2542f2f7c9406cd10c2580ed01e00e9a.ppt

- Количество слайдов: 41

LEAN and the Do. N Blocking & Tackling Fundamentals Do. N 2004 Logistics Conference Nick Kunesh Deputy Assistant Secretary of the Navy (Logistics) May 18, 2004

Do. N Total Obligation Authority (TOA) Requirements $115. 1 B 2

The Need to Transform What Are Our Leaders Saying? “…transforming the military. What is different today is this sense of urgency: The need to build this future force while fighting this present war. It is like overhauling a car engine while you are going 80 miles an hour. ” George W. Bush President of the United States “We simply have to transform this place. It is every bit as important to the success of the global war on terrorism as the other things we're doing. ” Donald B. Rumsfeld Secretary of Defense “Now a few words about transforming business practices. First of all, efficiency equals effectiveness. They go together. We should be constantly searching for improved effectiveness through improved efficiency. ” Gordon R. England Secretary of the Navy “As we look to the future, we must transform to retain the advantage against innovative and determined enemies. ” ADM Vern Clark Chief of Naval Operations It’s not a destination… it’s a journey! 3

Secretary of the Navy’s Near Term Priorities • Combat Capability – Win the War on Terrorism • People – Ensure quality of service • Technologies – Recapitalize our Forces • Improving Business Practices – Transform the Business of Defense Process characteristics needed to support SECNAV’s priorities: • • Speed Agility Flexibility Sustainment (TAV, ITV)

Efficiency Methodologies and Tools for Continuous Improvement • Enablers for speed, agility, flexibility & sustainment in an affordable manner. – Efficiency Methodologies • Theory of Constraints (TOC) • Lean • Six Sigma • Others : ISO 9000, Malcolm Baldridge Award, CMMI – Information Technology • Navy Enterprise Resource Planning (ERP) • Global Combat Support System (GCSS) –Marine Corps – Automatic Identification Technologies (AIT) • Unique Identification (UID) • Radio Frequency Identification (RFID) All provide an environment for lead time reduction in the Value Chain.

Lean is. . . A set of principles, concepts and techniques designed for a relentless pursuit in the elimination of waste. Producing an efficient just-in-time production system, that will deliver to our customers… Äexactly what they need Ä when they need it Äin the quantity they need Äin the right sequence Äwithout defects Äand at the lowest possible cost

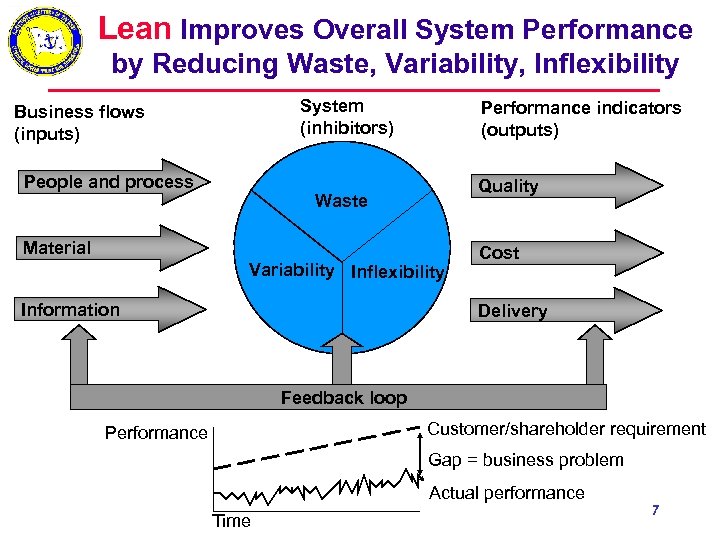

Lean Improves Overall System Performance by Reducing Waste, Variability, Inflexibility System (inhibitors) Business flows (inputs) People and process Performance indicators (outputs) Quality Waste Material Variability Inflexibility Information Cost Delivery Feedback loop Customer/shareholder requirement Performance Gap = business problem Actual performance Time 7

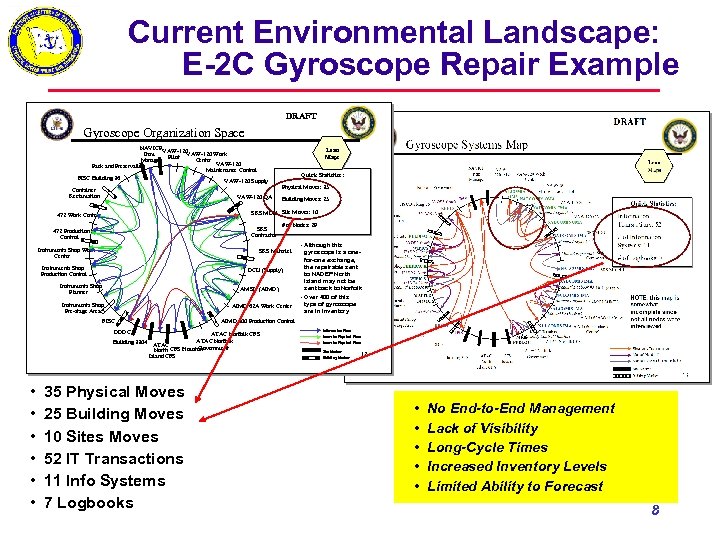

C Current Environmental Landscape: E-2 C Gyroscope Repair Example DRAFT Gyroscope Organization Space NAVICP Item VAW-120 Work Manager Pilot Center VAW-120 Pack and Preservation Maintenance Control FISC Building 36 VAW-120 Supply Quick Statistics: Physical Moves: 35 Container Reclamation VAW-120 QA Building Moves: 25 SRS MDU Site Moves: 10 472 Work Center SRS Contractor 472 Production Control Instruments Shop Work Center # of Nodes: 29 SRS Materiel Instruments Shop Production Control DCU (Supply) Instruments Shop Planner AMSU (AIMD) Instruments Shop Pre-stage Area AIMD 62 A Work Center FISC 35 Physical Moves 25 Building Moves 10 Sites Moves 52 IT Transactions 11 Info Systems 7 Logbooks • Although this gyroscope is a onefor-one exchange, the repairable sent to NADEP North Island may not be sent back to Norfolk • Over 400 of this type of gyroscope are in inventory AIMD 600 Production Control DDDC ATAC Norfolk CFS ATAC Norfolk Building 3304 ATAC Government North CFS Houston Island CFS • • • Lean Maps Information Flow Intra-site Physical Flow Inter-site Physical Flow Site Marker Building Marker 12 • • • No End-to-End Management Lack of Visibility Long-Cycle Times Increased Inventory Levels Limited Ability to Forecast 8

Lean-Pathways/Air. Speed Accelerated Improvement Workshop Onboard USS Harry S. Truman (CVN-75) 2 April 2004 700 Division BRU-32 AIRSpeed The Way Ahead 9

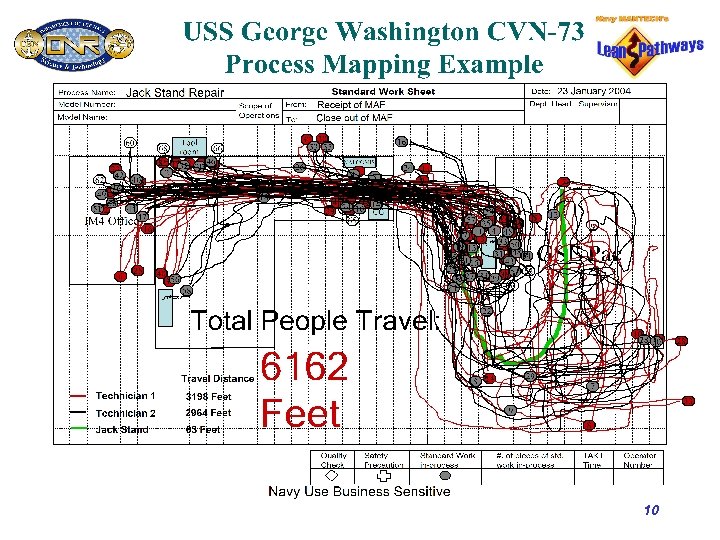

10

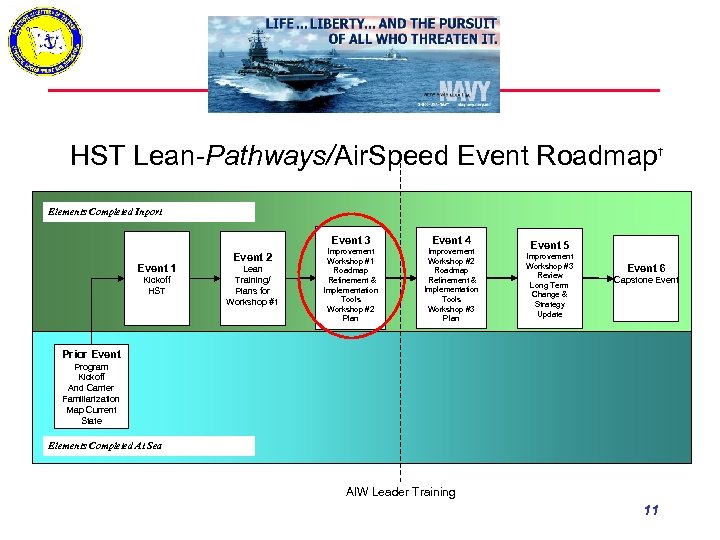

HST Lean-Pathways/Air. Speed Event Roadmap † Elements Completed Inport Event 3 Event 1 Kickoff HST Event 2 Lean Training/ Plans for Workshop #1 Event 4 Improvement Workshop #1 Roadmap Refinement & Implementation Tools Workshop #2 Plan Improvement Workshop #2 Roadmap Refinement & Implementation Tools Workshop #3 Plan Event 5 Improvement Workshop #3 Review Long Term Change & Strategy Update Event 6 Capstone Event Prior Event Program Kickoff And Carrier Familiarization Map Current State Elements Completed At Sea AIW Leader Training 11

BRU 32

BRU AIW Team Members: AE 2 Kemper, IM 2 AS 1 Thomas, IM 4 SK 2 Bobnock, MSP AM 1 Schulz, IM 2 AT 1 Halloran, IM 3 AE 1 Taylor, QA AO 2 Travers, IM 3 AE 1 Hamilton, IM 3 Team Leaders: LT Belmont LTJG Bast Process Owners: LT Dunn AOC Gilbert Facilitators: Ralph Day Rick Davidson Observers: LCDR Hunter AVCM Hawkins

Goals • Reduce people and part travel by 50% • Eliminate potential backlog • Improve availability of consumable parts within the work center for BRU-32 • 100% Consumable Parts Availability (bit piece parts) • Increase on-board repairable availability by 50% with a Stretch goal of 100% availability

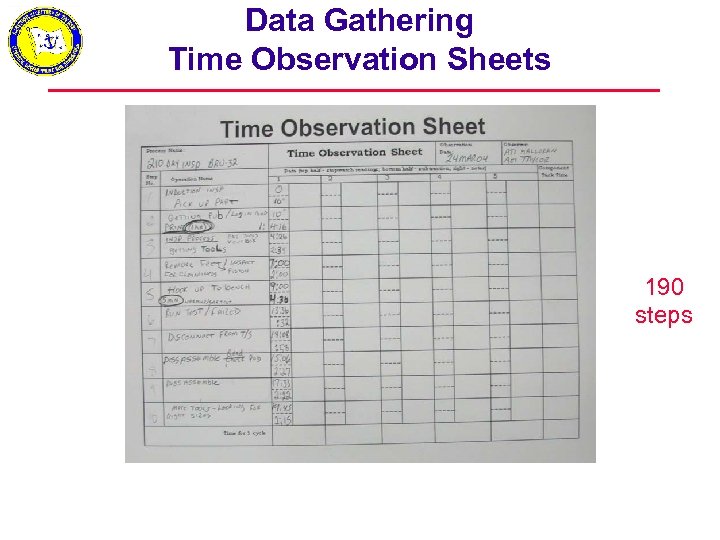

Data Gathering Time Observation Sheets 190 steps

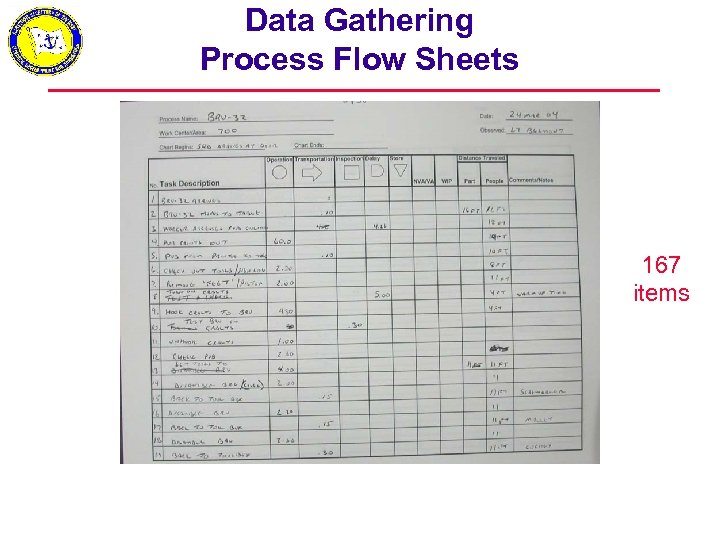

Data Gathering Process Flow Sheets 167 items

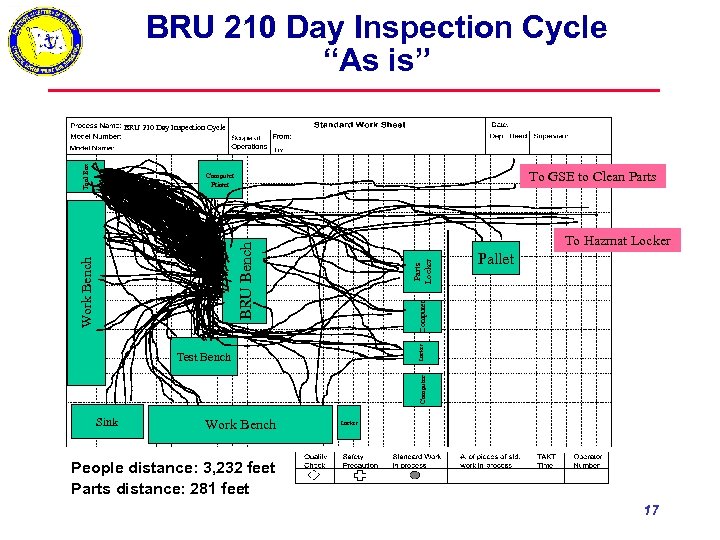

BRU 210 Day Inspection Cycle “As is” Tool Box BRU 210 Day Inspection Cycle To GSE to Clean Parts Computer Printer Parts Locker Computer Pallet Locker Work Bench BRU Bench To Hazmat Locker Computer Test Bench Sink Work Bench Locker People distance: 3, 232 feet Parts distance: 281 feet 17

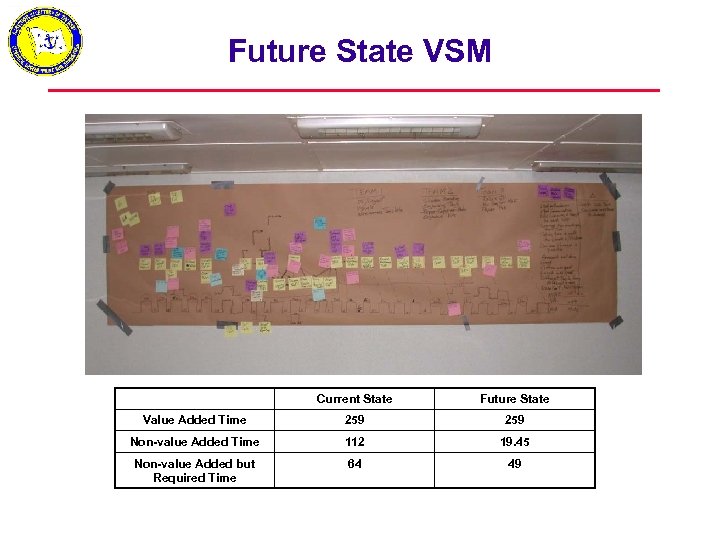

Future State VSM Current State Future State Value Added Time 259 Non-value Added Time 112 19. 45 Non-value Added but Required Time 64 49

Brainstorming

Ideas • • • Daily Hazmat Run or Local Hazmat Locker Dedicated AZ for NALCOMIS Parallel Processing Dedicated tool boxes Rotable kits New Parts Washer New Bench Mounted Test Set Parts Shadow Board 5 S Tabbed Pub, centrally located

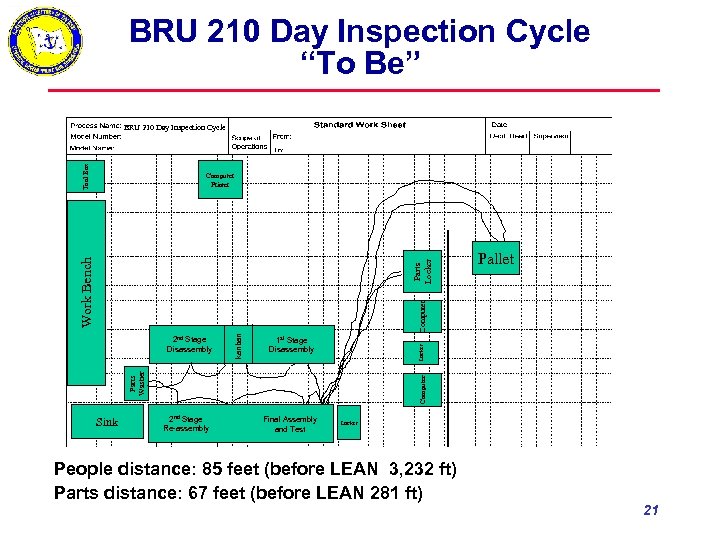

BRU 210 Day Inspection Cycle “To Be” Tool Box BRU 210 Day Inspection Cycle Pallet Locker 1 st Stage Disassembly Sink Computer Parts Washer 2 nd Stage Disassembly kanban Computer Parts Locker Work Bench Computer Printer 2 nd Stage Re-assembly Final Assembly and Test Locker People distance: 85 feet (before LEAN 3, 232 ft) Parts distance: 67 feet (before LEAN 281 ft) 21

Accomplishments Reduced people travel by 97% (Goal 50%) Reduced part travel by 76% (Goal 50%) Eliminate potential backlog Improve availability of consumable parts within the work center for BRU-32 100% Consumable Parts Availability (bit piece parts) Increase on-board repairable availability by 50% with a Stretch goal of 100% availability ?

External Supply Chain Lead-time Reduction Event F/A-18 E/F Nose Landing Gear 23

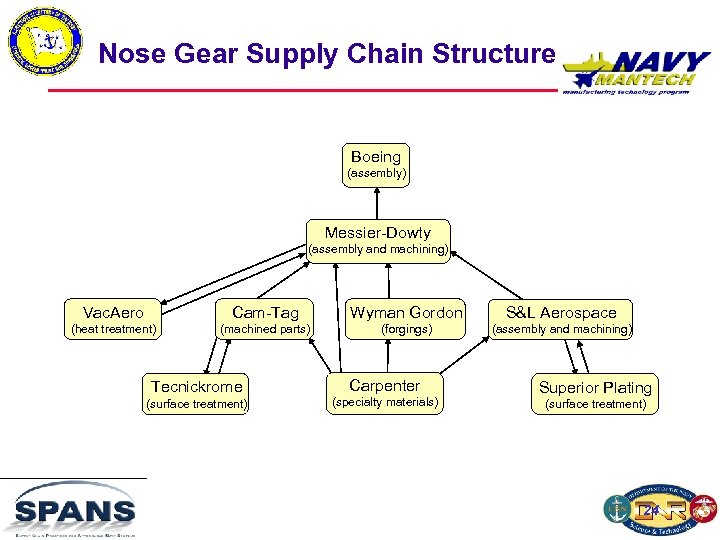

Nose Gear Supply Chain Structure Boeing (assembly) Messier-Dowty (assembly and machining) Vac. Aero Cam-Tag Wyman Gordon S&L Aerospace (heat treatment) (machined parts) (forgings) (assembly and machining) Tecnickrome (surface treatment) Carpenter (specialty materials) Superior Plating (surface treatment) 24

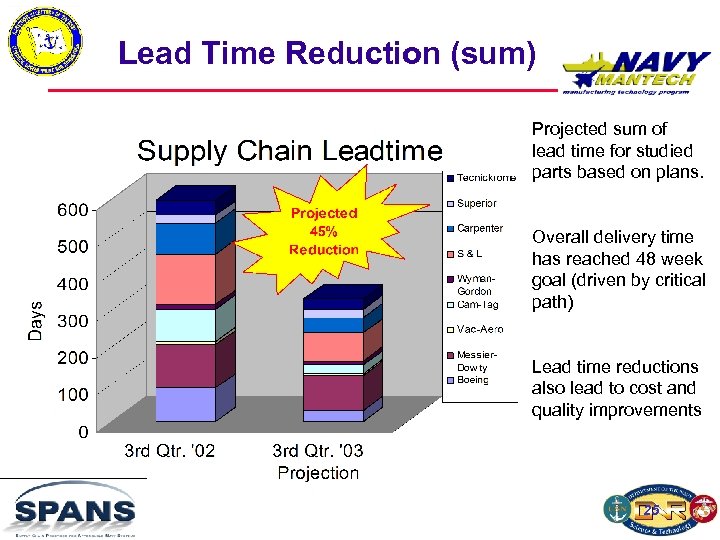

Lead Time Reduction (sum) Projected sum of lead time for studied parts based on plans. Overall delivery time has reached 48 week goal (driven by critical path) Lead time reductions also lead to cost and quality improvements 25

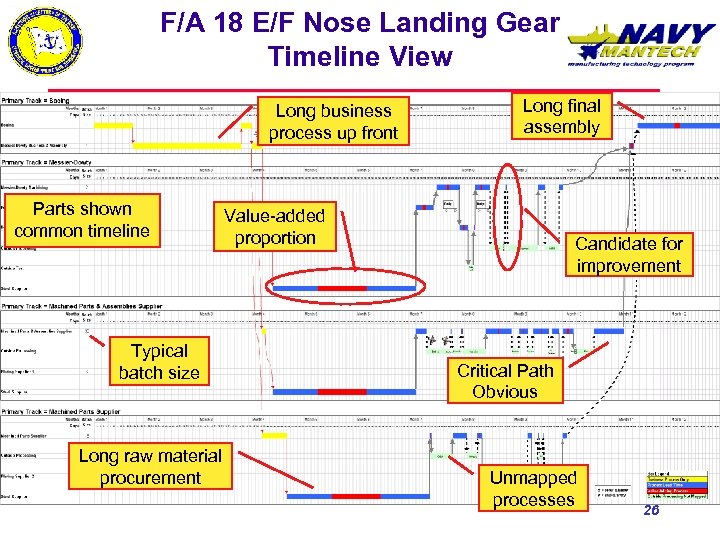

F/A 18 E/F Nose Landing Gear Timeline View Long business process up front Parts shown common timeline Typical batch size Long raw material procurement Long final assembly Value-added proportion Candidate for improvement Critical Path Obvious Unmapped processes 26

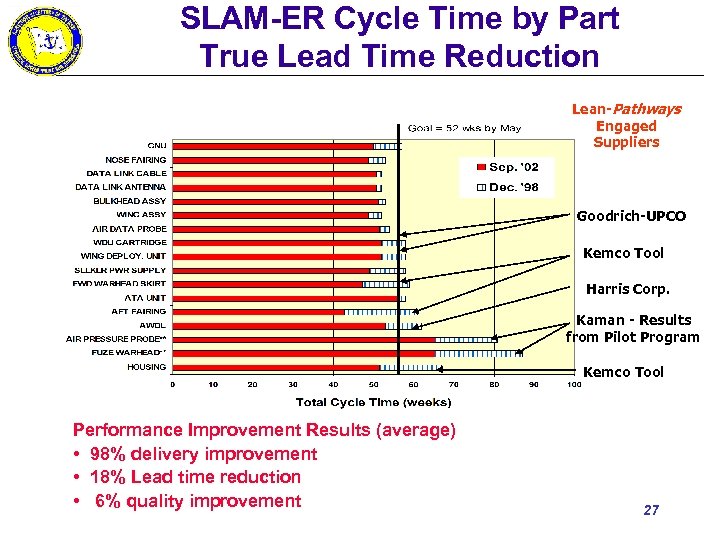

SLAM-ER Cycle Time by Part True Lead Time Reduction Lean-Pathways Engaged Suppliers Goodrich-UPCO Kemco Tool Harris Corp. Kaman - Results from Pilot Program Kemco Tool Performance Improvement Results (average) • 98% delivery improvement • 18% Lead time reduction • 6% quality improvement 27

NAVY INTERMEDIATE LEVEL MAINTENANCE LEAN FORUM 28

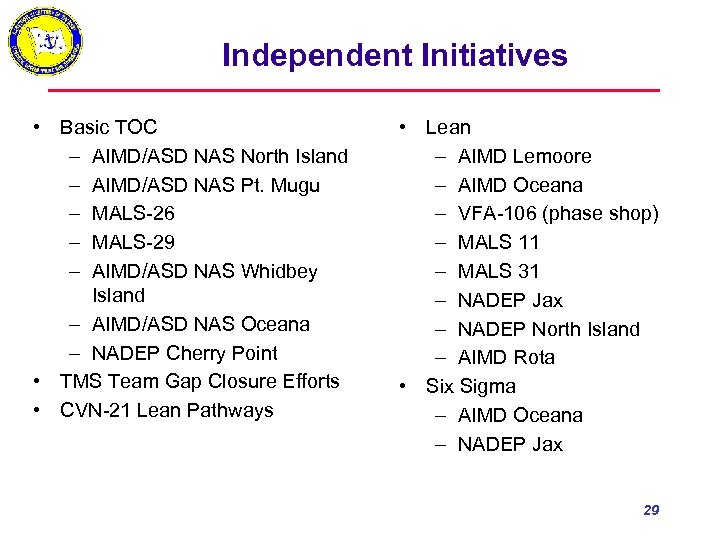

Independent Initiatives • Basic TOC – AIMD/ASD NAS North Island – AIMD/ASD NAS Pt. Mugu – MALS-26 – MALS-29 – AIMD/ASD NAS Whidbey Island – AIMD/ASD NAS Oceana – NADEP Cherry Point • TMS Team Gap Closure Efforts • CVN-21 Lean Pathways • Lean – AIMD Lemoore – AIMD Oceana – VFA-106 (phase shop) – MALS 11 – MALS 31 – NADEP Jax – NADEP North Island – AIMD Rota • Six Sigma – AIMD Oceana – NADEP Jax 29

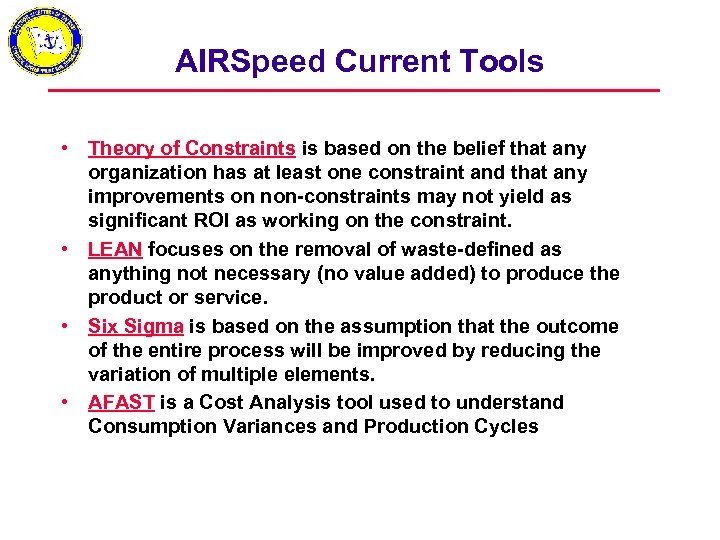

AIRSpeed Current Tools • Theory of Constraints is based on the belief that any organization has at least one constraint and that any improvements on non-constraints may not yield as significant ROI as working on the constraint. • LEAN focuses on the removal of waste-defined as anything not necessary (no value added) to produce the product or service. • Six Sigma is based on the assumption that the outcome of the entire process will be improved by reducing the variation of multiple elements. • AFAST is a Cost Analysis tool used to understand Consumption Variances and Production Cycles

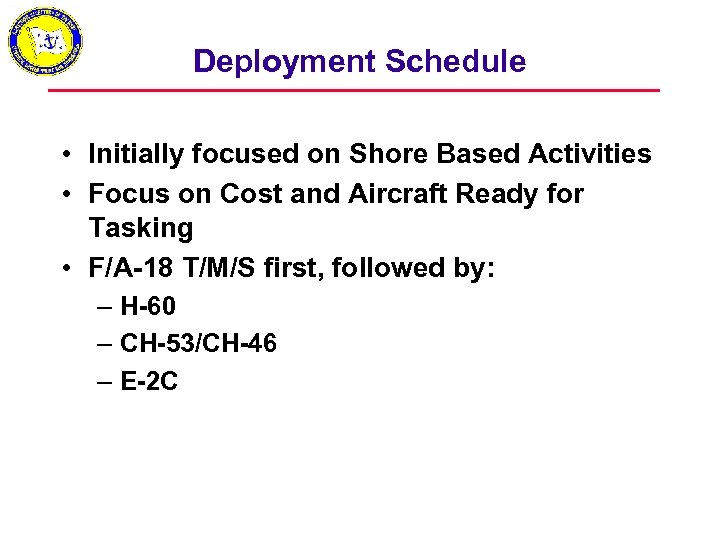

Deployment Schedule • Initially focused on Shore Based Activities • Focus on Cost and Aircraft Ready for Tasking • F/A-18 T/M/S first, followed by: – H-60 – CH-53/CH-46 – E-2 C

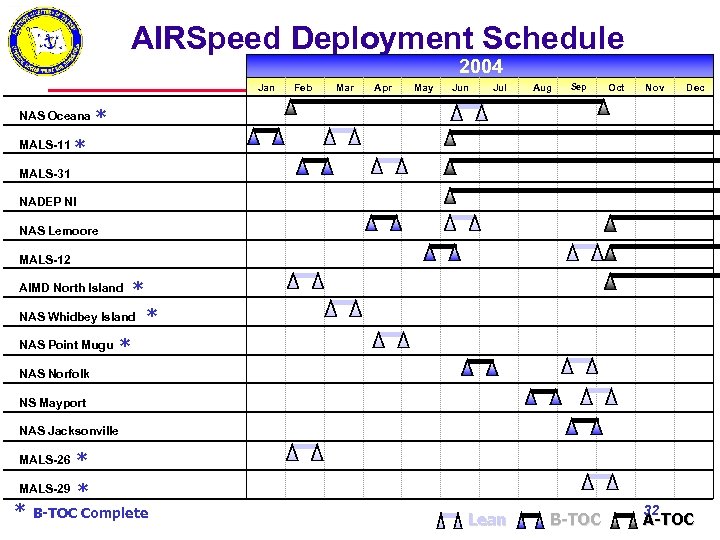

AIRSpeed Deployment Schedule 2004 Jan NAS Oceana MALS-11 Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec * * MALS-31 NADEP NI NAS Lemoore MALS-12 AIMD North Island * NAS Whidbey Island NAS Point Mugu * * NAS Norfolk NS Mayport NAS Jacksonville MALS-26 * MALS-29 * * B-TOC Complete Lean B-TOC 32 A-TOC

CDR CJ Jaynes’ journey begins……. . • • • Officer-in-Charge of Aircraft Intermediate Maintenance Detachment (June 2000 – May 2003) – Performed maintenance on F/A-18 components, systems, engines, hydraulics, life support equipment, etc. – 63 production work centers Total Workforce of 816 – 11 officers, 751 enlisted personnel, 54 civilians Immediate Challenges – High maintenance backlog – Production inefficiencies – Low sailor and civilian morale – “we’ve always done it that way” attitudes Something had to be done quickly…. .

NAS Lemoore Snapshot in time AIMD in June 2000 • • • Manning at 70% Backlog (other than engines) at 1260 items EXREPS = 200 Engine backlog @ 35 AWM Module backlog @ 190 AWM No light at the end of the tunnel

Plan for Success • • Teamed with Boeing and the F/A-18 Program Office Trained a core team of military Lean facilitators Trained all E-5 and above in Lean concepts Developed a roadmap: Held two AIW’s every month – every work center was effected • Make Lean a way of life – not just a program

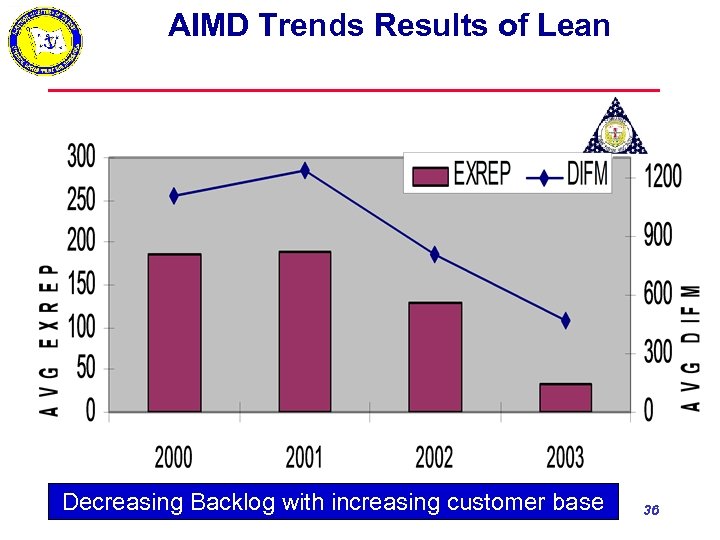

AIMD Trends Results of Lean Decreasing Backlog with increasing customer base 36

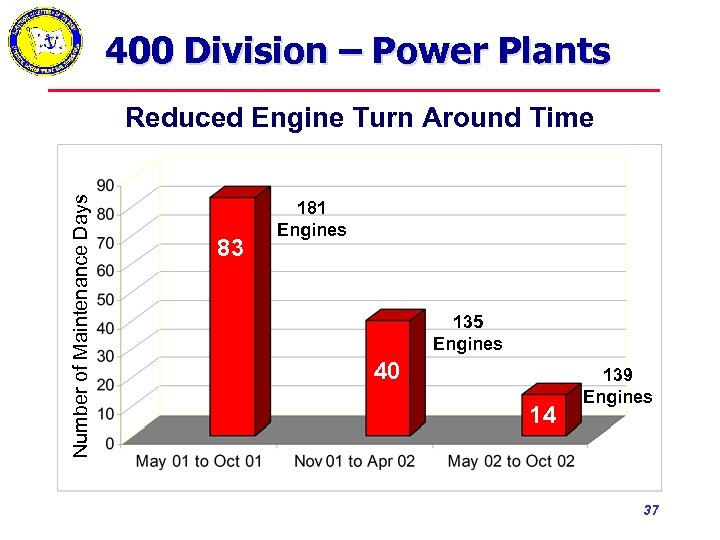

400 Division – Power Plants Number of Maintenance Days Reduced Engine Turn Around Time 83 181 Engines 135 Engines 40 14 139 Engines 37

AIMD Lemoore Power Plants BEFORE 38

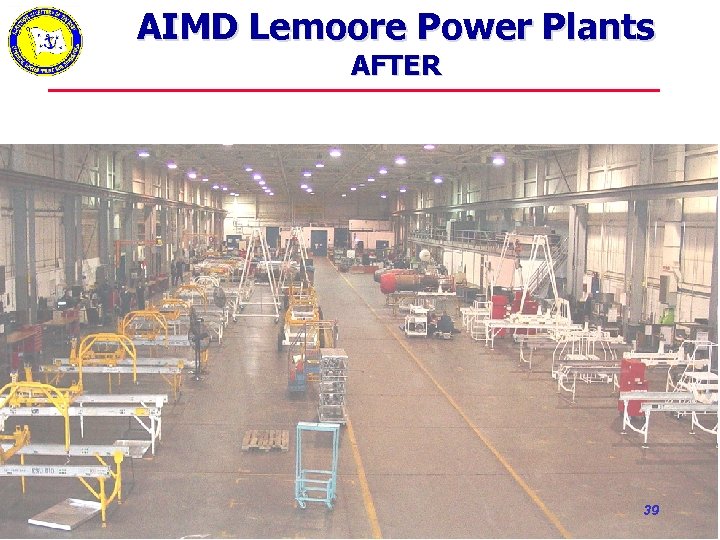

AIMD Lemoore Power Plants AFTER 39

What Does Lean Mean to the AIMD at NAS Lemoore? • AIMD Sailors are now able to work 8 hour days instead of 12 hour days. • Re-enlistment rates improved from less than 50% to over 76 % • More parts on the shelf and less in the repair cycle • More “up” aircraft on the ramp • Better quality product to the fleet • Established repeatable, consistent production processes

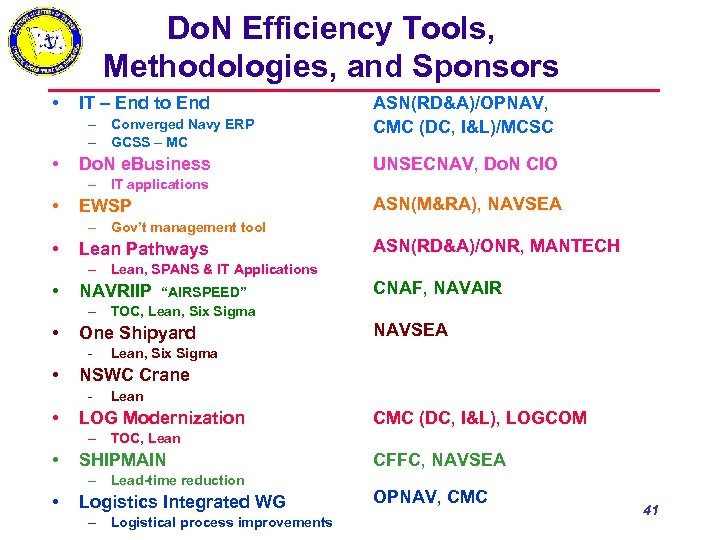

Do. N Efficiency Tools, Methodologies, and Sponsors • IT – End to End – Converged Navy ERP – GCSS – MC • Do. N e. Business ASN(RD&A)/OPNAV, CMC (DC, I&L)/MCSC UNSECNAV, Do. N CIO – IT applications • EWSP ASN(M&RA), NAVSEA – Gov’t management tool • Lean Pathways ASN(RD&A)/ONR, MANTECH – Lean, SPANS & IT Applications • NAVRIIP – • One Shipyard - • CNAF, NAVAIR NAVSEA Lean, Six Sigma NSWC Crane - • “AIRSPEED” TOC, Lean, Six Sigma Lean LOG Modernization CMC (DC, I&L), LOGCOM – TOC, Lean • SHIPMAIN – Lead-time reduction • Logistics Integrated WG – Logistical process improvements CFFC, NAVSEA OPNAV, CMC 41

2542f2f7c9406cd10c2580ed01e00e9a.ppt