534fd1c0d0f5ba276e91b1cc2ad07399.ppt

- Количество слайдов: 16

LARP Phase II Secondary Collimator RC 1 Collimator Test Program Plan Forward Revised 6/21/06 LARP LHC PHASE II COLL RC 1 TESTS - S. Lundgren 06 June 2006 No /17

LARP Phase II Secondary Collimator RC 1 Collimator Test Program Plan Forward Revised 6/21/06 LARP LHC PHASE II COLL RC 1 TESTS - S. Lundgren 06 June 2006 No /17

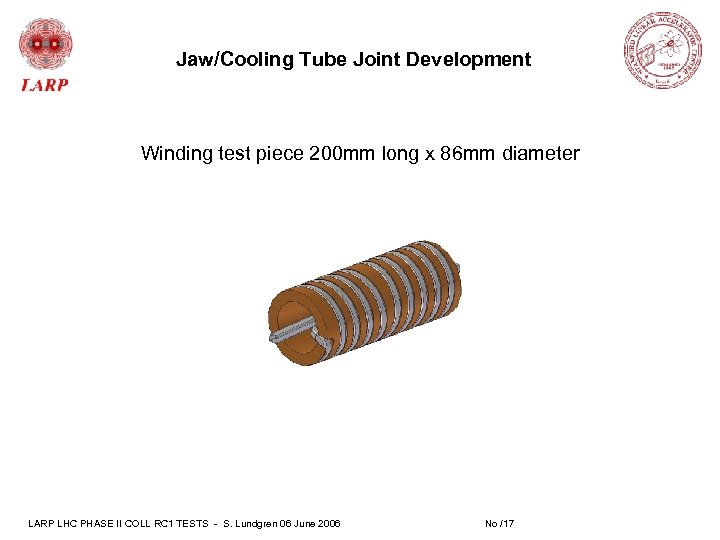

Jaw/Cooling Tube Joint Development Winding test piece 200 mm long x 86 mm diameter LARP LHC PHASE II COLL RC 1 TESTS - S. Lundgren 06 June 2006 No /17

Jaw/Cooling Tube Joint Development Winding test piece 200 mm long x 86 mm diameter LARP LHC PHASE II COLL RC 1 TESTS - S. Lundgren 06 June 2006 No /17

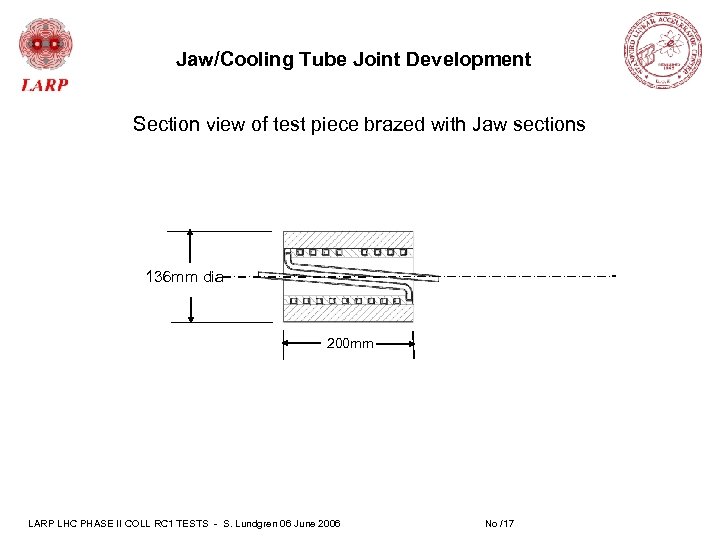

Jaw/Cooling Tube Joint Development Section view of test piece brazed with Jaw sections 136 mm dia 200 mm LARP LHC PHASE II COLL RC 1 TESTS - S. Lundgren 06 June 2006 No /17

Jaw/Cooling Tube Joint Development Section view of test piece brazed with Jaw sections 136 mm dia 200 mm LARP LHC PHASE II COLL RC 1 TESTS - S. Lundgren 06 June 2006 No /17

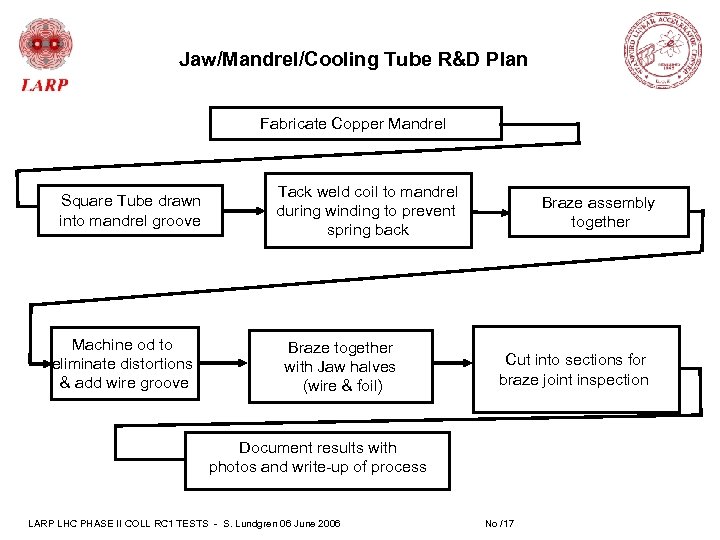

Jaw/Mandrel/Cooling Tube R&D Plan Fabricate Copper Mandrel Square Tube drawn into mandrel groove Machine od to eliminate distortions & add wire groove Tack weld coil to mandrel during winding to prevent spring back Braze together with Jaw halves (wire & foil) Braze assembly together Cut into sections for braze joint inspection Document results with photos and write-up of process LARP LHC PHASE II COLL RC 1 TESTS - S. Lundgren 06 June 2006 No /17

Jaw/Mandrel/Cooling Tube R&D Plan Fabricate Copper Mandrel Square Tube drawn into mandrel groove Machine od to eliminate distortions & add wire groove Tack weld coil to mandrel during winding to prevent spring back Braze together with Jaw halves (wire & foil) Braze assembly together Cut into sections for braze joint inspection Document results with photos and write-up of process LARP LHC PHASE II COLL RC 1 TESTS - S. Lundgren 06 June 2006 No /17

Single Jaw Thermal Test Hardware – Long lead items (2 -6 weeks) • • 2 x Heater controllers are on order… due now Ready to buy 4 x 5 k. W electric resistance heaters (380 mm long) Ready to buy Glidcop for 1 Jaw Ready to buy Glidcop for 1 Mandrel – Jaw to be bored for heater • Bore to be. 05 mm dia oversize of actual heater size (15. 88 mm dia) – Thermocouple attachments in Jaw • Locations, depth, size, electrical isolation features in Jaw TBD – Jaw Support( bearings and mount) • • RC 1 Bearings Mount them on “V” blocks or simple fixed supports – Rigid mounting for capacitance sensors • Locate at ends and center of Jaw LARP LHC PHASE II COLL RC 1 TESTS - S. Lundgren 06 June 2006 No /17

Single Jaw Thermal Test Hardware – Long lead items (2 -6 weeks) • • 2 x Heater controllers are on order… due now Ready to buy 4 x 5 k. W electric resistance heaters (380 mm long) Ready to buy Glidcop for 1 Jaw Ready to buy Glidcop for 1 Mandrel – Jaw to be bored for heater • Bore to be. 05 mm dia oversize of actual heater size (15. 88 mm dia) – Thermocouple attachments in Jaw • Locations, depth, size, electrical isolation features in Jaw TBD – Jaw Support( bearings and mount) • • RC 1 Bearings Mount them on “V” blocks or simple fixed supports – Rigid mounting for capacitance sensors • Locate at ends and center of Jaw LARP LHC PHASE II COLL RC 1 TESTS - S. Lundgren 06 June 2006 No /17

Single Jaw Thermal Test Hardware – Instrumentation is on order and is due early July: • • 1 each SCXI-1600 USB Data Acquisition and Control Module 1 each SCXI-1001 12 -Slot Chassis U. S. 120 VAC 1 each SCXI-1303 32 -Channel Isothermal Terminal Block 1 each SCXI-1102 B 32 -Channel Amplifier, 200 Hz Bandwidth 12 each SCXI-1361 Rear Filler Panel 8 each SCXI-1360 Front Filler Panel Cover 1 each Shielded Cable for interconnect Cost is about $4700 – Project has PC with Labview software installed an experienced Lab. View operator LARP LHC PHASE II COLL RC 1 TESTS - S. Lundgren 06 June 2006 No /17

Single Jaw Thermal Test Hardware – Instrumentation is on order and is due early July: • • 1 each SCXI-1600 USB Data Acquisition and Control Module 1 each SCXI-1001 12 -Slot Chassis U. S. 120 VAC 1 each SCXI-1303 32 -Channel Isothermal Terminal Block 1 each SCXI-1102 B 32 -Channel Amplifier, 200 Hz Bandwidth 12 each SCXI-1361 Rear Filler Panel 8 each SCXI-1360 Front Filler Panel Cover 1 each Shielded Cable for interconnect Cost is about $4700 – Project has PC with Labview software installed an experienced Lab. View operator LARP LHC PHASE II COLL RC 1 TESTS - S. Lundgren 06 June 2006 No /17

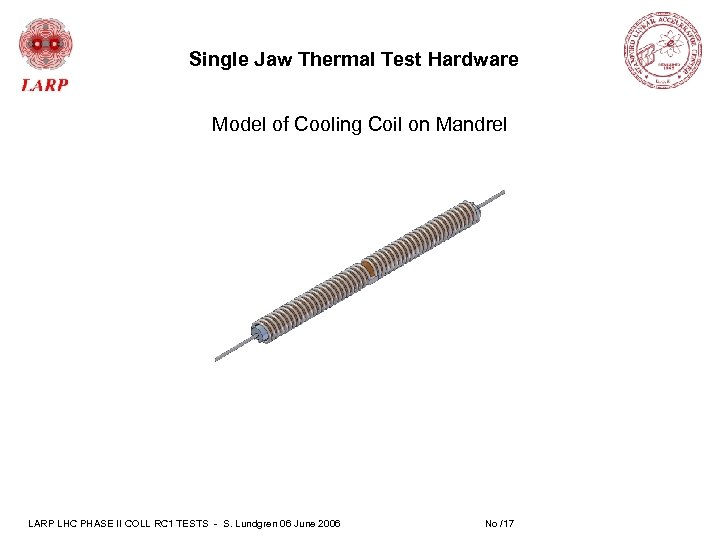

Single Jaw Thermal Test Hardware Model of Cooling Coil on Mandrel LARP LHC PHASE II COLL RC 1 TESTS - S. Lundgren 06 June 2006 No /17

Single Jaw Thermal Test Hardware Model of Cooling Coil on Mandrel LARP LHC PHASE II COLL RC 1 TESTS - S. Lundgren 06 June 2006 No /17

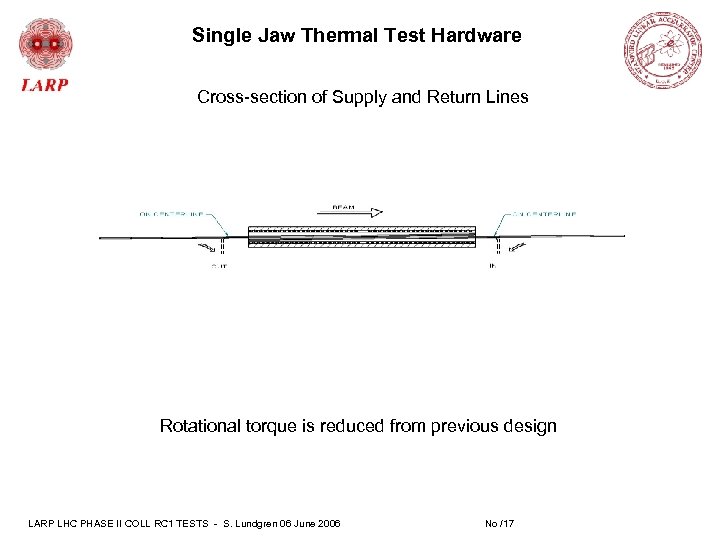

Single Jaw Thermal Test Hardware Cross-section of Supply and Return Lines Rotational torque is reduced from previous design LARP LHC PHASE II COLL RC 1 TESTS - S. Lundgren 06 June 2006 No /17

Single Jaw Thermal Test Hardware Cross-section of Supply and Return Lines Rotational torque is reduced from previous design LARP LHC PHASE II COLL RC 1 TESTS - S. Lundgren 06 June 2006 No /17

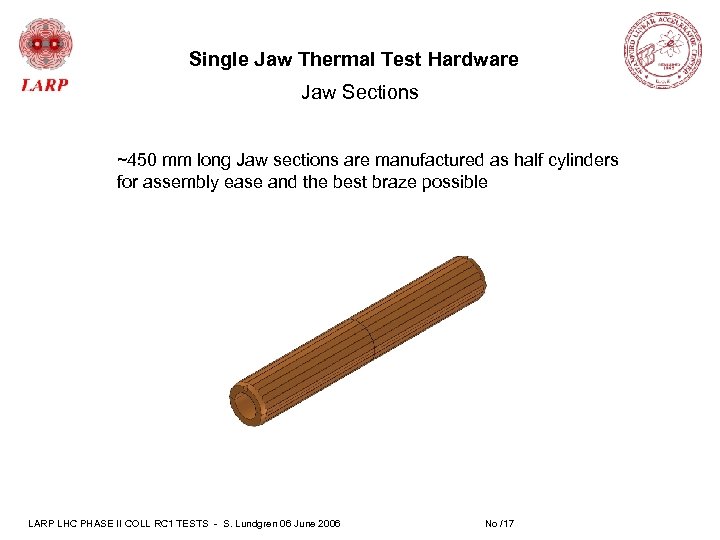

Single Jaw Thermal Test Hardware Jaw Sections ~450 mm long Jaw sections are manufactured as half cylinders for assembly ease and the best braze possible LARP LHC PHASE II COLL RC 1 TESTS - S. Lundgren 06 June 2006 No /17

Single Jaw Thermal Test Hardware Jaw Sections ~450 mm long Jaw sections are manufactured as half cylinders for assembly ease and the best braze possible LARP LHC PHASE II COLL RC 1 TESTS - S. Lundgren 06 June 2006 No /17

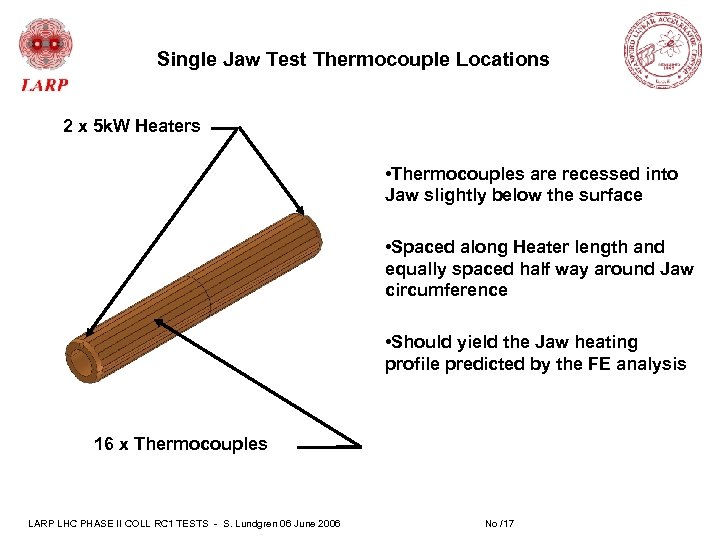

Single Jaw Test Thermocouple Locations 2 x 5 k. W Heaters • Thermocouples are recessed into Jaw slightly below the surface • Spaced along Heater length and equally spaced half way around Jaw circumference • Should yield the Jaw heating profile predicted by the FE analysis 16 x Thermocouples LARP LHC PHASE II COLL RC 1 TESTS - S. Lundgren 06 June 2006 No /17

Single Jaw Test Thermocouple Locations 2 x 5 k. W Heaters • Thermocouples are recessed into Jaw slightly below the surface • Spaced along Heater length and equally spaced half way around Jaw circumference • Should yield the Jaw heating profile predicted by the FE analysis 16 x Thermocouples LARP LHC PHASE II COLL RC 1 TESTS - S. Lundgren 06 June 2006 No /17

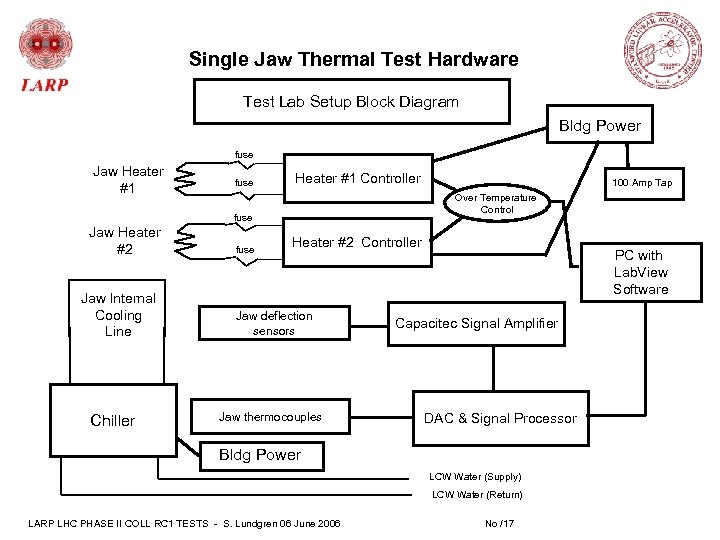

Single Jaw Thermal Test Hardware Test Lab Setup Block Diagram Bldg Power fuse Jaw Heater #1 fuse Heater #1 Controller Over Temperature Control fuse Jaw Heater #2 Jaw Internal Cooling Line Chiller fuse 100 Amp Tap Heater #2 Controller Jaw deflection sensors Jaw thermocouples PC with Lab. View Software Capacitec Signal Amplifier DAC & Signal Processor Bldg Power LCW Water (Supply) LCW Water (Return) LARP LHC PHASE II COLL RC 1 TESTS - S. Lundgren 06 June 2006 No /17

Single Jaw Thermal Test Hardware Test Lab Setup Block Diagram Bldg Power fuse Jaw Heater #1 fuse Heater #1 Controller Over Temperature Control fuse Jaw Heater #2 Jaw Internal Cooling Line Chiller fuse 100 Amp Tap Heater #2 Controller Jaw deflection sensors Jaw thermocouples PC with Lab. View Software Capacitec Signal Amplifier DAC & Signal Processor Bldg Power LCW Water (Supply) LCW Water (Return) LARP LHC PHASE II COLL RC 1 TESTS - S. Lundgren 06 June 2006 No /17

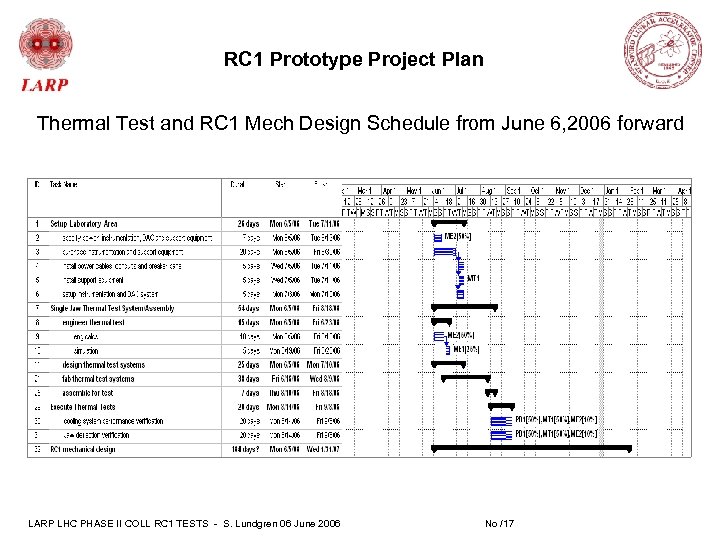

RC 1 Prototype Project Plan Thermal Test and RC 1 Mech Design Schedule from June 6, 2006 forward LARP LHC PHASE II COLL RC 1 TESTS - S. Lundgren 06 June 2006 No /17

RC 1 Prototype Project Plan Thermal Test and RC 1 Mech Design Schedule from June 6, 2006 forward LARP LHC PHASE II COLL RC 1 TESTS - S. Lundgren 06 June 2006 No /17

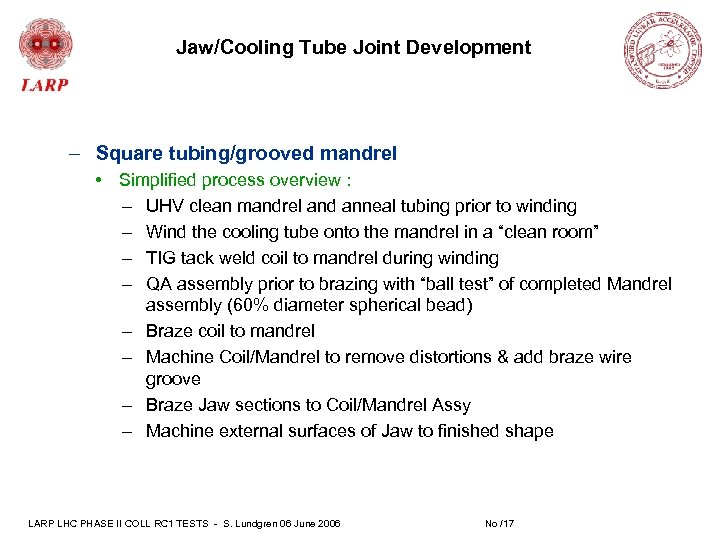

Jaw/Cooling Tube Joint Development – Square tubing/grooved mandrel • Simplified process overview : – UHV clean mandrel and anneal tubing prior to winding – Wind the cooling tube onto the mandrel in a “clean room” – TIG tack weld coil to mandrel during winding – QA assembly prior to brazing with “ball test” of completed Mandrel assembly (60% diameter spherical bead) – Braze coil to mandrel – Machine Coil/Mandrel to remove distortions & add braze wire groove – Braze Jaw sections to Coil/Mandrel Assy – Machine external surfaces of Jaw to finished shape LARP LHC PHASE II COLL RC 1 TESTS - S. Lundgren 06 June 2006 No /17

Jaw/Cooling Tube Joint Development – Square tubing/grooved mandrel • Simplified process overview : – UHV clean mandrel and anneal tubing prior to winding – Wind the cooling tube onto the mandrel in a “clean room” – TIG tack weld coil to mandrel during winding – QA assembly prior to brazing with “ball test” of completed Mandrel assembly (60% diameter spherical bead) – Braze coil to mandrel – Machine Coil/Mandrel to remove distortions & add braze wire groove – Braze Jaw sections to Coil/Mandrel Assy – Machine external surfaces of Jaw to finished shape LARP LHC PHASE II COLL RC 1 TESTS - S. Lundgren 06 June 2006 No /17

RC 1 Mechanical Prototype Test Purpose: bench top testing of the jaw actuating mechanism in CERN orientations – – – – – Vacuum tank with easy access CERN adjustment mechanism SLAC cooling water feed-throughs and flexible connections SLAC rotation mechanism Simplistic control system for jaw aperture Minimal instrumentation connections for position, temperature, etc. RC 2 will incorporate LHC-compliant interfaces Heat loading may not be possible Use CERN Phase I components as appropriate LARP LHC PHASE II COLL RC 1 TESTS - S. Lundgren 06 June 2006 No /17

RC 1 Mechanical Prototype Test Purpose: bench top testing of the jaw actuating mechanism in CERN orientations – – – – – Vacuum tank with easy access CERN adjustment mechanism SLAC cooling water feed-throughs and flexible connections SLAC rotation mechanism Simplistic control system for jaw aperture Minimal instrumentation connections for position, temperature, etc. RC 2 will incorporate LHC-compliant interfaces Heat loading may not be possible Use CERN Phase I components as appropriate LARP LHC PHASE II COLL RC 1 TESTS - S. Lundgren 06 June 2006 No /17

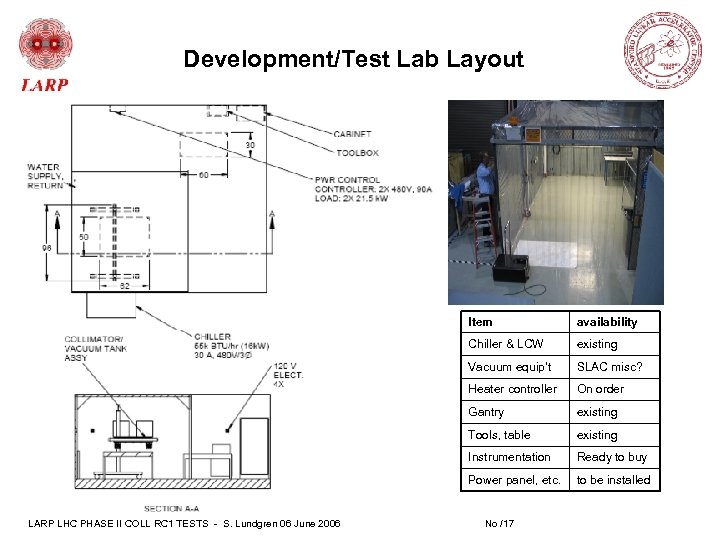

Development/Test Lab Layout Item Chiller & LCW existing Vacuum equip’t SLAC misc? Heater controller On order Gantry existing Tools, table existing Instrumentation Ready to buy Power panel, etc. LARP LHC PHASE II COLL RC 1 TESTS - S. Lundgren 06 June 2006 availability to be installed No /17

Development/Test Lab Layout Item Chiller & LCW existing Vacuum equip’t SLAC misc? Heater controller On order Gantry existing Tools, table existing Instrumentation Ready to buy Power panel, etc. LARP LHC PHASE II COLL RC 1 TESTS - S. Lundgren 06 June 2006 availability to be installed No /17

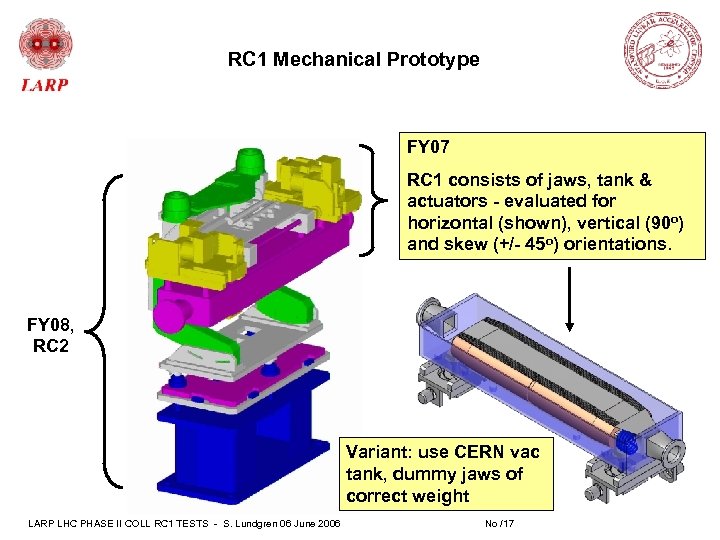

RC 1 Mechanical Prototype FY 07 RC 1 consists of jaws, tank & actuators - evaluated for horizontal (shown), vertical (90 o) and skew (+/- 45 o) orientations. FY 08, RC 2 Variant: use CERN vac tank, dummy jaws of correct weight LARP LHC PHASE II COLL RC 1 TESTS - S. Lundgren 06 June 2006 No /17

RC 1 Mechanical Prototype FY 07 RC 1 consists of jaws, tank & actuators - evaluated for horizontal (shown), vertical (90 o) and skew (+/- 45 o) orientations. FY 08, RC 2 Variant: use CERN vac tank, dummy jaws of correct weight LARP LHC PHASE II COLL RC 1 TESTS - S. Lundgren 06 June 2006 No /17