8dcf1792d797807a4e3a876d776bdb39.ppt

- Количество слайдов: 14

LCIA Bram Kale European Engineering manager OMRON . Omron Europe B. V 5 november 2008 Evoluon - Eindhoven OMRO

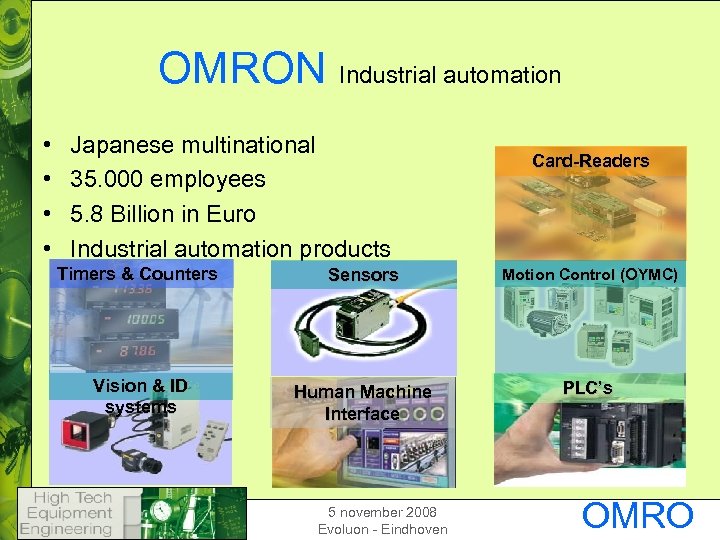

OMRON Industrial automation • • Japanese multinational 35. 000 employees 5. 8 Billion in Euro Industrial automation products Card-Readers Timers & Counters Sensors Motion Control (OYMC) Vision & ID systems Human Machine Interface PLC’s 5 november 2008 Evoluon - Eindhoven OMRO

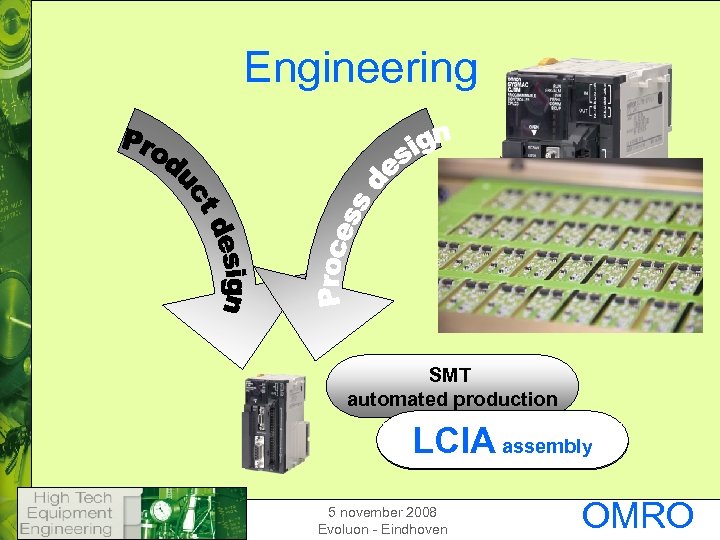

Engineering SMT automated production Assembly assembly Manual production LCIA 5 november 2008 Evoluon - Eindhoven OMRO

LCIA Assembly • Description LCIA – Low Cost Intelligent Automation is a system for effective manual production, where manual stages, simple control systems and clever tools are integrated to a flexible, productive and high quality method of assembly. 5 november 2008 Evoluon - Eindhoven OMRO

5 november 2008 Evoluon - Eindhoven OMRO

LCIA assembly Focus points: • Productivity improvement • Reduction of Quality problems • Increase production Flexibility 5 november 2008 Evoluon - Eindhoven OMRO

![LCIA assembly Drivers of the system 1. Consequent Elimination of Waste [Muda] -Overproduction -Waiting LCIA assembly Drivers of the system 1. Consequent Elimination of Waste [Muda] -Overproduction -Waiting](https://present5.com/presentation/8dcf1792d797807a4e3a876d776bdb39/image-7.jpg)

LCIA assembly Drivers of the system 1. Consequent Elimination of Waste [Muda] -Overproduction -Waiting time -Transportation -Processing -Inventory -Motion -Product defect Anchor in the line set up 2. Synchronization of Chain of Processes 5 november 2008 Evoluon - Eindhoven OMRO

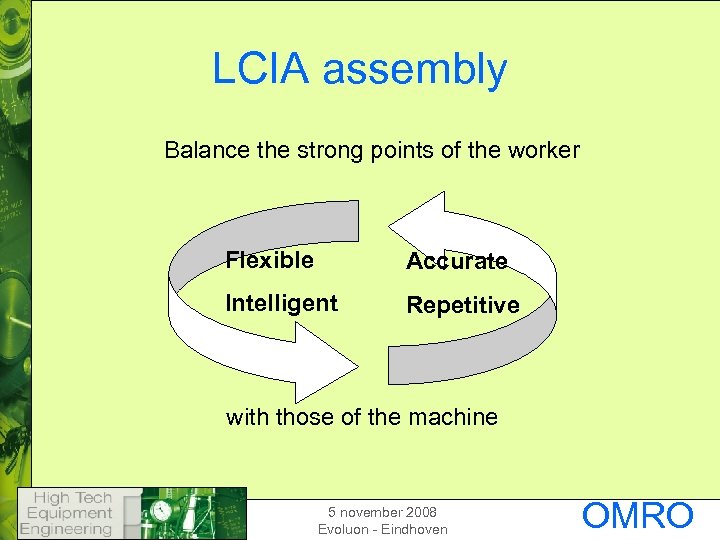

LCIA assembly Balance the strong points of the worker Flexible Accurate Intelligent Repetitive with those of the machine 5 november 2008 Evoluon - Eindhoven OMRO

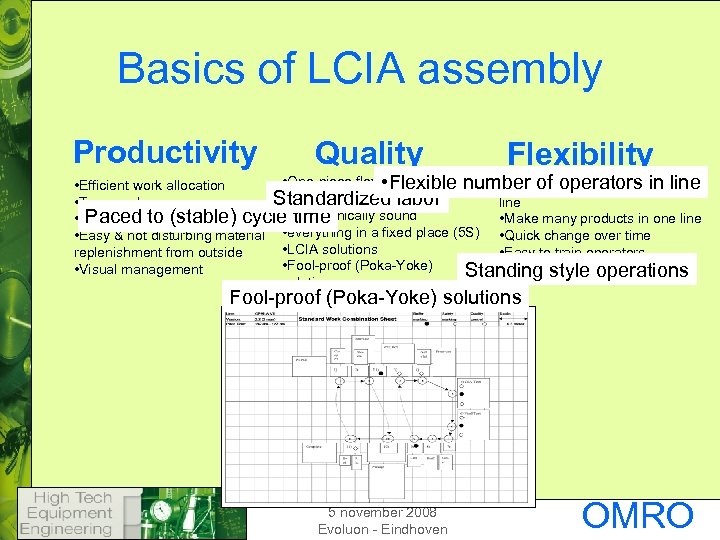

Basics of LCIA assembly Productivity Quality Flexibility • One-piece flow, fixed # WIP number of operators in • Flexible • Efficient work allocation • Flexible operators in line • Standardized labor • Teamwork line • time Paced to (stable) cycle. Ergonomically sound • Paced to (stable) cycle time • Make many products in one line • Easy & not disturbing material • everything in a fixed place (5 S) • Quick change over time • LCIA solutions replenishment from outside • Easy to train operators • Fool-proof (Poka-Yoke) • Visual management • Standing style operations solutions Fool-proof (Poka-Yoke) solutions 5 november 2008 Evoluon - Eindhoven OMRO

LCIA effect Productivity Quality Flexibility CQM 1 PLC assembly line: Cycle time reduction of 250% 5 november 2008 Evoluon - Eindhoven OMRO

LCIA effect LED allways on Intensity Wrong color No illumination Productivity Quality Flexibility From: • Manual visual check • Avg 63 customer complaints per year • Estimated >1000 defects per year To • Low cost vision system • Zero defect & Inspection time reduction (20 sec) 5 november 2008 Evoluon - Eindhoven OMRO

LCIA effect Productivity Quality Flexibility 35 different product in one line with change over time <30 sec. 5 november 2008 Evoluon - Eindhoven OMRO

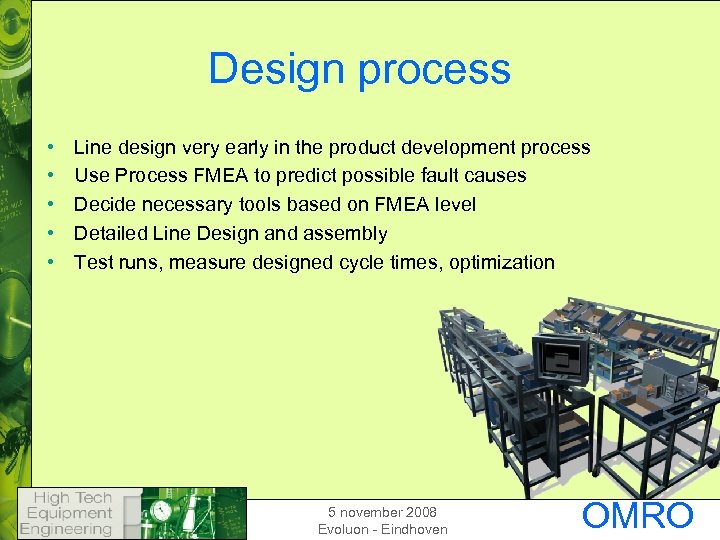

Design process • • • Line design very early in the product development process Use Process FMEA to predict possible fault causes Decide necessary tools based on FMEA level Detailed Line Design and assembly Test runs, measure designed cycle times, optimization 5 november 2008 Evoluon - Eindhoven OMRO

• Thank you for your attention 5 november 2008 Evoluon - Eindhoven OMRO

8dcf1792d797807a4e3a876d776bdb39.ppt