39d3aaa9a874f04e962dc5fc62ea046f.ppt

- Количество слайдов: 28

Korean National program on Fuel Cells: the way to Commercialization June 9, 2010 Seong-Ahn Hong Fuel Cell Center Korea Institute of Science and Technology

Korean National program on Fuel Cells: the way to Commercialization June 9, 2010 Seong-Ahn Hong Fuel Cell Center Korea Institute of Science and Technology

Energy Situation in Korea • Energy Security - 10 th in energy consumption (229. 3 MTOE) - Import 97% of primary energy - $ 66. 7 Billion in 2006 Primary Energy Import - Oil, Natural Gas, Coal - 5 th crude oil importer - 2 nd LNG importer • Environmental Issues - CO 2 reduction • Energy Industry - Energy paradigm shifts from resources to technology - Fuel Cell: Economic growth engine for next generation

Energy Situation in Korea • Energy Security - 10 th in energy consumption (229. 3 MTOE) - Import 97% of primary energy - $ 66. 7 Billion in 2006 Primary Energy Import - Oil, Natural Gas, Coal - 5 th crude oil importer - 2 nd LNG importer • Environmental Issues - CO 2 reduction • Energy Industry - Energy paradigm shifts from resources to technology - Fuel Cell: Economic growth engine for next generation

Low Carbon Green Growth • Last August 15 th in 2008, President Lee Myung-bak proclaimed “Low Carbon Green Growth” as his new development paradigm. “Green growth can not only minimize CO 2 emissions and environmental damage, but provide a new growth engine and more jobs, enhancing the quality of life, protecting the environment and contributing to international efforts addressing climate change. ”

Low Carbon Green Growth • Last August 15 th in 2008, President Lee Myung-bak proclaimed “Low Carbon Green Growth” as his new development paradigm. “Green growth can not only minimize CO 2 emissions and environmental damage, but provide a new growth engine and more jobs, enhancing the quality of life, protecting the environment and contributing to international efforts addressing climate change. ”

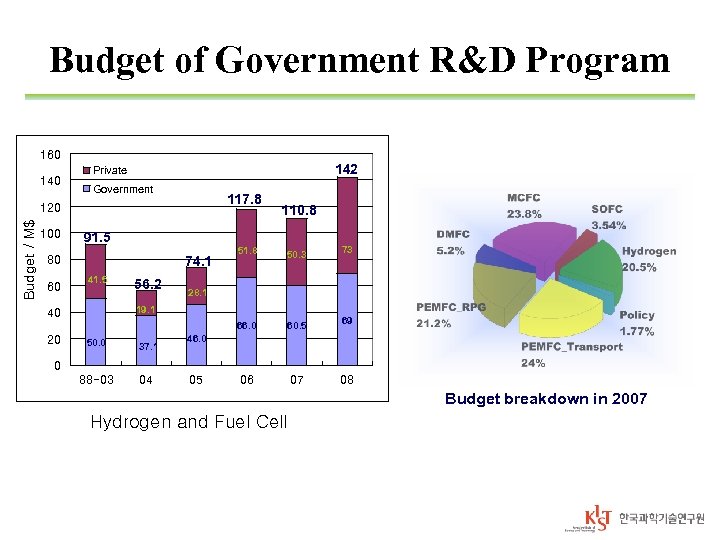

Budget of Government R&D Program 160 142 Private Government 117. 8 Budget / M$ 120 100 110. 8 91. 5 60 41. 5 50. 3 60. 5 06 07 73 28. 1 19. 1 40 20 56. 2 51. 8 66. 0 74. 1 80 50. 0 37. 1 88 -03 04 69 46. 0 0 05 08 Budget breakdown in 2007 Hydrogen and Fuel Cell

Budget of Government R&D Program 160 142 Private Government 117. 8 Budget / M$ 120 100 110. 8 91. 5 60 41. 5 50. 3 60. 5 06 07 73 28. 1 19. 1 40 20 56. 2 51. 8 66. 0 74. 1 80 50. 0 37. 1 88 -03 04 69 46. 0 0 05 08 Budget breakdown in 2007 Hydrogen and Fuel Cell

PEMFC for Transportation • Technical Issues − − − Stack Durability Cost Light Weight / Compactness High & Low Temperature Driving Range Hydrogen Infrastructure • Market Penetration − − − − R&D Leading Company / Supplier of Key Components Hydrogen Station Demonstration Investment / Budget Code & Standard Public Acceptance

PEMFC for Transportation • Technical Issues − − − Stack Durability Cost Light Weight / Compactness High & Low Temperature Driving Range Hydrogen Infrastructure • Market Penetration − − − − R&D Leading Company / Supplier of Key Components Hydrogen Station Demonstration Investment / Budget Code & Standard Public Acceptance

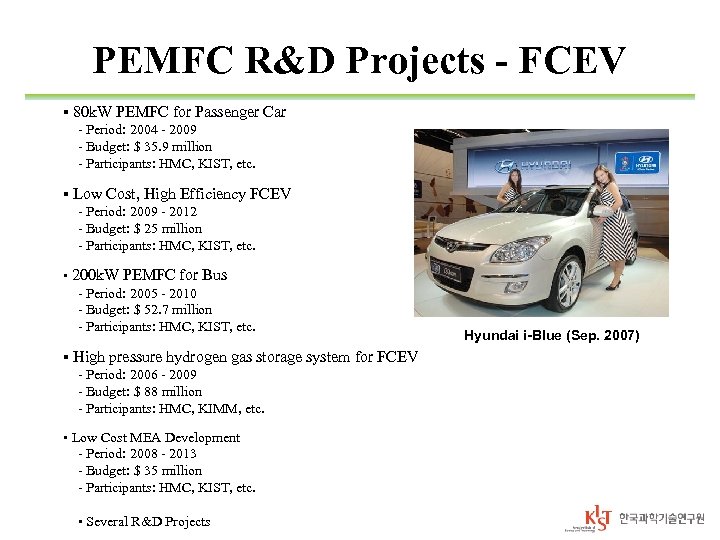

PEMFC R&D Projects - FCEV ▪ 80 k. W PEMFC for Passenger Car - Period: 2004 - 2009 - Budget: $ 35. 9 million - Participants: HMC, KIST, etc. ▪ Low Cost, High Efficiency FCEV - Period: 2009 - 2012 - Budget: $ 25 million - Participants: HMC, KIST, etc. ▪ 200 k. W PEMFC for Bus - Period: 2005 - 2010 - Budget: $ 52. 7 million - Participants: HMC, KIST, etc. ▪ High pressure hydrogen gas storage system for FCEV - Period: 2006 - 2009 - Budget: $ 88 million - Participants: HMC, KIMM, etc. ▪ Low Cost MEA Development - Period: 2008 - 2013 - Budget: $ 35 million - Participants: HMC, KIST, etc. ▪ Several R&D Projects Hyundai i-Blue (Sep. 2007)

PEMFC R&D Projects - FCEV ▪ 80 k. W PEMFC for Passenger Car - Period: 2004 - 2009 - Budget: $ 35. 9 million - Participants: HMC, KIST, etc. ▪ Low Cost, High Efficiency FCEV - Period: 2009 - 2012 - Budget: $ 25 million - Participants: HMC, KIST, etc. ▪ 200 k. W PEMFC for Bus - Period: 2005 - 2010 - Budget: $ 52. 7 million - Participants: HMC, KIST, etc. ▪ High pressure hydrogen gas storage system for FCEV - Period: 2006 - 2009 - Budget: $ 88 million - Participants: HMC, KIMM, etc. ▪ Low Cost MEA Development - Period: 2008 - 2013 - Budget: $ 35 million - Participants: HMC, KIST, etc. ▪ Several R&D Projects Hyundai i-Blue (Sep. 2007)

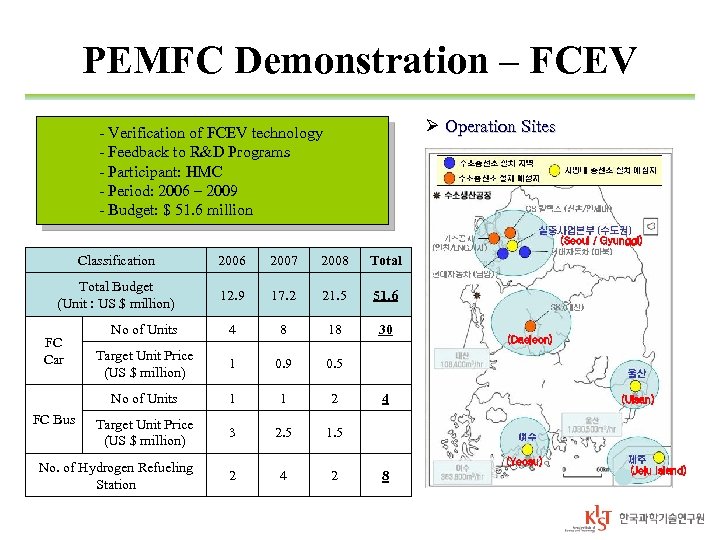

PEMFC Demonstration – FCEV Ø Operation Sites - Verification of FCEV technology - Feedback to R&D Programs - Participant: HMC - Period: 2006 – 2009 - Budget: $ 51. 6 million (Seoul / Gyunggi) Classification 2006 2007 2008 Total Budget (Unit : US $ million) 12. 9 17. 2 21. 5 51. 6 No of Units 4 8 18 30 Target Unit Price (US $ million) 1 0. 9 0. 5 No of Units 1 1 2 4 Target Unit Price (US $ million) 3 2. 5 1. 5 FC Car FC Bus No. of Hydrogen Refueling Station (Daejeon) (Ulsan) (Yeosu) 2 4 2 8 (Jeju Island)

PEMFC Demonstration – FCEV Ø Operation Sites - Verification of FCEV technology - Feedback to R&D Programs - Participant: HMC - Period: 2006 – 2009 - Budget: $ 51. 6 million (Seoul / Gyunggi) Classification 2006 2007 2008 Total Budget (Unit : US $ million) 12. 9 17. 2 21. 5 51. 6 No of Units 4 8 18 30 Target Unit Price (US $ million) 1 0. 9 0. 5 No of Units 1 1 2 4 Target Unit Price (US $ million) 3 2. 5 1. 5 FC Car FC Bus No. of Hydrogen Refueling Station (Daejeon) (Ulsan) (Yeosu) 2 4 2 8 (Jeju Island)

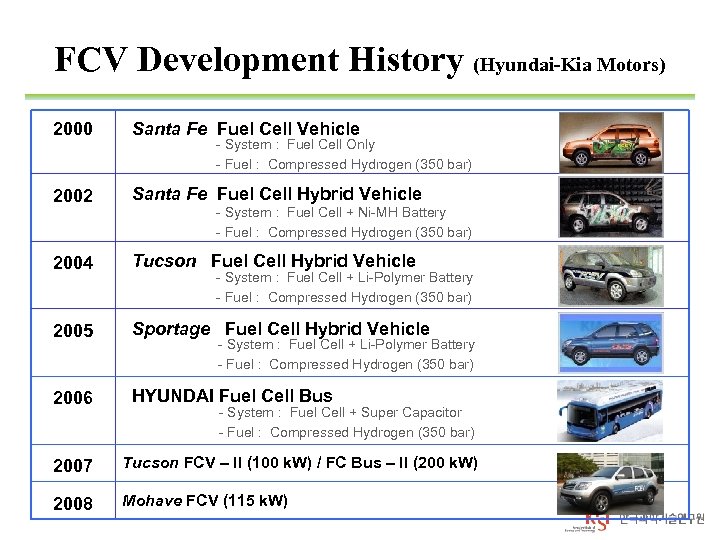

FCV Development History (Hyundai-Kia Motors) 2000 Santa Fe Fuel Cell Vehicle 2002 Santa Fe Fuel Cell Hybrid Vehicle 2004 Tucson Fuel Cell Hybrid Vehicle 2005 Sportage Fuel Cell Hybrid Vehicle 2006 HYUNDAI Fuel Cell Bus - System : Fuel Cell Only - Fuel : Compressed Hydrogen (350 bar) - System : Fuel Cell + Ni-MH Battery - Fuel : Compressed Hydrogen (350 bar) - System : Fuel Cell + Li-Polymer Battery - Fuel : Compressed Hydrogen (350 bar) - System : Fuel Cell + Super Capacitor - Fuel : Compressed Hydrogen (350 bar) 2007 Tucson FCV – II (100 k. W) / FC Bus – II (200 k. W) 2008 Mohave FCV (115 k. W)

FCV Development History (Hyundai-Kia Motors) 2000 Santa Fe Fuel Cell Vehicle 2002 Santa Fe Fuel Cell Hybrid Vehicle 2004 Tucson Fuel Cell Hybrid Vehicle 2005 Sportage Fuel Cell Hybrid Vehicle 2006 HYUNDAI Fuel Cell Bus - System : Fuel Cell Only - Fuel : Compressed Hydrogen (350 bar) - System : Fuel Cell + Ni-MH Battery - Fuel : Compressed Hydrogen (350 bar) - System : Fuel Cell + Li-Polymer Battery - Fuel : Compressed Hydrogen (350 bar) - System : Fuel Cell + Super Capacitor - Fuel : Compressed Hydrogen (350 bar) 2007 Tucson FCV – II (100 k. W) / FC Bus – II (200 k. W) 2008 Mohave FCV (115 k. W)

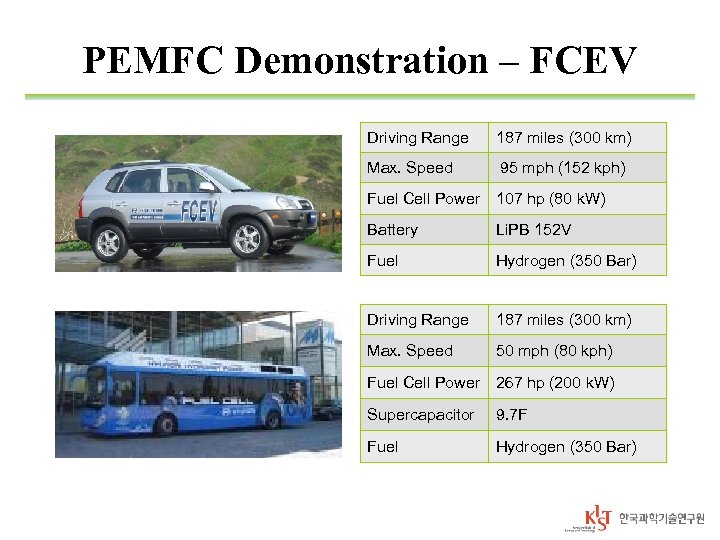

PEMFC Demonstration – FCEV Driving Range 187 miles (300 km) Max. Speed 95 mph (152 kph) Fuel Cell Power 107 hp (80 k. W) Battery Li. PB 152 V Fuel Hydrogen (350 Bar) Driving Range 187 miles (300 km) Max. Speed 50 mph (80 kph) Fuel Cell Power 267 hp (200 k. W) Supercapacitor 9. 7 F Fuel Hydrogen (350 Bar)

PEMFC Demonstration – FCEV Driving Range 187 miles (300 km) Max. Speed 95 mph (152 kph) Fuel Cell Power 107 hp (80 k. W) Battery Li. PB 152 V Fuel Hydrogen (350 Bar) Driving Range 187 miles (300 km) Max. Speed 50 mph (80 kph) Fuel Cell Power 267 hp (200 k. W) Supercapacitor 9. 7 F Fuel Hydrogen (350 Bar)

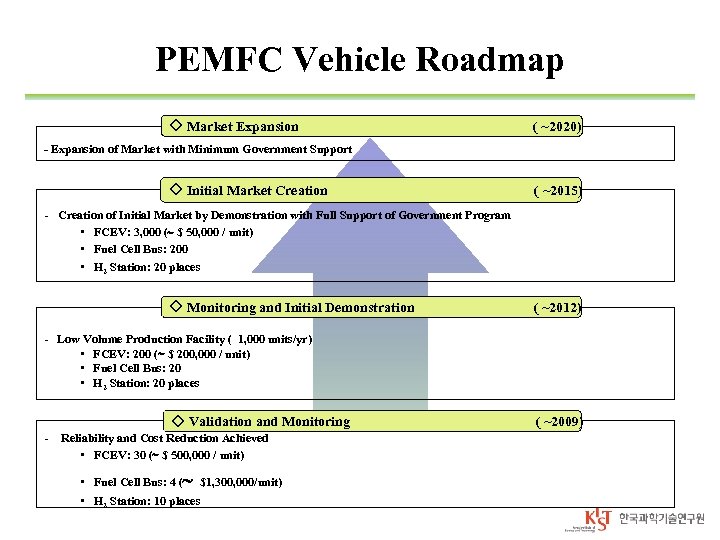

PEMFC Vehicle Roadmap ◇ Market Expansion ( ~2020) - Expansion of Market with Minimum Government Support ◇ Initial Market Creation ( ~2015) - Creation of Initial Market by Demonstration with Full Support of Government Program • FCEV: 3, 000 ( $ 50, 000 / unit) • Fuel Cell Bus: 200 • H 2 Station: 20 places ◇ Monitoring and Initial Demonstration ( ~2012) - Low Volume Production Facility ( 1, 000 units/yr) • FCEV: 200 ( $ 200, 000 / unit) • Fuel Cell Bus: 20 • H 2 Station: 20 places ◇ Validation and Monitoring - Reliability and Cost Reduction Achieved • FCEV: 30 ( $ 500, 000 / unit) • Fuel Cell Bus: 4 ( • H 2 Station: 10 places $1, 300, 000/unit) ( ~2009)

PEMFC Vehicle Roadmap ◇ Market Expansion ( ~2020) - Expansion of Market with Minimum Government Support ◇ Initial Market Creation ( ~2015) - Creation of Initial Market by Demonstration with Full Support of Government Program • FCEV: 3, 000 ( $ 50, 000 / unit) • Fuel Cell Bus: 200 • H 2 Station: 20 places ◇ Monitoring and Initial Demonstration ( ~2012) - Low Volume Production Facility ( 1, 000 units/yr) • FCEV: 200 ( $ 200, 000 / unit) • Fuel Cell Bus: 20 • H 2 Station: 20 places ◇ Validation and Monitoring - Reliability and Cost Reduction Achieved • FCEV: 30 ( $ 500, 000 / unit) • Fuel Cell Bus: 4 ( • H 2 Station: 10 places $1, 300, 000/unit) ( ~2009)

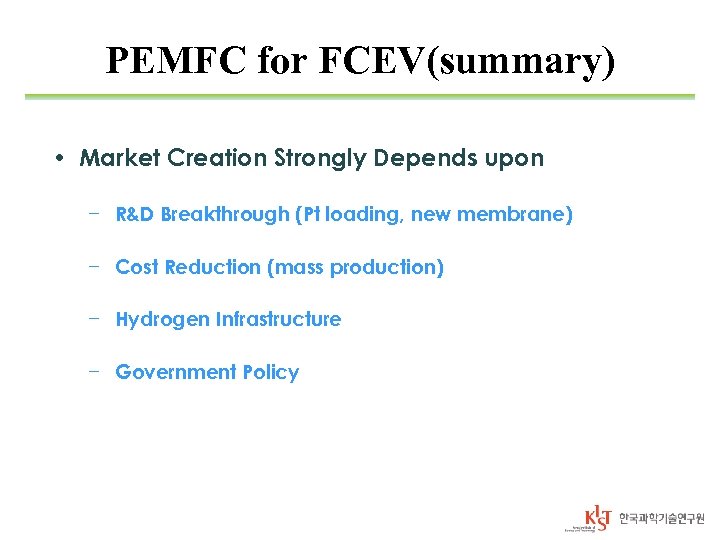

PEMFC for FCEV(summary) • Market Creation Strongly Depends upon − R&D Breakthrough (Pt loading, new membrane) − Cost Reduction (mass production) − Hydrogen Infrastructure − Government Policy

PEMFC for FCEV(summary) • Market Creation Strongly Depends upon − R&D Breakthrough (Pt loading, new membrane) − Cost Reduction (mass production) − Hydrogen Infrastructure − Government Policy

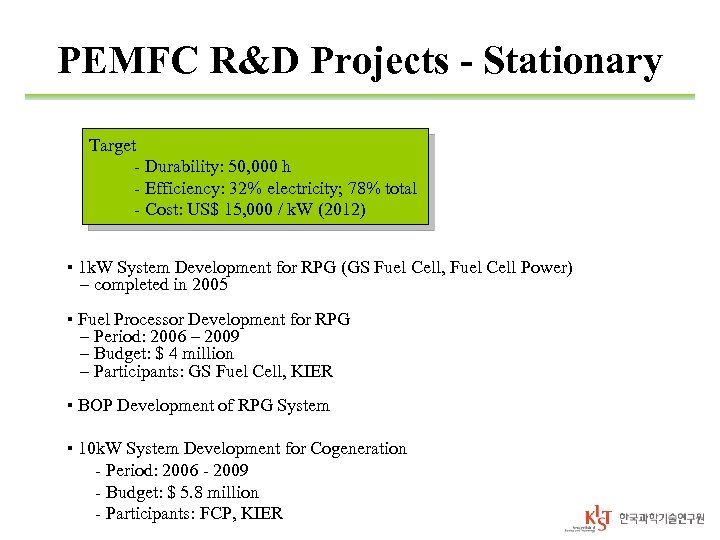

PEMFC R&D Projects - Stationary Target - Durability: 50, 000 h - Efficiency: 32% electricity; 78% total - Cost: US$ 15, 000 / k. W (2012) ▪ 1 k. W System Development for RPG (GS Fuel Cell, Fuel Cell Power) – completed in 2005 ▪ Fuel Processor Development for RPG – Period: 2006 – 2009 – Budget: $ 4 million – Participants: GS Fuel Cell, KIER ▪ BOP Development of RPG System ▪ 10 k. W System Development for Cogeneration - Period: 2006 - 2009 - Budget: $ 5. 8 million - Participants: FCP, KIER

PEMFC R&D Projects - Stationary Target - Durability: 50, 000 h - Efficiency: 32% electricity; 78% total - Cost: US$ 15, 000 / k. W (2012) ▪ 1 k. W System Development for RPG (GS Fuel Cell, Fuel Cell Power) – completed in 2005 ▪ Fuel Processor Development for RPG – Period: 2006 – 2009 – Budget: $ 4 million – Participants: GS Fuel Cell, KIER ▪ BOP Development of RPG System ▪ 10 k. W System Development for Cogeneration - Period: 2006 - 2009 - Budget: $ 5. 8 million - Participants: FCP, KIER

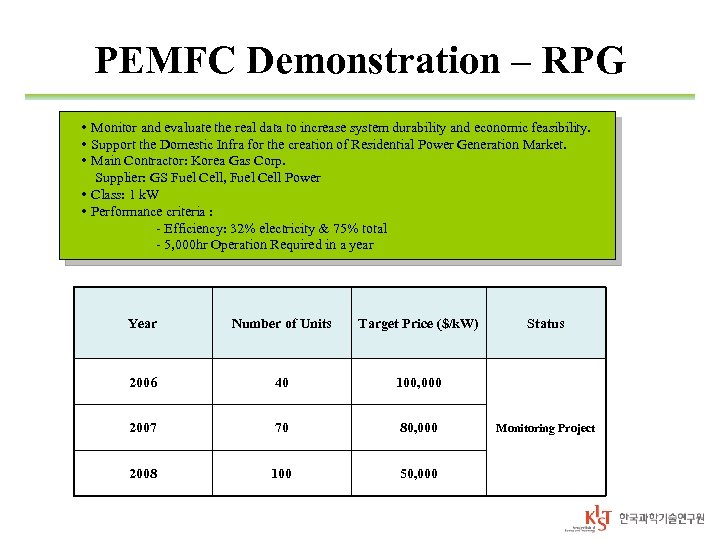

PEMFC Demonstration – RPG • Monitor and evaluate the real data to increase system durability and economic feasibility. • Support the Domestic Infra for the creation of Residential Power Generation Market. • Main Contractor: Korea Gas Corp. Supplier: GS Fuel Cell, Fuel Cell Power • Class: 1 k. W • Performance criteria : - Efficiency: 32% electricity & 75% total - 5, 000 hr Operation Required in a year Year Number of Units Target Price ($/k. W) 2006 40 100, 000 2007 70 80, 000 2008 100 50, 000 Status Monitoring Project

PEMFC Demonstration – RPG • Monitor and evaluate the real data to increase system durability and economic feasibility. • Support the Domestic Infra for the creation of Residential Power Generation Market. • Main Contractor: Korea Gas Corp. Supplier: GS Fuel Cell, Fuel Cell Power • Class: 1 k. W • Performance criteria : - Efficiency: 32% electricity & 75% total - 5, 000 hr Operation Required in a year Year Number of Units Target Price ($/k. W) 2006 40 100, 000 2007 70 80, 000 2008 100 50, 000 Status Monitoring Project

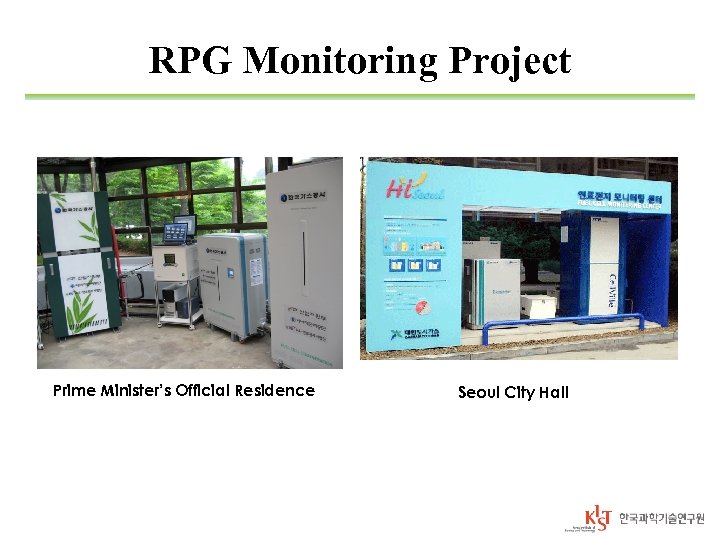

RPG Monitoring Project Prime Minister’s Official Residence Seoul City Hall

RPG Monitoring Project Prime Minister’s Official Residence Seoul City Hall

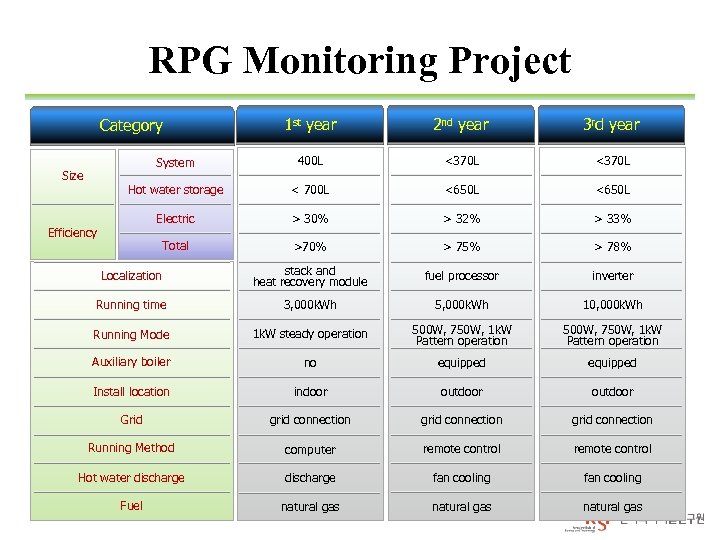

RPG Monitoring Project 1 st year 2 nd year 3 rd year System 400 L <370 L Hot water storage < 700 L <650 L Electric > 30% > 32% > 33% Total >70% > 75% > 78% Localization stack and heat recovery module fuel processor inverter Running time 3, 000 k. Wh 5, 000 k. Wh 10, 000 k. Wh Running Mode 1 k. W steady operation 500 W, 750 W, 1 k. W Pattern operation Auxiliary boiler no equipped Install location indoor outdoor Grid grid connection Running Method computer remote control Hot water discharge fan cooling Fuel natural gas Category Size Efficiency

RPG Monitoring Project 1 st year 2 nd year 3 rd year System 400 L <370 L Hot water storage < 700 L <650 L Electric > 30% > 32% > 33% Total >70% > 75% > 78% Localization stack and heat recovery module fuel processor inverter Running time 3, 000 k. Wh 5, 000 k. Wh 10, 000 k. Wh Running Mode 1 k. W steady operation 500 W, 750 W, 1 k. W Pattern operation Auxiliary boiler no equipped Install location indoor outdoor Grid grid connection Running Method computer remote control Hot water discharge fan cooling Fuel natural gas Category Size Efficiency

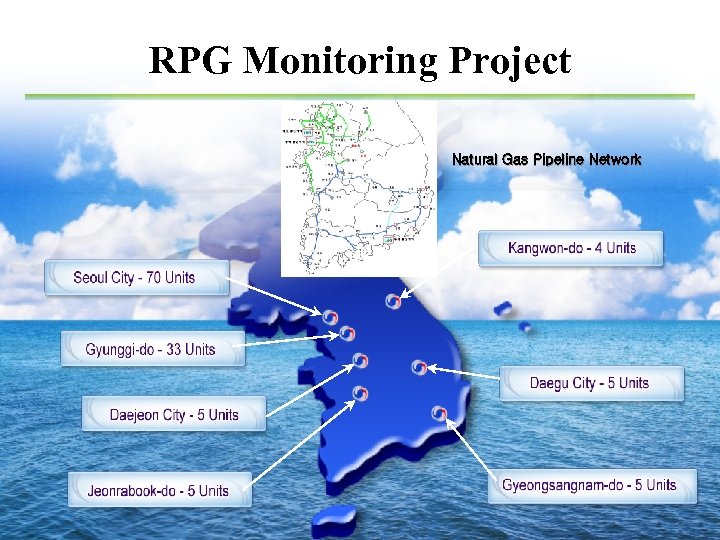

RPG Monitoring Project Natural Gas Pipeline Network

RPG Monitoring Project Natural Gas Pipeline Network

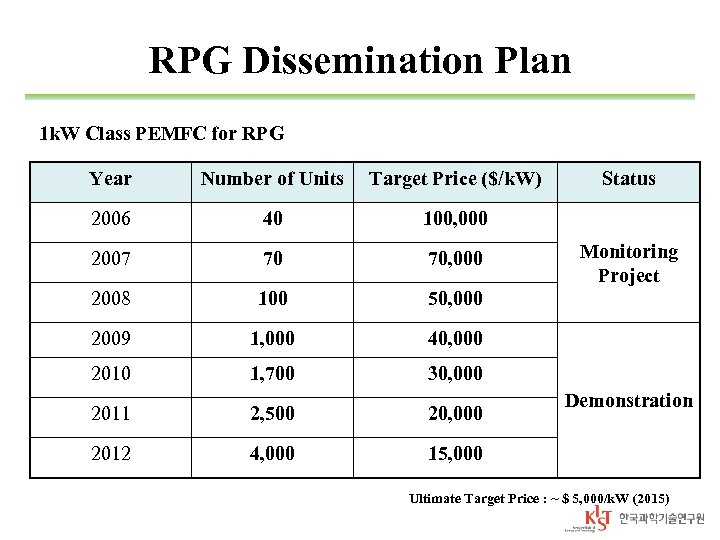

RPG Dissemination Plan 1 k. W Class PEMFC for RPG Year Number of Units Target Price ($/k. W) 2006 40 100, 000 2007 70 70, 000 2008 100 50, 000 2009 1, 000 40, 000 2010 1, 700 30, 000 2011 2, 500 20, 000 2012 4, 000 Status Monitoring Project Demonstration 15, 000 Ultimate Target Price : ~ $ 5, 000/k. W (2015)

RPG Dissemination Plan 1 k. W Class PEMFC for RPG Year Number of Units Target Price ($/k. W) 2006 40 100, 000 2007 70 70, 000 2008 100 50, 000 2009 1, 000 40, 000 2010 1, 700 30, 000 2011 2, 500 20, 000 2012 4, 000 Status Monitoring Project Demonstration 15, 000 Ultimate Target Price : ~ $ 5, 000/k. W (2015)

PEMFC for RPG(summary) • Market creation (and/or expansion) is another key factor for the commercialization of RPG system even though cost reduction and durability issue are achieved.

PEMFC for RPG(summary) • Market creation (and/or expansion) is another key factor for the commercialization of RPG system even though cost reduction and durability issue are achieved.

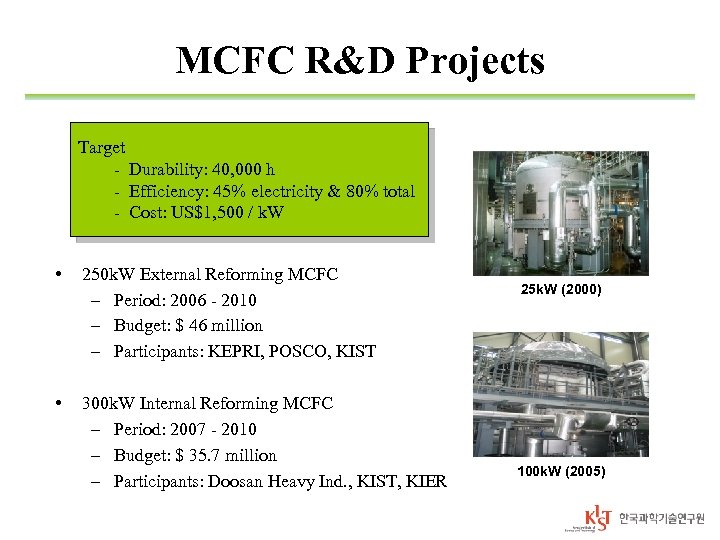

MCFC R&D Projects Target - Durability: 40, 000 h - Efficiency: 45% electricity & 80% total - Cost: US$1, 500 / k. W • 250 k. W External Reforming MCFC – Period: 2006 - 2010 – Budget: $ 46 million – Participants: KEPRI, POSCO, KIST • 300 k. W Internal Reforming MCFC – Period: 2007 - 2010 – Budget: $ 35. 7 million – Participants: Doosan Heavy Ind. , KIST, KIER 25 k. W (2000) 100 k. W (2005)

MCFC R&D Projects Target - Durability: 40, 000 h - Efficiency: 45% electricity & 80% total - Cost: US$1, 500 / k. W • 250 k. W External Reforming MCFC – Period: 2006 - 2010 – Budget: $ 46 million – Participants: KEPRI, POSCO, KIST • 300 k. W Internal Reforming MCFC – Period: 2007 - 2010 – Budget: $ 35. 7 million – Participants: Doosan Heavy Ind. , KIST, KIER 25 k. W (2000) 100 k. W (2005)

MCFC components manufacturing facilities DOOSAN installed components manufacturing facilities with 2~5 MW/yr capacity in early 2008 Slurry manufacturing system Tape casting machine Belt furnace Automatic electrode cutting machine

MCFC components manufacturing facilities DOOSAN installed components manufacturing facilities with 2~5 MW/yr capacity in early 2008 Slurry manufacturing system Tape casting machine Belt furnace Automatic electrode cutting machine

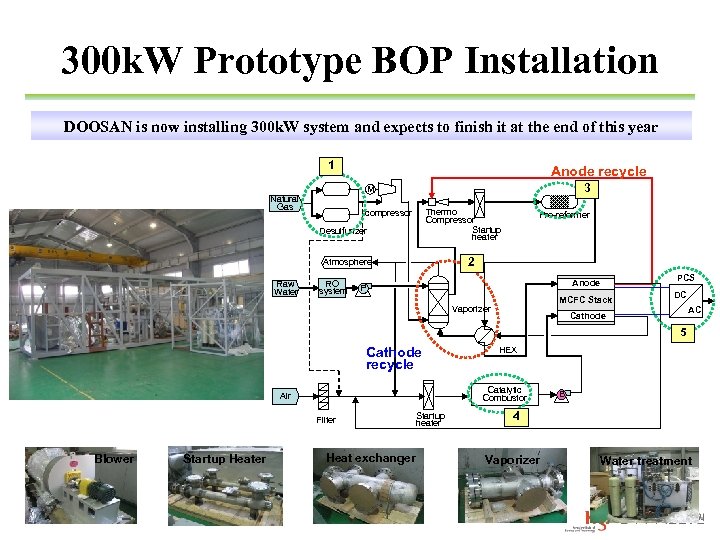

300 k. W Prototype BOP Installation DOOSAN is now installing 300 k. W system and expects to finish it at the end of this year 1 Anode recycle 3 M Natural Gas Thermo Compressor Startup heater compressor Desulfurizer 2 Atmosphere Raw Water RO system Pre-reformer PCS Anode P MCFC Stack Vaporizer DC AC Cathode 5 Cathode recycle Catalytic Combustor Air Filter Blower Startup Heater HEX Heat exchanger Startup heater B 4 Vaporizer Water treatment

300 k. W Prototype BOP Installation DOOSAN is now installing 300 k. W system and expects to finish it at the end of this year 1 Anode recycle 3 M Natural Gas Thermo Compressor Startup heater compressor Desulfurizer 2 Atmosphere Raw Water RO system Pre-reformer PCS Anode P MCFC Stack Vaporizer DC AC Cathode 5 Cathode recycle Catalytic Combustor Air Filter Blower Startup Heater HEX Heat exchanger Startup heater B 4 Vaporizer Water treatment

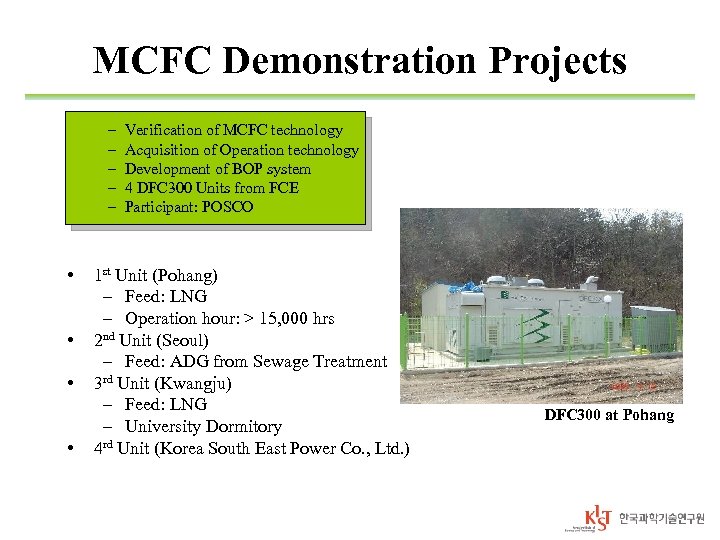

MCFC Demonstration Projects – – – • • Verification of MCFC technology Acquisition of Operation technology Development of BOP system 4 DFC 300 Units from FCE Participant: POSCO 1 st Unit (Pohang) – Feed: LNG – Operation hour: > 15, 000 hrs 2 nd Unit (Seoul) – Feed: ADG from Sewage Treatment 3 rd Unit (Kwangju) – Feed: LNG – University Dormitory 4 rd Unit (Korea South East Power Co. , Ltd. ) DFC 300 at Pohang

MCFC Demonstration Projects – – – • • Verification of MCFC technology Acquisition of Operation technology Development of BOP system 4 DFC 300 Units from FCE Participant: POSCO 1 st Unit (Pohang) – Feed: LNG – Operation hour: > 15, 000 hrs 2 nd Unit (Seoul) – Feed: ADG from Sewage Treatment 3 rd Unit (Kwangju) – Feed: LNG – University Dormitory 4 rd Unit (Korea South East Power Co. , Ltd. ) DFC 300 at Pohang

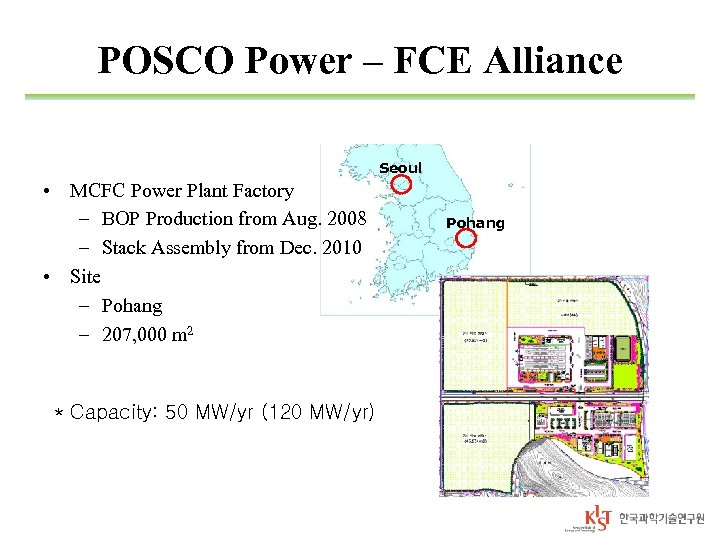

POSCO Power – FCE Alliance Seoul • MCFC Power Plant Factory – BOP Production from Aug. 2008 – Stack Assembly from Dec. 2010 • Site – Pohang – 207, 000 m 2 * Capacity: 50 MW/yr (120 MW/yr) Pohang

POSCO Power – FCE Alliance Seoul • MCFC Power Plant Factory – BOP Production from Aug. 2008 – Stack Assembly from Dec. 2010 • Site – Pohang – 207, 000 m 2 * Capacity: 50 MW/yr (120 MW/yr) Pohang

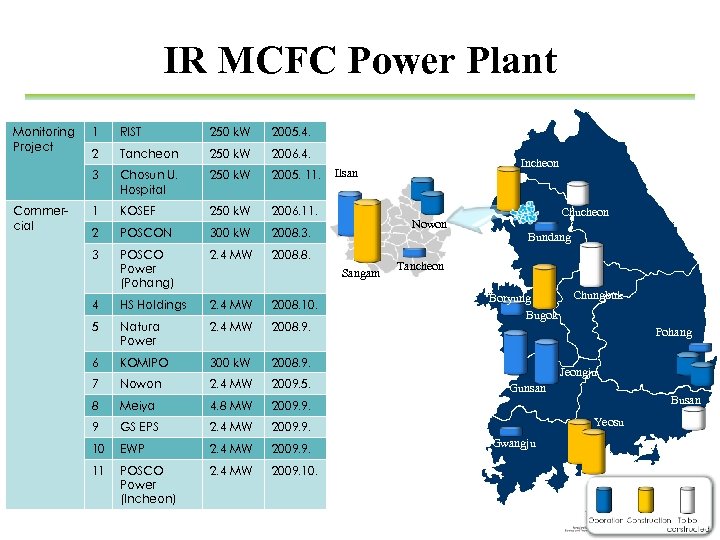

IR MCFC Power Plant No. Commercial Capacity Date 1 RIST 250 k. W 2005. 4. 2 Tancheon 250 k. W 2006. 4. 3 Monitoring Project Location Chosun U. Hospital 250 k. W 2005. 11. 1 KOSEF 250 k. W 2006. 11. 2 POSCON 300 k. W 2008. 3. 3 POSCO Power (Pohang) 2. 4 MW 2008. 8. 4 HS Holdings 2. 4 MW 2008. 10. 5 Natura Power 2. 4 MW 2008. 9. 6 KOMIPO 300 k. W 2008. 9. 7 Nowon 2. 4 MW 2009. 5. 8 Meiya 4. 8 MW 2009. 9. 9 GS EPS 2. 4 MW 2009. 9. 10 EWP 2. 4 MW 2009. 9. 11 POSCO Power (Incheon) 2. 4 MW 2009. 10. Incheon Ilsan Nowon Sangam Chucheon Bundang Tancheon Boryung Bugok Chungbuk Pohang Jeongju Gunsan Busan Yeosu Gwangju

IR MCFC Power Plant No. Commercial Capacity Date 1 RIST 250 k. W 2005. 4. 2 Tancheon 250 k. W 2006. 4. 3 Monitoring Project Location Chosun U. Hospital 250 k. W 2005. 11. 1 KOSEF 250 k. W 2006. 11. 2 POSCON 300 k. W 2008. 3. 3 POSCO Power (Pohang) 2. 4 MW 2008. 8. 4 HS Holdings 2. 4 MW 2008. 10. 5 Natura Power 2. 4 MW 2008. 9. 6 KOMIPO 300 k. W 2008. 9. 7 Nowon 2. 4 MW 2009. 5. 8 Meiya 4. 8 MW 2009. 9. 9 GS EPS 2. 4 MW 2009. 9. 10 EWP 2. 4 MW 2009. 9. 11 POSCO Power (Incheon) 2. 4 MW 2009. 10. Incheon Ilsan Nowon Sangam Chucheon Bundang Tancheon Boryung Bugok Chungbuk Pohang Jeongju Gunsan Busan Yeosu Gwangju

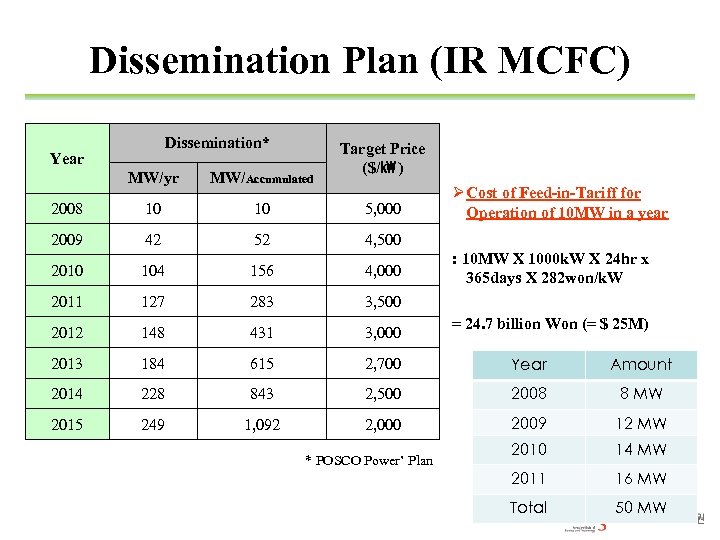

Dissemination Plan (IR MCFC) Dissemination* Year Target Price ($/㎾ ) MW/yr MW/Accumulated 2008 10 10 5, 000 2009 42 52 4, 500 2010 104 156 4, 000 2011 127 283 3, 500 2012 148 431 3, 000 2013 184 615 2, 700 Year Amount 2014 228 843 2, 500 2008 8 MW 2015 249 1, 092 2, 000 2009 12 MW 2010 14 MW 2011 16 MW Total 50 MW * POSCO Power’ Plan Ø Cost of Feed-in-Tariff for Operation of 10 MW in a year : 10 MW X 1000 k. W X 24 hr x 365 days X 282 won/k. W = 24. 7 billion Won (= $ 25 M)

Dissemination Plan (IR MCFC) Dissemination* Year Target Price ($/㎾ ) MW/yr MW/Accumulated 2008 10 10 5, 000 2009 42 52 4, 500 2010 104 156 4, 000 2011 127 283 3, 500 2012 148 431 3, 000 2013 184 615 2, 700 Year Amount 2014 228 843 2, 500 2008 8 MW 2015 249 1, 092 2, 000 2009 12 MW 2010 14 MW 2011 16 MW Total 50 MW * POSCO Power’ Plan Ø Cost of Feed-in-Tariff for Operation of 10 MW in a year : 10 MW X 1000 k. W X 24 hr x 365 days X 282 won/k. W = 24. 7 billion Won (= $ 25 M)

MCFC for Power Plant (summary) • Future direction of R&D for external reforming MCFC is very uncertain. • For internal reforming MCFC, market expansion entirely depends upon government support program and cost reduction.

MCFC for Power Plant (summary) • Future direction of R&D for external reforming MCFC is very uncertain. • For internal reforming MCFC, market expansion entirely depends upon government support program and cost reduction.

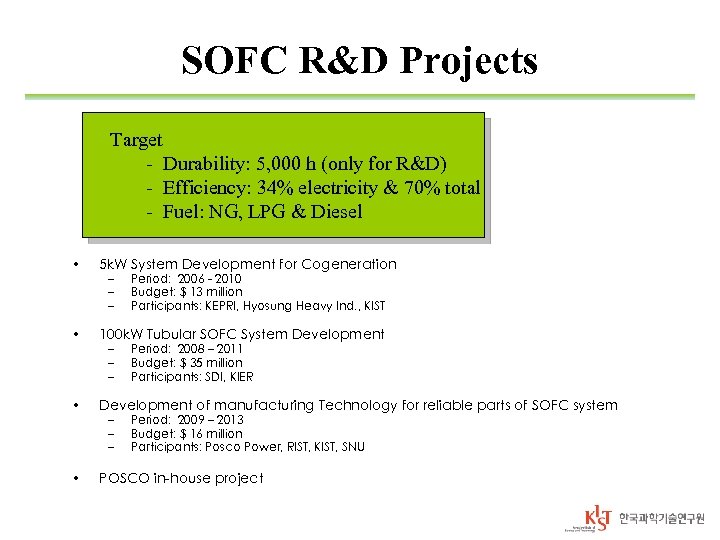

SOFC R&D Projects Target - Durability: 5, 000 h (only for R&D) - Efficiency: 34% electricity & 70% total - Fuel: NG, LPG & Diesel • 5 k. W System Development for Cogeneration • 100 k. W Tubular SOFC System Development • Development of manufacturing Technology for reliable parts of SOFC system • POSCO in-house project – – – – – Period: 2006 - 2010 Budget: $ 13 million Participants: KEPRI, Hyosung Heavy Ind. , KIST Period: 2008 – 2011 Budget: $ 35 million Participants: SDI, KIER Period: 2009 – 2013 Budget: $ 16 million Participants: Posco Power, RIST, KIST, SNU

SOFC R&D Projects Target - Durability: 5, 000 h (only for R&D) - Efficiency: 34% electricity & 70% total - Fuel: NG, LPG & Diesel • 5 k. W System Development for Cogeneration • 100 k. W Tubular SOFC System Development • Development of manufacturing Technology for reliable parts of SOFC system • POSCO in-house project – – – – – Period: 2006 - 2010 Budget: $ 13 million Participants: KEPRI, Hyosung Heavy Ind. , KIST Period: 2008 – 2011 Budget: $ 35 million Participants: SDI, KIER Period: 2009 – 2013 Budget: $ 16 million Participants: Posco Power, RIST, KIST, SNU

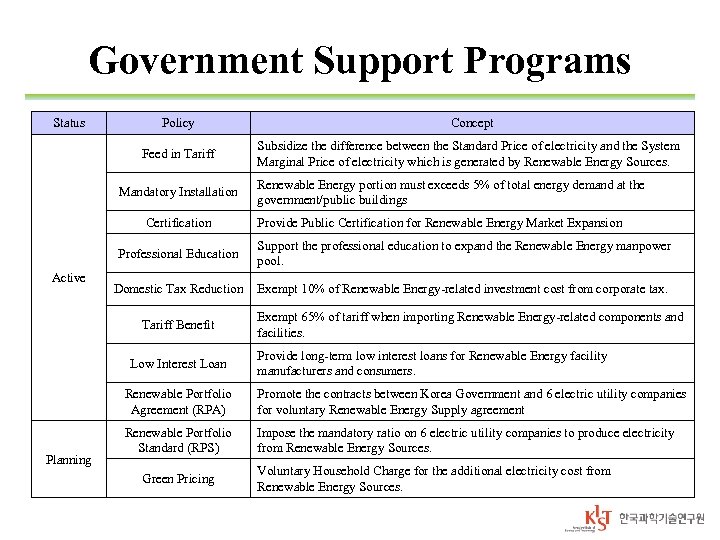

Government Support Programs Status Policy Concept Feed in Tariff Subsidize the difference between the Standard Price of electricity and the System Marginal Price of electricity which is generated by Renewable Energy Sources. Mandatory Installation Certification Renewable Energy portion must exceeds 5% of total energy demand at the government/public buildings Provide Public Certification for Renewable Energy Market Expansion Professional Education Active Support the professional education to expand the Renewable Energy manpower pool. Domestic Tax Reduction Exempt 10% of Renewable Energy-related investment cost from corporate tax. Tariff Benefit Low Interest Loan Exempt 65% of tariff when importing Renewable Energy-related components and facilities. Provide long-term low interest loans for Renewable Energy facility manufacturers and consumers. Renewable Portfolio Agreement (RPA) Planning Promote the contracts between Korea Government and 6 electric utility companies for voluntary Renewable Energy Supply agreement Renewable Portfolio Standard (RPS) Impose the mandatory ratio on 6 electric utility companies to produce electricity from Renewable Energy Sources. Green Pricing Voluntary Household Charge for the additional electricity cost from Renewable Energy Sources.

Government Support Programs Status Policy Concept Feed in Tariff Subsidize the difference between the Standard Price of electricity and the System Marginal Price of electricity which is generated by Renewable Energy Sources. Mandatory Installation Certification Renewable Energy portion must exceeds 5% of total energy demand at the government/public buildings Provide Public Certification for Renewable Energy Market Expansion Professional Education Active Support the professional education to expand the Renewable Energy manpower pool. Domestic Tax Reduction Exempt 10% of Renewable Energy-related investment cost from corporate tax. Tariff Benefit Low Interest Loan Exempt 65% of tariff when importing Renewable Energy-related components and facilities. Provide long-term low interest loans for Renewable Energy facility manufacturers and consumers. Renewable Portfolio Agreement (RPA) Planning Promote the contracts between Korea Government and 6 electric utility companies for voluntary Renewable Energy Supply agreement Renewable Portfolio Standard (RPS) Impose the mandatory ratio on 6 electric utility companies to produce electricity from Renewable Energy Sources. Green Pricing Voluntary Household Charge for the additional electricity cost from Renewable Energy Sources.