6b9d1e8f7990976a8f755b7abc7e1569.ppt

- Количество слайдов: 28

ITTTM Tool #25 Short Form “ISO and QS 9000 Maturing: Foundations For Quality Services, Auditing And Lean Improvements” Topics 1. ISO/QS introduced and overviewed 2. ISO requirements, focus, foundations 3. TS 16949 2002, environmental 14000 4. Auditing quality systems 5. General concerns, getting started 6. Kaizen, six sigma, lean relationships 7. Tool applications……… Short Form Tool 25

ITTTM Tool #25 Short Form “ISO and QS 9000 Maturing: Foundations For Quality Services, Auditing And Lean Improvements” Topics 1. ISO/QS introduced and overviewed 2. ISO requirements, focus, foundations 3. TS 16949 2002, environmental 14000 4. Auditing quality systems 5. General concerns, getting started 6. Kaizen, six sigma, lean relationships 7. Tool applications……… Short Form Tool 25

ITTTM ISO/QS Introduced And Overviewed ISO, international standards organization • Focused on global marketplace, and at home • QS, domestic customer/supplier issues • How we do business, future, contract issues • Consistent standards, level playing field 80% of ISO overlaps into QS standards • Automotive Industry Alliance Group (AIAG) • Key part of understanding customers • QS standard is mostly American ISO • Understanding, satisfying customers Short Form Tool 25

ITTTM ISO/QS Introduced And Overviewed ISO, international standards organization • Focused on global marketplace, and at home • QS, domestic customer/supplier issues • How we do business, future, contract issues • Consistent standards, level playing field 80% of ISO overlaps into QS standards • Automotive Industry Alliance Group (AIAG) • Key part of understanding customers • QS standard is mostly American ISO • Understanding, satisfying customers Short Form Tool 25

ITTTM ISO/QS Introduced And Overviewed ISO is about Baldridge, broad framework, TQM • Baldridge is through Commerce Department • American “push” for quality Baldridge basis, ISO, QS, relationships • Leadership, how we do business • Information and analysis • Strategic quality planning • Human resource development • Management of process quality, operations • Customer focus and satisfaction Short Form Tool 25

ITTTM ISO/QS Introduced And Overviewed ISO is about Baldridge, broad framework, TQM • Baldridge is through Commerce Department • American “push” for quality Baldridge basis, ISO, QS, relationships • Leadership, how we do business • Information and analysis • Strategic quality planning • Human resource development • Management of process quality, operations • Customer focus and satisfaction Short Form Tool 25

ITTTM ISO/QS Introduced And Overviewed Standards do not measure quality……. • Organization identifies, defines, standards • Manages production per customer demands • Specifies, certifies quality, compliance • Organization certifies, contractually, customer Registrar selected similar to any supplier • Registrar, body such as Underwriters Lab • Reviews documentation system, quality manual • Do pre-assessment, preparatory work internal • Must understand business, be customer focused • Objective, willing, to work your calendar Short Form Tool 25

ITTTM ISO/QS Introduced And Overviewed Standards do not measure quality……. • Organization identifies, defines, standards • Manages production per customer demands • Specifies, certifies quality, compliance • Organization certifies, contractually, customer Registrar selected similar to any supplier • Registrar, body such as Underwriters Lab • Reviews documentation system, quality manual • Do pre-assessment, preparatory work internal • Must understand business, be customer focused • Objective, willing, to work your calendar Short Form Tool 25

ITTTM ISO/QS Introduced And Overviewed Assessment, internal, external audit, certification • Internal is to comply, may not certify, correct • External certification, desired, third party Process design, documentation routinely updated • Describes what we do, who is responsible • Describes how all is done, records, practices Time to be registered generally 6 -12 months ++ • Organization size, processes, preparedness • Startup costs, $15 -25 K, total easily twice this Short Form Tool 25

ITTTM ISO/QS Introduced And Overviewed Assessment, internal, external audit, certification • Internal is to comply, may not certify, correct • External certification, desired, third party Process design, documentation routinely updated • Describes what we do, who is responsible • Describes how all is done, records, practices Time to be registered generally 6 -12 months ++ • Organization size, processes, preparedness • Startup costs, $15 -25 K, total easily twice this Short Form Tool 25

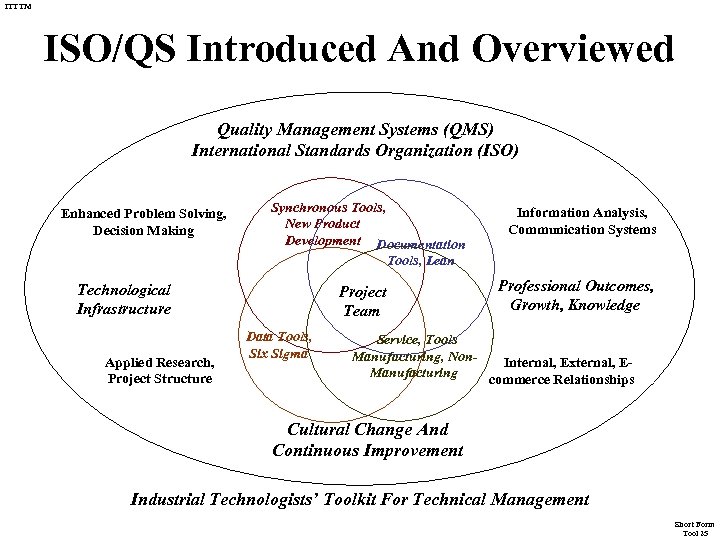

ITTTM ISO/QS Introduced And Overviewed Quality Management Systems (QMS) International Standards Organization (ISO) Enhanced Problem Solving, Decision Making Synchronous Tools, New Product Development Documentation Tools, Lean Technological Infrastructure Applied Research, Project Structure Project Team Data Tools, Six Sigma Information Analysis, Communication Systems Professional Outcomes, Growth, Knowledge Service, Tools Manufacturing, Non. Internal, External, EManufacturing commerce Relationships Cultural Change And Continuous Improvement Industrial Technologists’ Toolkit For Technical Management Short Form Tool 25

ITTTM ISO/QS Introduced And Overviewed Quality Management Systems (QMS) International Standards Organization (ISO) Enhanced Problem Solving, Decision Making Synchronous Tools, New Product Development Documentation Tools, Lean Technological Infrastructure Applied Research, Project Structure Project Team Data Tools, Six Sigma Information Analysis, Communication Systems Professional Outcomes, Growth, Knowledge Service, Tools Manufacturing, Non. Internal, External, EManufacturing commerce Relationships Cultural Change And Continuous Improvement Industrial Technologists’ Toolkit For Technical Management Short Form Tool 25

ITTTM ISO Requirements, Focus, Foundations Basic systems grew out of the 9000 framework • 9000 was a five part series, basic guidebook • 9001 was service, 9002 detailed production , and 9003 focused on inspection and testing • 9001, 9002, 9003 was audited by third party More recent ISO developments are QS 9000 • 20 elements which describe the standard • Elements detail specific areas for compliance • Totality of elements provide quality system • Documented quality manual, increasingly online Short Form Tool 25

ITTTM ISO Requirements, Focus, Foundations Basic systems grew out of the 9000 framework • 9000 was a five part series, basic guidebook • 9001 was service, 9002 detailed production , and 9003 focused on inspection and testing • 9001, 9002, 9003 was audited by third party More recent ISO developments are QS 9000 • 20 elements which describe the standard • Elements detail specific areas for compliance • Totality of elements provide quality system • Documented quality manual, increasingly online Short Form Tool 25

ITTTM ISO Requirements, Focus, Foundations 20 elements identified • Management responsibility • Quality system • Contract review • Design control • Document and data control • Purchasing • Control of customer supplied product • Product identification and traceability • Process control • Inspection and testing Short Form Tool 25

ITTTM ISO Requirements, Focus, Foundations 20 elements identified • Management responsibility • Quality system • Contract review • Design control • Document and data control • Purchasing • Control of customer supplied product • Product identification and traceability • Process control • Inspection and testing Short Form Tool 25

ITTTM ISO Requirements, Focus, Foundations 20 elements identified (cont. ) • Control of inspection, measuring, test equipment • Inspection and test status • Control of non-conforming product • Corrective and preventive action • Handling, storage, packaging, delivery preservation • Control of quality records • Internal quality audits • Training • Servicing • Statistical techniques Short Form Tool 25

ITTTM ISO Requirements, Focus, Foundations 20 elements identified (cont. ) • Control of inspection, measuring, test equipment • Inspection and test status • Control of non-conforming product • Corrective and preventive action • Handling, storage, packaging, delivery preservation • Control of quality records • Internal quality audits • Training • Servicing • Statistical techniques Short Form Tool 25

ITTTM ISO Requirements, Focus, Foundations Most complex, first tier is quality manual • Overall guide to organization • Policies and objectives Second level of complexity, procedural tier • Process descriptions • Flowcharts of the system Third level, work instructions, step by step • Standard operating procedures (SOPs) Fourth tier, lowest level, form and record • Detailed charts, records, systems’ elements Short Form Tool 25

ITTTM ISO Requirements, Focus, Foundations Most complex, first tier is quality manual • Overall guide to organization • Policies and objectives Second level of complexity, procedural tier • Process descriptions • Flowcharts of the system Third level, work instructions, step by step • Standard operating procedures (SOPs) Fourth tier, lowest level, form and record • Detailed charts, records, systems’ elements Short Form Tool 25

ITTTM ISO Requirements, Focus, Foundations Sector specific requirements……. . those requirements specific to your industry • Production part approval, verification: PPAP or PVP each focus on new product development platforms in supply chain • Continuous improvement: how this philosophy is addressed throughout the organization must be defined, explained • Manufacturing capabilities: cross functionalities impacting manufacturing issues must be accounted for, addressed Short Form Tool 25

ITTTM ISO Requirements, Focus, Foundations Sector specific requirements……. . those requirements specific to your industry • Production part approval, verification: PPAP or PVP each focus on new product development platforms in supply chain • Continuous improvement: how this philosophy is addressed throughout the organization must be defined, explained • Manufacturing capabilities: cross functionalities impacting manufacturing issues must be accounted for, addressed Short Form Tool 25

ITTTM TS 16949 2002, Environmental 14000 Seamless, integrated quality management systems • Based on ISO 9000 systems, traditions, three broad areas of concern for TS 16949 – Product development: one of the keys, how to manage customers and suppliers in the chain – Production processes: a second area focused on adding value in the stream of processes – Support processes: documenting technical functions required to facilitate production • These give an over-arching framework for TS 16949 systems, main processes for adding value Short Form Tool 25

ITTTM TS 16949 2002, Environmental 14000 Seamless, integrated quality management systems • Based on ISO 9000 systems, traditions, three broad areas of concern for TS 16949 – Product development: one of the keys, how to manage customers and suppliers in the chain – Production processes: a second area focused on adding value in the stream of processes – Support processes: documenting technical functions required to facilitate production • These give an over-arching framework for TS 16949 systems, main processes for adding value Short Form Tool 25

ITTTM TS 16949 2002, Environmental 14000 TS 16949 simplifies the previous 20 ISO elements to be more user friendly as five broad-based elements: • Quality management system: relationships and sequences for all functions • Management responsibility: demonstrable indications of top management commitment • Resource management: assuring that resources are available to fulfill commitments • Product realization: understanding quality objectives in product • Measurement, analysis and improvement: databased measures are used to improve Short Form Tool 25

ITTTM TS 16949 2002, Environmental 14000 TS 16949 simplifies the previous 20 ISO elements to be more user friendly as five broad-based elements: • Quality management system: relationships and sequences for all functions • Management responsibility: demonstrable indications of top management commitment • Resource management: assuring that resources are available to fulfill commitments • Product realization: understanding quality objectives in product • Measurement, analysis and improvement: databased measures are used to improve Short Form Tool 25

ITTTM TS 16949 2002, Environmental 14000 standard helps all to assess environmental performance in five areas: • General requirements: requires establishment of a system compliant with 14000 • Environmental policy: top management led environmental policy and commitment • Planning: procedures put in place to assure appropriate environmental actions • Implementation and operation: environmental management procedures, clearly documented • Management review: management’s scheduled evaluations of systems, for improvement Short Form Tool 25

ITTTM TS 16949 2002, Environmental 14000 standard helps all to assess environmental performance in five areas: • General requirements: requires establishment of a system compliant with 14000 • Environmental policy: top management led environmental policy and commitment • Planning: procedures put in place to assure appropriate environmental actions • Implementation and operation: environmental management procedures, clearly documented • Management review: management’s scheduled evaluations of systems, for improvement Short Form Tool 25

ITTTM Auditing Quality Systems A key method for improvement is the audit……. . • Audit is essentially a evaluative survey of system conducted for improvement • Commonly a review of documentation derived from quality system • Generally an independent review by someone outside the group or function being audited • Seeking to identify and resolve non-conformities • Usually done as external, internal or third party • Types of audits include financial, system, product and process Short Form Tool 25

ITTTM Auditing Quality Systems A key method for improvement is the audit……. . • Audit is essentially a evaluative survey of system conducted for improvement • Commonly a review of documentation derived from quality system • Generally an independent review by someone outside the group or function being audited • Seeking to identify and resolve non-conformities • Usually done as external, internal or third party • Types of audits include financial, system, product and process Short Form Tool 25

ITTTM Auditing Quality Systems A key method for improvement is the audit……. . • Financial audit focuses on accounting issues • Systemic audits look at broad policy, procedures • Product review, quality characteristic compliance • Process audits review total process, sub systems There are several reasons for doing the audit……. . • To assure compliance to standard • Monitor personnel improvement • Improve financial performance • Measure management effectiveness Short Form Tool 25

ITTTM Auditing Quality Systems A key method for improvement is the audit……. . • Financial audit focuses on accounting issues • Systemic audits look at broad policy, procedures • Product review, quality characteristic compliance • Process audits review total process, sub systems There are several reasons for doing the audit……. . • To assure compliance to standard • Monitor personnel improvement • Improve financial performance • Measure management effectiveness Short Form Tool 25

ITTTM Auditing Quality Systems ……. reasons for doing the audit……. . (cont. ) • Improve internal operations • Helps all stay focused, centered • Roles, responsibilities are flushed out • Firms up the best practices • Provides internal benchmarking systems Audit connects to long and short term improvement • Strategic planning • Based in facts, objectivity • Non-judgemental, non-punitive Short Form Tool 25

ITTTM Auditing Quality Systems ……. reasons for doing the audit……. . (cont. ) • Improve internal operations • Helps all stay focused, centered • Roles, responsibilities are flushed out • Firms up the best practices • Provides internal benchmarking systems Audit connects to long and short term improvement • Strategic planning • Based in facts, objectivity • Non-judgemental, non-punitive Short Form Tool 25

ITTTM Auditing Quality Systems Several key steps for doing the audit • Initiation: someone, circumstance necessitates the audit, requests or requires • Planning: persons charged with doing audit put a plan together which facilitates process • Conduct of audit: organized and systematic acquisition and analysis of all information • Reporting: findings from the audit are documented and shared with appropriate groups • Closing: group being audited has the opportunity to correct any misunderstandings Short Form Tool 25

ITTTM Auditing Quality Systems Several key steps for doing the audit • Initiation: someone, circumstance necessitates the audit, requests or requires • Planning: persons charged with doing audit put a plan together which facilitates process • Conduct of audit: organized and systematic acquisition and analysis of all information • Reporting: findings from the audit are documented and shared with appropriate groups • Closing: group being audited has the opportunity to correct any misunderstandings Short Form Tool 25

ITTTM General Concerns, Getting Started How we service, understand others, relationships • Managing organization, operating system • Paradigm shift in business accountability Over 90 countries, workable, useful standards • Democratization, globalization • Contract language, how we communicate Improved process linkages, efficiency • Teamwork, cooperation, flexibility, control • Improved ability of people to contribute • Decreased liability, increased reliability • Increased marketing abilities, advantages Short Form Tool 25

ITTTM General Concerns, Getting Started How we service, understand others, relationships • Managing organization, operating system • Paradigm shift in business accountability Over 90 countries, workable, useful standards • Democratization, globalization • Contract language, how we communicate Improved process linkages, efficiency • Teamwork, cooperation, flexibility, control • Improved ability of people to contribute • Decreased liability, increased reliability • Increased marketing abilities, advantages Short Form Tool 25

ITTTM General Concerns, Getting Started Involve all, broader purposes, not in a vacuum • Empower all, understand processes, use, improve • Determine how current systems do ISO/QS • If not doing something by standards--why? • Evaluate costs, implications of not implementing Infrastructure, hardware, software, people • Persons who “champion” must handle change • Have broad expertise in processes, products • Evaluate, implement, standards, grow, together • Infrastructure must be satisfactorily in place Short Form Tool 25

ITTTM General Concerns, Getting Started Involve all, broader purposes, not in a vacuum • Empower all, understand processes, use, improve • Determine how current systems do ISO/QS • If not doing something by standards--why? • Evaluate costs, implications of not implementing Infrastructure, hardware, software, people • Persons who “champion” must handle change • Have broad expertise in processes, products • Evaluate, implement, standards, grow, together • Infrastructure must be satisfactorily in place Short Form Tool 25

ITTTM Kaizen, Six Sigma, Lean Relationships ISO/QS 9000, increasingly becoming base • As key management system, this has breadth and scope to embody various other quality tools • ISO/QS are umbrella for all quality systems • Based on systemic analysis, many other tools and quality methods can be pursued • If not used in this way, many duplicative systems and sub systems can result • Basis for improvement is ISO/QS, but the system must be designed for these purposes • Total quality system must facilitate kaizen, six sigma, lean—all based around ISO/QS Short Form Tool 25

ITTTM Kaizen, Six Sigma, Lean Relationships ISO/QS 9000, increasingly becoming base • As key management system, this has breadth and scope to embody various other quality tools • ISO/QS are umbrella for all quality systems • Based on systemic analysis, many other tools and quality methods can be pursued • If not used in this way, many duplicative systems and sub systems can result • Basis for improvement is ISO/QS, but the system must be designed for these purposes • Total quality system must facilitate kaizen, six sigma, lean—all based around ISO/QS Short Form Tool 25

ITTTM Kaizen, Six Sigma, Lean Relationships ISO/QS 9000, increasingly becoming base (cont. ) • Each quality method requires data and documentation to do improvement • ISO/QS are umbrella for collecting data, documenting in ways to use for improvement • Cannot improve in absence of baseline data, well documented, designed for systematic applications • Many other quality methods will come and go, being brief buzz words……. . • ISO/QS systems have lasting value, mature base for total management, here to stay and enable many other quality methods Short Form Tool 25

ITTTM Kaizen, Six Sigma, Lean Relationships ISO/QS 9000, increasingly becoming base (cont. ) • Each quality method requires data and documentation to do improvement • ISO/QS are umbrella for collecting data, documenting in ways to use for improvement • Cannot improve in absence of baseline data, well documented, designed for systematic applications • Many other quality methods will come and go, being brief buzz words……. . • ISO/QS systems have lasting value, mature base for total management, here to stay and enable many other quality methods Short Form Tool 25

ITTTM Tool Applications……. Toolkit applications are a key part of the courseware • Located in separate folder of the CD • Provides the template for team portfolio • Each application s part of team project, portfolio • Designed to be done by all, each team member • First read long form, then short review, applications • Total contribution in application form is compiled • Portfolio is gradually evolved around applications Tool 25 applications are: • OPCP, introduced, continuously built, not just at start • PASPC also introduced, built gradually, evolved • Documentation System Design, Communication, DSDC • ISOQSAOPP, designed to help set a plan for team • GOTA, vacabulary, glossary of terms • All follow through, do and post, independently Short Form Tool 25

ITTTM Tool Applications……. Toolkit applications are a key part of the courseware • Located in separate folder of the CD • Provides the template for team portfolio • Each application s part of team project, portfolio • Designed to be done by all, each team member • First read long form, then short review, applications • Total contribution in application form is compiled • Portfolio is gradually evolved around applications Tool 25 applications are: • OPCP, introduced, continuously built, not just at start • PASPC also introduced, built gradually, evolved • Documentation System Design, Communication, DSDC • ISOQSAOPP, designed to help set a plan for team • GOTA, vacabulary, glossary of terms • All follow through, do and post, independently Short Form Tool 25

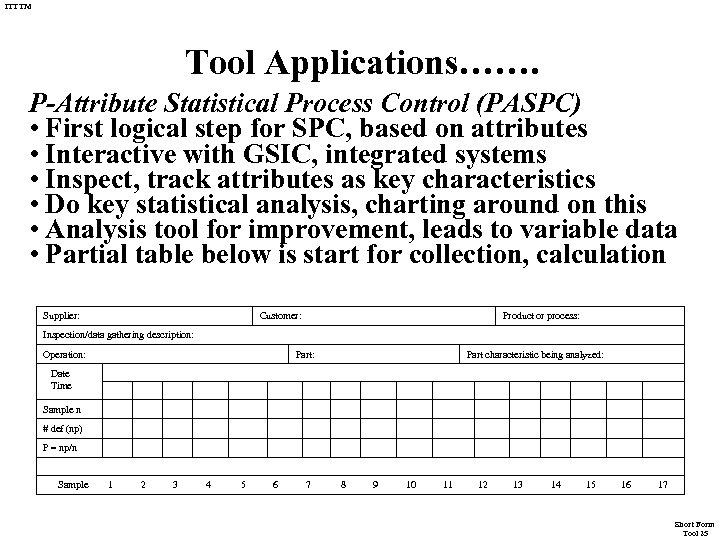

ITTTM Tool Applications……. P-Attribute Statistical Process Control (PASPC) • First logical step for SPC, based on attributes • Interactive with GSIC, integrated systems • Inspect, track attributes as key characteristics • Do key statistical analysis, charting around on this • Analysis tool for improvement, leads to variable data • Partial table below is start for collection, calculation Supplier: Customer: Product or process: Inspection/data gathering description: Operation: Part characteristic being analyzed: Date Time Sample n # def (np) P = np/n Sample 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 Short Form Tool 25

ITTTM Tool Applications……. P-Attribute Statistical Process Control (PASPC) • First logical step for SPC, based on attributes • Interactive with GSIC, integrated systems • Inspect, track attributes as key characteristics • Do key statistical analysis, charting around on this • Analysis tool for improvement, leads to variable data • Partial table below is start for collection, calculation Supplier: Customer: Product or process: Inspection/data gathering description: Operation: Part characteristic being analyzed: Date Time Sample n # def (np) P = np/n Sample 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 Short Form Tool 25

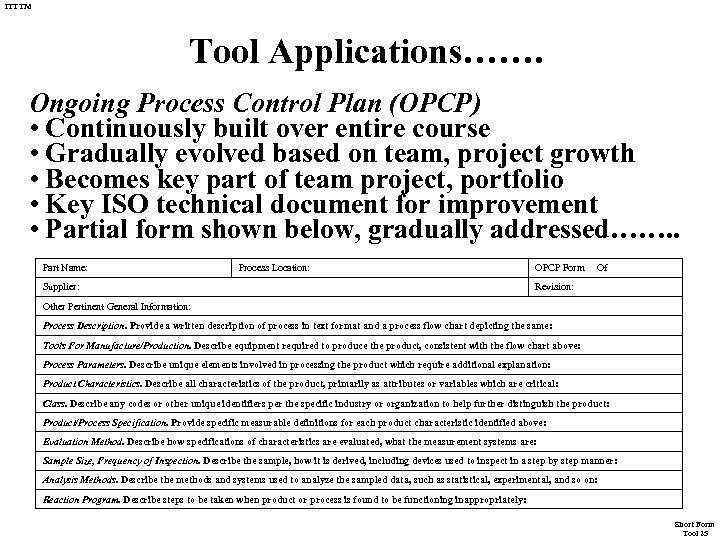

ITTTM Tool Applications……. Ongoing Process Control Plan (OPCP) • Continuously built over entire course • Gradually evolved based on team, project growth • Becomes key part of team project, portfolio • Key ISO technical document for improvement • Partial form shown below, gradually addressed……. . Part Name: Process Location: Supplier: OPCP Form Of Revision: Other Pertinent General Information: Process Description. Provide a written description of process in text format and a process flow chart depicting the same: Tools For Manufacture/Production. Describe equipment required to produce the product, consistent with the flow chart above: Process Parameters. Describe unique elements involved in processing the product which require additional explanation: Product Characteristics. Describe all characteristics of the product, primarily as attributes or variables which are critical: Class. Describe any codes or other unique identifiers per the specific industry or organization to help further distinguish the product: Product/Process Specification. Provide specific measurable definitions for each product characteristic identified above: Evaluation Method. Describe how specifications of characteristics are evaluated, what the measurement systems are: Sample Size, Frequency of Inspection. Describe the sample, how it is derived, including devices used to inspect in a step by step manner: Analysis Methods. Describe the methods and systems used to analyze the sampled data, such as statistical, experimental, and so on: Reaction Program. Describe steps to be taken when product or process is found to be functioning inappropriately: Short Form Tool 25

ITTTM Tool Applications……. Ongoing Process Control Plan (OPCP) • Continuously built over entire course • Gradually evolved based on team, project growth • Becomes key part of team project, portfolio • Key ISO technical document for improvement • Partial form shown below, gradually addressed……. . Part Name: Process Location: Supplier: OPCP Form Of Revision: Other Pertinent General Information: Process Description. Provide a written description of process in text format and a process flow chart depicting the same: Tools For Manufacture/Production. Describe equipment required to produce the product, consistent with the flow chart above: Process Parameters. Describe unique elements involved in processing the product which require additional explanation: Product Characteristics. Describe all characteristics of the product, primarily as attributes or variables which are critical: Class. Describe any codes or other unique identifiers per the specific industry or organization to help further distinguish the product: Product/Process Specification. Provide specific measurable definitions for each product characteristic identified above: Evaluation Method. Describe how specifications of characteristics are evaluated, what the measurement systems are: Sample Size, Frequency of Inspection. Describe the sample, how it is derived, including devices used to inspect in a step by step manner: Analysis Methods. Describe the methods and systems used to analyze the sampled data, such as statistical, experimental, and so on: Reaction Program. Describe steps to be taken when product or process is found to be functioning inappropriately: Short Form Tool 25

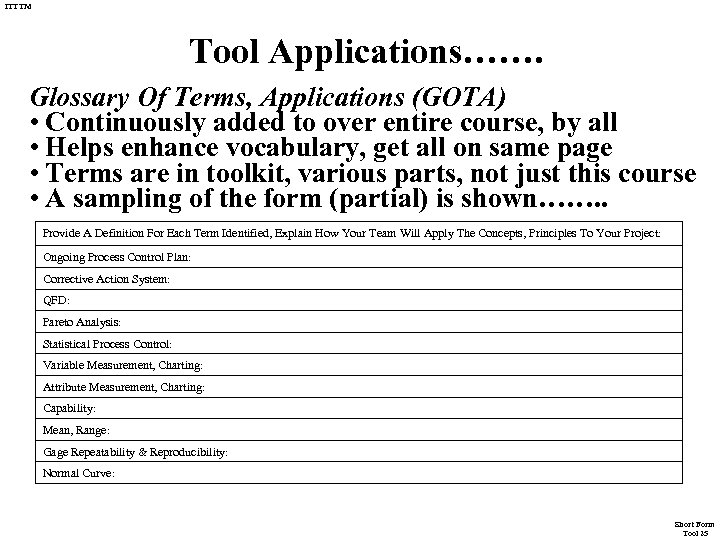

ITTTM Tool Applications……. Glossary Of Terms, Applications (GOTA) • Continuously added to over entire course, by all • Helps enhance vocabulary, get all on same page • Terms are in toolkit, various parts, not just this course • A sampling of the form (partial) is shown……. . Provide A Definition For Each Term Identified, Explain How Your Team Will Apply The Concepts, Principles To Your Project: Ongoing Process Control Plan: Corrective Action System: QFD: Pareto Analysis: Statistical Process Control: Variable Measurement, Charting: Attribute Measurement, Charting: Capability: Mean, Range: Gage Repeatability & Reproducibility: Normal Curve: Short Form Tool 25

ITTTM Tool Applications……. Glossary Of Terms, Applications (GOTA) • Continuously added to over entire course, by all • Helps enhance vocabulary, get all on same page • Terms are in toolkit, various parts, not just this course • A sampling of the form (partial) is shown……. . Provide A Definition For Each Term Identified, Explain How Your Team Will Apply The Concepts, Principles To Your Project: Ongoing Process Control Plan: Corrective Action System: QFD: Pareto Analysis: Statistical Process Control: Variable Measurement, Charting: Attribute Measurement, Charting: Capability: Mean, Range: Gage Repeatability & Reproducibility: Normal Curve: Short Form Tool 25

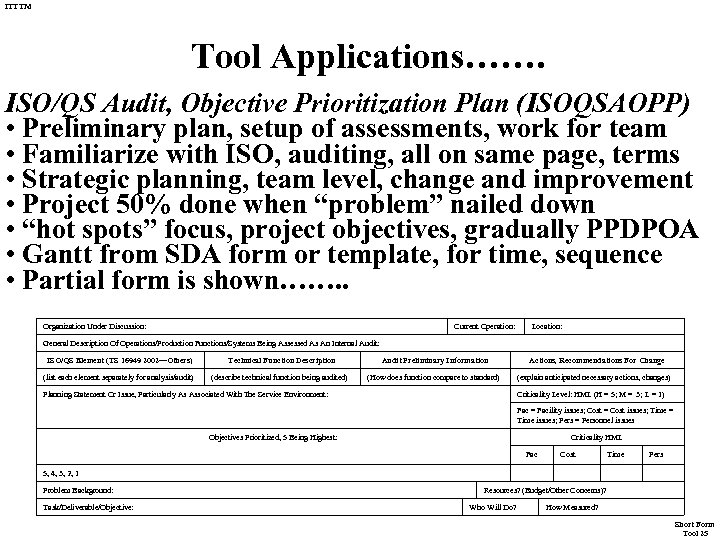

ITTTM Tool Applications……. ISO/QS Audit, Objective Prioritization Plan (ISOQSAOPP) • Preliminary plan, setup of assessments, work for team • Familiarize with ISO, auditing, all on same page, terms • Strategic planning, team level, change and improvement • Project 50% done when “problem” nailed down • “hot spots” focus, project objectives, gradually PPDPOA • Gantt from SDA form or template, for time, sequence • Partial form is shown……. . Organization Under Discussion: Current Operation: Location: General Description Of Operations/Production Functions/Systems Being Assessed As An Internal Audit: ISO/QS Element (TS 16949 2002—Others) Technical Function Description Audit Preliminary Information (list each element separately for analysis/audit) (describe technical function being audited) (How does function compare to standard) Planning Statement Or Issue, Particularly As Associated With The Service Environment: Actions, Recommendations For Change (explain anticipated necessary actions, changes) Criticality Level: HML (H = 5; M = 3; L = 1) Fac = Facility issues; Cost = Cost issues; Time = Time issues; Pers = Personnel issues Objectives Prioritized, 5 Being Highest: Criticality HML Fac Cost Time Pers 5, 4, 3, 2, 1 Problem Background: Task/Deliverable/Objective: Resources? (Budget/Other Concerns)? Who Will Do? How Measured? Short Form Tool 25

ITTTM Tool Applications……. ISO/QS Audit, Objective Prioritization Plan (ISOQSAOPP) • Preliminary plan, setup of assessments, work for team • Familiarize with ISO, auditing, all on same page, terms • Strategic planning, team level, change and improvement • Project 50% done when “problem” nailed down • “hot spots” focus, project objectives, gradually PPDPOA • Gantt from SDA form or template, for time, sequence • Partial form is shown……. . Organization Under Discussion: Current Operation: Location: General Description Of Operations/Production Functions/Systems Being Assessed As An Internal Audit: ISO/QS Element (TS 16949 2002—Others) Technical Function Description Audit Preliminary Information (list each element separately for analysis/audit) (describe technical function being audited) (How does function compare to standard) Planning Statement Or Issue, Particularly As Associated With The Service Environment: Actions, Recommendations For Change (explain anticipated necessary actions, changes) Criticality Level: HML (H = 5; M = 3; L = 1) Fac = Facility issues; Cost = Cost issues; Time = Time issues; Pers = Personnel issues Objectives Prioritized, 5 Being Highest: Criticality HML Fac Cost Time Pers 5, 4, 3, 2, 1 Problem Background: Task/Deliverable/Objective: Resources? (Budget/Other Concerns)? Who Will Do? How Measured? Short Form Tool 25

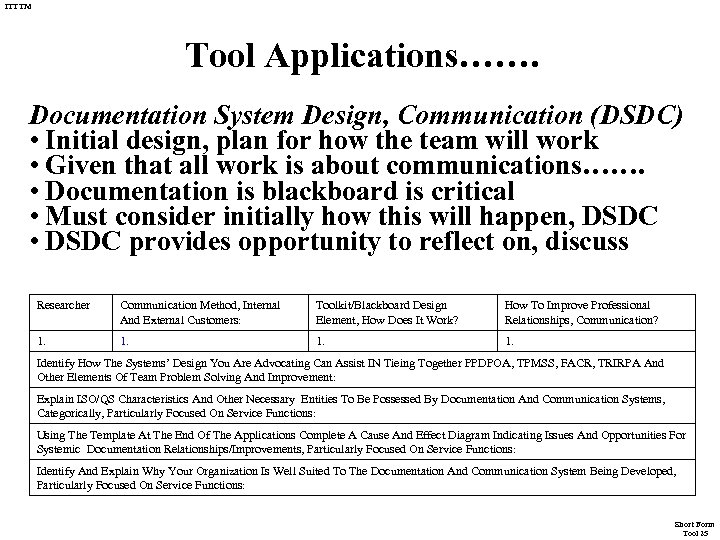

ITTTM Tool Applications……. Documentation System Design, Communication (DSDC) • Initial design, plan for how the team will work • Given that all work is about communications……. • Documentation is blackboard is critical • Must consider initially how this will happen, DSDC • DSDC provides opportunity to reflect on, discuss Researcher Communication Method, Internal And External Customers: Toolkit/Blackboard Design Element, How Does It Work? How To Improve Professional Relationships, Communication? 1. 1. Identify How The Systems’ Design You Are Advocating Can Assist IN Tieing Together PPDPOA, TPMSS, FACR, TRIRPA And Other Elements Of Team Problem Solving And Improvement: Explain ISO/QS Characteristics And Other Necessary Entities To Be Possessed By Documentation And Communication Systems, Categorically, Particularly Focused On Service Functions: Using The Template At The End Of The Applications Complete A Cause And Effect Diagram Indicating Issues And Opportunities For Systemic Documentation Relationships/Improvements, Particularly Focused On Service Functions: Identify And Explain Why Your Organization Is Well Suited To The Documentation And Communication System Being Developed, Particularly Focused On Service Functions: Short Form Tool 25

ITTTM Tool Applications……. Documentation System Design, Communication (DSDC) • Initial design, plan for how the team will work • Given that all work is about communications……. • Documentation is blackboard is critical • Must consider initially how this will happen, DSDC • DSDC provides opportunity to reflect on, discuss Researcher Communication Method, Internal And External Customers: Toolkit/Blackboard Design Element, How Does It Work? How To Improve Professional Relationships, Communication? 1. 1. Identify How The Systems’ Design You Are Advocating Can Assist IN Tieing Together PPDPOA, TPMSS, FACR, TRIRPA And Other Elements Of Team Problem Solving And Improvement: Explain ISO/QS Characteristics And Other Necessary Entities To Be Possessed By Documentation And Communication Systems, Categorically, Particularly Focused On Service Functions: Using The Template At The End Of The Applications Complete A Cause And Effect Diagram Indicating Issues And Opportunities For Systemic Documentation Relationships/Improvements, Particularly Focused On Service Functions: Identify And Explain Why Your Organization Is Well Suited To The Documentation And Communication System Being Developed, Particularly Focused On Service Functions: Short Form Tool 25