226da445608acf66e822ec01f01faa1c.ppt

- Количество слайдов: 10

Key R&D Activities for the LSST Camera DOE HEP Program Review June 13, 2007 Kirk Gilmore (SLAC) LSST Camera Manager Do. E HEP Program Review June 13, 2007

Key R&D Activities for the LSST Camera DOE HEP Program Review June 13, 2007 Kirk Gilmore (SLAC) LSST Camera Manager Do. E HEP Program Review June 13, 2007

LSST Camera Team Members Brandeis J. Bensiger, K. Hashemi, H. Wellenstein Brookhaven National Lab S. Aronson, C. Buttehorn, J. Frank, J. Haggerty, P. Kuczewski, M. May, P. O’Connor, V. Radeka, P. Takacs Florida State H. Wahl Harvard University N. Felt, J. Geary (Cf. A), J. Oliver, C. Stubbs Lawrence Livermore National Lab S. Asztalos, K. Baker, L. Hale, S. Olivier, D. Phillion, L. Seppala, W. Wistler Oak Ridge National Laboratory P. Stankus, G. Young, V. Cianciolo, C. Britton (joint faculty UT) N. Ericson (joint faculty UT) Ohio State University K. Honscheid, R. Hughes, B. Winer Purdue I. Shipsey, J. Peterson Rochester Institute of Technology D. Figer Stanford Linear Accelerator Center G. Bowden, P. Burchat (Stanford), D. Burke, M. Foss, K. Gilmore, G. Guiffre, M. Huffer, S. Kahn (Stanford), P. Kim, T. Lavine, S. Marshall, M. Nordby, M. Perl, L. Price, A. Rasmussen, D. Rich, R. Schindler, L. Simms (Stanford), T. Weber University of California, Berkeley J. G. Jernigan University of California, Davis P. Gee, A. Tyson University of California, Irvine D. Kirkby University of California, Santa Cruz T. Schalk University of Illinois, Urbana-Champaign J. Thaler University of Pennsylvania M. Newcomer, R. Van Berg University of Washington L. Rosenberg University of Tennessee B. Blalock, R. Chun Wayne State D. Cinabro 2

LSST Camera Team Members Brandeis J. Bensiger, K. Hashemi, H. Wellenstein Brookhaven National Lab S. Aronson, C. Buttehorn, J. Frank, J. Haggerty, P. Kuczewski, M. May, P. O’Connor, V. Radeka, P. Takacs Florida State H. Wahl Harvard University N. Felt, J. Geary (Cf. A), J. Oliver, C. Stubbs Lawrence Livermore National Lab S. Asztalos, K. Baker, L. Hale, S. Olivier, D. Phillion, L. Seppala, W. Wistler Oak Ridge National Laboratory P. Stankus, G. Young, V. Cianciolo, C. Britton (joint faculty UT) N. Ericson (joint faculty UT) Ohio State University K. Honscheid, R. Hughes, B. Winer Purdue I. Shipsey, J. Peterson Rochester Institute of Technology D. Figer Stanford Linear Accelerator Center G. Bowden, P. Burchat (Stanford), D. Burke, M. Foss, K. Gilmore, G. Guiffre, M. Huffer, S. Kahn (Stanford), P. Kim, T. Lavine, S. Marshall, M. Nordby, M. Perl, L. Price, A. Rasmussen, D. Rich, R. Schindler, L. Simms (Stanford), T. Weber University of California, Berkeley J. G. Jernigan University of California, Davis P. Gee, A. Tyson University of California, Irvine D. Kirkby University of California, Santa Cruz T. Schalk University of Illinois, Urbana-Champaign J. Thaler University of Pennsylvania M. Newcomer, R. Van Berg University of Washington L. Rosenberg University of Tennessee B. Blalock, R. Chun Wayne State D. Cinabro 2

Camera R&D Overview • Detector requirements: (Radeka/Geary - BNL/SAO) – 10 mm pixel size Pixel full-well > 90, 000 e– High QE 400 – 1000 nm – Low noise (< 5 e– rms), fast (< 2 sec) readout, stable T (-90 C) • Package large number of detectors, with integrated readout electronics, with high fill factor and serviceable design (O’Connor/Oliver - BNL/Harvard) • Sensor and focal plane precision alignment/stabilility/motion control Sensor flatness 5 u p-v, focal plane flatness 10 u p-v (Takacs/Rasmussen/Schindler - BNL/SLAC) • Cryostat contamination control - (Schindler - SLAC) • Fabricate large diameter (75 cm) filters with uniform coatings (Olivier - LLNL) • Data Acquisition/ Camera Control Protocol - (Schalk - UCSC) • Constrained volume (camera in beam) (Nordby - SLAC) –Makes shutter, filter exchange mechanisms challenging Do. E HEP Program Review June 13, 2007 3

Camera R&D Overview • Detector requirements: (Radeka/Geary - BNL/SAO) – 10 mm pixel size Pixel full-well > 90, 000 e– High QE 400 – 1000 nm – Low noise (< 5 e– rms), fast (< 2 sec) readout, stable T (-90 C) • Package large number of detectors, with integrated readout electronics, with high fill factor and serviceable design (O’Connor/Oliver - BNL/Harvard) • Sensor and focal plane precision alignment/stabilility/motion control Sensor flatness 5 u p-v, focal plane flatness 10 u p-v (Takacs/Rasmussen/Schindler - BNL/SLAC) • Cryostat contamination control - (Schindler - SLAC) • Fabricate large diameter (75 cm) filters with uniform coatings (Olivier - LLNL) • Data Acquisition/ Camera Control Protocol - (Schalk - UCSC) • Constrained volume (camera in beam) (Nordby - SLAC) –Makes shutter, filter exchange mechanisms challenging Do. E HEP Program Review June 13, 2007 3

Camera: International R&D Contributions Filter mechanism: M. Nordby (SLAC) The LPNHE team is taking responsibility of studying and prototyping. . . P. Antilogus (LPNHE) will act as contact scientist and G. Daubard (LPNHE) as technical contact. Shutter Development: M. Nordby (SLAC) Bonn Group is studying Gordon Bowden (SLAC) design. Dialog between Bonn and SLAC started. Klaus Reif of the University of Bonn is main contact and head of shutter group Filter development: K. Gilmore (SLAC) LSST is currently looking for qualified vendors to evaluate filters. R. Pain (LPNHE) and the LPNHE/Lyon teams will help coordinate SAGEM evaluation Analog signal processing ASIC: J. Oliver (Harvard) A joint LAL+LPNHE team will take responsibility of prototyping the FE ASIC. P. Antilogus (LPNHE) will act as contact scientist and V. Tocut (LAL) as technical contact. Software slow control: T. Schalk (SLAC/UCSC) The IN 2 P 3 groups will evaluate a possible contribution in the control software and hardware of the camera. P. Antilogus (LPNHE) will act as contact for this effort. Instrumental calibration: D. Burke (SLAC): The LPNHE group will participate in the definition of an instrumental calibration strategy for LSST. P. Astier (LPNHE) will act as contact scientist for this effort. 4

Camera: International R&D Contributions Filter mechanism: M. Nordby (SLAC) The LPNHE team is taking responsibility of studying and prototyping. . . P. Antilogus (LPNHE) will act as contact scientist and G. Daubard (LPNHE) as technical contact. Shutter Development: M. Nordby (SLAC) Bonn Group is studying Gordon Bowden (SLAC) design. Dialog between Bonn and SLAC started. Klaus Reif of the University of Bonn is main contact and head of shutter group Filter development: K. Gilmore (SLAC) LSST is currently looking for qualified vendors to evaluate filters. R. Pain (LPNHE) and the LPNHE/Lyon teams will help coordinate SAGEM evaluation Analog signal processing ASIC: J. Oliver (Harvard) A joint LAL+LPNHE team will take responsibility of prototyping the FE ASIC. P. Antilogus (LPNHE) will act as contact scientist and V. Tocut (LAL) as technical contact. Software slow control: T. Schalk (SLAC/UCSC) The IN 2 P 3 groups will evaluate a possible contribution in the control software and hardware of the camera. P. Antilogus (LPNHE) will act as contact for this effort. Instrumental calibration: D. Burke (SLAC): The LPNHE group will participate in the definition of an instrumental calibration strategy for LSST. P. Astier (LPNHE) will act as contact scientist for this effort. 4

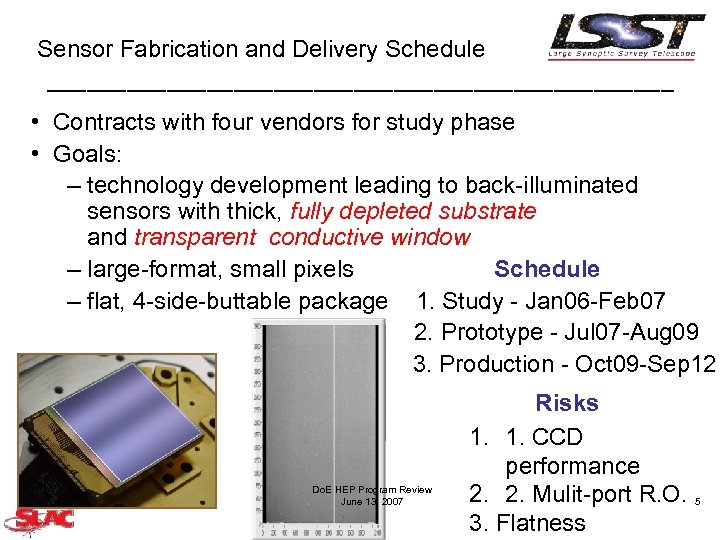

Sensor Fabrication and Delivery Schedule ________________________ • Contracts with four vendors for study phase • Goals: – technology development leading to back-illuminated sensors with thick, fully depleted substrate and transparent conductive window – large-format, small pixels Schedule – flat, 4 -side-buttable package 1. Study - Jan 06 -Feb 07 2. Prototype - Jul 07 -Aug 09 3. Production - Oct 09 -Sep 12 Do. E HEP Program Review June 13, 2007 Risks 1. 1. CCD performance 2. 2. Mulit-port R. O. 3. Flatness 5

Sensor Fabrication and Delivery Schedule ________________________ • Contracts with four vendors for study phase • Goals: – technology development leading to back-illuminated sensors with thick, fully depleted substrate and transparent conductive window – large-format, small pixels Schedule – flat, 4 -side-buttable package 1. Study - Jan 06 -Feb 07 2. Prototype - Jul 07 -Aug 09 3. Production - Oct 09 -Sep 12 Do. E HEP Program Review June 13, 2007 Risks 1. 1. CCD performance 2. 2. Mulit-port R. O. 3. Flatness 5

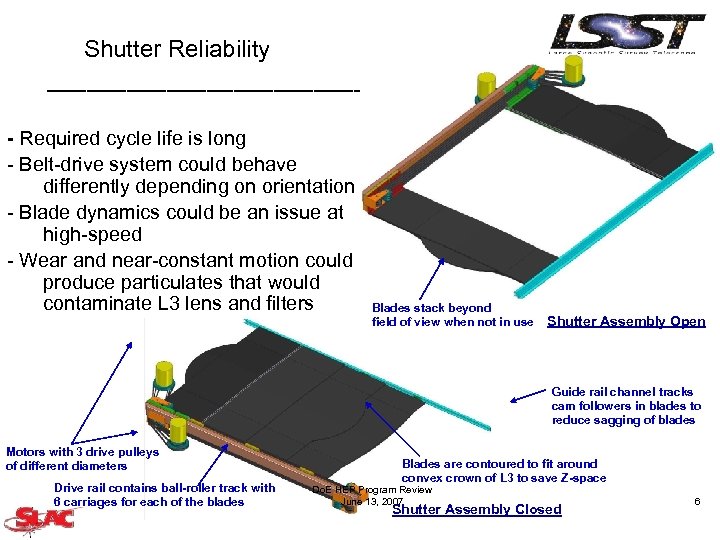

Shutter Reliability ________________________ - Required cycle life is long - Belt-drive system could behave differently depending on orientation - Blade dynamics could be an issue at high-speed - Wear and near-constant motion could produce particulates that would contaminate L 3 lens and filters Blades stack beyond field of view when not in use Shutter Assembly Open Guide rail channel tracks cam followers in blades to reduce sagging of blades Motors with 3 drive pulleys of different diameters Drive rail contains ball-roller track with 6 carriages for each of the blades Blades are contoured to fit around convex crown of L 3 to save Z-space Do. E HEP Program Review June 13, 2007 Shutter Assembly Closed 6

Shutter Reliability ________________________ - Required cycle life is long - Belt-drive system could behave differently depending on orientation - Blade dynamics could be an issue at high-speed - Wear and near-constant motion could produce particulates that would contaminate L 3 lens and filters Blades stack beyond field of view when not in use Shutter Assembly Open Guide rail channel tracks cam followers in blades to reduce sagging of blades Motors with 3 drive pulleys of different diameters Drive rail contains ball-roller track with 6 carriages for each of the blades Blades are contoured to fit around convex crown of L 3 to save Z-space Do. E HEP Program Review June 13, 2007 Shutter Assembly Closed 6

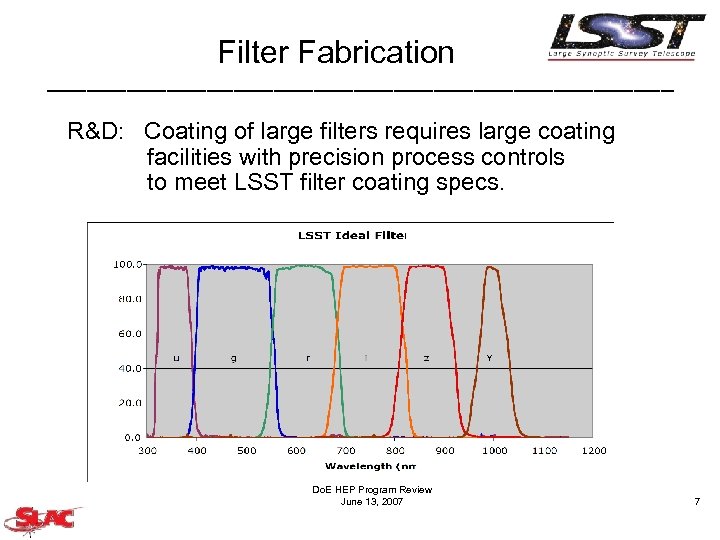

Filter Fabrication ________________________ R&D: Coating of large filters requires large coating facilities with precision process controls to meet LSST filter coating specs. Do. E HEP Program Review June 13, 2007 7

Filter Fabrication ________________________ R&D: Coating of large filters requires large coating facilities with precision process controls to meet LSST filter coating specs. Do. E HEP Program Review June 13, 2007 7

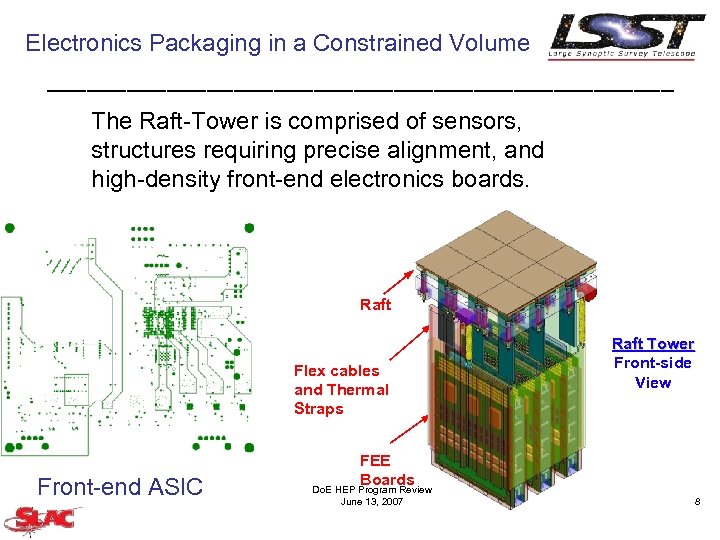

Electronics Packaging in a Constrained Volume ________________________ The Raft-Tower is comprised of sensors, structures requiring precise alignment, and high-density front-end electronics boards. Raft Flex cables and Thermal Straps Front-end ASIC Raft Tower Front-side View FEE Boards Do. E HEP Program Review June 13, 2007 8

Electronics Packaging in a Constrained Volume ________________________ The Raft-Tower is comprised of sensors, structures requiring precise alignment, and high-density front-end electronics boards. Raft Flex cables and Thermal Straps Front-end ASIC Raft Tower Front-side View FEE Boards Do. E HEP Program Review June 13, 2007 8

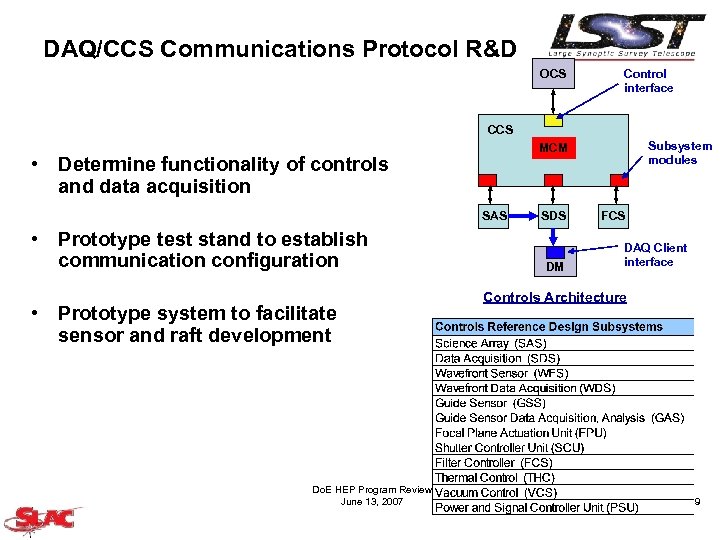

DAQ/CCS Communications Protocol R&D OCS Control interface CCS • Determine functionality of controls and data acquisition SAS • Prototype test stand to establish communication configuration • Prototype system to facilitate sensor and raft development Do. E HEP Program Review June 13, 2007 Subsystem modules MCM SDS DM FCS DAQ Client interface Controls Architecture 9

DAQ/CCS Communications Protocol R&D OCS Control interface CCS • Determine functionality of controls and data acquisition SAS • Prototype test stand to establish communication configuration • Prototype system to facilitate sensor and raft development Do. E HEP Program Review June 13, 2007 Subsystem modules MCM SDS DM FCS DAQ Client interface Controls Architecture 9

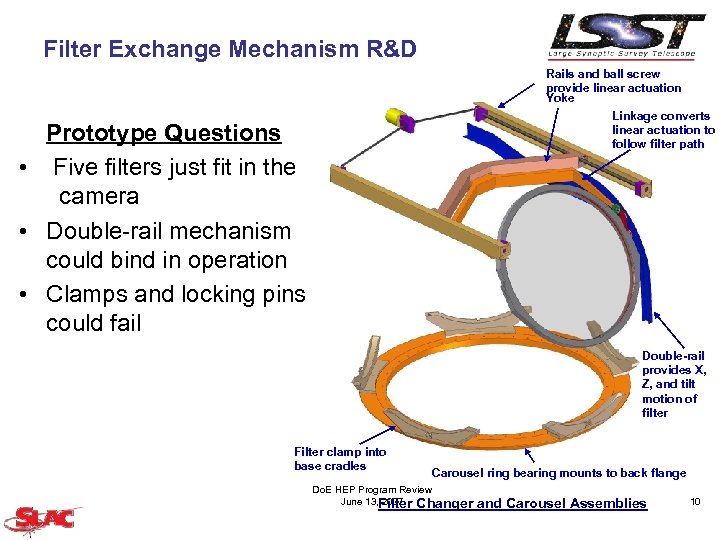

Filter Exchange Mechanism R&D Rails and ball screw provide linear actuation Yoke Linkage converts linear actuation to follow filter path Prototype Questions • Five filters just fit in the camera • Double-rail mechanism could bind in operation • Clamps and locking pins could fail Double-rail provides X, Z, and tilt motion of filter Filter clamp into base cradles Carousel ring bearing mounts to back flange Do. E HEP Program Review June 13, Filter Changer 2007 and Carousel Assemblies 10

Filter Exchange Mechanism R&D Rails and ball screw provide linear actuation Yoke Linkage converts linear actuation to follow filter path Prototype Questions • Five filters just fit in the camera • Double-rail mechanism could bind in operation • Clamps and locking pins could fail Double-rail provides X, Z, and tilt motion of filter Filter clamp into base cradles Carousel ring bearing mounts to back flange Do. E HEP Program Review June 13, Filter Changer 2007 and Carousel Assemblies 10