211a572c8692e833a59bcace40486474.ppt

- Количество слайдов: 87

Lead Competence Center Electrical Control Systems ABB LCC ECS - 1 © 2004 Industrial. IT Power Management System For Industrial Plants

Industrial. IT PMS for Industrial Plants Power Management Drivers PMS Architecture PMS Functionality Benefits References

Business Drivers for PMS Prevention of Blackouts n Reduction of Energy Costs n Reduction of Investment Costs n Reduction of Operational Costs n ABB LCC ECS - 3 © 2004 n Environmental, Health & Safety (EH&S) Risk Management

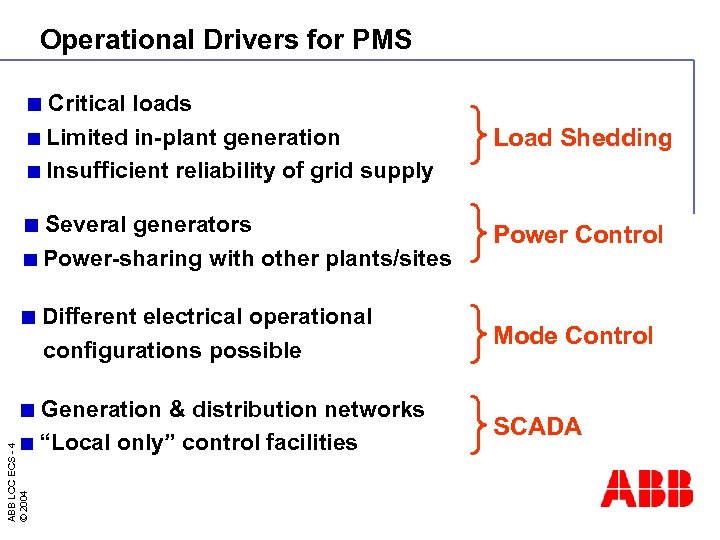

Operational Drivers for PMS Critical loads Limited in-plant generation Insufficient reliability of grid supply Several generators Power-sharing with other plants/sites ABB LCC ECS - 4 © 2004 Different electrical operational configurations possible Generation & distribution networks “Local only” control facilities } } Load Shedding Power Control Mode Control SCADA

ABB LCC ECS - 5 © 2004 Architecture

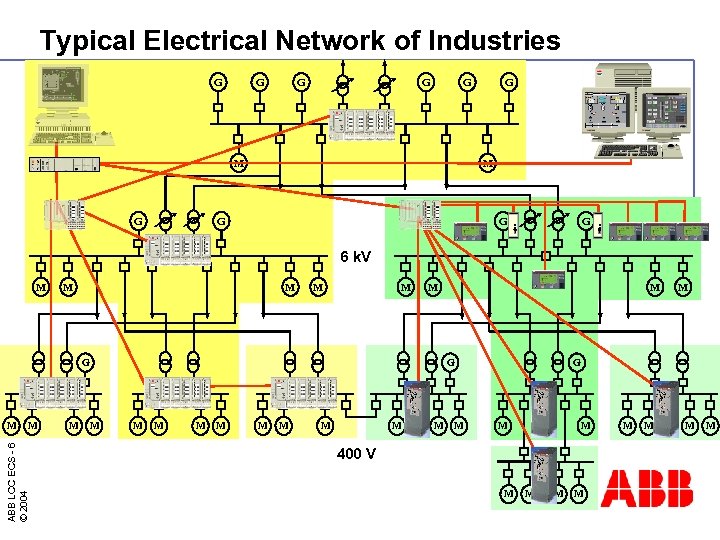

Typical Electrical Network of Industries G G G M G G G 6 k. V M M M G M ABB LCC ECS - 6 © 2004 M M M G M M M 400 V M M M M

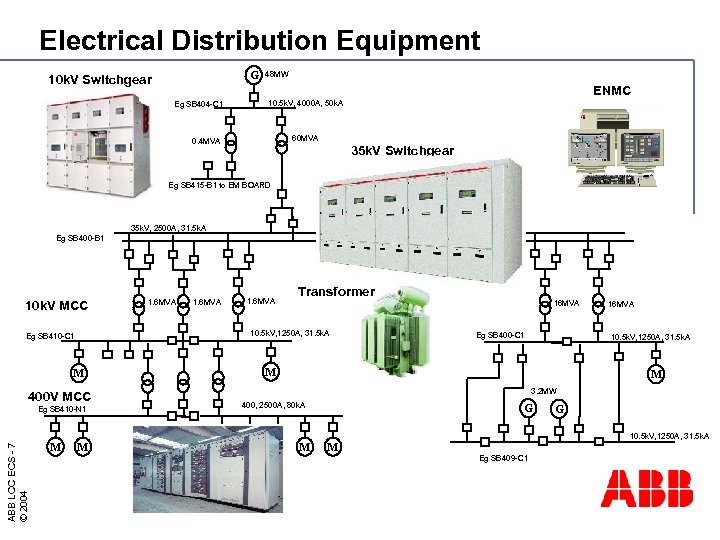

Electrical Distribution Equipment G 10 k. V Switchgear 48 MW ENMC Eg SB 404 -C 1 10. 5 k. V, 4000 A, 50 k. A 60 MVA 0. 4 MVA 35 k. V Switchgear Eg SB 415 -B 1 to EM BOARD 35 k. V, 2500 A, 31. 5 k. A Eg SB 400 -B 1 10 k. V MCC M 400 V MCC Eg SB 410 -N 1 ABB LCC ECS - 7 © 2004 1. 6 MVA Transformer 10. 5 k. V, 1250 A, 31. 5 k. A Eg SB 410 -C 1 M 1. 6 MVA M 16 MVA Eg SB 400 -C 1 16 MVA 10. 5 k. V, 1250 A, 31. 5 k. A M M 3. 2 MW 400, 2500 A, 80 k. A M G 10. 5 k. V, 1250 A, 31. 5 k. A Eg SB 409 -C 1

Industrial. IT System 800 x. A Architecture for PMS Fast Functions are performed by Controllers: Plant & Enterprise Management Systems Remote Users n Load Shedding / Re-Acceleration / Re-Starting n Power Control TCP/IP Network Server n Mode Control Operator Station Engineering Station Control Network AC 800 M Controller Serial links to AVR Serial links to Governor Serial Links to Emergency Diesel Generator ABB LCC ECS - 8 © 2004 S 800 I/O Substation 1 Substation 2 MCC Substation N ACS 601 Substation Z

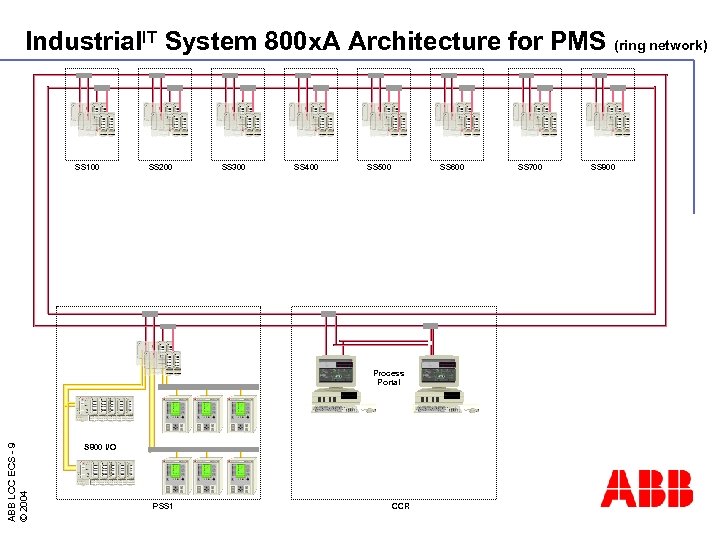

Industrial. IT System 800 x. A Architecture for PMS (ring network) SS 100 SS 200 SS 300 SS 400 SS 500 SS 600 ABB LCC ECS - 9 © 2004 Process Portal S 800 I/O PSS 1 CCR SS 700 SS 800

ABB LCC ECS - 10 © 2004 PMS Functionality

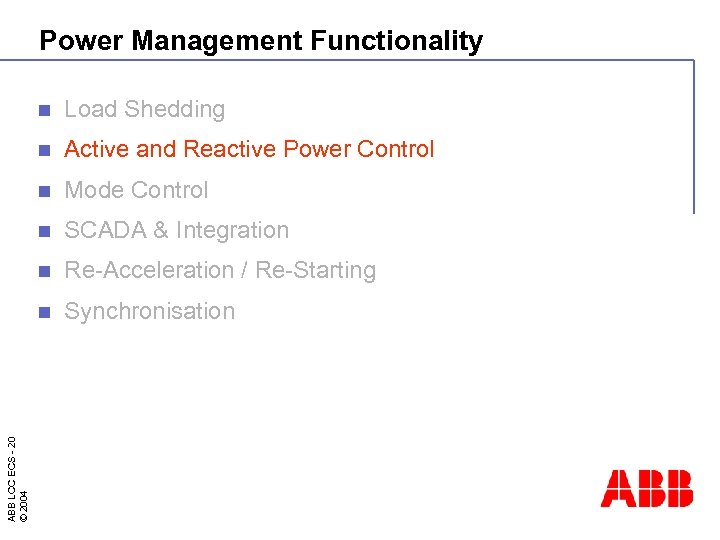

Power Management Functionality Load Shedding n Active and Reactive Power Control n Mode Control n SCADA & Integration n Re-Acceleration / Re-Starting n ABB LCC ECS - 11 © 2004 n Synchronisation

? ABB LCC ECS - 12 © 2004 With Load Shedding Without Load Shedding

Load Shedding: The types Fast Load Shedding on Loss of Power Resources n Load Shedding on Frequency Drop n Slow Load Shedding on Overload n Slow Load Shedding for Peak Shaving n ABB LCC ECS - 13 © 2004 n Manual Load Shedding

Load Shedding: Keywords Fast n Exact n Flexible n Co-ordinated n Deterministic n Security and Reliability n Accurate Event Logging n Operator Guidance n ABB LCC ECS - 14 © 2004 n Independent Back-up System

ABB’s Starting-point for Load Shedding M 1 Minimal disturbance to plant operation No spurious operation G 2 M 2 9 MW 6 MW (5) (3) ABB LCC ECS - 15 © 2004 Secure electrical power to critical loads n G 1 30 MW 20 MW n n 15 MW M 3 M 4 1 MW 20 MW (3) (1) M 5 M 6 M 7 10 MW 7 MW 12 MW (2) (4) (5)

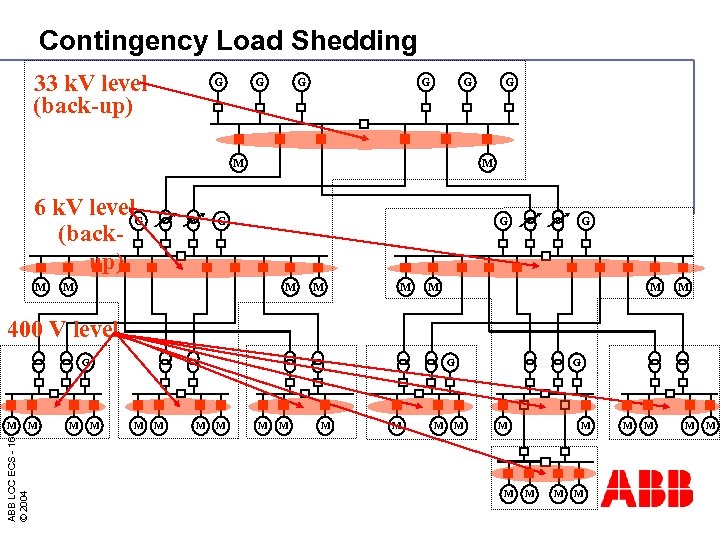

Contingency Load Shedding 33 k. V level (back-up) G G G M 6 k. V level. G (backup) M G G M M M 400 V level G M ABB LCC ECS - 16 © 2004 M M G M M M M M M

Technical Data Load Shedding Substation 1 G G G 11 k. V M G G 6 k. V M M M ABB LCC ECS - 17 © 2004 Initiation breakers: CB position 5 ms. Power Flow 1 s. G Substation N 6 k. V M M M Load Shed breakers: Open Command 5 ms. CB position 1 s. Power Flow 1 s. M M

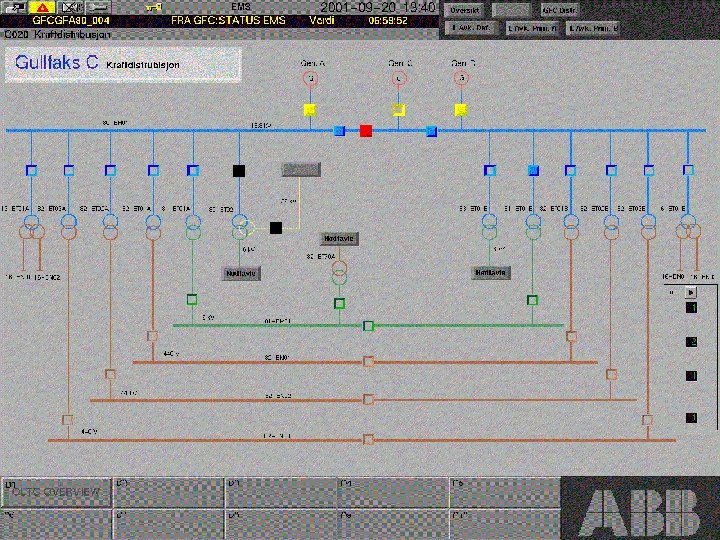

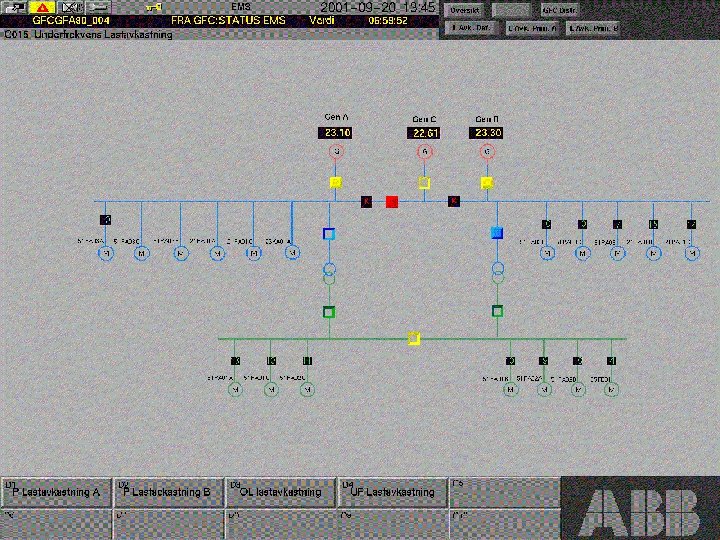

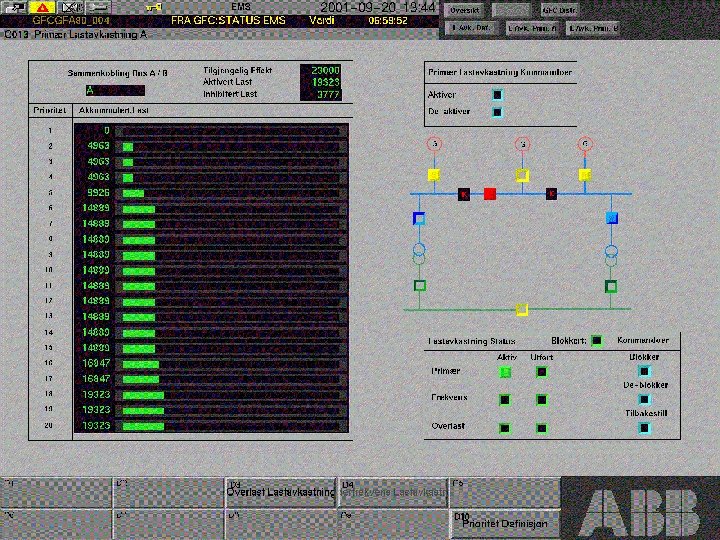

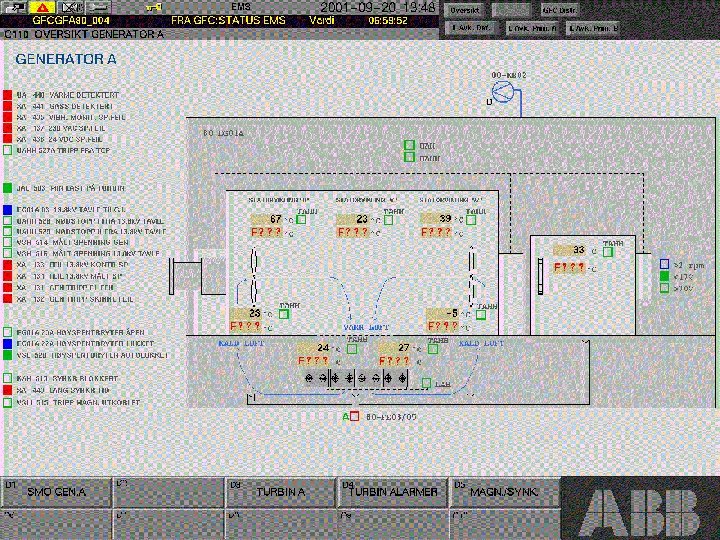

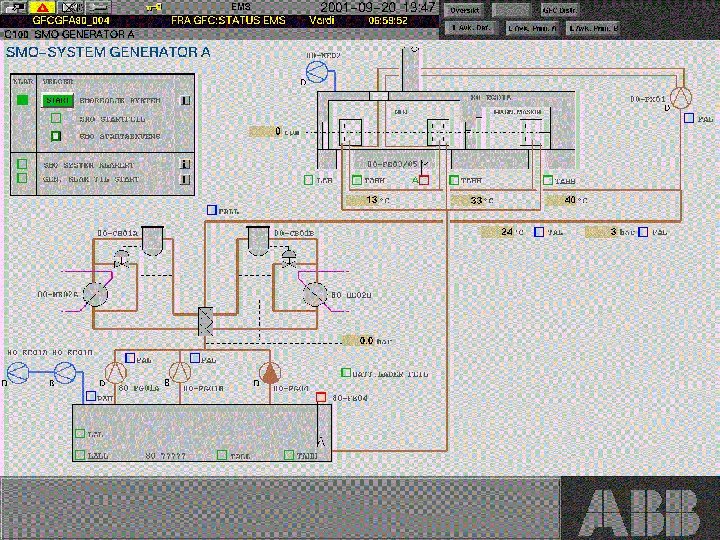

Display Load Shedding Overview

ABB LCC ECS - 19 © 2004

Power Management Functionality Load Shedding n Active and Reactive Power Control n Mode Control n SCADA & Integration n Re-Acceleration / Re-Starting n ABB LCC ECS - 20 © 2004 n Synchronisation

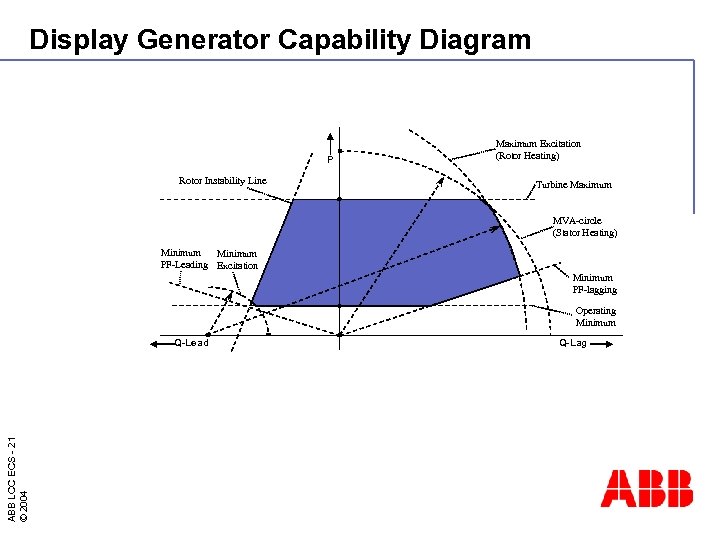

Display Generator Capability Diagram P Rotor Instability Line Maximum Excitation (Rotor Heating) Turbine Maximum MVA-circle (Stator Heating) Minimum PF-Leading Excitation Minimum PF-lagging Operating Minimum ABB LCC ECS - 21 © 2004 Q-Lead Q-Lag

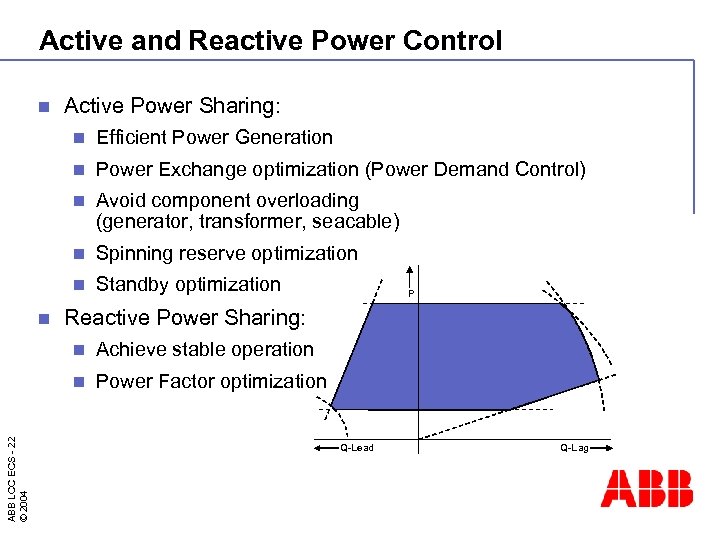

Active and Reactive Power Control n Active Power Sharing: n n Power Exchange optimization (Power Demand Control) n Avoid component overloading (generator, transformer, seacable) n Spinning reserve optimization n n Efficient Power Generation Standby optimization Reactive Power Sharing: n Achieve stable operation n ABB LCC ECS - 22 © 2004 P Power Factor optimization Q-Lead Q-Lag

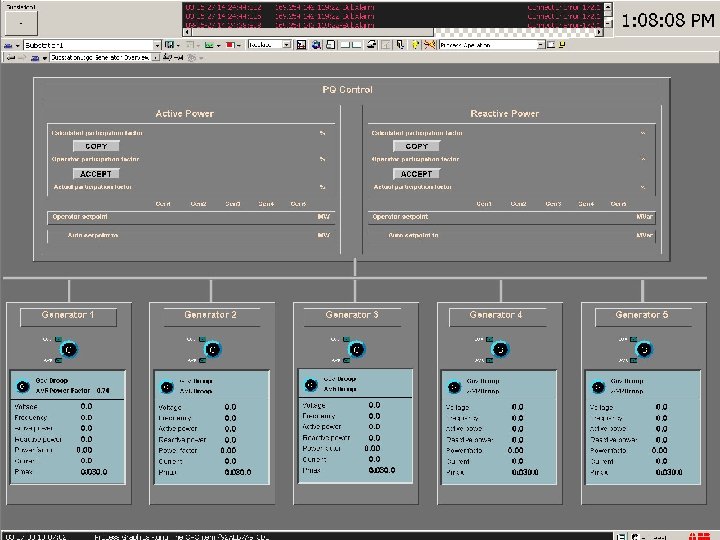

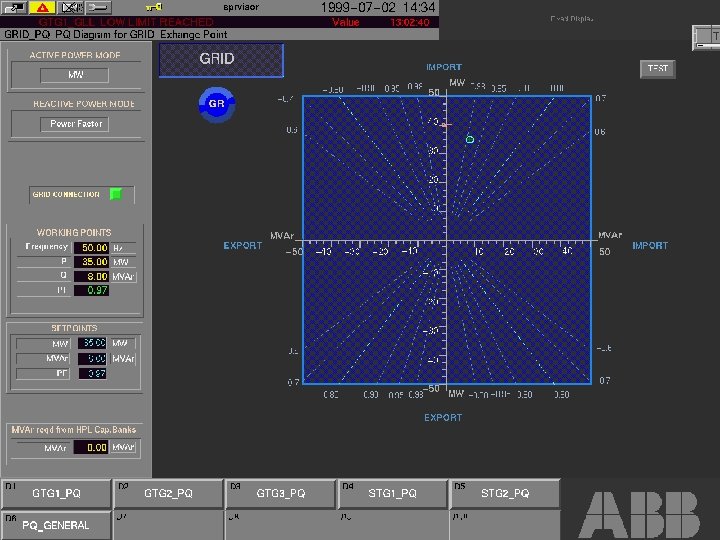

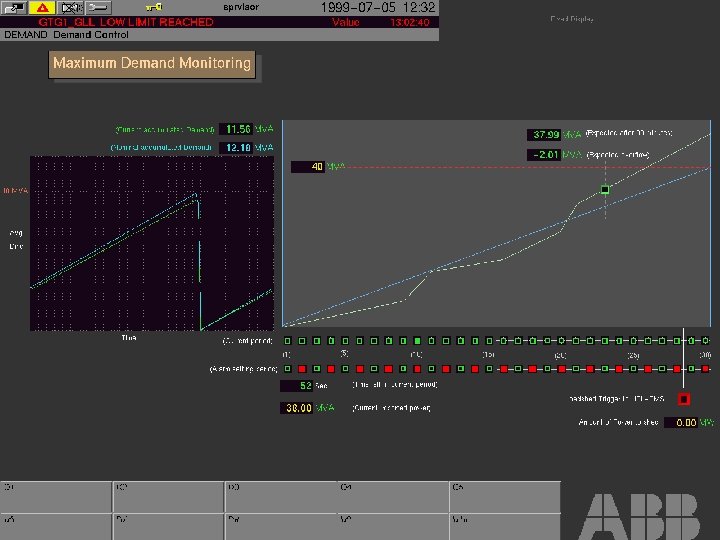

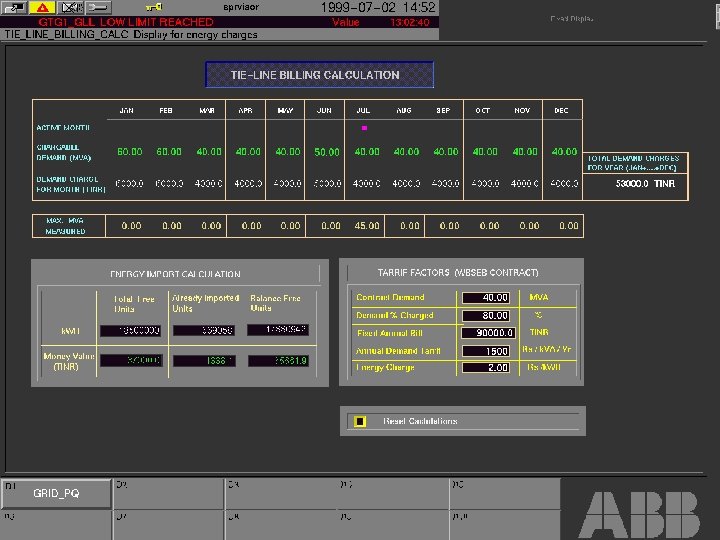

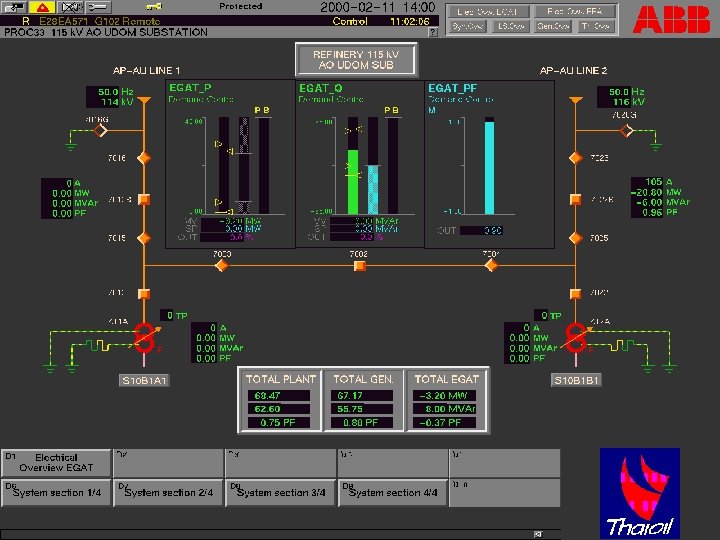

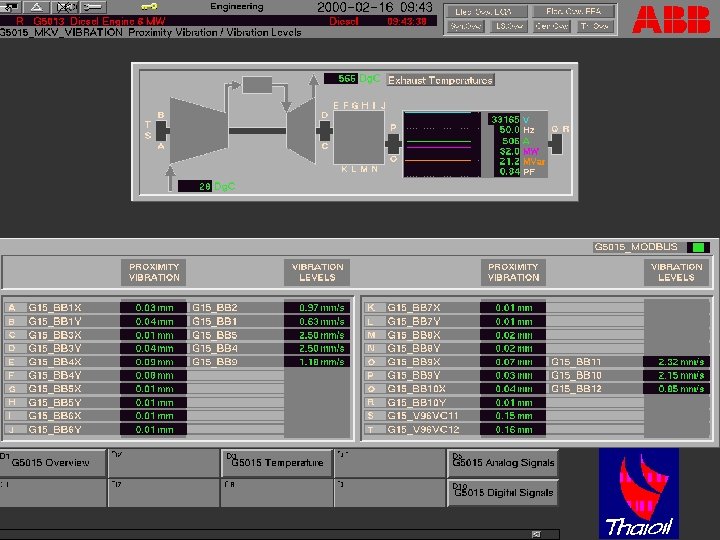

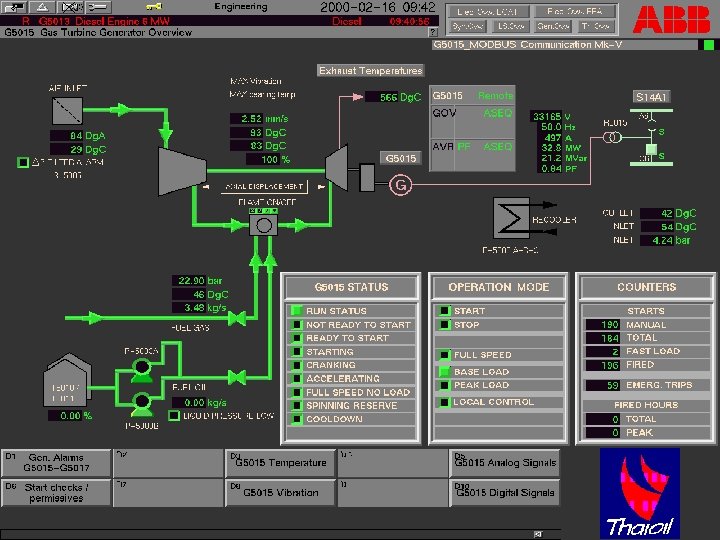

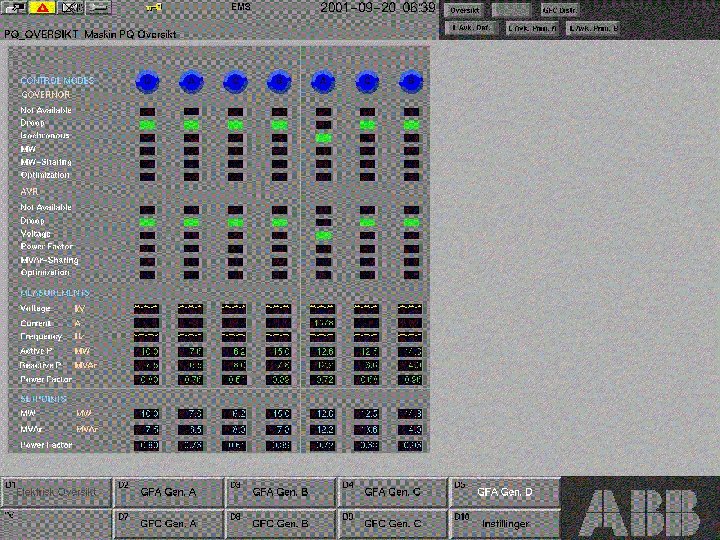

Power Control Example Displays Calculated Control Margins 2. Generator Capability Diagram 3. Grid Capability Diagram 4. Maximum Demand Monitoring 5. Tie-line Monitoring 6. Mark V Vibration 7. ABB LCC ECS - 23 © 2004 1. Mark V Gas Turbine Generator Overview

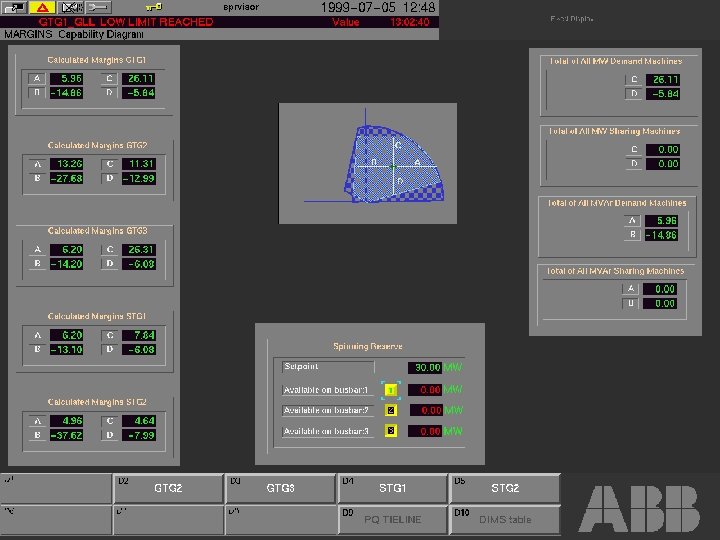

ABB LCC ECS - 24 © 2004 Display Calculated Control Margins

ABB LCC ECS - 25 © 2004

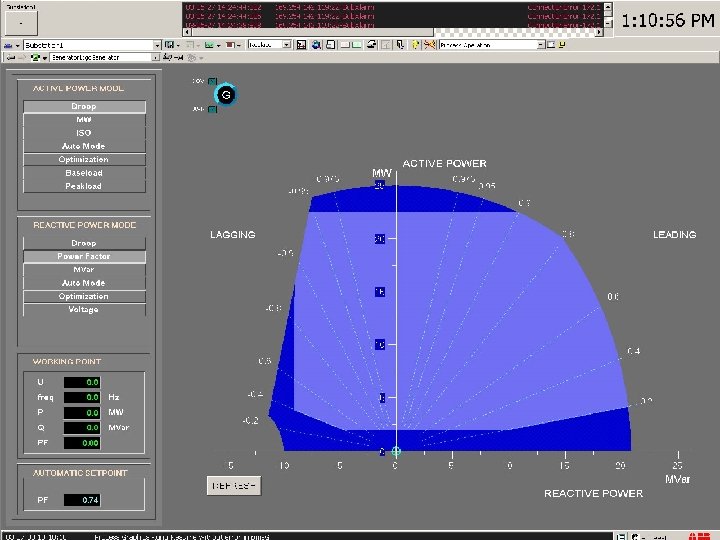

ABB LCC ECS - 26 © 2004

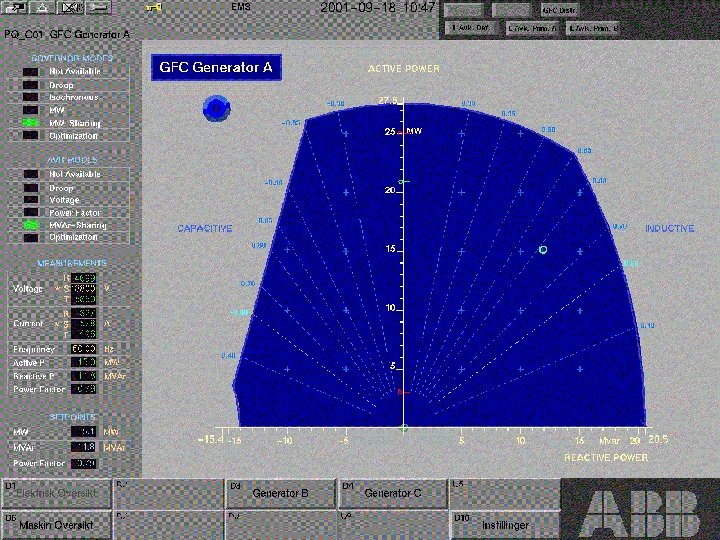

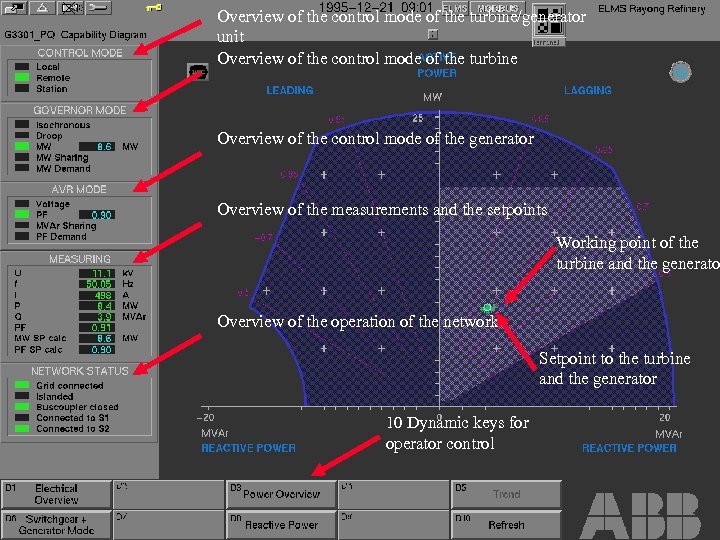

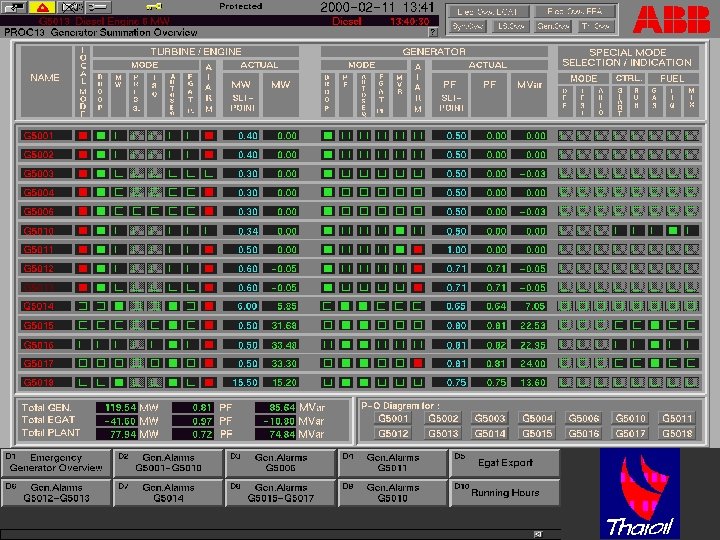

Overview of the control mode of the turbine/generator unit Overview of the control mode of the turbine Generator Capability Diagram Display Overview of the control mode of the generator Overview of the measurements and the setpoints Working point of the turbine and the generato Overview of the operation of the network ABB LCC ECS - 27 © 2004 Setpoint to the turbine and the generator 10 Dynamic keys for operator control

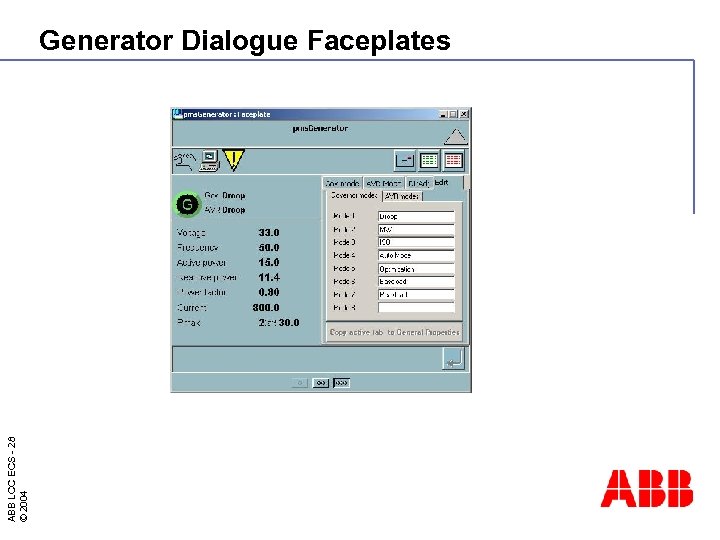

ABB LCC ECS - 28 © 2004 Generator Dialogue Faceplates

ABB LCC ECS - 29 © 2004

ABB LCC ECS - 30 © 2004 Display Grid Capability Diagram

ABB LCC ECS - 31 © 2004 Display Maximum Demand Monitoring

ABB LCC ECS - 32 © 2004 Display Tie-line Billing Calculation

ABB LCC ECS - 33 © 2004 Display Monitoring Tie-line

ABB LCC ECS - 34 © 2004 Display Mark V Vibration

ABB LCC ECS - 35 © 2004 Display Mark V Gas Turbine Generator Overview

Power Management Functionality Load Shedding n Active and Reactive Power Control n Mode Control n SCADA & Integration n Re-Acceleration / Re-Starting n ABB LCC ECS - 36 © 2004 n Synchronisation

Mode Control n for Generators for Turbines n for Transformers n ABB LCC ECS - 37 © 2004 n for Switchboards

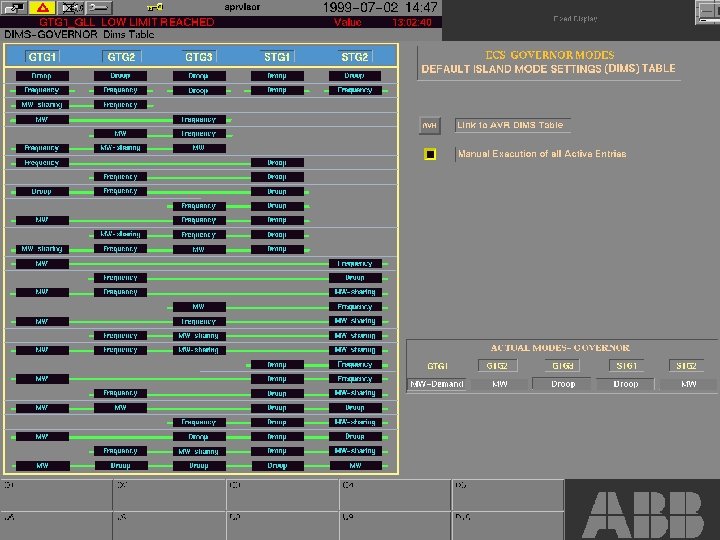

ABB LCC ECS - 38 © 2004 Display Governor Mode Control

ABB LCC ECS - 39 © 2004

ABB LCC ECS - 40 © 2004

Power Management Functionality Load Shedding n Active and Reactive Power Control n Mode Control n SCADA & Integration n Re-Acceleration / Re-Starting n ABB LCC ECS - 41 © 2004 n Synchronisation

Supervision, Control and Data Acquisition Clearly Structured Presentation n Controls - Select Before Execute n Status Indications n Consistency Analysis n Time Tagged Events (1 ms resolution) n Alarmhandling, Reports, Trends n Supervision and Self Diagnostics n ABB LCC ECS - 42 © 2004 n Single Window concept

Integration with Supervisory Systems Plant Information Systems - MIS n Regional Dispatch Centres n Power Generation Co-ordination Centres n Energy Trading n Utility Management Systems n ABB LCC ECS - 43 © 2004 n Process DCS

Integration with Subordinated Systems Satellite Time Receiver (GPS) n Alarm annunciators n SF-6 Density Monitoring Units n Motor Control Centres n Battery Chargers n Meteorological Stations n Diesel Generators n Generator- and turbine controller n ABB LCC ECS - 44 © 2004 n Protection and Control Units

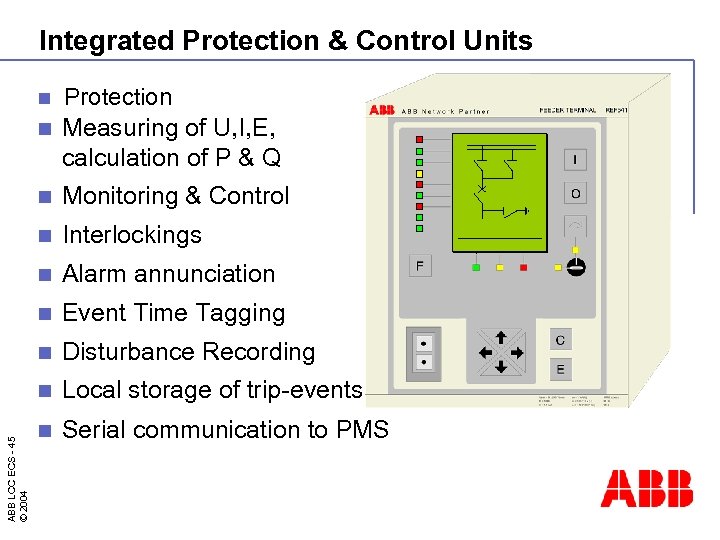

Integrated Protection & Control Units Protection n Measuring of U, I, E, calculation of P & Q n Monitoring & Control n Interlockings n Alarm annunciation n Event Time Tagging n Disturbance Recording n ABB LCC ECS - 45 © 2004 n Local storage of trip-events n Serial communication to PMS CB SPRING READY Events Measured Values CB TRUCK OUT NOC 3 Low: E 3 IL 1 Amps 800 IL 2 Amps 99 -07 -06 18: 34: 230 803 TEMPERATURE HIGH IL 3 Amps 801 NOC 3 Low: E 2 Io 0 Iob 99 -07 -06 14: 25: 52: 720 0 U 12 k. V 20 SF 6 GAS DENSITY 20 CB-HCU 2: Opened U 23 k. V U 31 k. V 99 -07 -06 14: 02: 48: 430 20 U 1 k. V 11. 5 U 2 k. V 11. 5 U 3 k. V 11. 5 Uo - Volts 0 LOADSHEDDED Use C-button to clear Events Use Up and Down to scroll view

Power Management Functionality Load Shedding n Active and Reactive Power Control n Mode Control n SCADA & Integration n Re-Acceleration / Re-Starting n ABB LCC ECS - 46 © 2004 n Synchronisation

Re-Acceleration / Re-Starting Triggered by Load Shedding or Under-voltage n Individual motors n Priority per motor n Max. allowed time delay per motor n Network configuration check n ABB LCC ECS - 47 © 2004 n Network restoration

Power Management Functionality Load Shedding n Active and Reactive Power Control n Mode Control n SCADA & Integration n Re-Acceleration / Re-Starting n ABB LCC ECS - 48 © 2004 n Synchronisation

Synchronisation Automatic Synchronisation after boiler trip n Automatic Synchronisation initiated by operator n Semi Automatic Synchronisation n ABB LCC ECS - 49 © 2004 n Manual Synchronisation

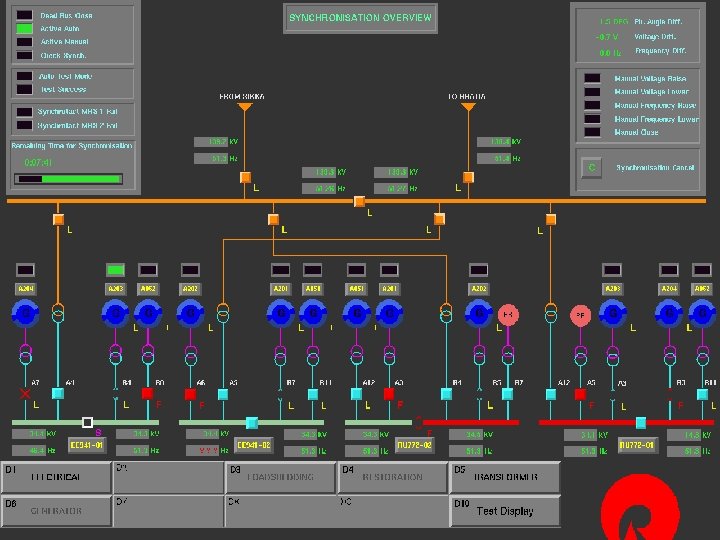

ABB LCC ECS - 50 © 2004 Display Synchronisation (Jamnagar)

Power Management Functionality: Summary Load Shedding n Active and Reactive Power Control n Mode Control n Supervision, Control and Data Acquisition (SCADA) n Re-Starting n Synchronisation n Circuit breaker Control n Transformer Control n Motor Control n Generator Control n ABB LCC ECS - 51 © 2004 n Network Configuration Determination

Tertiary Control State Estimator n Power Flow Analysis n Network Security Analysis n Fault Calculation n Fault Isolation n Unit Commitment n Optimal Power Flow n Economic Dispatch n Production Cost Monitoring n Transformer Load Management n ABB LCC ECS - 52 © 2004 n Transient System Simulator n Transformer Overload Management

ABB LCC ECS - 53 © 2004 PMS Benefits

ABB Industrial IT PMS allows you to: n Avoid black-outs (up to 500 k. USD / hour) Power control including voltage control, frequency control, sharing power among generators and tie-line(s). n High Speed Consistency Load Shedding (< 100 ms. ) n n Reduce electricity costs Peak-shaving n Re-active Power Control & Sharing n n Minimize operational costs Decreased number of operators n Event driven maintenance n Transformer Overload Management n Single Window concept ? n ABB LCC ECS - 54 © 2004 n Reduce investment costs In case of a shortage of electrical power, The total accumulated switched-off Minimized cabling and engineering The Human Machine Interfaces for all the Optimizing the stability of the operation of Power Control, Standby Optimization, secure the available power to critical loads shortcurrents by a circuitbreaker or n Optimized network design n n+1 Criteria, SCADA, etc. are performed by Limit electrical import during peak time and electrical sub-systems can be integrated in Serial interfaces with protection & control the electrical generation- and distribution by switching off the none important loads the number of generator starts No need for big oversizing of primary equipment units avoid spaghetti wiring & cable ducts reduce peak based charges Maintaining a good Power Factor the Energy Management System the system and not by the operators according to dynamic load tables are a trigger for maintenance network of a plant

Why ABB Industrial. IT PMS? n In-depth knowledge of the electrical process n 20 years experience in PMS implementations across the world n Standard software, well documented, tested, n Based on state-of-the-art Industrial IT System 800 x. A technology n Advanced technical features, including: n n ABB LCC ECS - 55 © 2004 High Resolution and Accuracy of Sequence of Event recording n n Fast Response Time for Load Shedding, Mode Control, Power Control, Re-acceleration Compliance to class 3 EMC immunity Single responsibility: One supplier for PMS integrated with: protection, governor, excitation, tapchanger, Motor Control Centre, Variable Speed Drive, etc.

ABB LCC ECS - 56 © 2004 References

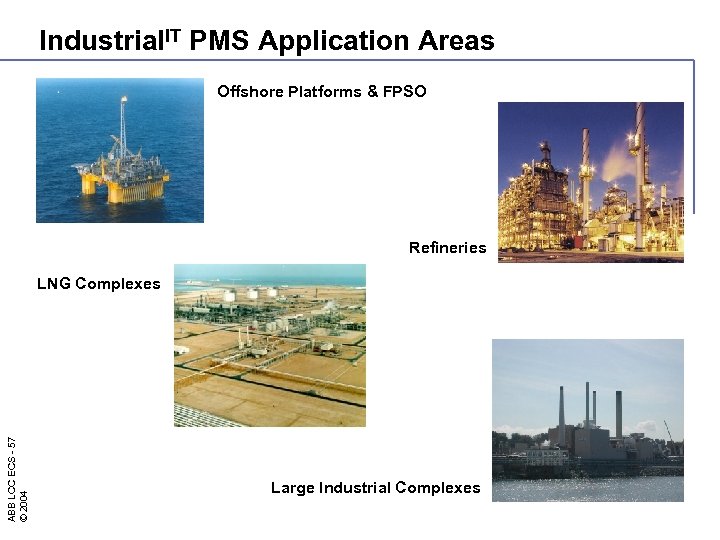

Industrial. IT PMS Application Areas Offshore Platforms & FPSO Refineries ABB LCC ECS - 57 © 2004 LNG Complexes Large Industrial Complexes

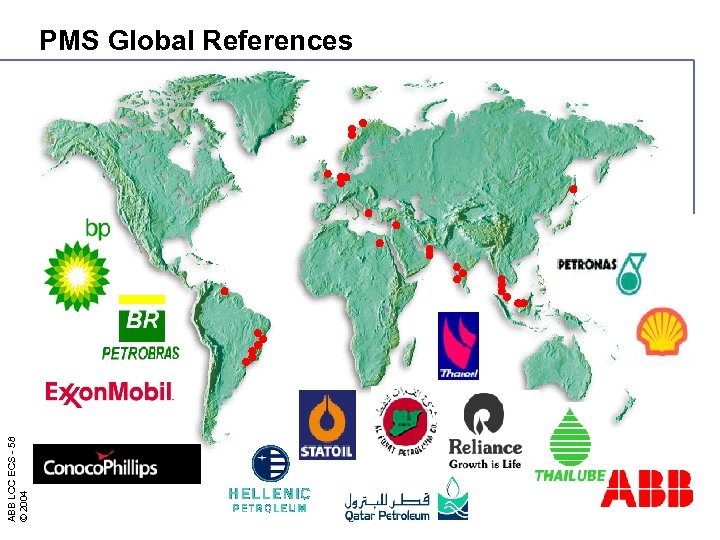

ABB LCC ECS - 58 © 2004 PMS Global References

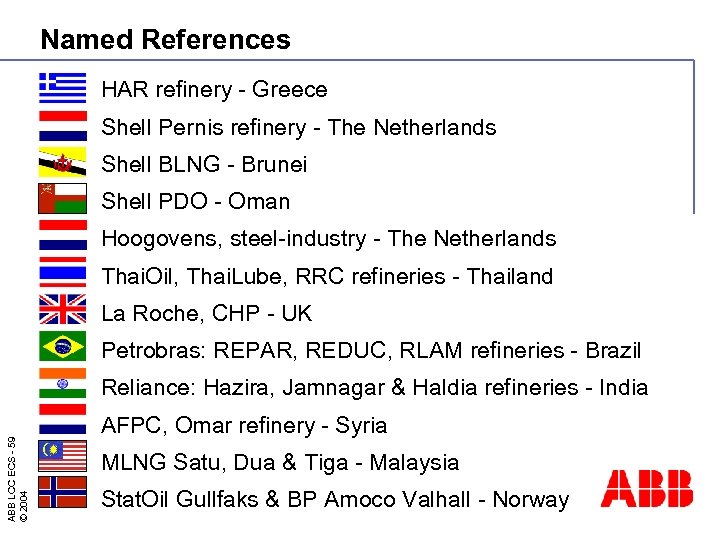

Named References HAR refinery - Greece Shell Pernis refinery - The Netherlands Shell BLNG - Brunei Shell PDO - Oman Hoogovens, steel-industry - The Netherlands Thai. Oil, Thai. Lube, RRC refineries - Thailand La Roche, CHP - UK Petrobras: REPAR, REDUC, RLAM refineries - Brazil ABB LCC ECS - 59 © 2004 Reliance: Hazira, Jamnagar & Haldia refineries - India AFPC, Omar refinery - Syria MLNG Satu, Dua & Tiga - Malaysia Stat. Oil Gullfaks & BP Amoco Valhall - Norway

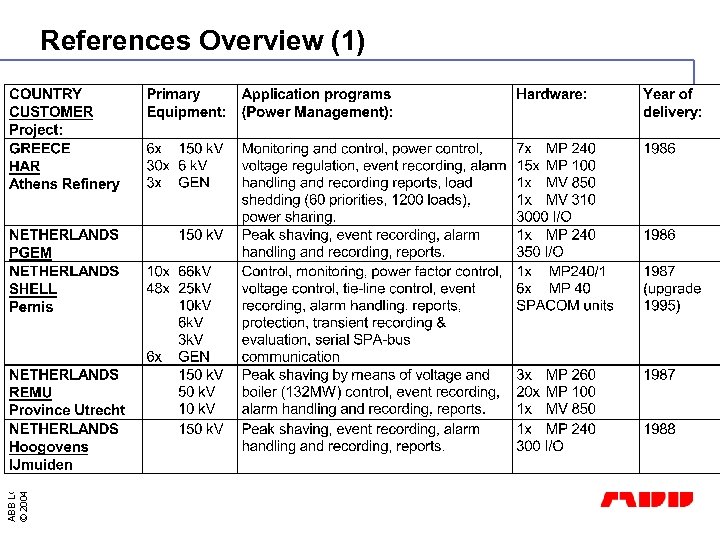

ABB LCC ECS - 60 © 2004 References Overview (1)

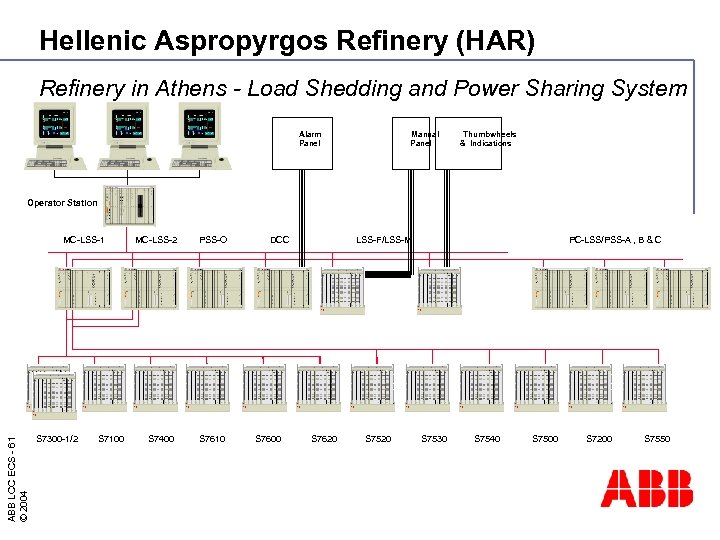

Hellenic Aspropyrgos Refinery (HAR) Refinery in Athens - Load Shedding and Power Sharing System Alarm Panel Manual Panel Thumbwheels & Indications Operator Station ABB LCC ECS - 61 © 2004 MC-LSS-1 MC-LSS-2 PSS-O DCC LSS-F/LSS-M PC-LSS/PSS-A , B & C S 7300 -1/2 S 7100 S 7400 S 7610 S 7600 S 7620 S 7530 S 7540 S 7500 S 7200 S 7550

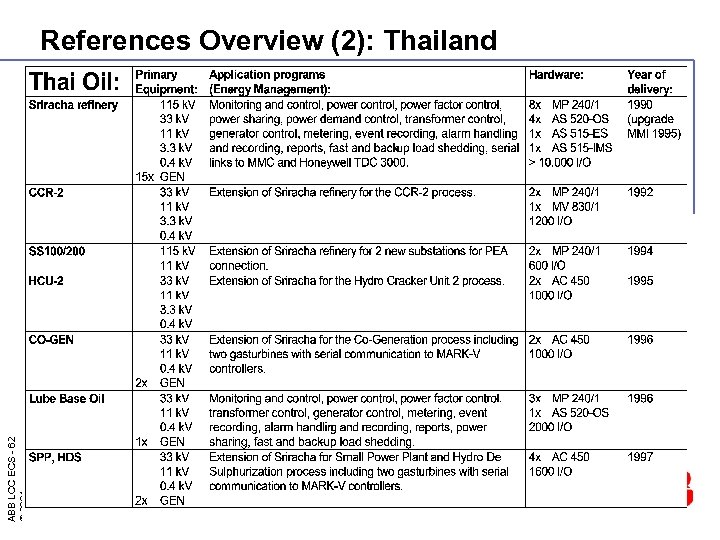

ABB LCC ECS - 62 © 2004 References Overview (2): Thailand

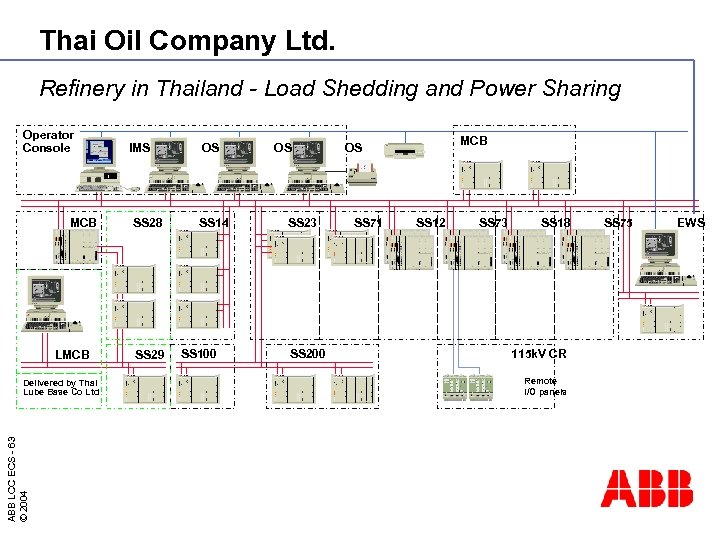

Thai Oil Company Ltd. Refinery in Thailand - Load Shedding and Power Sharing Operator Console MCB LMCB ABB LCC ECS - 63 © 2004 Delivered by Thai Lube Base Co Ltd IMS SS 28 SS 29 OS SS 14 SS 100 OS SS 23 SS 200 MCB OS SS 71 SS 12 SS 73 SS 18 115 k. V CR Remote I/O panels SS 75 EWS

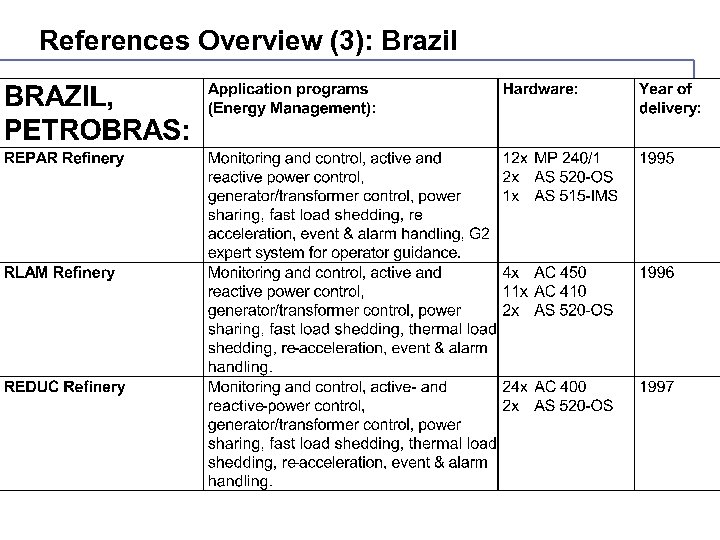

ABB LCC ECS - 64 © 2004 References Overview (3): Brazil

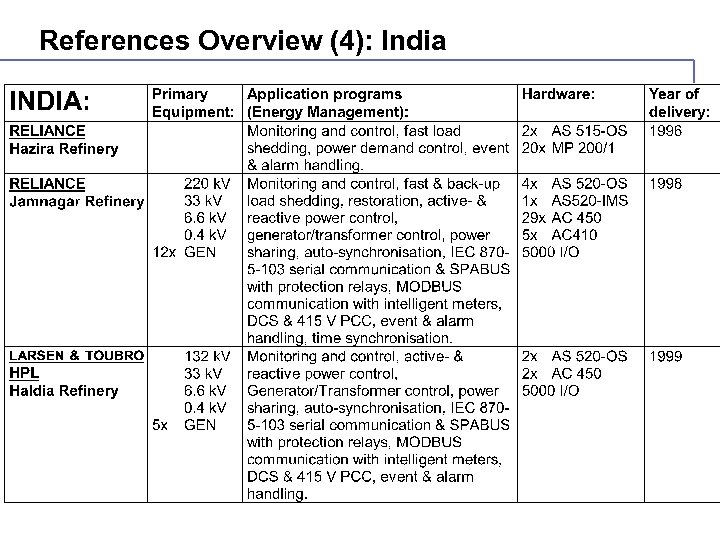

ABB LCC ECS - 65 © 2004 References Overview (4): India

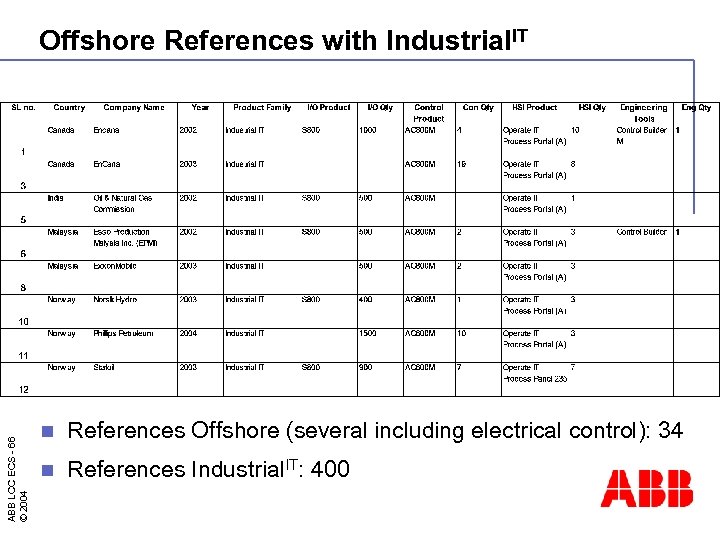

ABB LCC ECS - 66 © 2004 Offshore References with Industrial. IT n References Offshore (several including electrical control): 34 n References Industrial. IT: 400

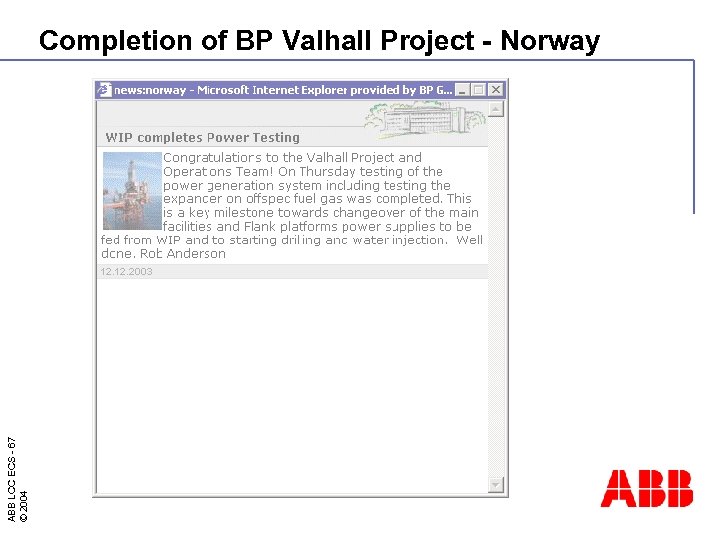

ABB LCC ECS - 67 © 2004 Completion of BP Valhall Project - Norway

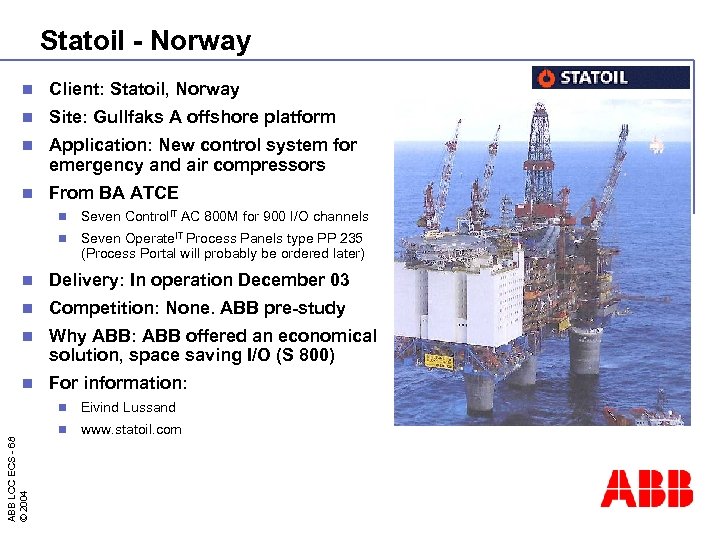

Statoil - Norway n Client: Statoil, Norway n Site: Gullfaks A offshore platform n Application: New control system for emergency and air compressors n From BA ATCE n Seven Control. IT AC 800 M for 900 I/O channels n Seven Operate. IT Process Panels type PP 235 (Process Portal will probably be ordered later) n Delivery: In operation December 03 n Competition: None. ABB pre-study n Why ABB: ABB offered an economical solution, space saving I/O (S 800) n For information: Eivind Lussand n ABB LCC ECS - 68 © 2004 n www. statoil. com

ABB LCC ECS - 69 © 2004

ABB LCC ECS - 70 © 2004

ABB LCC ECS - 71 © 2004

ABB LCC ECS - 72 © 2004

ABB LCC ECS - 73 © 2004

ABB LCC ECS - 74 © 2004

ABB LCC ECS - 75 © 2004

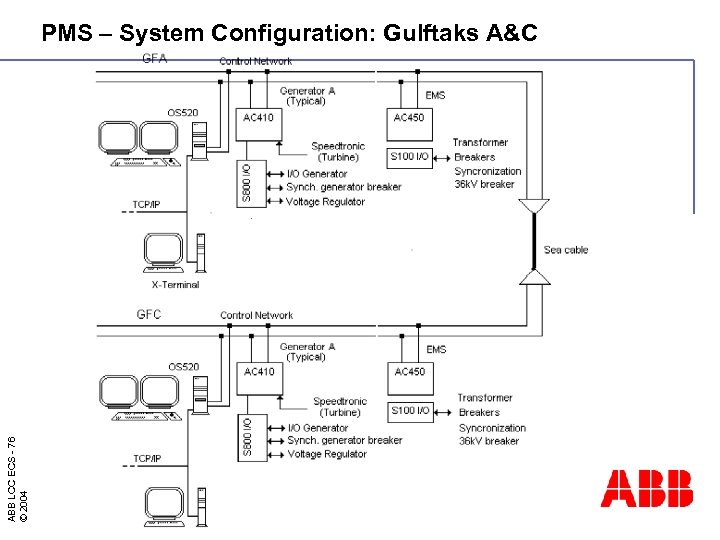

ABB LCC ECS - 76 © 2004 PMS – System Configuration: Gulftaks A&C

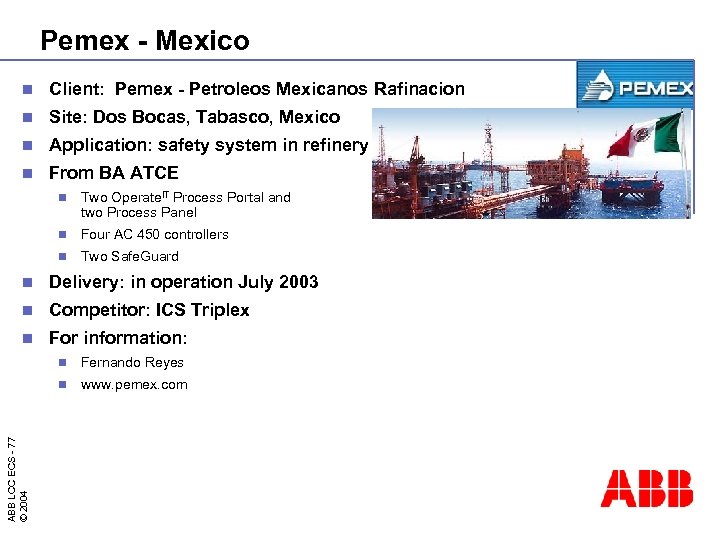

Pemex - Mexico n Client: Pemex - Petroleos Mexicanos Rafinacion n Site: Dos Bocas, Tabasco, Mexico n Application: safety system in refinery n From BA ATCE n Two Operate. IT Process Portal and two Process Panel n Four AC 450 controllers n Two Safe. Guard n Delivery: in operation July 2003 n Competitor: ICS Triplex n For information: Fernando Reyes n ABB LCC ECS - 77 © 2004 n www. pemex. com

En. Cana - UK n Client: En. Cana n One of the world's leading independent oil and gas companies n Based in Canada n Site: Buzzard oil and gas platform, North Sea, 57 km east Peterhead, North Scotland n Application: Total control and safety system of new platform n n Main contractor is CBI/John Brown Automation from ABB: n 10 Operate IT redundant Process Portal and 8 Control IT AC 800 M controllers, 8 Safeguard 400 safety controllers, training system. Option: instrumentation from ABB Start of installation mid of 2004 n Competition: Honeywell and Silvertech n For information: ABB LCC ECS - 78 © 2004 n n Brian Keeler n About Buzzard n www. encana. com

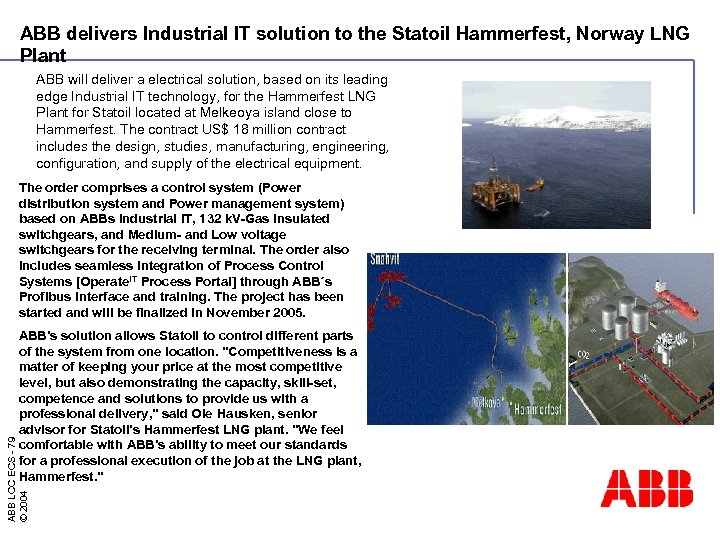

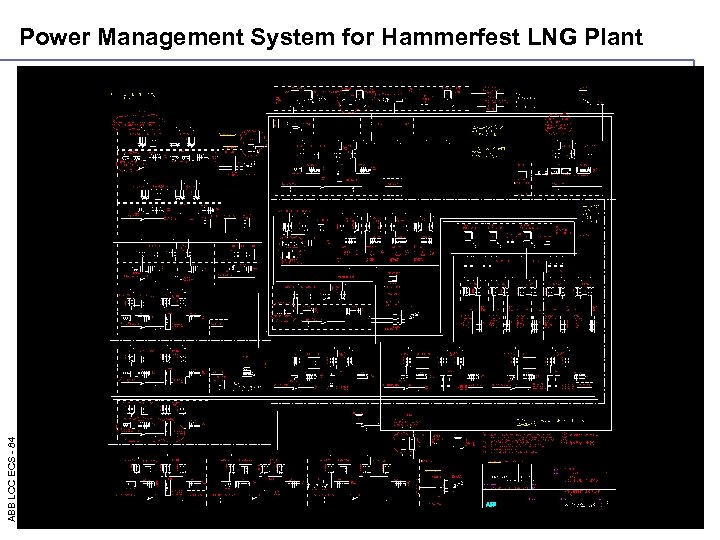

ABB delivers Industrial IT solution to the Statoil Hammerfest, Norway LNG Plant ABB will deliver a electrical solution, based on its leading edge Industrial IT technology, for the Hammerfest LNG Plant for Statoil located at Melkeoya island close to Hammerfest. The contract US$ 18 million contract includes the design, studies, manufacturing, engineering, configuration, and supply of the electrical equipment. The order comprises a control system (Power distribution system and Power management system) based on ABBs Industrial IT, 132 k. V-Gas insulated switchgears, and Medium- and Low voltage switchgears for the receiving terminal. The order also includes seamless integration of Process Control Systems [Operate. IT Process Portal] through ABB´s Profibus interface and training. The project has been started and will be finalized in November 2005. ABB LCC ECS - 79 © 2004 ABB’s solution allows Statoil to control different parts of the system from one location. "Competitiveness is a matter of keeping your price at the most competitive level, but also demonstrating the capacity, skill-set, competence and solutions to provide us with a professional delivery, " said Ole Hausken, senior advisor for Statoil’s Hammerfest LNG plant. "We feel comfortable with ABB’s ability to meet our standards for a professional execution of the job at the LNG plant, Hammerfest. "

Maersk Olie og Gas - Denmark n Client: Maersk Olie og Gas AS, part of A. P. Moller Group n Site: DAN-FG platform n n Application: Control system n n New production platform built in Singapore for the DAN-F field, the North Sea ABB has supplied all automation to all platforms in the DAN-F field From BA ATCE n n Four AC 800 M for some 3500 S 800 I/O channels n Two Safeguard systems n n Two Operate. IT Process Portal Also upgrading the whole ESD system for the DAN-F field For information: Henning Jorgensen n ABB LCC ECS - 80 © 2004 n www. maersk. com

ABB supplies Industrial. IT solutions for DONG platforms in the North Sea Automatic monitoring systems for unmanned production platforms ABB LCC ECS - 81 © 2004 Odense, Denmark, February 6, 2003 -- ABB, the leading power and automation technology group, has been chosen by Danish Oil and Natural Gas (DONG) A/S to install a number of automatic monitoring systems for the enlargement of the Siri field in the North Sea. DONG, Denmark’s new offshore player, is responsible for the supply, distribution and storage of natural gas and oil within Denmark. The contract comprises an order from Semco Maritime for a safety and automation system (SAS) for DONG’s two new unmanned platforms for oil and gas production at the Nini and Cecilie fields, as well as a direct order from DONG for the existing Siri production field. Supply ABB will supply three basic systems: one system for normal process control and logging of data; an Emergency Shut Down system primarily protecting the process equipment; and a fire and gas system. An Operate. IT operator station will control and monitor the Nini and Cecilie platforms. With ABB’s Industrial IT technology, all information is available in real-time to operators with just one mouse click. Explosion Proof Enclosure DONG has chosen Advant Controller 410 as the basis for all three basic systems. Installations in the North Sea make heavy demands on the enclosure of the equipment. ABB’s Control. IT I/O modules can be placed directly in hazardous areas, reducing cabling and heavy enclosures and saving DONG a significant amount of money.

Maersk Olie og Gas - Denmark n Client: Maersk Olie og Gas A/S, Denmark, part of A. P. Möller Group n Site: Dan FG oil and gas platform, part of the Dan F complex n Scope of supply: Automation system for oil and gas platform n From BA ATCE: n Industrial IT system for DCS/SCADA n Two Operate. IT Process Portal HMIs with dual screens n Four Control. IT AC 800 M controllers n Emergency Shutdown System n Two Safe. Guard 415 n One Safe. Guard 415 for existing Dan platform n 13 upgrades of older Safeguard 3000 to Safeguard 415 n Fire and Gas Detection System ABB LCC ECS - 82 © 2004 n Two Safeguard 415 n Commissioning: Q 2 2004 n Competition: Siemens n For more information: n Henning Jorgensen or http: //www. maersk. com

ONGC India chooses ABB Industrial. IT for offshore Fire and Gas System Mumbai, India, July 25, 2002 ABB, the power and automation technology group, will upgrade and install an Industrial IT Safe. Guard Fire and Gas Safety System for Oil & Natural Gas Corporation Limited (ONGC) at the WIN-Northern Offshore fields of Mumbai High in the Arabian Sea. ONGC is the largest oil producer in India. This order follows a similar, successful Fire and Gas Safety System Revamp by ABB for the BHN Platform of ONGC. The BHN Platform revamping job was the first of this nature and magnitude executed by an Indian Company, " said Vijay Kumar, Deputy General Manager (E&T) at ONGC. "We appreciate the effort put forward by the ABB team to complete this project. " ABB’s delivery for the WIN Project includes Fire, Gas, Smoke and Heat detectors along with Industrial IT for Safety - a TUV AK-6 (SIL-3) Certified Dual Modular Redundant Safe. Guard PLC based Fire and Gas System with Operate. IT operator stations. ABB’s scope of supply also includes the surveying of the existing facilities at the platform along with the design engineering of the entire Fire and Gas System. ABB LCC ECS - 83 © 2004 " Oil & Gas Natural Gas Corporation Limited (www. ongcindia. com) is a flagship public sector enterprise and India’s highest profit making corporation. Since its inception ONGC has produced more than 600 million metric tons of crude oil and supplied more than 200 billion cubic meters of gas, thus fuelling India’s economy.

ABB LCC ECS - 84 © 2004 Power Management System for Hammerfest LNG Plant

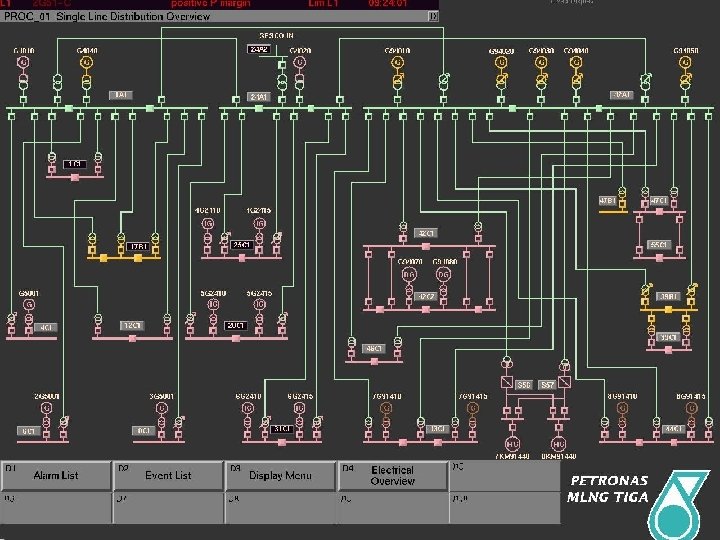

ABB LCC ECS - 85 © 2004

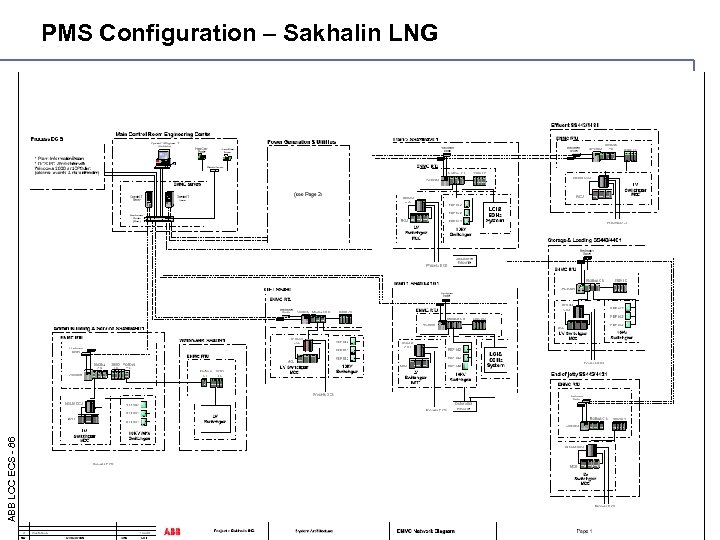

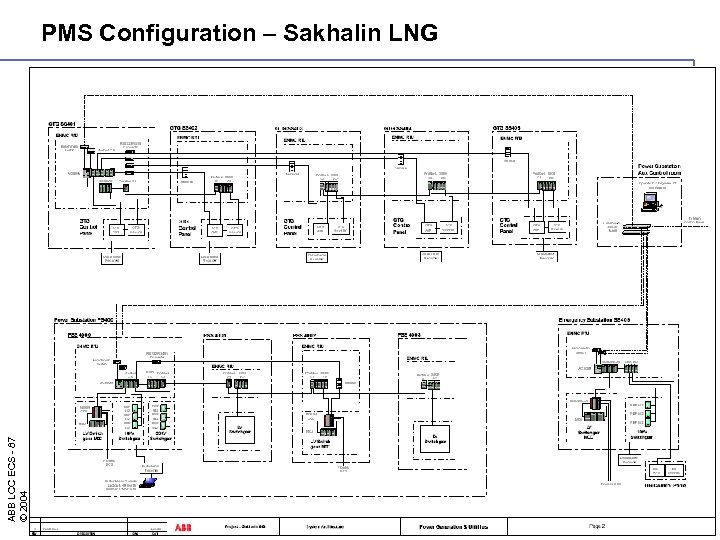

ABB LCC ECS - 86 © 2004 PMS Configuration – Sakhalin LNG

ABB LCC ECS - 87 © 2004 PMS Configuration – Sakhalin LNG

211a572c8692e833a59bcace40486474.ppt