4fbe5535a548d7d03885f0d6737e2a90.ppt

- Количество слайдов: 67

Lean e. Manufacturing Bob Reary Director, Supply Chain Product Strategy

Your ROI. . . From this session will be. . . w to see how the best of traditional ERP should be coupled with Lean Manufacturing for increased response, market share, and return-on-assets w to learn some of the basics of e. Manufacturing w to gain an understanding of the opportunities and challenges presented by the Next economy

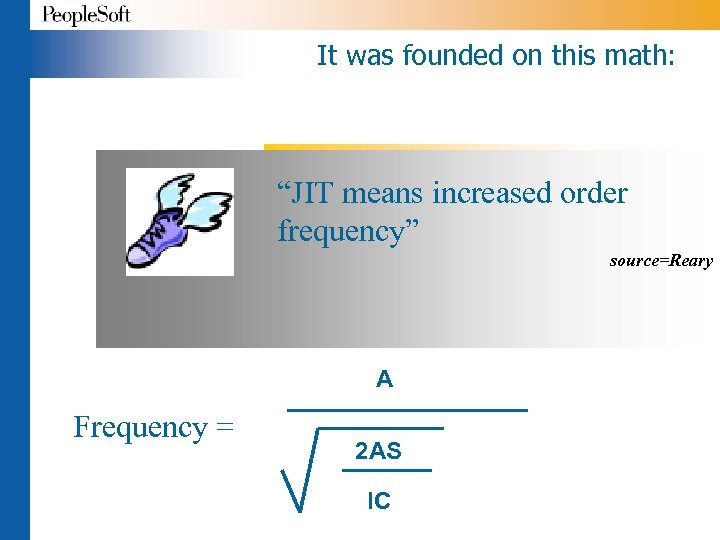

Historically, there has been a trade-off between setup and carrying costs

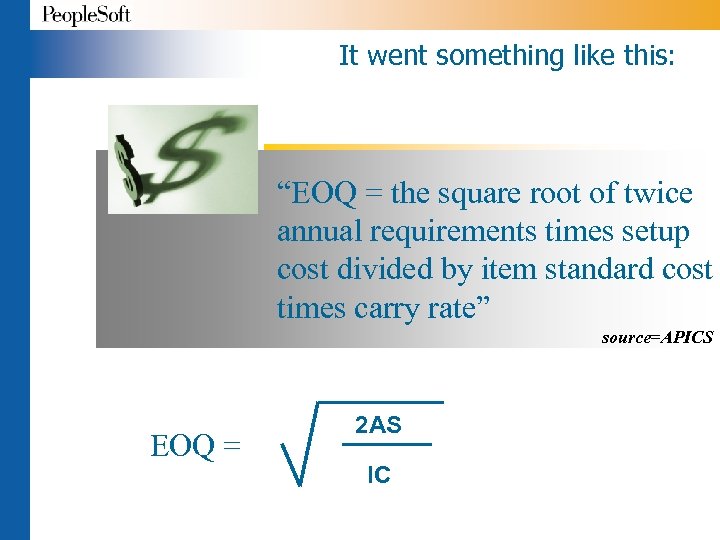

It went something like this: “EOQ = the square root of twice annual requirements times setup cost divided by item standard cost times carry rate” source=APICS EOQ = 2 AS IC

Early Manufacturing solutions were characterized by: . . Policies and practices of isolation (Sales-to-Planningto-Materials Mgmt. . Poor record accuracies. . High costs. . Redundancies

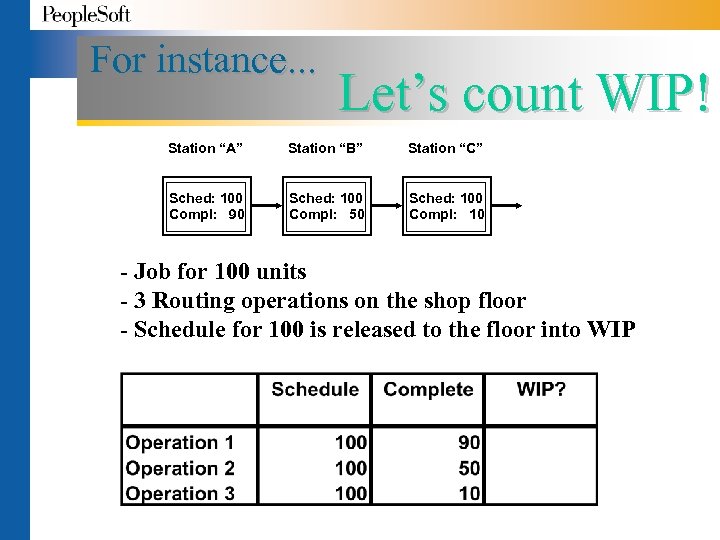

For instance. . . Let’s count WIP! Station “A” Station “B” Station “C” Sched: 100 Compl: 90 Sched: 100 Compl: 50 Sched: 100 Compl: 10 - Job for 100 units - 3 Routing operations on the shop floor - Schedule for 100 is released to the floor into WIP

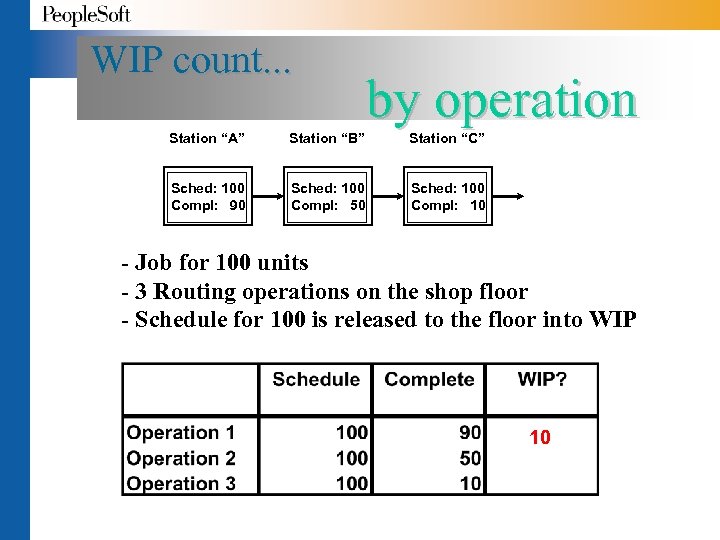

WIP count. . . by operation Station “A” Station “B” Station “C” Sched: 100 Compl: 90 Sched: 100 Compl: 50 Sched: 100 Compl: 10 - Job for 100 units - 3 Routing operations on the shop floor - Schedule for 100 is released to the floor into WIP 10

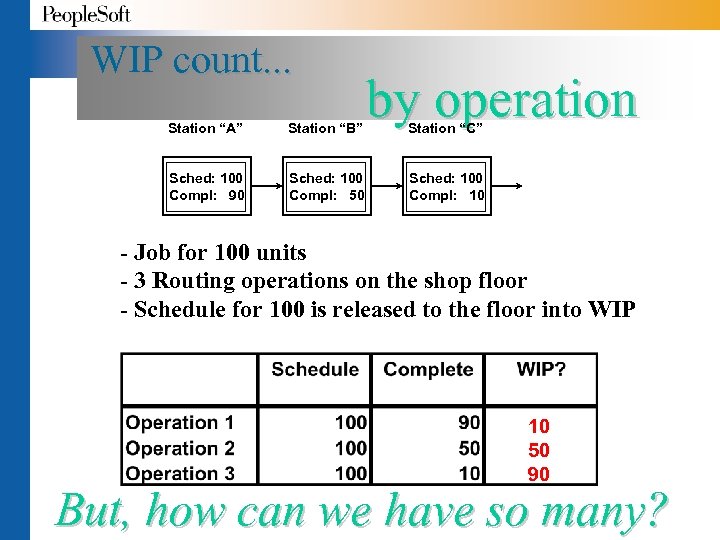

WIP count. . . Station “A” Station “B” Sched: 100 Compl: 90 Sched: 100 Compl: 50 by operation Station “C” Sched: 100 Compl: 10 - Job for 100 units - 3 Routing operations on the shop floor - Schedule for 100 is released to the floor into WIP 10 50 90 But, how can we have so many?

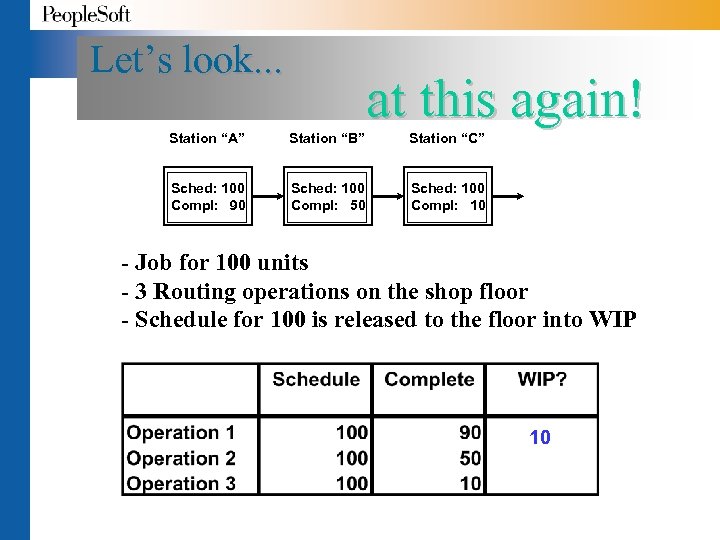

Let’s look. . . at this again! Station “A” Station “B” Station “C” Sched: 100 Compl: 90 Sched: 100 Compl: 50 Sched: 100 Compl: 10 - Job for 100 units - 3 Routing operations on the shop floor - Schedule for 100 is released to the floor into WIP 10

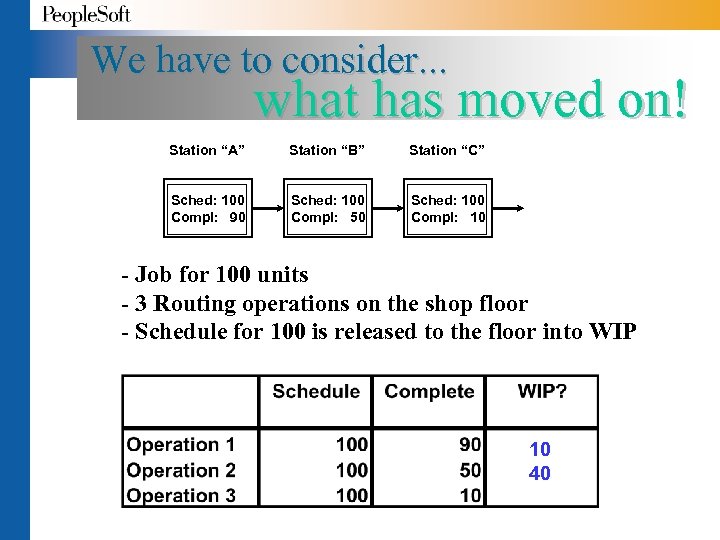

We have to consider. . . what has moved on! Station “A” Station “B” Station “C” Sched: 100 Compl: 90 Sched: 100 Compl: 50 Sched: 100 Compl: 10 - Job for 100 units - 3 Routing operations on the shop floor - Schedule for 100 is released to the floor into WIP 10 40

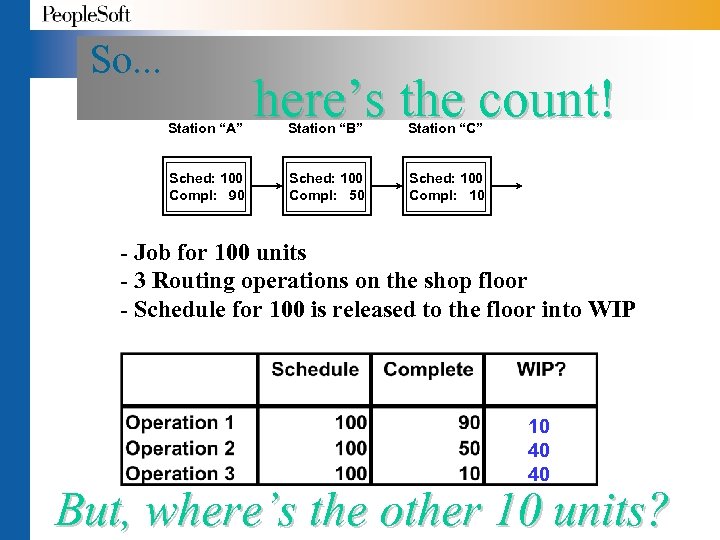

So. . . Station “A” Sched: 100 Compl: 90 here’s the count! Station “B” Station “C” Sched: 100 Compl: 50 Sched: 100 Compl: 10 - Job for 100 units - 3 Routing operations on the shop floor - Schedule for 100 is released to the floor into WIP 10 40 40 But, where’s the other 10 units?

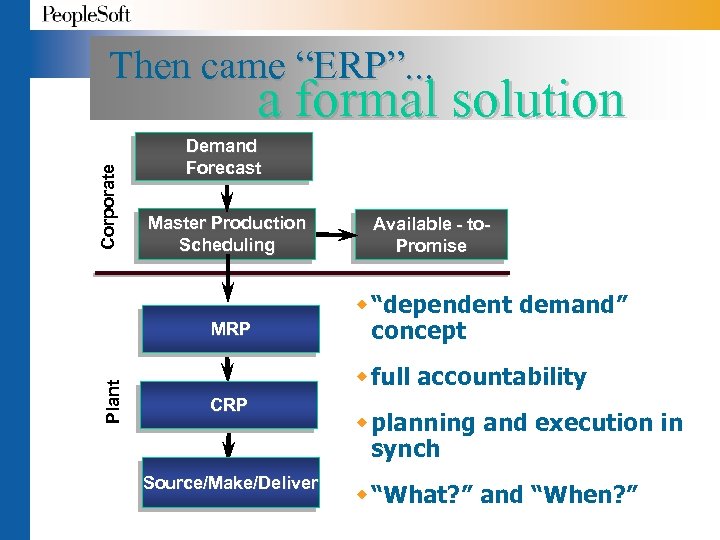

Then came “ERP”. . . Corporate a formal solution Demand Forecast Master Production Scheduling Plant MRP Available - to. Promise w “dependent demand” concept w full accountability CRP Source/Make/Deliver w planning and execution in synch w “What? ” and “When? ”

The along came Dr. Taiichi Ohno and Shigeo Shingo! Why count WIP? Why have WIP in the first place?

Philosophically: ERP said. . . w You need to reconcile assets to the balance sheet w You need tools for status and control; for coping; for buffering to solve problems w You need to schedule and re -schedule; to prioritize and re-prioritize …the desire to reconcile is insidious!!

Philosophically: Ohno said. . . w “When production control is properly understood, inventory control is unnecessary!” w WIP is a target for problems to stick to… keep the target small!

So the trade-off was improved on by the development of JIT! w Reduced inventories w Agile/Lean manufacturing w High throughput and efficiencies w Increased Stability and Quality

It was founded on this math: “JIT means increased order frequency” source=Reary A Frequency = 2 AS IC

Toyota Production System founded on: w JIT (Kanban) w “Automation with a human touch” (Jidoka) w Smoothing (Heijunka)

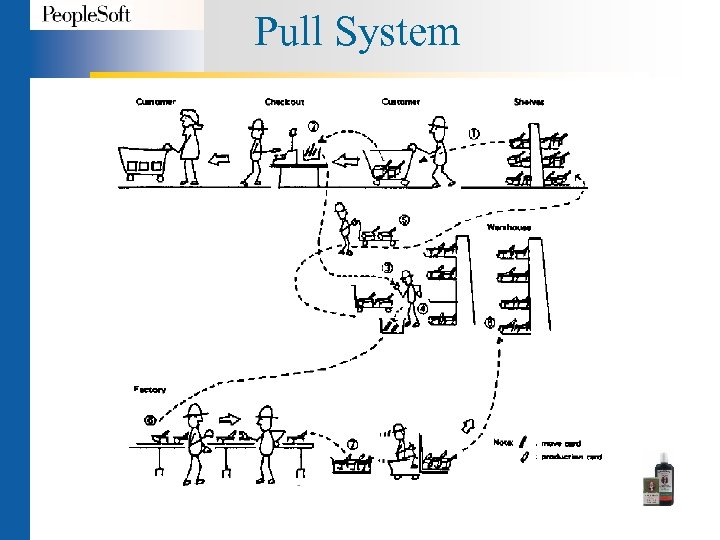

At the supermarket

Pull System

Tricks of the trade Grandpa's Wonder Pine Tar Soap 4. 25 oz. bar

So, why would Toyota buy an ERP package? w to gain Y 2 K compliance w to achieve lower IT costs through deployment of a common solution w adapt to constant change w proof-of-concept: facilitated by demonstrated success with “backoffice”

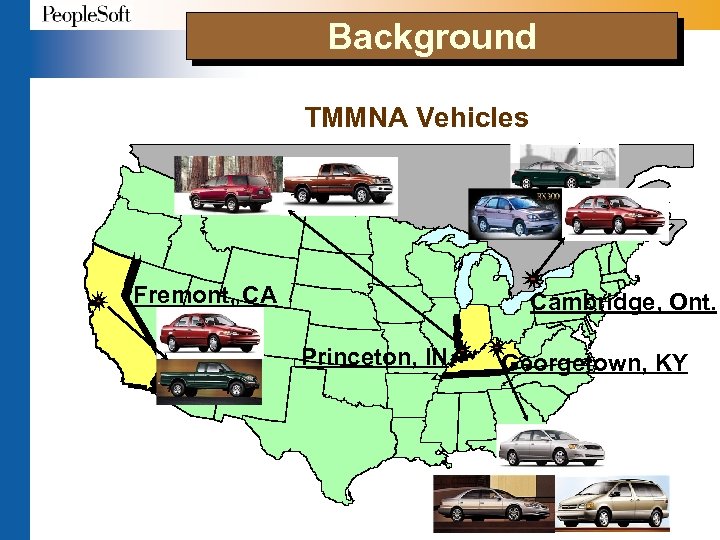

Background TMMNA Vehicles Fremont, CA Princeton, IN Cambridge, Ont. Georgetown, KY

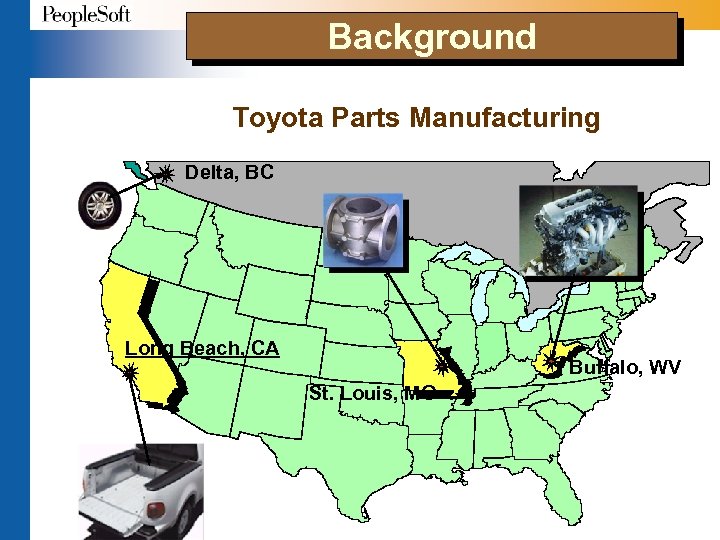

Background Toyota Parts Manufacturing Delta, BC Long Beach, CA Buffalo, WV St. Louis, MO

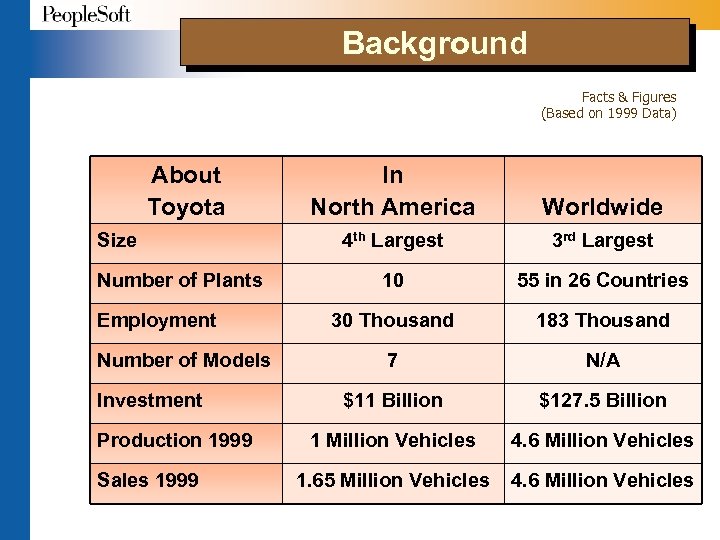

Background Facts & Figures (Based on 1999 Data) About Toyota Size Number of Plants Employment Number of Models Investment Production 1999 Sales 1999 In North America Worldwide 4 th Largest 3 rd Largest 10 55 in 26 Countries 30 Thousand 183 Thousand 7 N/A $11 Billion $127. 5 Billion 1 Million Vehicles 4. 6 Million Vehicles 1. 65 Million Vehicles 4. 6 Million Vehicles

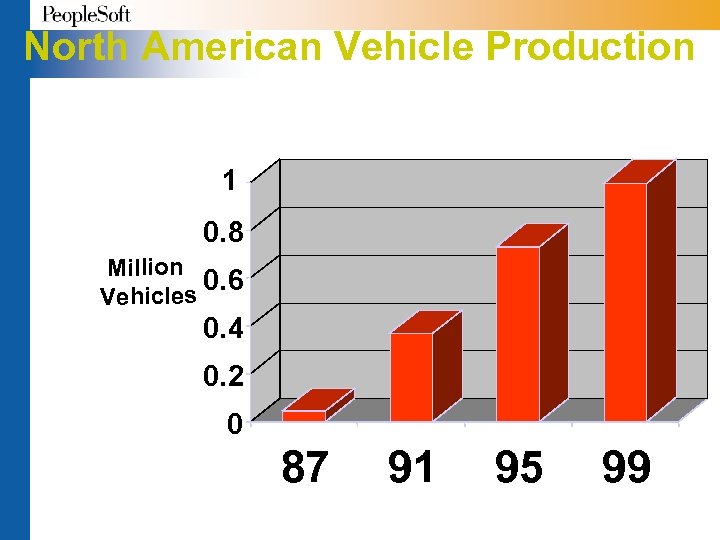

North American Vehicle Production 1 0. 8 Million 0. 6 les Vehic 0. 4 0. 2 0 87 91 95 99

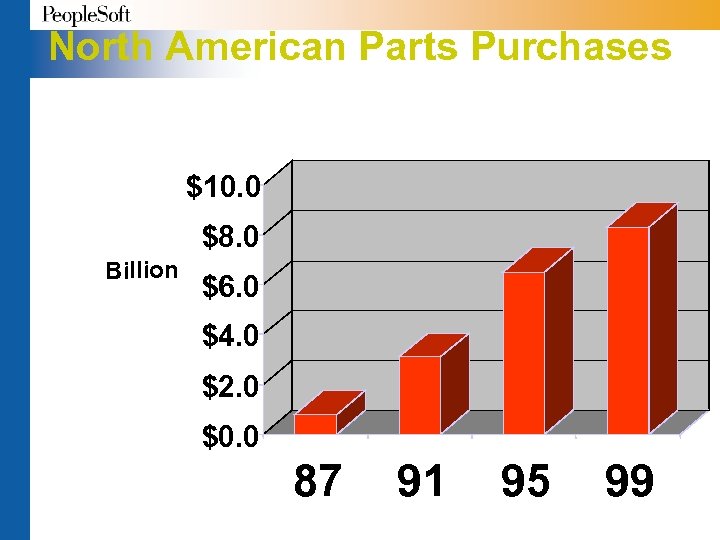

North American Parts Purchases $10. 0 $8. 0 Billion $6. 0 $4. 0 $2. 0 $0. 0 87 91 95 99

Background Service Parts Export Parts B 2 B

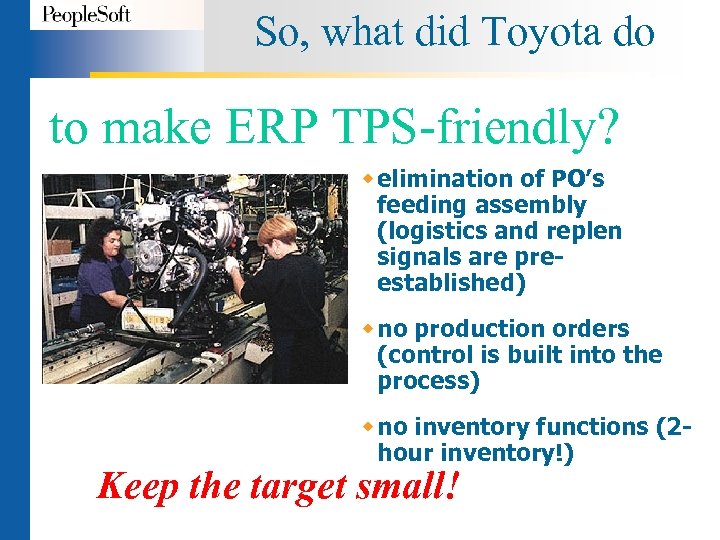

So, what did Toyota do to make ERP TPS-friendly? w elimination of PO’s feeding assembly (logistics and replen signals are preestablished) w no production orders (control is built into the process) w no inventory functions (2 hour inventory!) Keep the target small!

Where did ERP Demand Planning add value? w Level-by-level production planning (proprietary) Kanban Planning s to systematize Heijunka smoothing and capacity management s to drive planned replenishment signals w link Customer orders to production kanbans w electronic poka yokes aka “quality pictures”

Other key differentiators of TPS: w Customer demand mgmt to offset legacy system minimal functionality s order process s parts shipping schedule to Customer s visibility of part production w emphasize TAKT, not orders w stability, not reaction

But how about this “APS”? ? ? Advanced Planning & Scheduling w Optimization of key “constraints” w People. Soft was a pioneer in this technology

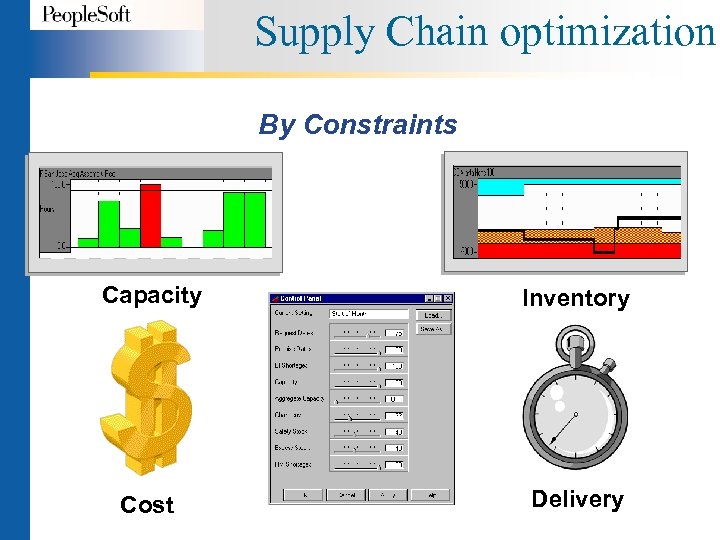

Supply Chain optimization By Constraints Capacity Inventory Cost Delivery

Fast forward… some pro’s and con’s of APS w PRO’s w CON’s w fast memory-resident modelling w implementation too long and complex w good at complex sequencing w loading the model is a “setup” cost that impedes frequency

So what? ? Why does it matter? Let’s take stock. . . ERP was for accounting and provided a foundation TPS is the chain So how does APS fit in?

TPS vs APS TPS founded on: w smoothing (averaging? ) w stability The bus. . . APS founded on: w responsiveness w event-driven planning and the elevator!

Then there was… Demand Flow Technology! w John Constanza Institute of Technology w Very similar to TPS s demand-driven execution s stable operations s stable patterns of supply

TPS and Flow w TPS s assumption of complex operations and transfer lines s preference for overtime to meet demand fluctuations w Demand Flow s assumption of light assembly s preference for line rebalancing to meet demand fluctuations Costanza’s Quality Stick is a Shingo Poka Yoke

The attributes of … Solution soup! w Bom depth (DFT) w Levelling (TPS) w Sequencing (APS) w Release (OPT-we ignored this one!) w Event-driven (APS) w Record keeping and Capacity management (ERP)

APS + TPS = FPS! Flow Production System

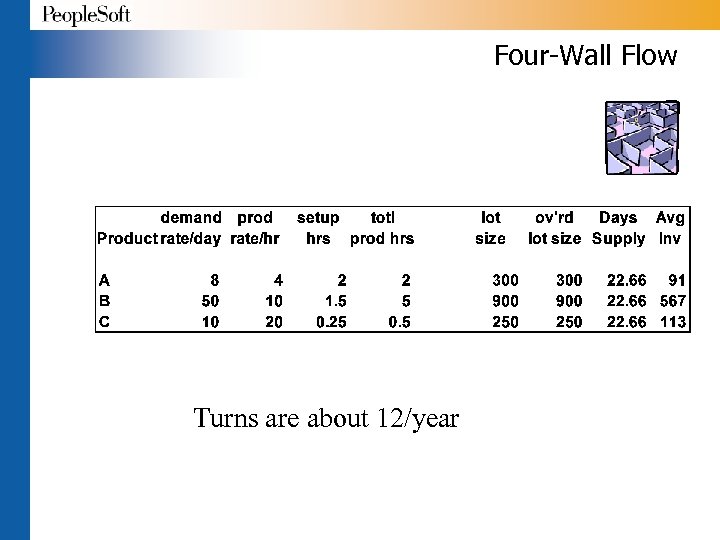

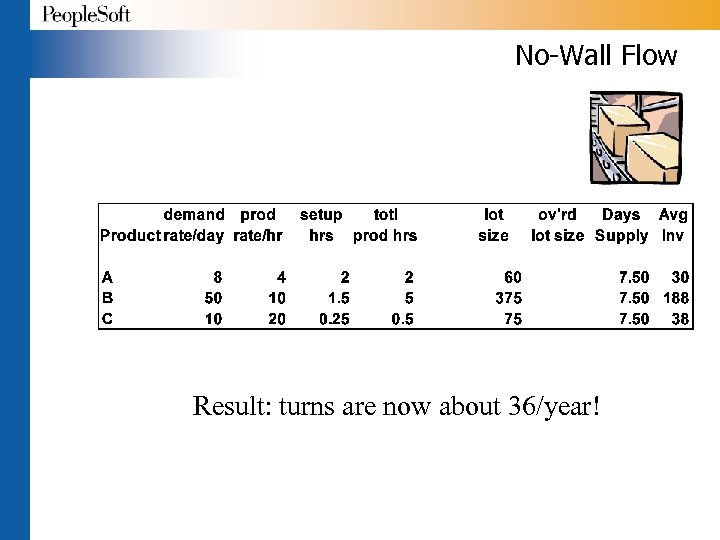

Four-Wall Flow Turns are about 12/year

No-Wall Flow Result: turns are now about 36/year!

The key is cross-web sharing Planning simplification Collaborate by Rate

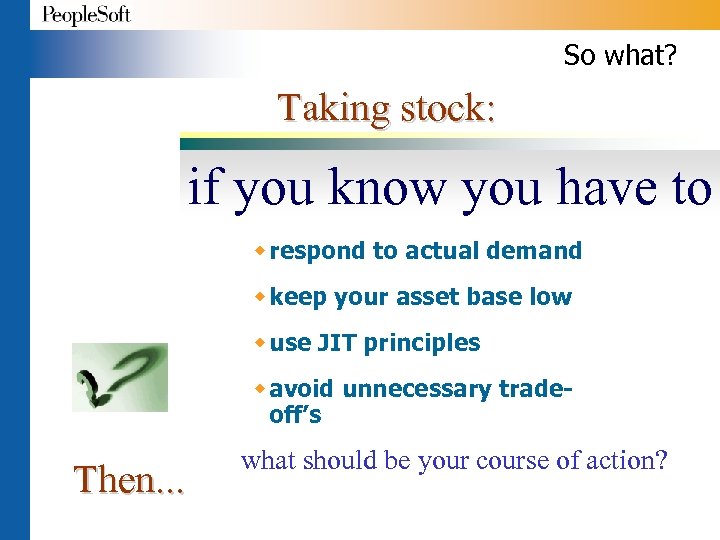

So what? Taking stock: if you know you have to w respond to actual demand w keep your asset base low w use JIT principles w avoid unnecessary tradeoff’s Then. . . what should be your course of action?

A given: This trade-off. . . Richness Reach

A given: … is exploding! Richness Reach

And “reach” is driving commoditization! w law of 95 -5 w high reach = high availability w high availability = low differentiability So the focus should be on the Supply web!

From… The age of reason where success meant w improve on the operational trade -offs w improve quality, change-over w stabilize operations s reduce number of suppliers s tightly connect to large Customers w increase market share through cost improvement w search downward opportunities

To… The age of “access” where success means w Search upward opportunities w leverage access w increase share through response to actual demand w keep flexibility at lowest point

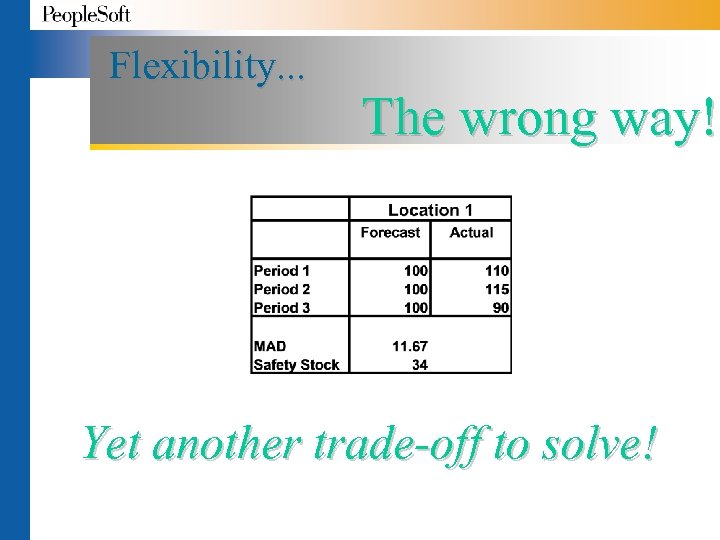

Flexibility. . . The wrong way! Yet another trade-off to solve!

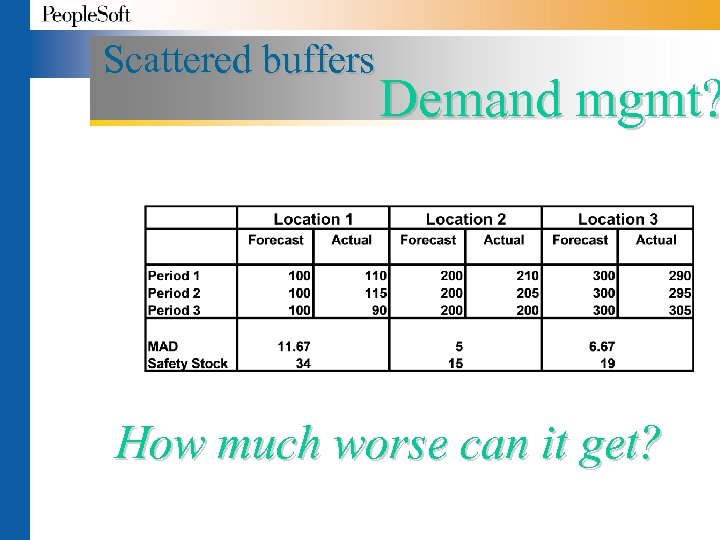

Scattered buffers Demand mgmt? How much worse can it get?

Looking through. . . that car up ahead

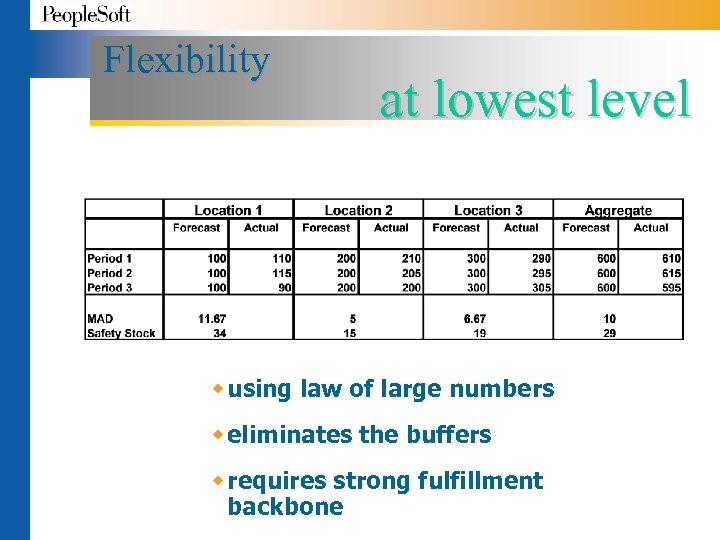

Flexibility at lowest level w using law of large numbers w eliminates the buffers w requires strong fulfillment backbone

e. Manufacturing? What is it’s promise? w Tactically: ease of training and deployment w Strategically: interconnectedness to reduce time and buffers w Improve responsiveness in: s design s demand management s replenishment

The “Next” Economy Transitioning w From “What and When” to “Where” (the reach of e) w Metcalf’s Law w “New” was B 2 C and B 2 B w “Next” is C 4 B

The “Next” Economy To be characterized by. . . “Compadres for Business” 4 w The Internet has infinite capacity w We have to stop thinking in hierarchies!

Down on the shop floor , Manufacturing wants w better demand w input on designs (for manufacturability) w betters tools for production flexibility w ease of access to relevant information just like any other supplier!

Challenges & Vision Capacity promising assumptions across the supply web Traditional countermeasure: under-capacity planning Future countermeasure: real options planning

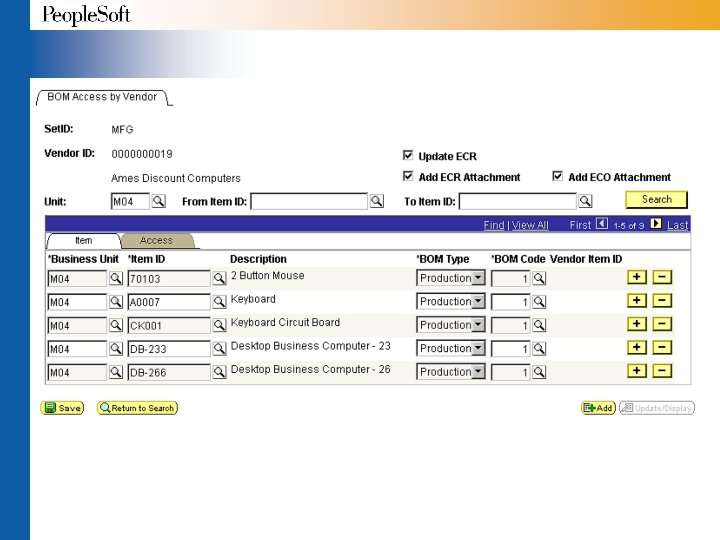

Challenges & Vision Instability of ECO process Traditional countermeasure: ECO clumping on a fixed schedule (“bus”) Future countermeasure: process integration upstream

Challenges & Vision Instability of transition management Traditional countermeasure: buffers Future countermeasure: “budget-achieved, life ends”

Challenges & Vision Balancing “flexibility” (reach) with “stability” (differentiable richness) Traditional countermeasure: year-to-year internal policy and metric mgmt Future countermeasure: shared policy in the supply web

Challenges & Vision Shared record accuracy Traditional countermeasure: recent history-->few successes! Future countermeasure: data model simplification and standards

Typical Benefits of implementing Lean e. Manufacturing w 30% throughput increase with no corresponding asset increase (yields greater share) w turns increase of 50 -100% coupled with service increase (5 -15 points) w 30 -50% reduction in cost of quality

OK. . . Recommendations. . . w simplify the transaction system and expand reach through collaboration and standards w focus heavily on improving shared policies, practices and physical operations w connect to actual demand through multilevels w Pursue and use the opportunities afforded by chaos!

Questions? ? ? Lean e. Manufacturing Bob Reary Director, Supply Chain Product Strategy

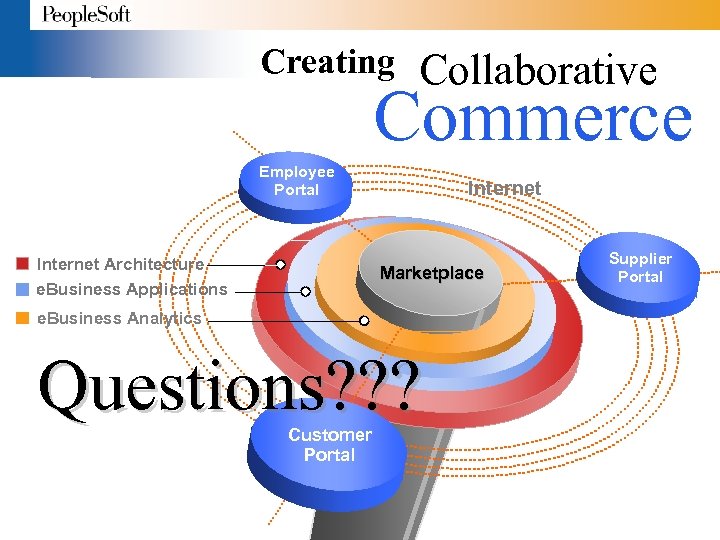

Creating Collaborative Commerce Employee Portal Internet Architecture e. Business Applications Internet Marketplace e. Business Analytics Questions? ? ? Customer Portal Supplier Portal

4fbe5535a548d7d03885f0d6737e2a90.ppt