bcf94ab297cc77d4e5bb172526c8a725.ppt

- Количество слайдов: 30

LEAN CONSTRUCTION IN FINLAND Magnus Nygård Head of Road Procurement Unit Finnish Transport Agency, Road Department

LEAN CONSTRUCTION IN FINLAND Magnus Nygård Head of Road Procurement Unit Finnish Transport Agency, Road Department

Authors Professor Harri Haapasalo University of Oulu harri. haapasalo@oulu. fi Tel. +358 405 182 275 M. S (eng. ) Lauri Merikallio lauri. merikallio@vakeva. fi lauri. merikallio@oulu. fi tel. +358 400 450 217

Authors Professor Harri Haapasalo University of Oulu harri. haapasalo@oulu. fi Tel. +358 405 182 275 M. S (eng. ) Lauri Merikallio lauri. merikallio@vakeva. fi lauri. merikallio@oulu. fi tel. +358 400 450 217

THE LEAN IDEAL Give customer products exactly fit for purpose, instantly, with no waste Maximize value for customer and minimize waste

THE LEAN IDEAL Give customer products exactly fit for purpose, instantly, with no waste Maximize value for customer and minimize waste

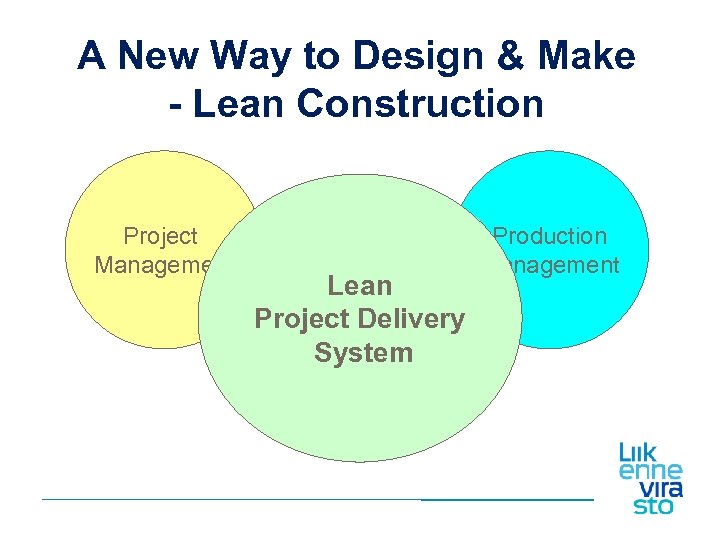

A New Way to Design & Make - Lean Construction Project Management Lean Project Delivery System Production Management

A New Way to Design & Make - Lean Construction Project Management Lean Project Delivery System Production Management

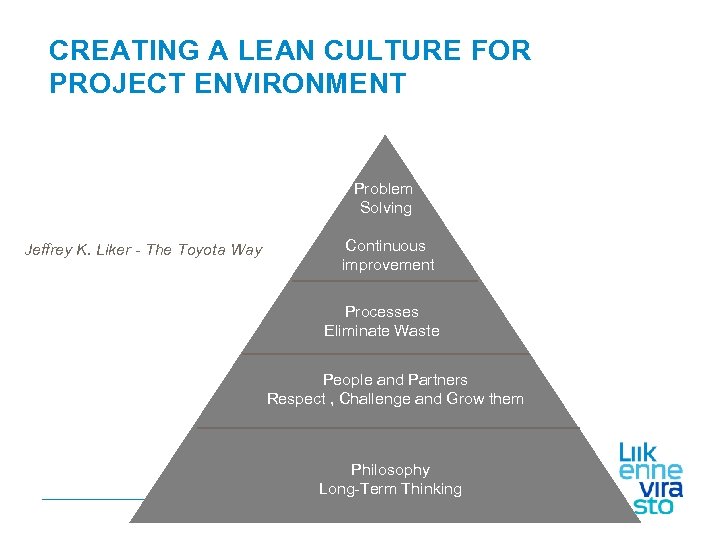

CREATING A LEAN CULTURE FOR PROJECT ENVIRONMENT Problem Solving Jeffrey K. Liker - The Toyota Way Continuous improvement Processes Eliminate Waste People and Partners Respect , Challenge and Grow them Philosophy Long-Term Thinking

CREATING A LEAN CULTURE FOR PROJECT ENVIRONMENT Problem Solving Jeffrey K. Liker - The Toyota Way Continuous improvement Processes Eliminate Waste People and Partners Respect , Challenge and Grow them Philosophy Long-Term Thinking

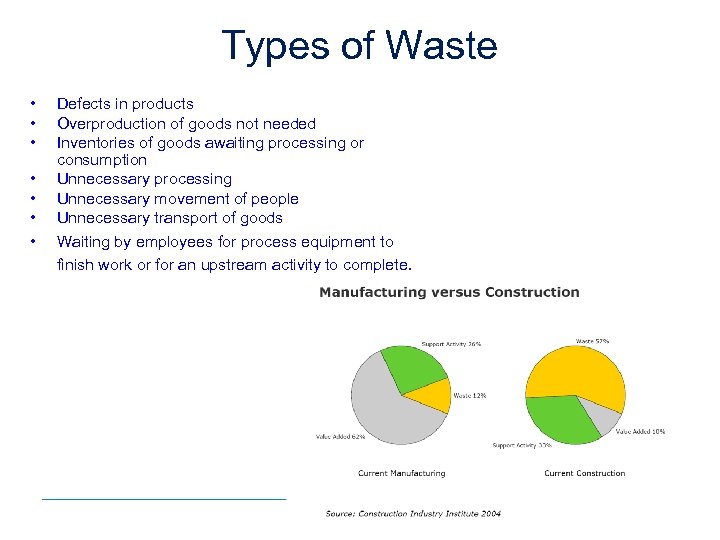

Types of Waste • • Defects in products Overproduction of goods not needed Inventories of goods awaiting processing or consumption Unnecessary processing Unnecessary movement of people Unnecessary transport of goods Waiting by employees for process equipment to finish work or for an upstream activity to complete.

Types of Waste • • Defects in products Overproduction of goods not needed Inventories of goods awaiting processing or consumption Unnecessary processing Unnecessary movement of people Unnecessary transport of goods Waiting by employees for process equipment to finish work or for an upstream activity to complete.

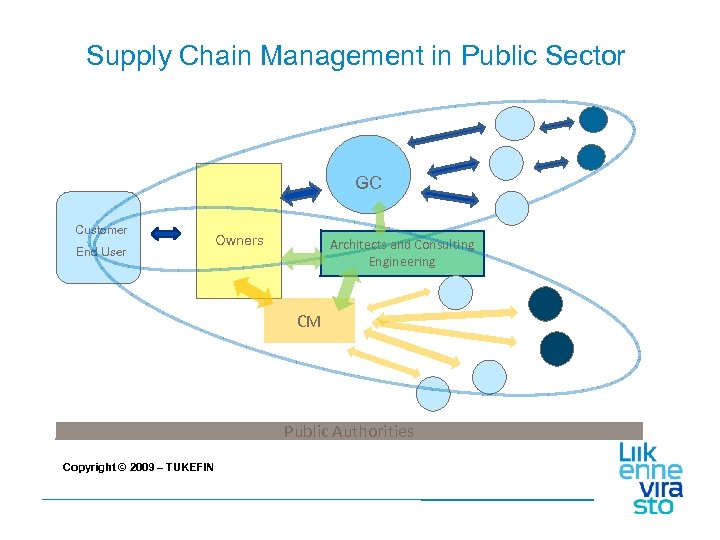

Supply Chain Management in Public Sector GC Customer End User Owners Architects and Consulting Engineering CM Public Authorities Copyright © 2009 – TUKEFIN

Supply Chain Management in Public Sector GC Customer End User Owners Architects and Consulting Engineering CM Public Authorities Copyright © 2009 – TUKEFIN

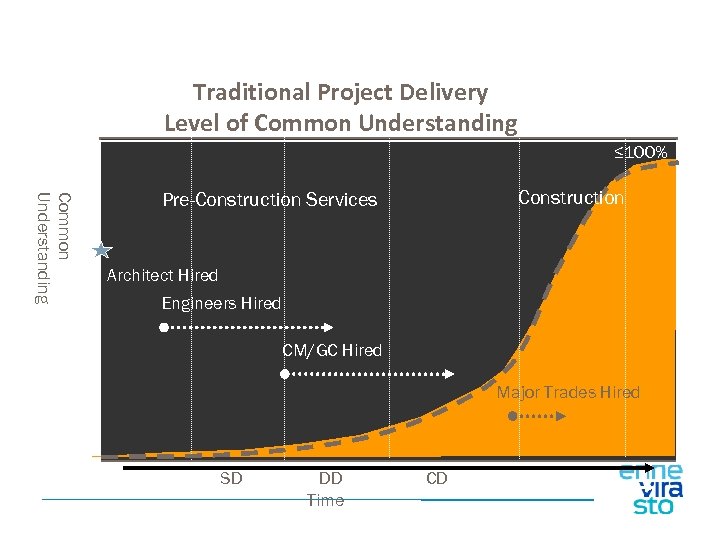

Traditional Project Delivery Level of Common Understanding ≤ 100% Common Understanding Construction Pre-Construction Services Architect Hired Engineers Hired CM/GC Hired Major Trades Hired SD DD Time CD

Traditional Project Delivery Level of Common Understanding ≤ 100% Common Understanding Construction Pre-Construction Services Architect Hired Engineers Hired CM/GC Hired Major Trades Hired SD DD Time CD

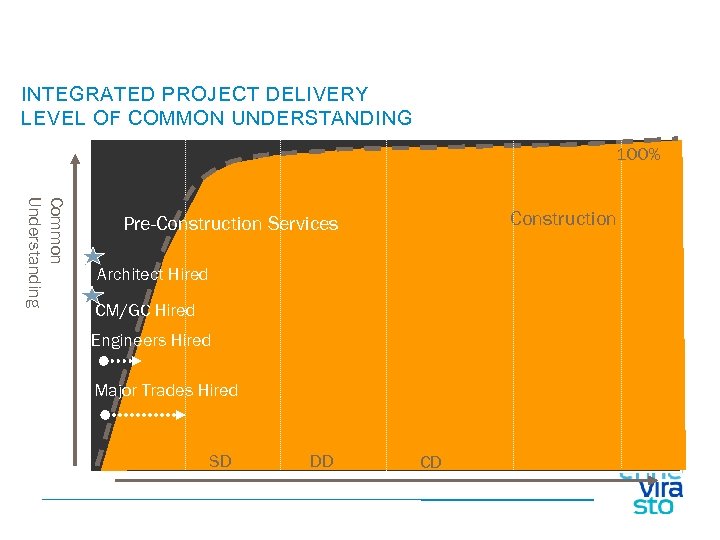

INTEGRATED PROJECT DELIVERY LEVEL OF COMMON UNDERSTANDING 100% Common Understanding Construction Pre-Construction Services Architect Hired CM/GC Hired Engineers Hired Major Trades Hired SD DD CD

INTEGRATED PROJECT DELIVERY LEVEL OF COMMON UNDERSTANDING 100% Common Understanding Construction Pre-Construction Services Architect Hired CM/GC Hired Engineers Hired Major Trades Hired SD DD CD

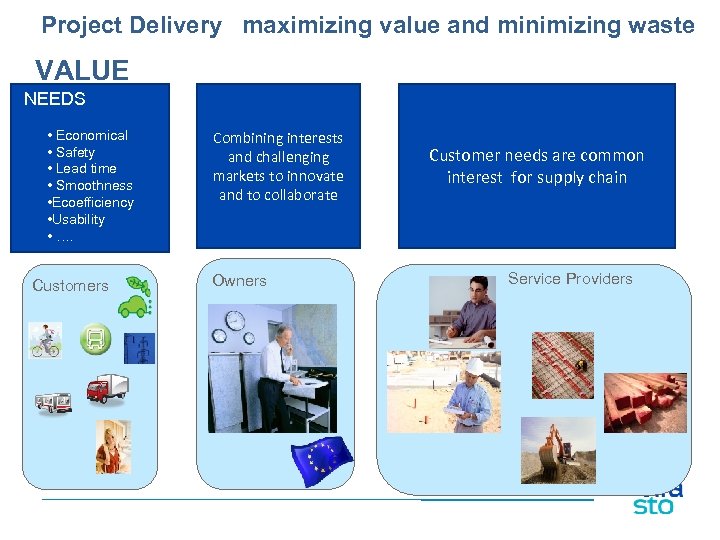

Project Delivery maximizing value and minimizing waste VALUE NEEDS • Economical • Safety • Lead time • Smoothness • Ecoefficiency • Usability • …. Customers Combining interests and challenging markets to innovate and to collaborate Owners Customer needs are common interest for supply chain Service Providers

Project Delivery maximizing value and minimizing waste VALUE NEEDS • Economical • Safety • Lead time • Smoothness • Ecoefficiency • Usability • …. Customers Combining interests and challenging markets to innovate and to collaborate Owners Customer needs are common interest for supply chain Service Providers

Challenges and Trends in Construction

Challenges and Trends in Construction

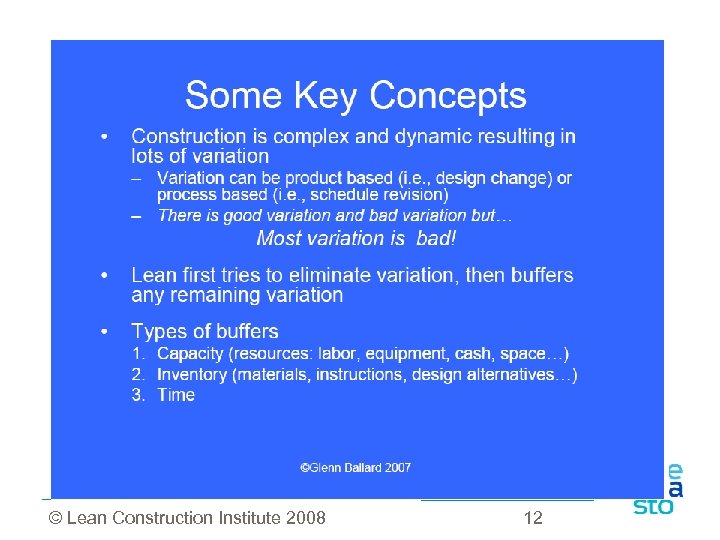

© Lean Construction Institute 2008 12

© Lean Construction Institute 2008 12

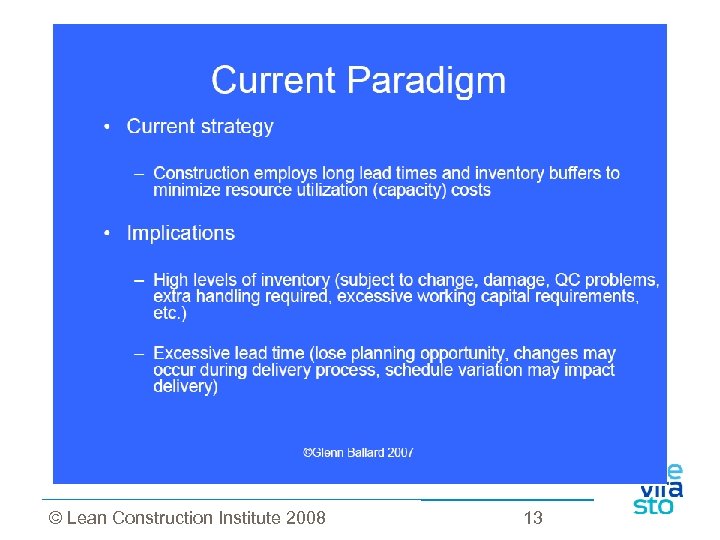

© Lean Construction Institute 2008 13

© Lean Construction Institute 2008 13

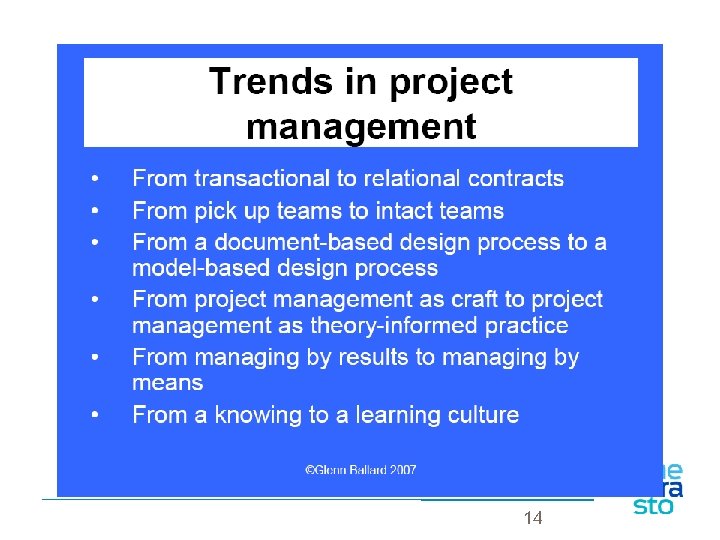

14

14

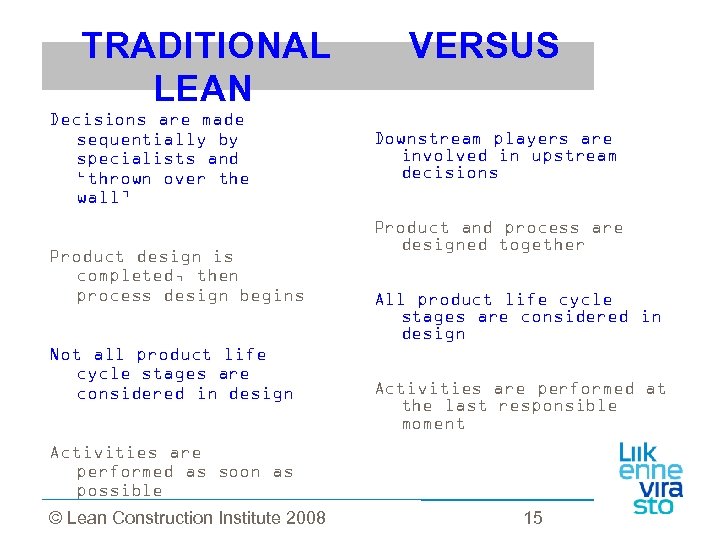

TRADITIONAL VERSUS LEAN Decisions are made sequentially by specialists and ‘thrown over the wall’ Product design is completed, then process design begins Not all product life cycle stages are considered in design Downstream players are involved in upstream decisions Product and process are designed together All product life cycle stages are considered in design Activities are performed at the last responsible moment Activities are performed as soon as possible © Lean Construction Institute 2008 15

TRADITIONAL VERSUS LEAN Decisions are made sequentially by specialists and ‘thrown over the wall’ Product design is completed, then process design begins Not all product life cycle stages are considered in design Downstream players are involved in upstream decisions Product and process are designed together All product life cycle stages are considered in design Activities are performed at the last responsible moment Activities are performed as soon as possible © Lean Construction Institute 2008 15

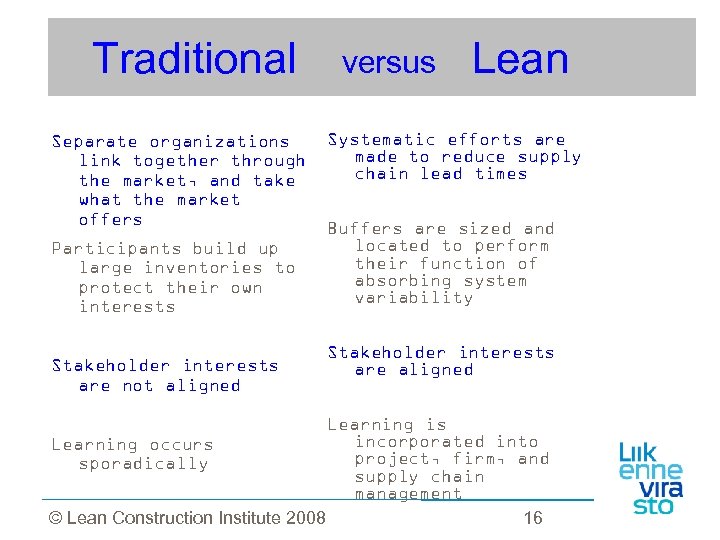

Traditional Separate organizations link together through the market, and take what the market offers Participants build up large inventories to protect their own interests Stakeholder interests are not aligned versus Lean Systematic efforts are made to reduce supply chain lead times Buffers are sized and located to perform their function of absorbing system variability Stakeholder interests are aligned Learning is incorporated into Learning occurs project, firm, and sporadically supply chain management © Lean Construction Institute 2008 16

Traditional Separate organizations link together through the market, and take what the market offers Participants build up large inventories to protect their own interests Stakeholder interests are not aligned versus Lean Systematic efforts are made to reduce supply chain lead times Buffers are sized and located to perform their function of absorbing system variability Stakeholder interests are aligned Learning is incorporated into Learning occurs project, firm, and sporadically supply chain management © Lean Construction Institute 2008 16

THE RECENT DEVELOPMENT OF LEAN IN THE PUBLIC SECTOR IN FINLAND

THE RECENT DEVELOPMENT OF LEAN IN THE PUBLIC SECTOR IN FINLAND

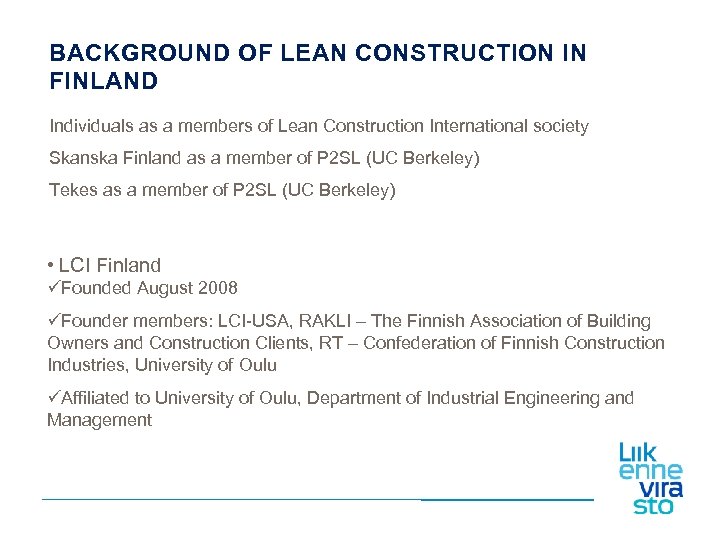

BACKGROUND OF LEAN CONSTRUCTION IN FINLAND Individuals as a members of Lean Construction International society Skanska Finland as a member of P 2 SL (UC Berkeley) Tekes as a member of P 2 SL (UC Berkeley) • LCI Finland üFounded August 2008 üFounder members: LCI-USA, RAKLI – The Finnish Association of Building Owners and Construction Clients, RT – Confederation of Finnish Construction Industries, University of Oulu üAffiliated to University of Oulu, Department of Industrial Engineering and Management

BACKGROUND OF LEAN CONSTRUCTION IN FINLAND Individuals as a members of Lean Construction International society Skanska Finland as a member of P 2 SL (UC Berkeley) Tekes as a member of P 2 SL (UC Berkeley) • LCI Finland üFounded August 2008 üFounder members: LCI-USA, RAKLI – The Finnish Association of Building Owners and Construction Clients, RT – Confederation of Finnish Construction Industries, University of Oulu üAffiliated to University of Oulu, Department of Industrial Engineering and Management

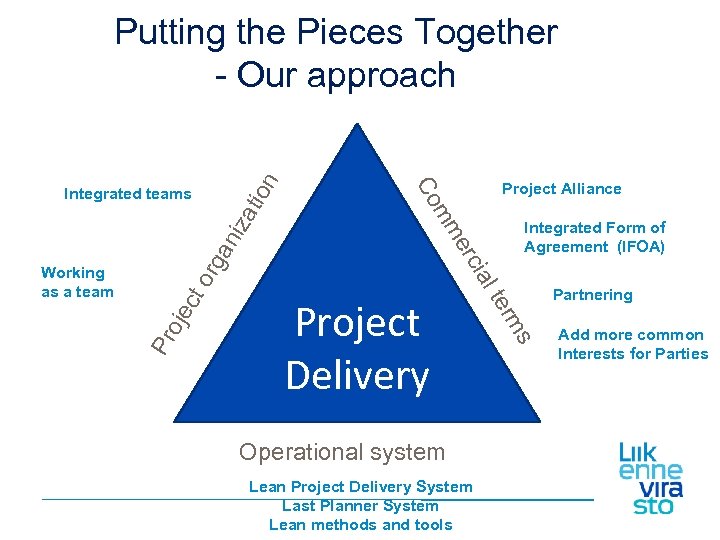

an Operational system Lean Project Delivery System Last Planner System Lean methods and tools ct oje s Project Delivery m ter Pr Integrated Form of Agreement (IFOA) ial org erc Working as a team Project Alliance mm iza Integrated teams Co tio n Putting the Pieces Together - Our approach Partnering Add more common Interests for Parties

an Operational system Lean Project Delivery System Last Planner System Lean methods and tools ct oje s Project Delivery m ter Pr Integrated Form of Agreement (IFOA) ial org erc Working as a team Project Alliance mm iza Integrated teams Co tio n Putting the Pieces Together - Our approach Partnering Add more common Interests for Parties

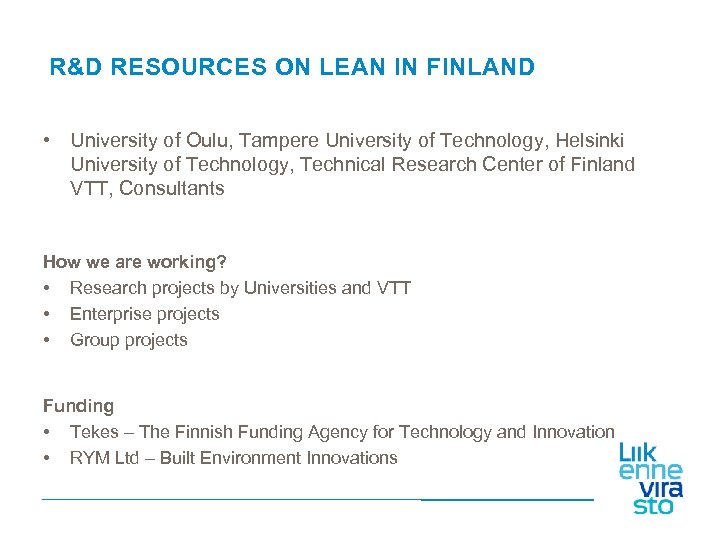

R&D RESOURCES ON LEAN IN FINLAND • University of Oulu, Tampere University of Technology, Helsinki University of Technology, Technical Research Center of Finland VTT, Consultants How we are working? • Research projects by Universities and VTT • Enterprise projects • Group projects Funding • Tekes – The Finnish Funding Agency for Technology and Innovation • RYM Ltd – Built Environment Innovations

R&D RESOURCES ON LEAN IN FINLAND • University of Oulu, Tampere University of Technology, Helsinki University of Technology, Technical Research Center of Finland VTT, Consultants How we are working? • Research projects by Universities and VTT • Enterprise projects • Group projects Funding • Tekes – The Finnish Funding Agency for Technology and Innovation • RYM Ltd – Built Environment Innovations

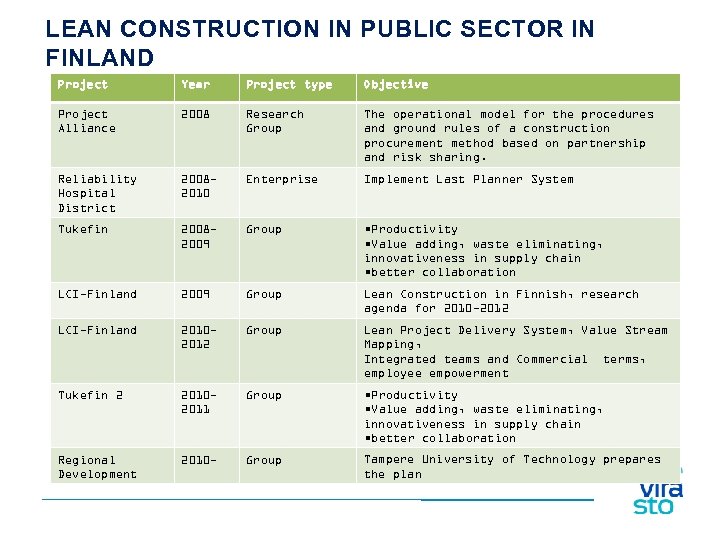

LEAN CONSTRUCTION IN PUBLIC SECTOR IN FINLAND Project Year Project type Objective Project Alliance 2008 Research Group The operational model for the procedures and ground rules of a construction procurement method based on partnership and risk sharing. Reliability Hospital District 20082010 Enterprise Implement Last Planner System Tukefin 20082009 Group • Productivity • Value adding, waste eliminating, innovativeness in supply chain • better collaboration LCI-Finland 2009 Group Lean Construction in Finnish, research agenda for 2010 -2012 LCI-Finland 20102012 Group Lean Project Delivery System, Value Stream Mapping, Integrated teams and Commercial terms, employee empowerment Tukefin 2 20102011 Group • Productivity • Value adding, waste eliminating, innovativeness in supply chain • better collaboration Regional Development 2010 - Group Tampere University of Technology prepares the plan

LEAN CONSTRUCTION IN PUBLIC SECTOR IN FINLAND Project Year Project type Objective Project Alliance 2008 Research Group The operational model for the procedures and ground rules of a construction procurement method based on partnership and risk sharing. Reliability Hospital District 20082010 Enterprise Implement Last Planner System Tukefin 20082009 Group • Productivity • Value adding, waste eliminating, innovativeness in supply chain • better collaboration LCI-Finland 2009 Group Lean Construction in Finnish, research agenda for 2010 -2012 LCI-Finland 20102012 Group Lean Project Delivery System, Value Stream Mapping, Integrated teams and Commercial terms, employee empowerment Tukefin 2 20102011 Group • Productivity • Value adding, waste eliminating, innovativeness in supply chain • better collaboration Regional Development 2010 - Group Tampere University of Technology prepares the plan

Project Alliance in Finland The competitive single target-cost approach Common research project between ü Finnish Road Administration, Finnish Rail Administration ü Seven General Contractors and three consulting engineering companies ü Carried out by VTT in 2008 The result of the research project was the operational model where selection takes place through elimination of candidates and a subsequent two-phase tendering process: ü the qualitative tender precedes the workshops that are part of evaluation, ü followed by submission of tender price That model has not been tested yet • Spring 2010 two workshops with the owners and the industry • The objective is 1 -2 pilot projects near future

Project Alliance in Finland The competitive single target-cost approach Common research project between ü Finnish Road Administration, Finnish Rail Administration ü Seven General Contractors and three consulting engineering companies ü Carried out by VTT in 2008 The result of the research project was the operational model where selection takes place through elimination of candidates and a subsequent two-phase tendering process: ü the qualitative tender precedes the workshops that are part of evaluation, ü followed by submission of tender price That model has not been tested yet • Spring 2010 two workshops with the owners and the industry • The objective is 1 -2 pilot projects near future

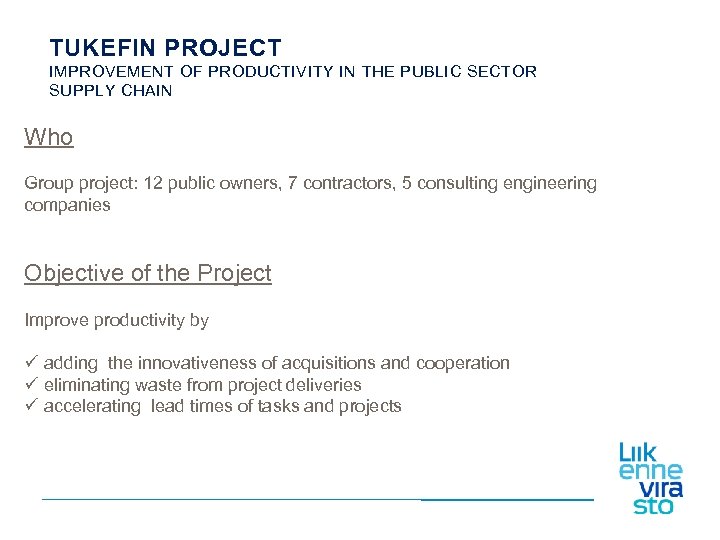

TUKEFIN PROJECT IMPROVEMENT OF PRODUCTIVITY IN THE PUBLIC SECTOR SUPPLY CHAIN Who Group project: 12 public owners, 7 contractors, 5 consulting engineering companies Objective of the Project Improve productivity by ü adding the innovativeness of acquisitions and cooperation ü eliminating waste from project deliveries ü accelerating lead times of tasks and projects

TUKEFIN PROJECT IMPROVEMENT OF PRODUCTIVITY IN THE PUBLIC SECTOR SUPPLY CHAIN Who Group project: 12 public owners, 7 contractors, 5 consulting engineering companies Objective of the Project Improve productivity by ü adding the innovativeness of acquisitions and cooperation ü eliminating waste from project deliveries ü accelerating lead times of tasks and projects

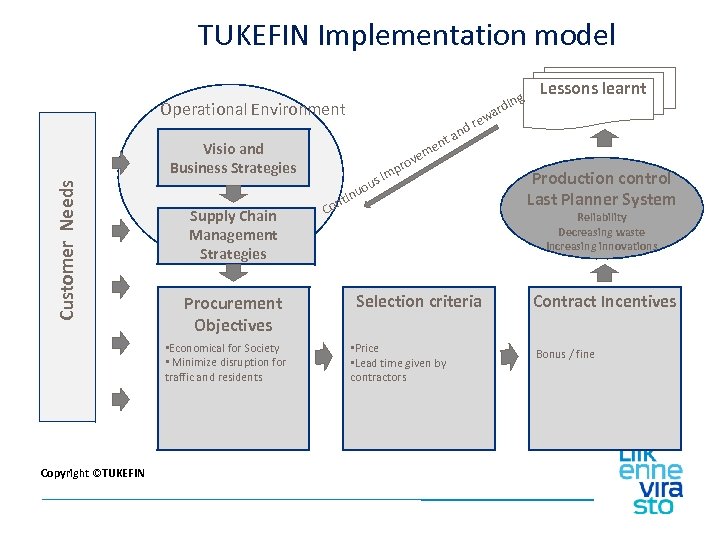

TUKEFIN Implementation model Operational Environment Customer Needs Supply Chain Management Strategies Procurement Objectives • Economical for Society • Minimize disruption for traffic and residents Copyright ©TUKEFIN Lessons learnt a Visio and Business Strategies nt me ve ew dr an ro p s im u uo tin n Co ng rdi Production control Last Planner System Reliability Decreasing waste Increasing innovations Selection criteria • Price • Lead time given by contractors Contract Incentives Bonus / fine

TUKEFIN Implementation model Operational Environment Customer Needs Supply Chain Management Strategies Procurement Objectives • Economical for Society • Minimize disruption for traffic and residents Copyright ©TUKEFIN Lessons learnt a Visio and Business Strategies nt me ve ew dr an ro p s im u uo tin n Co ng rdi Production control Last Planner System Reliability Decreasing waste Increasing innovations Selection criteria • Price • Lead time given by contractors Contract Incentives Bonus / fine

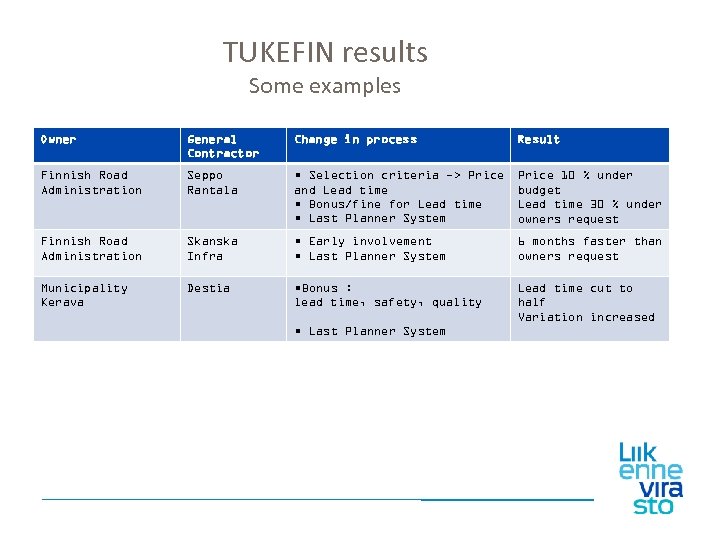

TUKEFIN results Some examples Owner General Contractor Change in process Result Finnish Road Administration Seppo Rantala • Selection criteria -> Price and Lead time • Bonus/fine for Lead time • Last Planner System Price 10 % under budget Lead time 30 % under owners request Finnish Road Administration Skanska Infra • Early involvement • Last Planner System 6 months faster than owners request Municipality Kerava Destia • Bonus : lead time, safety, quality Lead time cut to half Variation increased • Last Planner System

TUKEFIN results Some examples Owner General Contractor Change in process Result Finnish Road Administration Seppo Rantala • Selection criteria -> Price and Lead time • Bonus/fine for Lead time • Last Planner System Price 10 % under budget Lead time 30 % under owners request Finnish Road Administration Skanska Infra • Early involvement • Last Planner System 6 months faster than owners request Municipality Kerava Destia • Bonus : lead time, safety, quality Lead time cut to half Variation increased • Last Planner System

LAST PLANNER SYSTEM USED IN PUBLIC SECTOR PROJECTS • Skanska • Destia • NCC • Lemminkäinen • Several in piloting phase

LAST PLANNER SYSTEM USED IN PUBLIC SECTOR PROJECTS • Skanska • Destia • NCC • Lemminkäinen • Several in piloting phase

LCI-FINLAND PROJECT FALL 2009 • The objective of the project was to clarify and to estimate the Lean Construction tools and their potential in the Finnish construction industry. • The development work was based on the Lean Project Delivery System • Group project, seven participants, fund by participants and Tekes • Focus on renovation and public construction Results • Report in Finnish: Lean and Lean Construction - Philosophy, tools and methods • Evaluation and applications for Finnish Construction Industry • Cases

LCI-FINLAND PROJECT FALL 2009 • The objective of the project was to clarify and to estimate the Lean Construction tools and their potential in the Finnish construction industry. • The development work was based on the Lean Project Delivery System • Group project, seven participants, fund by participants and Tekes • Focus on renovation and public construction Results • Report in Finnish: Lean and Lean Construction - Philosophy, tools and methods • Evaluation and applications for Finnish Construction Industry • Cases

LCI-FINLAND GROUP PROJECT 2010 -2012 ü 6 -8 participants: Public Owners, Consultant Engineering companies, General Contractors, Construction Managers, University of Oulu ü Focus on renovation and public sector construction ü Common Interest: • Best Practices, Lean Project Delivery System • Value Stream Mapping models • Implementation models • Integrated teams and commercial terms • Learning • Employee empowerment • Company specific research and demonstration projects ü Funded by participants and Tekes

LCI-FINLAND GROUP PROJECT 2010 -2012 ü 6 -8 participants: Public Owners, Consultant Engineering companies, General Contractors, Construction Managers, University of Oulu ü Focus on renovation and public sector construction ü Common Interest: • Best Practices, Lean Project Delivery System • Value Stream Mapping models • Implementation models • Integrated teams and commercial terms • Learning • Employee empowerment • Company specific research and demonstration projects ü Funded by participants and Tekes

LCI-FINLAND OTHER PROJECTS 2010 -2012 Helsinki University of Technology Four Lean Construction research and enterprise projects on real estate field Tampere University of Technology Two research project on building sector

LCI-FINLAND OTHER PROJECTS 2010 -2012 Helsinki University of Technology Four Lean Construction research and enterprise projects on real estate field Tampere University of Technology Two research project on building sector

Summary q Timing is perfect for Lean Construction in the public sector q Development environment in Finland is better than ever q Few organizations have worked on Lean Construction in Finland for some years Now there has been time to expand level out a common understanding q EU-legislation does not avoid to implement Lean Construction philosophies, methods and tools in the public sector q Next three years will show big an issue Lean Construction will be in Finland in the public sector

Summary q Timing is perfect for Lean Construction in the public sector q Development environment in Finland is better than ever q Few organizations have worked on Lean Construction in Finland for some years Now there has been time to expand level out a common understanding q EU-legislation does not avoid to implement Lean Construction philosophies, methods and tools in the public sector q Next three years will show big an issue Lean Construction will be in Finland in the public sector