c3d6a548304412e4dd01e98469711d85.ppt

- Количество слайдов: 63

LABORATORY QUALITY CONTROL Course Code RIT 2. 2 Revision C

Definitions: • Quality Control: – the process of detecting errors • Quality Assurance: – the systems or procedures in place to avoid errors occurring

… to ensure the reliability of the test results to give the best patient care !

Unreliable Performance ? • Potential consequences include: – patient misdiagnosis – delays in treatment – increased costs • avoidable retests cost US 200 million USD per year • Even a small calibration bias can effect treatment rates: – 1% +ve bias in cholesterol result 5% increase in patients exceeding the treatment cut-off – 3% +ve bias 15% increase in patient treatment.

Error Classification. . • Pre-analytical: – errors before the sample reaches the laboratory • Analytical: – errors during the analysis of the sample • Post-analytical: – errors occurring after the analysis

Pre - Analytical Errors. . • Improper preparation of the patient: – patient fasting • glucose test – stress and anxiety • urinary protein

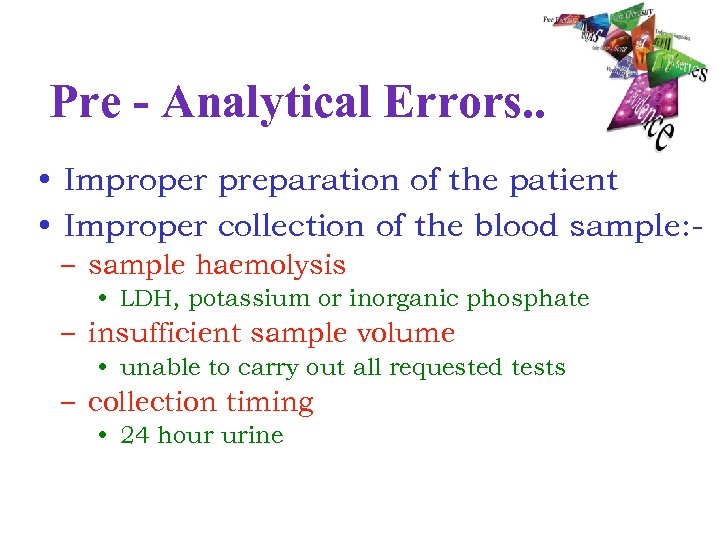

Pre - Analytical Errors. . • Improper preparation of the patient • Improper collection of the blood sample: – sample haemolysis • LDH, potassium or inorganic phosphate – insufficient sample volume • unable to carry out all requested tests – collection timing • 24 hour urine

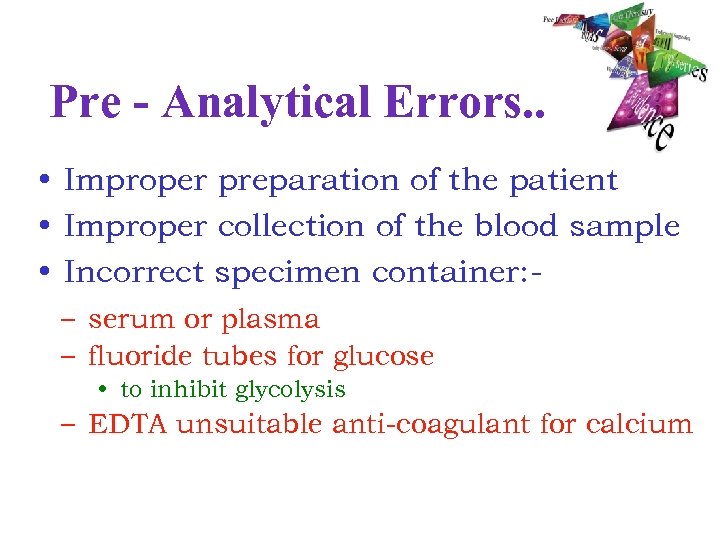

Pre - Analytical Errors. . • Improper preparation of the patient • Improper collection of the blood sample • Incorrect specimen container: – serum or plasma – fluoride tubes for glucose • to inhibit glycolysis – EDTA unsuitable anti-coagulant for calcium

Pre - Analytical Errors. . • • Improper preparation of the patient Improper collection of the blood sample Incorrect specimen container Incorrect specimen storage: – sample left overnight at room temperature • falsely elevated K, Pi and red cell enzymes – delay in sample delivery • falsely lowered levels of unstable analytes

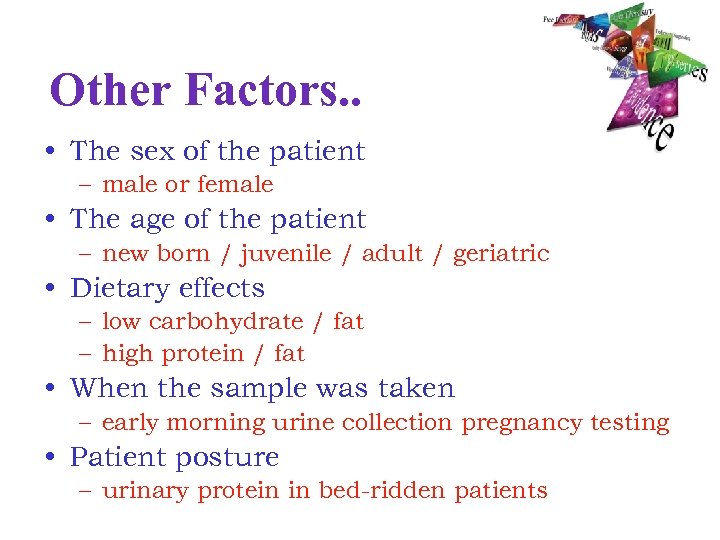

Other Factors. . • The sex of the patient – male or female • The age of the patient – new born / juvenile / adult / geriatric • Dietary effects – low carbohydrate / fat – high protein / fat • When the sample was taken – early morning urine collection pregnancy testing • Patient posture – urinary protein in bed-ridden patients

Other Factors. . • Effects of exercise – creatine kinase / CRP • Medical history – heart disease / diabetes / existing medication • Pregnancy – hormonal effects • Effects of drugs and alcohol – liver enzymes / dehydration

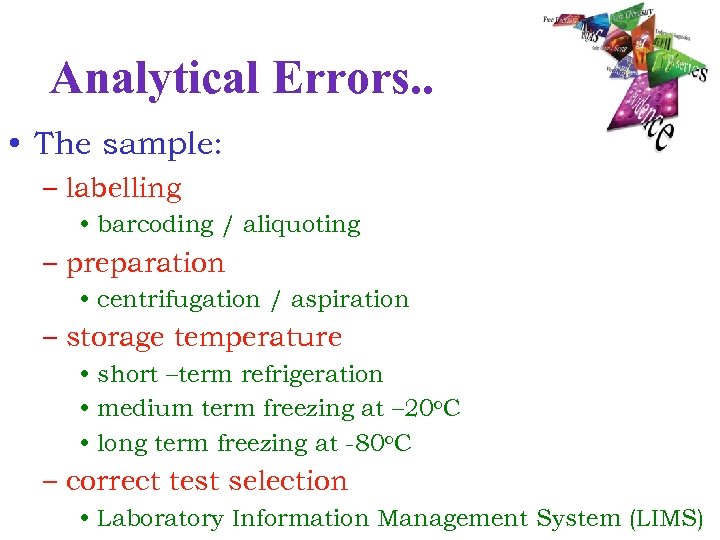

Analytical Errors. . • The sample: – labelling • barcoding / aliquoting – preparation • centrifugation / aspiration – storage temperature • short –term refrigeration • medium term freezing at – 20 o. C • long term freezing at -80 o. C – correct test selection • Laboratory Information Management System (LIMS)

Analytical Errors. . • The sample: • Glassware / pipettes / balances: – used incorrectly – contaminated – poorly calibrated – reuse of pipette tips

Analytical Errors. . • The sample: • Glassware / pipettes / balances: • Reagents / calibrators / controls: – poor quality – inappropriate storage • correct temperature • badly maintained fridges or freezers – stability • shelf-life / working reagent – incorrect preparation

Analytical Errors. . • • The sample: Glassware / pipettes / balances: Reagents / calibrators / controls: The application: – incorrect analytical procedures – poorly optimised instrument settings

Analytical Errors. . • • • The sample: Glassware / pipettes / balances: Reagents / calibrators / controls: The application: The instrument: – operational limitations • temperature control/read times/mixing/carry-over – lack of maintenance • worn tubing / optics / cuvettes / probes

Other Factors. . • Calculation errors: – incorrect factor / wrong calibration values • Transcription errors: • Dilutions errors: – incorrect dilution or dilution factor used • Lack of training: • The human factor: – tiredness / carelessness / stress

Post - Analytical Errors. . • The prompt and correct delivery of the correct report on the correct patient to the correct Doctor. • How the Clinician interprets the data to the full benefit of the patient.

Accuracy ? How correct your result is.

Precision ? The reproducibility of your results.

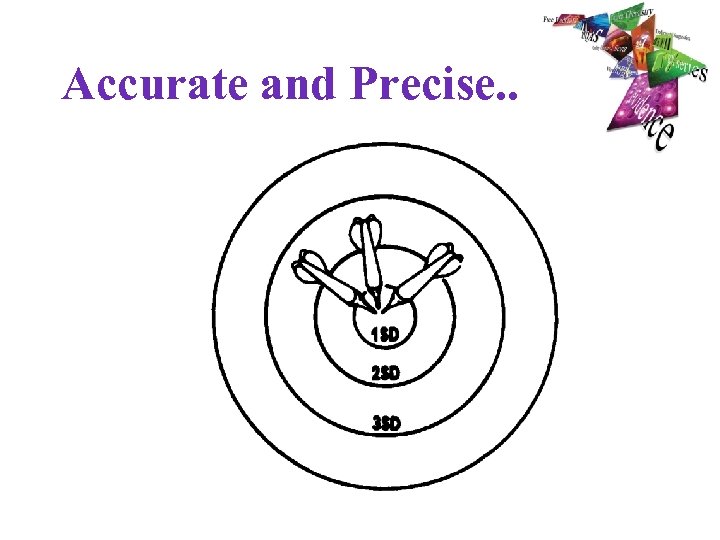

Accurate and Precise. .

Imprecise but Accurate !

Precise but Inaccurate !

Specificity ? • The ability of a method to measure solely the component of interest. • A lack of specificity will affect accuracy – falsely elevated values • hormones and drugs – falsely low values • BCP method with bovine albumin

Sensitivity ? • The ability to detect small quantities of a measured component. – will affect both precision and accuracy at the bottom end of the assay range.

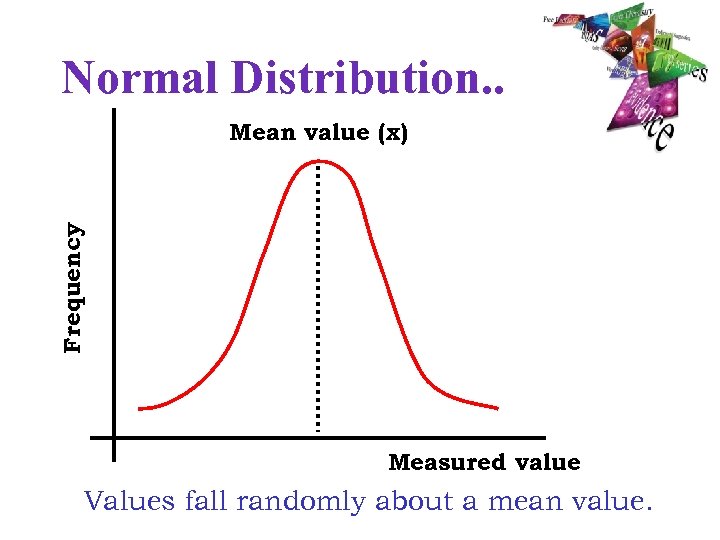

Normal Distribution. . Frequency Mean value (x) Measured value Values fall randomly about a mean value.

Precision ? • How disperse the values are. • Quantified by measuring the Standard Deviation (SD) of the set of results.

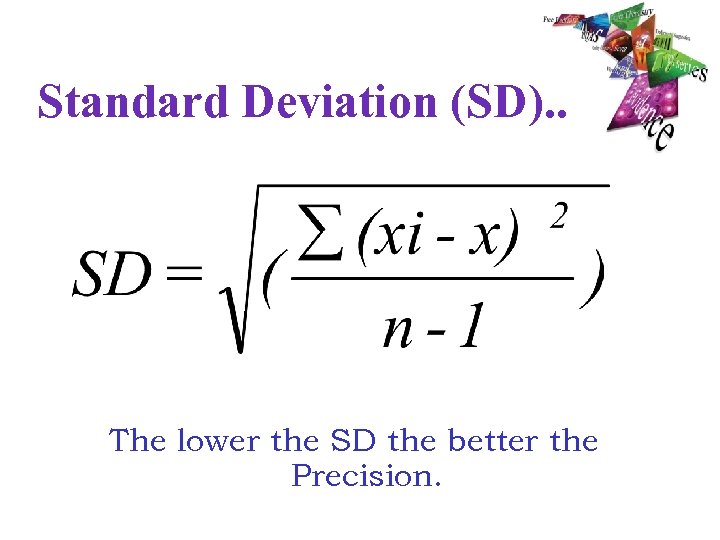

Standard Deviation (SD). . The lower the SD the better the Precision.

Example: Mean result (x) = 100 mmol/L Standard deviation (SD) = 1. 0 mmol/L Number of results (n) = 100

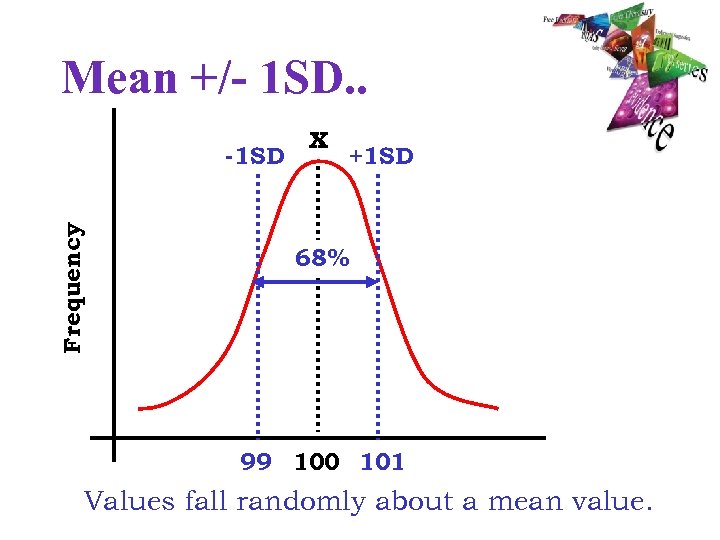

Mean +/- 1 SD. . Frequency -1 SD x +1 SD 68% 99 100 101 Values fall randomly about a mean value.

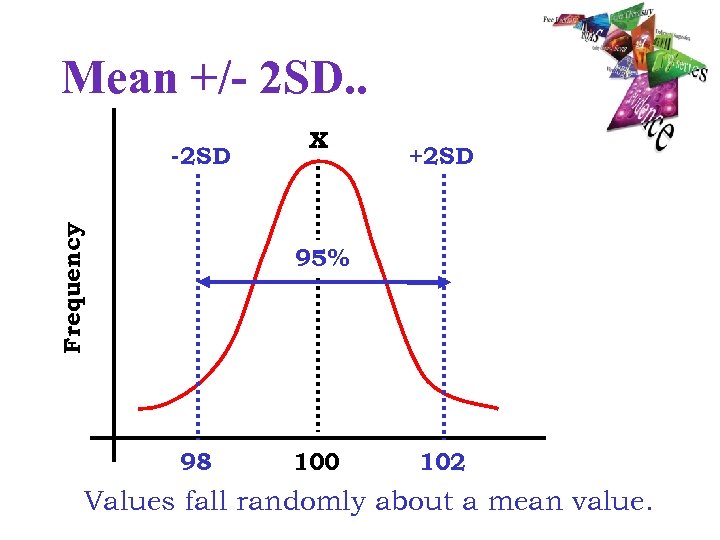

Mean +/- 2 SD. . Frequency -2 SD x +2 SD 95% 98 100 102 Values fall randomly about a mean value.

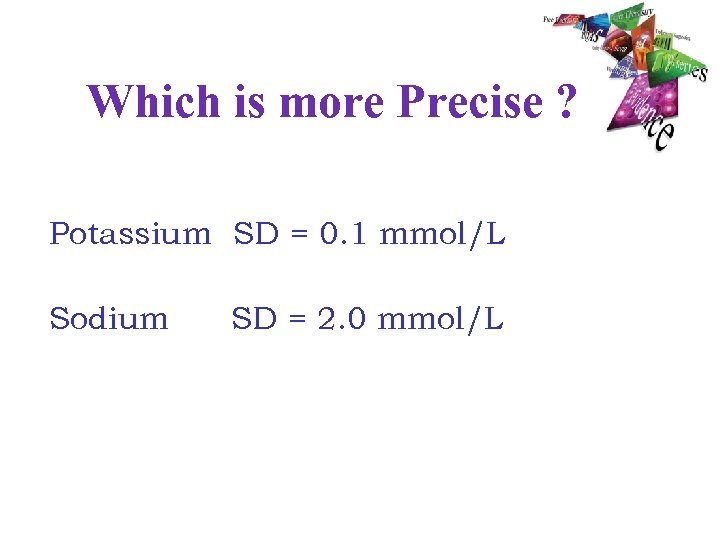

Which is more Precise ? Potassium SD = 0. 1 mmol/L Sodium SD = 2. 0 mmol/L

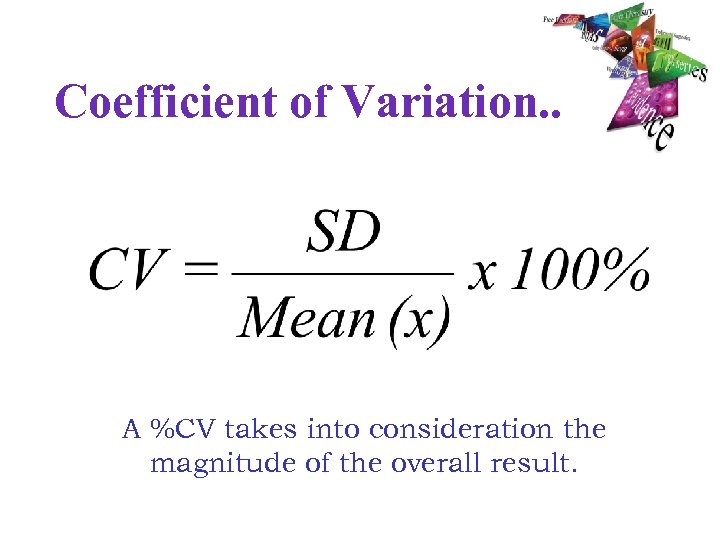

Coefficient of Variation. . A %CV takes into consideration the magnitude of the overall result.

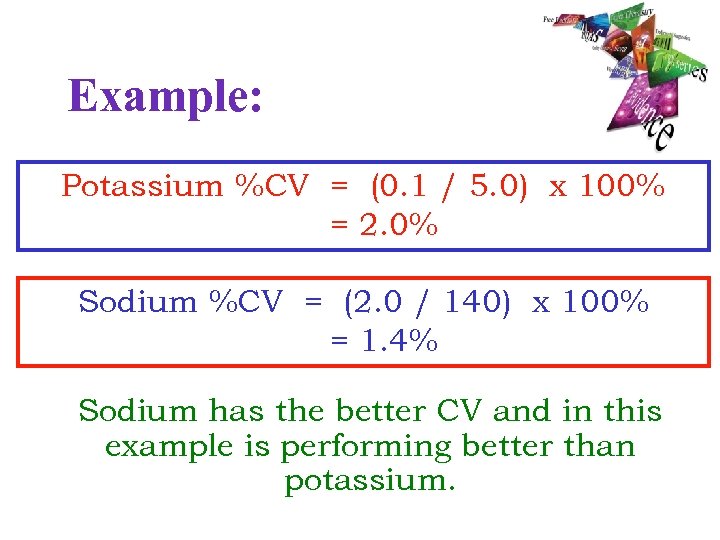

Example: Potassium %CV = (0. 1 / 5. 0) x 100% = 2. 0% Sodium %CV = (2. 0 / 140) x 100% = 1. 4% Sodium has the better CV and in this example is performing better than potassium.

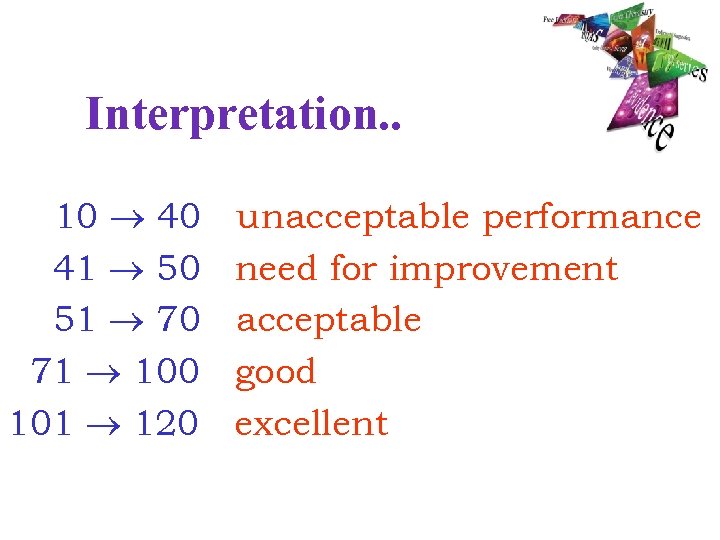

Interpretation. . 10 40 41 50 51 70 71 100 101 120 unacceptable performance need for improvement acceptable good excellent

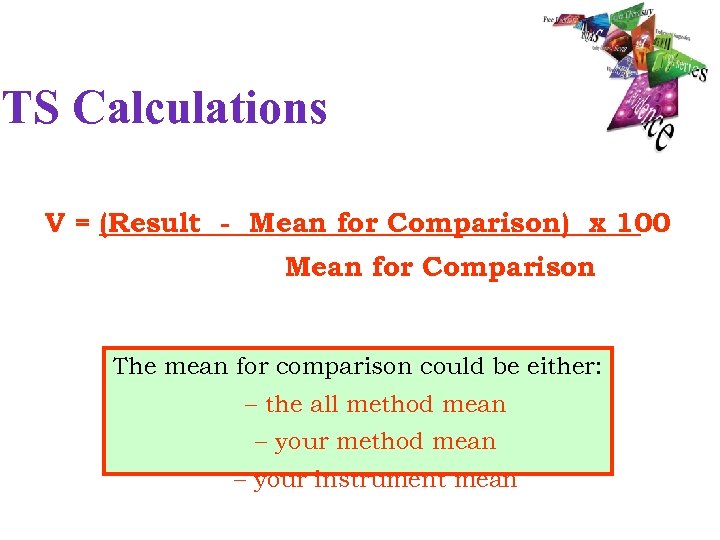

TS Calculations V = (Result - Mean for Comparison) x 100 Mean for Comparison The mean for comparison could be either: – the all method mean – your instrument mean

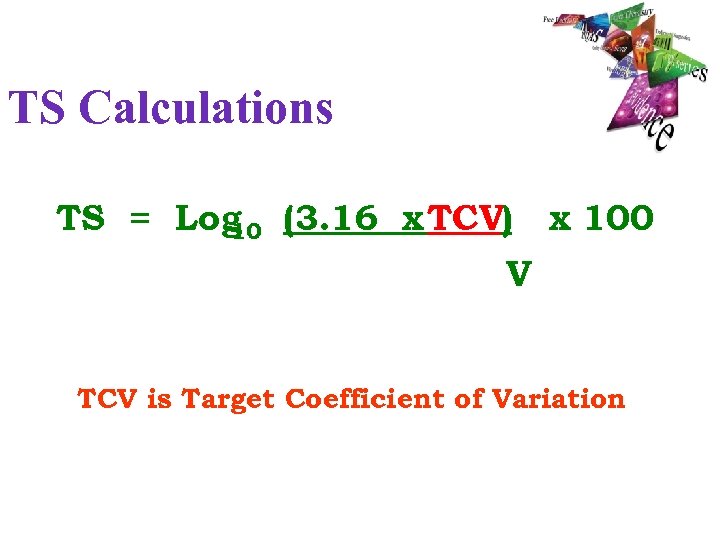

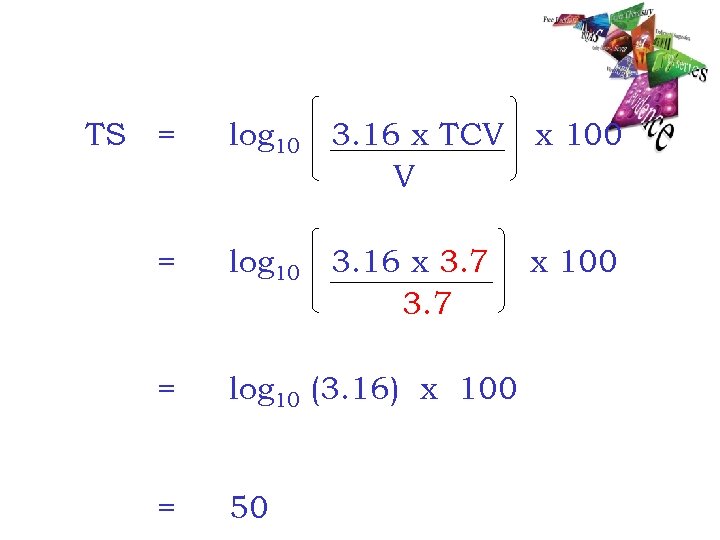

TS Calculations TS = Log (3. 16 x TCV) x 100 10 V TCV is Target Coefficient of Variation

TS Calculations TS = Log (3. 16 x TCV) x 100 10 V 3. 16 is selected as a constant because: – the log 10 of 3. 16 is 0. 5 – so if V = TCV, then the target score will be 50

TS = log 10 3. 16 x TCV x 100 V = log 10 3. 16 x 3. 7 = log 10 (3. 16) x 100 = 50 x 100

How can Analytical Quality be Controlled ?

• Internal Quality Control (IQC). – daily monitoring of quality control sera • External Quality Assessment (EQA). – comparing of performance to other laboratories.

Internal Quality Control. . • Daily monitoring – precision – accuracy • Quality control sera – results within control limits indicates that analytical system is running satisfactorily

What is Acceptable ? A sodium control has a target value of 140 mmol/L 139 mmol/L 120 mmol/L 140 mmol/L 160 mmol/L 141 mmol/L 180 mmol/L

What is Acceptable ? • A range of acceptable values is established • Sodium Control: - 137 143 mmol/L.

What are the Options ? • Unassayed serum: – the cheaper option ! • but the laboratory must establish its own ranges – cannot be used to assess accuracy ! • no externally assigned target values • Assayed serum: – with predetermined targets and ranges • established by the manufacturer.

Unassayed Serum. . • Analysed extensively by the laboratory. – a minimum of 20 sets of data generated – a mean +/- 2 SD range established • 95% of results acceptable – some laboratories may adopt tighter ranges

Assayed Serum. . • Targets and ranges generated by the manufacturer: – abc utilises RIQAS • database of 5, 000 laboratories • method / instrument / temperature specific values

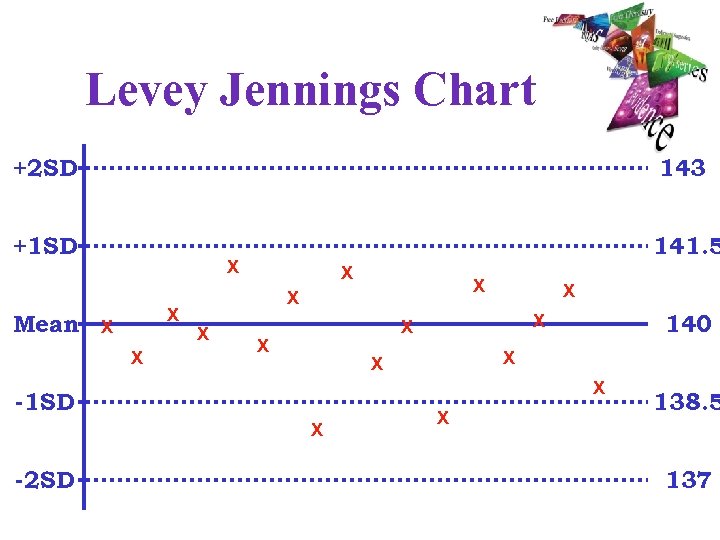

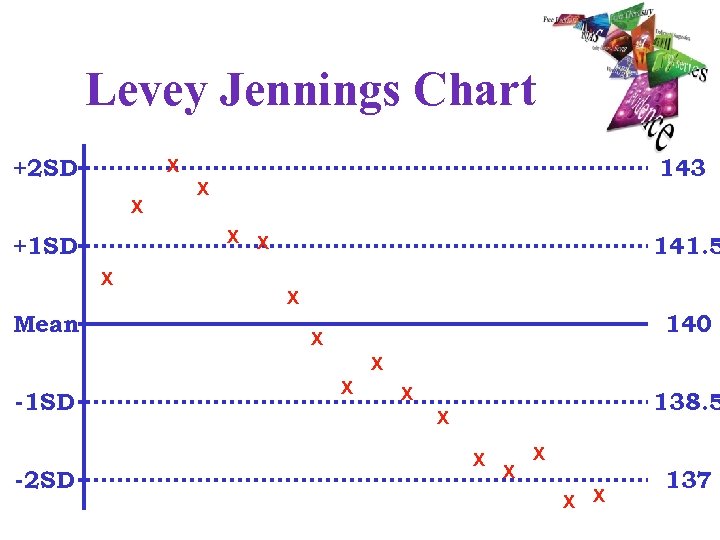

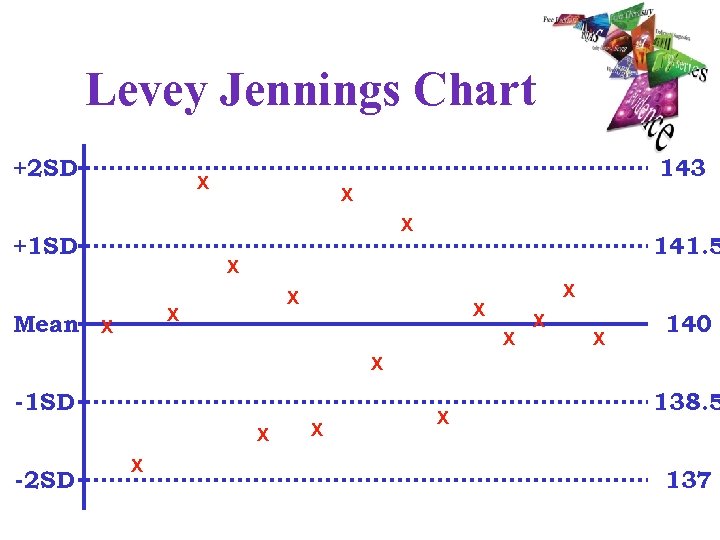

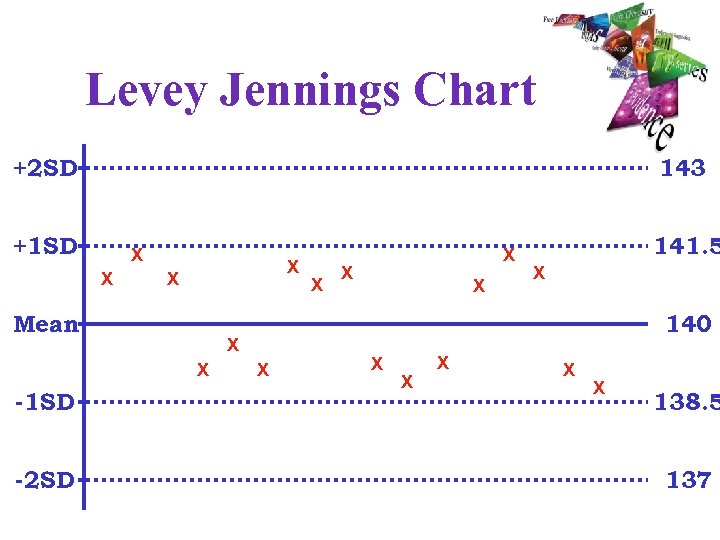

Levey Jennings Chart +2 SD 143 +1 SD 141. 5 Mean X X X X 140 X X X -1 SD X -2 SD X X X 138. 5 137

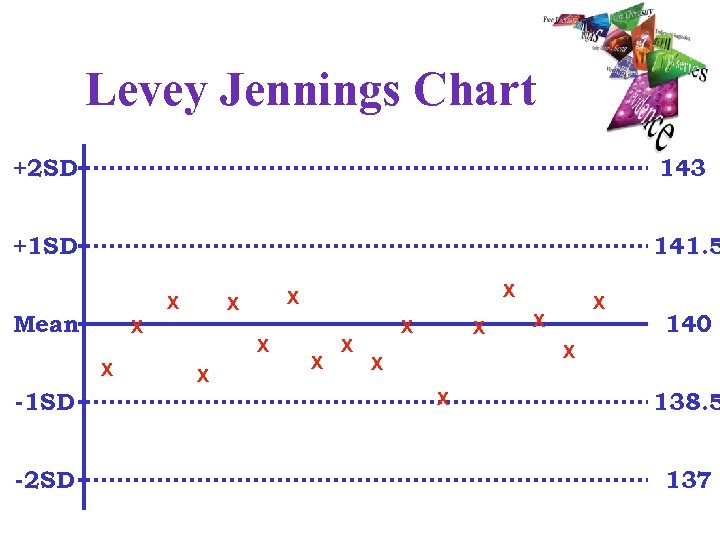

Levey Jennings Chart +2 SD 143 +1 SD 141. 5 X Mean X X -1 SD -2 SD X X X 140 X X X 138. 5 137

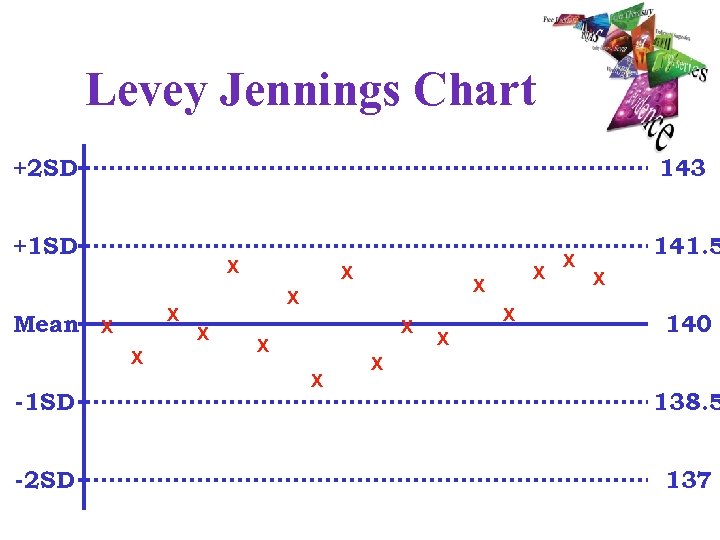

Levey Jennings Chart +2 SD 143 +1 SD Mean X X -1 SD -2 SD X X X 141. 5 X 140 X 138. 5 137

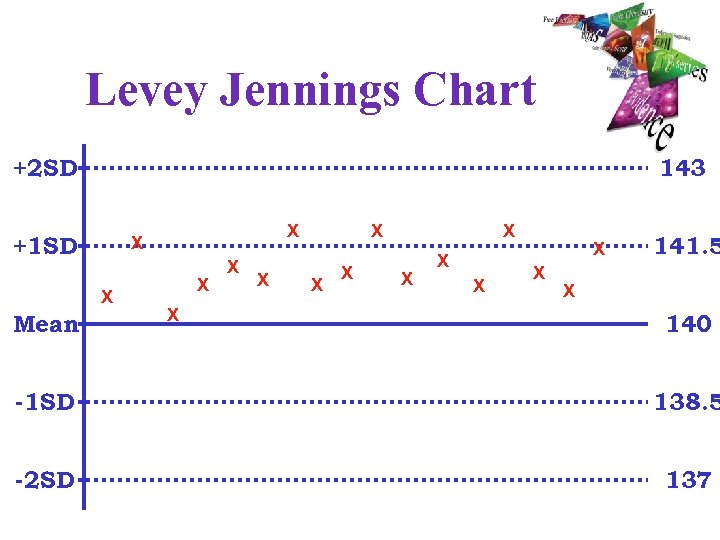

Levey Jennings Chart +2 SD 143 +1 SD X Mean X X X X 141. 5 X 140 -1 SD 138. 5 -2 SD 137

Levey Jennings Chart +2 SD X X X +1 SD X Mean 143 X 141. 5 X X 140 X X -1 SD -2 SD X X 138. 5 X X X 137

Levey Jennings Chart +2 SD X X +1 SD Mean 143 X 141. 5 X X X X X 140 X -1 SD X -2 SD X X X 138. 5 137

Levey Jennings Chart +2 SD 143 +1 SD X X Mean -1 SD -2 SD X X 141. 5 X 140 X X X X X 138. 5 137

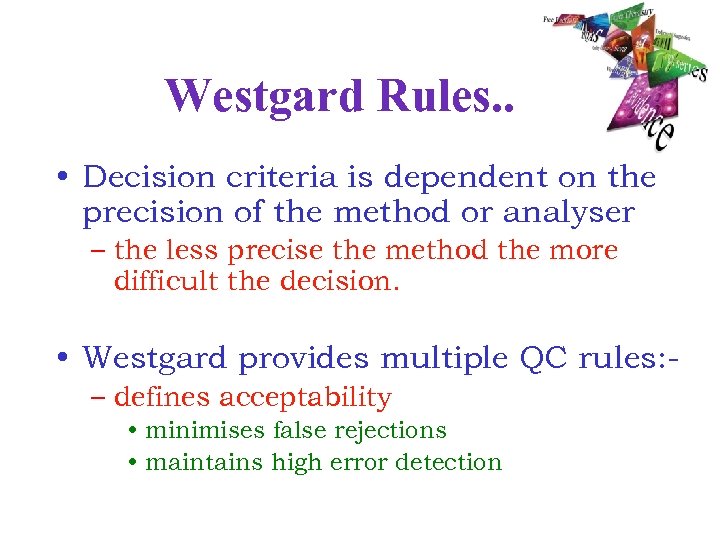

Westgard Rules. . • Decision criteria is dependent on the precision of the method or analyser – the less precise the method the more difficult the decision. • Westgard provides multiple QC rules: – defines acceptability • minimises false rejections • maintains high error detection

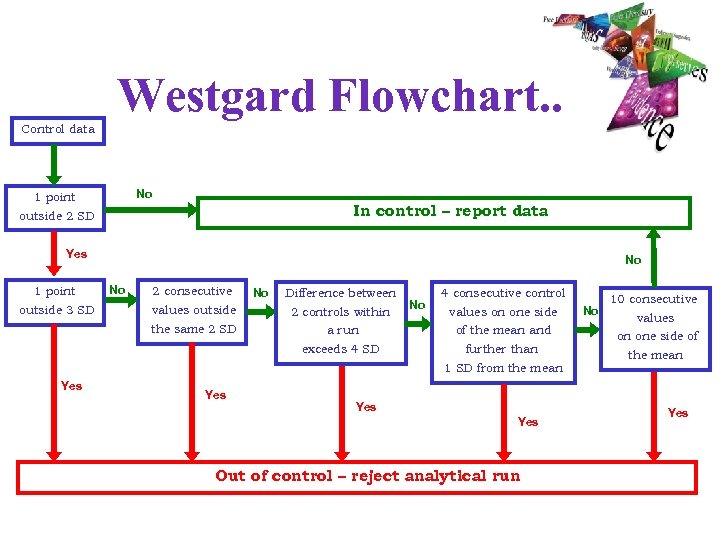

Westgard Flowchart. . Control data No 1 point In control – report data outside 2 SD Yes 1 point outside 3 SD No No 2 consecutive No Difference between No 4 consecutive control values outside 2 controls within the same 2 SD a run of the mean and exceeds 4 SD further than values on one side 1 SD from the mean Yes Yes Out of control – reject analytical run No 10 consecutive values on one side of the mean Yes

External Quality Assessment. . the main objective of EQA is not to bring about day to day consistency but to establish inter-laboratory comparability

EQA Options. . • International / National / Regional • International schemes provide: – a larger database of results – a wider range of analytical methods – a global representation of diagnostic manufacturers • Compulsory or Voluntary

A Typical EQA Scheme. . • Participants receive unknown samples. – these are analysed ‘blind’ – the results returned to scheme organiser – they are statistically analysed – to generate a comparative report – report sent to participant

RIQAS • abc International Quality Assessment Scheme – launched in 1988 – 5000 participants • Management tool – to assess, review and improve performance

RIQAS. . • Annual subscription – two six monthly cycles • Weekly samples – one vial reconstituted per week – tested blind as if a patient sample • Results reported back to abc – statistically analysed • Weekly Report generated

c3d6a548304412e4dd01e98469711d85.ppt