92560006bc643d6ab0af830c20218f31.ppt

- Количество слайдов: 17

Kenan Center for the Utilization of CO 2 in Manufacturing Ruben Carbonell, Director Joseph M. De. Simone, Co-Director Page 1 NSF STC

Kenan Center for the Utilization of CO 2 in Manufacturing Ruben Carbonell, Director Joseph M. De. Simone, Co-Director Page 1 NSF STC

Current Industrial Membership • Recent withdrawals include: – Rohm & Haas – Mitsubishi Rayon – Michelin – Nomacorc Page 2 NSF STC

Current Industrial Membership • Recent withdrawals include: – Rohm & Haas – Mitsubishi Rayon – Michelin – Nomacorc Page 2 NSF STC

Kenan Center • Major industrial outreach component of the NSF Science and Technology Center for Environmentally Responsible Solvents and Processes (NSF STC) – NSF S&T CERSP Established 1999 • Research supported by corporate memberships and the Kenan Institute for Engineering, Technology and Science Kenan Center Established 1997 Page 3 NSF STC

Kenan Center • Major industrial outreach component of the NSF Science and Technology Center for Environmentally Responsible Solvents and Processes (NSF STC) – NSF S&T CERSP Established 1999 • Research supported by corporate memberships and the Kenan Institute for Engineering, Technology and Science Kenan Center Established 1997 Page 3 NSF STC

Relation of CERSP to the Kenan Center • NSF S&T CERSP – Basic information – Understanding of mechanisms, characterization • Kenan Center – Development of applications – Address industrial concerns – Main mechanism for technology transfer – Intellectual property Page 4 NSF STC

Relation of CERSP to the Kenan Center • NSF S&T CERSP – Basic information – Understanding of mechanisms, characterization • Kenan Center – Development of applications – Address industrial concerns – Main mechanism for technology transfer – Intellectual property Page 4 NSF STC

Advantages of Kenan Center Membership • Cost-effective look at new technologies • Outstanding leverage with NSF STC funds • Network of companies with similar interests • Access to specialized high pressure equipment • Access to intellectual property • Access to faculty expertise • Industrial members in residence • Flexible research alternatives – Core projects – Enhancement projects – External projects • Two yearly review meetings and newsletters Page 5 NSF STC

Advantages of Kenan Center Membership • Cost-effective look at new technologies • Outstanding leverage with NSF STC funds • Network of companies with similar interests • Access to specialized high pressure equipment • Access to intellectual property • Access to faculty expertise • Industrial members in residence • Flexible research alternatives – Core projects – Enhancement projects – External projects • Two yearly review meetings and newsletters Page 5 NSF STC

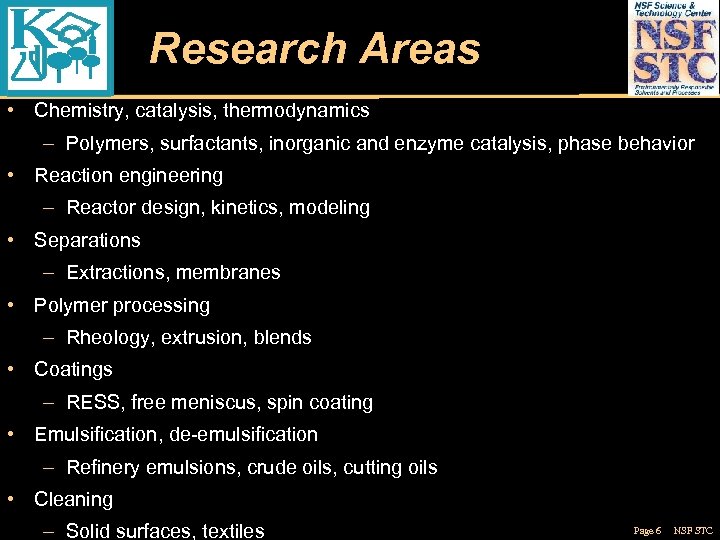

Research Areas • Chemistry, catalysis, thermodynamics – Polymers, surfactants, inorganic and enzyme catalysis, phase behavior • Reaction engineering – Reactor design, kinetics, modeling • Separations – Extractions, membranes • Polymer processing – Rheology, extrusion, blends • Coatings – RESS, free meniscus, spin coating • Emulsification, de-emulsification – Refinery emulsions, crude oils, cutting oils • Cleaning – Solid surfaces, textiles Page 6 NSF STC

Research Areas • Chemistry, catalysis, thermodynamics – Polymers, surfactants, inorganic and enzyme catalysis, phase behavior • Reaction engineering – Reactor design, kinetics, modeling • Separations – Extractions, membranes • Polymer processing – Rheology, extrusion, blends • Coatings – RESS, free meniscus, spin coating • Emulsification, de-emulsification – Refinery emulsions, crude oils, cutting oils • Cleaning – Solid surfaces, textiles Page 6 NSF STC

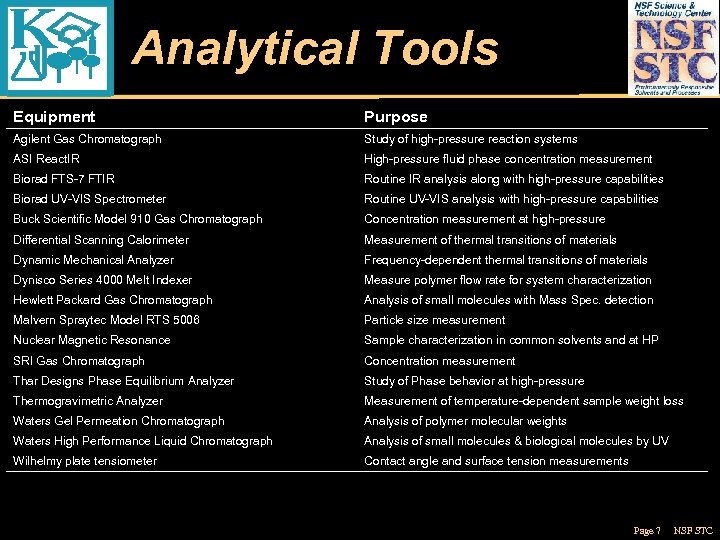

Analytical Tools Equipment Purpose Agilent Gas Chromatograph Study of high-pressure reaction systems ASI React. IR High-pressure fluid phase concentration measurement Biorad FTS-7 FTIR Routine IR analysis along with high-pressure capabilities Biorad UV-VIS Spectrometer Routine UV-VIS analysis with high-pressure capabilities Buck Scientific Model 910 Gas Chromatograph Concentration measurement at high-pressure Differential Scanning Calorimeter Measurement of thermal transitions of materials Dynamic Mechanical Analyzer Frequency-dependent thermal transitions of materials Dynisco Series 4000 Melt Indexer Measure polymer flow rate for system characterization Hewlett Packard Gas Chromatograph Analysis of small molecules with Mass Spec. detection Malvern Spraytec Model RTS 5006 Particle size measurement Nuclear Magnetic Resonance Sample characterization in common solvents and at HP SRI Gas Chromatograph Concentration measurement Thar Designs Phase Equilibrium Analyzer Study of Phase behavior at high-pressure Thermogravimetric Analyzer Measurement of temperature-dependent sample weight loss Waters Gel Permeation Chromatograph Analysis of polymer molecular weights Waters High Performance Liquid Chromatograph Analysis of small molecules & biological molecules by UV Wilhelmy plate tensiometer Contact angle and surface tension measurements Page 7 NSF STC

Analytical Tools Equipment Purpose Agilent Gas Chromatograph Study of high-pressure reaction systems ASI React. IR High-pressure fluid phase concentration measurement Biorad FTS-7 FTIR Routine IR analysis along with high-pressure capabilities Biorad UV-VIS Spectrometer Routine UV-VIS analysis with high-pressure capabilities Buck Scientific Model 910 Gas Chromatograph Concentration measurement at high-pressure Differential Scanning Calorimeter Measurement of thermal transitions of materials Dynamic Mechanical Analyzer Frequency-dependent thermal transitions of materials Dynisco Series 4000 Melt Indexer Measure polymer flow rate for system characterization Hewlett Packard Gas Chromatograph Analysis of small molecules with Mass Spec. detection Malvern Spraytec Model RTS 5006 Particle size measurement Nuclear Magnetic Resonance Sample characterization in common solvents and at HP SRI Gas Chromatograph Concentration measurement Thar Designs Phase Equilibrium Analyzer Study of Phase behavior at high-pressure Thermogravimetric Analyzer Measurement of temperature-dependent sample weight loss Waters Gel Permeation Chromatograph Analysis of polymer molecular weights Waters High Performance Liquid Chromatograph Analysis of small molecules & biological molecules by UV Wilhelmy plate tensiometer Contact angle and surface tension measurements Page 7 NSF STC

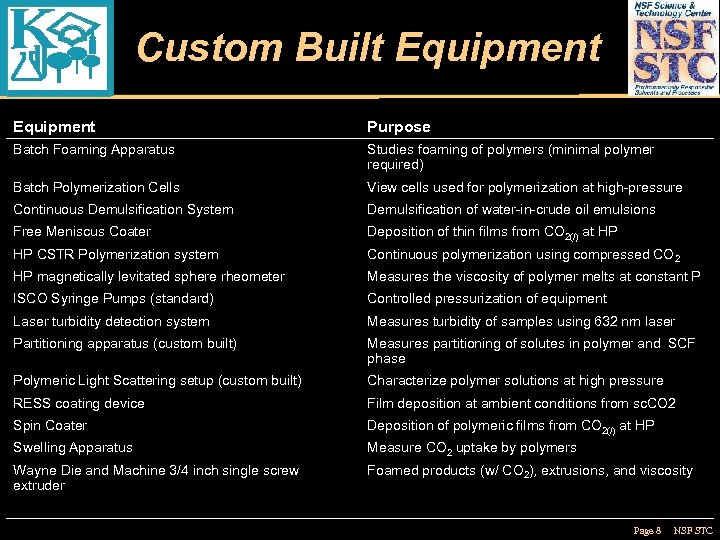

Custom Built Equipment Purpose Batch Foaming Apparatus Studies foaming of polymers (minimal polymer required) Batch Polymerization Cells View cells used for polymerization at high-pressure Continuous Demulsification System Demulsification of water-in-crude oil emulsions Free Meniscus Coater Deposition of thin films from CO 2(ll) at HP 2( HP CSTR Polymerization system Continuous polymerization using compressed CO 2 HP magnetically levitated sphere rheometer Measures the viscosity of polymer melts at constant P ISCO Syringe Pumps (standard) Controlled pressurization of equipment Laser turbidity detection system Measures turbidity of samples using 632 nm laser Partitioning apparatus (custom built) Measures partitioning of solutes in polymer and SCF phase Polymeric Light Scattering setup (custom built) Characterize polymer solutions at high pressure RESS coating device Film deposition at ambient conditions from sc. CO 2 Spin Coater Deposition of polymeric films from CO 2(ll) at HP 2( Swelling Apparatus Measure CO 2 uptake by polymers Wayne Die and Machine 3/4 inch single screw extruder Foamed products (w/ CO 2), extrusions, and viscosity Page 8 NSF STC

Custom Built Equipment Purpose Batch Foaming Apparatus Studies foaming of polymers (minimal polymer required) Batch Polymerization Cells View cells used for polymerization at high-pressure Continuous Demulsification System Demulsification of water-in-crude oil emulsions Free Meniscus Coater Deposition of thin films from CO 2(ll) at HP 2( HP CSTR Polymerization system Continuous polymerization using compressed CO 2 HP magnetically levitated sphere rheometer Measures the viscosity of polymer melts at constant P ISCO Syringe Pumps (standard) Controlled pressurization of equipment Laser turbidity detection system Measures turbidity of samples using 632 nm laser Partitioning apparatus (custom built) Measures partitioning of solutes in polymer and SCF phase Polymeric Light Scattering setup (custom built) Characterize polymer solutions at high pressure RESS coating device Film deposition at ambient conditions from sc. CO 2 Spin Coater Deposition of polymeric films from CO 2(ll) at HP 2( Swelling Apparatus Measure CO 2 uptake by polymers Wayne Die and Machine 3/4 inch single screw extruder Foamed products (w/ CO 2), extrusions, and viscosity Page 8 NSF STC

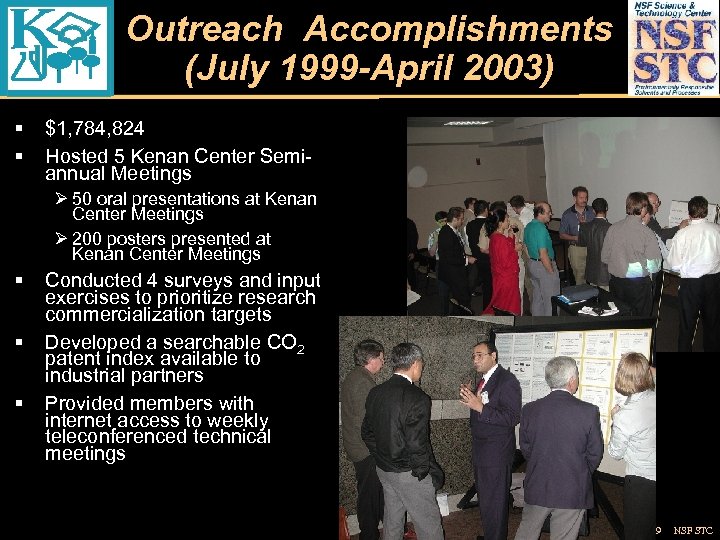

Outreach Accomplishments (July 1999 -April 2003) § § $1, 784, 824 Hosted 5 Kenan Center Semiannual Meetings Ø 50 oral presentations at Kenan Center Meetings Ø 200 posters presented at Kenan Center Meetings § § § Conducted 4 surveys and input exercises to prioritize research commercialization targets Developed a searchable CO 2 patent index available to industrial partners Provided members with internet access to weekly teleconferenced technical meetings Page 9 NSF STC

Outreach Accomplishments (July 1999 -April 2003) § § $1, 784, 824 Hosted 5 Kenan Center Semiannual Meetings Ø 50 oral presentations at Kenan Center Meetings Ø 200 posters presented at Kenan Center Meetings § § § Conducted 4 surveys and input exercises to prioritize research commercialization targets Developed a searchable CO 2 patent index available to industrial partners Provided members with internet access to weekly teleconferenced technical meetings Page 9 NSF STC

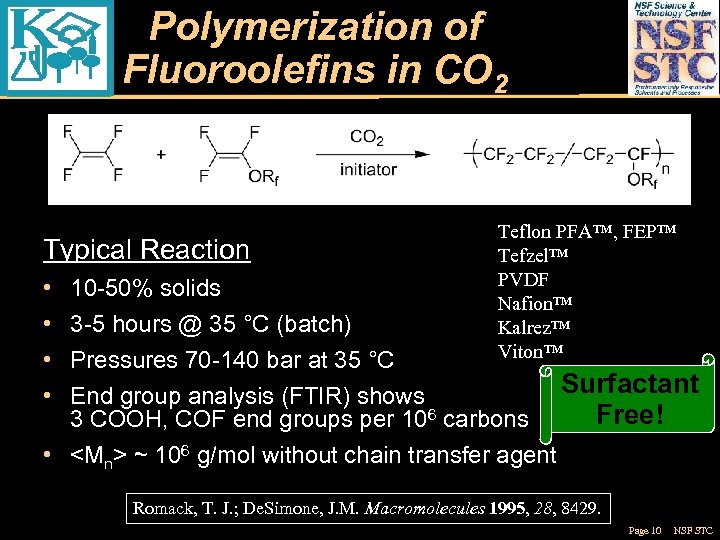

Polymerization of Fluoroolefins in CO 2 Typical Reaction • • 10 -50% solids 3 -5 hours @ 35 °C (batch) Teflon PFA™, FEP™ Tefzel™ PVDF Nafion™ Kalrez™ Viton™ Pressures 70 -140 bar at 35 °C Surfactant End group analysis (FTIR) shows Free! 3 COOH, COF end groups per 106 carbons •

Polymerization of Fluoroolefins in CO 2 Typical Reaction • • 10 -50% solids 3 -5 hours @ 35 °C (batch) Teflon PFA™, FEP™ Tefzel™ PVDF Nafion™ Kalrez™ Viton™ Pressures 70 -140 bar at 35 °C Surfactant End group analysis (FTIR) shows Free! 3 COOH, COF end groups per 106 carbons •

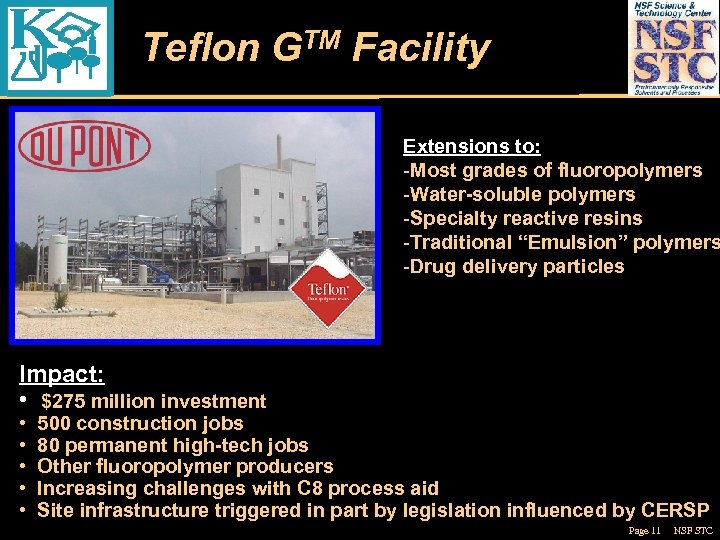

Teflon GTM Facility Extensions to: -Most grades of fluoropolymers -Water-soluble polymers -Specialty reactive resins -Traditional “Emulsion” polymers -Drug delivery particles Impact: • $275 million investment • • • 500 construction jobs 80 permanent high-tech jobs Other fluoropolymer producers Increasing challenges with C 8 process aid Site infrastructure triggered in part by legislation influenced by CERSP Page 11 NSF STC

Teflon GTM Facility Extensions to: -Most grades of fluoropolymers -Water-soluble polymers -Specialty reactive resins -Traditional “Emulsion” polymers -Drug delivery particles Impact: • $275 million investment • • • 500 construction jobs 80 permanent high-tech jobs Other fluoropolymer producers Increasing challenges with C 8 process aid Site infrastructure triggered in part by legislation influenced by CERSP Page 11 NSF STC

Rationale for Reorganizing the Kenan Center • Technological impact of the CO 2 technology platform has changed significantly since the Kenan Center was founded – Supercritical CO 2 cleaning now on International Technology Roadmap for Semiconductors (ITRS) • Interest of Kenan Center corporate members continues to evolve • Re-organization will allow one-on-one relationship with companies in specific areas outside of the microelectronics field Page 12 NSF STC

Rationale for Reorganizing the Kenan Center • Technological impact of the CO 2 technology platform has changed significantly since the Kenan Center was founded – Supercritical CO 2 cleaning now on International Technology Roadmap for Semiconductors (ITRS) • Interest of Kenan Center corporate members continues to evolve • Re-organization will allow one-on-one relationship with companies in specific areas outside of the microelectronics field Page 12 NSF STC

Consortium for Integrated CO 2 Technologies in Microelectronics • New consortium with a “microelectronics-only” focus • Consortium designed to have the requisite membership necessary to give advice, counsel, input and in-kind support that will ultimately allow the science and technology of the CO 2 platform to move forward in the microelectronics industry • Members receive reduced rates on use of new ASML 193 nm 5500/950 B stepper (operational January 2004) Page 13 NSF STC

Consortium for Integrated CO 2 Technologies in Microelectronics • New consortium with a “microelectronics-only” focus • Consortium designed to have the requisite membership necessary to give advice, counsel, input and in-kind support that will ultimately allow the science and technology of the CO 2 platform to move forward in the microelectronics industry • Members receive reduced rates on use of new ASML 193 nm 5500/950 B stepper (operational January 2004) Page 13 NSF STC

Distinguishing Features of New Consortium • New name with focus on microelectronics • A simplified licensing trigger clock • Jointly conceived of inventions are held jointly by both the company and the University (The old agreement has jointly conceived inventions belonging to the University) • Membership fee of $45, 000 (Exception for the current Kenan Center Members which keeps the fees at $35, 000 for three years) Page 14 NSF STC

Distinguishing Features of New Consortium • New name with focus on microelectronics • A simplified licensing trigger clock • Jointly conceived of inventions are held jointly by both the company and the University (The old agreement has jointly conceived inventions belonging to the University) • Membership fee of $45, 000 (Exception for the current Kenan Center Members which keeps the fees at $35, 000 for three years) Page 14 NSF STC

Compelling Need for New Consortium in Microelectronics “The 1. 7 Kilogram Microchip: Energy and Material Use in the Production of Semiconductor Devices”, E. D. Willaims, R. U. Ayres, M. Heller Environ. Sci. & Technol. 2002, 36, 5504. 32 MB DRAM chip weighing 2. 0 grams requires: fuel 1. 7 kilogram of chemical inputs and fossil 32 kilograms of water 0. 7 kilograms of elemental gases Page 15 NSF STC

Compelling Need for New Consortium in Microelectronics “The 1. 7 Kilogram Microchip: Energy and Material Use in the Production of Semiconductor Devices”, E. D. Willaims, R. U. Ayres, M. Heller Environ. Sci. & Technol. 2002, 36, 5504. 32 MB DRAM chip weighing 2. 0 grams requires: fuel 1. 7 kilogram of chemical inputs and fossil 32 kilograms of water 0. 7 kilograms of elemental gases Page 15 NSF STC

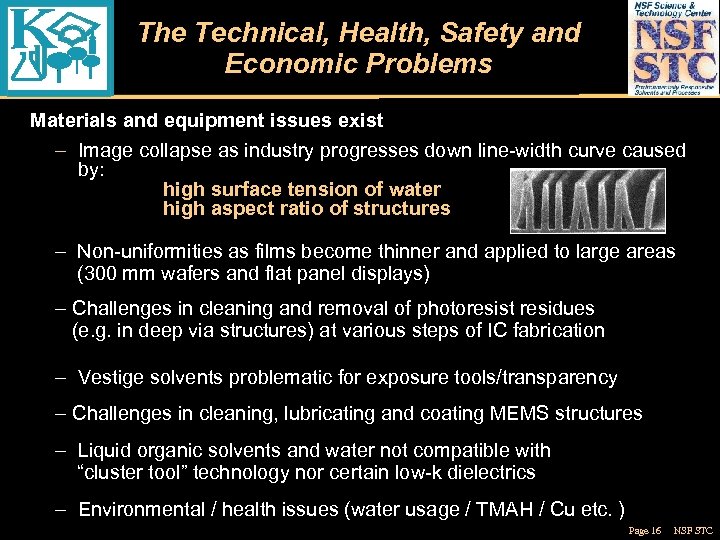

The Technical, Health, Safety and Economic Problems Materials and equipment issues exist – Image collapse as industry progresses down line-width curve caused by: high surface tension of water high aspect ratio of structures – Non-uniformities as films become thinner and applied to large areas (300 mm wafers and flat panel displays) – Challenges in cleaning and removal of photoresist residues (e. g. in deep via structures) at various steps of IC fabrication – Vestige solvents problematic for exposure tools/transparency – Challenges in cleaning, lubricating and coating MEMS structures – Liquid organic solvents and water not compatible with “cluster tool” technology nor certain low-k dielectrics – Environmental / health issues (water usage / TMAH / Cu etc. ) Page 16 NSF STC

The Technical, Health, Safety and Economic Problems Materials and equipment issues exist – Image collapse as industry progresses down line-width curve caused by: high surface tension of water high aspect ratio of structures – Non-uniformities as films become thinner and applied to large areas (300 mm wafers and flat panel displays) – Challenges in cleaning and removal of photoresist residues (e. g. in deep via structures) at various steps of IC fabrication – Vestige solvents problematic for exposure tools/transparency – Challenges in cleaning, lubricating and coating MEMS structures – Liquid organic solvents and water not compatible with “cluster tool” technology nor certain low-k dielectrics – Environmental / health issues (water usage / TMAH / Cu etc. ) Page 16 NSF STC

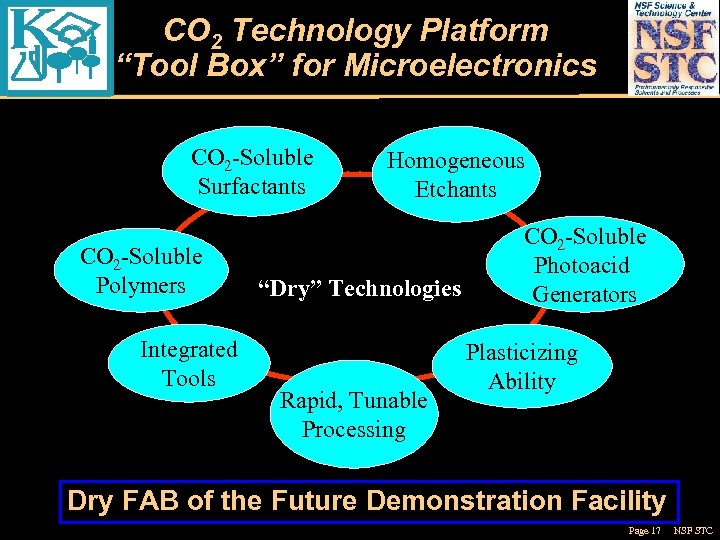

CO 2 Technology Platform “Tool Box” for Microelectronics CO 2 -Soluble Surfactants CO 2 -Soluble Polymers Integrated Tools Homogeneous Etchants “Dry” Technologies Rapid, Tunable Processing CO 2 -Soluble Photoacid Generators Plasticizing Ability Dry FAB of the Future Demonstration Facility Page 17 NSF STC

CO 2 Technology Platform “Tool Box” for Microelectronics CO 2 -Soluble Surfactants CO 2 -Soluble Polymers Integrated Tools Homogeneous Etchants “Dry” Technologies Rapid, Tunable Processing CO 2 -Soluble Photoacid Generators Plasticizing Ability Dry FAB of the Future Demonstration Facility Page 17 NSF STC