4fa9c79b30e2aff3fdcaf8b1a5a4b755.ppt

- Количество слайдов: 90

Lean Introduction 6 3/19/2018 © 2010 RLM & Associates LLC 1

Lean Introduction 6 3/19/2018 © 2010 RLM & Associates LLC 1

Seven Wastes Instructor Bios Bruce De. Runtz is a Professor in the Department of Technology at Southern Illinois University. He received his Ph. D. in Workforce Education and Development. Bruce was a Quality Professional in industry working for A. O. Smith Automotive Products, Emerson Electric Company and the Illinois Manufacturing Extension Program. He teaches classes in Manufacturing Processes, Quality, Industrial Metrology, and Project Management. He is a Fellow with the American Society for Quality and holds certifications for Six Sigma Black Belt and Quality Engineer. 3/19/2018 © 2010 RLM & Associates LLC 2

Seven Wastes Instructor Bios Bruce De. Runtz is a Professor in the Department of Technology at Southern Illinois University. He received his Ph. D. in Workforce Education and Development. Bruce was a Quality Professional in industry working for A. O. Smith Automotive Products, Emerson Electric Company and the Illinois Manufacturing Extension Program. He teaches classes in Manufacturing Processes, Quality, Industrial Metrology, and Project Management. He is a Fellow with the American Society for Quality and holds certifications for Six Sigma Black Belt and Quality Engineer. 3/19/2018 © 2010 RLM & Associates LLC 2

Seven Wastes Instructor Bios Sam Hoskins comes from the manufacturing sector and has extensive hands-on experience in Lean principles as well as Mistake-Proofing. He spent 12 years as a manufacturing quality engineer and quality manager for an international commercial explosives manufacturer. Sam is a certified Mistake-Proofing trainer and facilitator. He authored the Mistake-Proofing portion of the Ensign-Bickford Company’s successful application for the 2002 Shingo Prize for Excellence in Manufacturing. He has led dozens of successful Mistake-Proofing events which resulted in large gains in quality, productivity, and safety. Sam is an American Society for Quality certified Lean/Six Sigma Black Belt. 3/19/2018 © 2010 RLM & Associates LLC 3

Seven Wastes Instructor Bios Sam Hoskins comes from the manufacturing sector and has extensive hands-on experience in Lean principles as well as Mistake-Proofing. He spent 12 years as a manufacturing quality engineer and quality manager for an international commercial explosives manufacturer. Sam is a certified Mistake-Proofing trainer and facilitator. He authored the Mistake-Proofing portion of the Ensign-Bickford Company’s successful application for the 2002 Shingo Prize for Excellence in Manufacturing. He has led dozens of successful Mistake-Proofing events which resulted in large gains in quality, productivity, and safety. Sam is an American Society for Quality certified Lean/Six Sigma Black Belt. 3/19/2018 © 2010 RLM & Associates LLC 3

Seven Wastes Instructor Bios Ron Meier has held faculty positions at Iowa State University and Illinois State University. He teaches Master's Degree level courses in project and quality management. During the 1980’s and 90’s he managed projects for IBM Global Business Services, Microsoft, and XL Capital Insurance. Ron is an American Society for Quality Certified Manager of Quality/ Organizational Excellence (CMQ/OE) and Project Management Institute Program Management Professional (Pg. MP). 3/19/2018 © 2010 RLM & Associates LLC 4

Seven Wastes Instructor Bios Ron Meier has held faculty positions at Iowa State University and Illinois State University. He teaches Master's Degree level courses in project and quality management. During the 1980’s and 90’s he managed projects for IBM Global Business Services, Microsoft, and XL Capital Insurance. Ron is an American Society for Quality Certified Manager of Quality/ Organizational Excellence (CMQ/OE) and Project Management Institute Program Management Professional (Pg. MP). 3/19/2018 © 2010 RLM & Associates LLC 4

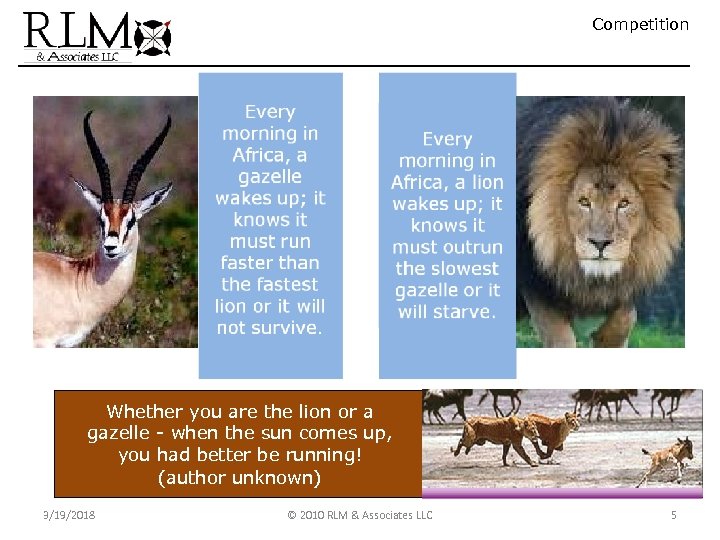

Competition Whether you are the lion or a gazelle - when the sun comes up, you had better be running! (author unknown) 3/19/2018 © 2010 RLM & Associates LLC 5

Competition Whether you are the lion or a gazelle - when the sun comes up, you had better be running! (author unknown) 3/19/2018 © 2010 RLM & Associates LLC 5

LSS Company Stock Performance Research 52 Publicly Traded Organizations with Company-Wide 6 Deployments Source: Proficiency Systems Research 3/19/2018 © 2009 RLM & Associates LLC 6

LSS Company Stock Performance Research 52 Publicly Traded Organizations with Company-Wide 6 Deployments Source: Proficiency Systems Research 3/19/2018 © 2009 RLM & Associates LLC 6

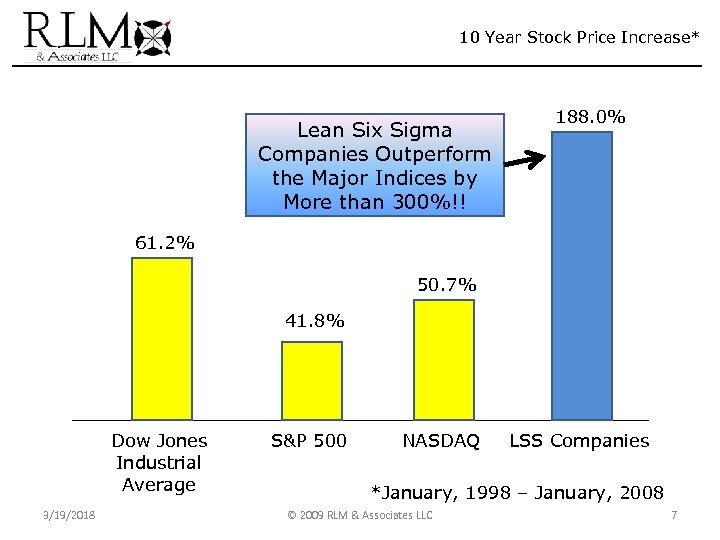

10 Year Stock Price Increase* Lean Six Sigma Companies Outperform the Major Indices by More than 300%!! 188. 0% 61. 2% 50. 7% 41. 8% Dow Jones Industrial Average 3/19/2018 S&P 500 NASDAQ LSS Companies *January, 1998 – January, 2008 © 2009 RLM & Associates LLC 7

10 Year Stock Price Increase* Lean Six Sigma Companies Outperform the Major Indices by More than 300%!! 188. 0% 61. 2% 50. 7% 41. 8% Dow Jones Industrial Average 3/19/2018 S&P 500 NASDAQ LSS Companies *January, 1998 – January, 2008 © 2009 RLM & Associates LLC 7

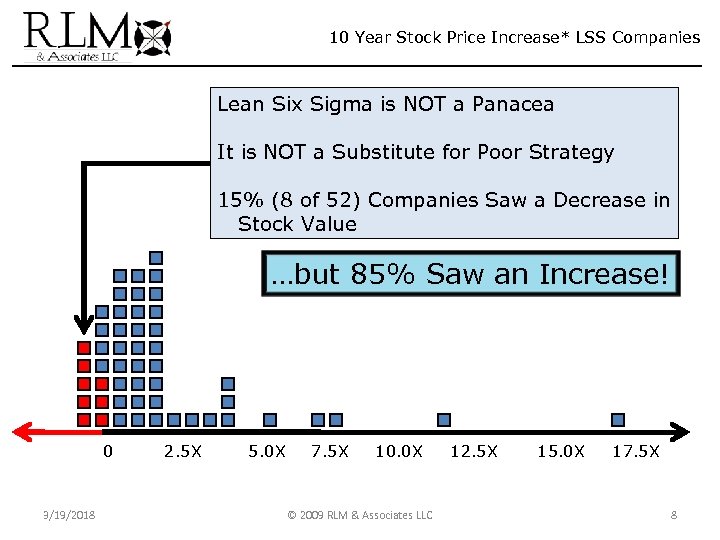

10 Year Stock Price Increase* LSS Companies Lean Six Sigma is NOT a Panacea It is NOT a Substitute for Poor Strategy 15% (8 of 52) Companies Saw a Decrease in Stock Value …but 85% Saw an Increase! 0 3/19/2018 2. 5 X 5. 0 X 7. 5 X 10. 0 X © 2009 RLM & Associates LLC 12. 5 X 15. 0 X 17. 5 X 8

10 Year Stock Price Increase* LSS Companies Lean Six Sigma is NOT a Panacea It is NOT a Substitute for Poor Strategy 15% (8 of 52) Companies Saw a Decrease in Stock Value …but 85% Saw an Increase! 0 3/19/2018 2. 5 X 5. 0 X 7. 5 X 10. 0 X © 2009 RLM & Associates LLC 12. 5 X 15. 0 X 17. 5 X 8

Course Overview Course Purpose: These materials have been developed specifically to create an understanding of the impact of a Lean Six Sigma initiative as a Business Process Improvement program. The Goal of this Training is to: a) Enhance your understanding of Lean Six Sigma techniques as a tool of continuous improvement. b) Provide self-awareness of the impact you can have on your organizations continuous improvement efforts c) Increase your understanding of the role you play in the success of this Lean Six Sigma initiative. Participant Expectations: After successful completion of this course you will be able to assist your organization in their continuous improvement efforts by applying your analytical and problem solving skills to enhance organizational efficiencies and effectiveness. 3/19/2018 © 2010 RLM & Associates LLC 9

Course Overview Course Purpose: These materials have been developed specifically to create an understanding of the impact of a Lean Six Sigma initiative as a Business Process Improvement program. The Goal of this Training is to: a) Enhance your understanding of Lean Six Sigma techniques as a tool of continuous improvement. b) Provide self-awareness of the impact you can have on your organizations continuous improvement efforts c) Increase your understanding of the role you play in the success of this Lean Six Sigma initiative. Participant Expectations: After successful completion of this course you will be able to assist your organization in their continuous improvement efforts by applying your analytical and problem solving skills to enhance organizational efficiencies and effectiveness. 3/19/2018 © 2010 RLM & Associates LLC 9

Course Objectives 1. Obtain an understanding of and be able to work within a Lean Six Sigma culture 2. Realize daily work is a systematic process-oriented activity 3. Understand the relationships between business functions and processes 4. Implement control mechanisms and monitoring processes to maintain existing processes. 5. Get ready to implement Lean Six Sigma 3/19/2018 © 2010 RLM & Associates LLC 10

Course Objectives 1. Obtain an understanding of and be able to work within a Lean Six Sigma culture 2. Realize daily work is a systematic process-oriented activity 3. Understand the relationships between business functions and processes 4. Implement control mechanisms and monitoring processes to maintain existing processes. 5. Get ready to implement Lean Six Sigma 3/19/2018 © 2010 RLM & Associates LLC 10

Defining Lean Six Sigma What is Lean Six Sigma? Lean: eliminates WASTE while improving process flow to achieve speed and agility at lower cost Six Sigma: eliminates DEFECTS and VARIATION Lean Six Sigma: is an approach to IMPROVE the PERFORMANCE of your organization 3/19/2018 © 2010 RLM & Associates LLC 11

Defining Lean Six Sigma What is Lean Six Sigma? Lean: eliminates WASTE while improving process flow to achieve speed and agility at lower cost Six Sigma: eliminates DEFECTS and VARIATION Lean Six Sigma: is an approach to IMPROVE the PERFORMANCE of your organization 3/19/2018 © 2010 RLM & Associates LLC 11

Status of Lean Six Sigma Deployment Lean & Six Sigma in the Food Production Industry Why Lean/Six Sigma are not being implemented 1) Organizations claim to not have the time, money, or the labor resources 2) Education – lack awareness of the benefits 3) Lack of baselines and poor measurement systems Food. Processing. com 2009 3/19/2018 © 2010 RLM & Associates LLC 12

Status of Lean Six Sigma Deployment Lean & Six Sigma in the Food Production Industry Why Lean/Six Sigma are not being implemented 1) Organizations claim to not have the time, money, or the labor resources 2) Education – lack awareness of the benefits 3) Lack of baselines and poor measurement systems Food. Processing. com 2009 3/19/2018 © 2010 RLM & Associates LLC 12

Status of Lean Six Sigma Deployment Survey on Consumer and Industrial Products Practice 45% of Food Processing organizations were employing some Lean thinking and practices 10% were using Six Sigma Grant Thorton LLP 2009 3/19/2018 © 2010 RLM & Associates LLC 13

Status of Lean Six Sigma Deployment Survey on Consumer and Industrial Products Practice 45% of Food Processing organizations were employing some Lean thinking and practices 10% were using Six Sigma Grant Thorton LLP 2009 3/19/2018 © 2010 RLM & Associates LLC 13

Status of Lean Six Sigma Deployment Survey on Consumer and Industrial Products Practice For many food processing organizations 70% of their costs are in raw materials and other direct costs. That leaves only 30% you can control. Areas to target include: 1. Freight 2. Information Technologies 3. Procurement 4. Contractual Maintenance 3/19/2018 © 2010 RLM & Associates LLC Grant Thorton LLP 2009 14

Status of Lean Six Sigma Deployment Survey on Consumer and Industrial Products Practice For many food processing organizations 70% of their costs are in raw materials and other direct costs. That leaves only 30% you can control. Areas to target include: 1. Freight 2. Information Technologies 3. Procurement 4. Contractual Maintenance 3/19/2018 © 2010 RLM & Associates LLC Grant Thorton LLP 2009 14

Status of Lean Six Sigma Deployment FDA & USDA Regulatory Issues 5 S can be used as a tool to maintain cleanliness and order – which meshes well with the food industry’s regulatory focus on preventing contamination 5 S embodies organization and visualization tools therefore empowering employees to self-manage their working environment Are You Playing the Lean Game? www. foodmanufacturing. com 3/19/2018 © 2010 RLM & Associates LLC 15

Status of Lean Six Sigma Deployment FDA & USDA Regulatory Issues 5 S can be used as a tool to maintain cleanliness and order – which meshes well with the food industry’s regulatory focus on preventing contamination 5 S embodies organization and visualization tools therefore empowering employees to self-manage their working environment Are You Playing the Lean Game? www. foodmanufacturing. com 3/19/2018 © 2010 RLM & Associates LLC 15

Status of Lean Six Sigma Deployment Continuous Improvement Opportunities The Food industry is facing an explosion of product variation, serious food safety concerns, and increasing raw materials and transportations costs Lean is a tool to help organizations cut costs Are You Playing the Lean Game? www. foodmanufacturing. com 3/19/2018 © 2010 RLM & Associates LLC 16

Status of Lean Six Sigma Deployment Continuous Improvement Opportunities The Food industry is facing an explosion of product variation, serious food safety concerns, and increasing raw materials and transportations costs Lean is a tool to help organizations cut costs Are You Playing the Lean Game? www. foodmanufacturing. com 3/19/2018 © 2010 RLM & Associates LLC 16

Team Work Lean and Six Sigma are not something extra to add to your daily roles and responsibilities! Lean and Six Sigma ARE your daily responsibility. 3/19/2018 © 2010 RLM & Associates LLC 17

Team Work Lean and Six Sigma are not something extra to add to your daily roles and responsibilities! Lean and Six Sigma ARE your daily responsibility. 3/19/2018 © 2010 RLM & Associates LLC 17

The Goals of the Lean Enterprise 3/19/2018 © 2010 RLM & Associates LLC 18

The Goals of the Lean Enterprise 3/19/2018 © 2010 RLM & Associates LLC 18

Team Work - Process improvement efforts are undertaken by teams of people. Below is a list of benefits to utilizing teams: 1. Learning opportunity for employees 2. Sharing of the workload 3. Broader range of input relative to the process 4. Buy-in by all those impacted 5. Increased employee satisfaction 3/19/2018 © 2010 RLM & Associates LLC 19

Team Work - Process improvement efforts are undertaken by teams of people. Below is a list of benefits to utilizing teams: 1. Learning opportunity for employees 2. Sharing of the workload 3. Broader range of input relative to the process 4. Buy-in by all those impacted 5. Increased employee satisfaction 3/19/2018 © 2010 RLM & Associates LLC 19

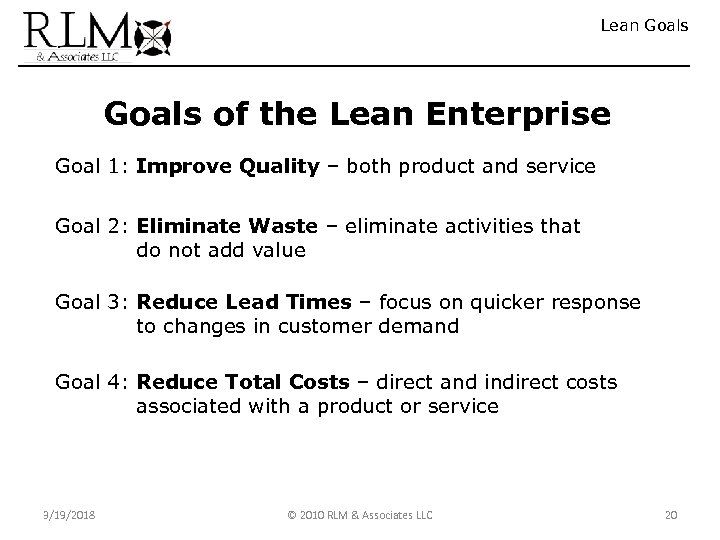

Lean Goals of the Lean Enterprise Goal 1: Improve Quality – both product and service Goal 2: Eliminate Waste – eliminate activities that do not add value Goal 3: Reduce Lead Times – focus on quicker response to changes in customer demand Goal 4: Reduce Total Costs – direct and indirect costs associated with a product or service 3/19/2018 © 2010 RLM & Associates LLC 20

Lean Goals of the Lean Enterprise Goal 1: Improve Quality – both product and service Goal 2: Eliminate Waste – eliminate activities that do not add value Goal 3: Reduce Lead Times – focus on quicker response to changes in customer demand Goal 4: Reduce Total Costs – direct and indirect costs associated with a product or service 3/19/2018 © 2010 RLM & Associates LLC 20

Lean Goals How to Achieve Improved Quality 1. Document customer expectations and requirements 2. Review characteristics of service or product design to verify that they meet the customers’ requirements 3. Review your process metrics to verify capability to meet customers’ requirements 4. Identify processes where errors can create defects 5. Conduct problem solving activities to identify root causes 6. Apply error proofing techniques to prevent defects 7. Establish performance metrics to evaluate effectiveness 3/19/2018 © 2010 RLM & Associates LLC 21

Lean Goals How to Achieve Improved Quality 1. Document customer expectations and requirements 2. Review characteristics of service or product design to verify that they meet the customers’ requirements 3. Review your process metrics to verify capability to meet customers’ requirements 4. Identify processes where errors can create defects 5. Conduct problem solving activities to identify root causes 6. Apply error proofing techniques to prevent defects 7. Establish performance metrics to evaluate effectiveness 3/19/2018 © 2010 RLM & Associates LLC 21

Lean Goals How to Eliminate Wastes 1. Identify a product or service that is inefficient 2. Identify associated processes that perform poorly – start with an operation that has the lowest production output 3. Create a Value Stream Map (VSM) 4. Review the VSM and identify wastes 5. Determine metrics for identifying the frequency and severity of the wastes 6. Periodically review the metrics to continue eliminating wastes 3/19/2018 © 2010 RLM & Associates LLC 22

Lean Goals How to Eliminate Wastes 1. Identify a product or service that is inefficient 2. Identify associated processes that perform poorly – start with an operation that has the lowest production output 3. Create a Value Stream Map (VSM) 4. Review the VSM and identify wastes 5. Determine metrics for identifying the frequency and severity of the wastes 6. Periodically review the metrics to continue eliminating wastes 3/19/2018 © 2010 RLM & Associates LLC 22

Lean Goals How to Reduce Lead Times 1. Create a Value Stream Map (VSM) 2. Calculate the times required for the value-added steps 3. Review the VSM to identify where you can reduce lead times 4. Identify the constraints in the process and develop a plan to eliminate them or mitigate them 5. Determine metrics to identify the location, duration and frequency of the lead times within the process 6. Once the plan is implemented measure and document the improvements 3/19/2018 © 2010 RLM & Associates LLC 23

Lean Goals How to Reduce Lead Times 1. Create a Value Stream Map (VSM) 2. Calculate the times required for the value-added steps 3. Review the VSM to identify where you can reduce lead times 4. Identify the constraints in the process and develop a plan to eliminate them or mitigate them 5. Determine metrics to identify the location, duration and frequency of the lead times within the process 6. Once the plan is implemented measure and document the improvements 3/19/2018 © 2010 RLM & Associates LLC 23

Lean Goals How to Reduce Total Costs 1. Determine if improvement efforts will start with new or existing production lines 2. If the focus is on new products use target pricing, target costing and value engineering 3. If the focus is on existing products – identify the high cost products and apply Kaizen costing and cost maintenance 4. Identify the constraints in the process and develop a plan to eliminate them or mitigate them 3/19/2018 © 2010 RLM & Associates LLC 24

Lean Goals How to Reduce Total Costs 1. Determine if improvement efforts will start with new or existing production lines 2. If the focus is on new products use target pricing, target costing and value engineering 3. If the focus is on existing products – identify the high cost products and apply Kaizen costing and cost maintenance 4. Identify the constraints in the process and develop a plan to eliminate them or mitigate them 3/19/2018 © 2010 RLM & Associates LLC 24

Food Processing Obstacles Organizational Obstacles to Adopting Lean 1. Lack of persistent and challenging leadership 2. Lack of a clear vision of the future and what can be achieved 3. Failure to link Kaizen processes to everyone’s formal work 4. Lack of patience and follow through 5. Failure to perceive LEAN as a viable strategy for competitive advantage 6. Failure to engage and involve employees at an early stage 7. Lack of constant visibility by management on the shop floor 8. CULTURE Author: Brian Heymans Lean Manufacturing and the Food Industry “Continuous Systems Improvement” 2009. 3/19/2018 © 2010 RLM & Associates LLC 25

Food Processing Obstacles Organizational Obstacles to Adopting Lean 1. Lack of persistent and challenging leadership 2. Lack of a clear vision of the future and what can be achieved 3. Failure to link Kaizen processes to everyone’s formal work 4. Lack of patience and follow through 5. Failure to perceive LEAN as a viable strategy for competitive advantage 6. Failure to engage and involve employees at an early stage 7. Lack of constant visibility by management on the shop floor 8. CULTURE Author: Brian Heymans Lean Manufacturing and the Food Industry “Continuous Systems Improvement” 2009. 3/19/2018 © 2010 RLM & Associates LLC 25

Food Processing Specific Obstacles Marketplace Obstacles to Adopting Lean 1. Extraordinary long procurement lead times – agricultural products long growing seasons and maturing cycles – not uncommon for procurement cycles to be over a year (dairy, coffee, cocoa, wheat, corn products, soybean and vegetable oils, nuts, meat products, and sugar and other sweeteners) 2. Short shelf life 3. Production lead times are very short Author: Brian Heymans Lean Manufacturing and the Food Industry “Continuous Systems Improvement” 2009. 3/19/2018 © 2010 RLM & Associates LLC 26

Food Processing Specific Obstacles Marketplace Obstacles to Adopting Lean 1. Extraordinary long procurement lead times – agricultural products long growing seasons and maturing cycles – not uncommon for procurement cycles to be over a year (dairy, coffee, cocoa, wheat, corn products, soybean and vegetable oils, nuts, meat products, and sugar and other sweeteners) 2. Short shelf life 3. Production lead times are very short Author: Brian Heymans Lean Manufacturing and the Food Industry “Continuous Systems Improvement” 2009. 3/19/2018 © 2010 RLM & Associates LLC 26

Cost of Poor Quality 3/19/2018 © 2010 RLM & Associates LLC 27

Cost of Poor Quality 3/19/2018 © 2010 RLM & Associates LLC 27

What is Quality? What is Quality – Historical Definition? Quality: has two meanings: 1. the characteristics of a product or service that bear on its ability to satisfy stated or implied needs; 2. a product or service free of deficiencies. http: //www. asq. org/glossary/q. htm According to Juran, quality means “fitness for use; ” According to Crosby, it means “conformance to requirements. ” 3/19/2018 © 2010 RLM & Associates LLC 28

What is Quality? What is Quality – Historical Definition? Quality: has two meanings: 1. the characteristics of a product or service that bear on its ability to satisfy stated or implied needs; 2. a product or service free of deficiencies. http: //www. asq. org/glossary/q. htm According to Juran, quality means “fitness for use; ” According to Crosby, it means “conformance to requirements. ” 3/19/2018 © 2010 RLM & Associates LLC 28

What is Quality? What is Quality in 2010? Quality is defined in terms of first pass yields – or in other words the efficiency in which a product comes down the production line. The question is no longer whether the product shipped to the customer will be good but rather, what is the cost of attaining first pass yields of greater than 90% without inspection. Six Sigma and Leadership. Columbia Business School 2009 3/19/2018 © 2010 RLM & Associates LLC 29

What is Quality? What is Quality in 2010? Quality is defined in terms of first pass yields – or in other words the efficiency in which a product comes down the production line. The question is no longer whether the product shipped to the customer will be good but rather, what is the cost of attaining first pass yields of greater than 90% without inspection. Six Sigma and Leadership. Columbia Business School 2009 3/19/2018 © 2010 RLM & Associates LLC 29

Definition of COPQ Cost Of Poor Quality Ø COPQ consists of those costs which are generated as a result of producing defective material Ø This cost includes the cost involved in fulfilling the gap between the desired and actual product/service quality. It also includes the cost of lost opportunity due to the loss of resources used in rectifying the defect Ø This cost includes all the labor cost, rework cost, disposition costs, and material costs that have been added to the unit up to the point of rejection Ø COPQ does not include detection and prevention cost http: //www. isixsigma. com/dictionary 3/19/2018 © 2010 RLM & Associates LLC 30

Definition of COPQ Cost Of Poor Quality Ø COPQ consists of those costs which are generated as a result of producing defective material Ø This cost includes the cost involved in fulfilling the gap between the desired and actual product/service quality. It also includes the cost of lost opportunity due to the loss of resources used in rectifying the defect Ø This cost includes all the labor cost, rework cost, disposition costs, and material costs that have been added to the unit up to the point of rejection Ø COPQ does not include detection and prevention cost http: //www. isixsigma. com/dictionary 3/19/2018 © 2010 RLM & Associates LLC 30

Definition of COPQ Cost Of Poor Quality The Cost of Quality category codes are the following: 1. Prevention Costs (P) 2. Appraisal Costs (A) 3. Internal Error Costs (I) 4. External Error Costs (E) 3/19/2018 © 2010 RLM & Associates LLC 31

Definition of COPQ Cost Of Poor Quality The Cost of Quality category codes are the following: 1. Prevention Costs (P) 2. Appraisal Costs (A) 3. Internal Error Costs (I) 4. External Error Costs (E) 3/19/2018 © 2010 RLM & Associates LLC 31

Definition of COPQ Cost Of Poor Quality Prevention costs are investments made ahead of time in an effort to ensure conformance to requirements. Examples: New product review, Quality planning, Supplier capability surveys, Process capability evaluations, Quality improvement team meetings, Quality improvement project, Quality education and training Appraisal costs are costs incurred to identify defects after the fact. Examples: Incoming and source inspection/test of purchased material, In-process and final inspection/test, Product, process or service audits, Calibration of measuring and test equipment, Associated supplies and materials 3/19/2018 © 2010 RLM & Associates LLC 32

Definition of COPQ Cost Of Poor Quality Prevention costs are investments made ahead of time in an effort to ensure conformance to requirements. Examples: New product review, Quality planning, Supplier capability surveys, Process capability evaluations, Quality improvement team meetings, Quality improvement project, Quality education and training Appraisal costs are costs incurred to identify defects after the fact. Examples: Incoming and source inspection/test of purchased material, In-process and final inspection/test, Product, process or service audits, Calibration of measuring and test equipment, Associated supplies and materials 3/19/2018 © 2010 RLM & Associates LLC 32

Definition of COPQ Cost Of Poor Quality Internal error costs are the costs of rework and repair before delivery to a customer. Examples: Scrap, Rework, Re-inspection, Re-testing, Material review, Downgrading External error costs are the costs of rework and repair after delivery to a customer. Examples: Technical support calls, Preparation of support answer books, Investigation of customer complaints, Refunds and recalls, Shipping of updated product, Lost sales, Lost customer goodwill, Discounts to resellers to encourage them to keep selling the product, Warranty costs, Liability costs, Government investigations, Penalties, All other costs imposed by law 3/19/2018 © 2010 RLM & Associates LLC 33

Definition of COPQ Cost Of Poor Quality Internal error costs are the costs of rework and repair before delivery to a customer. Examples: Scrap, Rework, Re-inspection, Re-testing, Material review, Downgrading External error costs are the costs of rework and repair after delivery to a customer. Examples: Technical support calls, Preparation of support answer books, Investigation of customer complaints, Refunds and recalls, Shipping of updated product, Lost sales, Lost customer goodwill, Discounts to resellers to encourage them to keep selling the product, Warranty costs, Liability costs, Government investigations, Penalties, All other costs imposed by law 3/19/2018 © 2010 RLM & Associates LLC 33

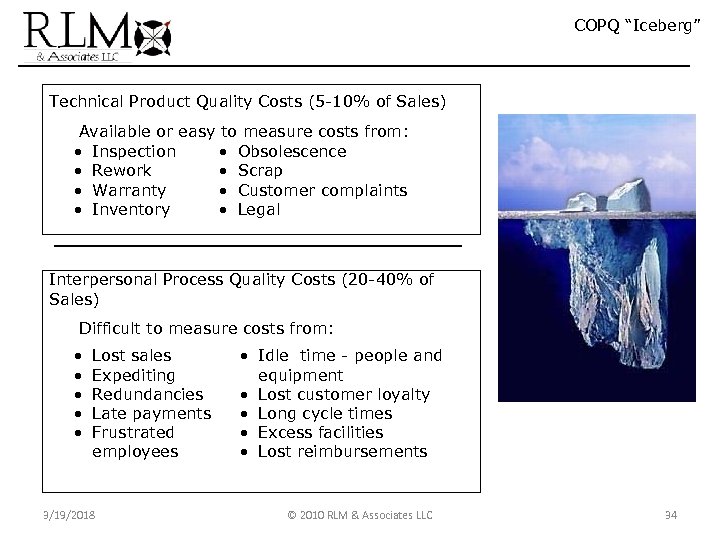

COPQ “Iceberg” Technical Product Quality Costs (5 -10% of Sales) Available or easy to measure costs from: • • Inspection Rework Warranty Inventory • • Obsolescence Scrap Customer complaints Legal Interpersonal Process Quality Costs (20 -40% of Sales) Difficult to measure costs from: • • • Lost sales Expediting Redundancies Late payments Frustrated employees 3/19/2018 • Idle time - people and equipment • Lost customer loyalty • Long cycle times • Excess facilities • Lost reimbursements © 2010 RLM & Associates LLC 34

COPQ “Iceberg” Technical Product Quality Costs (5 -10% of Sales) Available or easy to measure costs from: • • Inspection Rework Warranty Inventory • • Obsolescence Scrap Customer complaints Legal Interpersonal Process Quality Costs (20 -40% of Sales) Difficult to measure costs from: • • • Lost sales Expediting Redundancies Late payments Frustrated employees 3/19/2018 • Idle time - people and equipment • Lost customer loyalty • Long cycle times • Excess facilities • Lost reimbursements © 2010 RLM & Associates LLC 34

Lean Principles 3/19/2018 © 2010 RLM & Associates LLC 35

Lean Principles 3/19/2018 © 2010 RLM & Associates LLC 35

Lean Principles “Lean production is aimed at the elimination of waste in every area of production including customer relations, product design, supplier networks and factory management. Its goal is to incorporate less human effort, less inventory, less time to develop products, and less space to become highly responsive to customer demand while producing top quality products in the most efficient and economical manner possible. ” http: //lean 2. mit. edu/ 3/19/2018 © 2010 RLM & Associates LLC 36

Lean Principles “Lean production is aimed at the elimination of waste in every area of production including customer relations, product design, supplier networks and factory management. Its goal is to incorporate less human effort, less inventory, less time to develop products, and less space to become highly responsive to customer demand while producing top quality products in the most efficient and economical manner possible. ” http: //lean 2. mit. edu/ 3/19/2018 © 2010 RLM & Associates LLC 36

Lean Management Systems Need for Evaluating the Management System 1. How does Kraft engage and align people to determine which problems are important? 2. How does Kraft tackle the important issues, solve the problems, and evaluate proposals rising from the bottom of the organization where the greatest amount of knowledge of the problems exist? 3. How well is work standardized? How are supervisors and managers held accountable? 4. How is Kraft creating the next generation of managers? Especially, Lean and Six Sigma management. Lean for the Long Term http: //lean 2. mit. edu/ 3/19/2018 © 2010 RLM & Associates LLC 37

Lean Management Systems Need for Evaluating the Management System 1. How does Kraft engage and align people to determine which problems are important? 2. How does Kraft tackle the important issues, solve the problems, and evaluate proposals rising from the bottom of the organization where the greatest amount of knowledge of the problems exist? 3. How well is work standardized? How are supervisors and managers held accountable? 4. How is Kraft creating the next generation of managers? Especially, Lean and Six Sigma management. Lean for the Long Term http: //lean 2. mit. edu/ 3/19/2018 © 2010 RLM & Associates LLC 37

Lean Principles Kraft Foods 2011 Sustainability Goals: ØReduce plant energy usage by 25% ØReduce plant energy related carbon dioxide emissions 25% Ø Reduce plant water consumption by 15% Ø Reduce plant waste by 15% Ø Eliminate 150, 000 lbs of packaging materials Ø Support agricultural sustainability on key commodities – e. g. coffee and cocoa 3/19/2018 © 2010 RLM & Associates LLC 38

Lean Principles Kraft Foods 2011 Sustainability Goals: ØReduce plant energy usage by 25% ØReduce plant energy related carbon dioxide emissions 25% Ø Reduce plant water consumption by 15% Ø Reduce plant waste by 15% Ø Eliminate 150, 000 lbs of packaging materials Ø Support agricultural sustainability on key commodities – e. g. coffee and cocoa 3/19/2018 © 2010 RLM & Associates LLC 38

Wastes Seven Areas of WASTE 1. Defects A defect is a product or service that does not conform to the customers’ specifications. Correcting or repairing a defect in materials or parts adds unnecessary costs because of additional equipment and labor expenses. An example is the labor cost of scheduling employees to work overtime to rework defects. 3/19/2018 © 2010 RLM & Associates LLC 39

Wastes Seven Areas of WASTE 1. Defects A defect is a product or service that does not conform to the customers’ specifications. Correcting or repairing a defect in materials or parts adds unnecessary costs because of additional equipment and labor expenses. An example is the labor cost of scheduling employees to work overtime to rework defects. 3/19/2018 © 2010 RLM & Associates LLC 39

Wastes Examples of Defect Wastes 1. ______________________ 2. ______________________ 3. ______________________ 4. ______________________ 5. ______________________ 3/19/2018 © 2010 RLM & Associates LLC 40

Wastes Examples of Defect Wastes 1. ______________________ 2. ______________________ 3. ______________________ 4. ______________________ 5. ______________________ 3/19/2018 © 2010 RLM & Associates LLC 40

Wastes 2. Overproduction Ø Producing more product than is required by the customer. Ø Producing parts at a faster rate than processed customer orders. Doing this requires more raw product inventory than necessary, over uses machines and people and requires more storage area. 3/19/2018 © 2010 RLM & Associates LLC 41

Wastes 2. Overproduction Ø Producing more product than is required by the customer. Ø Producing parts at a faster rate than processed customer orders. Doing this requires more raw product inventory than necessary, over uses machines and people and requires more storage area. 3/19/2018 © 2010 RLM & Associates LLC 41

Wastes Examples of Overproduction Wastes 1. ______________________ 2. ______________________ 3. ______________________ 4. ______________________ 5. ______________________ 3/19/2018 © 2010 RLM & Associates LLC 42

Wastes Examples of Overproduction Wastes 1. ______________________ 2. ______________________ 3. ______________________ 4. ______________________ 5. ______________________ 3/19/2018 © 2010 RLM & Associates LLC 42

Wastes Demand-Based Production Decisions Kraft must create a focus on understanding product demand. How are demand signals received and passed on to suppliers? There needs to be COLLABORATION. There needs to be a “Smooth” flow of both information and materials to facilitate Lean production. Demand based signals can eliminate the need forecasting. There needs to be real-time visibility to deliver the right products – to the right places – at the right times – in the right quantities. 3/19/2018 © 2010 RLM & Associates LLC 43

Wastes Demand-Based Production Decisions Kraft must create a focus on understanding product demand. How are demand signals received and passed on to suppliers? There needs to be COLLABORATION. There needs to be a “Smooth” flow of both information and materials to facilitate Lean production. Demand based signals can eliminate the need forecasting. There needs to be real-time visibility to deliver the right products – to the right places – at the right times – in the right quantities. 3/19/2018 © 2010 RLM & Associates LLC 43

Wastes 3. Extra or Over Processing - work that has no relationship to advancing the production line or improving the quality of a product or service. Example: When an inside sales person must obtain customer information that should have been obtained by the outside salesperson handling the account. 3/19/2018 © 2010 RLM & Associates LLC 44

Wastes 3. Extra or Over Processing - work that has no relationship to advancing the production line or improving the quality of a product or service. Example: When an inside sales person must obtain customer information that should have been obtained by the outside salesperson handling the account. 3/19/2018 © 2010 RLM & Associates LLC 44

Wastes Examples of Extra/Over Processing Wastes 1. ______________________ 2. ______________________ 3. ______________________ 4. ______________________ 5. ______________________ 3/19/2018 © 2010 RLM & Associates LLC 45

Wastes Examples of Extra/Over Processing Wastes 1. ______________________ 2. ______________________ 3. ______________________ 4. ______________________ 5. ______________________ 3/19/2018 © 2010 RLM & Associates LLC 45

Wastes 4. Transportation is a secondary required action that does not directly contribute value to the product. It’s essential to avoid unnecessary transportation of products – (1) transportation adds time to the process and (2) the products can be damaged during transportation. 3/19/2018 © 2010 RLM & Associates LLC 46

Wastes 4. Transportation is a secondary required action that does not directly contribute value to the product. It’s essential to avoid unnecessary transportation of products – (1) transportation adds time to the process and (2) the products can be damaged during transportation. 3/19/2018 © 2010 RLM & Associates LLC 46

Wastes Examples of Transportation Wastes 1. ______________________ 2. ______________________ 3. ______________________ 4. ______________________ 5. ______________________ 3/19/2018 © 2010 RLM & Associates LLC 47

Wastes Examples of Transportation Wastes 1. ______________________ 2. ______________________ 3. ______________________ 4. ______________________ 5. ______________________ 3/19/2018 © 2010 RLM & Associates LLC 47

Wastes Kraft Reducing Transportation Wastes Kraft is using software provided by Transportation Warehouse Optimization at its 20 largest plants and distribution centers to optimize outbound truckloads, maximize weight and cube and put more products on fewer trucks. 1500 less trucks on the road and 1, 000 miles less traveled. www. kraftfoods. com 2009 3/19/2018 © 2010 RLM & Associates LLC 48

Wastes Kraft Reducing Transportation Wastes Kraft is using software provided by Transportation Warehouse Optimization at its 20 largest plants and distribution centers to optimize outbound truckloads, maximize weight and cube and put more products on fewer trucks. 1500 less trucks on the road and 1, 000 miles less traveled. www. kraftfoods. com 2009 3/19/2018 © 2010 RLM & Associates LLC 48

Wastes 5. Inventory is a drain on an organization’s capital. The more inventory - the higher the carrying costs. If quality issues arise defective material may be hidden in finished goods. To remain flexible to ever changing customer requirements and to control product variations inventory must be minimized. Inventory hides unacceptable change-over times, excessive downtimes and production scheduling inefficiencies. 3/19/2018 © 2010 RLM & Associates LLC 49

Wastes 5. Inventory is a drain on an organization’s capital. The more inventory - the higher the carrying costs. If quality issues arise defective material may be hidden in finished goods. To remain flexible to ever changing customer requirements and to control product variations inventory must be minimized. Inventory hides unacceptable change-over times, excessive downtimes and production scheduling inefficiencies. 3/19/2018 © 2010 RLM & Associates LLC 49

Wastes Examples of Inventory Wastes 1. ______________________ 2. ______________________ 3. ______________________ 4. ______________________ 5. ______________________ 3/19/2018 © 2010 RLM & Associates LLC 50

Wastes Examples of Inventory Wastes 1. ______________________ 2. ______________________ 3. ______________________ 4. ______________________ 5. ______________________ 3/19/2018 © 2010 RLM & Associates LLC 50

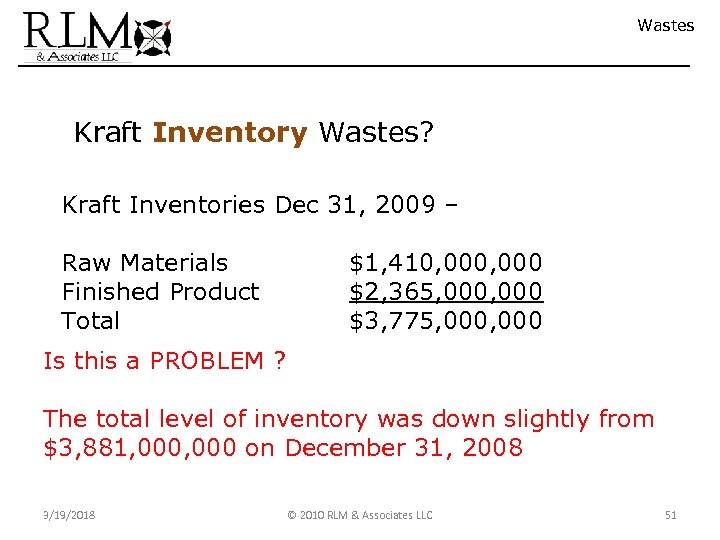

Wastes Kraft Inventory Wastes? Kraft Inventories Dec 31, 2009 – Raw Materials Finished Product Total $1, 410, 000 $2, 365, 000 $3, 775, 000 Is this a PROBLEM ? The total level of inventory was down slightly from $3, 881, 000 on December 31, 2008 3/19/2018 © 2010 RLM & Associates LLC 51

Wastes Kraft Inventory Wastes? Kraft Inventories Dec 31, 2009 – Raw Materials Finished Product Total $1, 410, 000 $2, 365, 000 $3, 775, 000 Is this a PROBLEM ? The total level of inventory was down slightly from $3, 881, 000 on December 31, 2008 3/19/2018 © 2010 RLM & Associates LLC 51

Wastes 6. Motion waste refers to people moving within and outside of their immediate work area to find tools or materials. Any movement of people or machinery that does not contribute added value to the product; i. e. , programming delay times and excessive walking distance between operations or operator’s having to walk back and forth to retrieve materials not available in the immediate work area. 3/19/2018 © 2010 RLM & Associates LLC 52

Wastes 6. Motion waste refers to people moving within and outside of their immediate work area to find tools or materials. Any movement of people or machinery that does not contribute added value to the product; i. e. , programming delay times and excessive walking distance between operations or operator’s having to walk back and forth to retrieve materials not available in the immediate work area. 3/19/2018 © 2010 RLM & Associates LLC 52

Wastes Examples of Motion Wastes 1. ______________________ 2. ______________________ 3. ______________________ 4. ______________________ 5. ______________________ 3/19/2018 © 2010 RLM & Associates LLC 53

Wastes Examples of Motion Wastes 1. ______________________ 2. ______________________ 3. ______________________ 4. ______________________ 5. ______________________ 3/19/2018 © 2010 RLM & Associates LLC 53

Wastes 7. Waiting or Queuing Idle time between operations or events, i. e. an employee waiting for machine cycle to finish or a machine waiting for the operator to load new parts. Periods of inactivity in a downstream process that occur because an upstream activity does not deliver product on time. 3/19/2018 © 2010 RLM & Associates LLC 54

Wastes 7. Waiting or Queuing Idle time between operations or events, i. e. an employee waiting for machine cycle to finish or a machine waiting for the operator to load new parts. Periods of inactivity in a downstream process that occur because an upstream activity does not deliver product on time. 3/19/2018 © 2010 RLM & Associates LLC 54

Wastes Examples of Waiting Wastes 1. ______________________ 2. ______________________ 3. ______________________ 4. ______________________ 5. ______________________ 3/19/2018 © 2010 RLM & Associates LLC 55

Wastes Examples of Waiting Wastes 1. ______________________ 2. ______________________ 3. ______________________ 4. ______________________ 5. ______________________ 3/19/2018 © 2010 RLM & Associates LLC 55

Applying the 5 S Principles 3/19/2018 © 2010 RLM & Associates LLC 56

Applying the 5 S Principles 3/19/2018 © 2010 RLM & Associates LLC 56

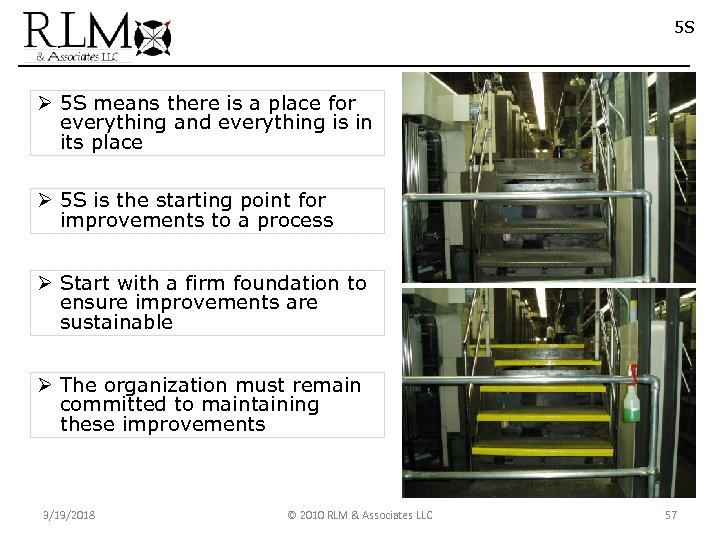

5 S Ø 5 S means there is a place for everything and everything is in its place Ø 5 S is the starting point for improvements to a process Ø Start with a firm foundation to ensure improvements are sustainable Ø The organization must remain committed to maintaining these improvements 3/19/2018 © 2010 RLM & Associates LLC 57

5 S Ø 5 S means there is a place for everything and everything is in its place Ø 5 S is the starting point for improvements to a process Ø Start with a firm foundation to ensure improvements are sustainable Ø The organization must remain committed to maintaining these improvements 3/19/2018 © 2010 RLM & Associates LLC 57

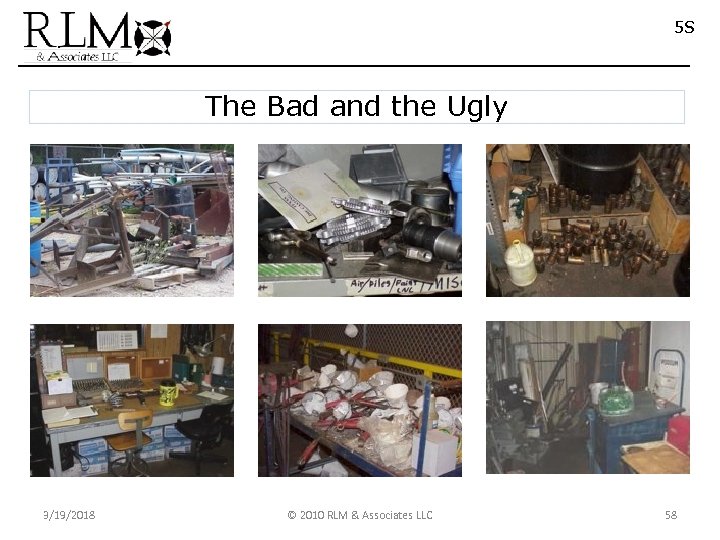

5 S The Bad and the Ugly 3/19/2018 © 2010 RLM & Associates LLC 58

5 S The Bad and the Ugly 3/19/2018 © 2010 RLM & Associates LLC 58

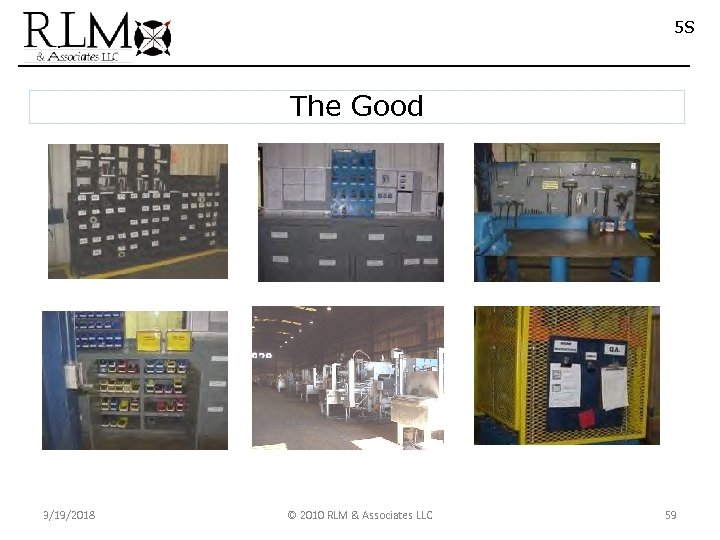

5 S The Good 3/19/2018 © 2010 RLM & Associates LLC 59

5 S The Good 3/19/2018 © 2010 RLM & Associates LLC 59

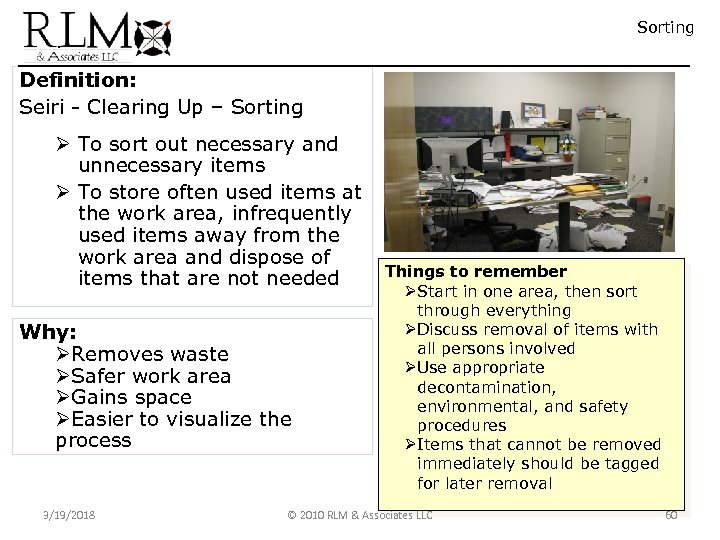

Sorting Definition: Seiri - Clearing Up – Sorting Ø To sort out necessary and unnecessary items Ø To store often used items at the work area, infrequently used items away from the work area and dispose of items that are not needed Why: ØRemoves waste ØSafer work area ØGains space ØEasier to visualize the process 3/19/2018 Things to remember ØStart in one area, then sort through everything ØDiscuss removal of items with all persons involved ØUse appropriate decontamination, environmental, and safety procedures ØItems that cannot be removed immediately should be tagged for later removal © 2010 RLM & Associates LLC 60

Sorting Definition: Seiri - Clearing Up – Sorting Ø To sort out necessary and unnecessary items Ø To store often used items at the work area, infrequently used items away from the work area and dispose of items that are not needed Why: ØRemoves waste ØSafer work area ØGains space ØEasier to visualize the process 3/19/2018 Things to remember ØStart in one area, then sort through everything ØDiscuss removal of items with all persons involved ØUse appropriate decontamination, environmental, and safety procedures ØItems that cannot be removed immediately should be tagged for later removal © 2010 RLM & Associates LLC 60

Straightening Definition: Seiton - Organizing – Straightening Ø To arrange all necessary items Ø To have a designated place for everything Ø A place for everything and everything in its place Ø Easily visible and accessible Why: ØVisually shows what is required or is out of place ØMore efficient to find items and documents (silhouettes/labels) ØSaves time by not having to search for items ØShorter travel distances 3/19/2018 © 2010 RLM & Associates LLC Things to remember Ø Things used together should be kept together Ø Use labels, tape, floor markings, signs, and shadow outlines Ø Sharable items should be kept at a central location (eliminated excess) 61

Straightening Definition: Seiton - Organizing – Straightening Ø To arrange all necessary items Ø To have a designated place for everything Ø A place for everything and everything in its place Ø Easily visible and accessible Why: ØVisually shows what is required or is out of place ØMore efficient to find items and documents (silhouettes/labels) ØSaves time by not having to search for items ØShorter travel distances 3/19/2018 © 2010 RLM & Associates LLC Things to remember Ø Things used together should be kept together Ø Use labels, tape, floor markings, signs, and shadow outlines Ø Sharable items should be kept at a central location (eliminated excess) 61

Shining Definition: Seiso - Cleaning – Shining Ø Clean everything and find ways to keep it clean Ø Make cleaning a part of everyday work Things to remember Why: ØA clean workplace indicates a quality product and process ØDust and dirt cause product contamination and potential health hazards. ØA clean workplace helps identify abnormal conditions 3/19/2018 Ø “Everything in its place” frees up time for cleaning Ø Use an office or facility layout as a visual aid to identify individual responsibilities for cleaning. This eliminates “no man’s land” Ø Cleaning the work area is like bathing. It relieves stress and strain, removes sweat and dirt, and prepares the body for the next day © 2010 RLM & Associates LLC 62

Shining Definition: Seiso - Cleaning – Shining Ø Clean everything and find ways to keep it clean Ø Make cleaning a part of everyday work Things to remember Why: ØA clean workplace indicates a quality product and process ØDust and dirt cause product contamination and potential health hazards. ØA clean workplace helps identify abnormal conditions 3/19/2018 Ø “Everything in its place” frees up time for cleaning Ø Use an office or facility layout as a visual aid to identify individual responsibilities for cleaning. This eliminates “no man’s land” Ø Cleaning the work area is like bathing. It relieves stress and strain, removes sweat and dirt, and prepares the body for the next day © 2010 RLM & Associates LLC 62

Standardizing Definition: Seketsu – Standardizing Ø To maintain the workplace at a level that uncovers problems and makes them obvious Ø To continuously improve your office or facility by continuous assessment and action Why: ØTo sustain sorting, storage and shining activities every day 3/19/2018 Things to remember ØWe must keep the work place neat enough for visual identifiers to be effective in uncovering hidden problems ØDevelop a system that enables everyone in the workplace to see problems when they occur © 2010 RLM & Associates LLC 63

Standardizing Definition: Seketsu – Standardizing Ø To maintain the workplace at a level that uncovers problems and makes them obvious Ø To continuously improve your office or facility by continuous assessment and action Why: ØTo sustain sorting, storage and shining activities every day 3/19/2018 Things to remember ØWe must keep the work place neat enough for visual identifiers to be effective in uncovering hidden problems ØDevelop a system that enables everyone in the workplace to see problems when they occur © 2010 RLM & Associates LLC 63

Sustaining Definition: Shitsuke - Training & Discipline – Sustaining Ø To maintain our discipline, we need to practice and repeat until it becomes a way of life Why: ØTo build 5 S into our everyday process 3/19/2018 Things to Remember Ø Develop schedules and check lists Ø Good habits are hard to establish Ø Commitment and discipline toward housekeeping are essential first steps toward being world class © 2010 RLM & Associates LLC 64

Sustaining Definition: Shitsuke - Training & Discipline – Sustaining Ø To maintain our discipline, we need to practice and repeat until it becomes a way of life Why: ØTo build 5 S into our everyday process 3/19/2018 Things to Remember Ø Develop schedules and check lists Ø Good habits are hard to establish Ø Commitment and discipline toward housekeeping are essential first steps toward being world class © 2010 RLM & Associates LLC 64

Poka-Yoke Methods 3/19/2018 © 2010 RLM & Associates LLC 65

Poka-Yoke Methods 3/19/2018 © 2010 RLM & Associates LLC 65

Poka-Yoke Ø Pronounced POH-kah YOH-kay Ø “To make mistakes impossible” Ø Plain English: “Mistake Proofing” Ø Developed by S. Shingo of Toyota Ø Why is Poka-Yoke important? Ø One of the simplest tools to learn Ø Extremely high impact - often at little cost Ø Poka-Yoke has two parts: Ø Making mistakes impossible (prevention) Ø Making mistakes immediately obvious (detection) 3/19/2018 © 2010 RLM & Associates LLC 66

Poka-Yoke Ø Pronounced POH-kah YOH-kay Ø “To make mistakes impossible” Ø Plain English: “Mistake Proofing” Ø Developed by S. Shingo of Toyota Ø Why is Poka-Yoke important? Ø One of the simplest tools to learn Ø Extremely high impact - often at little cost Ø Poka-Yoke has two parts: Ø Making mistakes impossible (prevention) Ø Making mistakes immediately obvious (detection) 3/19/2018 © 2010 RLM & Associates LLC 66

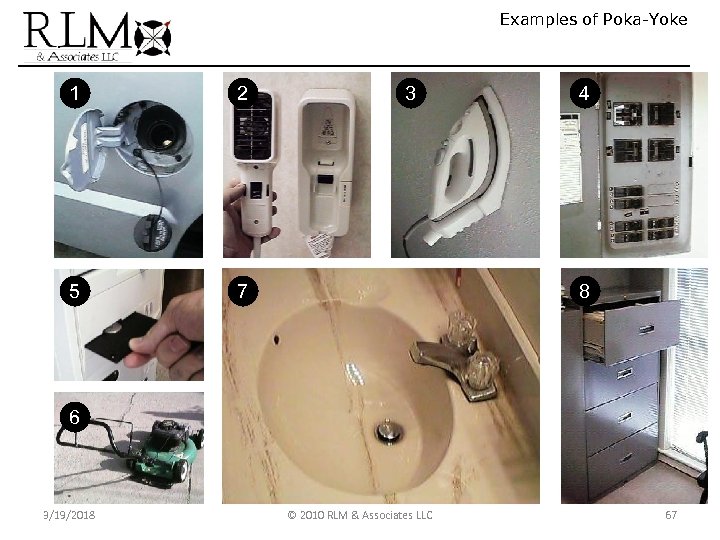

Examples of Poka-Yoke 1 2 5 3 7 4 8 6 3/19/2018 © 2010 RLM & Associates LLC 67

Examples of Poka-Yoke 1 2 5 3 7 4 8 6 3/19/2018 © 2010 RLM & Associates LLC 67

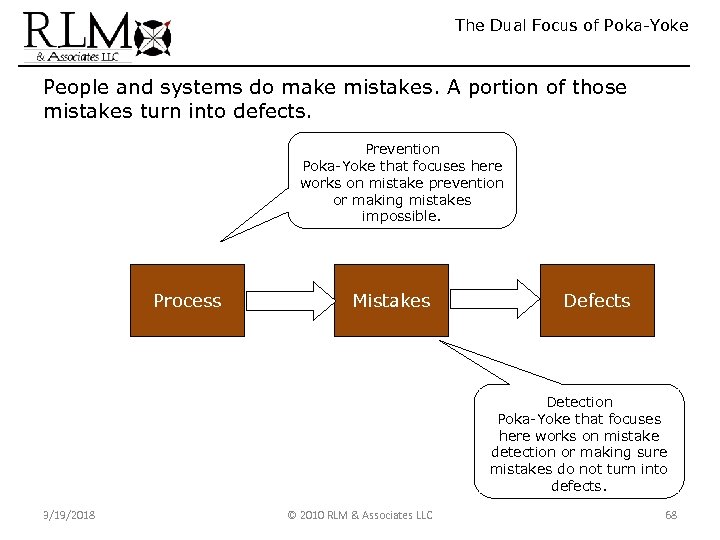

The Dual Focus of Poka-Yoke People and systems do make mistakes. A portion of those mistakes turn into defects. Prevention Poka-Yoke that focuses here works on mistake prevention or making mistakes impossible. Process Mistakes Defects Detection Poka-Yoke that focuses here works on mistake detection or making sure mistakes do not turn into defects. 3/19/2018 © 2010 RLM & Associates LLC 68

The Dual Focus of Poka-Yoke People and systems do make mistakes. A portion of those mistakes turn into defects. Prevention Poka-Yoke that focuses here works on mistake prevention or making mistakes impossible. Process Mistakes Defects Detection Poka-Yoke that focuses here works on mistake detection or making sure mistakes do not turn into defects. 3/19/2018 © 2010 RLM & Associates LLC 68

Poka-Yokes All Around Us Examples (Which are Prevention, Which are Detection): Ø Physical geometry, such as guide pins or stops, makes incorrect geometry impossible – P or D? Ø Automated vision inspection – P or D? Ø Limiting mechanisms on equipment controls – P or D? Ø Inspection checklists – P or D? Modern automobiles have many Poka-Yokes built into them. How many can you identify? 3/19/2018 © 2010 RLM & Associates LLC 69

Poka-Yokes All Around Us Examples (Which are Prevention, Which are Detection): Ø Physical geometry, such as guide pins or stops, makes incorrect geometry impossible – P or D? Ø Automated vision inspection – P or D? Ø Limiting mechanisms on equipment controls – P or D? Ø Inspection checklists – P or D? Modern automobiles have many Poka-Yokes built into them. How many can you identify? 3/19/2018 © 2010 RLM & Associates LLC 69

Summary What Poka-Yoke IS NOT: Ø Retraining people Ø Disciplining people who make mistakes Ø Work instructions Ø Improving the attentiveness of people Ø Increased human attention or intervention What Poka-Yoke IS: Ø Poka-Yoke means “mistake proofing” Ø Poka-Yoke focuses on preventing and detecting mistakes Ø Poka-Yoke is directly connected with the occurrence and detectability tasks of FMEA Ø Poka-Yoke is classified as a control method but can be considered as a solution to a problem as well if it prevents a problem from occurring 3/19/2018 © 2010 RLM & Associates LLC 70

Summary What Poka-Yoke IS NOT: Ø Retraining people Ø Disciplining people who make mistakes Ø Work instructions Ø Improving the attentiveness of people Ø Increased human attention or intervention What Poka-Yoke IS: Ø Poka-Yoke means “mistake proofing” Ø Poka-Yoke focuses on preventing and detecting mistakes Ø Poka-Yoke is directly connected with the occurrence and detectability tasks of FMEA Ø Poka-Yoke is classified as a control method but can be considered as a solution to a problem as well if it prevents a problem from occurring 3/19/2018 © 2010 RLM & Associates LLC 70

What Happens in a Lean Event? 3/19/2018 © 2010 RLM & Associates LLC 71

What Happens in a Lean Event? 3/19/2018 © 2010 RLM & Associates LLC 71

Pre-Event 1. Meet with Leadership 2. Walk the Process 3. Leadership Kicks off the Event 3/19/2018 © 2010 RLM & Associates LLC 72

Pre-Event 1. Meet with Leadership 2. Walk the Process 3. Leadership Kicks off the Event 3/19/2018 © 2010 RLM & Associates LLC 72

During the Event Team Operating Guidelines Ø Cell phones, Blackberries, i. Phones, etc. turned off Ø Be on time Ø Limit side conversations – Only one person speaking at a time Ø Listen for understanding - Let the person finish before you speak Ø Have respect for one another – Attack issues and facts…not people or their ideas! 3/19/2018 © 2010 RLM & Associates LLC 73

During the Event Team Operating Guidelines Ø Cell phones, Blackberries, i. Phones, etc. turned off Ø Be on time Ø Limit side conversations – Only one person speaking at a time Ø Listen for understanding - Let the person finish before you speak Ø Have respect for one another – Attack issues and facts…not people or their ideas! 3/19/2018 © 2010 RLM & Associates LLC 73

During the Event 4. Document the Current State 5. Describe/Map an Ideal State – One where there are no constraints inhibiting the flow of work 3/19/2018 © 2010 RLM & Associates LLC 74

During the Event 4. Document the Current State 5. Describe/Map an Ideal State – One where there are no constraints inhibiting the flow of work 3/19/2018 © 2010 RLM & Associates LLC 74

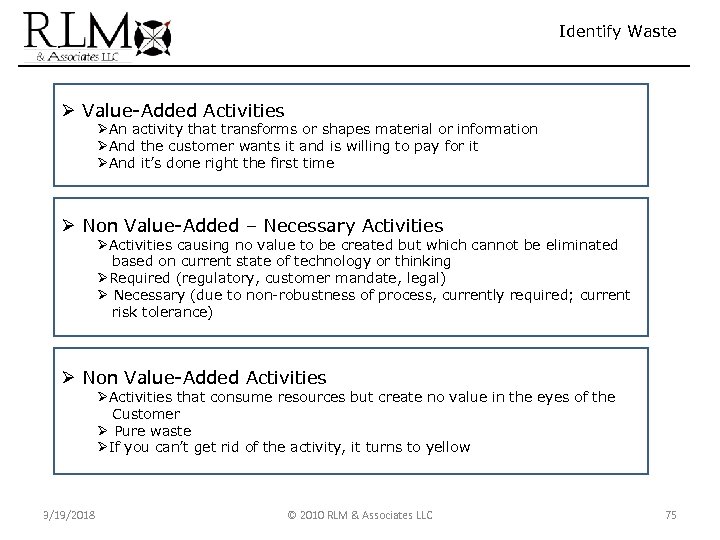

Identify Waste Ø Value-Added Activities ØAn activity that transforms or shapes material or information ØAnd the customer wants it and is willing to pay for it ØAnd it’s done right the first time Ø Non Value-Added – Necessary Activities ØActivities causing no value to be created but which cannot be eliminated based on current state of technology or thinking ØRequired (regulatory, customer mandate, legal) Ø Necessary (due to non-robustness of process, currently required; current risk tolerance) Ø Non Value-Added Activities ØActivities that consume resources but create no value in the eyes of the Customer Ø Pure waste ØIf you can’t get rid of the activity, it turns to yellow 3/19/2018 © 2010 RLM & Associates LLC 75

Identify Waste Ø Value-Added Activities ØAn activity that transforms or shapes material or information ØAnd the customer wants it and is willing to pay for it ØAnd it’s done right the first time Ø Non Value-Added – Necessary Activities ØActivities causing no value to be created but which cannot be eliminated based on current state of technology or thinking ØRequired (regulatory, customer mandate, legal) Ø Necessary (due to non-robustness of process, currently required; current risk tolerance) Ø Non Value-Added Activities ØActivities that consume resources but create no value in the eyes of the Customer Ø Pure waste ØIf you can’t get rid of the activity, it turns to yellow 3/19/2018 © 2010 RLM & Associates LLC 75

Future State Diagram 6. Develop a Future State 7. Create an Implementation Plan 3/19/2018 © 2010 RLM & Associates LLC 76

Future State Diagram 6. Develop a Future State 7. Create an Implementation Plan 3/19/2018 © 2010 RLM & Associates LLC 76

Implementation 8. Implement & Sustain 9. Continuously Improve 3/19/2018 © 2010 RLM & Associates LLC 77

Implementation 8. Implement & Sustain 9. Continuously Improve 3/19/2018 © 2010 RLM & Associates LLC 77

Lean Value Stream Analysis 3/19/2018 © 2010 RLM & Associates LLC 78

Lean Value Stream Analysis 3/19/2018 © 2010 RLM & Associates LLC 78

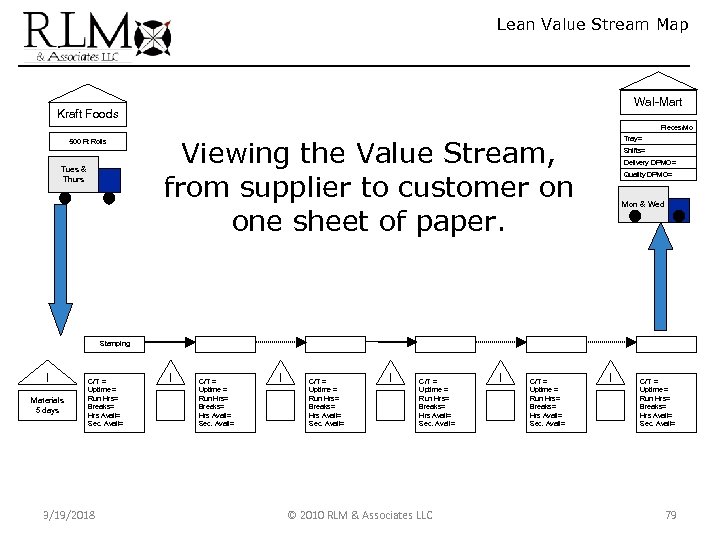

Lean Value Stream Map Wal-Mart Kraft Foods Pieces/Mo 500 Ft Rolls Tues & Thurs Tray= Viewing the Value Stream, from supplier to customer on one sheet of paper. Shifts= Delivery DPMO= Quality DPMO= Mon & Wed Stamping I Materials 5 days C/T = Uptime = Run Hrs= Breaks= Hrs Avail= Sec. Avail= 3/19/2018 I C/T = Uptime = Run Hrs= Breaks= Hrs Avail= Sec. Avail= © 2010 RLM & Associates LLC I C/T = Uptime = Run Hrs= Breaks= Hrs Avail= Sec. Avail= 79

Lean Value Stream Map Wal-Mart Kraft Foods Pieces/Mo 500 Ft Rolls Tues & Thurs Tray= Viewing the Value Stream, from supplier to customer on one sheet of paper. Shifts= Delivery DPMO= Quality DPMO= Mon & Wed Stamping I Materials 5 days C/T = Uptime = Run Hrs= Breaks= Hrs Avail= Sec. Avail= 3/19/2018 I C/T = Uptime = Run Hrs= Breaks= Hrs Avail= Sec. Avail= © 2010 RLM & Associates LLC I C/T = Uptime = Run Hrs= Breaks= Hrs Avail= Sec. Avail= 79

Value Stream Analysis 1. Value Stream Analysis helps you visualize the entire system; i. e. order entry, invoicing, shipping, assembly, test, etc 2. Value Stream Analysis is a qualitative process allowing you to visualize how your organization should operate 3. Value Stream Analysis helps you see sources of inefficiency and problems in the delivery of your service or product 4. Value Stream Analysis forms the basis of an improvement vision and plan by helping understand how door-to-door flow should be performed to optimize costs, cycle times & quality 5. Value Stream Analysis conceptualizes Six Sigma projects as well as other improvement efforts 6. Value Stream Analysis is good for describing what you will do to change businessperformance levels 3/19/2018 © 2010 RLM & Associates LLC 80

Value Stream Analysis 1. Value Stream Analysis helps you visualize the entire system; i. e. order entry, invoicing, shipping, assembly, test, etc 2. Value Stream Analysis is a qualitative process allowing you to visualize how your organization should operate 3. Value Stream Analysis helps you see sources of inefficiency and problems in the delivery of your service or product 4. Value Stream Analysis forms the basis of an improvement vision and plan by helping understand how door-to-door flow should be performed to optimize costs, cycle times & quality 5. Value Stream Analysis conceptualizes Six Sigma projects as well as other improvement efforts 6. Value Stream Analysis is good for describing what you will do to change businessperformance levels 3/19/2018 © 2010 RLM & Associates LLC 80

Value Stream Analysis Ø Value Stream Analysis puts the relevant information with regard to the total work effort on one sheet of paper - the current-state map Ø Map information flow; i. e. , customer and supplier ordering, material flows, and production control to complete the picture Ø Overall performance and process-specific problems become visible and analysis can be done as a part of the overall representation of the process Ø Identify efficiency and effectiveness targets Ø The final result is a future-state map with a plan that is achieved through Lean Six Sigma projects 3/19/2018 © 2010 RLM & Associates LLC 81

Value Stream Analysis Ø Value Stream Analysis puts the relevant information with regard to the total work effort on one sheet of paper - the current-state map Ø Map information flow; i. e. , customer and supplier ordering, material flows, and production control to complete the picture Ø Overall performance and process-specific problems become visible and analysis can be done as a part of the overall representation of the process Ø Identify efficiency and effectiveness targets Ø The final result is a future-state map with a plan that is achieved through Lean Six Sigma projects 3/19/2018 © 2010 RLM & Associates LLC 81

Process Management 3/19/2018 © 2010 RLM & Associates LLC 82

Process Management 3/19/2018 © 2010 RLM & Associates LLC 82

Process Management A Functional Business Unit represents a major group of business processes, which together completely support a stand-alone unit. A Functional Business Unit is static in nature, and has no definite beginning or ending points. A Functional Business Unit is a logical, related, sequential (connected) set of activities and tasks that takes an input from a “supplier, ” adds value to it and produces an output that goes to a “customer. ” Examples of Functional Business Units include Procurement, Asset Management, Human Resources and Finance Management. A Business Process is a description of a series of Supporting Activities or sub-processes that together produce a tangible result, usually in support of a function. It manipulates (transforms, controls or manages) information and/or physical things in the business. It is typically described in terms of its inputs, outputs, and/or controls and can be composed of additional processes. An example of a Business Process would be Procure Raw Materials, which supports the overall Business Function of Procurement. Another example would be Recruit & Hire Employees, which supports the overall Business Function of Human Resources. 3/19/2018 © 2010 RLM & Associates LLC 83

Process Management A Functional Business Unit represents a major group of business processes, which together completely support a stand-alone unit. A Functional Business Unit is static in nature, and has no definite beginning or ending points. A Functional Business Unit is a logical, related, sequential (connected) set of activities and tasks that takes an input from a “supplier, ” adds value to it and produces an output that goes to a “customer. ” Examples of Functional Business Units include Procurement, Asset Management, Human Resources and Finance Management. A Business Process is a description of a series of Supporting Activities or sub-processes that together produce a tangible result, usually in support of a function. It manipulates (transforms, controls or manages) information and/or physical things in the business. It is typically described in terms of its inputs, outputs, and/or controls and can be composed of additional processes. An example of a Business Process would be Procure Raw Materials, which supports the overall Business Function of Procurement. Another example would be Recruit & Hire Employees, which supports the overall Business Function of Human Resources. 3/19/2018 © 2010 RLM & Associates LLC 83

Process Management A Supporting Activity or Sub-Process is a portion of a major process that accomplishes a specific objective in support of the major process. A Supporting Activity or Sub-Process is a breakdown of a Business Process and represents a specific activity within the process. An example of a Supporting Activity within Procure Raw Materials would be the creation of a Purchase Order. On the Recruit & Hire Employees side an example of a Supporting Activity would be to make a job offer and negotiate details. A Supporting Task is a step involved in performing a specific Supporting Activity or Sub-Process and is a subset of an overall Business Process. They are usually performed by a single unit (a person, a machine or a department). An activity is usually documented in an instruction. An example of a Supporting Task would be the creation of a Purchase Order for a consumable versus stock item. Using a Payroll example for a Supporting Task would be paying employees by direct deposit versus generating a check. Steps in a Supporting Activity are defined to the transaction level, (which become business steps). A Supporting Step walks one through a Supporting Activity and identifies the decision points one will have to make to complete the task. This really defines the flow of how one will do a job. 3/19/2018 © 2010 RLM & Associates LLC 84

Process Management A Supporting Activity or Sub-Process is a portion of a major process that accomplishes a specific objective in support of the major process. A Supporting Activity or Sub-Process is a breakdown of a Business Process and represents a specific activity within the process. An example of a Supporting Activity within Procure Raw Materials would be the creation of a Purchase Order. On the Recruit & Hire Employees side an example of a Supporting Activity would be to make a job offer and negotiate details. A Supporting Task is a step involved in performing a specific Supporting Activity or Sub-Process and is a subset of an overall Business Process. They are usually performed by a single unit (a person, a machine or a department). An activity is usually documented in an instruction. An example of a Supporting Task would be the creation of a Purchase Order for a consumable versus stock item. Using a Payroll example for a Supporting Task would be paying employees by direct deposit versus generating a check. Steps in a Supporting Activity are defined to the transaction level, (which become business steps). A Supporting Step walks one through a Supporting Activity and identifies the decision points one will have to make to complete the task. This really defines the flow of how one will do a job. 3/19/2018 © 2010 RLM & Associates LLC 84

Process Management A Supplier is an external entity that provides common off the shelf or standard products or services A Customer is any entity, person or another process that receives an output from the process under investigation Product/Service Business Processes are involved in producing the delivered product or service such as manufacturing a car or processing an ATM withdrawal Enabling Processes support processes such as order processing, accounts payable and hiring processes A Key Process is defined as a process that is important to the success of the business or the customer 3/19/2018 © 2010 RLM & Associates LLC 85

Process Management A Supplier is an external entity that provides common off the shelf or standard products or services A Customer is any entity, person or another process that receives an output from the process under investigation Product/Service Business Processes are involved in producing the delivered product or service such as manufacturing a car or processing an ATM withdrawal Enabling Processes support processes such as order processing, accounts payable and hiring processes A Key Process is defined as a process that is important to the success of the business or the customer 3/19/2018 © 2010 RLM & Associates LLC 85

Process Management A Process Management System ensures the outputs of work is: 1. predictable 2. meets customer requirements 3. performed quickly and at low cost 4. aligned to deliver value to the customer 5. capable of quickly changing to meet market and customer demands Process Owner’s manage a process from end-to-end to ensure an acceptable level of overall performance Process Member’s are key supporters for the deliverables from the process 3/19/2018 © 2010 RLM & Associates LLC 86

Process Management A Process Management System ensures the outputs of work is: 1. predictable 2. meets customer requirements 3. performed quickly and at low cost 4. aligned to deliver value to the customer 5. capable of quickly changing to meet market and customer demands Process Owner’s manage a process from end-to-end to ensure an acceptable level of overall performance Process Member’s are key supporters for the deliverables from the process 3/19/2018 © 2010 RLM & Associates LLC 86

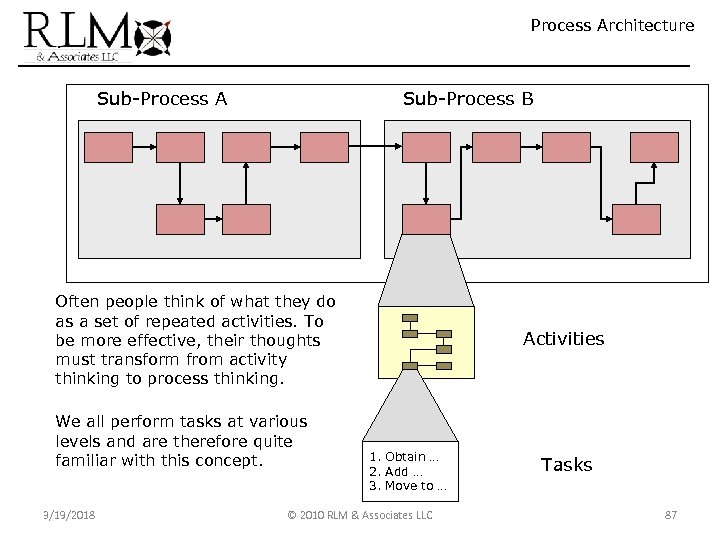

Process Architecture Sub-Process A Sub-Process B Often people think of what they do as a set of repeated activities. To be more effective, their thoughts must transform from activity thinking to process thinking. We all perform tasks at various levels and are therefore quite familiar with this concept. 3/19/2018 Activities 1. Obtain … 2. Add … 3. Move to … © 2010 RLM & Associates LLC Tasks 87

Process Architecture Sub-Process A Sub-Process B Often people think of what they do as a set of repeated activities. To be more effective, their thoughts must transform from activity thinking to process thinking. We all perform tasks at various levels and are therefore quite familiar with this concept. 3/19/2018 Activities 1. Obtain … 2. Add … 3. Move to … © 2010 RLM & Associates LLC Tasks 87

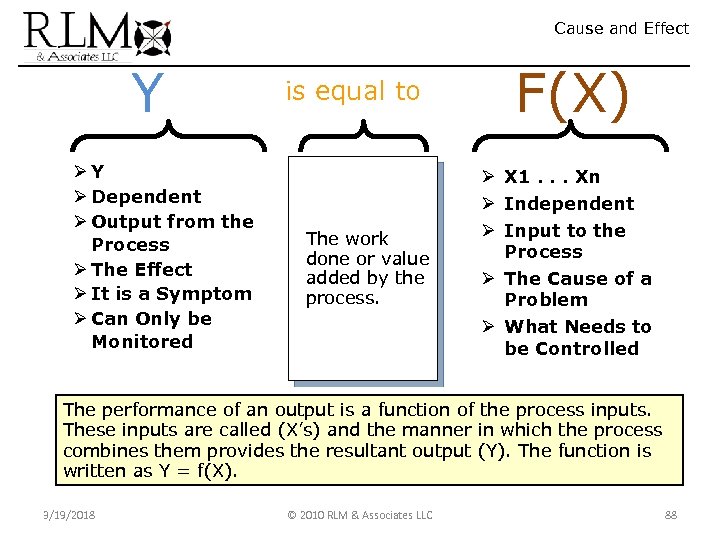

Cause and Effect Y ØY Ø Dependent Ø Output from the Process Ø The Effect Ø It is a Symptom Ø Can Only be Monitored is equal to The work done or value added by the process. F(X) Ø X 1. . . Xn Ø Independent Ø Input to the Process Ø The Cause of a Problem Ø What Needs to be Controlled The performance of an output is a function of the process inputs. These inputs are called (X’s) and the manner in which the process combines them provides the resultant output (Y). The function is written as Y = f(X). 3/19/2018 © 2010 RLM & Associates LLC 88

Cause and Effect Y ØY Ø Dependent Ø Output from the Process Ø The Effect Ø It is a Symptom Ø Can Only be Monitored is equal to The work done or value added by the process. F(X) Ø X 1. . . Xn Ø Independent Ø Input to the Process Ø The Cause of a Problem Ø What Needs to be Controlled The performance of an output is a function of the process inputs. These inputs are called (X’s) and the manner in which the process combines them provides the resultant output (Y). The function is written as Y = f(X). 3/19/2018 © 2010 RLM & Associates LLC 88

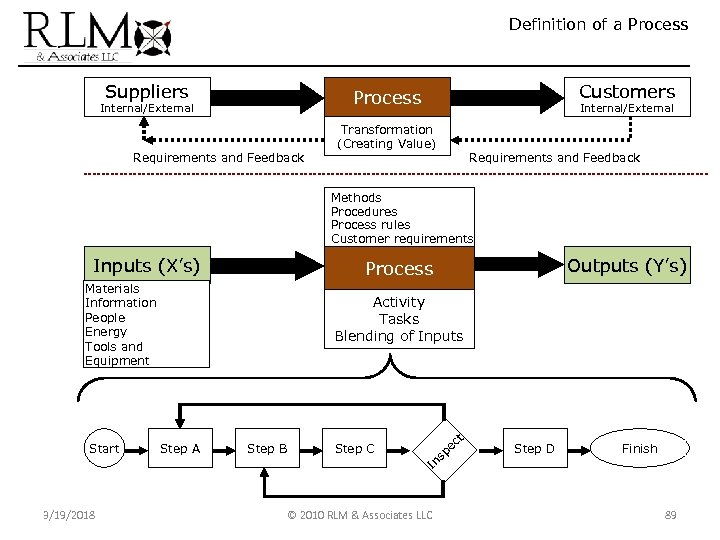

Definition of a Process Suppliers Customers Process Internal/External Requirements and Feedback Internal/External Transformation (Creating Value) Requirements and Feedback Methods Procedures Process rules Customer requirements Inputs (X’s) Materials Information People Energy Tools and Equipment Step A Step B pe ct Activity Tasks Blending of Inputs Step C Step D Finish In s Start Outputs (Y’s) Process 3/19/2018 © 2010 RLM & Associates LLC 89

Definition of a Process Suppliers Customers Process Internal/External Requirements and Feedback Internal/External Transformation (Creating Value) Requirements and Feedback Methods Procedures Process rules Customer requirements Inputs (X’s) Materials Information People Energy Tools and Equipment Step A Step B pe ct Activity Tasks Blending of Inputs Step C Step D Finish In s Start Outputs (Y’s) Process 3/19/2018 © 2010 RLM & Associates LLC 89

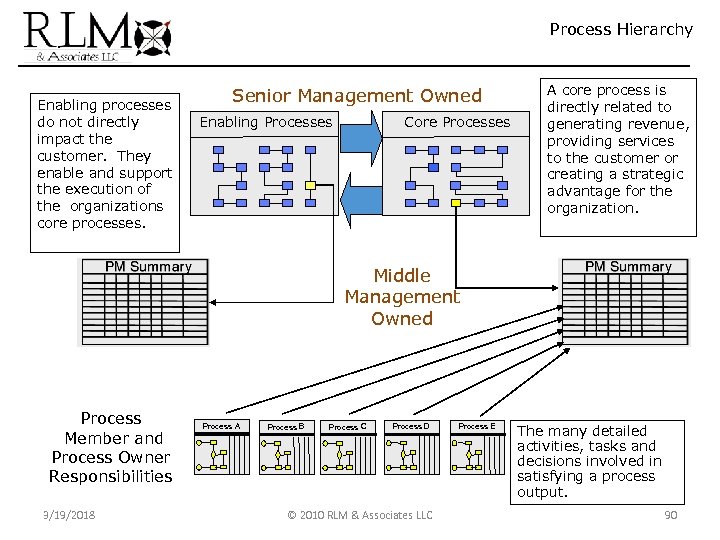

Process Hierarchy Enabling processes do not directly impact the customer. They enable and support the execution of the organizations core processes. Senior Management Owned Enabling Processes Core Processes A core process is directly related to generating revenue, providing services to the customer or creating a strategic advantage for the organization. Middle Management Owned Process Member and Process Owner Responsibilities 3/19/2018 Process A Process B Process C Process D © 2010 RLM & Associates LLC Process E The many detailed activities, tasks and decisions involved in satisfying a process output. 90

Process Hierarchy Enabling processes do not directly impact the customer. They enable and support the execution of the organizations core processes. Senior Management Owned Enabling Processes Core Processes A core process is directly related to generating revenue, providing services to the customer or creating a strategic advantage for the organization. Middle Management Owned Process Member and Process Owner Responsibilities 3/19/2018 Process A Process B Process C Process D © 2010 RLM & Associates LLC Process E The many detailed activities, tasks and decisions involved in satisfying a process output. 90