35794cb1a5712ed4f1b1fc64f9c354b0.ppt

- Количество слайдов: 26

July 2007 egeplast Werner Strumann Gmb. H & Co. KG Robert-Bosch-Straße 7 48268 Greven

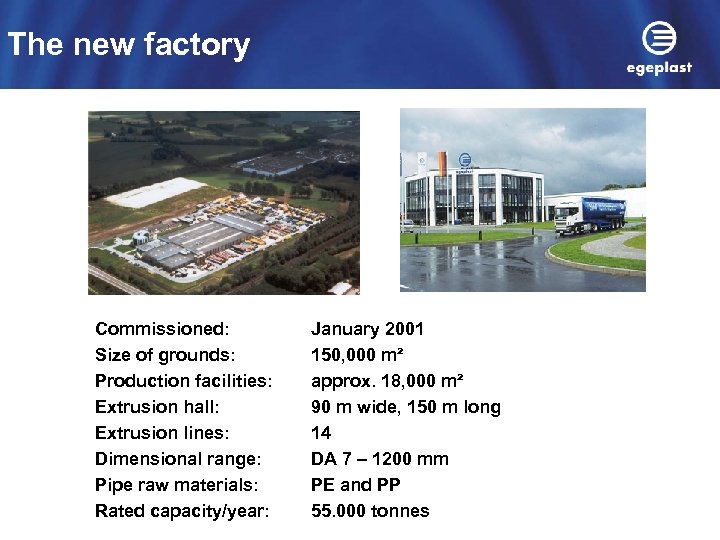

The new factory Commissioned: Size of grounds: Production facilities: Extrusion hall: Extrusion lines: Dimensional range: Pipe raw materials: Rated capacity/year: January 2001 150, 000 m² approx. 18, 000 m² 90 m wide, 150 m long 14 DA 7 – 1200 mm PE and PP 55. 000 tonnes

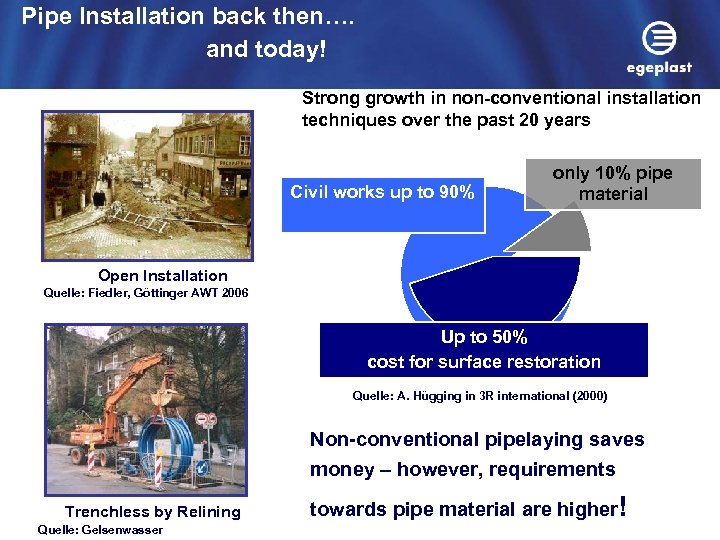

Pipe Installation back then…. and today! Strong growth in non-conventional installation techniques over the past 20 years Civil works up to 90% only 10% pipe material Open Installation Quelle: Fiedler, Göttinger AWT 2006 Up to 50% cost for surface restoration Quelle: A. Hügging in 3 R international (2000) Non-conventional pipelaying saves money – however, requirements Trenchless by Relining Quelle: Gelsenwasser towards pipe material are higher!

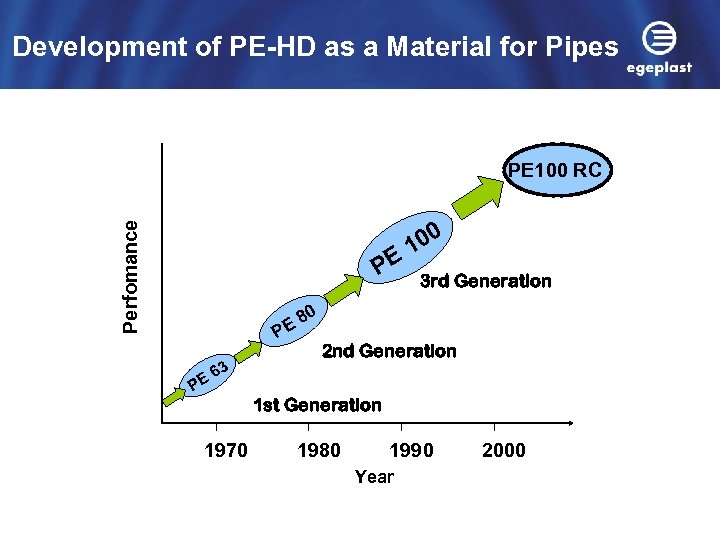

Development of PE-HD as a Material for Pipes Perfomance PE 100 RC 0 10 E P 3 rd Generation 80 E P E 6 P 3 1970 2 nd Generation 1 st Generation 1980 1990 Year 2000

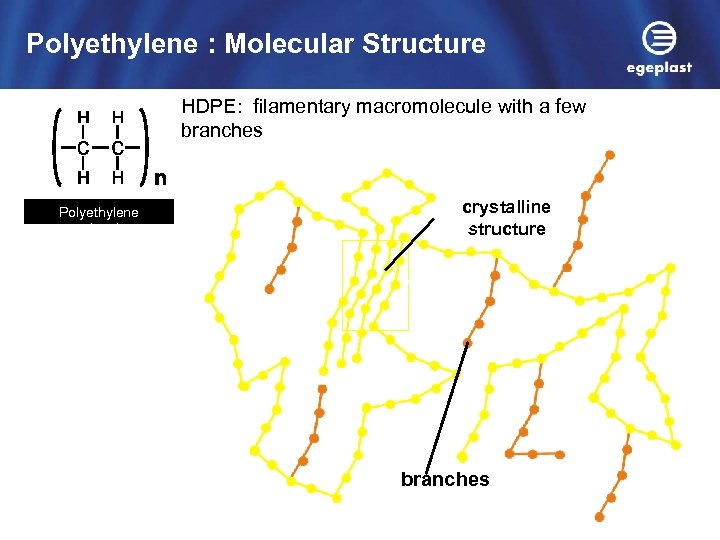

Polyethylene : Molecular Structure HDPE: filamentary macromolecule with a few branches Polyethylene molecule crystalline structure branches

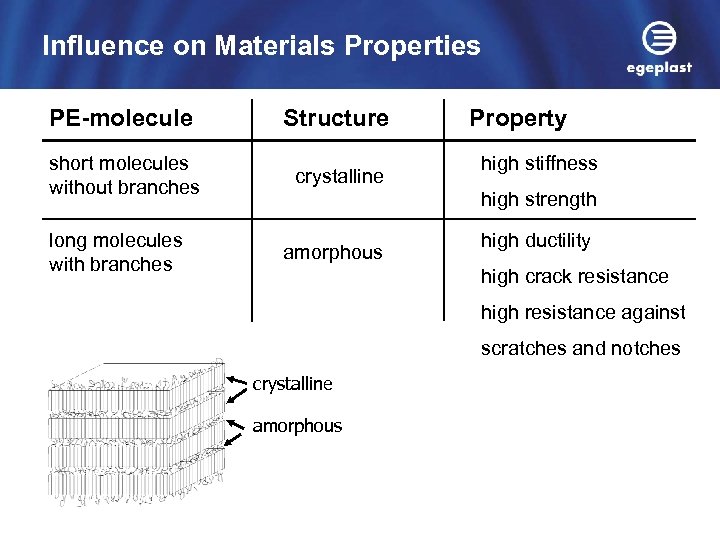

Influence on Materials Properties PE-molecule Structure short molecules without branches crystalline long molecules with branches Property high stiffness high strength amorphous high ductility high crack resistance high resistance against scratches and notches crystalline amorphous

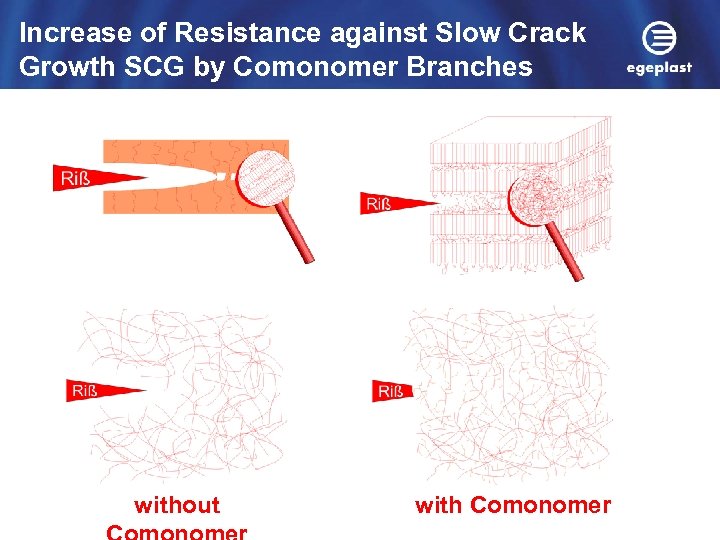

Increase of Resistance against Slow Crack Growth SCG by Comonomer Branches without with Comonomer

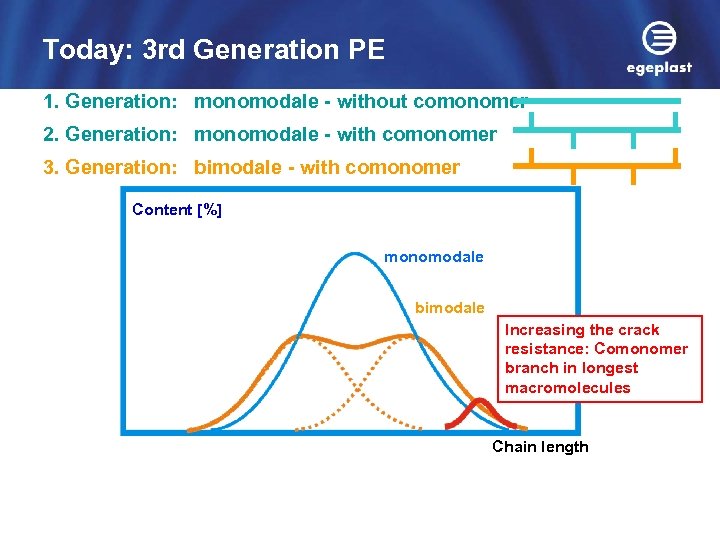

Today: 3 rd Generation PE 1. Generation: monomodale - without comonomer 2. Generation: monomodale - with comonomer 3. Generation: bimodale - with comonomer Content [%] monomodale bimodale Increasing the crack resistance: Comonomer branch in longest macromolecules Chain length By bimodal distribution strength and ductility were equally increased

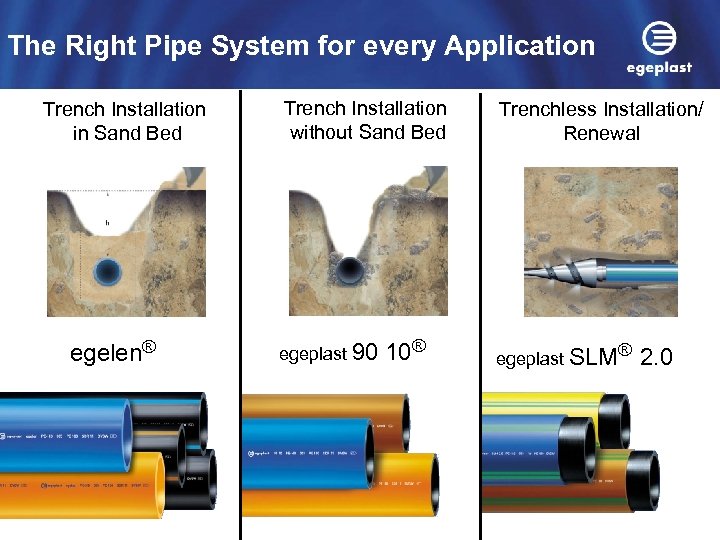

The Right Pipe System for every Application Trench Installation in Sand Bed egelen® Trench Installation without Sand Bed egeplast 90 10® Trenchless Installation/ Renewal egeplast SLM® 2. 0

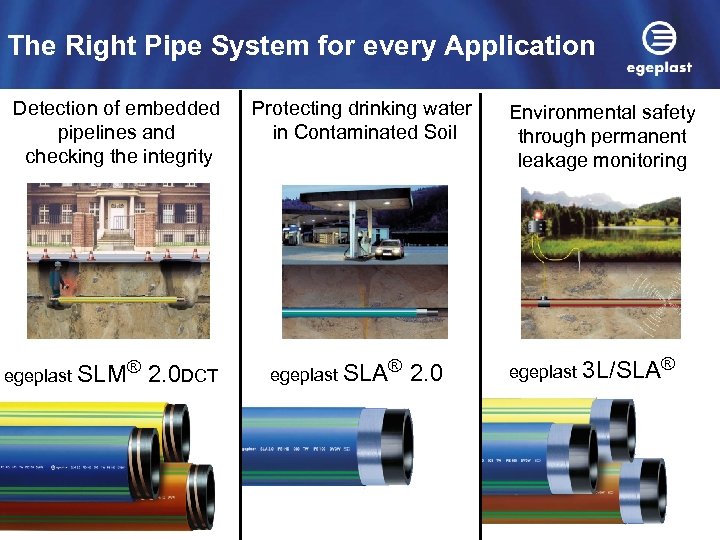

The Right Pipe System for every Application Detection of embedded pipelines and checking the integrity egeplast SLM® 2. 0 DCT Protecting drinking water in Contaminated Soil egeplast SLA® 2. 0 Environmental safety through permanent leakage monitoring egeplast 3 L/SLA®

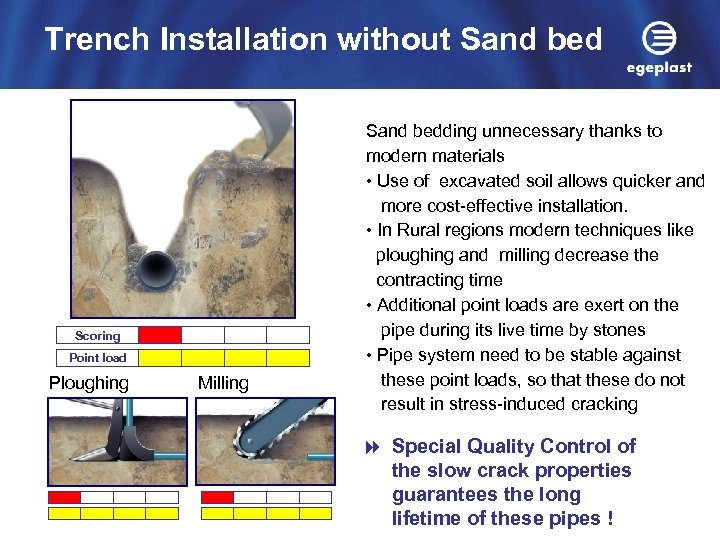

Trench Installation without Sand bed Scoring Point load Ploughing Milling Sand bedding unnecessary thanks to modern materials • Use of excavated soil allows quicker and more cost-effective installation. • In Rural regions modern techniques like ploughing and milling decrease the contracting time • Additional point loads are exert on the pipe during its live time by stones • Pipe system need to be stable against these point loads, so that these do not result in stress-induced cracking 8 Special Quality Control of the slow crack properties guarantees the long lifetime of these pipes !

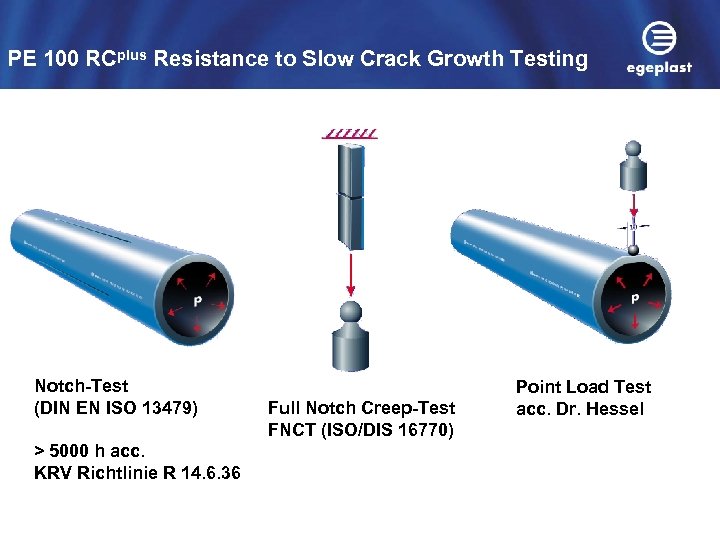

PE 100 RCplus Resistance to Slow Crack Growth Testing Notch-Test (DIN EN ISO 13479) > 5000 h acc. KRV Richtlinie R 14. 6. 36 Full Notch Creep-Test FNCT (ISO/DIS 16770) Point Load Test acc. Dr. Hessel

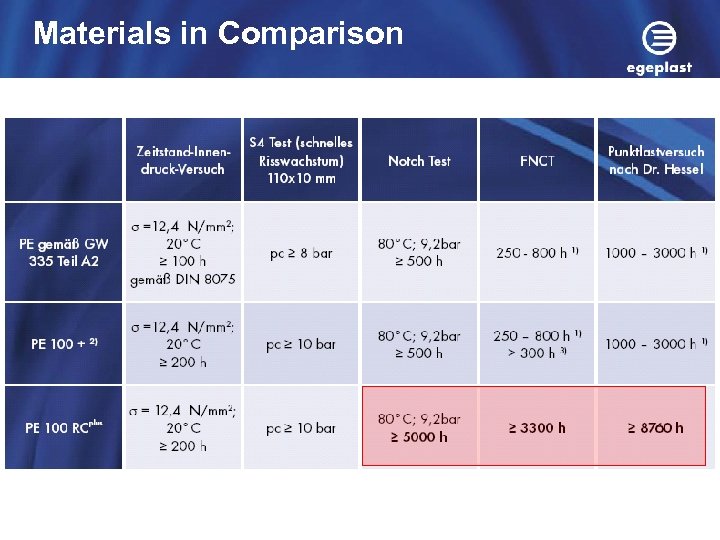

Materials in Comparison

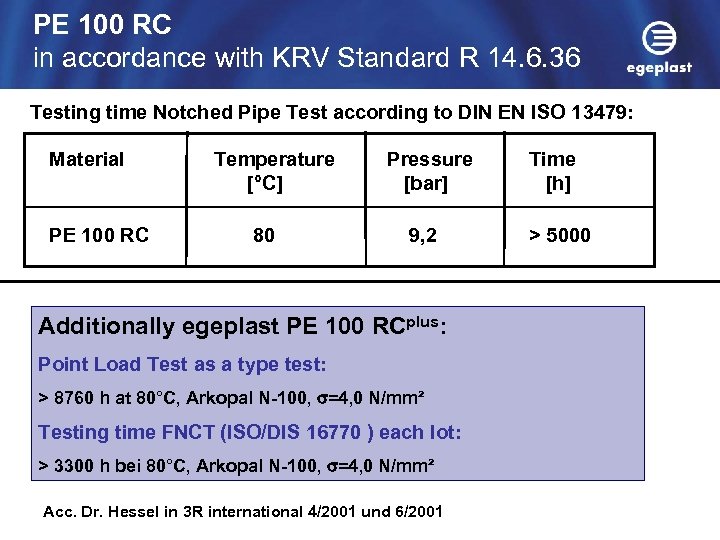

PE 100 RC in accordance with KRV Standard R 14. 6. 36 Testing time Notched Pipe Test according to DIN EN ISO 13479: Material PE 100 RC Temperature [°C] 80 Pressure [bar] 9, 2 Additionally egeplast PE 100 RCplus: Point Load Test as a type test: > 8760 h at 80°C, Arkopal N-100, s=4, 0 N/mm² Testing time FNCT (ISO/DIS 16770 ) each lot: > 3300 h bei 80°C, Arkopal N-100, s=4, 0 N/mm² Acc. Dr. Hessel in 3 R international 4/2001 und 6/2001 Time [h] > 5000

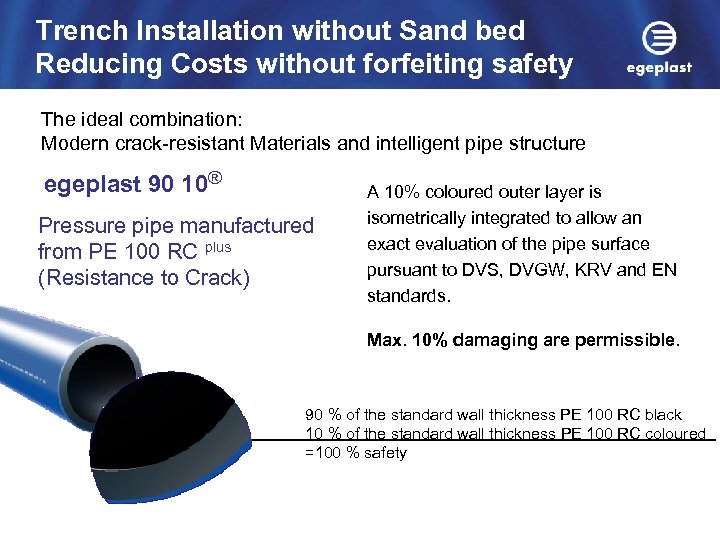

Trench Installation without Sand bed Reducing Costs without forfeiting safety The ideal combination: Modern crack-resistant Materials and intelligent pipe structure egeplast 90 10® Pressure pipe manufactured from PE 100 RC plus (Resistance to Crack) A 10% coloured outer layer is isometrically integrated to allow an exact evaluation of the pipe surface pursuant to DVS, DVGW, KRV and EN standards. Max. 10% damaging are permissible. 90 % of the standard wall thickness PE 100 RC black 10 % of the standard wall thickness PE 100 RC coloured =100 % safety

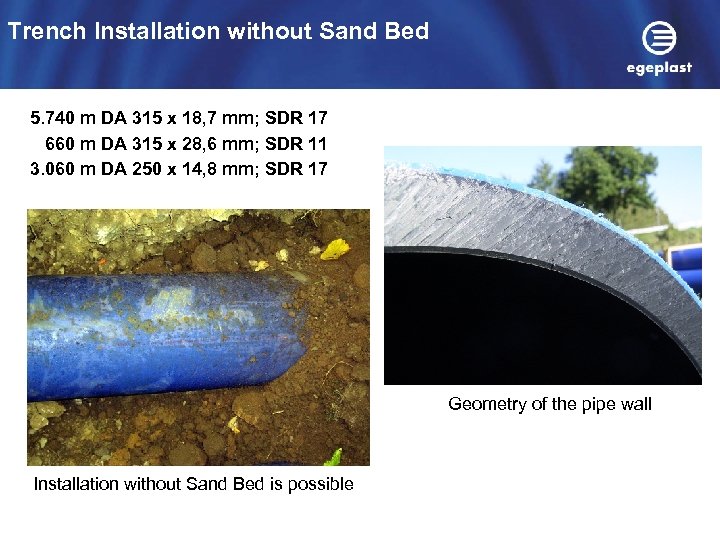

Trench Installation without Sand Bed 5. 740 m DA 315 x 18, 7 mm; SDR 17 660 m DA 315 x 28, 6 mm; SDR 11 3. 060 m DA 250 x 14, 8 mm; SDR 17 Geometry of the pipe wall Installation without Sand Bed is possible

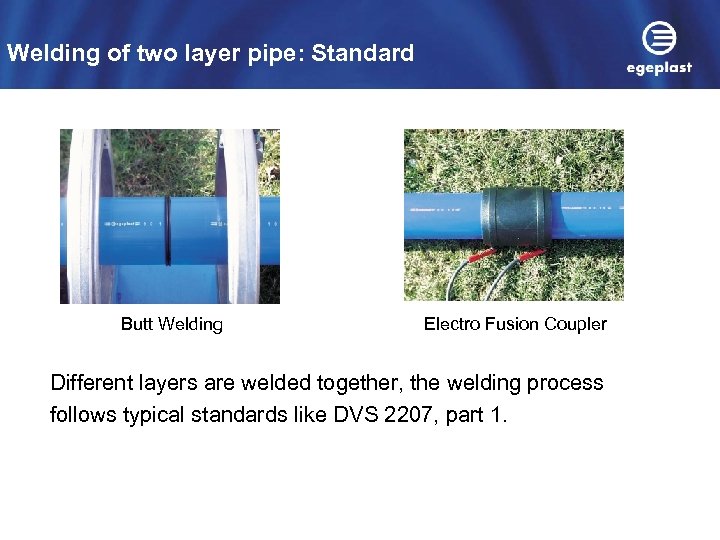

Welding of two layer pipe: Standard Butt Welding Electro Fusion Coupler Different layers are welded together, the welding process follows typical standards like DVS 2207, part 1.

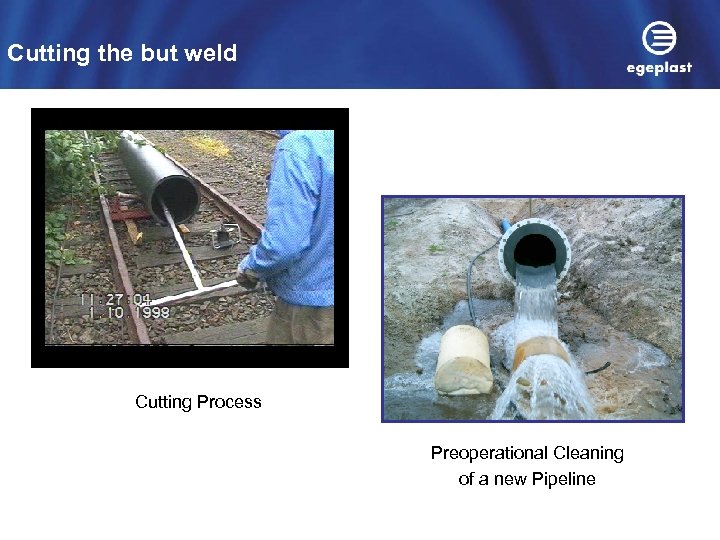

Cutting the but weld Cutting Process Preoperational Cleaning of a new Pipeline

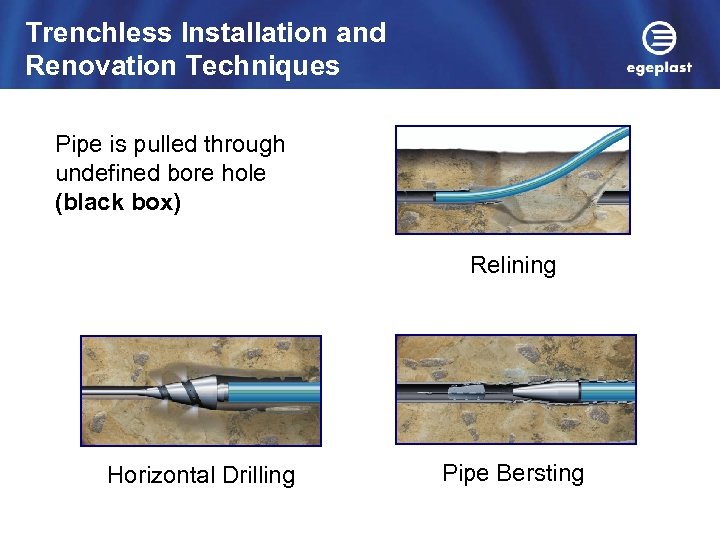

Trenchless Installation and Renovation Techniques Pipe is pulled through undefined bore hole (black box) Relining Horizontal Drilling Pipe Bersting

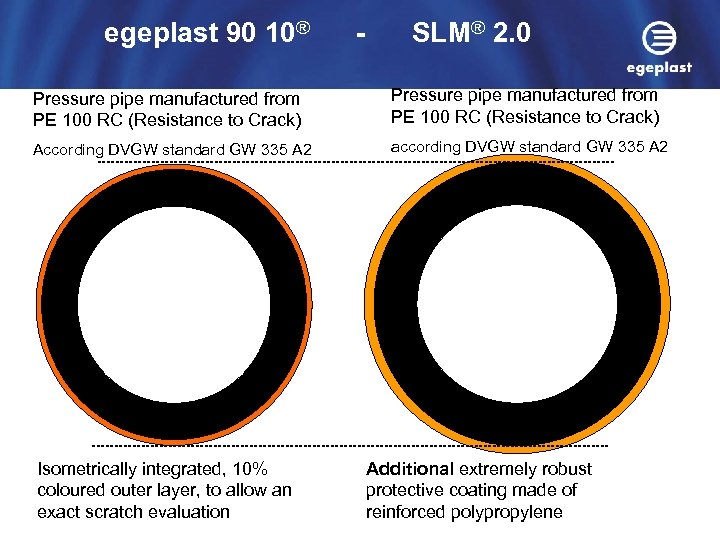

egeplast 90 10® - SLM® 2. 0 Pressure pipe manufactured from PE 100 RC (Resistance to Crack) According DVGW standard GW 335 A 2 according DVGW standard GW 335 A 2 Isometrically integrated, 10% coloured outer layer, to allow an exact scratch evaluation Additional extremely robust protective coating made of reinforced polypropylene

![Unprotected PE-Pipe vs. Coated Pipe after No-Dig Technology 1 0 1 2 3 [mm] Unprotected PE-Pipe vs. Coated Pipe after No-Dig Technology 1 0 1 2 3 [mm]](https://present5.com/presentation/35794cb1a5712ed4f1b1fc64f9c354b0/image-21.jpg)

Unprotected PE-Pipe vs. Coated Pipe after No-Dig Technology 1 0 1 2 3 [mm] 0 [mm] Unprotected PE Pipe Coextruded Multilayer egeplast SLM® 2. 0 Pipe e. g. egeplast 9010® • Scratches penetrate polyethylene pipes 3 times deeper than coating • No Damages under the coating No-Dig Technology

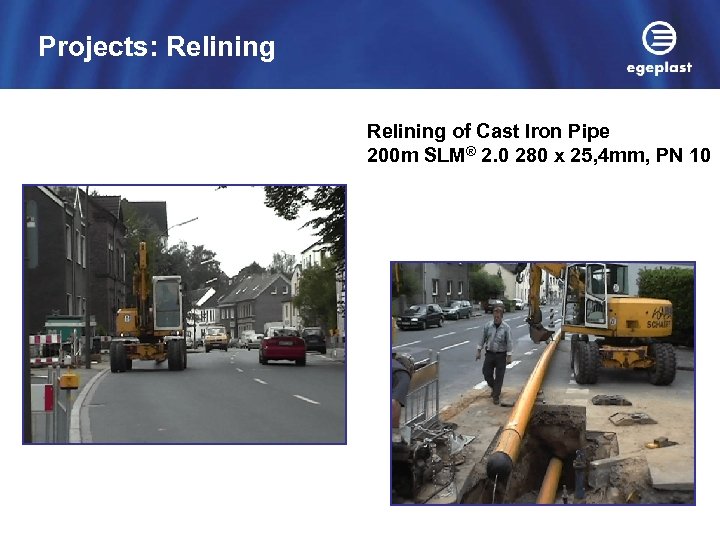

Projects: Relining of Cast Iron Pipe 200 m SLM® 2. 0 280 x 25, 4 mm, PN 10

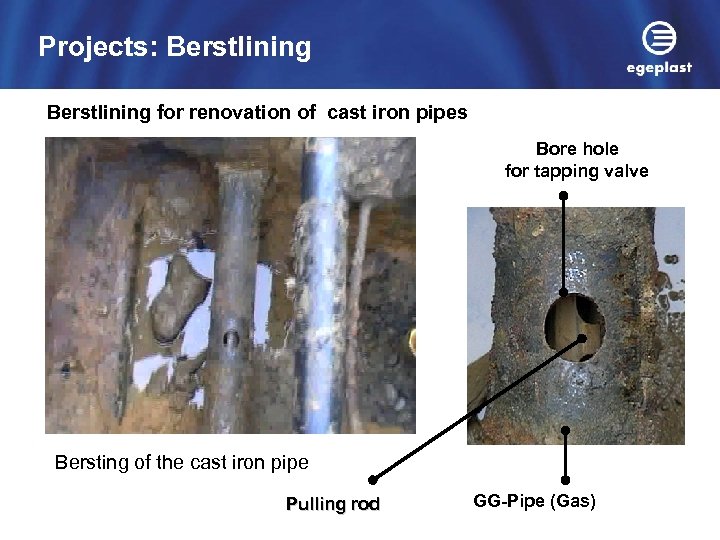

Projects: Berstlining for renovation of cast iron pipes Bore hole for tapping valve Bersting of the cast iron pipe Pulling rod GG-Pipe (Gas)

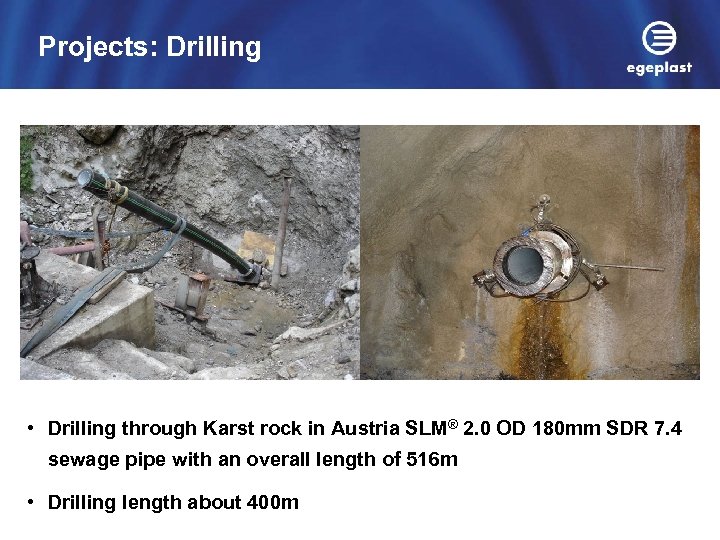

Projects: Drilling • Drilling through Karst rock in Austria SLM® 2. 0 OD 180 mm SDR 7. 4 sewage pipe with an overall length of 516 m • Drilling length about 400 m

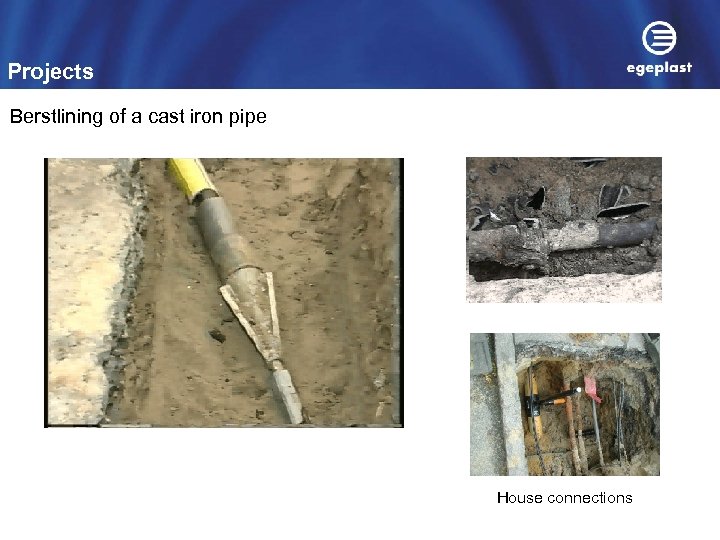

Projects Berstlining of a cast iron pipe House connections

Thank you for your attention!

35794cb1a5712ed4f1b1fc64f9c354b0.ppt