4d065130575e3faaf575bfb5eceb31aa.ppt

- Количество слайдов: 21

J. B. Mallay, PE, LEED AP SSRCx, LLC High Performance Buildings 2007 Marketing Commissioning Services to Building Owners

Agenda § Some Goals of Owner’s § Marketing Professional Service § 3 Things § Owner’s Burning Issues § Identifying Types of Salesmen § What is your unique Differentiator – What makes your company different ? § Keeping Commissioning in the Budget § The Value of Commissioning

Some Goals of Owner’s n The client doesn’t want to buy commissioning services; they want to buy smooth relations with the community, trustees, business districts, boards. n He wants to buy an on-time on budget delay free project. n Someone to help with Their Challenges n Someone to Trust who has the Owners interests as priority.

Marketing Professional Commissioning Services n Marketing (generating the lead) and Selling (converting a lead into a sale) n By the time you are sitting and talking you have successfully marketed – now it’s selling n “Who have you worked for? ” “What are your capabilities? ” “What depth of personnel do you have? ” “How good are your references? ” n All things being equal-Do I want to work with you ?

3 Important Things n. Bring Value n. Bring Trust ( earn) n. Bring Solutions to Their Problems n I hate to be sold, but I may be willing to buy if you can show me that my company and I have some problems to solve

Trust n Personal risk. Skeptical. Concerned Value n Give me some new information. Tell me what my competitors are up to. Tell me what you’ve been doing for other companies like mine. Find a way to be helpful to me. n Give me an education. Tell me about alternate ways that common problems of my industry might be dealt with. Help me understand the advantages and disadvantages of some of the things I have been reading about.

Case History- Owner’s Comments They Want : n a set of Independent eyes n A partner with Owner’s interest as first Priority n A team with a mix of appropriate experience and background n Someone to make sure the facility works n Someone to help free-up engineering and maintenance staff n Value for their money n Someone to push the contractors and subs

Owner’s Burning Issues Do research n Ask the Right Questions. n Know What they are to Address later in the RFP n

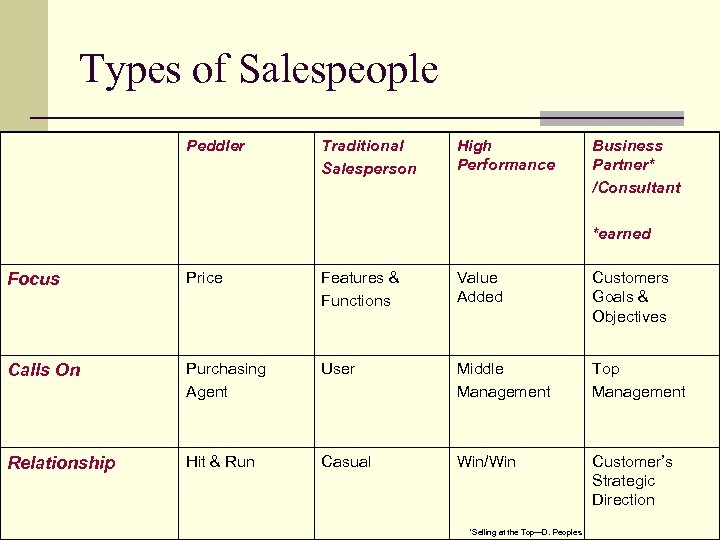

Types of Salespeople Peddler Traditional Salesperson High Performance Business Partner* /Consultant *earned Focus Price Features & Functions Value Added Customers Goals & Objectives Calls On Purchasing Agent User Middle Management Top Management Relationship Hit & Run Casual Win/Win Customer’s Strategic Direction *Selling at the Top—D. Peoples

Differentiation n Unique Experience in the Project Type n Most common , least effective n Commissioning Process is Different & Superior n Effective in QC conscious world n Value of Services is Quantitatively Better n Most effective n Branding and Uniqueness of Your Firm n Sets you apart. The more things are the same the more differences are important

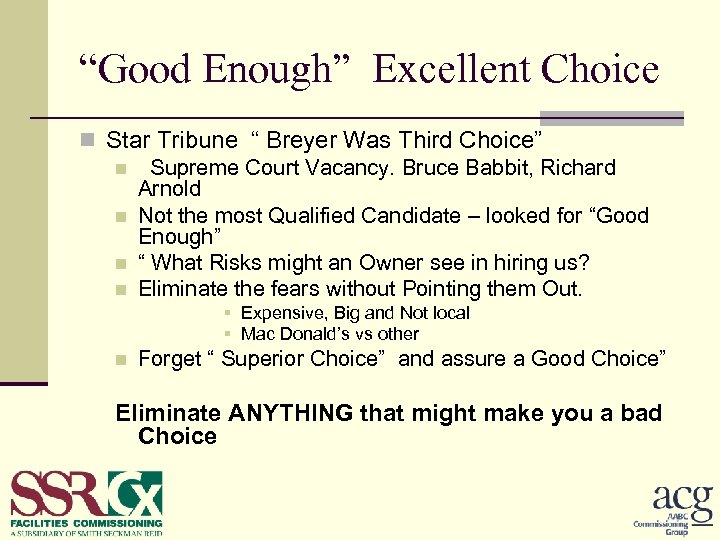

“Good Enough” Excellent Choice n Star Tribune “ Breyer Was Third Choice” n Supreme Court Vacancy. Bruce Babbit, Richard Arnold n Not the most Qualified Candidate – looked for “Good Enough” n “ What Risks might an Owner see in hiring us? n Eliminate the fears without Pointing them Out. § Expensive, Big and Not local § Mac Donald’s vs other n Forget “ Superior Choice” and assure a Good Choice” Eliminate ANYTHING that might make you a bad Choice

What is the Value Proposition of Commissioning? § Solution to the Owner’s Issues related to bringing in a project on time, in budget and as contracted § Documented Savings § Documented Effectiveness

Commissioning Team and Design Team working together to produce most complete documents possible

Partnering/Team Building Commissioning is a Facilitation Process

Pre-Functional Checking

Functional Testing • Functional Performance Tests

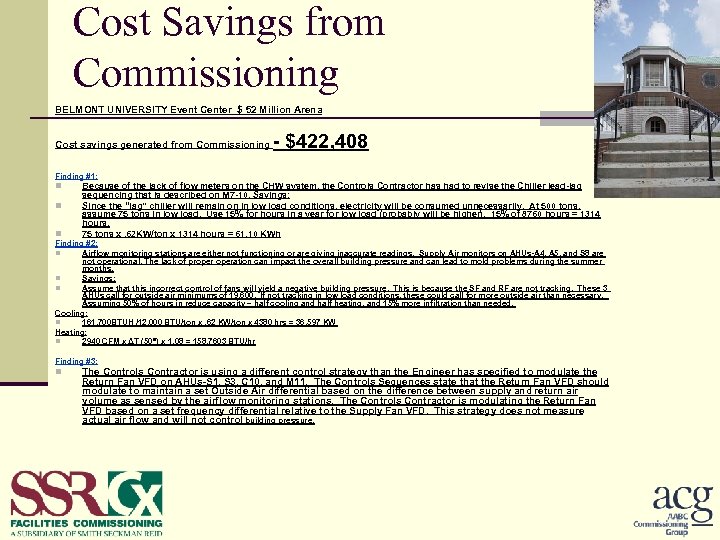

Cost Savings from Commissioning BELMONT UNIVERSITY Event Center $ 52 Million Arena Cost savings generated from Commissioning - $422, 408 Finding #1: n n n Because of the lack of flow meters on the CHW system, the Controls Contractor has had to revise the Chiller lead-lag sequencing that is described on M 7 -10. Savings: Since the “lag” chiller will remain on in low load conditions, electricity will be consumed unnecessarily. At 500 tons, assume 75 tons in low load. Use 15% for hours in a year for low load (probably will be higher). 15% of 8760 hours = 1314 hours. 75 tons x. 62 KW/ton x 1314 hours = 61. 10 KWh Finding #2: n Airflow monitoring stations are either not functioning or are giving inaccurate readings. Supply Air monitors on AHUs-A 4, A 5, and S 8 are not operational. The lack of properation can impact the overall building pressure and can lead to mold problems during the summer months. n Savings: n Assume that this incorrect control of fans will yield a negative building pressure. This is because the SF and RF are not tracking. These 3 AHUs call for outside air minimums of 19, 600. If not tracking in low load conditions, these could call for more outside air than necessary. Assuming 50% of hours in reduce capacity – half cooling and half heating, and 15% more infiltration than needed. Cooling: n 161, 700 BTUH /12, 000 BTU/ton x. 62 KW/ton x 4380 hrs = 36, 597 KW Heating: n 2940 CFM x ΔT (50 ) x 1. 08 = 158, 7603 BTU/hr Finding #3: n The Controls Contractor is using a different control strategy than the Engineer has specified to modulate the Return Fan VFD on AHUs-S 1, S 3, C 10, and M 11. The Controls Sequences state that the Return Fan VFD should modulate to maintain a set Outside Air differential based on the difference between supply and return air volume as sensed by the airflow monitoring stations. The Controls Contractor is modulating the Return Fan VFD based on a set frequency differential relative to the Supply Fan VFD. This strategy does not measure actual air flow and will not control building pressure.

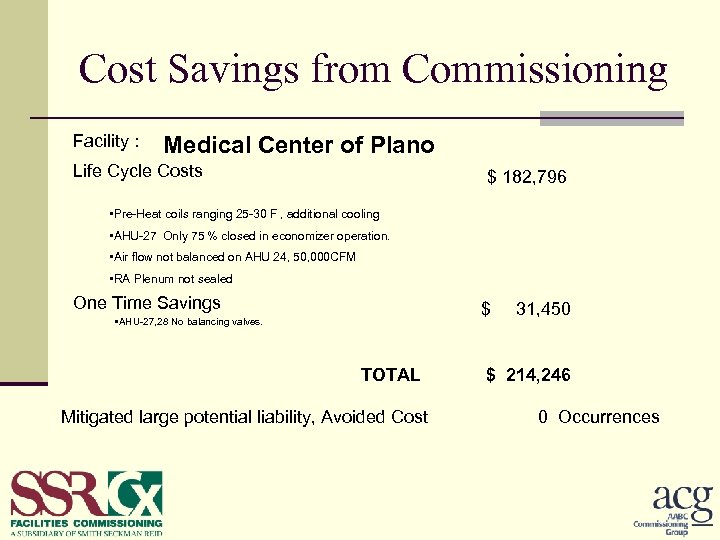

Cost Savings from Commissioning Facility : Medical Center of Plano Life Cycle Costs $ 182, 796 • Pre-Heat coils ranging 25 -30 F , additional cooling • AHU-27 Only 75 % closed in economizer operation. • Air flow not balanced on AHU 24, 50, 000 CFM • RA Plenum not sealed One Time Savings $ • AHU-27, 28 No balancing valves. TOTAL Mitigated large potential liability, Avoided Cost 31, 450 $ 214, 246 0 Occurrences

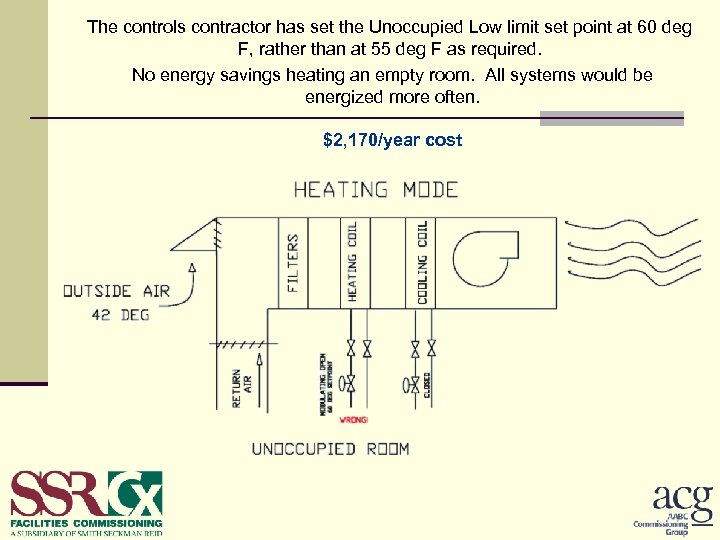

The controls contractor has set the Unoccupied Low limit set point at 60 deg F, rather than at 55 deg F as required. No energy savings heating an empty room. All systems would be energized more often. $2, 170/year cost

Keep It in The Budget n Burning issues that have been identified earlier n Sustainability is driving a driving force. n Persistent Performance, LEED Financial Impacts n Risks n Good Leadership n Good job of Identifying Value to the Project Champion” early in the Process. n “

Questions and Comments Questions? Thank You!

4d065130575e3faaf575bfb5eceb31aa.ppt