1daf9d32500485be81e639bf2cc3f58b.ppt

- Количество слайдов: 15

LBNL CCD Packaging “Yale Mount” Mechanical Analysis Dan Cheng LBNL 4/19/2003 Dan Cheng

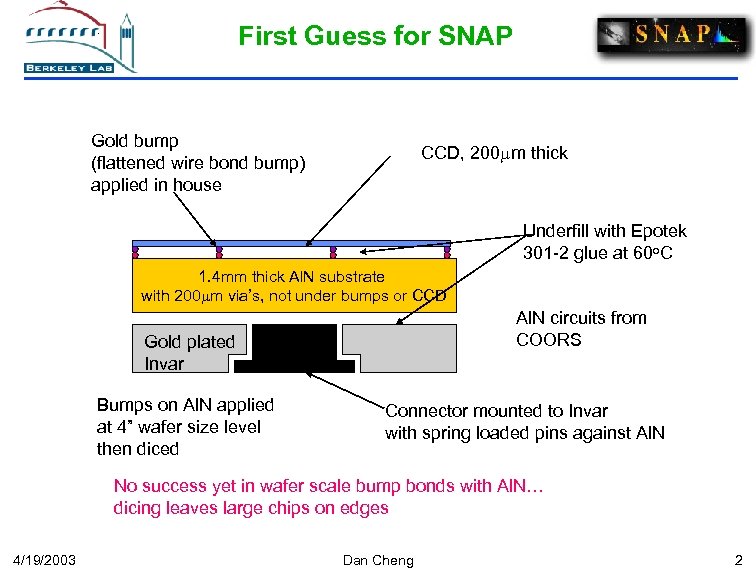

First Guess for SNAP Gold bump (flattened wire bond bump) applied in house CCD, 200 mm thick Underfill with Epotek 301 -2 glue at 60 o. C 1. 4 mm thick Al. N substrate with 200 mm via’s, not under bumps or CCD Al. N circuits from COORS Gold plated Invar Bumps on Al. N applied at 4” wafer size level then diced Connector mounted to Invar with spring loaded pins against Al. N No success yet in wafer scale bump bonds with Al. N… dicing leaves large chips on edges 4/19/2003 Dan Cheng 2

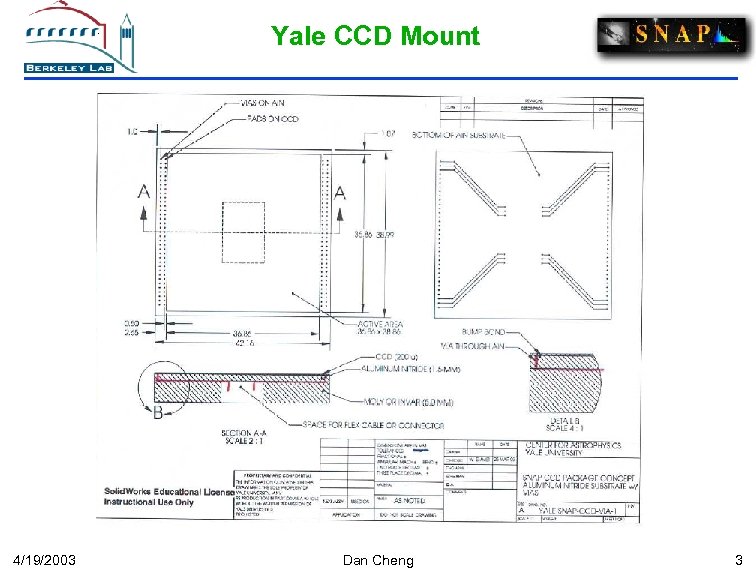

Yale CCD Mount 4/19/2003 Dan Cheng 3

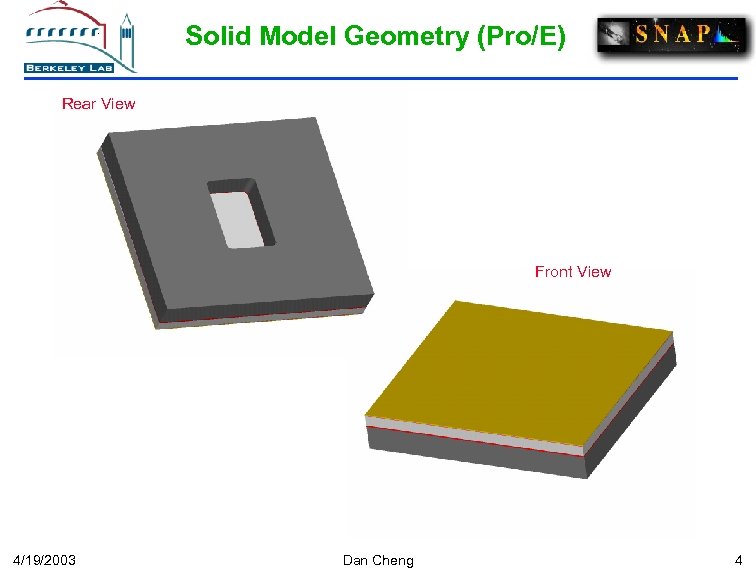

Solid Model Geometry (Pro/E) Rear View Front View 4/19/2003 Dan Cheng 4

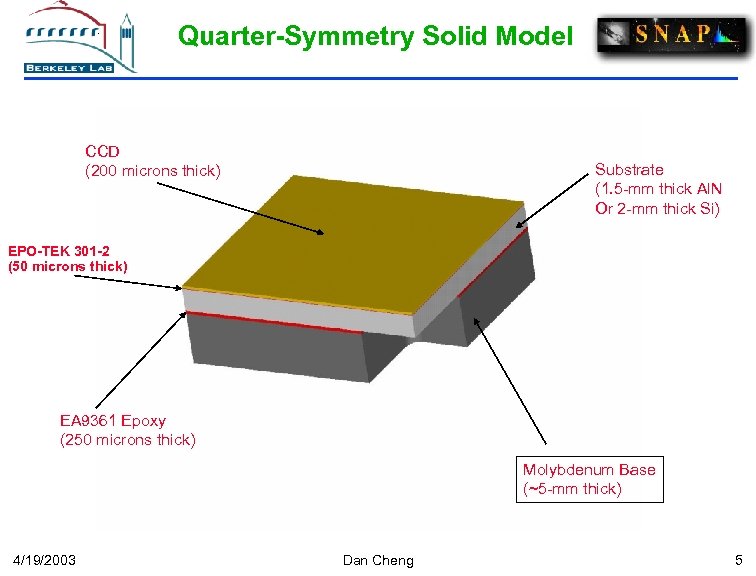

Quarter-Symmetry Solid Model CCD (200 microns thick) Substrate (1. 5 -mm thick Al. N Or 2 -mm thick Si) EPO-TEK 301 -2 (50 microns thick) EA 9361 Epoxy (250 microns thick) Molybdenum Base (~5 -mm thick) 4/19/2003 Dan Cheng 5

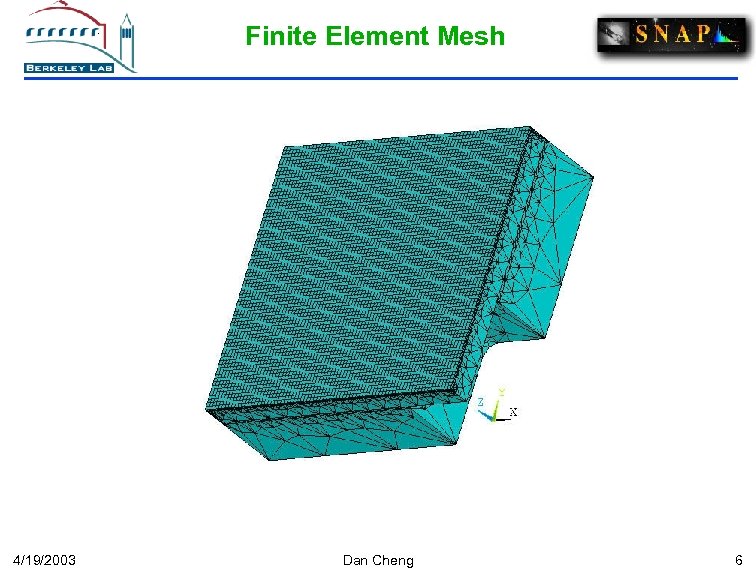

Finite Element Mesh 4/19/2003 Dan Cheng 6

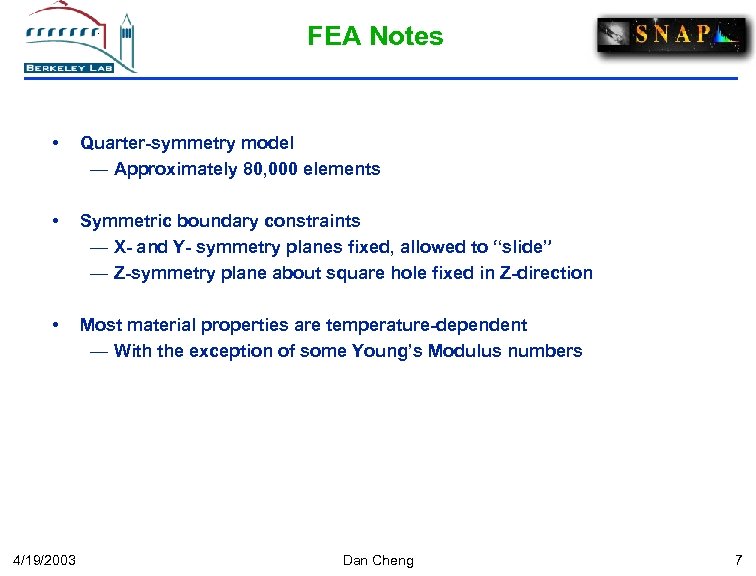

FEA Notes • Quarter-symmetry model — Approximately 80, 000 elements • Symmetric boundary constraints — X- and Y- symmetry planes fixed, allowed to “slide” — Z-symmetry plane about square hole fixed in Z-direction • Most material properties are temperature-dependent — With the exception of some Young’s Modulus numbers 4/19/2003 Dan Cheng 7

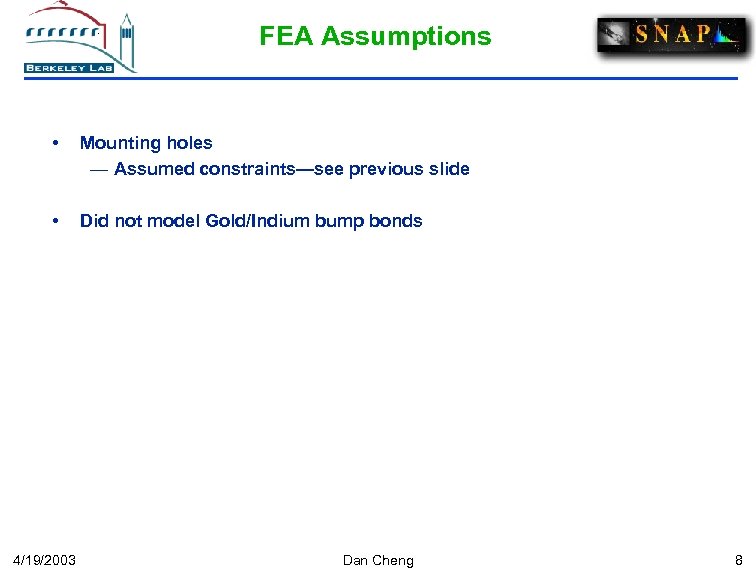

FEA Assumptions • Mounting holes — Assumed constraints—see previous slide • Did not model Gold/Indium bump bonds 4/19/2003 Dan Cheng 8

FEA Notes • 4/19/2003 Ran four cases — Case 1: Al. N Substrate, Square hole — Case 2: Si Substrate, Square hole — Case 3: Al. N Substrate, Square hole w/Fillets — Case 4: Si Substrate, Square hole w/Fillets Dan Cheng 9

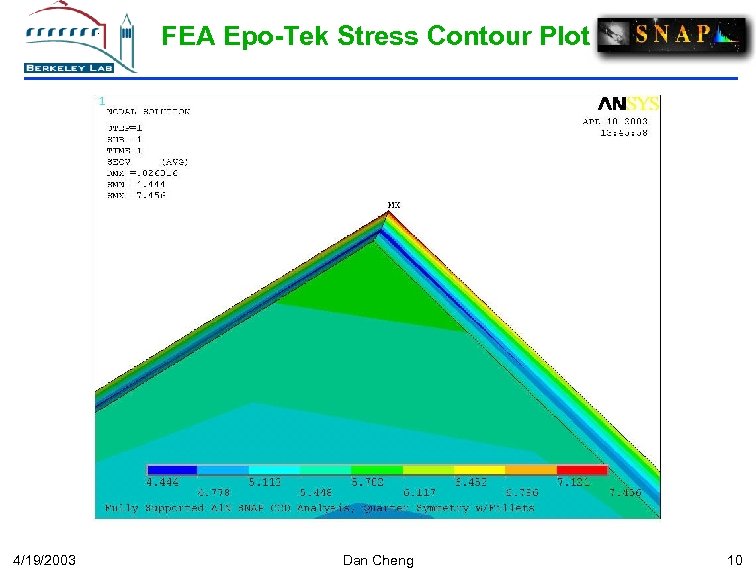

FEA Epo-Tek Stress Contour Plot 4/19/2003 Dan Cheng 10

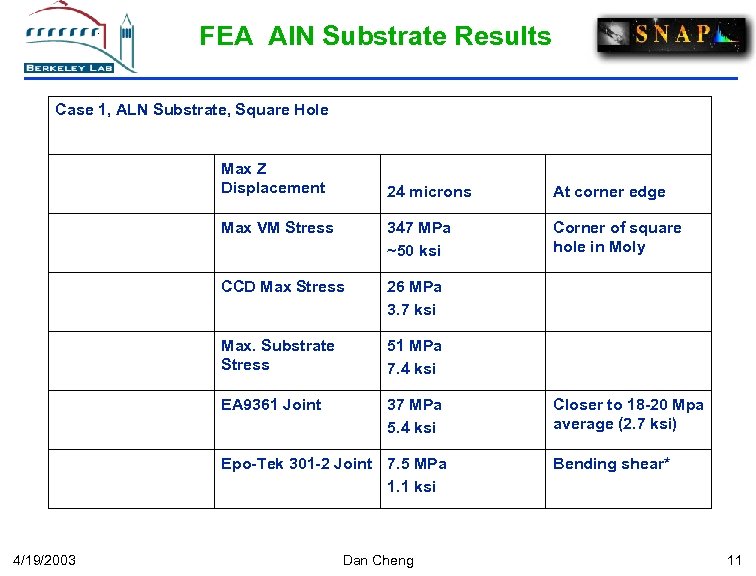

FEA Al. N Substrate Results Case 1, ALN Substrate, Square Hole Max Z Displacement 24 microns At corner edge Max VM Stress 347 MPa ~50 ksi Corner of square hole in Moly CCD Max Stress 26 MPa 3. 7 ksi Max. Substrate Stress 51 MPa 7. 4 ksi EA 9361 Joint 37 MPa 5. 4 ksi Epo-Tek 301 -2 Joint 7. 5 MPa 1. 1 ksi 4/19/2003 Dan Cheng Closer to 18 -20 Mpa average (2. 7 ksi) Bending shear* 11

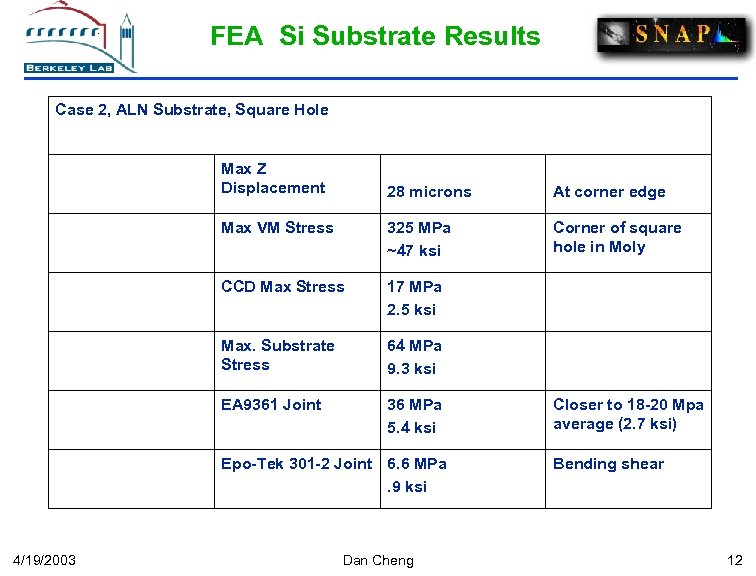

FEA Si Substrate Results Case 2, ALN Substrate, Square Hole Max Z Displacement 28 microns At corner edge Max VM Stress 325 MPa ~47 ksi Corner of square hole in Moly CCD Max Stress 17 MPa 2. 5 ksi Max. Substrate Stress 64 MPa 9. 3 ksi EA 9361 Joint 36 MPa 5. 4 ksi Epo-Tek 301 -2 Joint 6. 6 MPa. 9 ksi 4/19/2003 Dan Cheng Closer to 18 -20 Mpa average (2. 7 ksi) Bending shear 12

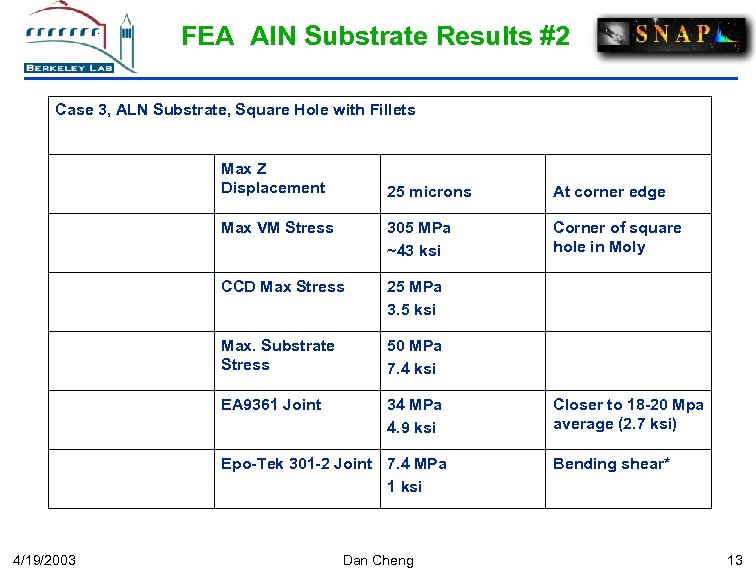

FEA Al. N Substrate Results #2 Case 3, ALN Substrate, Square Hole with Fillets Max Z Displacement 25 microns At corner edge Max VM Stress 305 MPa ~43 ksi Corner of square hole in Moly CCD Max Stress 25 MPa 3. 5 ksi Max. Substrate Stress 50 MPa 7. 4 ksi EA 9361 Joint 34 MPa 4. 9 ksi Epo-Tek 301 -2 Joint 7. 4 MPa 1 ksi 4/19/2003 Dan Cheng Closer to 18 -20 Mpa average (2. 7 ksi) Bending shear* 13

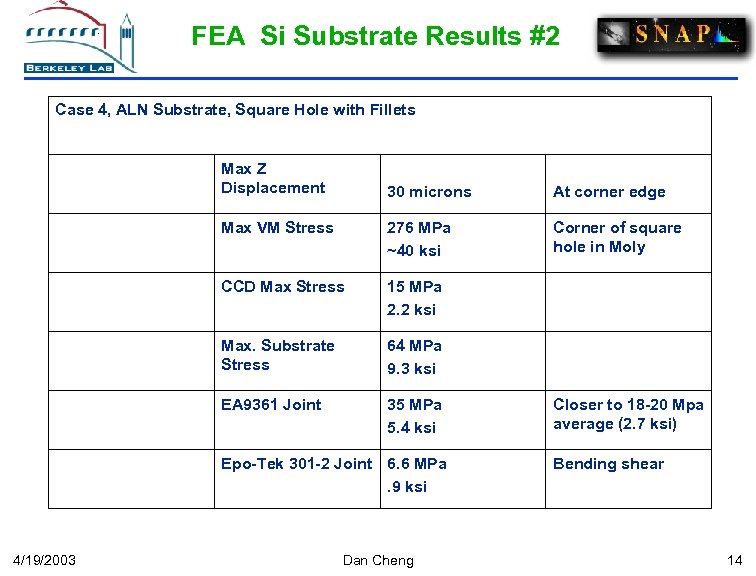

FEA Si Substrate Results #2 Case 4, ALN Substrate, Square Hole with Fillets Max Z Displacement 30 microns At corner edge Max VM Stress 276 MPa ~40 ksi Corner of square hole in Moly CCD Max Stress 15 MPa 2. 2 ksi Max. Substrate Stress 64 MPa 9. 3 ksi EA 9361 Joint 35 MPa 5. 4 ksi Epo-Tek 301 -2 Joint 6. 6 MPa. 9 ksi 4/19/2003 Dan Cheng Closer to 18 -20 Mpa average (2. 7 ksi) Bending shear 14

FEA Summary • Some material properties need to be defined at operating temperature (140 K) • Current design shows critical Epo-Tek joint at above Yield Stress of 926 psi (may change with model) 4/19/2003 Dan Cheng 15

1daf9d32500485be81e639bf2cc3f58b.ppt