Garden Centres (Retailers) Those responsible for the maintenance of public horticultural products, spaces and amenities

Audience for Toolkit Businesses involved in both edible and amenity horticulture supply chains within Wales. These can include: Independent growers Nurseries Garden Centres (Retailers) Those responsible for the maintenance of public horticultural products, spaces and amenities

How Toolkit can/should be used The guide is sufficiently general to be used by growers and retailers It is a reference document that can be accessed on-line or used in a hard copy format It takes users through a series of concepts, tools and techniques which can signpost them into analysing key components of their business (Diagnostics) It enables them to apply Lean principles to improve efficiency in their businesses (Implementation) Each tool or technique is categorised by ‘What’, ‘Why’, and ‘How’ to explain what it is, why it is useful and how it can be used.

How Toolkit can/should be used The guide is sufficiently general to be used by growers and retailers It is a reference document that can be accessed on-line or used in a hard copy format It takes users through a series of concepts, tools and techniques which can signpost them into analysing key components of their business (Diagnostics) It enables them to apply Lean principles to improve efficiency in their businesses (Implementation) Each tool or technique is categorised by ‘What’, ‘Why’, and ‘How’ to explain what it is, why it is useful and how it can be used.

Case Studies Practical examples showing how businesses are using Lean approaches can be found throughout the toolkit. The four detailed Case Studies showcase horticulture-related companies who are using Lean tools and techniques to great effect. (In the case of Double H Nurseries, these are recognised as an exemplar within the horticulture supply chain). Summaries of improvement opportunities and benefits across the supply chain (Supplier, Process, Customers and other complementary benefits) for each case are shown in the next seven pages.

Case Studies Practical examples showing how businesses are using Lean approaches can be found throughout the toolkit. The four detailed Case Studies showcase horticulture-related companies who are using Lean tools and techniques to great effect. (In the case of Double H Nurseries, these are recognised as an exemplar within the horticulture supply chain). Summaries of improvement opportunities and benefits across the supply chain (Supplier, Process, Customers and other complementary benefits) for each case are shown in the next seven pages.

Case Study 1: Potatoes Supplier Inputs - Improvement Opportunities and/or Benefits Process - Improvement Opportunities Other Improvement Opportunities & and/or Benefits 2% of incoming potatoes are rejected Reduced yield variance from current Standard Operating Procedures on receipt by potato processor. levels of 45 -65% to 25% could realise up (SOPs) (including standard machine These are not right first time. to £ 1. 25 m in savings. settings) Improvement indentified. Reduction in downtime and lost output Ways of working - improved planning incurred on dicing line by 50% = 21% process and related activities improvement in overall output Visual management Improved quality checks throughout the processing activities and changeovers FIFO system operated by Fork Lift Improved H & S - reduced risk of slips Truck drivers to ensure old stock used and accidents on the production line first Improved changeovers at flexi pump dicer (quick changeovers) Up to £ 1. 25 m potential savings identified for initial improvements

Case Study 1: Potatoes Supplier Inputs - Improvement Opportunities and/or Benefits Process - Improvement Opportunities Other Improvement Opportunities & and/or Benefits 2% of incoming potatoes are rejected Reduced yield variance from current Standard Operating Procedures on receipt by potato processor. levels of 45 -65% to 25% could realise up (SOPs) (including standard machine These are not right first time. to £ 1. 25 m in savings. settings) Improvement indentified. Reduction in downtime and lost output Ways of working - improved planning incurred on dicing line by 50% = 21% process and related activities improvement in overall output Visual management Improved quality checks throughout the processing activities and changeovers FIFO system operated by Fork Lift Improved H & S - reduced risk of slips Truck drivers to ensure old stock used and accidents on the production line first Improved changeovers at flexi pump dicer (quick changeovers) Up to £ 1. 25 m potential savings identified for initial improvements

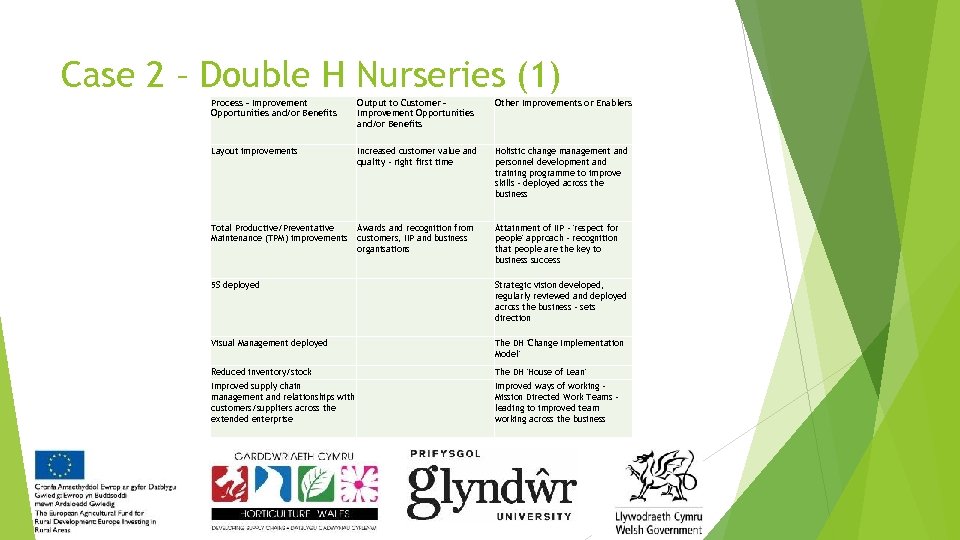

Case 2 – Double H Nurseries (1) Process - Improvement Opportunities and/or Benefits Output to Customer Improvement Opportunities and/or Benefits Other Improvements or Enablers Layout improvements Increased customer value and quality - right first time Holistic change management and personnel development and training programme to improve skills - deployed across the business Total Productive/Preventative Maintenance (TPM) improvements Awards and recognition from customers, IIP and business organisations Attainment of IIP - 'respect for people' approach - recognition that people are the key to business success 5 S deployed Strategic vision developed, regularly reviewed and deployed across the business - sets direction Visual Management deployed The DH 'Change Implementation Model' Reduced inventory/stock The DH 'House of Lean' Improved supply chain management and relationships with customers/suppliers across the extended enterprise Improved ways of working Mission Directed Work Teams leading to improved team working across the business

Case 2 – Double H Nurseries (1) Process - Improvement Opportunities and/or Benefits Output to Customer Improvement Opportunities and/or Benefits Other Improvements or Enablers Layout improvements Increased customer value and quality - right first time Holistic change management and personnel development and training programme to improve skills - deployed across the business Total Productive/Preventative Maintenance (TPM) improvements Awards and recognition from customers, IIP and business organisations Attainment of IIP - 'respect for people' approach - recognition that people are the key to business success 5 S deployed Strategic vision developed, regularly reviewed and deployed across the business - sets direction Visual Management deployed The DH 'Change Implementation Model' Reduced inventory/stock The DH 'House of Lean' Improved supply chain management and relationships with customers/suppliers across the extended enterprise Improved ways of working Mission Directed Work Teams leading to improved team working across the business

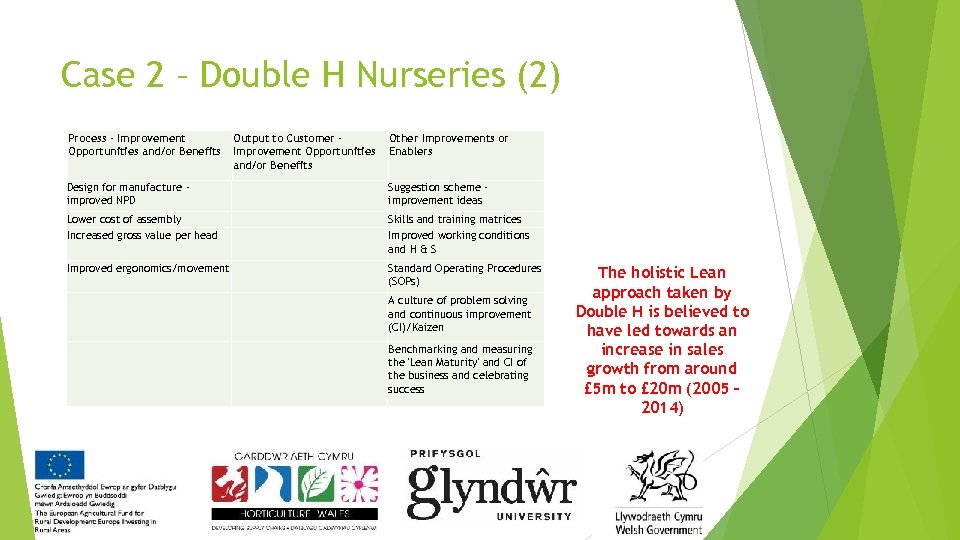

Case 2 – Double H Nurseries (2) Process - Improvement Opportunities and/or Benefits Output to Customer Improvement Opportunities and/or Benefits Other Improvements or Enablers Design for manufacture improved NPD Suggestion scheme improvement ideas Lower cost of assembly Increased gross value per head Skills and training matrices Improved working conditions and H & S Improved ergonomics/movement Standard Operating Procedures (SOPs) A culture of problem solving and continuous improvement (CI)/Kaizen Benchmarking and measuring the 'Lean Maturity' and CI of the business and celebrating success The holistic Lean approach taken by Double H is believed to have led towards an increase in sales growth from around £ 5 m to £ 20 m (2005 – 2014)

Case 2 – Double H Nurseries (2) Process - Improvement Opportunities and/or Benefits Output to Customer Improvement Opportunities and/or Benefits Other Improvements or Enablers Design for manufacture improved NPD Suggestion scheme improvement ideas Lower cost of assembly Increased gross value per head Skills and training matrices Improved working conditions and H & S Improved ergonomics/movement Standard Operating Procedures (SOPs) A culture of problem solving and continuous improvement (CI)/Kaizen Benchmarking and measuring the 'Lean Maturity' and CI of the business and celebrating success The holistic Lean approach taken by Double H is believed to have led towards an increase in sales growth from around £ 5 m to £ 20 m (2005 – 2014)

Case 3 – Flowers (1) Process - Improvement Output to Customer Other Improvement Opportunities and/or Benefits Improvement Opportunities & Benefits and/or Benefits Reduced 'out of life' product Improved 'supplier' quality and Improved 'ways of working' compliance robust problem solving and root cause analysis - now a way of life. Manage by fact. Improvement/efficiencies to pack house operations Introduced effective KPIs and performance management systems Reduced demand amplification leading to level loading of orders and processing Clear, standardised plan Improved stock dwell time from 20% to 80% Standardised manning levels Increased productivity by 50% on Bouquet product line (creation of capacity to use in other areas/process new orders)

Case 3 – Flowers (1) Process - Improvement Output to Customer Other Improvement Opportunities and/or Benefits Improvement Opportunities & Benefits and/or Benefits Reduced 'out of life' product Improved 'supplier' quality and Improved 'ways of working' compliance robust problem solving and root cause analysis - now a way of life. Manage by fact. Improvement/efficiencies to pack house operations Introduced effective KPIs and performance management systems Reduced demand amplification leading to level loading of orders and processing Clear, standardised plan Improved stock dwell time from 20% to 80% Standardised manning levels Increased productivity by 50% on Bouquet product line (creation of capacity to use in other areas/process new orders)

Case 3 – Flowers (2) Process - Improvement Opportunities and/or Benefits Output to Customer Improvement Opportunities and/or Benefits Other Improvement Opportunities & Benefits Reduced damage to produce Increased line efficiencies 35% production savings on some product lines 10% back office savings - released personnel to do other value adding work and reduced need to recruit more staff Overall waste reduced by 3% to date Improved Visual Management Improved supplier ordering and stock management Potential benefits are around £ 200 k from this initial project work

Case 3 – Flowers (2) Process - Improvement Opportunities and/or Benefits Output to Customer Improvement Opportunities and/or Benefits Other Improvement Opportunities & Benefits Reduced damage to produce Increased line efficiencies 35% production savings on some product lines 10% back office savings - released personnel to do other value adding work and reduced need to recruit more staff Overall waste reduced by 3% to date Improved Visual Management Improved supplier ordering and stock management Potential benefits are around £ 200 k from this initial project work

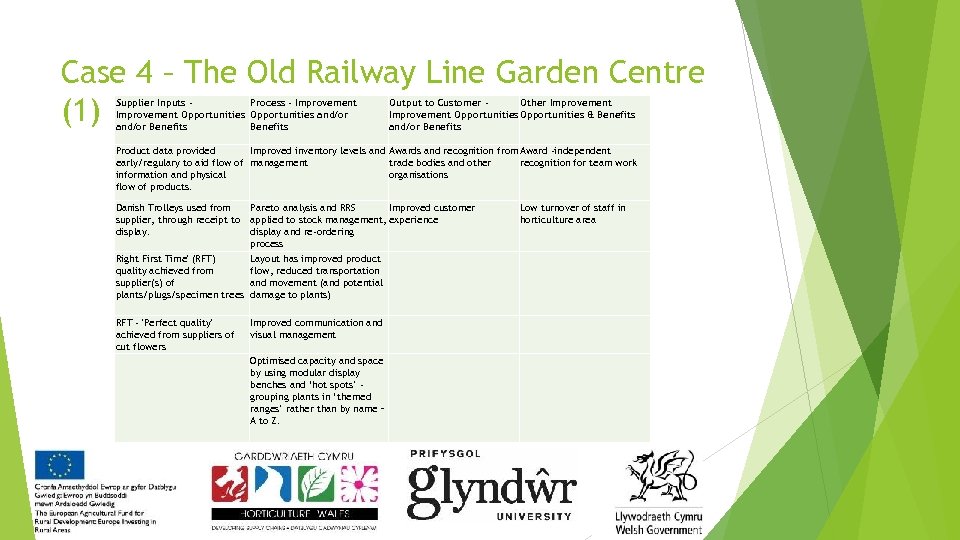

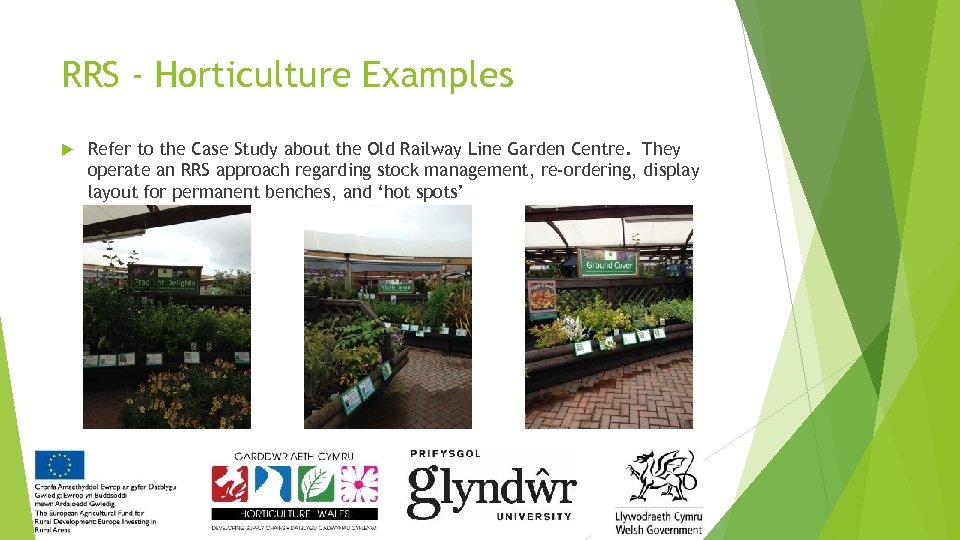

Case 4 – The Old Railway Line Garden Centre (1) Supplier Inputs Process - Improvement Opportunities and/or Benefits Output to Customer Other Improvement Opportunities & Benefits and/or Benefits Product data provided Improved inventory levels and Awards and recognition from Award -independent early/regulary to aid flow of management trade bodies and other recognition for team work information and physical organisations flow of products. Danish Trolleys used from supplier, through receipt to display. Pareto analysis and RRS Improved customer applied to stock management, experience display and re-ordering process Low turnover of staff in horticulture area Right First Time' (RFT) quality achieved from supplier(s) of plants/plugs/specimen trees Layout has improved product flow, reduced transportation and movement (and potential damage to plants) RFT - 'Perfect quality' achieved from suppliers of cut flowers Improved communication and visual management Optimised capacity and space by using modular display benches and ‘hot spots’ grouping plants in ‘themed ranges’ rather than by name – A to Z.

Case 4 – The Old Railway Line Garden Centre (1) Supplier Inputs Process - Improvement Opportunities and/or Benefits Output to Customer Other Improvement Opportunities & Benefits and/or Benefits Product data provided Improved inventory levels and Awards and recognition from Award -independent early/regulary to aid flow of management trade bodies and other recognition for team work information and physical organisations flow of products. Danish Trolleys used from supplier, through receipt to display. Pareto analysis and RRS Improved customer applied to stock management, experience display and re-ordering process Low turnover of staff in horticulture area Right First Time' (RFT) quality achieved from supplier(s) of plants/plugs/specimen trees Layout has improved product flow, reduced transportation and movement (and potential damage to plants) RFT - 'Perfect quality' achieved from suppliers of cut flowers Improved communication and visual management Optimised capacity and space by using modular display benches and ‘hot spots’ grouping plants in ‘themed ranges’ rather than by name – A to Z.

Case 4 – The Old Railway Line Garden Centre (2) Supplier Inputs Improvement Opportunities and/or Benefits Process - Improvement Output to Customer Other Improvement Opportunities and/or Benefits Improvement Opportunities & Benefits and/or Benefits Layout improvements have led to the receipt area now being under cover to protect plants and reduce damage in bad weather. Improved back office operations Reduced water consumption Danish Trolleys used from supplier, through receipt to display. Optimised & flexible use of layout - modular areas – ‘Hot Spots’ for ‘Runners’ e. g. impulse buys such as seasonal bedding plants. Quick changeovers. Improved 5 S and Visual Management Efficient stock-turn and product freshness KPIs – ‘no plant celebrates it’s birthday’. Continuing to improve overall business performance

Case 4 – The Old Railway Line Garden Centre (2) Supplier Inputs Improvement Opportunities and/or Benefits Process - Improvement Output to Customer Other Improvement Opportunities and/or Benefits Improvement Opportunities & Benefits and/or Benefits Layout improvements have led to the receipt area now being under cover to protect plants and reduce damage in bad weather. Improved back office operations Reduced water consumption Danish Trolleys used from supplier, through receipt to display. Optimised & flexible use of layout - modular areas – ‘Hot Spots’ for ‘Runners’ e. g. impulse buys such as seasonal bedding plants. Quick changeovers. Improved 5 S and Visual Management Efficient stock-turn and product freshness KPIs – ‘no plant celebrates it’s birthday’. Continuing to improve overall business performance

What is Lean? The purpose of this section is to understand what lean is, where it came from and why it matters

What is Lean? The purpose of this section is to understand what lean is, where it came from and why it matters

What is Lean? - Index What is Lean? Where did Lean come from? Lean Concepts and Techniques Organisations Going Lean Why bother with Lean? The ‘So What’ Question

What is Lean? - Index What is Lean? Where did Lean come from? Lean Concepts and Techniques Organisations Going Lean Why bother with Lean? The ‘So What’ Question

What is Lean? Some definitions: Lean in a means of achieving profitable growth through the relentless pursuit of customer value Lean is a consumer-focused approach to the provision of effective and efficient processes Lean is doing more with less Lean is a philosophy which encourages people to subconsciously seek perfection in their everyday work.

What is Lean? Some definitions: Lean in a means of achieving profitable growth through the relentless pursuit of customer value Lean is a consumer-focused approach to the provision of effective and efficient processes Lean is doing more with less Lean is a philosophy which encourages people to subconsciously seek perfection in their everyday work.

What Lean is Not Sales fall Customer service suffers Process performance falls There is a profit problem Beware of the Cost Cutting Spiral! The business shrinks! Constrain development & Demotivate people Reaction: Cut Costs! Cut the budgets Target areas of excess spending

What Lean is Not Sales fall Customer service suffers Process performance falls There is a profit problem Beware of the Cost Cutting Spiral! The business shrinks! Constrain development & Demotivate people Reaction: Cut Costs! Cut the budgets Target areas of excess spending

Where did Lean come from? The term ‘Lean’ was made popular Womack, Jones and Roos (1990) following their influential and best-selling management book entitled The Machine That Changed The World. They selected the word ‘Lean’ to capture the essence of the Toyota Production System (TPS) compared with typical Western ‘resource intensive’ production systems. Lean is defined in terms of its outcomes: ‘compared to mass production it uses less of everything – half the human effort in the factory, half the manufacturing space, half the investment in tools, half the engineering hours to develop a new product in half the time. Also, it requires keeping far less than half the needed inventory on site, results in many fewer defects, and produces a greater and ever growing variety of products’. (Womack et al. , 1990, p. 13) The authors went onto to publish Lean Thinking in which they identify some of the principles that underpin Lean and illustrate their ideas with case studies. Together these two texts triggered a movement and, although Lean started in the automotive sector, in the last two decades it has spread through to other industries. This means that in some sectors Lean is fairly mature, while in other sectors (including the horticultural sector) Lean is still relatively new.

Where did Lean come from? The term ‘Lean’ was made popular Womack, Jones and Roos (1990) following their influential and best-selling management book entitled The Machine That Changed The World. They selected the word ‘Lean’ to capture the essence of the Toyota Production System (TPS) compared with typical Western ‘resource intensive’ production systems. Lean is defined in terms of its outcomes: ‘compared to mass production it uses less of everything – half the human effort in the factory, half the manufacturing space, half the investment in tools, half the engineering hours to develop a new product in half the time. Also, it requires keeping far less than half the needed inventory on site, results in many fewer defects, and produces a greater and ever growing variety of products’. (Womack et al. , 1990, p. 13) The authors went onto to publish Lean Thinking in which they identify some of the principles that underpin Lean and illustrate their ideas with case studies. Together these two texts triggered a movement and, although Lean started in the automotive sector, in the last two decades it has spread through to other industries. This means that in some sectors Lean is fairly mature, while in other sectors (including the horticultural sector) Lean is still relatively new.

Lean Concepts and Techniques Lean is about making tomorrow better then today Lean is a broad church that encompasses many concepts and many analytical tools and techniques Some Lean tools and techniques help to diagnose organisational problems and root out waste; others are implementation tools or techniques that are found in the very best organisations In this workbook we have been deliberately selective about which concepts, tools and techniques to introduce you to. Our aim is to give you enough to get you started.

Lean Concepts and Techniques Lean is about making tomorrow better then today Lean is a broad church that encompasses many concepts and many analytical tools and techniques Some Lean tools and techniques help to diagnose organisational problems and root out waste; others are implementation tools or techniques that are found in the very best organisations In this workbook we have been deliberately selective about which concepts, tools and techniques to introduce you to. Our aim is to give you enough to get you started.

Organisations Going Lean Organisations are at different states of their Lean maturity. For some Lean has been around for a while and is fairly mature, while in other sectors (like horticulture) Lean is still relatively new. Although we will show you a case study of a horticultural company that has been on its Lean journey for over a decade. Organisations tend to view Lean in different ways: Some use Lean to change their organisational culture and transform themselves Others use Lean as a methodology to improve their performance This toolkit has been designed to introduce Lean to you as a practical methodology to help you make a difference in your everyday working lives.

Organisations Going Lean Organisations are at different states of their Lean maturity. For some Lean has been around for a while and is fairly mature, while in other sectors (like horticulture) Lean is still relatively new. Although we will show you a case study of a horticultural company that has been on its Lean journey for over a decade. Organisations tend to view Lean in different ways: Some use Lean to change their organisational culture and transform themselves Others use Lean as a methodology to improve their performance This toolkit has been designed to introduce Lean to you as a practical methodology to help you make a difference in your everyday working lives.

Why Bother With Lean? The ‘So What? ’ Question…… The purpose is to deliver business benefits. While it is almost impossible to pinpoint the precise benefits you can expect, these are typical benefits that other organisations have seen: Improved quality with 20 -40% reduction in defects Improved productivity by 10 -20% Increased flexibility – lead time reductions of up to 50% Reduced costs by 10 -15% Increased customer satisfaction Reduced organisational environmental impact Raised employee engagement and involvement leading to productivity improvements of up to 50% Reduced stock levels by up to 75%

Why Bother With Lean? The ‘So What? ’ Question…… The purpose is to deliver business benefits. While it is almost impossible to pinpoint the precise benefits you can expect, these are typical benefits that other organisations have seen: Improved quality with 20 -40% reduction in defects Improved productivity by 10 -20% Increased flexibility – lead time reductions of up to 50% Reduced costs by 10 -15% Increased customer satisfaction Reduced organisational environmental impact Raised employee engagement and involvement leading to productivity improvements of up to 50% Reduced stock levels by up to 75%

Horticultural Cost Savings Example Savings running into £ 10, 000 s per annum were identified in a commercial tomato nursery as part of HDC Project PC 257. Little or no capital investment required Return on Investment recouped within two years (Source: Lean Manufacturing, 2008, Agriculture & Horticulture Development Board)

Horticultural Cost Savings Example Savings running into £ 10, 000 s per annum were identified in a commercial tomato nursery as part of HDC Project PC 257. Little or no capital investment required Return on Investment recouped within two years (Source: Lean Manufacturing, 2008, Agriculture & Horticulture Development Board)

Lean Philosophy and Concepts The purpose of this section is to help users understand some core Lean principles and ideas

Lean Philosophy and Concepts The purpose of this section is to help users understand some core Lean principles and ideas

Lean Philosophy & Concepts - Index Understanding the Lean Characteristics The 5 Lean Principles Customer First – Customer Value Respect for People House of Lean Total Productive (or Preventative) Maintenance (TPM) Wastes – The original 7 Wastes; Variations on the Original 7 Wastes and the Service Wastes Value Add (VA)/Non-Value Add (NVA)/Necessary but Non-Value Add (NNVA) Gemba Supply Chain Management (SCM) Quality, Continuous Improvement (CI) & Kaizen

Lean Philosophy & Concepts - Index Understanding the Lean Characteristics The 5 Lean Principles Customer First – Customer Value Respect for People House of Lean Total Productive (or Preventative) Maintenance (TPM) Wastes – The original 7 Wastes; Variations on the Original 7 Wastes and the Service Wastes Value Add (VA)/Non-Value Add (NVA)/Necessary but Non-Value Add (NNVA) Gemba Supply Chain Management (SCM) Quality, Continuous Improvement (CI) & Kaizen

Understanding the Lean Characteristics Characteristic Customer What It Means The external customer is the starting and ending point. Seek to maximise value to the customer. Optimise around the customer and not around internal operations. Understand the customer’s true demand (what he would like not what can be supplied). Simplicity Lean is not simple but simplicity pervades. Simplicity in operation, system and technology. Visibility Seek to make all operations as visible and transparent as possible. Regularity Look for no surprises in operations – we run our lives on regularity, we must do the same in operations. Synchronisation Look to ‘keep it moving’ (flow) – this will mean synchronising operations so that it all comes together in the end. Pull Seek for operations to work at the customer’s rate of demand. Waste is endemic. Learn to recognise it and wear your ‘muda spectacles’ at all times. Process Organise and think with a process view – horizontal not vertical. Prevention is always better (and less costly) than cure. Inspect the process not the product. Time Improvement Partnership Time is the single best overall measure. Continuous improvement is everybody’s concern. Seek cooperation and collaboration with all partners including suppliers, employees, customers and other stakeholders. Go to the workplace and seek the facts. Variety is good but variation is bad. Learn to understand common and special variation and to react appropriately. Employee should share responsibility for success and failure. Give them the opportunity to solve problems. Gemba Variation Participation Adapted from Bicheno, 2000

Understanding the Lean Characteristics Characteristic Customer What It Means The external customer is the starting and ending point. Seek to maximise value to the customer. Optimise around the customer and not around internal operations. Understand the customer’s true demand (what he would like not what can be supplied). Simplicity Lean is not simple but simplicity pervades. Simplicity in operation, system and technology. Visibility Seek to make all operations as visible and transparent as possible. Regularity Look for no surprises in operations – we run our lives on regularity, we must do the same in operations. Synchronisation Look to ‘keep it moving’ (flow) – this will mean synchronising operations so that it all comes together in the end. Pull Seek for operations to work at the customer’s rate of demand. Waste is endemic. Learn to recognise it and wear your ‘muda spectacles’ at all times. Process Organise and think with a process view – horizontal not vertical. Prevention is always better (and less costly) than cure. Inspect the process not the product. Time Improvement Partnership Time is the single best overall measure. Continuous improvement is everybody’s concern. Seek cooperation and collaboration with all partners including suppliers, employees, customers and other stakeholders. Go to the workplace and seek the facts. Variety is good but variation is bad. Learn to understand common and special variation and to react appropriately. Employee should share responsibility for success and failure. Give them the opportunity to solve problems. Gemba Variation Participation Adapted from Bicheno, 2000

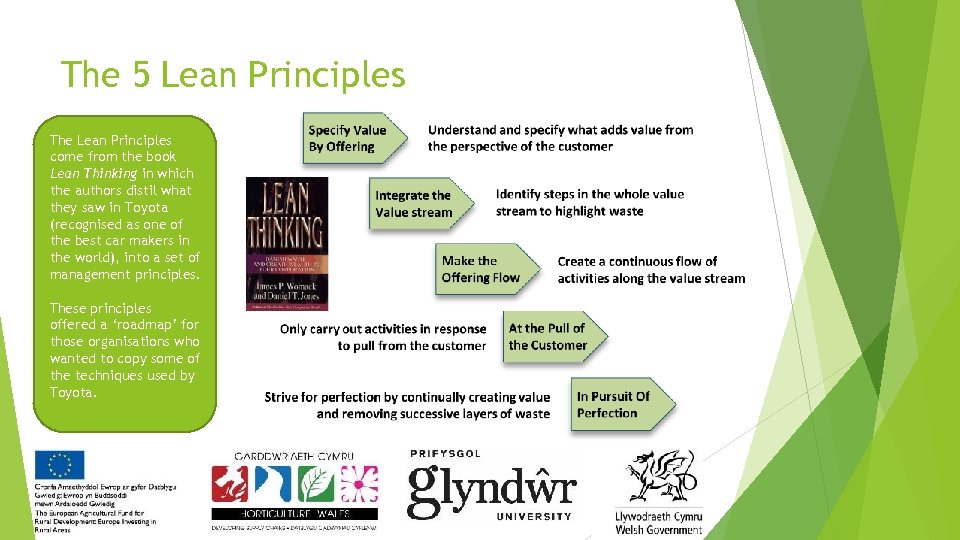

The 5 Lean Principles The Lean Principles come from the book Lean Thinking in which the authors distil what they saw in Toyota (recognised as one of the best car makers in the world), into a set of management principles. These principles offered a ‘roadmap’ for those organisations who wanted to copy some of the techniques used by Toyota.

The 5 Lean Principles The Lean Principles come from the book Lean Thinking in which the authors distil what they saw in Toyota (recognised as one of the best car makers in the world), into a set of management principles. These principles offered a ‘roadmap’ for those organisations who wanted to copy some of the techniques used by Toyota.

Pull & Flow in Horticulture …. Pull and flow can indicate a need to hold low levels of stock and achieve short delivery times whilst maintaining maximum utilisation of processing capacity – a dichotomy? The traditional method of meeting customer demand through off shelf delivery is to hold high levels of stock – a large investment It is difficult to hold high levels of stock in crop production because of product freshness The short marketable period helps to avoid the need to hold high stock levels to manage customer demand Control can be applied in processing and packaging where it may be possible to ‘stop’ operations (save cost) for produce that does not yet have a confirmed order. Process the order at customer pull …………. (Source: Lean Manufacturing, 2008, Agriculture & Horticulture Development Board) NB - There a number of products that help improve the flow of produce through the supply chain. See for example: http: //www. hortwee k. com/market-reportnurserytransport/ornamental s/article/1228018

Pull & Flow in Horticulture …. Pull and flow can indicate a need to hold low levels of stock and achieve short delivery times whilst maintaining maximum utilisation of processing capacity – a dichotomy? The traditional method of meeting customer demand through off shelf delivery is to hold high levels of stock – a large investment It is difficult to hold high levels of stock in crop production because of product freshness The short marketable period helps to avoid the need to hold high stock levels to manage customer demand Control can be applied in processing and packaging where it may be possible to ‘stop’ operations (save cost) for produce that does not yet have a confirmed order. Process the order at customer pull …………. (Source: Lean Manufacturing, 2008, Agriculture & Horticulture Development Board) NB - There a number of products that help improve the flow of produce through the supply chain. See for example: http: //www. hortwee k. com/market-reportnurserytransport/ornamental s/article/1228018

Customer First – Customer Value The first Lean principle is to specify value from the perspective of the customer This principle is about specifying what does and does not create value from the customers’ perspective and not from the perspective of individual firms, functions and departments We often assume we know what customers want Lean helps us challenge our assumptions This first principle means that customer value should be at the heart of everything we do. Examples of good customer value may include: • Good quality • Accurate content • Convenient delivery times • Flexible delivery times • Excellent customer service ~ going that one step further to help • Proactive approaches to meeting their needs • Expert knowledge of subject area and understanding of individual needs

Customer First – Customer Value The first Lean principle is to specify value from the perspective of the customer This principle is about specifying what does and does not create value from the customers’ perspective and not from the perspective of individual firms, functions and departments We often assume we know what customers want Lean helps us challenge our assumptions This first principle means that customer value should be at the heart of everything we do. Examples of good customer value may include: • Good quality • Accurate content • Convenient delivery times • Flexible delivery times • Excellent customer service ~ going that one step further to help • Proactive approaches to meeting their needs • Expert knowledge of subject area and understanding of individual needs

Respect for People Lean has sometimes been associated with cost cutting, losing heads and down-sizing (See slide on the Cost Cutting Spiral). After all, it is about reducing waste and sometimes that means people losing their jobs – right? Wrong! Lean is all about giving workers their right to use their natural ingenuity and talent in the workplace and not just their hands. It should be remembered what we tend to pick up on now is a mix of what Lean was originally and how it has been interpreted by some companies If you really want your people to join you in a journey to Lean, they have to feel comfortable that they are not going to improve themselves out of their jobs Otherwise they will use all that latent ingenuity and talent to sabotage your efforts. Ohno believed in two underlying principles: Respect for People and Lead with Humility

Respect for People Lean has sometimes been associated with cost cutting, losing heads and down-sizing (See slide on the Cost Cutting Spiral). After all, it is about reducing waste and sometimes that means people losing their jobs – right? Wrong! Lean is all about giving workers their right to use their natural ingenuity and talent in the workplace and not just their hands. It should be remembered what we tend to pick up on now is a mix of what Lean was originally and how it has been interpreted by some companies If you really want your people to join you in a journey to Lean, they have to feel comfortable that they are not going to improve themselves out of their jobs Otherwise they will use all that latent ingenuity and talent to sabotage your efforts. Ohno believed in two underlying principles: Respect for People and Lead with Humility

House of Lean The array of concepts that underpin Lean can seem overwhelming It can be useful to think of a journey to becoming Lean in terms of building a house. The foundations must be solid The house needs to be protected by a roof An example of a typical Lean house ….

House of Lean The array of concepts that underpin Lean can seem overwhelming It can be useful to think of a journey to becoming Lean in terms of building a house. The foundations must be solid The house needs to be protected by a roof An example of a typical Lean house ….

A ‘House of Lean’ for Horticulture Customer Value Quality Cost Delivery Variety Safety Demand Management RFT Quality & Continuous Improvement Standardised Operations & Visual Management Process Stability & Reliability Respect for People

A ‘House of Lean’ for Horticulture Customer Value Quality Cost Delivery Variety Safety Demand Management RFT Quality & Continuous Improvement Standardised Operations & Visual Management Process Stability & Reliability Respect for People

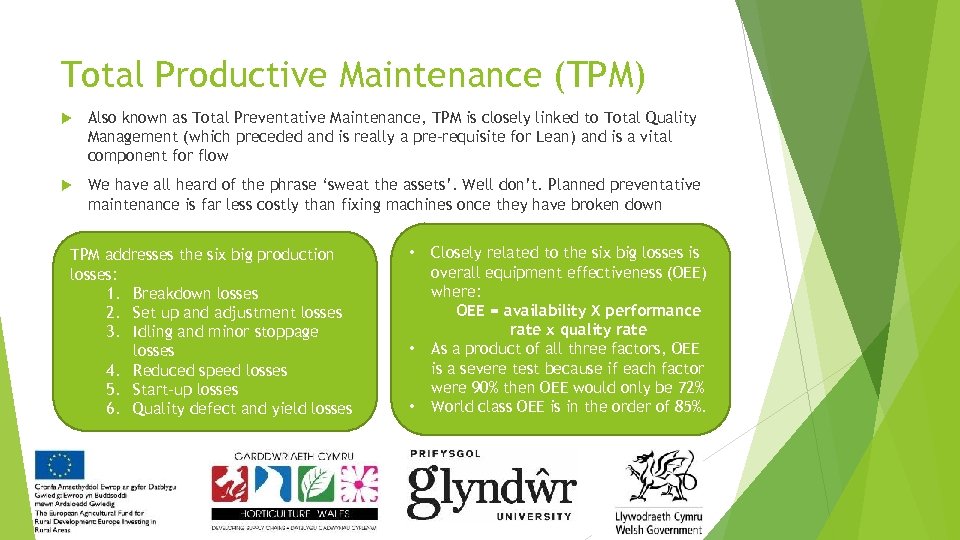

Total Productive Maintenance (TPM) Also known as Total Preventative Maintenance, TPM is closely linked to Total Quality Management (which preceded and is really a pre-requisite for Lean) and is a vital component for flow We have all heard of the phrase ‘sweat the assets’. Well don’t. Planned preventative maintenance is far less costly than fixing machines once they have broken down TPM addresses the six big production losses: 1. Breakdown losses 2. Set up and adjustment losses 3. Idling and minor stoppage losses 4. Reduced speed losses 5. Start-up losses 6. Quality defect and yield losses • • • Closely related to the six big losses is overall equipment effectiveness (OEE) where: OEE = availability X performance rate x quality rate As a product of all three factors, OEE is a severe test because if each factor were 90% then OEE would only be 72% World class OEE is in the order of 85%.

Total Productive Maintenance (TPM) Also known as Total Preventative Maintenance, TPM is closely linked to Total Quality Management (which preceded and is really a pre-requisite for Lean) and is a vital component for flow We have all heard of the phrase ‘sweat the assets’. Well don’t. Planned preventative maintenance is far less costly than fixing machines once they have broken down TPM addresses the six big production losses: 1. Breakdown losses 2. Set up and adjustment losses 3. Idling and minor stoppage losses 4. Reduced speed losses 5. Start-up losses 6. Quality defect and yield losses • • • Closely related to the six big losses is overall equipment effectiveness (OEE) where: OEE = availability X performance rate x quality rate As a product of all three factors, OEE is a severe test because if each factor were 90% then OEE would only be 72% World class OEE is in the order of 85%.

TPM Examples in Horticulture Maintenance of all equipment for example: Vehicles e. g. tractors & trailers, harvesting or picking equipment Machinery for cleaning, sorting and processing produce

TPM Examples in Horticulture Maintenance of all equipment for example: Vehicles e. g. tractors & trailers, harvesting or picking equipment Machinery for cleaning, sorting and processing produce

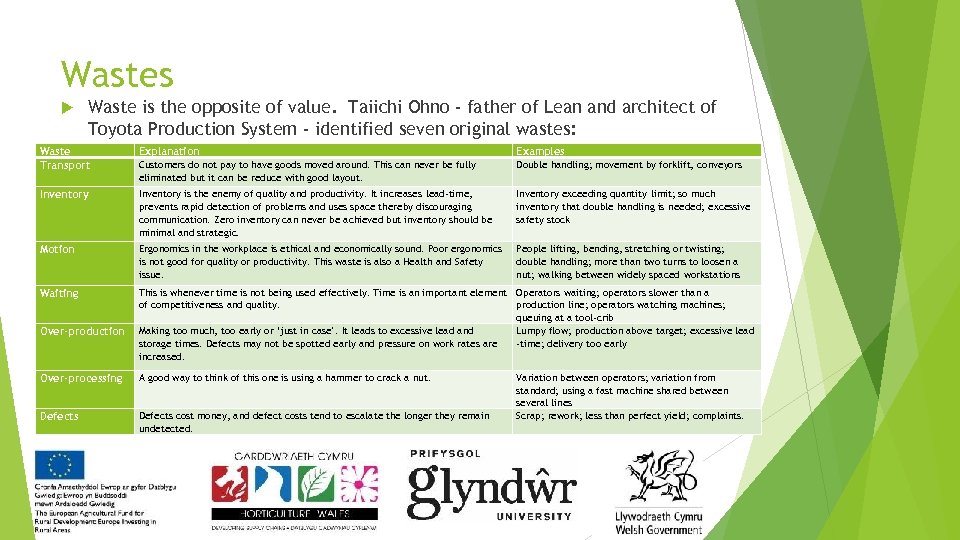

Wastes Waste is the opposite of value. Taiichi Ohno - father of Lean and architect of Toyota Production System - identified seven original wastes: Waste Transport Explanation Examples Customers do not pay to have goods moved around. This can never be fully eliminated but it can be reduce with good layout. Double handling; movement by forklift, conveyors Inventory is the enemy of quality and productivity. It increases lead-time, prevents rapid detection of problems and uses space thereby discouraging communication. Zero inventory can never be achieved but inventory should be minimal and strategic. Inventory exceeding quantity limit; so much inventory that double handling is needed; excessive safety stock Motion Ergonomics in the workplace is ethical and economically sound. Poor ergonomics is not good for quality or productivity. This waste is also a Health and Safety issue. People lifting, bending, stretching or twisting; double handling; more than two turns to loosen a nut; walking between widely spaced workstations Waiting This is whenever time is not being used effectively. Time is an important element Operators waiting; operators slower than a of competitiveness and quality. production line; operators watching machines; queuing at a tool-crib Making too much, too early or ‘just in case’. It leads to excessive lead and Lumpy flow; production above target; excessive lead storage times. Defects may not be spotted early and pressure on work rates are -time; delivery too early increased. Over-production Over-processing A good way to think of this one is using a hammer to crack a nut. Defects cost money, and defect costs tend to escalate the longer they remain undetected. Variation between operators; variation from standard; using a fast machine shared between several lines Scrap; rework; less than perfect yield; complaints.

Wastes Waste is the opposite of value. Taiichi Ohno - father of Lean and architect of Toyota Production System - identified seven original wastes: Waste Transport Explanation Examples Customers do not pay to have goods moved around. This can never be fully eliminated but it can be reduce with good layout. Double handling; movement by forklift, conveyors Inventory is the enemy of quality and productivity. It increases lead-time, prevents rapid detection of problems and uses space thereby discouraging communication. Zero inventory can never be achieved but inventory should be minimal and strategic. Inventory exceeding quantity limit; so much inventory that double handling is needed; excessive safety stock Motion Ergonomics in the workplace is ethical and economically sound. Poor ergonomics is not good for quality or productivity. This waste is also a Health and Safety issue. People lifting, bending, stretching or twisting; double handling; more than two turns to loosen a nut; walking between widely spaced workstations Waiting This is whenever time is not being used effectively. Time is an important element Operators waiting; operators slower than a of competitiveness and quality. production line; operators watching machines; queuing at a tool-crib Making too much, too early or ‘just in case’. It leads to excessive lead and Lumpy flow; production above target; excessive lead storage times. Defects may not be spotted early and pressure on work rates are -time; delivery too early increased. Over-production Over-processing A good way to think of this one is using a hammer to crack a nut. Defects cost money, and defect costs tend to escalate the longer they remain undetected. Variation between operators; variation from standard; using a fast machine shared between several lines Scrap; rework; less than perfect yield; complaints.

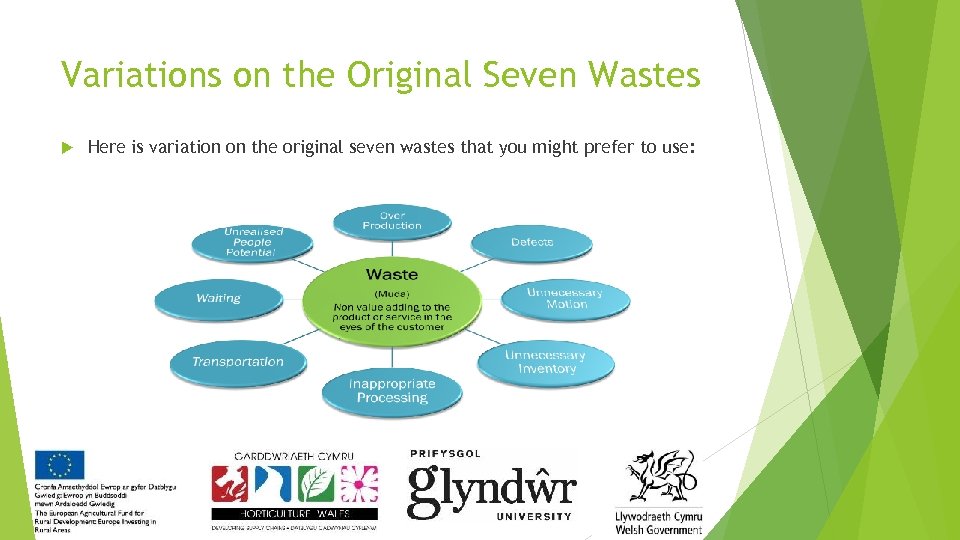

Variations on the Original Seven Wastes Ohno famously identified overproduction as the most important waste in car manufacturing. Hence the move towards ‘Just In Time’ production Here we have presented the original seven in an order which spells TIMWOOD to help you remember them. You could also use the acronym DOWNTIME (replacing over processing with excess processing) There are many variations on the original seven wastes. Bicheno, for example developed the seven new wastes and later the Lean service wastes (Bicheno, 1998, 2005 and Bicheno and Holweg, 2009) It is worth spending some time working out what the main wastes are in your own particular work environment.

Variations on the Original Seven Wastes Ohno famously identified overproduction as the most important waste in car manufacturing. Hence the move towards ‘Just In Time’ production Here we have presented the original seven in an order which spells TIMWOOD to help you remember them. You could also use the acronym DOWNTIME (replacing over processing with excess processing) There are many variations on the original seven wastes. Bicheno, for example developed the seven new wastes and later the Lean service wastes (Bicheno, 1998, 2005 and Bicheno and Holweg, 2009) It is worth spending some time working out what the main wastes are in your own particular work environment.

Variations on the Original Seven Wastes Here is variation on the original seven wastes that you might prefer to use:

Variations on the Original Seven Wastes Here is variation on the original seven wastes that you might prefer to use:

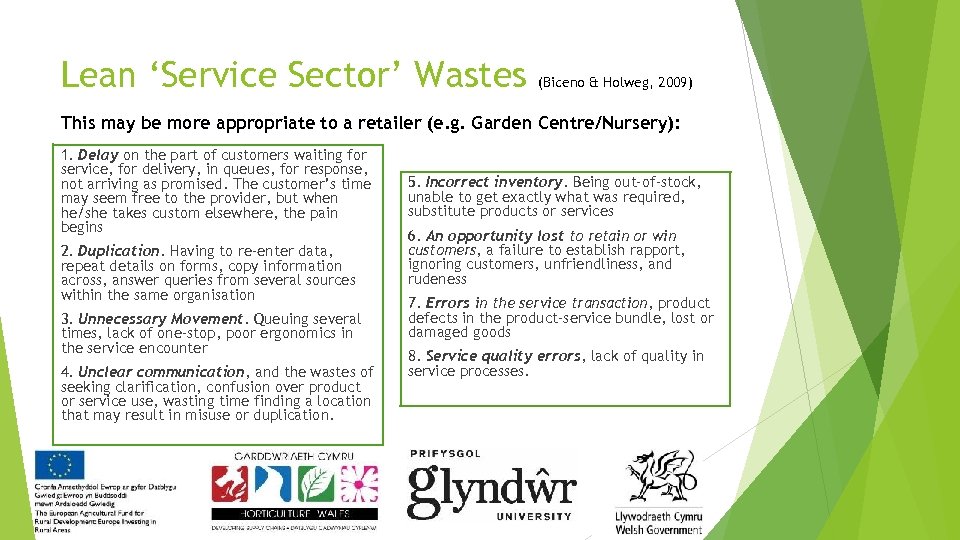

Lean ‘Service Sector’ Wastes (Biceno & Holweg, 2009) This may be more appropriate to a retailer (e. g. Garden Centre/Nursery): 1. Delay on the part of customers waiting for service, for delivery, in queues, for response, not arriving as promised. The customer’s time may seem free to the provider, but when he/she takes custom elsewhere, the pain begins 2. Duplication. Having to re-enter data, repeat details on forms, copy information across, answer queries from several sources within the same organisation 3. Unnecessary Movement. Queuing several times, lack of one-stop, poor ergonomics in the service encounter 4. Unclear communication, and the wastes of seeking clarification, confusion over product or service use, wasting time finding a location that may result in misuse or duplication. 5. Incorrect inventory. Being out-of-stock, unable to get exactly what was required, substitute products or services 6. An opportunity lost to retain or win customers, a failure to establish rapport, ignoring customers, unfriendliness, and rudeness 7. Errors in the service transaction, product defects in the product-service bundle, lost or damaged goods 8. Service quality errors, lack of quality in service processes.

Lean ‘Service Sector’ Wastes (Biceno & Holweg, 2009) This may be more appropriate to a retailer (e. g. Garden Centre/Nursery): 1. Delay on the part of customers waiting for service, for delivery, in queues, for response, not arriving as promised. The customer’s time may seem free to the provider, but when he/she takes custom elsewhere, the pain begins 2. Duplication. Having to re-enter data, repeat details on forms, copy information across, answer queries from several sources within the same organisation 3. Unnecessary Movement. Queuing several times, lack of one-stop, poor ergonomics in the service encounter 4. Unclear communication, and the wastes of seeking clarification, confusion over product or service use, wasting time finding a location that may result in misuse or duplication. 5. Incorrect inventory. Being out-of-stock, unable to get exactly what was required, substitute products or services 6. An opportunity lost to retain or win customers, a failure to establish rapport, ignoring customers, unfriendliness, and rudeness 7. Errors in the service transaction, product defects in the product-service bundle, lost or damaged goods 8. Service quality errors, lack of quality in service processes.

Examples of Over Production & Transport of Product in Horticulture Overproduction is inherent in the way in which produce (e. g. fruit) is grown – a biological process beyond the control of the grower …. Transport of product may relate to fresh produce, fertiliser, pallets, punnets …… As an example, buying a year’s requirement of punnets – consider implications on cost of storage, location of store, transportation when needed ……. Consider buying in smaller batches in regular deliveries straight to the pack house to match customer demand Just in time reduces costs through lower stocks, storage, transportation etc. but must be balanced with managing the risk of stoppages or not meeting customer demand ……. . This can be managed: Do not pick and pack produce where there is no demand – only pack to order. Then only surplus produce can be disposed of, without the cost of the packaging Pick produce to guaranteed orders into punnets and remaining produce into boxes – put into punnets when ordered…. This may look like re-work but it does offer flexibility and may be more costeffective (Source: Lean Manufacturing, 2008, Agriculture & Horticulture Development Board)

Examples of Over Production & Transport of Product in Horticulture Overproduction is inherent in the way in which produce (e. g. fruit) is grown – a biological process beyond the control of the grower …. Transport of product may relate to fresh produce, fertiliser, pallets, punnets …… As an example, buying a year’s requirement of punnets – consider implications on cost of storage, location of store, transportation when needed ……. Consider buying in smaller batches in regular deliveries straight to the pack house to match customer demand Just in time reduces costs through lower stocks, storage, transportation etc. but must be balanced with managing the risk of stoppages or not meeting customer demand ……. . This can be managed: Do not pick and pack produce where there is no demand – only pack to order. Then only surplus produce can be disposed of, without the cost of the packaging Pick produce to guaranteed orders into punnets and remaining produce into boxes – put into punnets when ordered…. This may look like re-work but it does offer flexibility and may be more costeffective (Source: Lean Manufacturing, 2008, Agriculture & Horticulture Development Board)

Examples of Over-Processing, Waiting & Delays in Horticulture Over-processing – for example ‘giveaway’ or over supply Some growers accept this as 5% even though it costs £ 20, 000/Ha p. a. Better investment in production could reduce over supply and a three year return on investment could allow the £ 12 k/Ha/p. a to be invested for every 1% improvement realised. Packaging is largely specified by retailer. However, it could be argued that specific punnets, printed film wrap and labelling could be over -processing in the eyes of the end customer… Losses incurred from waiting and delays are a common inefficiency when, for example, people and equipment are not where they are needed: A flat battery on a work platform or someone has borrowed it and not returned it! Run out of boxes/punnets in the greenhouse and the picking team stops Run out of produce in the pack house and the packing line grinds to a halt Someone or something is blocking your way when changing rows … (Source: Lean Manufacturing, 2008, Agriculture & Horticulture Development Board)

Examples of Over-Processing, Waiting & Delays in Horticulture Over-processing – for example ‘giveaway’ or over supply Some growers accept this as 5% even though it costs £ 20, 000/Ha p. a. Better investment in production could reduce over supply and a three year return on investment could allow the £ 12 k/Ha/p. a to be invested for every 1% improvement realised. Packaging is largely specified by retailer. However, it could be argued that specific punnets, printed film wrap and labelling could be over -processing in the eyes of the end customer… Losses incurred from waiting and delays are a common inefficiency when, for example, people and equipment are not where they are needed: A flat battery on a work platform or someone has borrowed it and not returned it! Run out of boxes/punnets in the greenhouse and the picking team stops Run out of produce in the pack house and the packing line grinds to a halt Someone or something is blocking your way when changing rows … (Source: Lean Manufacturing, 2008, Agriculture & Horticulture Development Board)

Example of Waiting & Delays from Horticulture …. . On-site Communications: A single picking team leader loses 15 minutes per day searching for the supervisor Total time wasted over a 30 week picking season = 37. 5 hours – 1 full week Proposed Solution: Fixed radio point in each greenhouse Full access to ‘communication system’ Whilst this would save time – a better solution would be to find out the root causes for the needs to speak to the supervisor and establish ‘Standard Operating Procedures’ to resolve these … (Source: Lean Manufacturing, 2008, Agriculture & Horticulture Development Board)

Example of Waiting & Delays from Horticulture …. . On-site Communications: A single picking team leader loses 15 minutes per day searching for the supervisor Total time wasted over a 30 week picking season = 37. 5 hours – 1 full week Proposed Solution: Fixed radio point in each greenhouse Full access to ‘communication system’ Whilst this would save time – a better solution would be to find out the root causes for the needs to speak to the supervisor and establish ‘Standard Operating Procedures’ to resolve these … (Source: Lean Manufacturing, 2008, Agriculture & Horticulture Development Board)

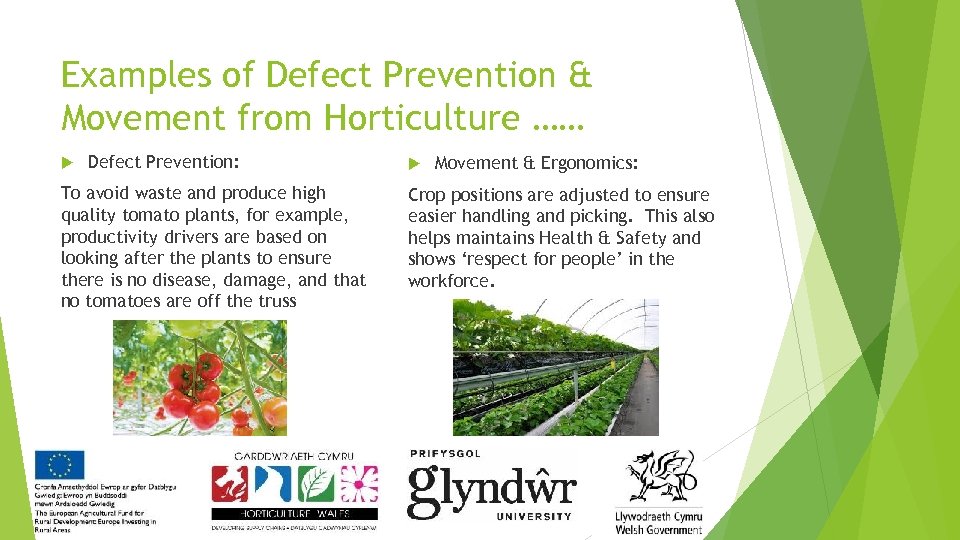

Examples of Defect Prevention & Movement from Horticulture …… Defect Prevention: To avoid waste and produce high quality tomato plants, for example, productivity drivers are based on looking after the plants to ensure there is no disease, damage, and that no tomatoes are off the truss Movement & Ergonomics: Crop positions are adjusted to ensure easier handling and picking. This also helps maintains Health & Safety and shows ‘respect for people’ in the workforce.

Examples of Defect Prevention & Movement from Horticulture …… Defect Prevention: To avoid waste and produce high quality tomato plants, for example, productivity drivers are based on looking after the plants to ensure there is no disease, damage, and that no tomatoes are off the truss Movement & Ergonomics: Crop positions are adjusted to ensure easier handling and picking. This also helps maintains Health & Safety and shows ‘respect for people’ in the workforce.

Waste Mapping at a Fruit Grower/Processor Waste analysis will help you to identify where to focus your Lean/improvement efforts first.

Waste Mapping at a Fruit Grower/Processor Waste analysis will help you to identify where to focus your Lean/improvement efforts first.

Other Examples of ‘Wastes’ from Horticulture (1) A new nursery business opened near Brecon in 2013. During the first year, the owner adopted a cold composting system. This lead to a lot of weed re-growth when the compost was used in the production/growing process for new flowers, herbs, fruits, and vegetables. Learning from this, there is now an effective and efficient six week ‘hot composting’ process which supports the growing process. Supermarkets operate a ‘RTM’ (return to manufacturer) system whereby surplus produce is returned to the grower/supplier – this impacts on over-production, movement, transportation etc. The less times that edible produce is ‘handled’ minimises the opportunity of damage and helps maintain high quality and freshness. For example: Pick direct to containers and avoid sorting processes On vine tomatoes are picked once a week and can command a higher price than off vine tomatoes, which can be up to 20% cheaper.

Other Examples of ‘Wastes’ from Horticulture (1) A new nursery business opened near Brecon in 2013. During the first year, the owner adopted a cold composting system. This lead to a lot of weed re-growth when the compost was used in the production/growing process for new flowers, herbs, fruits, and vegetables. Learning from this, there is now an effective and efficient six week ‘hot composting’ process which supports the growing process. Supermarkets operate a ‘RTM’ (return to manufacturer) system whereby surplus produce is returned to the grower/supplier – this impacts on over-production, movement, transportation etc. The less times that edible produce is ‘handled’ minimises the opportunity of damage and helps maintain high quality and freshness. For example: Pick direct to containers and avoid sorting processes On vine tomatoes are picked once a week and can command a higher price than off vine tomatoes, which can be up to 20% cheaper.

Other Examples of ‘Wastes’ from Horticulture (2) Many supermarkets across the range (e. g. quality retailers to those more cost conscious) now stock fresh flowers and plants. Their staff are not trained to care for these horticultural products, which often ‘go to waste’ or have to be sold at reduced prices as the quality deteriorates as they are incorrectly displayed or not maintained. Therefore retailers require strategies to manage all stock – including horticultural products.

Other Examples of ‘Wastes’ from Horticulture (2) Many supermarkets across the range (e. g. quality retailers to those more cost conscious) now stock fresh flowers and plants. Their staff are not trained to care for these horticultural products, which often ‘go to waste’ or have to be sold at reduced prices as the quality deteriorates as they are incorrectly displayed or not maintained. Therefore retailers require strategies to manage all stock – including horticultural products.

Value Add (VA)/Non-Value Add (NVA)/Necessary but Non-Value Add (NNVA) The first Lean principle is value in the eyes of the customer. However deciding what adds value to the customer and what does not is not always easy A practical approach is to think about whether the customer would be willing to pay for it Doing so allows us to identify three main categories: Value adding (VA) – those activities or process steps that unambiguously add value e. g. welding the tubes of bicycle together; flying a passenger from Cardiff to Europe. Necessary but non value adding (NNVA) – those activities or process steps that create no value but are unavoidable because of current production and/or technology constraints or because of external factors such as legislation e. g. some inspection, testing. Non value adding (NVA) – This is pure waste - these are steps create no value and are avoidable. It is third category (NVA) that is the main target for Lean improvement but we should seek to minimise NNVA too. When you analyse end to end processes through mapping it is often shocking how much NVA is present.

Value Add (VA)/Non-Value Add (NVA)/Necessary but Non-Value Add (NNVA) The first Lean principle is value in the eyes of the customer. However deciding what adds value to the customer and what does not is not always easy A practical approach is to think about whether the customer would be willing to pay for it Doing so allows us to identify three main categories: Value adding (VA) – those activities or process steps that unambiguously add value e. g. welding the tubes of bicycle together; flying a passenger from Cardiff to Europe. Necessary but non value adding (NNVA) – those activities or process steps that create no value but are unavoidable because of current production and/or technology constraints or because of external factors such as legislation e. g. some inspection, testing. Non value adding (NVA) – This is pure waste - these are steps create no value and are avoidable. It is third category (NVA) that is the main target for Lean improvement but we should seek to minimise NNVA too. When you analyse end to end processes through mapping it is often shocking how much NVA is present.

Value Add and Non-Value Add VA and NVA Pie Chart: Top Tip: You don’t have to eliminate or remove all the wastes at once – prioritise by importance to your business

Value Add and Non-Value Add VA and NVA Pie Chart: Top Tip: You don’t have to eliminate or remove all the wastes at once – prioritise by importance to your business

Examples of VA/NNVA and NVA in Horticulture Source: Lean Manufacturing, 2008, Agriculture and Horticulture Development Board

Examples of VA/NNVA and NVA in Horticulture Source: Lean Manufacturing, 2008, Agriculture and Horticulture Development Board

Gemba is the workplace Ohno said ‘management begins at the workplace’ and famously drew a circle on the factory floor, making his engineers stand in them and watch what was actually happening. Contrast gemba with the traditional way we manage – staying the office and discussing opinions Gemba is a mindset, a way of thinking. If there is problem, go to where the problem is occurring first. Gemba means: • Go to the actual workplace • Look at the actual process • Observe what is actually happening • Collect actual data

Gemba is the workplace Ohno said ‘management begins at the workplace’ and famously drew a circle on the factory floor, making his engineers stand in them and watch what was actually happening. Contrast gemba with the traditional way we manage – staying the office and discussing opinions Gemba is a mindset, a way of thinking. If there is problem, go to where the problem is occurring first. Gemba means: • Go to the actual workplace • Look at the actual process • Observe what is actually happening • Collect actual data

Supply Chain Management (SCM) The concept of Supply Chain Management developed at the same time and alongside Lean. SCM is based on two core ideas: The first is that practically every product that reaches an end user represents the cumulative effort of multiple organisations. These organisations are referred to collectively as the supply chain The second idea is that while supply chains have existed for a long time, most organisations have only paid attention to what was happening within their ‘four walls’. Few understood, much less managed, the entire chain of activities that ultimately delivered products to the final customer. The result was disjointed and often ineffective supply chains. Supply chain management, then, is the active management of supply chain activities to maximize customer value and achieve a sustainable competitive advantage.

Supply Chain Management (SCM) The concept of Supply Chain Management developed at the same time and alongside Lean. SCM is based on two core ideas: The first is that practically every product that reaches an end user represents the cumulative effort of multiple organisations. These organisations are referred to collectively as the supply chain The second idea is that while supply chains have existed for a long time, most organisations have only paid attention to what was happening within their ‘four walls’. Few understood, much less managed, the entire chain of activities that ultimately delivered products to the final customer. The result was disjointed and often ineffective supply chains. Supply chain management, then, is the active management of supply chain activities to maximize customer value and achieve a sustainable competitive advantage.

Supply Chain Management (SCM) Supply chain activities cover everything from product development, sourcing, production, and logistics, as well as the information systems needed to coordinate these activities. The organisations that make up the supply chain are linked together through physical flows and information flows: Physical flows involve the transformation, movement, and storage of goods and materials. They are the most visible piece of the supply chain. Information flows allow the various supply chain partners to coordinate their long-term plans, and to control the day-to-day flow of goods and material up and down the supply chain.

Supply Chain Management (SCM) Supply chain activities cover everything from product development, sourcing, production, and logistics, as well as the information systems needed to coordinate these activities. The organisations that make up the supply chain are linked together through physical flows and information flows: Physical flows involve the transformation, movement, and storage of goods and materials. They are the most visible piece of the supply chain. Information flows allow the various supply chain partners to coordinate their long-term plans, and to control the day-to-day flow of goods and material up and down the supply chain.

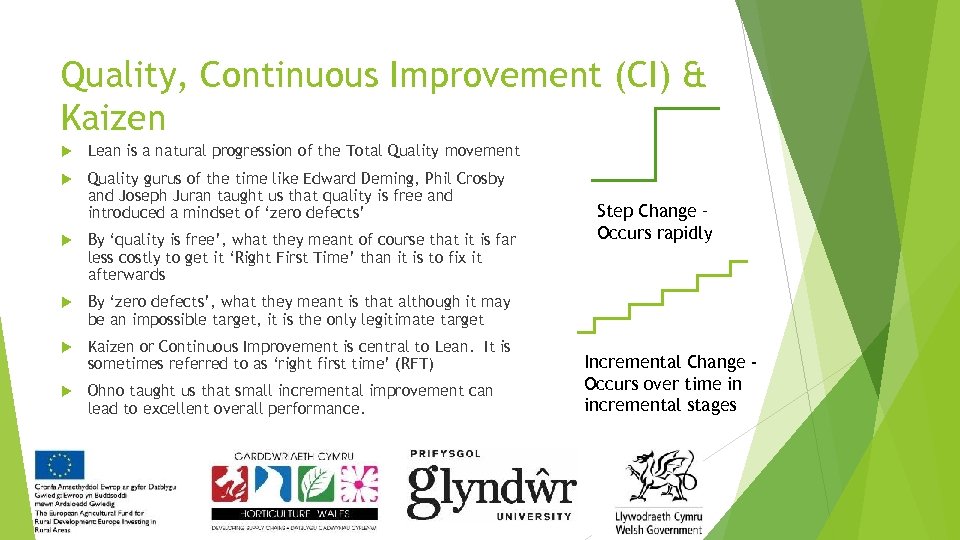

Quality, Continuous Improvement (CI) & Kaizen Lean is a natural progression of the Total Quality movement Quality gurus of the time like Edward Deming, Phil Crosby and Joseph Juran taught us that quality is free and introduced a mindset of ‘zero defects’ By ‘quality is free’, what they meant of course that it is far less costly to get it ‘Right First Time’ than it is to fix it afterwards By ‘zero defects’, what they meant is that although it may be an impossible target, it is the only legitimate target Kaizen or Continuous Improvement is central to Lean. It is sometimes referred to as ‘right first time’ (RFT) Ohno taught us that small incremental improvement can lead to excellent overall performance. Step Change – Occurs rapidly Incremental Change Occurs over time in incremental stages

Quality, Continuous Improvement (CI) & Kaizen Lean is a natural progression of the Total Quality movement Quality gurus of the time like Edward Deming, Phil Crosby and Joseph Juran taught us that quality is free and introduced a mindset of ‘zero defects’ By ‘quality is free’, what they meant of course that it is far less costly to get it ‘Right First Time’ than it is to fix it afterwards By ‘zero defects’, what they meant is that although it may be an impossible target, it is the only legitimate target Kaizen or Continuous Improvement is central to Lean. It is sometimes referred to as ‘right first time’ (RFT) Ohno taught us that small incremental improvement can lead to excellent overall performance. Step Change – Occurs rapidly Incremental Change Occurs over time in incremental stages

Lean Tools & Techniques The purpose of this section is to introduce you to some simple Lean diagnostic and implementation methods

Lean Tools & Techniques The purpose of this section is to introduce you to some simple Lean diagnostic and implementation methods

Lean Tools & Techniques – Index (1) The Kano Model Voice of the Customer (Vo. C) Failsafing (or Poke Yoke) Project Charter Mapping: Value Stream Mapping (VSM) Brown Paper Mapping (BPM) Process Activity Mapping (PAM) Spaghetti Diagram Four Fields Mapping (4 FM) SIPOC (Suppliers, Inputs, Process, Outputs, Customers)

Lean Tools & Techniques – Index (1) The Kano Model Voice of the Customer (Vo. C) Failsafing (or Poke Yoke) Project Charter Mapping: Value Stream Mapping (VSM) Brown Paper Mapping (BPM) Process Activity Mapping (PAM) Spaghetti Diagram Four Fields Mapping (4 FM) SIPOC (Suppliers, Inputs, Process, Outputs, Customers)

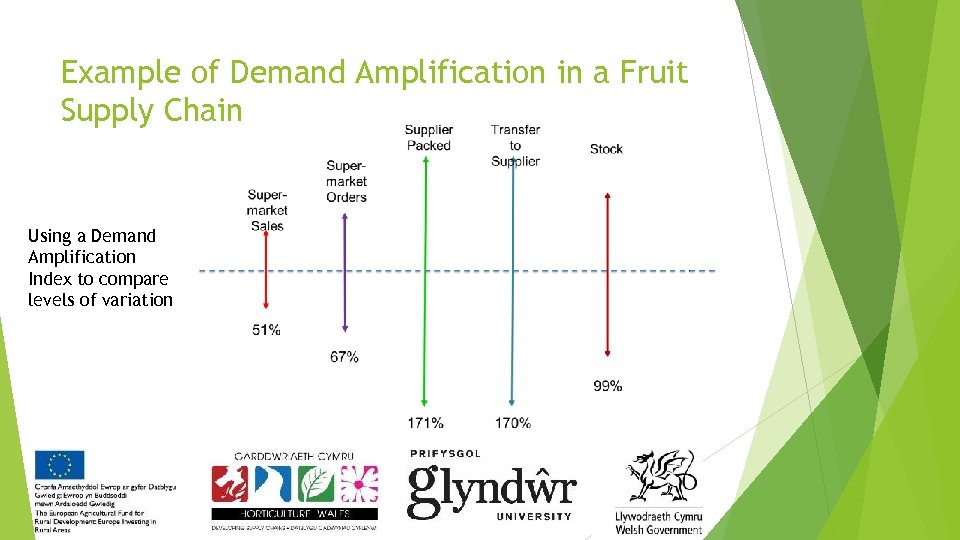

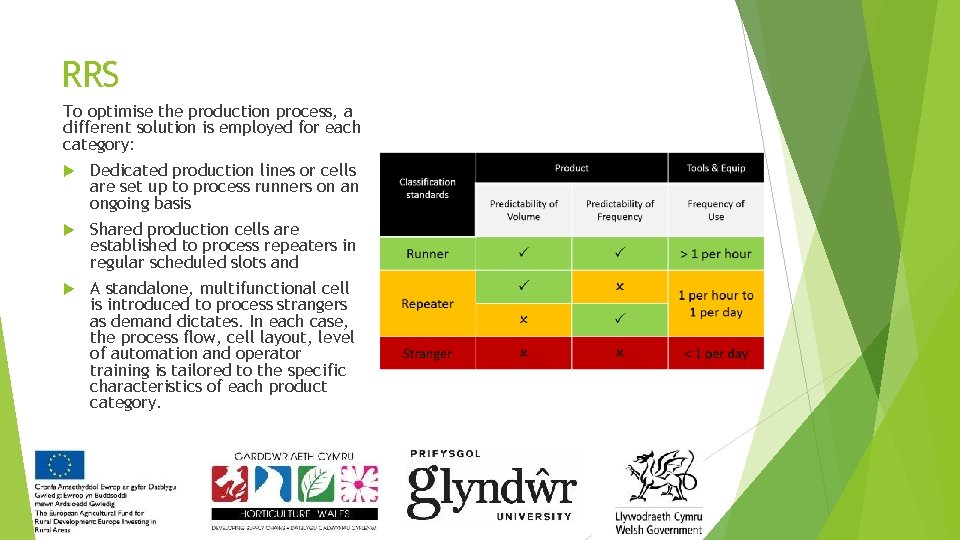

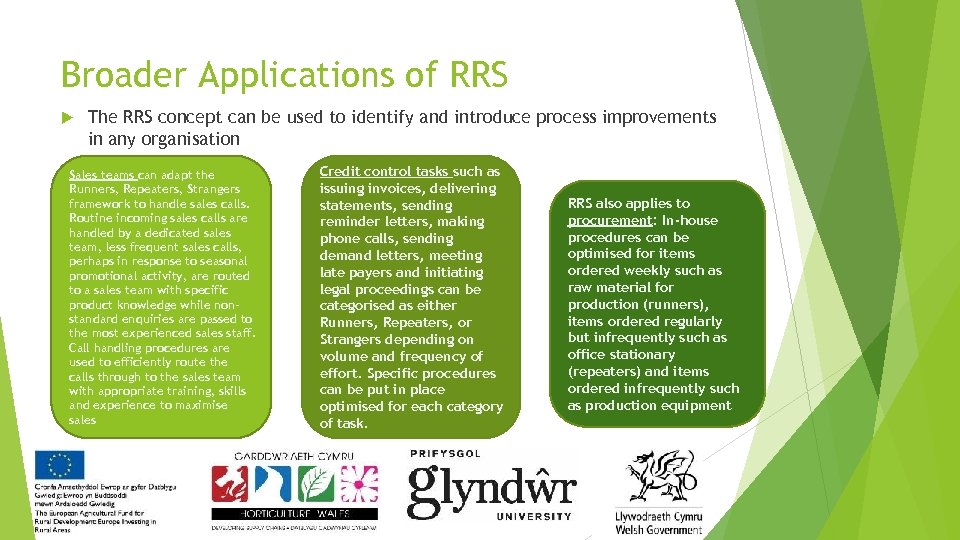

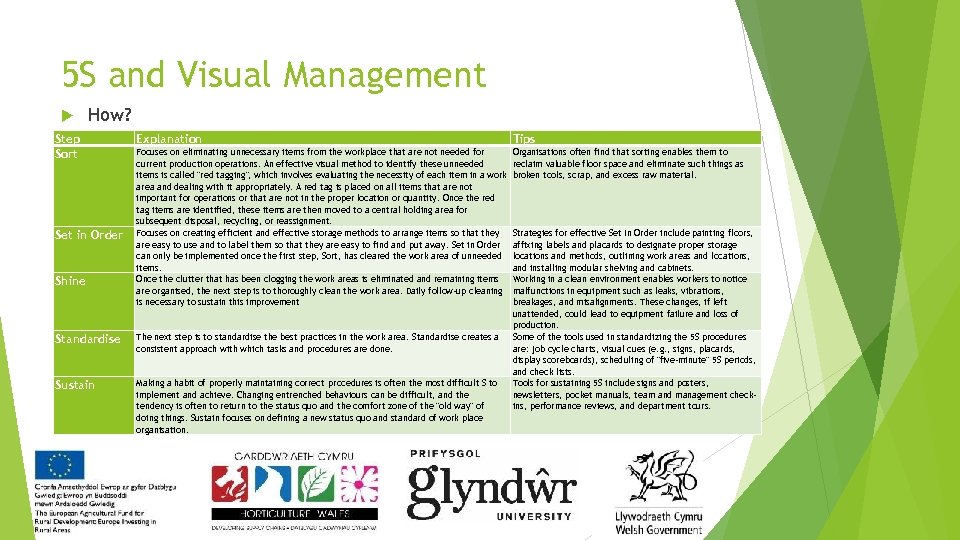

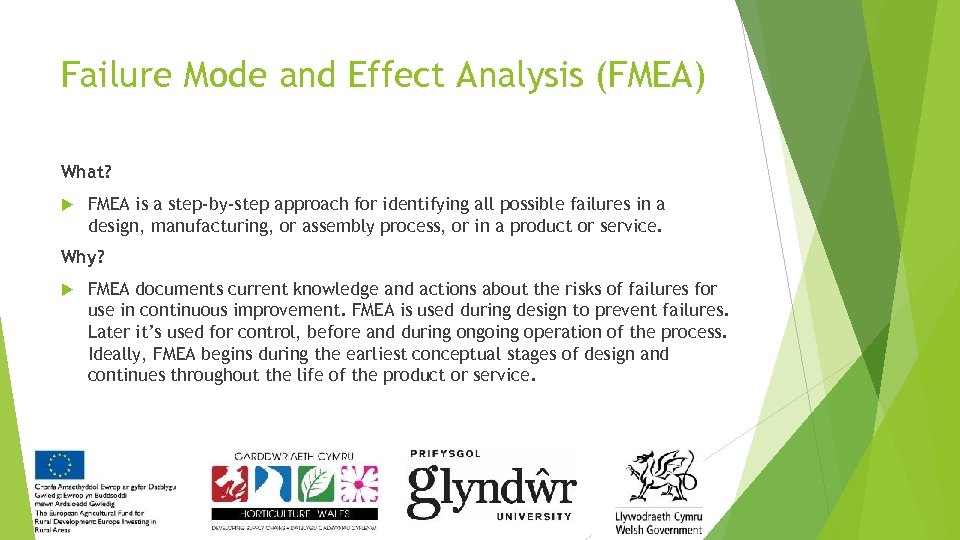

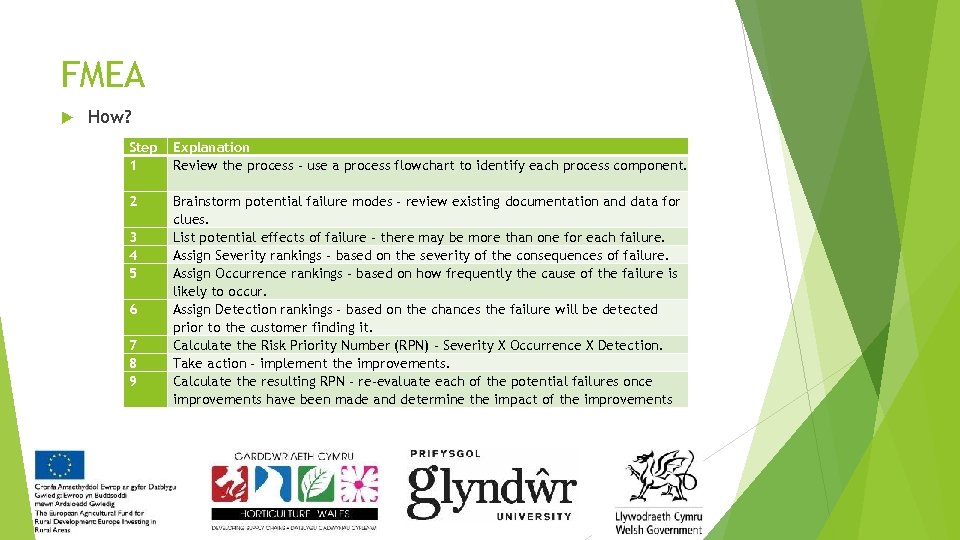

Lean Tools & Techniques – Index (2) Demand Amplification (DA) Runner, Repeater, Stranger (RRS) Problem Solving & PDCA (Plan, Do, Check, Act) Fishbone (Ishikawa) Diagram 5 Whys 5 S and Visual Management Failure Mode and Effect Analysis (FMEA) Quick Changeovers Cellular Layout

Lean Tools & Techniques – Index (2) Demand Amplification (DA) Runner, Repeater, Stranger (RRS) Problem Solving & PDCA (Plan, Do, Check, Act) Fishbone (Ishikawa) Diagram 5 Whys 5 S and Visual Management Failure Mode and Effect Analysis (FMEA) Quick Changeovers Cellular Layout

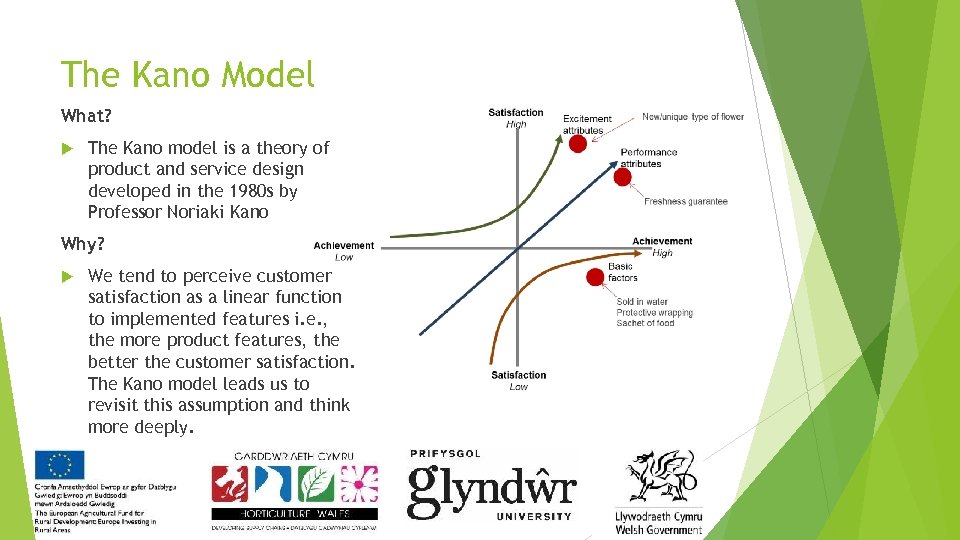

The Kano Model What? The Kano model is a theory of product and service design developed in the 1980 s by Professor Noriaki Kano Why? We tend to perceive customer satisfaction as a linear function to implemented features i. e. , the more product features, the better the customer satisfaction. The Kano model leads us to revisit this assumption and think more deeply.

The Kano Model What? The Kano model is a theory of product and service design developed in the 1980 s by Professor Noriaki Kano Why? We tend to perceive customer satisfaction as a linear function to implemented features i. e. , the more product features, the better the customer satisfaction. The Kano model leads us to revisit this assumption and think more deeply.

The Kano Model How? The Kano model classifies customer requirements into three categories (see right) The Kano Model highlights that these factors are not static – what may be a delighter this year may well be a basic in a few year’s time. What is a delighter in one part of the world may be a basic in another. Category Basic Explanation Must be factors that a customer implicitly expects to be there. If not present the customer will be dissatisfied or even disgusted. Performance More/faster/easier are examples of such ‘better’ factors. Delighter Unexpected factors. Example Clean sheets in a hotel; windscreen washers in a car; a tuner on a radio. Speed of check-in at a hotel; fuel consumption; ease of tuning on a radio. Wine or flowers waiting in a hotel room; silence when closing a car door; a radio that tunes itself.

The Kano Model How? The Kano model classifies customer requirements into three categories (see right) The Kano Model highlights that these factors are not static – what may be a delighter this year may well be a basic in a few year’s time. What is a delighter in one part of the world may be a basic in another. Category Basic Explanation Must be factors that a customer implicitly expects to be there. If not present the customer will be dissatisfied or even disgusted. Performance More/faster/easier are examples of such ‘better’ factors. Delighter Unexpected factors. Example Clean sheets in a hotel; windscreen washers in a car; a tuner on a radio. Speed of check-in at a hotel; fuel consumption; ease of tuning on a radio. Wine or flowers waiting in a hotel room; silence when closing a car door; a radio that tunes itself.

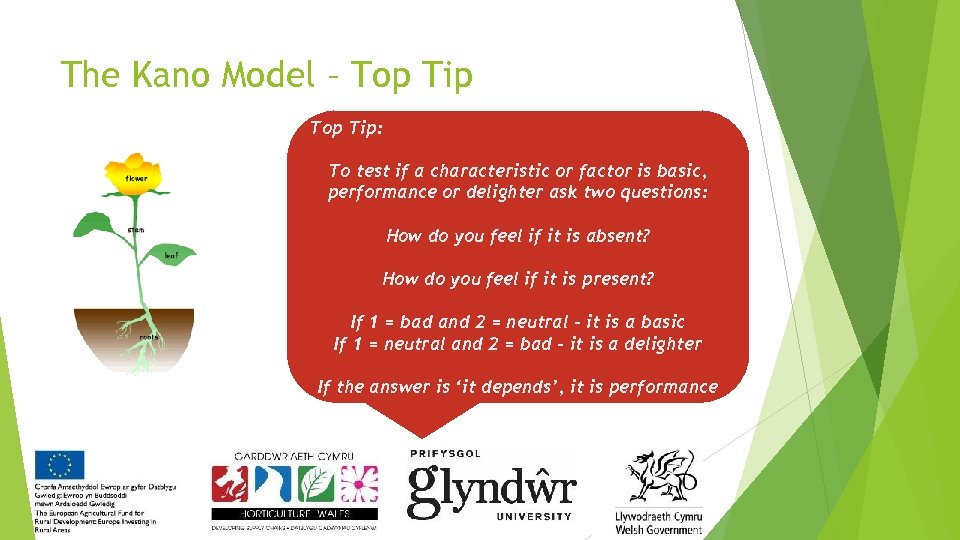

The Kano Model – Top Tip: To test if a characteristic or factor is basic, performance or delighter ask two questions: How do you feel if it is absent? How do you feel if it is present? If 1 = bad and 2 = neutral – it is a basic If 1 = neutral and 2 = bad – it is a delighter If the answer is ‘it depends’, it is performance

The Kano Model – Top Tip: To test if a characteristic or factor is basic, performance or delighter ask two questions: How do you feel if it is absent? How do you feel if it is present? If 1 = bad and 2 = neutral – it is a basic If 1 = neutral and 2 = bad – it is a delighter If the answer is ‘it depends’, it is performance

Voice of the Customer (Vo. C) What? Vo. C tends to be used as a generic term used to identify any means of tapping into customer preferences and expression of value Why? Organisations tend to over-rely on customer satisfaction survey to gauge customer value. While customer surveys are useful, they lack depth and detail. If it is possible it is best to complement the information gathered through more qualitative approaches such as direct observation, interviews, or focus groups How? Talking to customers will yield rich information and insight. The difficulty comes with analysing qualitative data, making overall sense of it. However, if you can use this method to tease out key value criteria, you can then use the Vo. C template to compare yourself to your competitors, your best suppliers and against your own expectations.

Voice of the Customer (Vo. C) What? Vo. C tends to be used as a generic term used to identify any means of tapping into customer preferences and expression of value Why? Organisations tend to over-rely on customer satisfaction survey to gauge customer value. While customer surveys are useful, they lack depth and detail. If it is possible it is best to complement the information gathered through more qualitative approaches such as direct observation, interviews, or focus groups How? Talking to customers will yield rich information and insight. The difficulty comes with analysing qualitative data, making overall sense of it. However, if you can use this method to tease out key value criteria, you can then use the Vo. C template to compare yourself to your competitors, your best suppliers and against your own expectations.

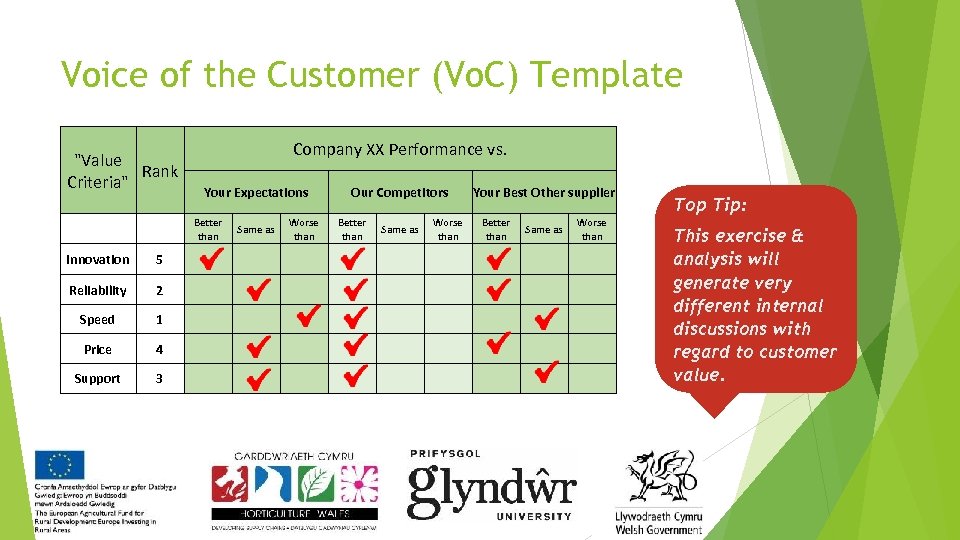

Voice of the Customer (Vo. C) Template "Value Rank Criteria" Company XX Performance vs. Your Expectations Our Competitors Your Best Other supplier Better than Same as Worse than Innovation 5 Reliability 2 Speed 1 Price 4 Support 3 Top Tip: This exercise & analysis will generate very different internal discussions with regard to customer value.

Voice of the Customer (Vo. C) Template "Value Rank Criteria" Company XX Performance vs. Your Expectations Our Competitors Your Best Other supplier Better than Same as Worse than Innovation 5 Reliability 2 Speed 1 Price 4 Support 3 Top Tip: This exercise & analysis will generate very different internal discussions with regard to customer value.

Failsafing (or Poke Yoke) What? A failsafe device is one that literally prevents defects from being made. It undertakes 100% inspection and either stops or gives warning when a defect is discovered Why? It does not rely on the fallibility of human memory or action. A classic example is a three pin plug which only fits one way into a socket – the right way! How? Failsafing should be designed into processes wherever possible.

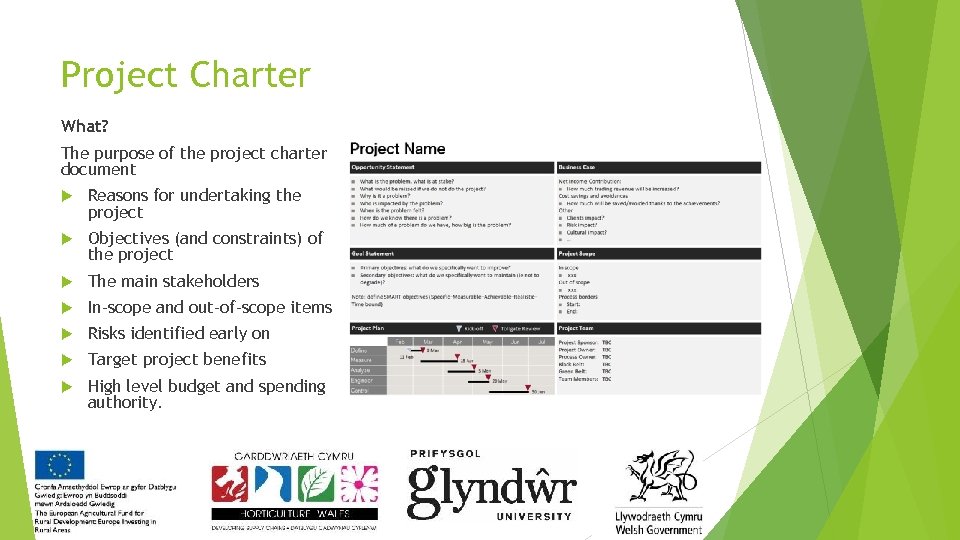

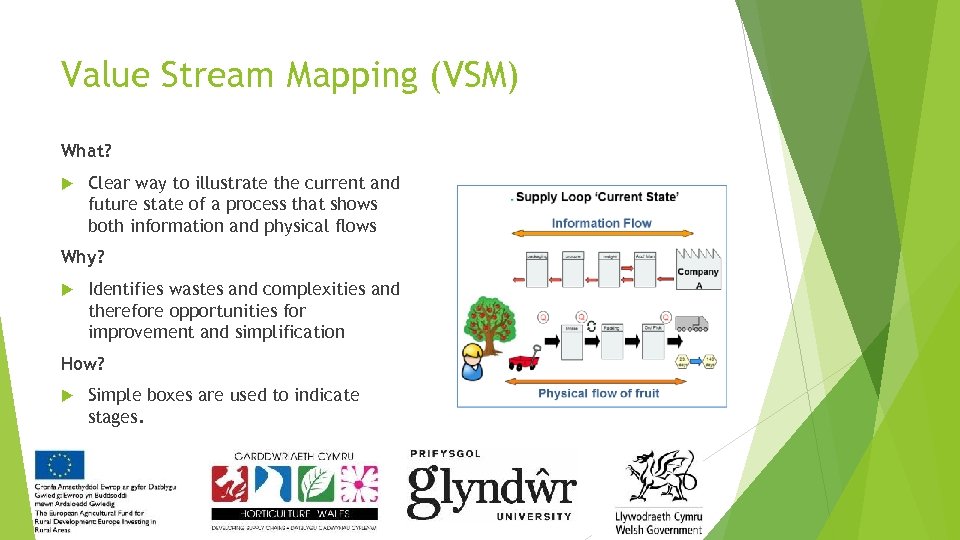

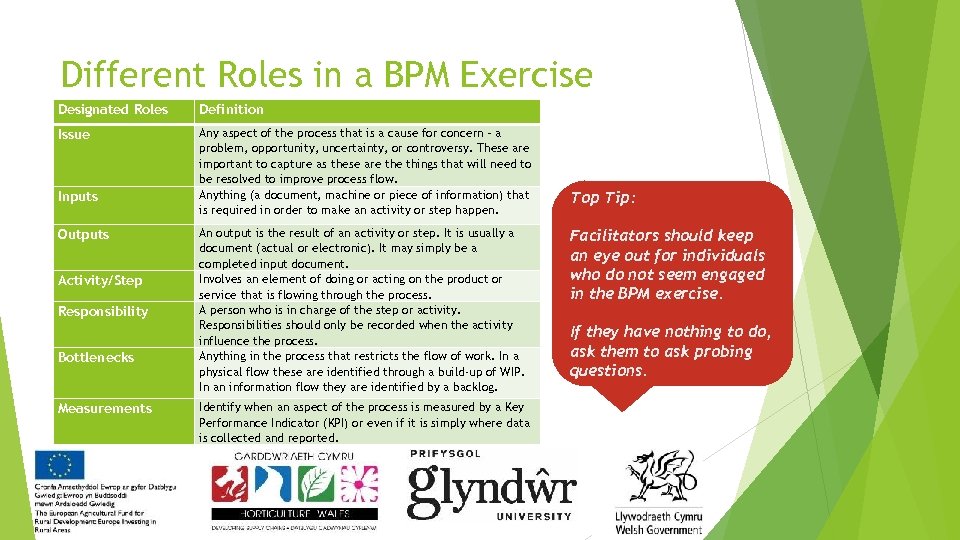

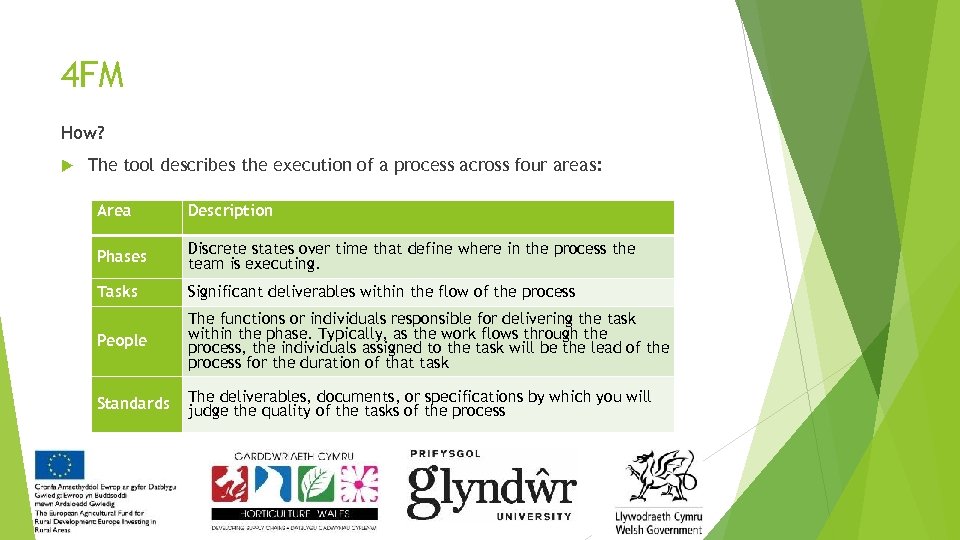

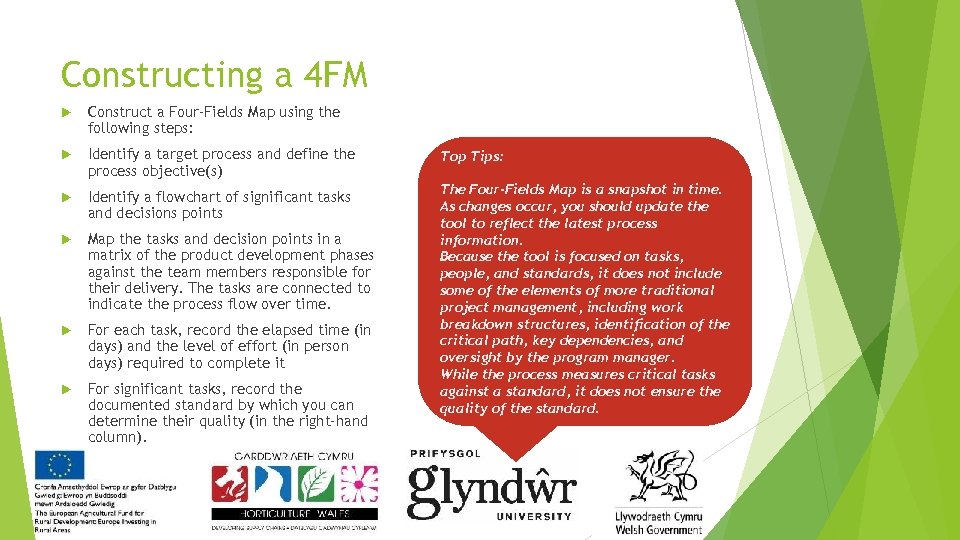

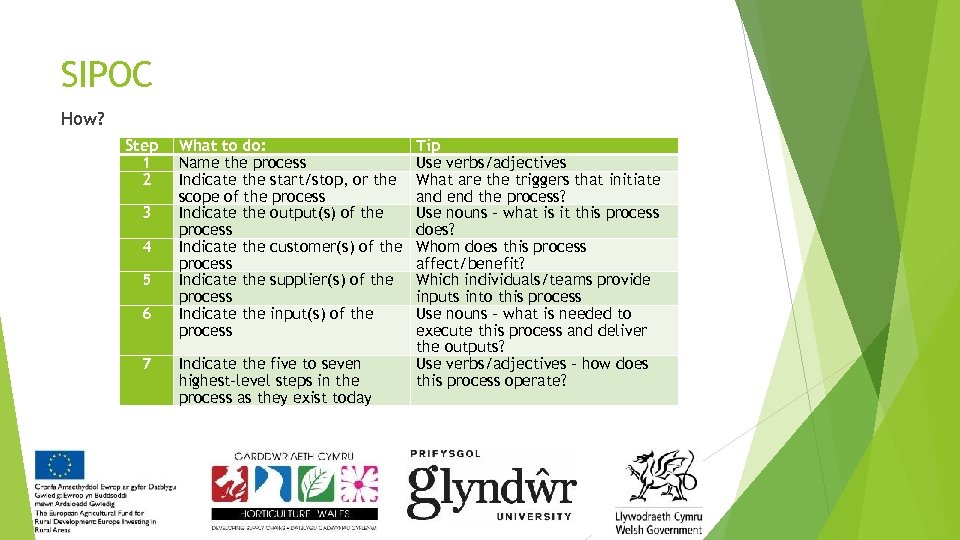

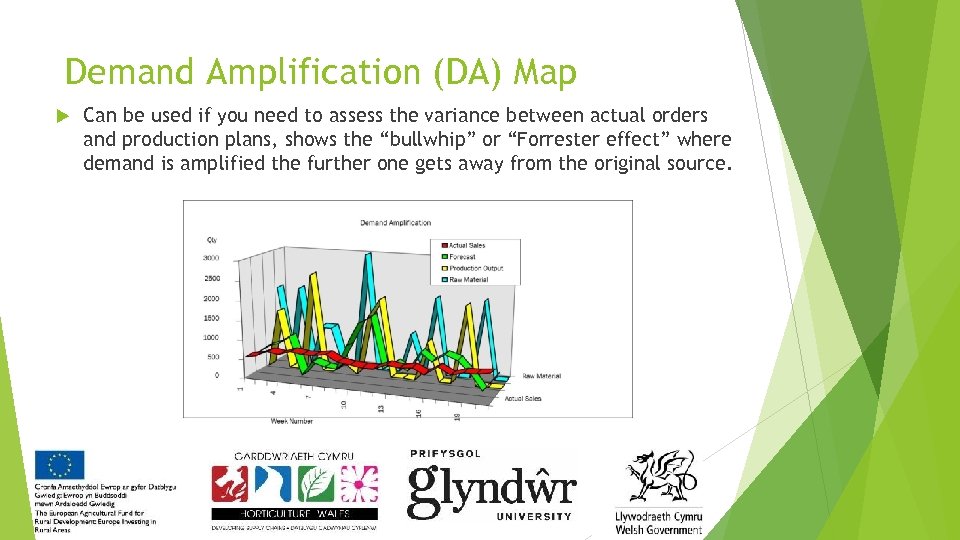

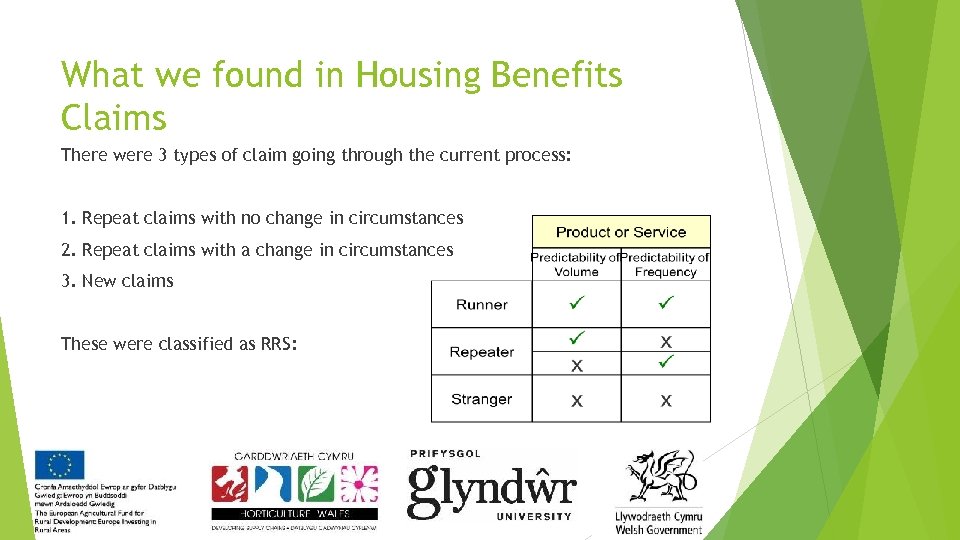

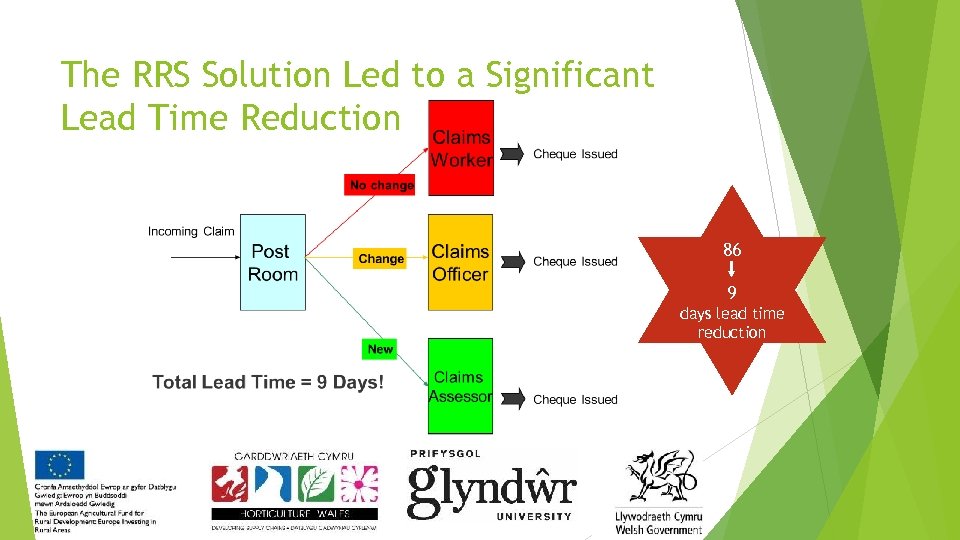

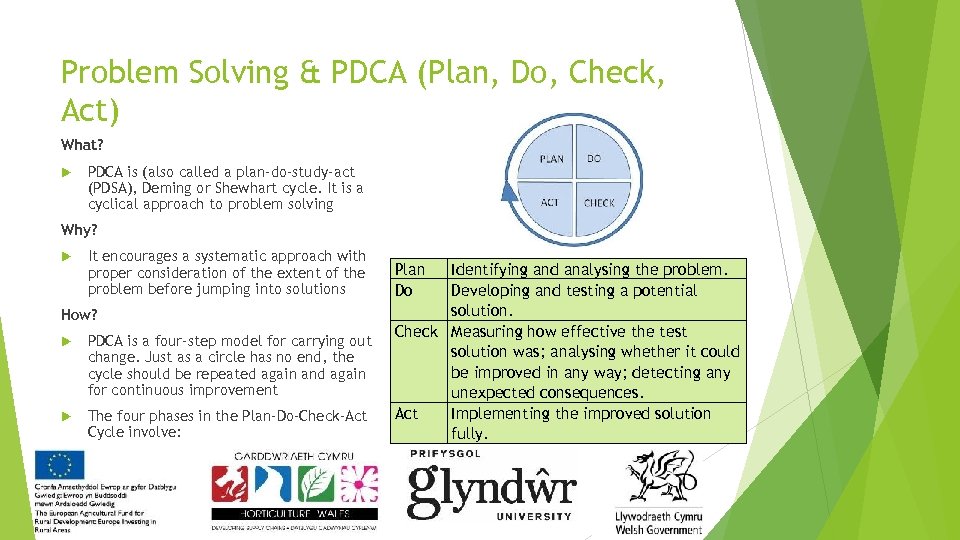

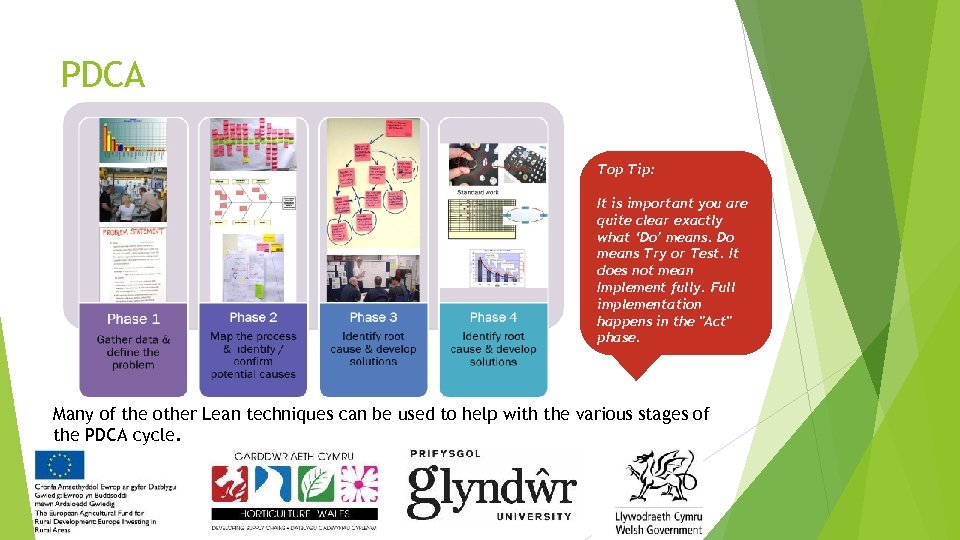

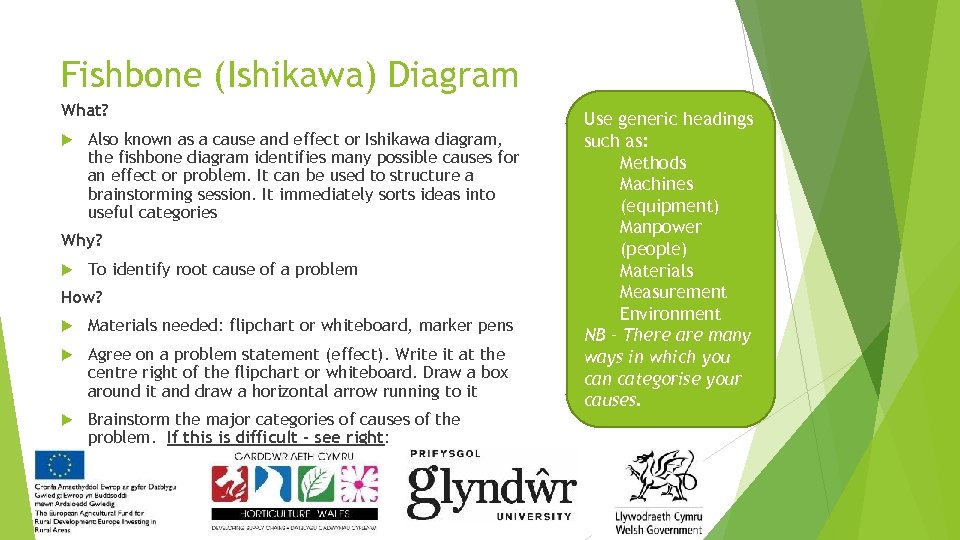

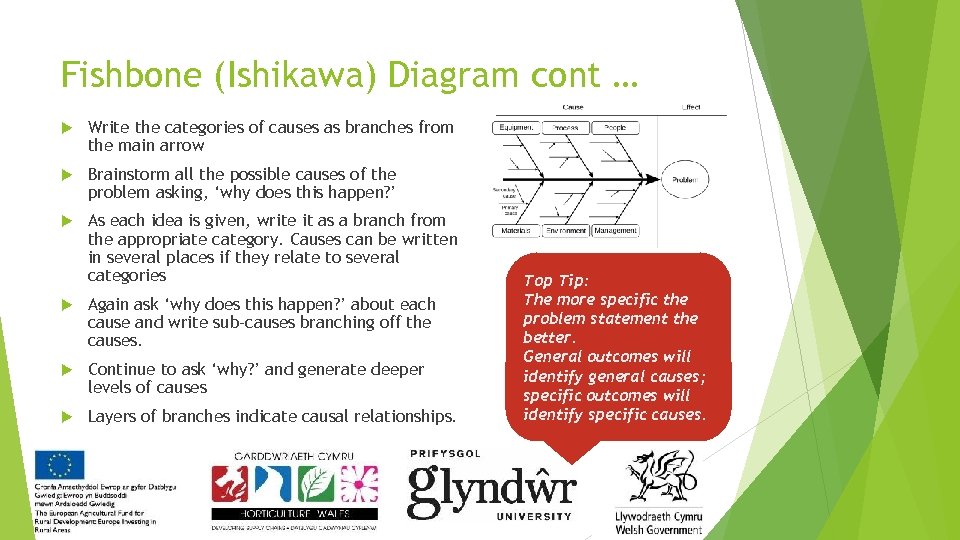

Failsafing (or Poke Yoke) What? A failsafe device is one that literally prevents defects from being made. It undertakes 100% inspection and either stops or gives warning when a defect is discovered Why? It does not rely on the fallibility of human memory or action. A classic example is a three pin plug which only fits one way into a socket – the right way! How? Failsafing should be designed into processes wherever possible.