813e27bcf498f66e9499ae39b412ea0b.ppt

- Количество слайдов: 26

Joint tracking in friction stir welding Paul Fleming Vanderbilt University Welding Automation Laboratory

Joint tracking in friction stir welding Paul Fleming Vanderbilt University Welding Automation Laboratory

Introduction This research presents methods for the monitoring of tool alignment relative to the jointseam in Friction Stir Welding, as well as techniques for implementing automatic seamtracking for Friction Stir Welding

Introduction This research presents methods for the monitoring of tool alignment relative to the jointseam in Friction Stir Welding, as well as techniques for implementing automatic seamtracking for Friction Stir Welding

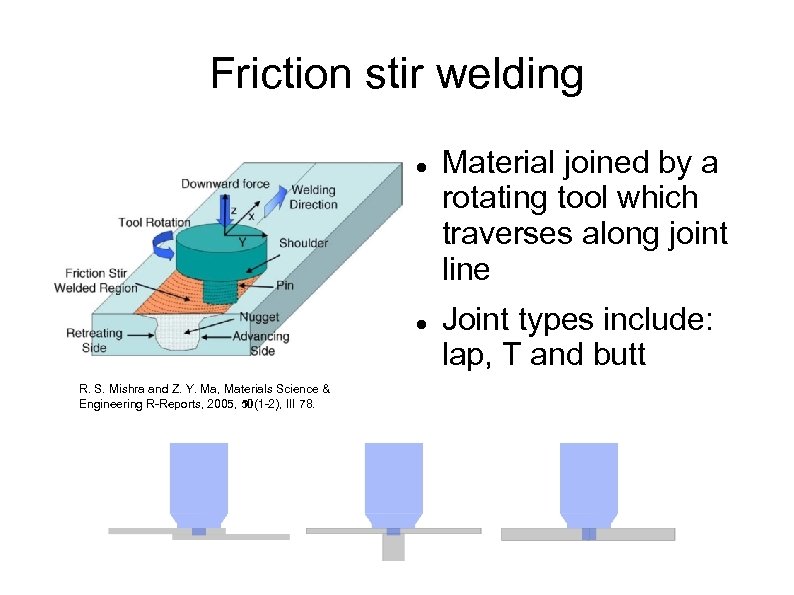

Friction stir welding R. S. Mishra and Z. Y. Ma, Materials Science & Engineering R-Reports, 2005, 50(1 -2), III 78. Material joined by a rotating tool which traverses along joint line Joint types include: lap, T and butt

Friction stir welding R. S. Mishra and Z. Y. Ma, Materials Science & Engineering R-Reports, 2005, 50(1 -2), III 78. Material joined by a rotating tool which traverses along joint line Joint types include: lap, T and butt

Goal of this research Develop system capable of detecting the lateral position of the FSW with respect to a desired position such as centered about the weld seam Developing system which utilizes above estimator in a feedback control system which maintains a desired lateral position This is “Through the Tool Tracking” (TTT) Patent pending serial number Serial No. is 12/130, 622

Goal of this research Develop system capable of detecting the lateral position of the FSW with respect to a desired position such as centered about the weld seam Developing system which utilizes above estimator in a feedback control system which maintains a desired lateral position This is “Through the Tool Tracking” (TTT) Patent pending serial number Serial No. is 12/130, 622

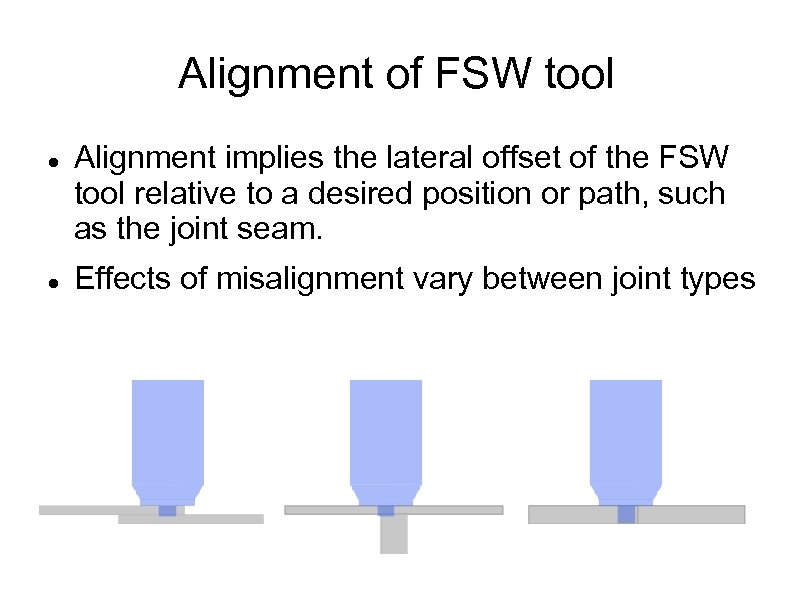

Alignment of FSW tool Alignment implies the lateral offset of the FSW tool relative to a desired position or path, such as the joint seam. Effects of misalignment vary between joint types

Alignment of FSW tool Alignment implies the lateral offset of the FSW tool relative to a desired position or path, such as the joint seam. Effects of misalignment vary between joint types

Purpose of research The estimator itself could be used as an insystem quality check: misalignment can cause a number of quality flaws and in some jointtypes (such as blind T-joints) it may not be possible to determine lateral position by visual inspection TTT would provide automated seam-tracking, which could allow for tracking of linear and nonlinear weld seams.

Purpose of research The estimator itself could be used as an insystem quality check: misalignment can cause a number of quality flaws and in some jointtypes (such as blind T-joints) it may not be possible to determine lateral position by visual inspection TTT would provide automated seam-tracking, which could allow for tracking of linear and nonlinear weld seams.

Force as a feedback signal Forces collected during the weld are used as the feedback signal to determine lateral position Force signals have already been used in FSW: Discover metallurgical defects Detect gaps in sample fit-up Implement load-control Estimate tensile strength

Force as a feedback signal Forces collected during the weld are used as the feedback signal to determine lateral position Force signals have already been used in FSW: Discover metallurgical defects Detect gaps in sample fit-up Implement load-control Estimate tensile strength

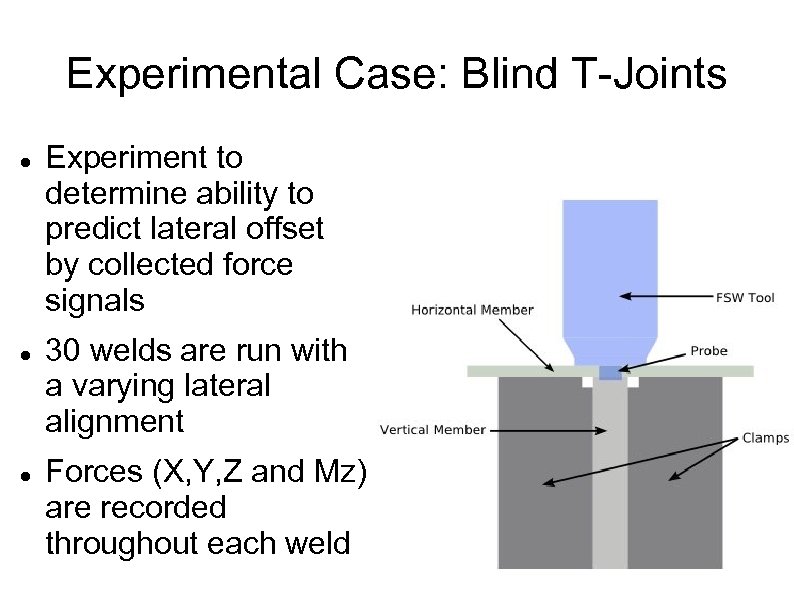

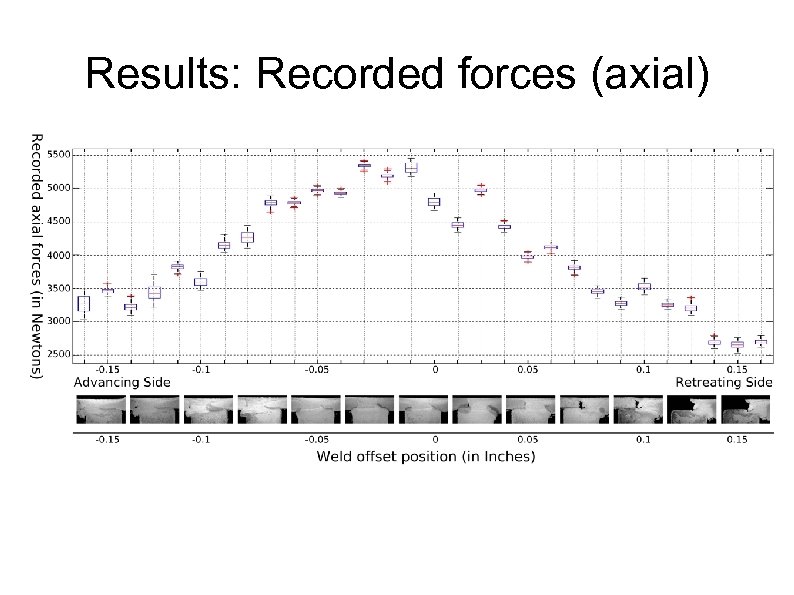

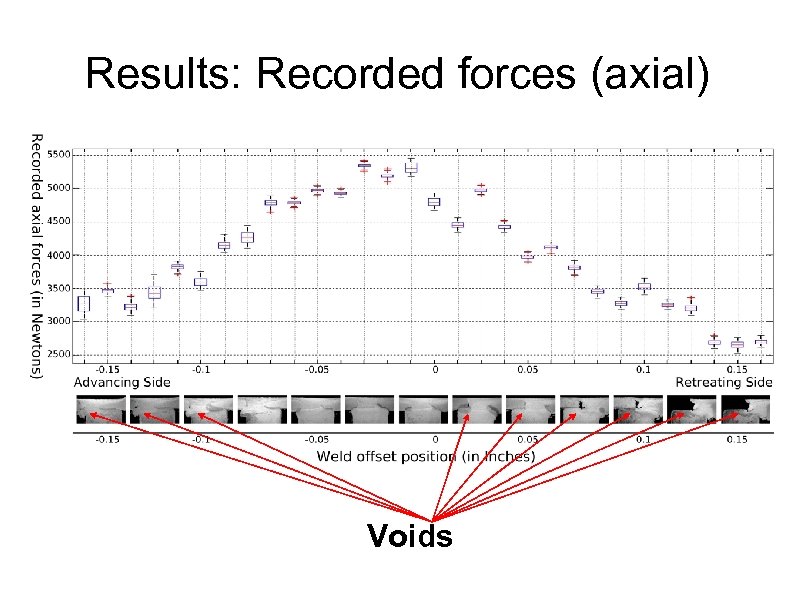

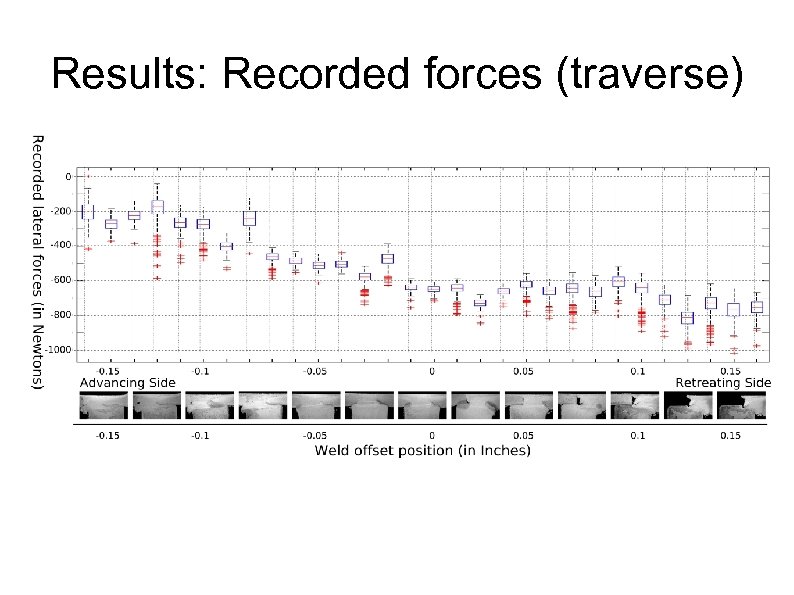

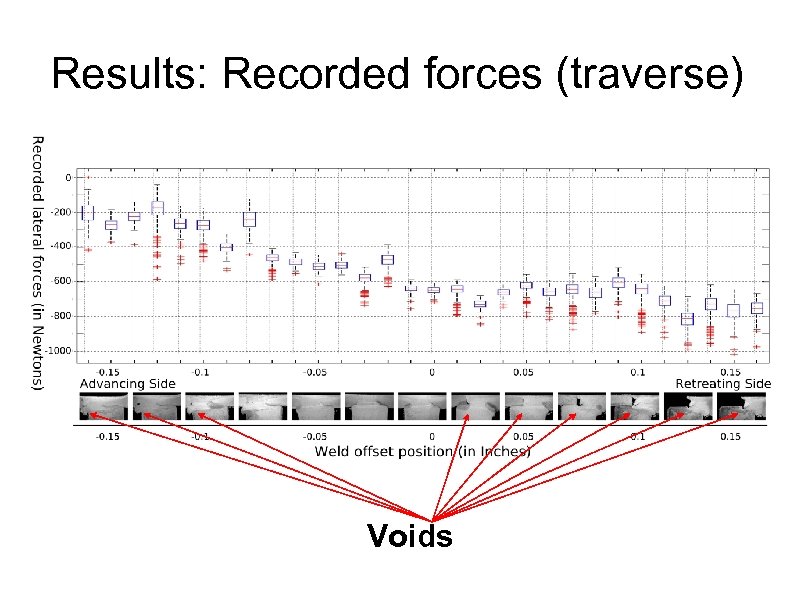

Experimental Case: Blind T-Joints Experiment to determine ability to predict lateral offset by collected force signals 30 welds are run with a varying lateral alignment Forces (X, Y, Z and Mz) are recorded throughout each weld

Experimental Case: Blind T-Joints Experiment to determine ability to predict lateral offset by collected force signals 30 welds are run with a varying lateral alignment Forces (X, Y, Z and Mz) are recorded throughout each weld

Results: Recorded forces (axial)

Results: Recorded forces (axial)

Results: Recorded forces (axial) Voids

Results: Recorded forces (axial) Voids

Results: Recorded forces (traverse)

Results: Recorded forces (traverse)

Results: Recorded forces (traverse) Voids

Results: Recorded forces (traverse) Voids

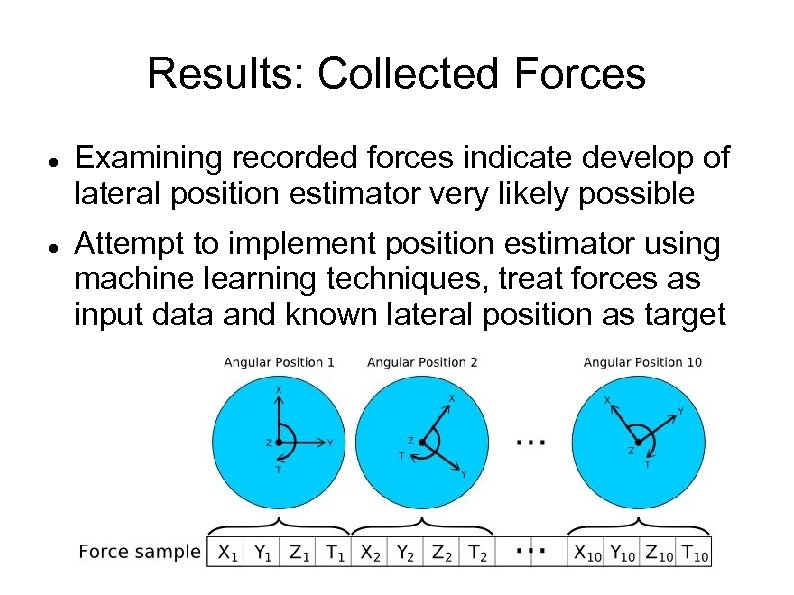

Results: Collected Forces Examining recorded forces indicate develop of lateral position estimator very likely possible Attempt to implement position estimator using machine learning techniques, treat forces as input data and known lateral position as target

Results: Collected Forces Examining recorded forces indicate develop of lateral position estimator very likely possible Attempt to implement position estimator using machine learning techniques, treat forces as input data and known lateral position as target

Position estimation Desire to construct an estimator which can predict offset position given gathered forces. Many possible choices: linear or non-linear regression, regression tree, SVM General regression neural network chosen

Position estimation Desire to construct an estimator which can predict offset position given gathered forces. Many possible choices: linear or non-linear regression, regression tree, SVM General regression neural network chosen

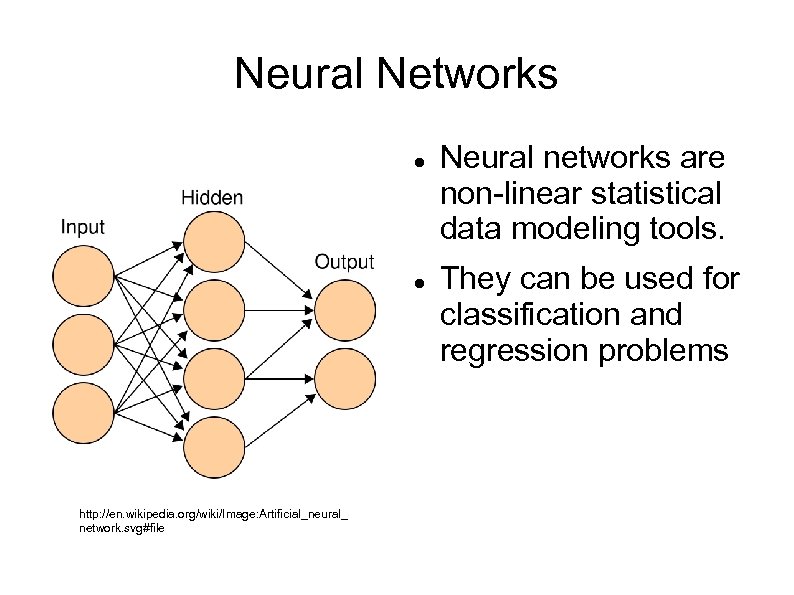

Neural Networks http: //en. wikipedia. org/wiki/Image: Artificial_neural_ network. svg#file Neural networks are non-linear statistical data modeling tools. They can be used for classification and regression problems

Neural Networks http: //en. wikipedia. org/wiki/Image: Artificial_neural_ network. svg#file Neural networks are non-linear statistical data modeling tools. They can be used for classification and regression problems

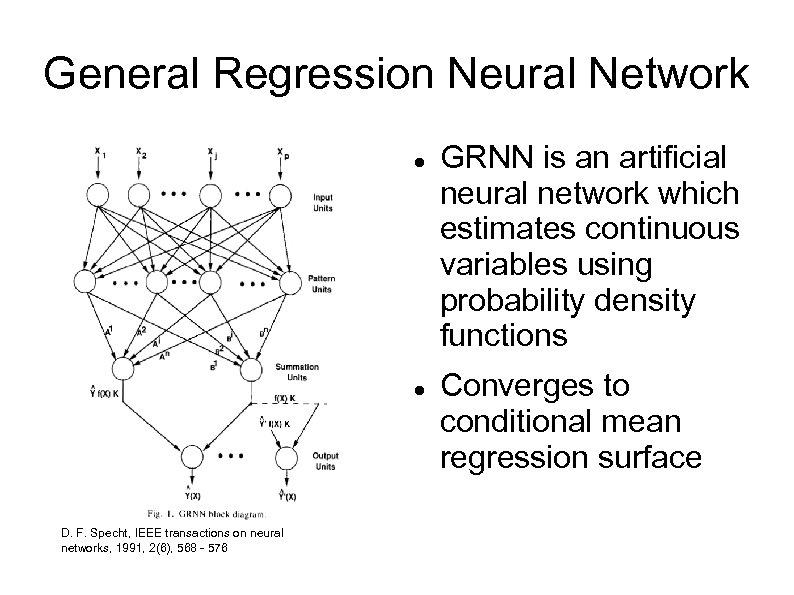

General Regression Neural Network D. F. Specht, IEEE transactions on neural networks, 1991, 2(6), 568 - 576 GRNN is an artificial neural network which estimates continuous variables using probability density functions Converges to conditional mean regression surface

General Regression Neural Network D. F. Specht, IEEE transactions on neural networks, 1991, 2(6), 568 - 576 GRNN is an artificial neural network which estimates continuous variables using probability density functions Converges to conditional mean regression surface

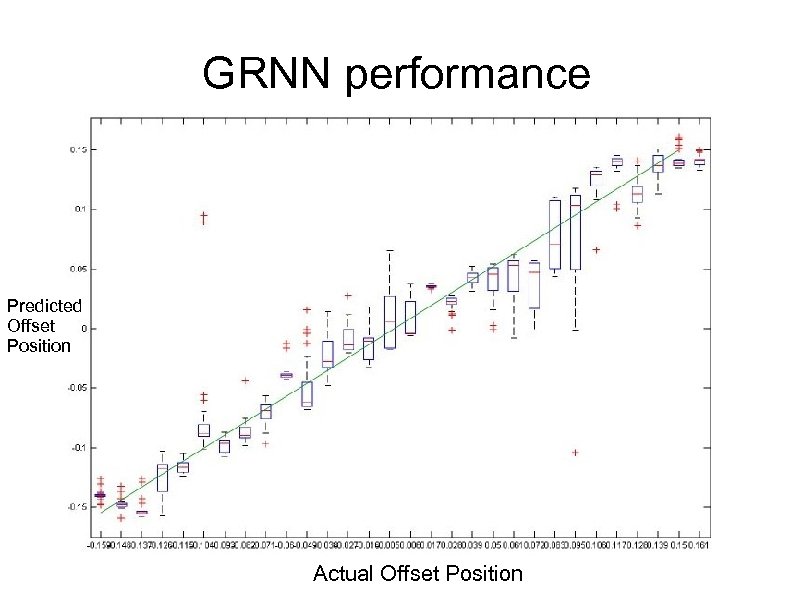

GRNN performance Predicted Offset Position Actual Offset Position

GRNN performance Predicted Offset Position Actual Offset Position

Continuous monitoring of weld After learning the GRNN using training data, then applied network to weld runs where the lateral offset was changed several times throughout the weld

Continuous monitoring of weld After learning the GRNN using training data, then applied network to weld runs where the lateral offset was changed several times throughout the weld

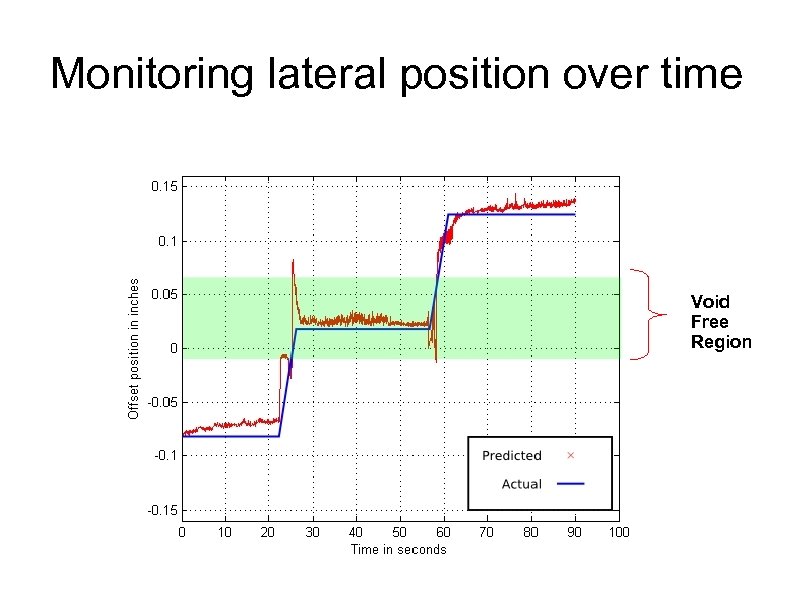

Monitoring lateral position over time Void Free Region

Monitoring lateral position over time Void Free Region

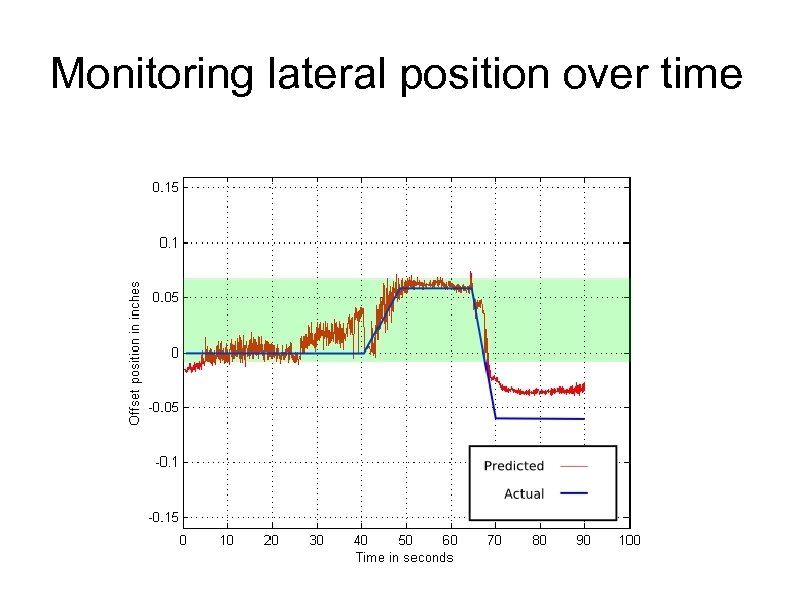

Monitoring lateral position over time

Monitoring lateral position over time

Research into Monitoring Capabilities Presented research demonstrates effectiveness of technique for determining offset position in “open-air” T-joints Current research seeks to apply the same technique to lap-joints Additional research topics: Enhancing the signal Applicaitions. . .

Research into Monitoring Capabilities Presented research demonstrates effectiveness of technique for determining offset position in “open-air” T-joints Current research seeks to apply the same technique to lap-joints Additional research topics: Enhancing the signal Applicaitions. . .

Using system for on-line tracking The system as described could be used for quality monitoring of an FSW process Additionally, the system could be used as a lateral position estimator in an FSW seamtracking system FSW PLANT Lateral Position Estimator

Using system for on-line tracking The system as described could be used for quality monitoring of an FSW process Additionally, the system could be used as a lateral position estimator in an FSW seamtracking system FSW PLANT Lateral Position Estimator

On-line seam-tracking The system is envisioned in two-varieties In one, it is assumed that it is capable for an estimator block to be developed which can determine the magnitude and direction of lateral offset. A controller maintains the desired offset throughout the weld In another case, a signal is maximized at a certain position (such as the axial force in this experiment around the centered position). In this case, the system weaves back and forth to gain the center position.

On-line seam-tracking The system is envisioned in two-varieties In one, it is assumed that it is capable for an estimator block to be developed which can determine the magnitude and direction of lateral offset. A controller maintains the desired offset throughout the weld In another case, a signal is maximized at a certain position (such as the axial force in this experiment around the centered position). In this case, the system weaves back and forth to gain the center position.

Incorporating load control Load control is a component of some FSW systems. The seam tracking system, which uses forces as its input signal, could be made to include load control by operating in two alternating stages: Use seam-tracking to move tool to desired offset Use load control to obtain desired axial force as known location

Incorporating load control Load control is a component of some FSW systems. The seam tracking system, which uses forces as its input signal, could be made to include load control by operating in two alternating stages: Use seam-tracking to move tool to desired offset Use load control to obtain desired axial force as known location

Future research for both monitoring and control Monitoring: Improving the offset monitoring system and applying to more joint types Tracking: Development and testing of systems which automatically track the weld seam

Future research for both monitoring and control Monitoring: Improving the offset monitoring system and applying to more joint types Tracking: Development and testing of systems which automatically track the weld seam

Thank you Questions?

Thank you Questions?