9499fed258d8be6822679c44ab82afb4.ppt

- Количество слайдов: 18

Klean Korea Corp. www. kleankorea. co. kr 1

Klean Korea Corp. www. kleankorea. co. kr 1

Introduction Klean Korea Corp. Headquater (Pyeongtaek Plant) - Re-refining of Waste Oil - Parts Washer Business 2 nd Plant(Ankang Plant) - Treatment of various Hazardous Wastes - Solvent Recycling - Production of W. D. F and other relevant products 2

Introduction Klean Korea Corp. Headquater (Pyeongtaek Plant) - Re-refining of Waste Oil - Parts Washer Business 2 nd Plant(Ankang Plant) - Treatment of various Hazardous Wastes - Solvent Recycling - Production of W. D. F and other relevant products 2

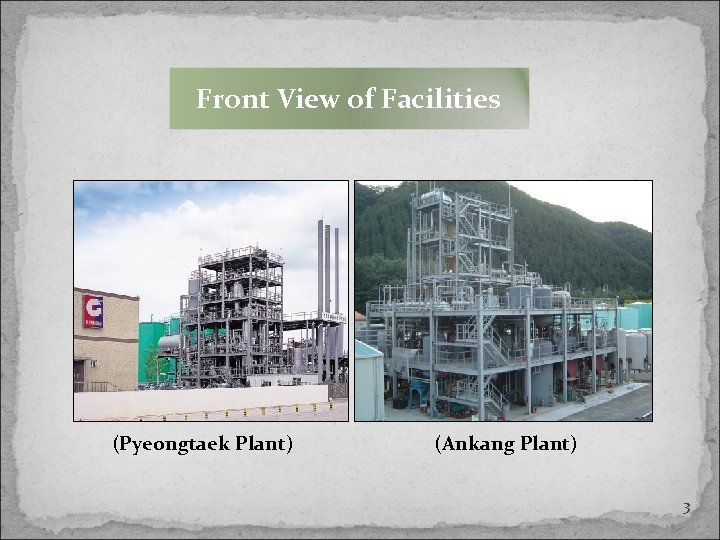

Front View of Facilities (Pyeongtaek Plant) (Ankang Plant) 3

Front View of Facilities (Pyeongtaek Plant) (Ankang Plant) 3

Business Policies 1. Business based on Principle and Transparency 2. Respect Individual Ability and Creative mind 3. Get the Best Market Share in Recycling Market 4. Be the Front Runner in Developing the New Market 4

Business Policies 1. Business based on Principle and Transparency 2. Respect Individual Ability and Creative mind 3. Get the Best Market Share in Recycling Market 4. Be the Front Runner in Developing the New Market 4

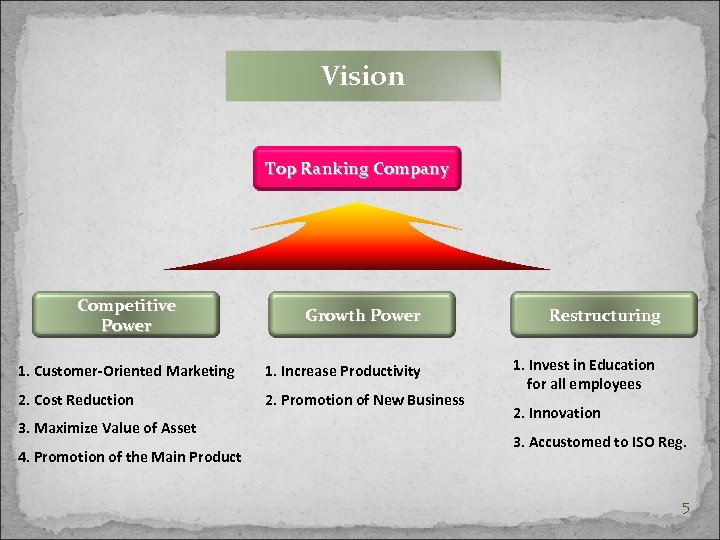

Vision Top Ranking Company Competitive Power Growth Power 1. Customer-Oriented Marketing 1. Increase Productivity 2. Cost Reduction 2. Promotion of New Business 3. Maximize Value of Asset 4. Promotion of the Main Product Restructuring 1. Invest in Education for all employees 2. Innovation 3. Accustomed to ISO Reg. 5

Vision Top Ranking Company Competitive Power Growth Power 1. Customer-Oriented Marketing 1. Increase Productivity 2. Cost Reduction 2. Promotion of New Business 3. Maximize Value of Asset 4. Promotion of the Main Product Restructuring 1. Invest in Education for all employees 2. Innovation 3. Accustomed to ISO Reg. 5

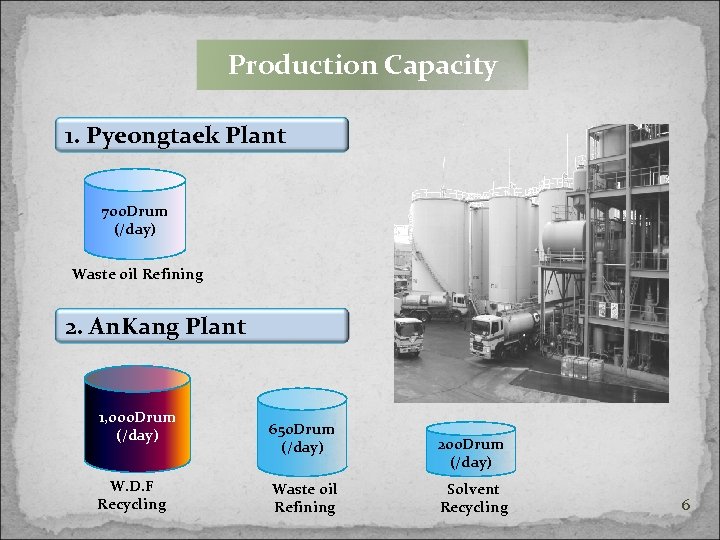

Production Capacity 1. Pyeongtaek Plant 700 Drum (/day) Waste oil Refining 2. An. Kang Plant 1, 000 Drum (/day) W. D. F Recycling 650 Drum (/day) Waste oil Refining 200 Drum (/day) Solvent Recycling 6

Production Capacity 1. Pyeongtaek Plant 700 Drum (/day) Waste oil Refining 2. An. Kang Plant 1, 000 Drum (/day) W. D. F Recycling 650 Drum (/day) Waste oil Refining 200 Drum (/day) Solvent Recycling 6

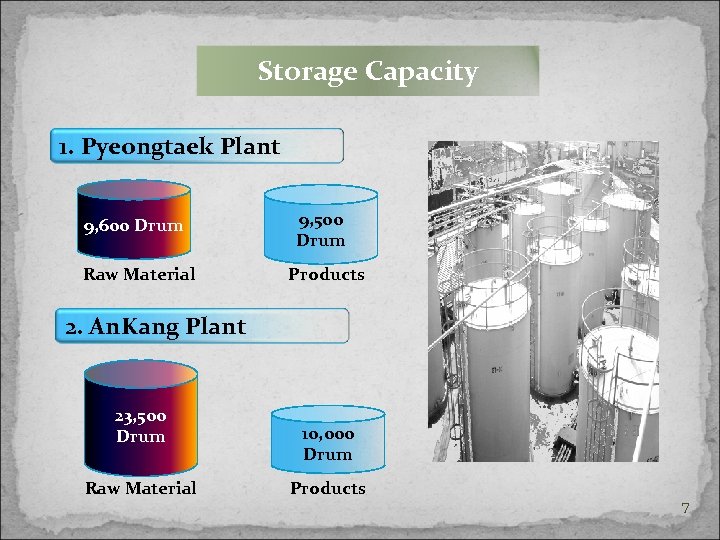

Storage Capacity 1. Pyeongtaek Plant 9, 600 Drum Raw Material 9, 500 Drum Products 2. An. Kang Plant 23, 500 Drum Raw Material 10, 000 Drum Products 7

Storage Capacity 1. Pyeongtaek Plant 9, 600 Drum Raw Material 9, 500 Drum Products 2. An. Kang Plant 23, 500 Drum Raw Material 10, 000 Drum Products 7

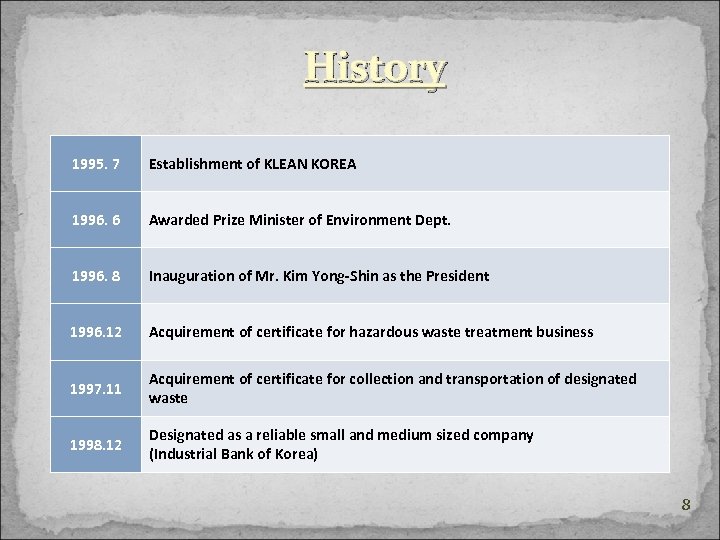

History 1995. 7 Establishment of KLEAN KOREA 1996. 6 Awarded Prize Minister of Environment Dept. 1996. 8 Inauguration of Mr. Kim Yong-Shin as the President 1996. 12 Acquirement of certificate for hazardous waste treatment business 1997. 11 Acquirement of certificate for collection and transportation of designated waste 1998. 12 Designated as a reliable small and medium sized company (Industrial Bank of Korea) 8

History 1995. 7 Establishment of KLEAN KOREA 1996. 6 Awarded Prize Minister of Environment Dept. 1996. 8 Inauguration of Mr. Kim Yong-Shin as the President 1996. 12 Acquirement of certificate for hazardous waste treatment business 1997. 11 Acquirement of certificate for collection and transportation of designated waste 1998. 12 Designated as a reliable small and medium sized company (Industrial Bank of Korea) 8

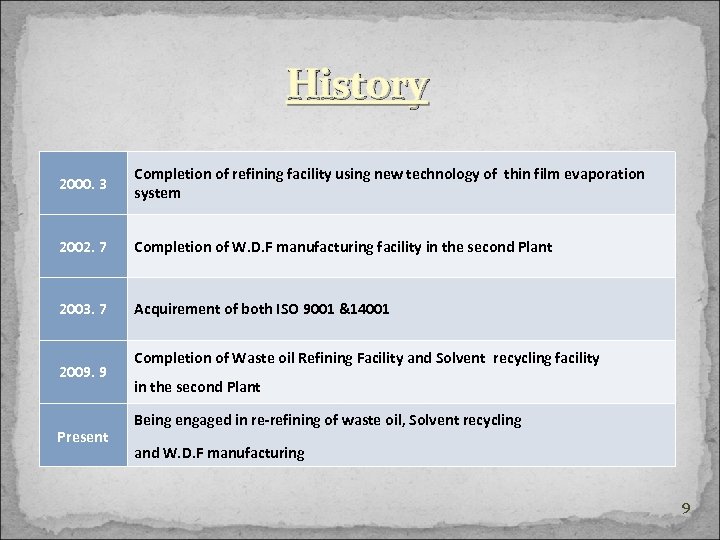

History 2000. 3 Completion of refining facility using new technology of thin film evaporation system 2002. 7 Completion of W. D. F manufacturing facility in the second Plant 2003. 7 Acquirement of both ISO 9001 &14001 2009. 9 Present Completion of Waste oil Refining Facility and Solvent recycling facility in the second Plant Being engaged in re-refining of waste oil, Solvent recycling and W. D. F manufacturing 9

History 2000. 3 Completion of refining facility using new technology of thin film evaporation system 2002. 7 Completion of W. D. F manufacturing facility in the second Plant 2003. 7 Acquirement of both ISO 9001 &14001 2009. 9 Present Completion of Waste oil Refining Facility and Solvent recycling facility in the second Plant Being engaged in re-refining of waste oil, Solvent recycling and W. D. F manufacturing 9

Awards 1999. 06 Awarded Prize Minister of Environment Dept. 2002. 06 Awarded “Grand Environmental Prize” from Prime Minister 2004. 03 Awarded “Prime Minister’s Prize ” 2005. 06 Awarded “the Prize of Ministry of Environment” 2006. 06 Awarded “President’s Prize” 2006. 06 Awarded “Grand Environmental Prize” by chosun-daily 10

Awards 1999. 06 Awarded Prize Minister of Environment Dept. 2002. 06 Awarded “Grand Environmental Prize” from Prime Minister 2004. 03 Awarded “Prime Minister’s Prize ” 2005. 06 Awarded “the Prize of Ministry of Environment” 2006. 06 Awarded “President’s Prize” 2006. 06 Awarded “Grand Environmental Prize” by chosun-daily 10

Sales (Unit: Million Won) 20, 000 11

Sales (Unit: Million Won) 20, 000 11

Main Products 1. Re-refined Fuel(Vacuumed) It is used for heating fuel in Industrial Facilities instead of Diesel or Kerosene 2. Re-refined Fuel(Ion) It is used for heating fuel in Industrial Facilities instead of Bunker C Oil 3. W. D. F(Wastes Derived Fuel) It is supplementary Fuel for Soft Coal in Cement Manufacture Facilities 12

Main Products 1. Re-refined Fuel(Vacuumed) It is used for heating fuel in Industrial Facilities instead of Diesel or Kerosene 2. Re-refined Fuel(Ion) It is used for heating fuel in Industrial Facilities instead of Bunker C Oil 3. W. D. F(Wastes Derived Fuel) It is supplementary Fuel for Soft Coal in Cement Manufacture Facilities 12

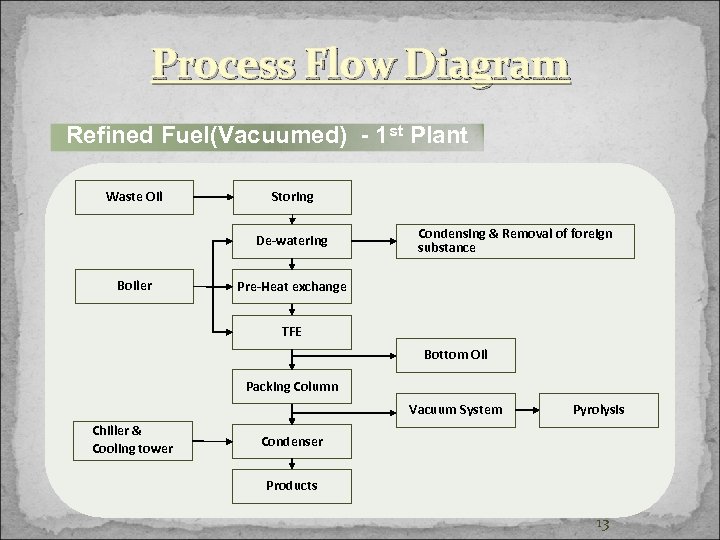

Process Flow Diagram Refined Fuel(Vacuumed) - 1 st Plant Waste Oil Storing De-watering Boiler Condensing & Removal of foreign substance Pre-Heat exchange TFE Bottom Oil Packing Column Vacuum System Chiller & Cooling tower Pyrolysis Condenser Products 13

Process Flow Diagram Refined Fuel(Vacuumed) - 1 st Plant Waste Oil Storing De-watering Boiler Condensing & Removal of foreign substance Pre-Heat exchange TFE Bottom Oil Packing Column Vacuum System Chiller & Cooling tower Pyrolysis Condenser Products 13

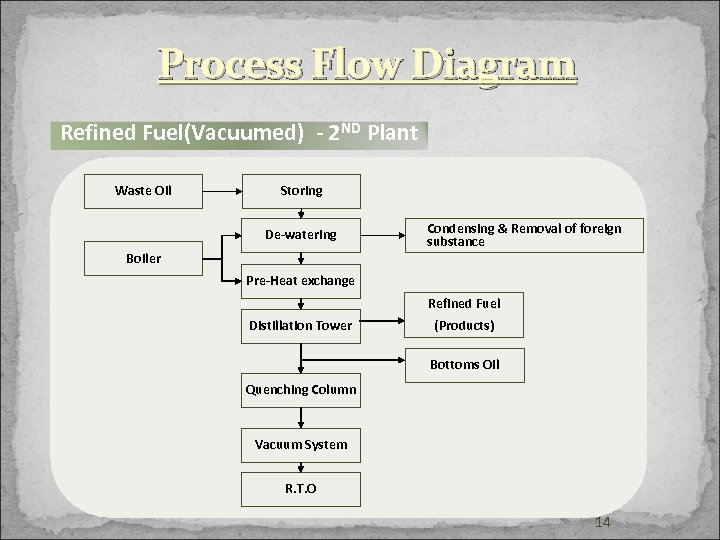

Process Flow Diagram Refined Fuel(Vacuumed) - 2 ND Plant Waste Oil Storing De-watering Boiler Condensing & Removal of foreign substance Pre-Heat exchange Refined Fuel Distillation Tower (Products) Bottoms Oil Quenching Column Vacuum System R. T. O 14

Process Flow Diagram Refined Fuel(Vacuumed) - 2 ND Plant Waste Oil Storing De-watering Boiler Condensing & Removal of foreign substance Pre-Heat exchange Refined Fuel Distillation Tower (Products) Bottoms Oil Quenching Column Vacuum System R. T. O 14

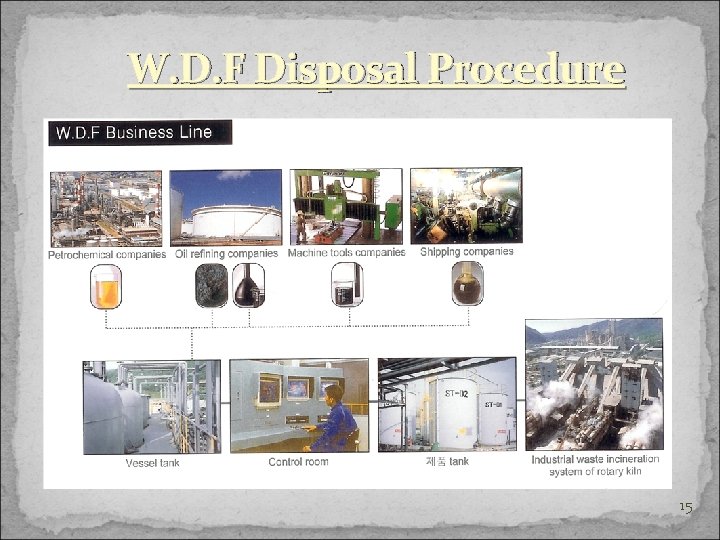

W. D. F Disposal Procedure 15

W. D. F Disposal Procedure 15

The 21 st Century “Investment on education is one for the country and the future. ” “As a spearhead of environment industry, we have grown up on the management philosophy of principle and transparency. ” 16

The 21 st Century “Investment on education is one for the country and the future. ” “As a spearhead of environment industry, we have grown up on the management philosophy of principle and transparency. ” 16

The Latest News Broadcasted on the famous TV program 17

The Latest News Broadcasted on the famous TV program 17

경영지원팀 심희창 과장 010 -8770 -8131 shimhc@kleankorea. co. kr 김태수 사원 010 -3314 -1901 tskim@kleankorea. co. kr 18

경영지원팀 심희창 과장 010 -8770 -8131 shimhc@kleankorea. co. kr 김태수 사원 010 -3314 -1901 tskim@kleankorea. co. kr 18