1a85bc5cb27a236ca0b2cd3cf8d00228.ppt

- Количество слайдов: 36

Lean 6 S Training Mercy Medical Center 5046 LDLEAN 6 S - Version 8/20/2009 1

Lean 6 S Training Mercy Medical Center 5046 LDLEAN 6 S - Version 8/20/2009 1

Ø What are the 8 Forms of Waste? Ø What is 6 S? Ø How do I conduct a 6 S? Ø Examples of Mercy 6 S results 2

Ø What are the 8 Forms of Waste? Ø What is 6 S? Ø How do I conduct a 6 S? Ø Examples of Mercy 6 S results 2

8 Forms of Waste 1. WASTED HUMAN TALENT 2. DEFECTS 3. INVENTORY 4. OVERPRODUCTION 5. WAITING TIME 6. MOTION 7. TRANSPORTATION 8. PROCESSING WASTE 3

8 Forms of Waste 1. WASTED HUMAN TALENT 2. DEFECTS 3. INVENTORY 4. OVERPRODUCTION 5. WAITING TIME 6. MOTION 7. TRANSPORTATION 8. PROCESSING WASTE 3

1. Wasted Human Talent I’ve made a few changes to the process. I wish someone would ask OUR opinion…! Staff Manager Staff Not asking the staff that works the process how to improve it 4

1. Wasted Human Talent I’ve made a few changes to the process. I wish someone would ask OUR opinion…! Staff Manager Staff Not asking the staff that works the process how to improve it 4

2. Defects Another defect!! @*&#! ! A negative outcome from process failure 5

2. Defects Another defect!! @*&#! ! A negative outcome from process failure 5

3. Inventory Did I really order this much? ? Items in greater quantities than can be immediately processed or used. 6

3. Inventory Did I really order this much? ? Items in greater quantities than can be immediately processed or used. 6

4. Over Production Hey…are these multiple orders for the same thing? @#$&*!! Pharmacist I didn’t get my order yet… I’ll send another fax. Staff Generating more work than is really required 7

4. Over Production Hey…are these multiple orders for the same thing? @#$&*!! Pharmacist I didn’t get my order yet… I’ll send another fax. Staff Generating more work than is really required 7

5. Waiting People waiting for items (patients, supplies, specimens, etc. ) to process 8

5. Waiting People waiting for items (patients, supplies, specimens, etc. ) to process 8

6. Motion Why can’t I get anything done? Unnecessary human movement 9

6. Motion Why can’t I get anything done? Unnecessary human movement 9

7. Transportation Waiting Area I’ll bring the patient right over. I have orders to run some tests. Sigh…. . !! Unnecessary movement or relocation of items 10

7. Transportation Waiting Area I’ll bring the patient right over. I have orders to run some tests. Sigh…. . !! Unnecessary movement or relocation of items 10

8. Over Processing Please approve. 11

8. Over Processing Please approve. 11

8. Over Processing I’m the final approval. Please ? ? ? The final approve. approval? !! + Applying effort to activities that are not required in the process 12

8. Over Processing I’m the final approval. Please ? ? ? The final approve. approval? !! + Applying effort to activities that are not required in the process 12

What is 6 S? 1. 2. 3. 4. 5. Sort Straighten Scrub Standardi ze Sustain 6. Safety 13

What is 6 S? 1. 2. 3. 4. 5. Sort Straighten Scrub Standardi ze Sustain 6. Safety 13

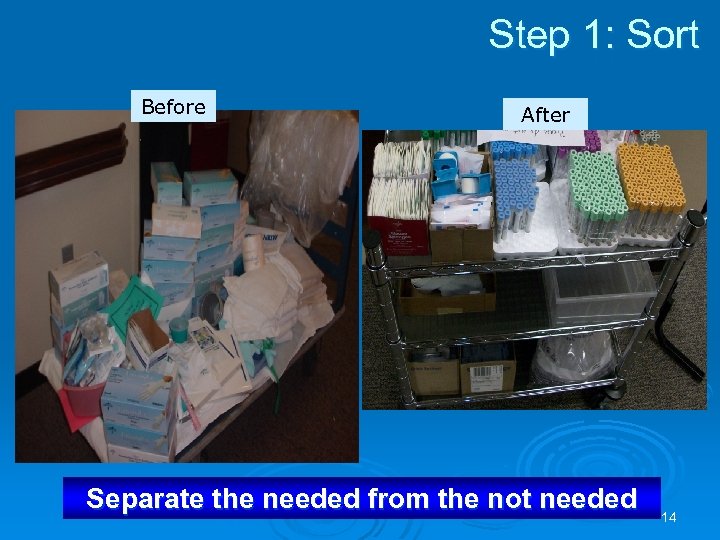

Step 1: Sort Before After Separate the needed from the not needed 14

Step 1: Sort Before After Separate the needed from the not needed 14

Step 2: Straighten BEFORE AFTER A place for everything & everything in its place! 15

Step 2: Straighten BEFORE AFTER A place for everything & everything in its place! 15

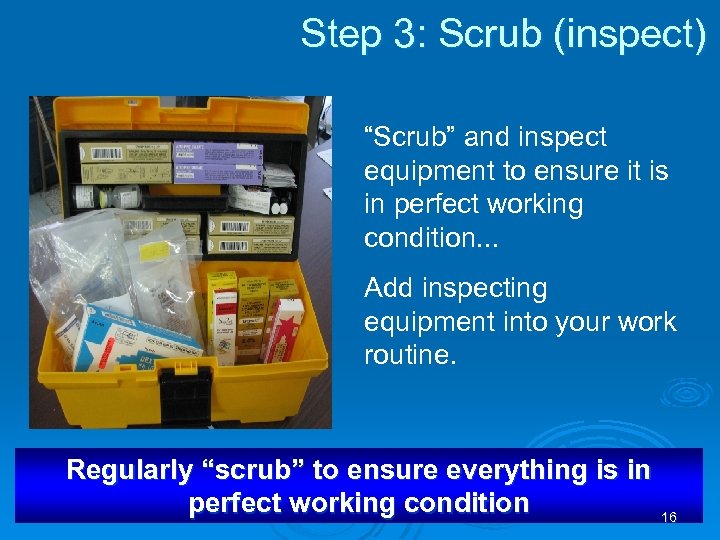

Step 3: Scrub (inspect) “Scrub” and inspect equipment to ensure it is in perfect working condition. . . Add inspecting equipment into your work routine. Regularly “scrub” to ensure everything is in perfect working condition 16

Step 3: Scrub (inspect) “Scrub” and inspect equipment to ensure it is in perfect working condition. . . Add inspecting equipment into your work routine. Regularly “scrub” to ensure everything is in perfect working condition 16

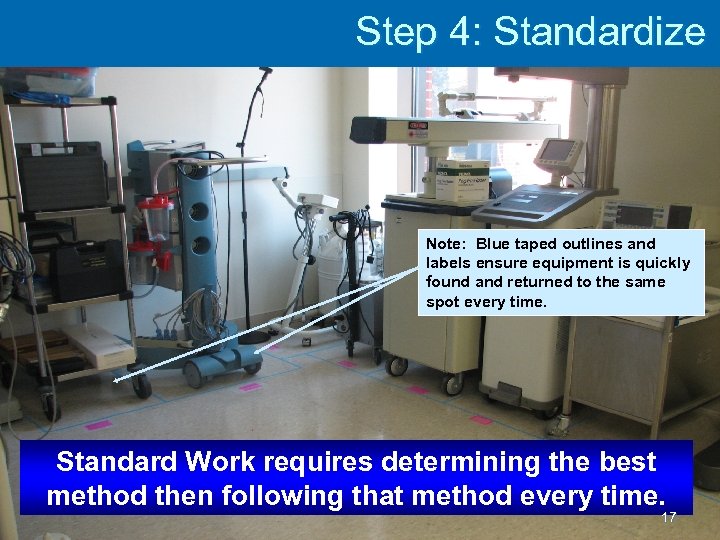

Step 4: Standardize Note: Blue taped outlines and labels ensure equipment is quickly found and returned to the same spot every time. Standard Work requires determining the best method then following that method every time. 17

Step 4: Standardize Note: Blue taped outlines and labels ensure equipment is quickly found and returned to the same spot every time. Standard Work requires determining the best method then following that method every time. 17

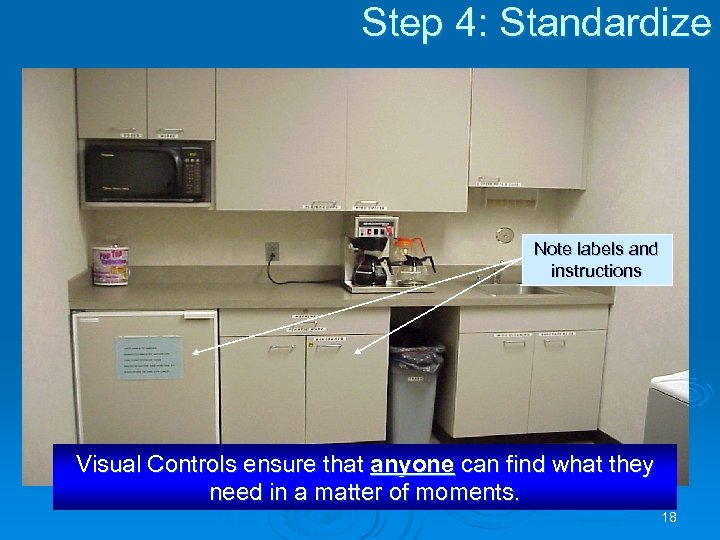

Step 4: Standardize Note labels and instructions Visual Controls ensure that anyone can find what they need in a matter of moments. 18

Step 4: Standardize Note labels and instructions Visual Controls ensure that anyone can find what they need in a matter of moments. 18

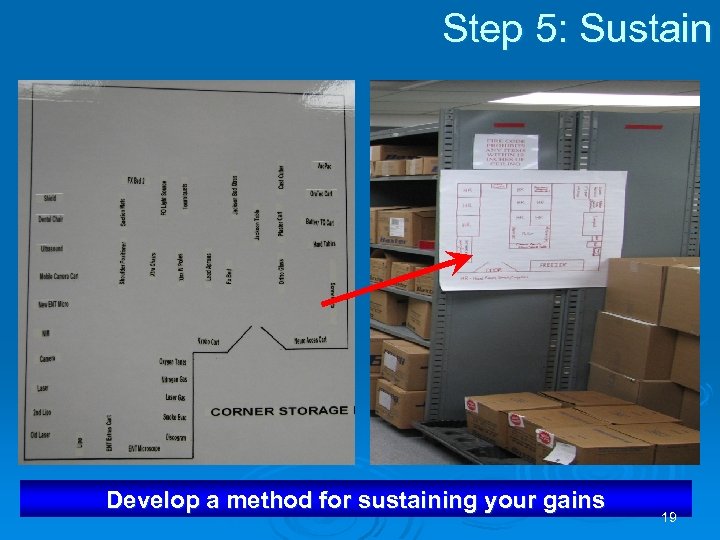

Step 5: Sustain Develop a method for sustaining your gains 19

Step 5: Sustain Develop a method for sustaining your gains 19

Step 6: Safety Ø Safety first when determining where items are to be located: l Keep fire hydrants clear l Electrical a safe distance from plumbing l All items accessible - Not too high, not too low l Uncluttered traffic areas - no tripping hazards l Emergency phone numbers and procedures prominently posted Safety is a top priority in all that you do! 20

Step 6: Safety Ø Safety first when determining where items are to be located: l Keep fire hydrants clear l Electrical a safe distance from plumbing l All items accessible - Not too high, not too low l Uncluttered traffic areas - no tripping hazards l Emergency phone numbers and procedures prominently posted Safety is a top priority in all that you do! 20

How do I Conduct a 6 S? 21

How do I Conduct a 6 S? 21

Preparation Ø Observe the process first hand (Gemba walk) Ø Create a spaghetti diagram - a hand drawn map of your process including: l l l Tasks in the sequence they are done Location of supplies and equipment Measure distance traveled and time spent searching or waiting Good preparation is the key to successful results! 22

Preparation Ø Observe the process first hand (Gemba walk) Ø Create a spaghetti diagram - a hand drawn map of your process including: l l l Tasks in the sequence they are done Location of supplies and equipment Measure distance traveled and time spent searching or waiting Good preparation is the key to successful results! 22

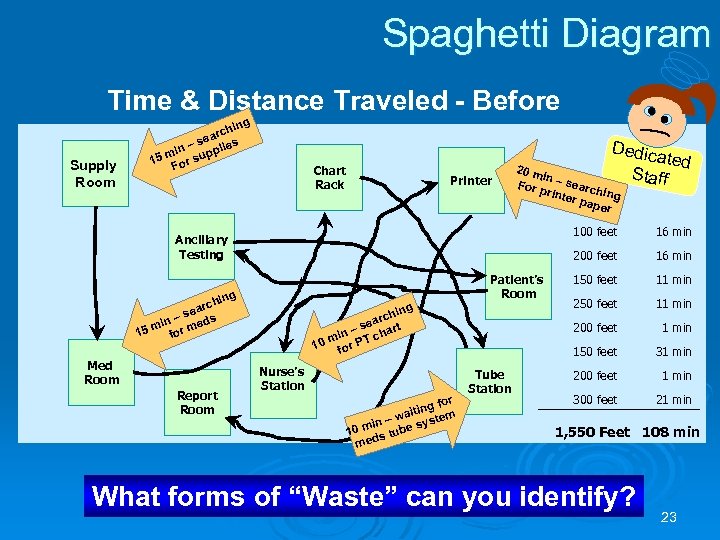

Spaghetti Diagram Time & Distance Traveled - Before g Supply Room n chi ear s – s lie min supp 15 or F Chart Rack Printer 20 m in For p – searc hi rinte r pap ng er 100 feet ing rch sea s in – ed 5 m for m 1 Report Room Nurse’s Station r g fo aitin tem w in – sys 10 m s tube med Tube Station 150 feet 11 min 250 feet 11 min 150 feet ing rch sea rt in – T cha m 10 for P 16 min 200 feet Patient’s Room 16 min 200 feet Ancillary Testing Med Room Dedica ted Staff 31 min 200 feet 1 min 300 feet 21 min 1, 550 Feet 108 min What forms of “Waste” can you identify? 23

Spaghetti Diagram Time & Distance Traveled - Before g Supply Room n chi ear s – s lie min supp 15 or F Chart Rack Printer 20 m in For p – searc hi rinte r pap ng er 100 feet ing rch sea s in – ed 5 m for m 1 Report Room Nurse’s Station r g fo aitin tem w in – sys 10 m s tube med Tube Station 150 feet 11 min 250 feet 11 min 150 feet ing rch sea rt in – T cha m 10 for P 16 min 200 feet Patient’s Room 16 min 200 feet Ancillary Testing Med Room Dedica ted Staff 31 min 200 feet 1 min 300 feet 21 min 1, 550 Feet 108 min What forms of “Waste” can you identify? 23

How Can We Improve? What would you do to improve? Ø Sort out the need from the not needed Ø Have a place for everything so there is no searching Ø Move supplies or equipment closer to where they are needed Ø Co-locate tasks or people Ø Change the sequence in which tasks are done Ø Be creative with your solutions – you, after all, are the expert! Applying 6 S eliminates waste! 24

How Can We Improve? What would you do to improve? Ø Sort out the need from the not needed Ø Have a place for everything so there is no searching Ø Move supplies or equipment closer to where they are needed Ø Co-locate tasks or people Ø Change the sequence in which tasks are done Ø Be creative with your solutions – you, after all, are the expert! Applying 6 S eliminates waste! 24

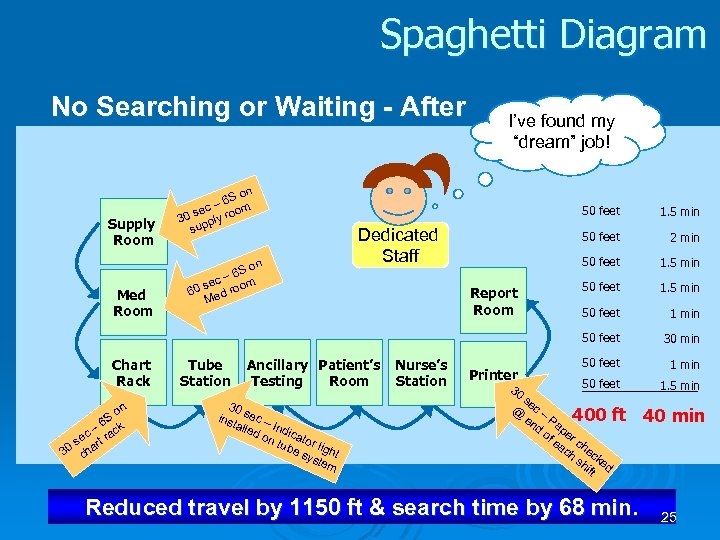

Spaghetti Diagram No Searching or Waiting - After on 6 S – om sec 30 pply ro su I’ve found my “dream” job! Med Room Chart Rack on S 6 k c – rac se rt 30 cha n So – 6 m sec 60 ed roo M Tube Station Ancillary Patient’s Testing Room 30 ins sec – tall ed Indic a on tub tor lig es yst ht em 50 feet Nurse’s Station 30 1. 5 min 50 feet 1 min 30 min 50 feet 1 min 50 feet Printer 1. 5 min 50 feet Report Room 2 min 50 feet Dedicated Staff 1. 5 min 50 feet Supply Room 50 feet 1. 5 min se @ c– en Pa 400 ft d of per ea ch ch ec sh ked ift Reduced travel by 1150 ft & search time by 68 min. 40 min 25

Spaghetti Diagram No Searching or Waiting - After on 6 S – om sec 30 pply ro su I’ve found my “dream” job! Med Room Chart Rack on S 6 k c – rac se rt 30 cha n So – 6 m sec 60 ed roo M Tube Station Ancillary Patient’s Testing Room 30 ins sec – tall ed Indic a on tub tor lig es yst ht em 50 feet Nurse’s Station 30 1. 5 min 50 feet 1 min 30 min 50 feet 1 min 50 feet Printer 1. 5 min 50 feet Report Room 2 min 50 feet Dedicated Staff 1. 5 min 50 feet Supply Room 50 feet 1. 5 min se @ c– en Pa 400 ft d of per ea ch ch ec sh ked ift Reduced travel by 1150 ft & search time by 68 min. 40 min 25

Ø Suggest you insert some before and after pictures/examples of 6 S results in the next few slides. 26

Ø Suggest you insert some before and after pictures/examples of 6 S results in the next few slides. 26

ØSimulation – Round 1 27

ØSimulation – Round 1 27

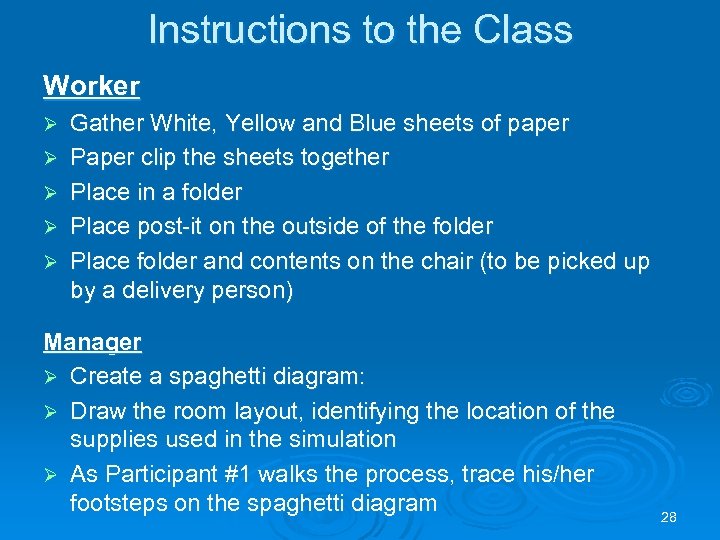

Instructions to the Class Worker Ø Ø Ø Gather White, Yellow and Blue sheets of paper Paper clip the sheets together Place in a folder Place post-it on the outside of the folder Place folder and contents on the chair (to be picked up by a delivery person) Manager Ø Create a spaghetti diagram: Ø Draw the room layout, identifying the location of the supplies used in the simulation Ø As Participant #1 walks the process, trace his/her footsteps on the spaghetti diagram 28

Instructions to the Class Worker Ø Ø Ø Gather White, Yellow and Blue sheets of paper Paper clip the sheets together Place in a folder Place post-it on the outside of the folder Place folder and contents on the chair (to be picked up by a delivery person) Manager Ø Create a spaghetti diagram: Ø Draw the room layout, identifying the location of the supplies used in the simulation Ø As Participant #1 walks the process, trace his/her footsteps on the spaghetti diagram 28

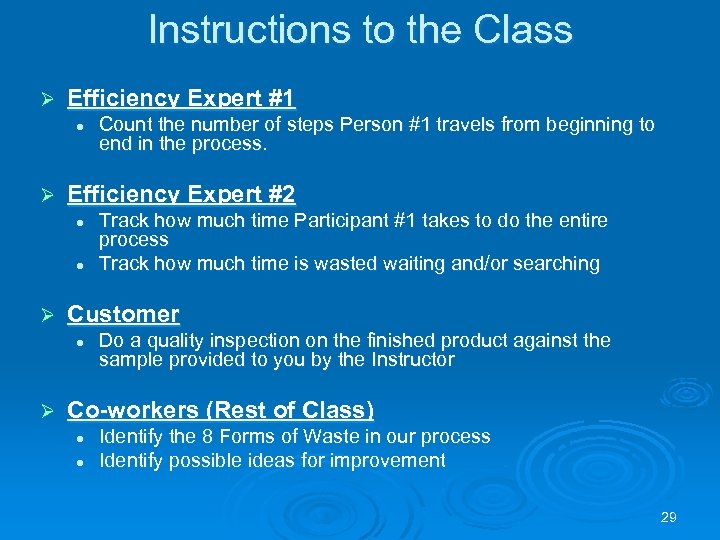

Instructions to the Class Ø Efficiency Expert #1 l Ø Efficiency Expert #2 l l Ø Track how much time Participant #1 takes to do the entire process Track how much time is wasted waiting and/or searching Customer l Ø Count the number of steps Person #1 travels from beginning to end in the process. Do a quality inspection on the finished product against the sample provided to you by the Instructor Co-workers (Rest of Class) l l Identify the 8 Forms of Waste in our process Identify possible ideas for improvement 29

Instructions to the Class Ø Efficiency Expert #1 l Ø Efficiency Expert #2 l l Ø Track how much time Participant #1 takes to do the entire process Track how much time is wasted waiting and/or searching Customer l Ø Count the number of steps Person #1 travels from beginning to end in the process. Do a quality inspection on the finished product against the sample provided to you by the Instructor Co-workers (Rest of Class) l l Identify the 8 Forms of Waste in our process Identify possible ideas for improvement 29

Quantifying the Results Capture the Results from Round 1 30

Quantifying the Results Capture the Results from Round 1 30

What Are the Results? Ø Manager l Ø Efficiency Expert #1 l Ø l How much time did the entire process take? How much time wasted waiting and/or searching? Customer l Ø How many steps did it take for the worker to do the process? Efficiency Expert #2 l Ø What does the spaghetti diagram show us? Was the customer happy with the service provided (quality inspection)? Rest of Class l l Identify forms of waste in the process Include possible ideas for improvement 31

What Are the Results? Ø Manager l Ø Efficiency Expert #1 l Ø l How much time did the entire process take? How much time wasted waiting and/or searching? Customer l Ø How many steps did it take for the worker to do the process? Efficiency Expert #2 l Ø What does the spaghetti diagram show us? Was the customer happy with the service provided (quality inspection)? Rest of Class l l Identify forms of waste in the process Include possible ideas for improvement 31

What Waste Did You Observe? 1. Wasted Human Talent 2. Defects 3. Inventory 4. Over Producing 5. Waiting 6. Motion 7. Transportation 8. Over Processing 32

What Waste Did You Observe? 1. Wasted Human Talent 2. Defects 3. Inventory 4. Over Producing 5. Waiting 6. Motion 7. Transportation 8. Over Processing 32

How Can We Use 6 S to Improve? 1. Sort – Separate the needed from the not needed 2. Straighten – A place for everything and everything in its place 3. Scrub – Ensure everything is in perfect working condition 4. Standardize – Determine the best method – visual queues, labeling, etc. 5. Sustain – Develop Standard Work 6. Safety – Safety first at all times 33

How Can We Use 6 S to Improve? 1. Sort – Separate the needed from the not needed 2. Straighten – A place for everything and everything in its place 3. Scrub – Ensure everything is in perfect working condition 4. Standardize – Determine the best method – visual queues, labeling, etc. 5. Sustain – Develop Standard Work 6. Safety – Safety first at all times 33

ØSimulation – Round 2 34

ØSimulation – Round 2 34

Instructions to the Class Ø Now that you have identified the waste and the opportunities for improvement in the process l Put your recommended improvements in place l We’ll run the simulation a second time l Then we’ll measure the results… …. and celebrate our success!! 35

Instructions to the Class Ø Now that you have identified the waste and the opportunities for improvement in the process l Put your recommended improvements in place l We’ll run the simulation a second time l Then we’ll measure the results… …. and celebrate our success!! 35

Quantifying the Results Capture the Results from Round 2 36

Quantifying the Results Capture the Results from Round 2 36