98e9a89ddcc9291174adef2f169015f3.ppt

- Количество слайдов: 36

Khaled Mostafa, ABB Electrical Industries, Nov. 2012. New Trends in process Automation Power of Integration

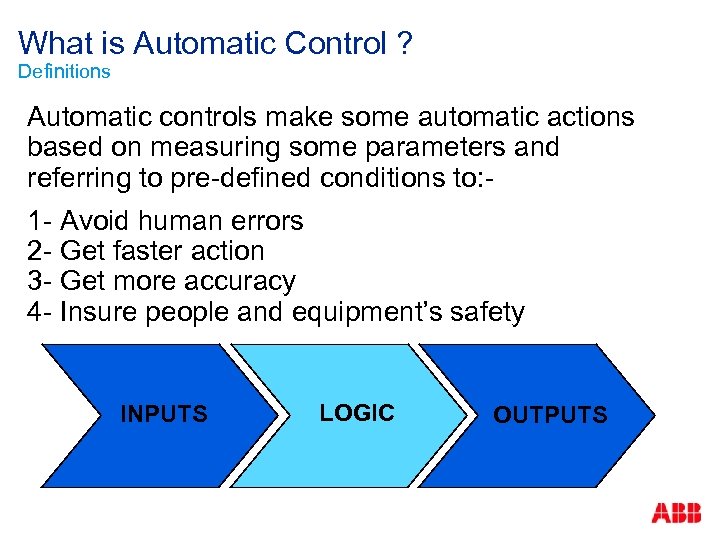

What is Automatic Control ? Definitions Automatic controls make some automatic actions based on measuring some parameters and referring to pre-defined conditions to: 1 - Avoid human errors 2 - Get faster action 3 - Get more accuracy 4 - Insure people and equipment’s safety INPUTS LOGIC OUTPUTS

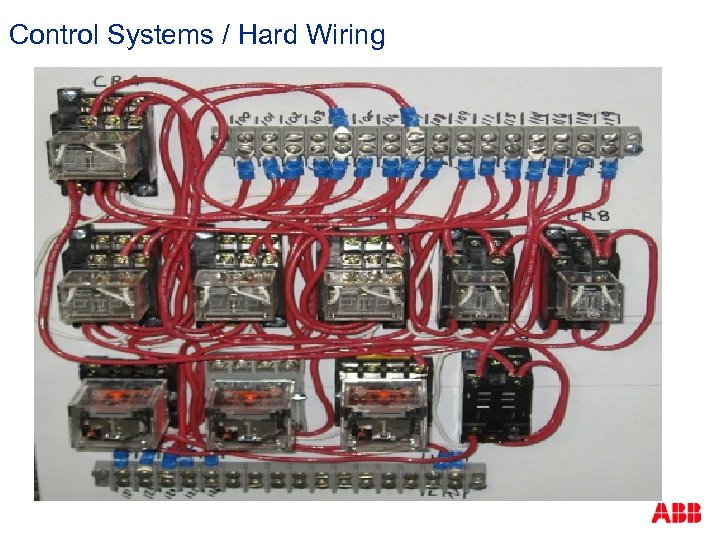

Process Automation Basics Hard wiring Logic Gates Micro Controller

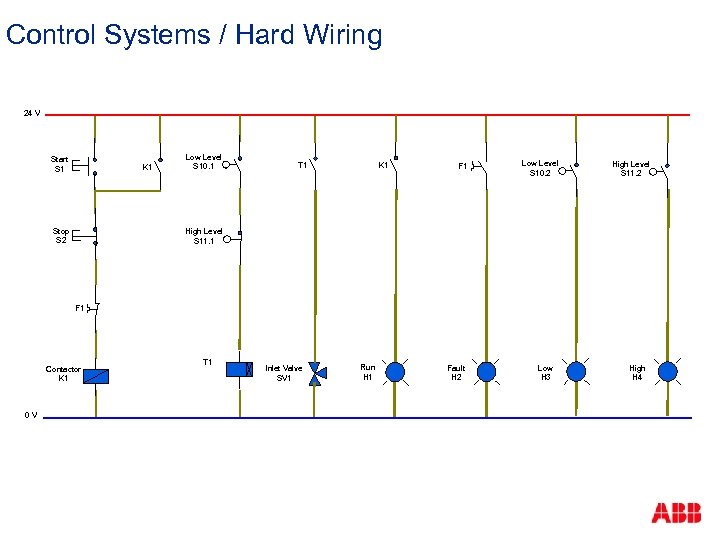

Control Systems / Hard Wiring 24 V Start S 1 K 1 Stop S 2 Low Level S 10. 1 K 1 T 1 F 1 Low Level S 10. 2 High Level S 11. 1 F 1 Contactor K 1 0 V T 1 Inlet Valve SV 1 Run H 1 Fault H 2 Low H 3 High H 4

Control Systems / Hard Wiring

The Process Industry Hardwiring

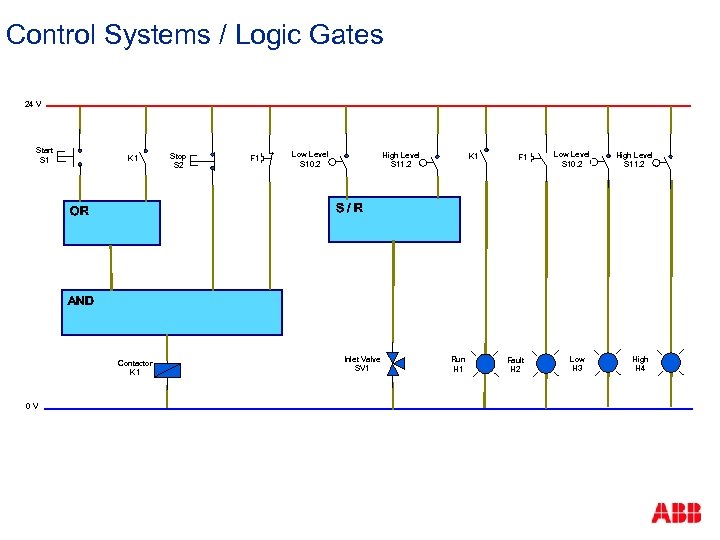

Control Systems / Logic Gates 24 V Start S 1 K 1 Stop S 2 F 1 Low Level S 10. 2 High Level S 11. 2 K 1 F 1 Low Level S 10. 2 High Level S 11. 2 S/R OR AND Contactor K 1 0 V Inlet Valve SV 1 Run H 1 Fault H 2 Low H 3 High H 4

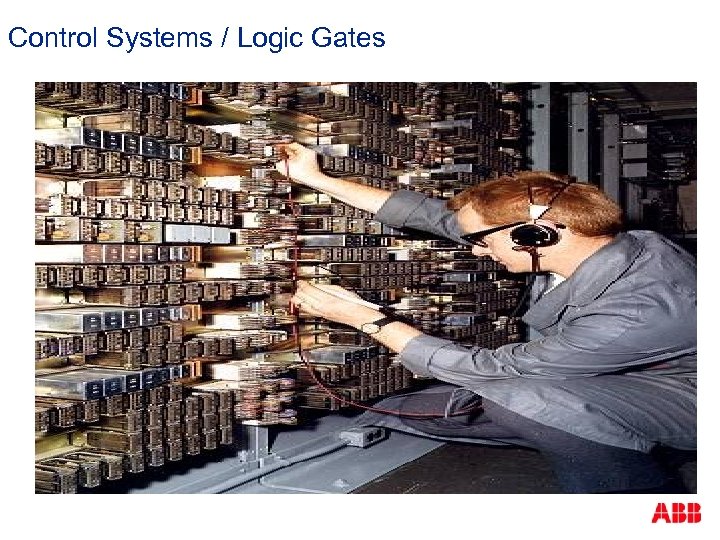

Control Systems / Logic Gates

The Process Industry Logic Gates

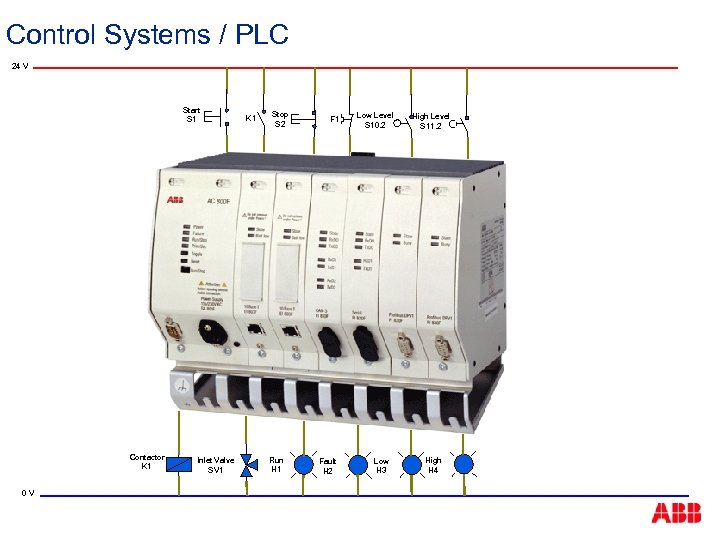

Control Systems / PLC 24 V Start S 1 Contactor K 1 0 V Inlet Valve SV 1 K 1 Stop S 2 Run H 1 Fault H 2 Low Level S 10. 2 Low H 3 High Level S 11. 2 High H 4

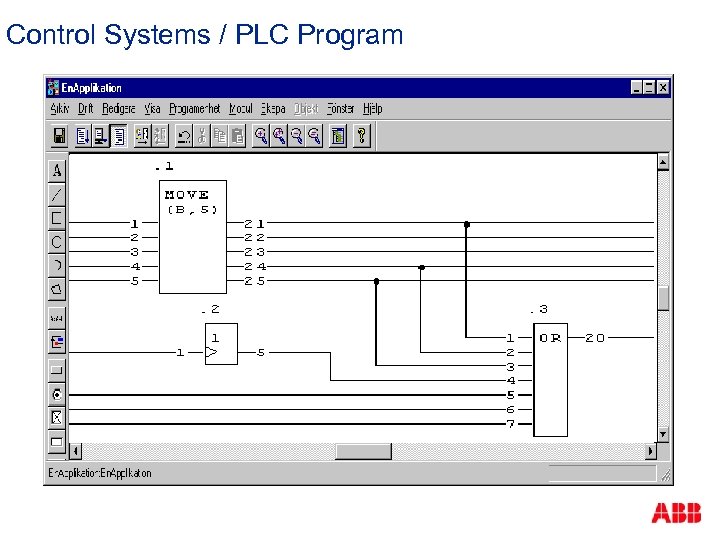

Control Systems / PLC Program

Control Systems Low Maintenance Cost

The Process Industry Operator Interface

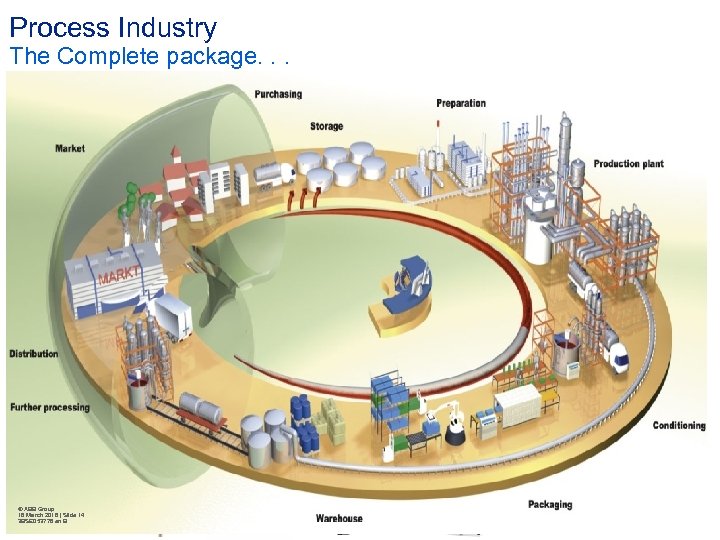

Process Industry The Complete package. . . © ABB Group 16 March 2018 | Slide 14 3 BSE 053778 en B

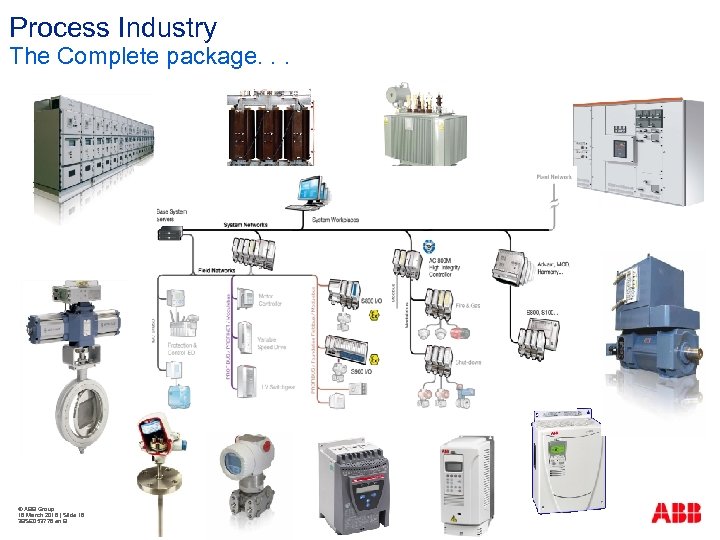

Process Industry The Complete package. . . © ABB Group 16 March 2018 | Slide 15 3 BSE 053778 en B

Process Industry The Complete package. . . © ABB Group 16 March 2018 | Slide 16 3 BSE 053778 en B

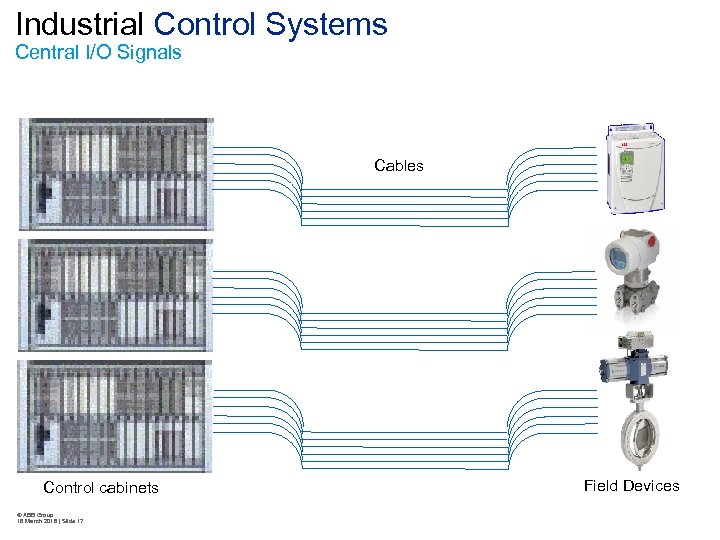

Industrial Control Systems Central I/O Signals Cables Control cabinets © ABB Group 16 March 2018 | Slide 17 Field Devices

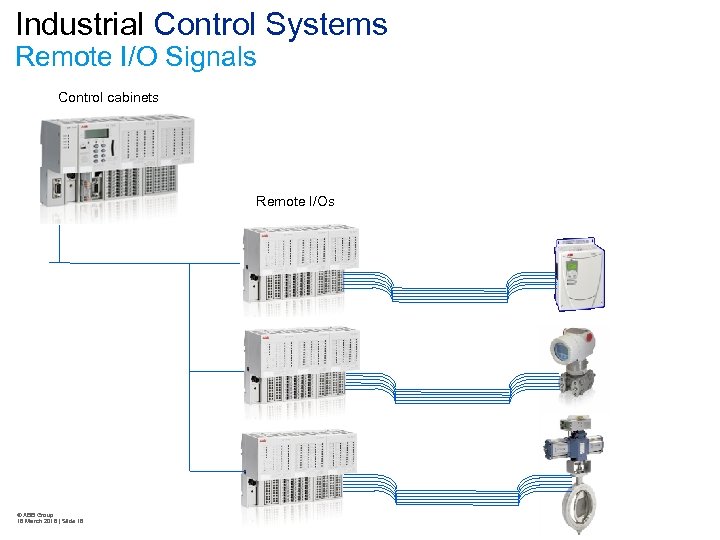

Industrial Control Systems Remote I/O Signals Control cabinets Remote I/Os © ABB Group 16 March 2018 | Slide 18

Industrial Control Systems Field Buses Control cabinets Field Devices

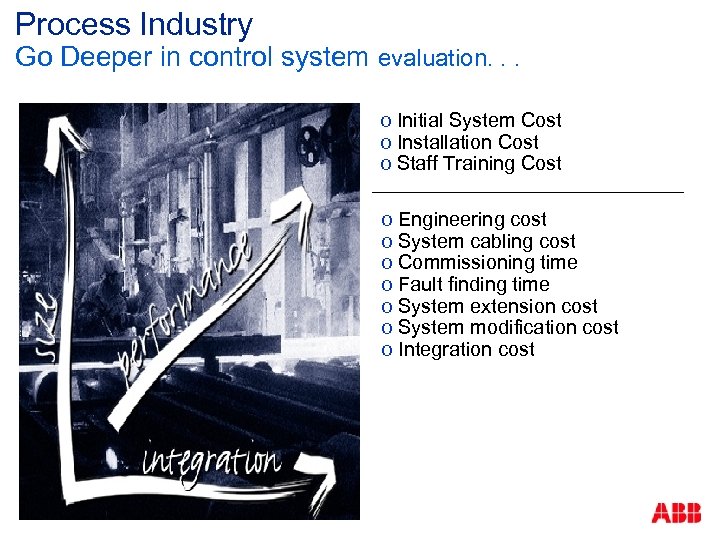

Process Industry Go Deeper in control system evaluation. . . o Initial System Cost o Installation Cost o Staff Training Cost o Engineering cost o System cabling cost o Commissioning time o Fault finding time o System extension cost o System modification cost o Integration cost

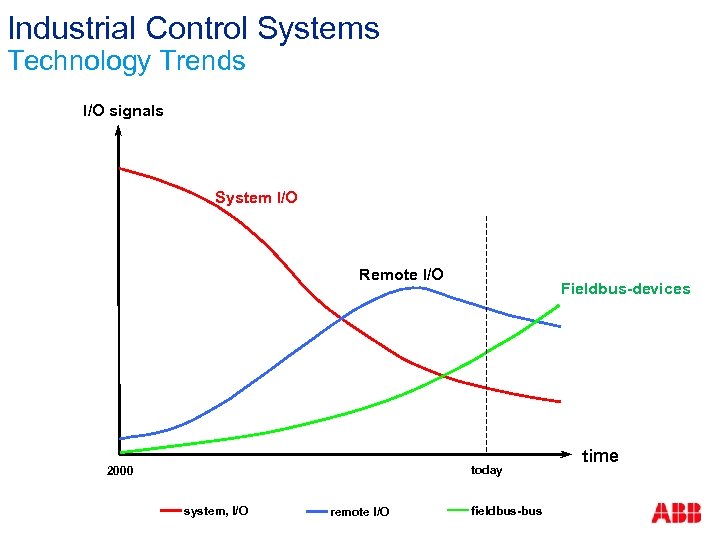

Industrial Control Systems Technology Trends I/O signals System I/O Remote I/O Fieldbus-devices today 2000 system, I/O remote I/O fieldbus-bus time

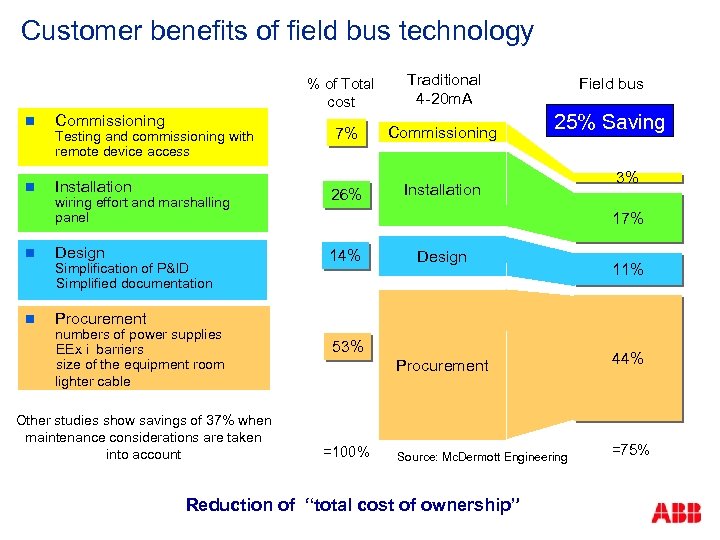

Customer benefits of field bus technology % of Total cost n Commissioning Testing and commissioning with remote device access n Installation wiring effort and marshalling panel n Design Simplification of P&ID Simplified documentation n Traditional 4 -20 m. A 7% Commissioning 26% Field bus 25% Saving Installation 3% 17% 14% Design 11% Procurement numbers of power supplies EEx i barriers size of the equipment room lighter cable Other studies show savings of 37% when maintenance considerations are taken into account 53% Procurement =100% Source: Mc. Dermott Engineering Reduction of “total cost of ownership” 44% =75%

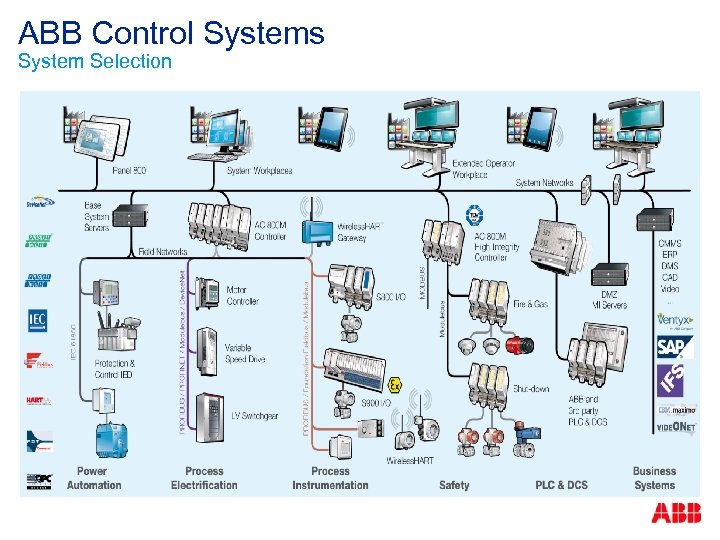

ABB Control Systems System Selection

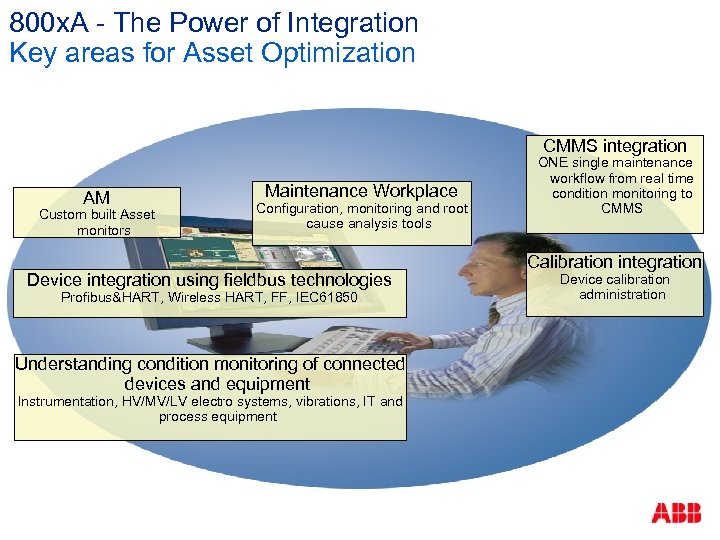

800 x. A - The Power of Integration Key areas for Asset Optimization CMMS integration AM Custom built Asset monitors Maintenance Workplace Configuration, monitoring and root cause analysis tools Device integration using fieldbus technologies Profibus&HART, Wireless HART, FF, IEC 61850 Understanding condition monitoring of connected devices and equipment Instrumentation, HV/MV/LV electro systems, vibrations, IT and process equipment ONE single maintenance workflow from real time condition monitoring to CMMS Calibration integration Device calibration administration

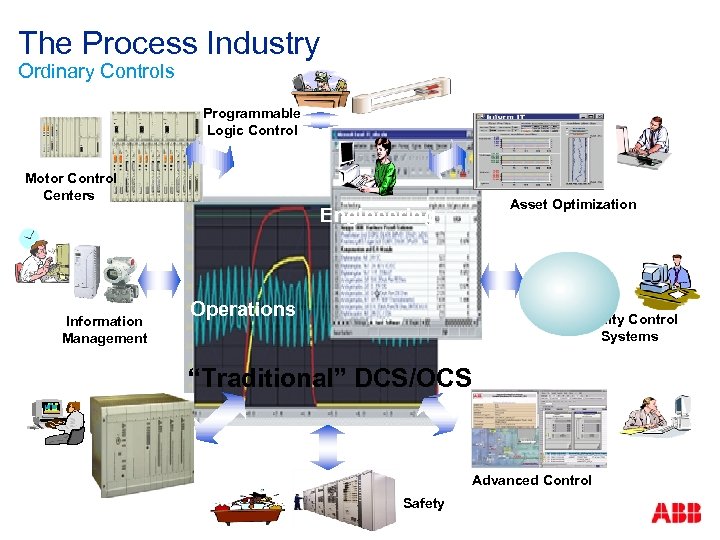

The Process Industry Ordinary Controls Programmable Logic Control Motor Control Centers Information Management Process Control Engineering Asset Optimization Operations Quality Control Systems “Traditional” DCS/OCS Advanced Control Safety

The Process Industry Modern Controls Process and Logic Control Asset Optimization Motor Control Centers Operations Engineering Information Management An Industrial. IT System Instrumentation & Drives Safety Advanced Control And Industry Solutions Quality Control Systems

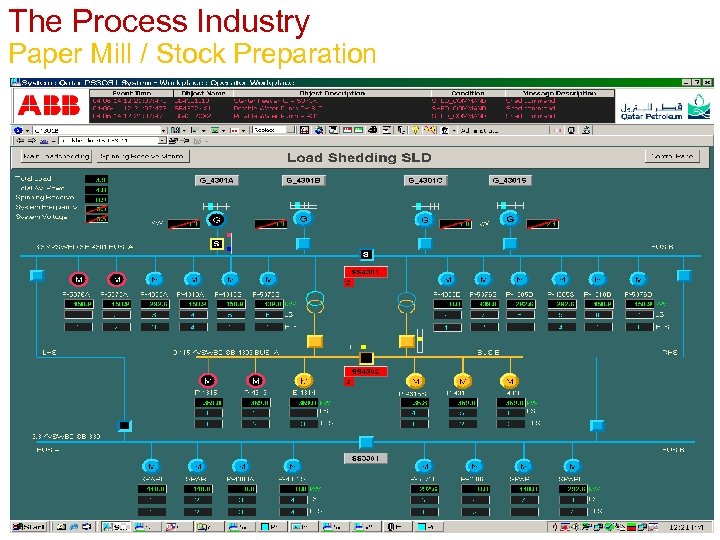

The Process Industry Paper Mill / Stock Preparation

The Process Industry Power Management System 3. 9 MW 4. 8 MW 1. 5 MW 50. 12. Hz 3. 3 k. V MW 0. 0 MW 1. 8 MW 2. 1 MW

Khaled Mostafa, Nov. 2012 Energy Index Improvement Sugar Industry © ABB Month DD, YYYY | Slide 29

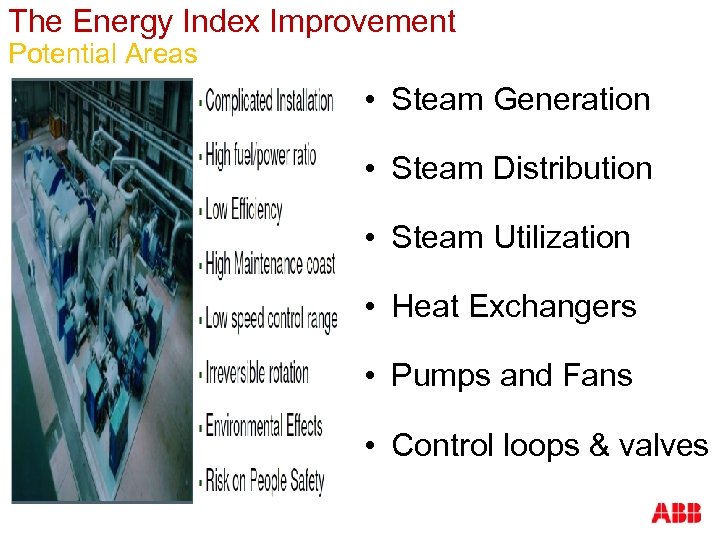

The Energy Index Improvement Potential Areas • Steam Generation • Steam Distribution • Steam Utilization • Heat Exchangers • Pumps and Fans • Control loops & valves

The Energy Index Improvement Example 30% Efficiency Steam Turbines Driving Sugar Cane Mills, Fans and Pumps

The Energy Index Improvement Steam Turbines in Sugar Mills

The Energy Index Improvement Replace Steam Turbines with VSD

The Energy Index Improvement Electric Drives 45% Efficiency Steam Turbines to drive Electric Generators, feeding VSD

Electric Motors vs Steam Turbines Higher Efficiency Flexible Control Easy Maintenance Use of excess Power Less Footprint, space saving Simple Construction

© ABB Group 16 March 2018 | Slide 36

98e9a89ddcc9291174adef2f169015f3.ppt