c04031549bf7836591a7c8d81cb5d725.ppt

- Количество слайдов: 19

Laboratory Information Management System for Sensor and Raft testing. Requirements. Ivan Kotov for BNL group March 22, 2012

Introduction Single sensors and Raft Tower Modules have to be tested and characterized before the focal plane assembly • large volume of testing – high throughput is required – can not be achieved without automation Ø automate tests from the very beginning ü CCD test facility was set up at Brookhaven National Laboratory Instrumentation Division ü Study contract sensors have been tested – sensor format from 2 k x 0. 5 k to 4 k x 2 k – >50, 000 image files (FITS format) were produced, analyzed and stored

Introduction (cont. ) • in testing mode Metadata is as important as Image • an image is useless without knowledge of measurement conditions: temperature, bias voltages, clock levels and timing etc § Automation approach is based on • • Rts 2 (robotic telescope system 2) bash scripts My. SQL database Express analysis, C/C++ code in ROOT framework details are in http: //dx. doi. org/10. 1016/j. nima. 2011. 013

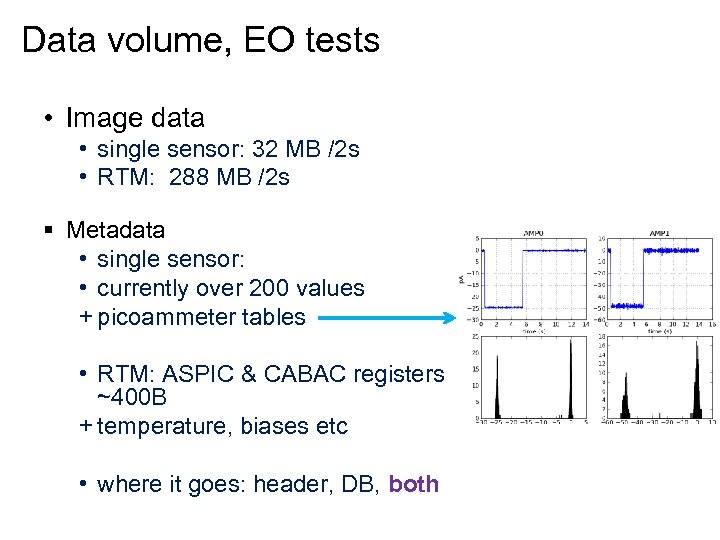

Data volume, EO tests • Image data • single sensor: 32 MB /2 s • RTM: 288 MB /2 s § Metadata • single sensor: • currently over 200 values + picoammeter tables • RTM: ASPIC & CABAC registers ~400 B + temperature, biases etc • where it goes: header, DB, both

Analysis code • variety of development platforms is in use • • ROOT framework, C/C++ code Python code Mathematica etc § storage of analysis results § data base entries with analysis summary § version control

Production needs Ø cyber security of operations ü data storage ü database ü version control § traveler § workflow monitor § inventory tracking § reporting § instrument calibration and maintenance record & schedule • etc Laboratory Information Management System, LIMS

Requirements & Proposed Solutions Ø cyber security of operations • computers in LSST clean rooms, buildings 510 and 535 B are a mixture of machines running Linux and Windows operating systems. • machines will be on a private local area network (LAN) behind a dual homed gateway machine • allow outgoing traffic from the machines • not allow incoming traffic to go directly to the internal machines • machines can be accessed by logging into the gateway machine

Requirements & Proposed Solutions ü data storage ü Use existing RHIC and ATLAS Computing Facility (RACF) at BNL which is managed and maintained by the RACF staff. Data files are stored on a dedicated file server residing in the facility. ü files are backed up nightly using RACF backup system and are archived using the IBM High Performance Storage System (HPSS) also within the RACF. ü These backups provide both disaster recovery and long-term availability of the data.

Requirements & Proposed Solutions ü database ü My. SQL database will be used as the LIMS back end ü This database will be installed on an RACF machine ü Write access to the database will be limited to machines in the clean room and an authenticated web interface ü a read-only replica of the database can be installed at remote locations

Requirements & Proposed Solutions ü version control ü A Subversion (SVN) server will track all code and scripts used in test procedures in the clean rooms as well as changes made to the code and scripts. ü Versions of all code and scripts used for a particular test will be recorded in the database allowing subsequent searches on this information.

End of presentation

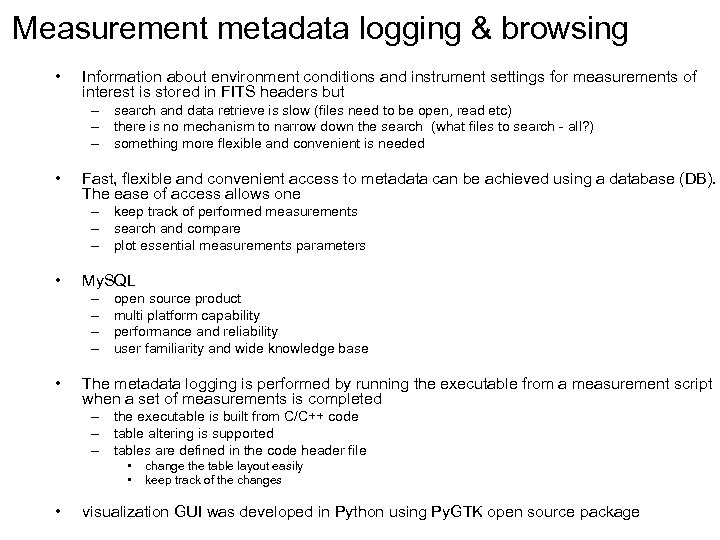

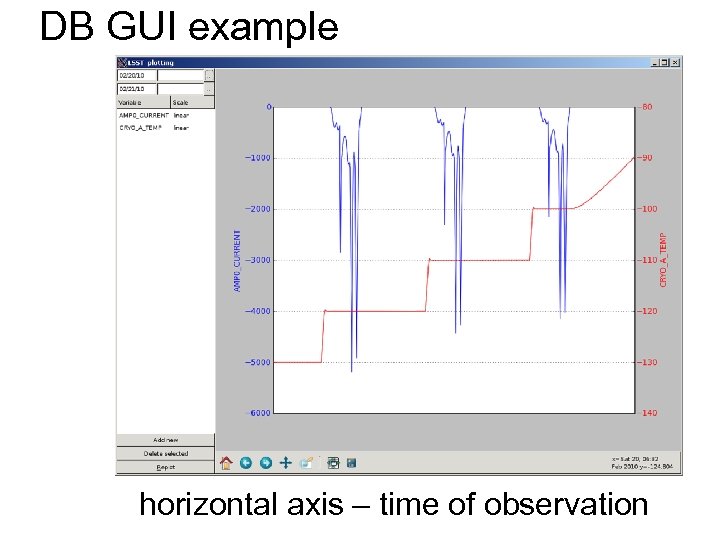

Measurement metadata logging & browsing • Information about environment conditions and instrument settings for measurements of interest is stored in FITS headers but – search and data retrieve is slow (files need to be open, read etc) – there is no mechanism to narrow down the search (what files to search - all? ) – something more flexible and convenient is needed • Fast, flexible and convenient access to metadata can be achieved using a database (DB). The ease of access allows one – keep track of performed measurements – search and compare – plot essential measurements parameters • My. SQL – – • open source product multi platform capability performance and reliability user familiarity and wide knowledge base The metadata logging is performed by running the executable from a measurement script when a set of measurements is completed – the executable is built from C/C++ code – table altering is supported – tables are defined in the code header file • • • change the table layout easily keep track of the changes visualization GUI was developed in Python using Py. GTK open source package

DB GUI example horizontal axis – time of observation

Express analysis of 55 Fe data (1) • standard input signal ( Ka 1620 e-) • provide absolute calibration of the entire electronics chain in a very straightforward way • what CCD parameters can be measured: – system gain – system noise – CTE – PSF

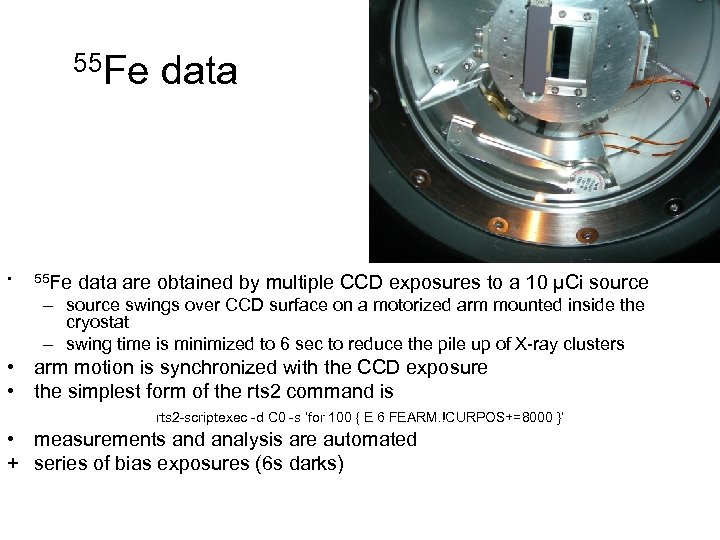

55 Fe • 55 Fe data are obtained by multiple CCD exposures to a 10 μCi source – source swings over CCD surface on a motorized arm mounted inside the cryostat – swing time is minimized to 6 sec to reduce the pile up of X-ray clusters • arm motion is synchronized with the CCD exposure • the simplest form of the rts 2 command is rts 2 -scriptexec -d C 0 -s ’for 100 { E 6 FEARM. !CURPOS+=8000 }’ • measurements and analysis are automated + series of bias exposures (6 s darks)

55 Fe data analysis outline 1. base line subtraction (IEEE Transactions on Nuclear Science, Vol. 57, p. 2200 -2204, August 2010, DOI: 10. 1109/TNS. 2010. 2049660) – bias exposures – evaluated from the 55 Fe image itself Ø read-out noise in a. d. u. § cluster finding algorithm to find X-ray hits – – § cluster seeds = pixels with amplitude above 5 s noise seeds are ordered automatically in amplitude decrease order n × n pixels zone around a seed is analyzed ( usually n = 3) n × n zone is cleared statistical analysis of X-ray clusters – gain determination – charge transfer efficiency – etc. .

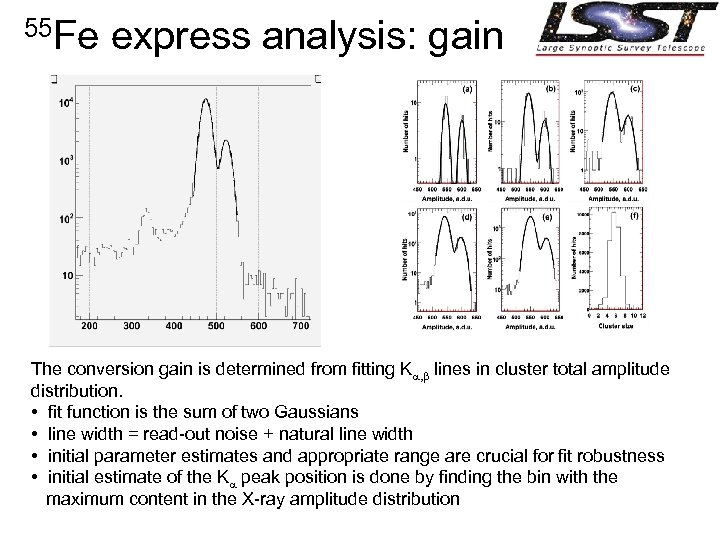

55 Fe express analysis: gain The conversion gain is determined from fitting Ka, b lines in cluster total amplitude distribution. • fit function is the sum of two Gaussians • line width = read-out noise + natural line width • initial parameter estimates and appropriate range are crucial for fit robustness • initial estimate of the Ka peak position is done by finding the bin with the maximum content in the X-ray amplitude distribution

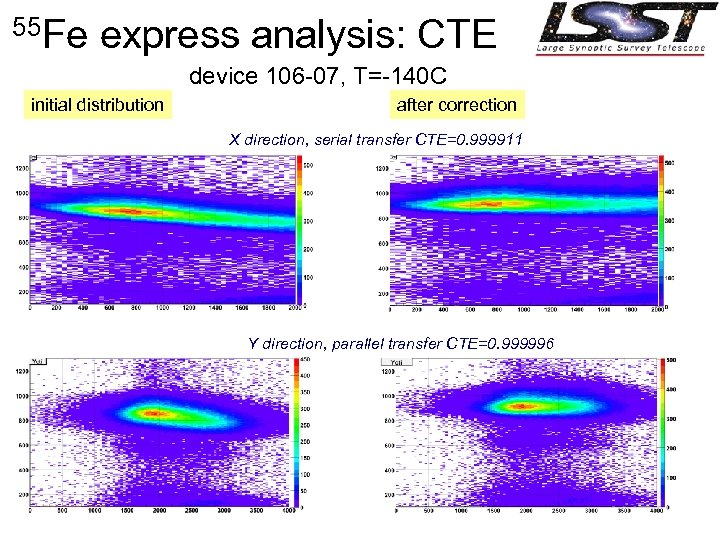

55 Fe express analysis: CTE device 106 -07, T=-140 C initial distribution after correction X direction, serial transfer CTE=0. 999911 Y direction, parallel transfer CTE=0. 999996

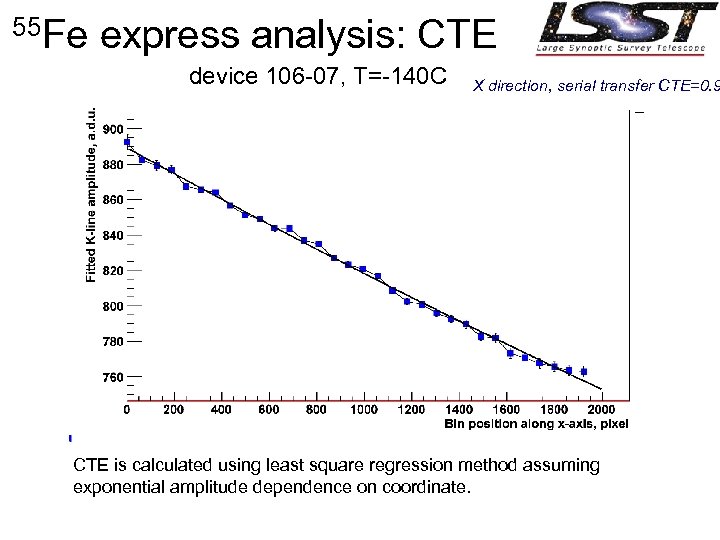

55 Fe express analysis: CTE device 106 -07, T=-140 C X direction, serial transfer CTE=0. 9 CTE is calculated using least square regression method assuming exponential amplitude dependence on coordinate.

c04031549bf7836591a7c8d81cb5d725.ppt