5eca84aed2187a703c4376c79a4f4f11.ppt

- Количество слайдов: 32

Jürgen Wüst October 2008

§ Agenda - Introductions Jack Vann - Visi-Trak Traceability Jay Wood - Sure-Trak 2 Die Casting Controls Greg Solands - Total-Trak HMI Brian De Boer - Questions Jürgen Wüst October 2008

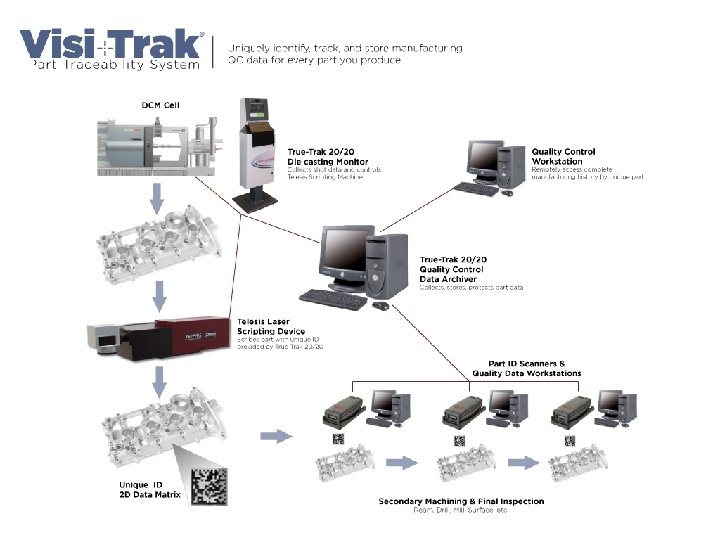

VISI-TRAK TRACEABILITY Uniquely Identify, Track, and Store QC Data for Every Part SYSTEM Jürgen Wüst October 2008

Key Features: § Automatically collect and archive valuable shot data for each part. § Uniquely identify each part you produce. § Capture and link important secondary machining data. § Analyze your data to inform your customers and improve quality. § Archive your information for future access. Jürgen Wüst October 2008

Jürgen Wüst October 2008

Jürgen Wüst October 2008

A Pro-active Approach to Process Control § Monitor key variables - Shot-end Hydraulic characteristics – Position, Velocity, Pressure, Vacuum - Furnace and die temperatures. - Tie-bar stress - Cycle times. § Casting characteristics are calculated and reported on by monitoring equipment. Jürgen Wüst October 2008

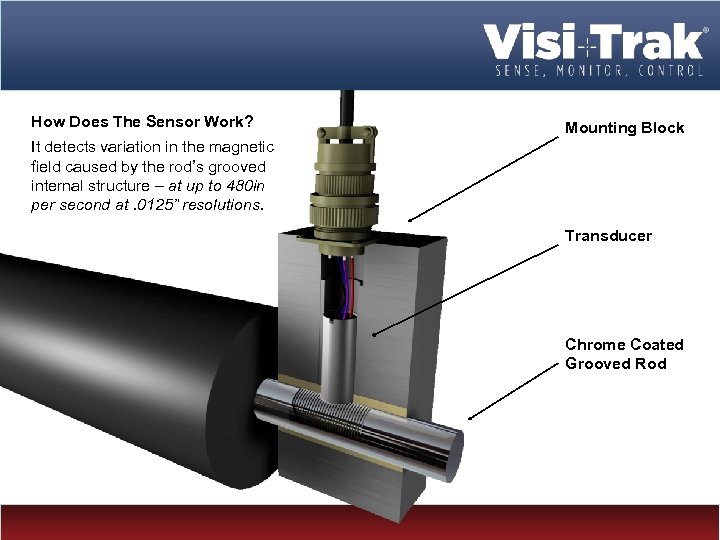

How Does The Sensor Work? Mounting Block It detects variation in the magnetic field caused by the rod’s grooved internal structure – at up to 480 in per second at. 0125” resolutions. Transducer Chrome Coated Grooved Rod Jürgen Wüst October 2008

TOUGH + RELIABLE • • Extreme Accuracy up to 480 IPS/12 MPS. • Non-contact sensor minimizes equipment wear. • No calibration or alignment means no set-up problems. • Proven Performance for over 25 years. • Jürgen Wüst Design Simplicity for inherent reliability. Easy to install & operate nearly maintenance free. October 2008

Sure-Trak 2™ Control Benefits: § Reduce Air Entrapment during Slow Phase § Smooth Metal Flow & Flexibility of adjustments during Fast Shot/ Fill Phase § Repeatability regardless of changes § Deceleration for Low Impact Jürgen Wüst § Programmability in engineering units for fast and repeatable Set-ups § Programmable Pressure Control § Store, Recall and Download Set-ups § Easily Retrofitted to Existing Machines or Specify on New Machines October 2008

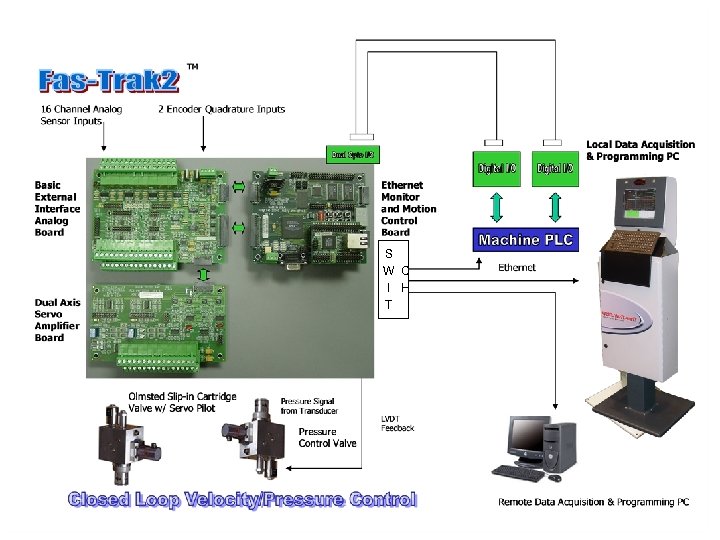

S W C I H T Jürgen Wüst October 2008

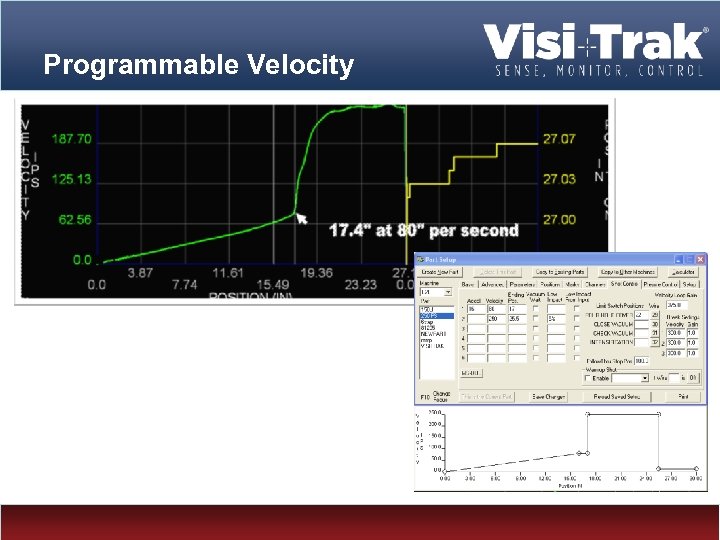

Programmable Velocity Jürgen Wüst October 2008

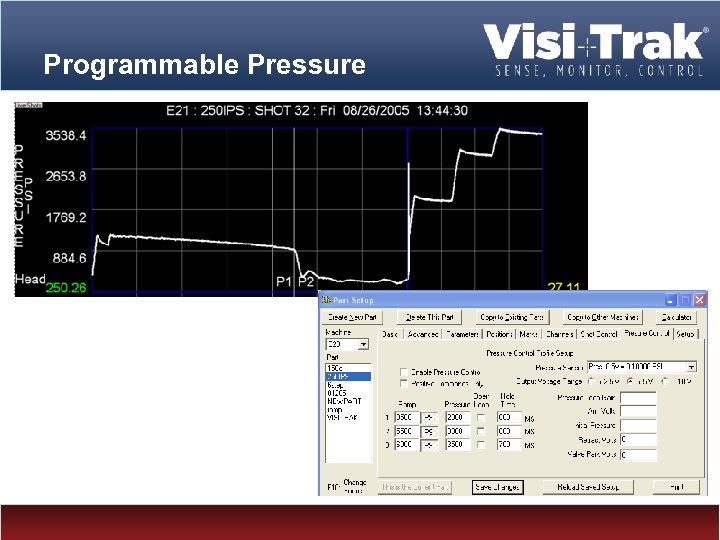

Programmable Pressure Jürgen Wüst October 2008

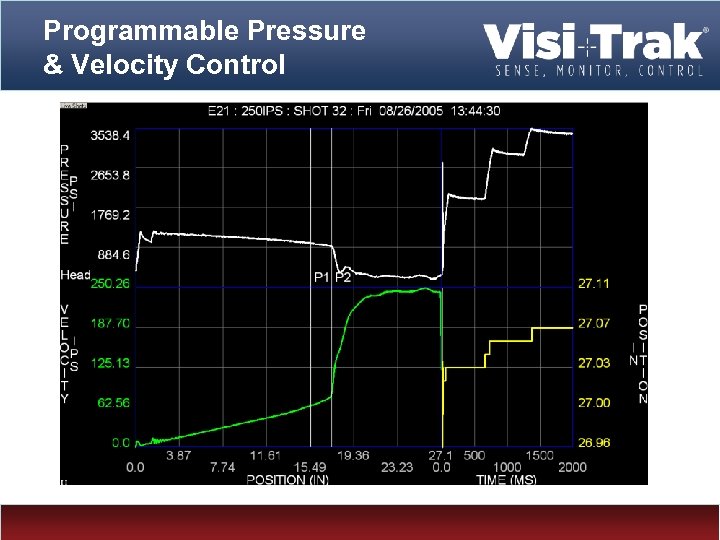

Programmable Pressure & Velocity Control Jürgen Wüst October 2008

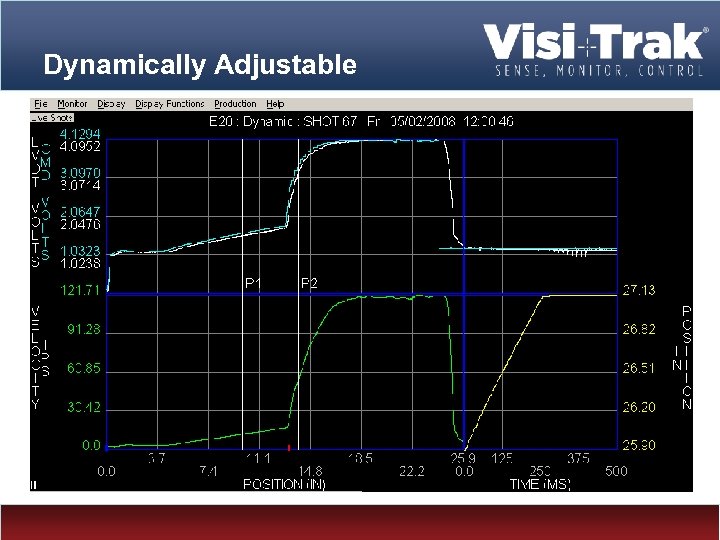

Dynamically Adjustable Jürgen Wüst October 2008

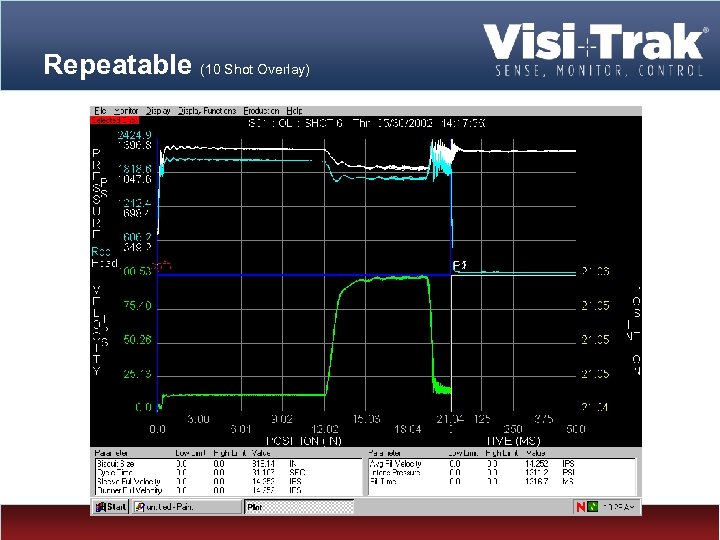

Repeatable (10 Shot Overlay) Jürgen Wüst October 2008

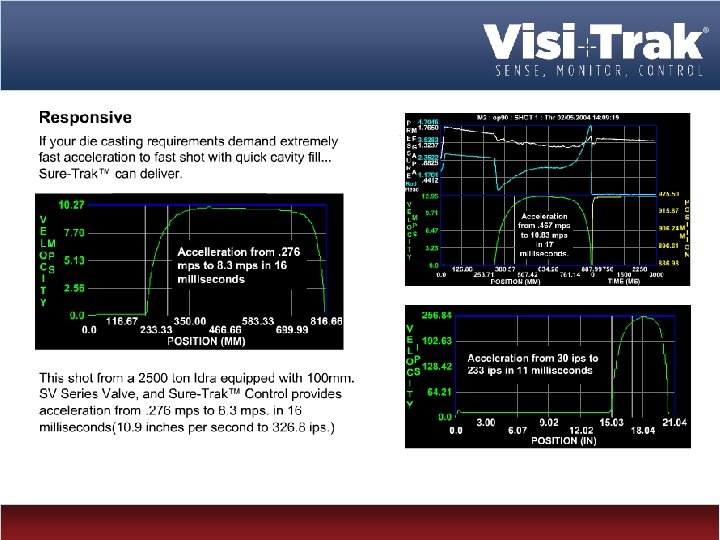

Jürgen Wüst October 2008

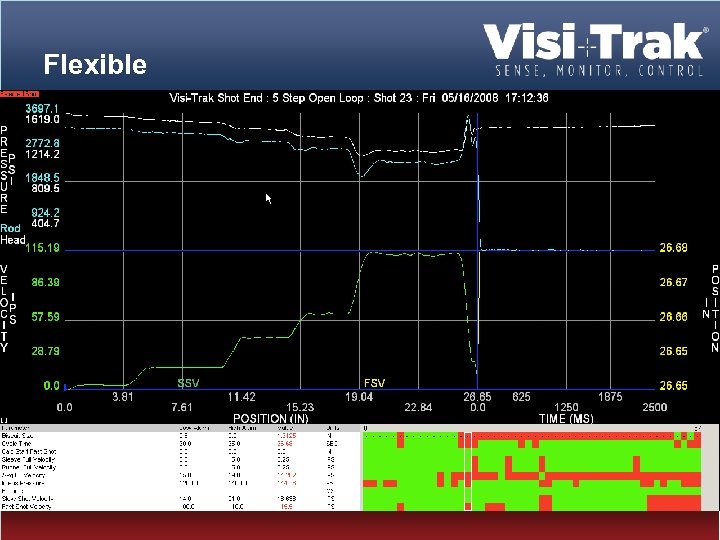

Flexible Jürgen Wüst October 2008

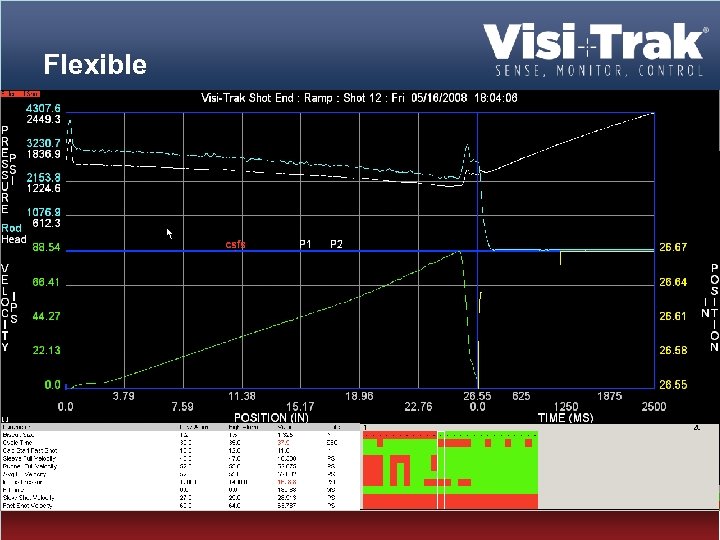

Flexible Jürgen Wüst October 2008

“We could not make the castings we are making today without the flexibility and performance that our Sure-Trak 2™ shot controls provide. At Diamond Casting, we have a Sure-Trak 2™ on every machine. ” GERRY LETENDRE President Diamond Casting and Machine Company, Hollis, NH Jürgen Wüst October 2008

Why a New Monitoring & Control System? § Expert design & implementation means no guess-work. § Extend the life & capabilities of your existing shot-end. § Any shape shot profile; any injection process. § Integrated with complete PLC/HMI § Extensive 30 -year experience in retro-fitting and supplying new OEM systems § Complete & ongoing engineering support Jürgen Wüst October 2008

A. Retro-fit your existing DCM Jürgen Wüst October 2008

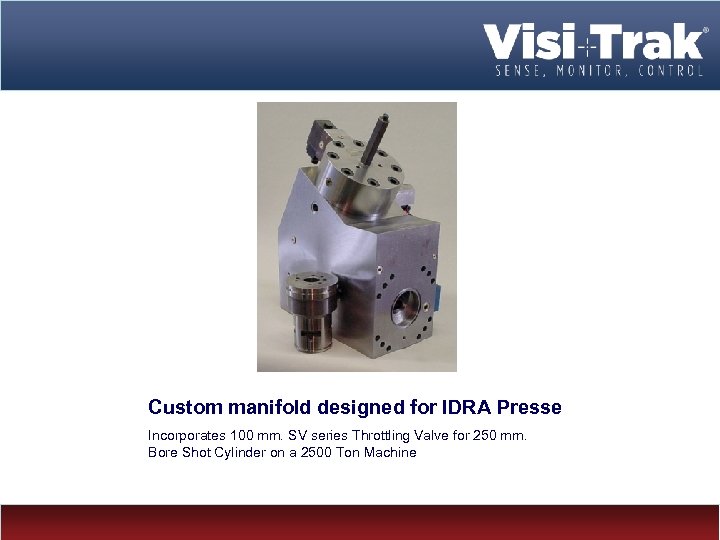

Custom manifold designed for IDRA Presse Incorporates 100 mm. SV series Throttling Valve for 250 mm. Bore Shot Cylinder on a 2500 Ton Machine Jürgen Wüst October 2008

B. Integrate into a New Shot End Jürgen Wüst October 2008

C. Specify on your New Machine Jürgen Wüst October 2008

Retro-fit Integrations Engineered for: § Toshiba § Ube § Kux § B&T § Triullzi § Weingarten § Agrati § Buhler “B” series machines – meter-in design § HPM § IDRA Jürgen Wüst § And more… October 2008

OEM Systems Supplied to: § Agrati Machine § Brescia Presse § HPM § IDRA § Prince Machine § Zitai Machine Jürgen Wüst October 2008

“The retrofit package and the Sure-Trak 2 Control from Visi-Trak®, has given us a shot system with outstanding control & performance. This economical solution extended the service life of the machine and helps us continue to make cost-effective castings after they have outgrown the clamp tonnage capacity of the machine. Its a lot of bang for the buck. ” DAVE BROCKMAN Senior Fabrication Project Engineer The Toro Company, Windom, MN Jürgen Wüst October 2008

TOTAL-TRAK HMI PLC Front-end created specifically for die-casters Jürgen Wüst October 2008

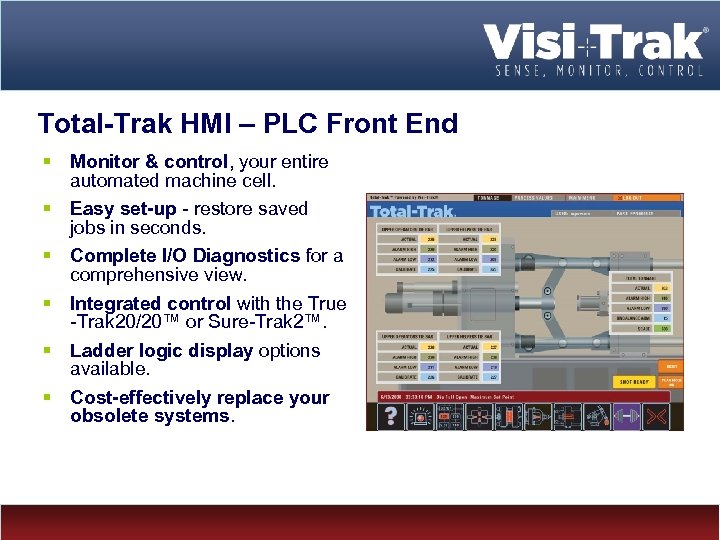

Total-Trak HMI – PLC Front End § Monitor & control, your entire automated machine cell. § Easy set-up - restore saved jobs in seconds. § Complete I/O Diagnostics for a comprehensive view. § Integrated control with the True -Trak 20/20™ or Sure-Trak 2™. § Ladder logic display options available. § Cost-effectively replace your obsolete systems. Jürgen Wüst October 2008

Jürgen Wüst October 2008

Visi-Trak Worldwide, LLC. 8400 Sweet Valley Drive Suite 406 Valley View, Ohio 44125 Phone: Fax: (216) 524 -2363 (216) 524 -9594 www. Visi-Trak. com Jürgen Wüst October 2008

5eca84aed2187a703c4376c79a4f4f11.ppt