f492cb8a5f86da1feeb8a7b37eda6549.ppt

- Количество слайдов: 10

LBNL Electrical Equipment Safety Program (EESP) Mark Scott, EHSS Division, Doug Fleming, EHSS Division, Kem Robinson Engineering Division, and Becky Cornett, Procurement Department September 20, 2012

Unsafe electrical equipment poses a risk to Berkeley Lab staff and visitors • In FY 2012 50% of all LBNL scientific division occurrences have been electrical equipment related (23% of total) • In the US between 2003 – 2007, – 1, 213 people were killed by electrical accidents. – 13, 150 people suffered lost time injuries from electrical accidents • The 3 rd leading category of electrical fatalities involved workers coming into contact with electric current from machines, tools, appliances, or light fixtures. • Accidental electrocution due to contact with tools and apparatus whose grounding conductors were faulty … accounted for 18 percent of all electrical fatalities and 35 percent of nonfatal electrical accidents [in the period 2003 -2007]. (Source: Brent C. Brenner, Occupational Electrical Injury and Fatality Trends and Statistics: 1992– 2007, IAEI Magazine, May 5, 2009 2

In order to reduce risk, all electrical equipment must be approved in order to be used • DOE, OSHA, and the NEC require that electrical equipment (>50 V) must be accepted/listed by a Nationally Recognized Testing Laboratory (NRTL) or be accepted by the Authority Having Jurisdiction (AHJ) • The DOE site office has delegated the AHJ authority to the Laboratory Director, who has further delegated to: • The AHJ for electrical safety is EHSS Electrical Safety • The AHJ for R&D electrical equipment is the Engineering Division Director • The AHJ for infrastructure power distribution and premises wiring is Facilities Division Director • The program we put in place to address this risk must be sustainable and implement a graded approach based on risk 3

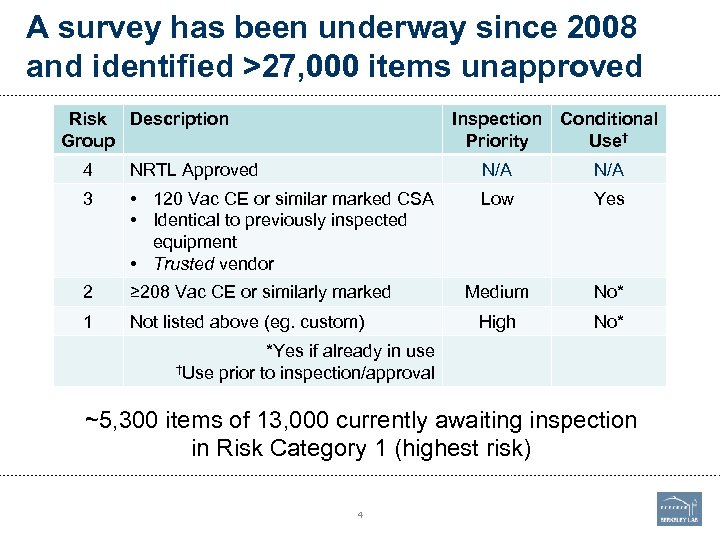

A survey has been underway since 2008 and identified >27, 000 items unapproved Risk Description Group Inspection Conditional Priority Use† 4 NRTL Approved N/A 3 • 120 Vac CE or similar marked CSA • Identical to previously inspected equipment • Trusted vendor Low Yes 2 ≥ 208 Vac CE or similarly marked Medium No* 1 Not listed above (eg. custom) High No* *Yes if already in use †Use prior to inspection/approval ~5, 300 items of 13, 000 currently awaiting inspection in Risk Category 1 (highest risk) 4

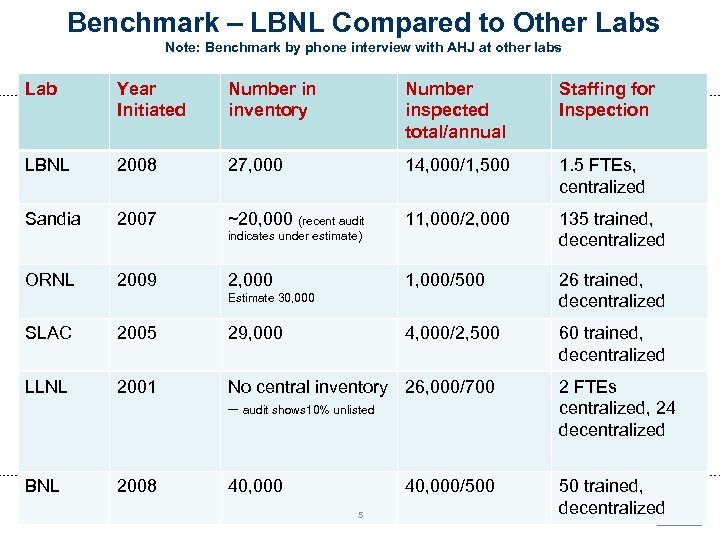

Benchmark – LBNL Compared to Other Labs Note: Benchmark by phone interview with AHJ at other labs Lab Year Initiated Number in inventory Number inspected total/annual Staffing for Inspection LBNL 2008 27, 000 14, 000/1, 500 1. 5 FTEs, centralized Sandia 2007 ~20, 000 (recent audit 11, 000/2, 000 135 trained, decentralized 1, 000/500 26 trained, decentralized 4, 000/2, 500 60 trained, decentralized indicates under estimate) ORNL 2009 2, 000 Estimate 30, 000 SLAC 2005 29, 000 LLNL 2001 No central inventory 26, 000/700 – audit shows 10% unlisted 2 FTEs centralized, 24 decentralized BNL 2008 40, 000 50 trained, decentralized 40, 000/500 5

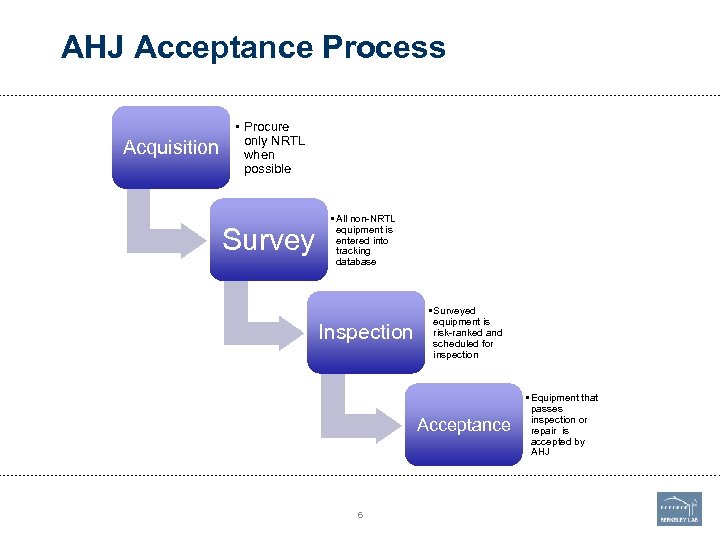

AHJ Acceptance Process Acquisition • Procure only NRTL when possible Survey • All non-NRTL equipment is entered into tracking database Inspection • Surveyed equipment is risk-ranked and scheduled for inspection Acceptance 6 • Equipment that passes inspection or repair is accepted by AHJ

Addressing the risk going forward (1) Acquisition • Continue existing requirement that equipment must be NRTL approved or AHJ accepted before being put into operation. • The cost of inspection of newly acquired (after 3/30/13) non. NRTL equipment will be borne by the acquiring division/program/project 7 Can I buy a listed centrifuge?

Addressing the risk going forward (2) Survey • Each division is responsible for identifying/surveying all unlisted electrical equipment* – Divisions to identify surveyors by November 1, 2012 and trained by December 15, 2012* – Survey all division equipment before September 30, 2013 – On-going assurance through combination of EHSS and division programs Survey looks for UL or other NRTL Labels *EHSS will provide training to division surveyors 8

Addressing the risk going forward (3) Inspection • The cost of inspections of all non. NRTL equipment identified by September 30, 2013 will be borne by the Electrical Equipment Safety Program (EESP) Inspection training at LBNL • Costs of repairs / alterations of electrical equipment necessary to receive AHJ approval is borne by the division/program/project that owns the equipment LBNL sticker 9

Summary Acquisition Survey Inspection Acceptance • Procurement will build etools to help users purchase NRTL listed equipment (or confirm no listed equipment exits) • Divisions will purchase listed equipment when possible • Divisions, with EHSS help, will identify electrical surveyors by 11/1/12 • Divisions will complete surveys of electrical equipment by 9/30/12 • Project established to eliminate backlog of electrical equipment inspections – equipment in inventory as of 9/30/13 will be inspected at Lab expense • Divisions will pay for inspections of new equipment after 3/30/13 • Lab management will fund project • Overall Electrical Equipment Inspection Program (EESP) must be sustainable 10

f492cb8a5f86da1feeb8a7b37eda6549.ppt