11fd52f069063412e92e7f2b018ce48b.ppt

- Количество слайдов: 35

ITER CODAC status and implementation plan (May 2009) N. Utzel 1, WD. Klotz 1, A. Wallander 1, H. Dave 1, F. Di Maio 1, H. K. Gulati 1, C. Hansalia 1, D. Joonekindt 2, JY. Journeaux 1, K. Mahajan 1, P. Makijarvi 1, L. Scibile 1, D. Stepanov 1, I. Yonekawa 1 1 ITER Organization, CS 90 046, 13067 St. Paul-lez-Durance Cedex, France 2 Atos Origin, 36 Chemin du Vieux-Chêne, BP 104, 38243 Meylan Cedex, France 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 1/35

ITER CODAC status and implementation plan (May 2009) N. Utzel 1, WD. Klotz 1, A. Wallander 1, H. Dave 1, F. Di Maio 1, H. K. Gulati 1, C. Hansalia 1, D. Joonekindt 2, JY. Journeaux 1, K. Mahajan 1, P. Makijarvi 1, L. Scibile 1, D. Stepanov 1, I. Yonekawa 1 1 ITER Organization, CS 90 046, 13067 St. Paul-lez-Durance Cedex, France 2 Atos Origin, 36 Chemin du Vieux-Chêne, BP 104, 38243 Meylan Cedex, France 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 1/35

Introduction • ITER context • CODAC or the ITER plant central control system • ITER procurement model poses enormous challenges – Deep impact on CODAC architecture design, – Requires a strong standardisation for better integration and future maintenance • CODAC conceptual design brief description • Current actions taken to move to engineering design • Plans ahead 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 2/35

Introduction • ITER context • CODAC or the ITER plant central control system • ITER procurement model poses enormous challenges – Deep impact on CODAC architecture design, – Requires a strong standardisation for better integration and future maintenance • CODAC conceptual design brief description • Current actions taken to move to engineering design • Plans ahead 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 2/35

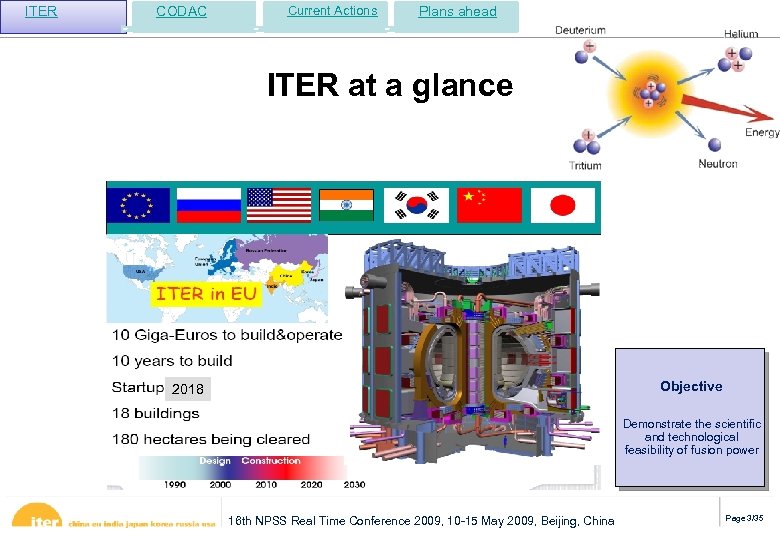

Current Actions CODAC ITER Plans ahead ITER at a glance Objective 2018 Demonstrate the scientific and technological feasibility of fusion power 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 3/35

Current Actions CODAC ITER Plans ahead ITER at a glance Objective 2018 Demonstrate the scientific and technological feasibility of fusion power 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 3/35

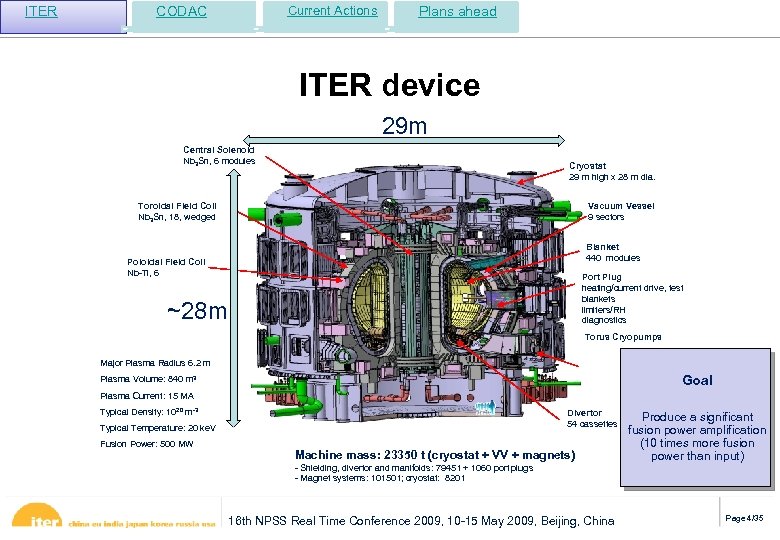

CODAC Current Actions ITER Plans ahead ITER device 29 m Central Solenoid Nb 3 Sn, 6 modules Cryostat 29 m high x 28 m dia. Toroidal Field Coil Nb 3 Sn, 18, wedged Vacuum Vessel 9 sectors Blanket 440 modules Poloidal Field Coil Nb-Ti, 6 Port Plug heating/current drive, test blankets limiters/RH diagnostics ~28 m Torus Cryopumps Major Plasma Radius 6. 2 m Goal Plasma Volume: 840 m 3 Plasma Current: 15 MA Typical Density: 1020 m-3 Divertor 54 cassettes Typical Temperature: 20 ke. V Fusion Power: 500 MW Machine mass: 23350 t (cryostat + VV + magnets) - Shielding, divertor and manifolds: 7945 t + 1060 port plugs - Magnet systems: 10150 t; cryostat: 820 t 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Produce a significant fusion power amplification (10 times more fusion power than input) Page 4/35

CODAC Current Actions ITER Plans ahead ITER device 29 m Central Solenoid Nb 3 Sn, 6 modules Cryostat 29 m high x 28 m dia. Toroidal Field Coil Nb 3 Sn, 18, wedged Vacuum Vessel 9 sectors Blanket 440 modules Poloidal Field Coil Nb-Ti, 6 Port Plug heating/current drive, test blankets limiters/RH diagnostics ~28 m Torus Cryopumps Major Plasma Radius 6. 2 m Goal Plasma Volume: 840 m 3 Plasma Current: 15 MA Typical Density: 1020 m-3 Divertor 54 cassettes Typical Temperature: 20 ke. V Fusion Power: 500 MW Machine mass: 23350 t (cryostat + VV + magnets) - Shielding, divertor and manifolds: 7945 t + 1060 port plugs - Magnet systems: 10150 t; cryostat: 820 t 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Produce a significant fusion power amplification (10 times more fusion power than input) Page 4/35

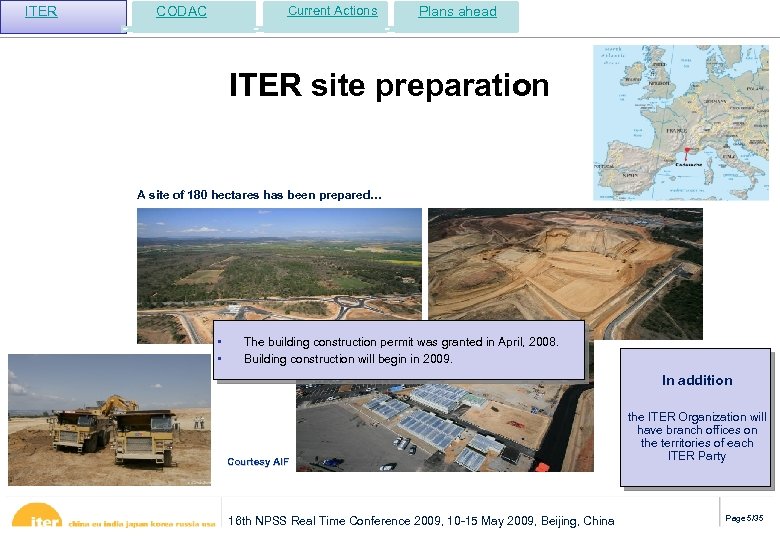

CODAC Current Actions ITER Plans ahead ITER site preparation A site of 180 hectares has been prepared… • • The building construction permit was granted in April, 2008. Building construction will begin in 2009. In addition Courtesy AIF 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China the ITER Organization will have branch offices on the territories of each ITER Party Page 5/35

CODAC Current Actions ITER Plans ahead ITER site preparation A site of 180 hectares has been prepared… • • The building construction permit was granted in April, 2008. Building construction will begin in 2009. In addition Courtesy AIF 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China the ITER Organization will have branch offices on the territories of each ITER Party Page 5/35

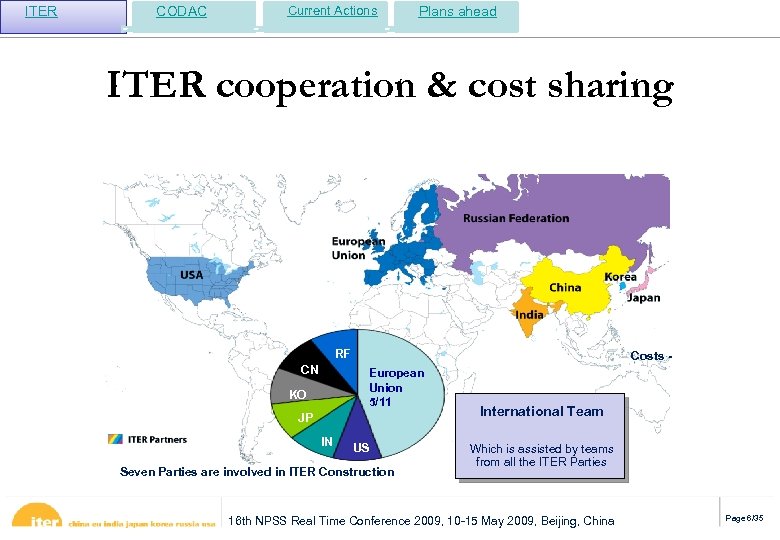

Current Actions CODAC ITER Plans ahead ITER cooperation & cost sharing RF CN Costs European Union 5/11 KO JP IN US Seven Parties are involved in ITER Construction International Team Which is assisted by teams from all the ITER Parties 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 6/35

Current Actions CODAC ITER Plans ahead ITER cooperation & cost sharing RF CN Costs European Union 5/11 KO JP IN US Seven Parties are involved in ITER Construction International Team Which is assisted by teams from all the ITER Parties 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 6/35

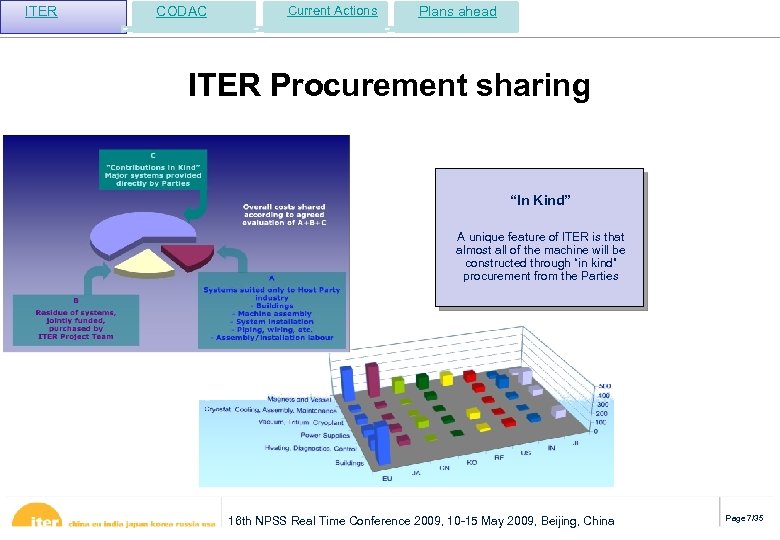

Current Actions CODAC ITER Plans ahead ITER Procurement sharing “In Kind” A unique feature of ITER is that almost all of the machine will be constructed through “in kind” procurement from the Parties 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 7/35

Current Actions CODAC ITER Plans ahead ITER Procurement sharing “In Kind” A unique feature of ITER is that almost all of the machine will be constructed through “in kind” procurement from the Parties 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 7/35

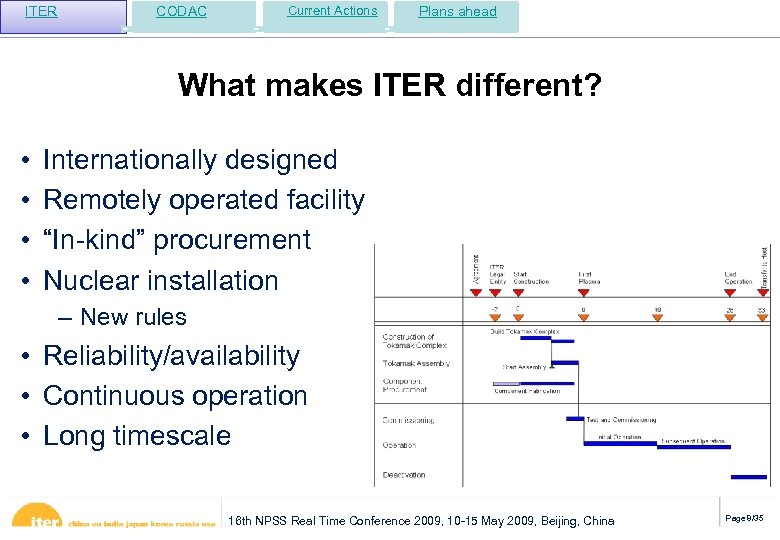

Current Actions CODAC ITER Plans ahead What makes ITER different? • • Internationally designed Remotely operated facility “In-kind” procurement Nuclear installation – New rules • Reliability/availability • Continuous operation • Long timescale 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 8/35

Current Actions CODAC ITER Plans ahead What makes ITER different? • • Internationally designed Remotely operated facility “In-kind” procurement Nuclear installation – New rules • Reliability/availability • Continuous operation • Long timescale 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 8/35

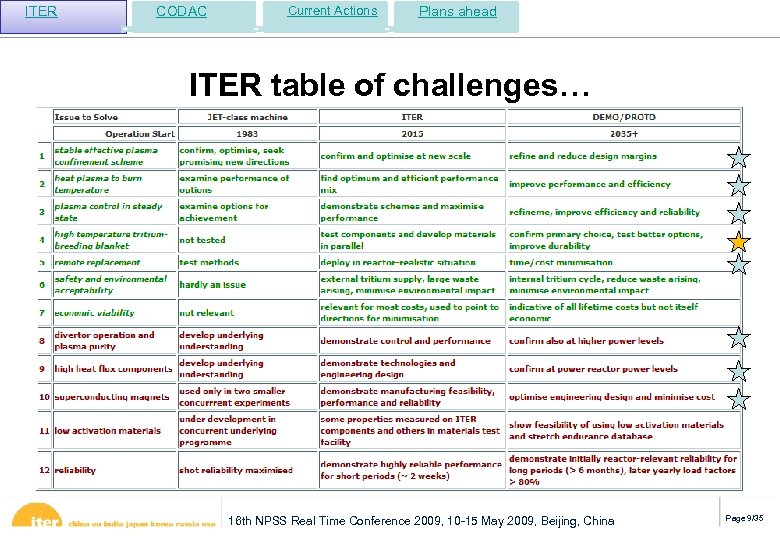

Current Actions CODAC ITER Plans ahead ITER table of challenges… 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 9/35

Current Actions CODAC ITER Plans ahead ITER table of challenges… 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 9/35

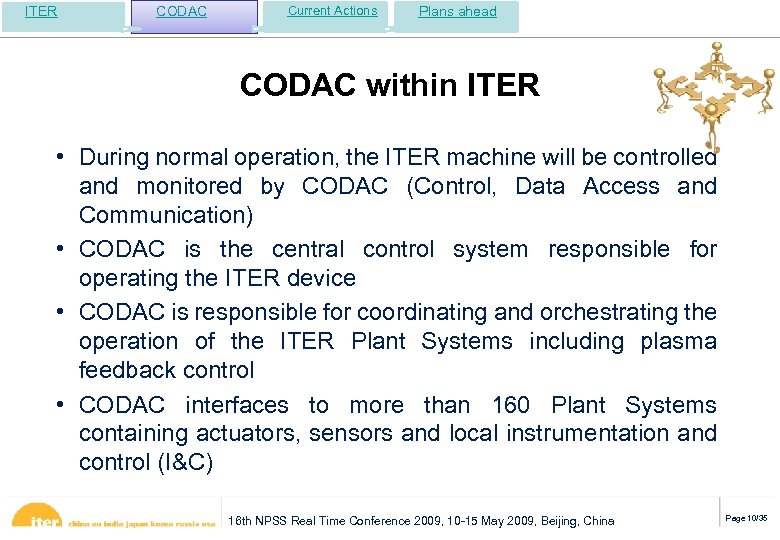

Current Actions CODAC ITER Plans ahead CODAC within ITER • During normal operation, the ITER machine will be controlled and monitored by CODAC (Control, Data Access and Communication) • CODAC is the central control system responsible for operating the ITER device • CODAC is responsible for coordinating and orchestrating the operation of the ITER Plant Systems including plasma feedback control • CODAC interfaces to more than 160 Plant Systems containing actuators, sensors and local instrumentation and control (I&C) 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 10/35

Current Actions CODAC ITER Plans ahead CODAC within ITER • During normal operation, the ITER machine will be controlled and monitored by CODAC (Control, Data Access and Communication) • CODAC is the central control system responsible for operating the ITER device • CODAC is responsible for coordinating and orchestrating the operation of the ITER Plant Systems including plasma feedback control • CODAC interfaces to more than 160 Plant Systems containing actuators, sensors and local instrumentation and control (I&C) 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 10/35

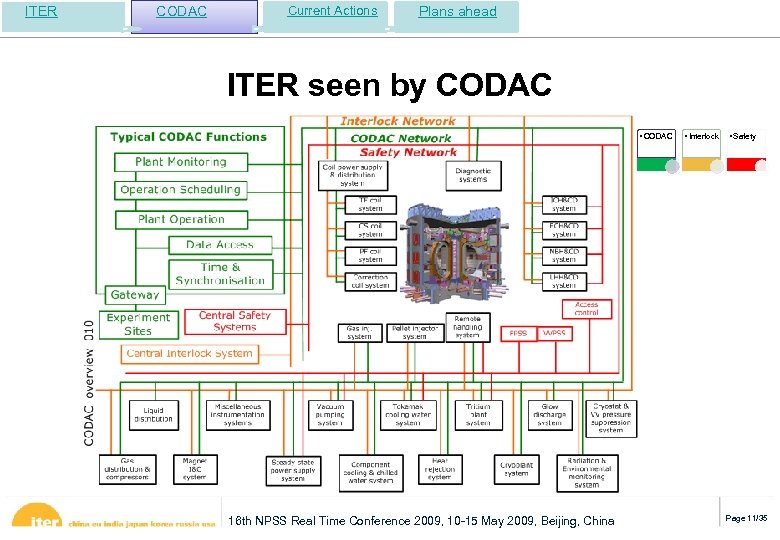

Current Actions CODAC ITER Plans ahead ITER seen by CODAC • CODAC • Safety 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China • Interlock Page 11/35

Current Actions CODAC ITER Plans ahead ITER seen by CODAC • CODAC • Safety 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China • Interlock Page 11/35

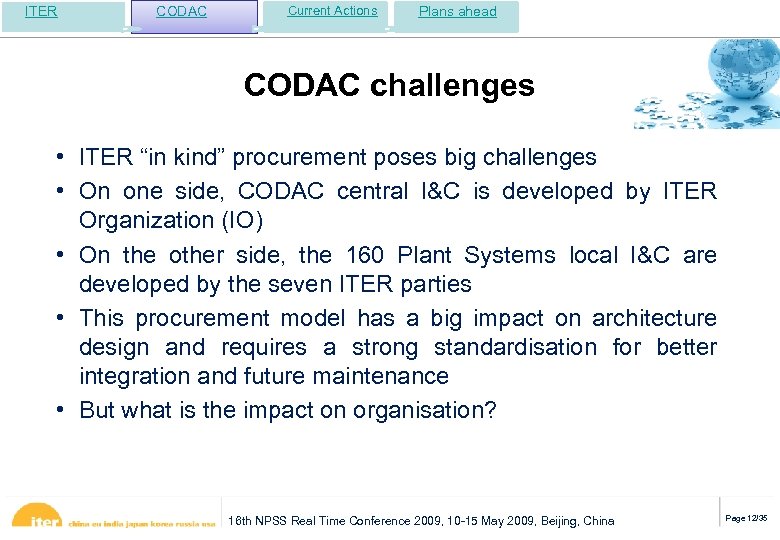

Current Actions CODAC ITER Plans ahead CODAC challenges • ITER “in kind” procurement poses big challenges • On one side, CODAC central I&C is developed by ITER Organization (IO) • On the other side, the 160 Plant Systems local I&C are developed by the seven ITER parties • This procurement model has a big impact on architecture design and requires a strong standardisation for better integration and future maintenance • But what is the impact on organisation? 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 12/35

Current Actions CODAC ITER Plans ahead CODAC challenges • ITER “in kind” procurement poses big challenges • On one side, CODAC central I&C is developed by ITER Organization (IO) • On the other side, the 160 Plant Systems local I&C are developed by the seven ITER parties • This procurement model has a big impact on architecture design and requires a strong standardisation for better integration and future maintenance • But what is the impact on organisation? 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 12/35

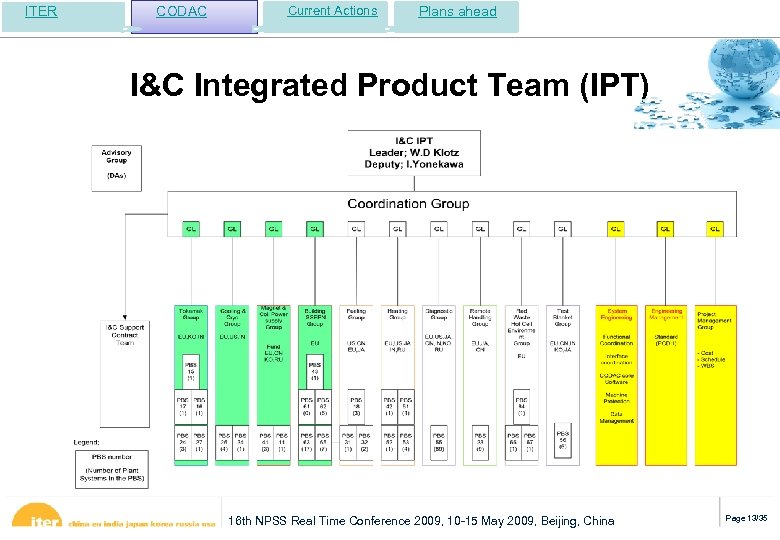

CODAC Current Actions ITER Plans ahead I&C Integrated Product Team (IPT) 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 13/35

CODAC Current Actions ITER Plans ahead I&C Integrated Product Team (IPT) 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 13/35

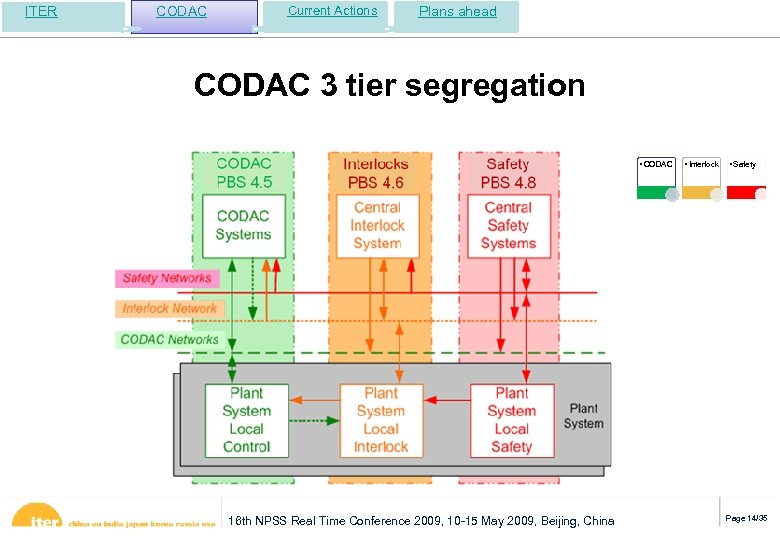

Current Actions CODAC ITER Plans ahead CODAC 3 tier segregation • CODAC • Safety 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China • Interlock Page 14/35

Current Actions CODAC ITER Plans ahead CODAC 3 tier segregation • CODAC • Safety 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China • Interlock Page 14/35

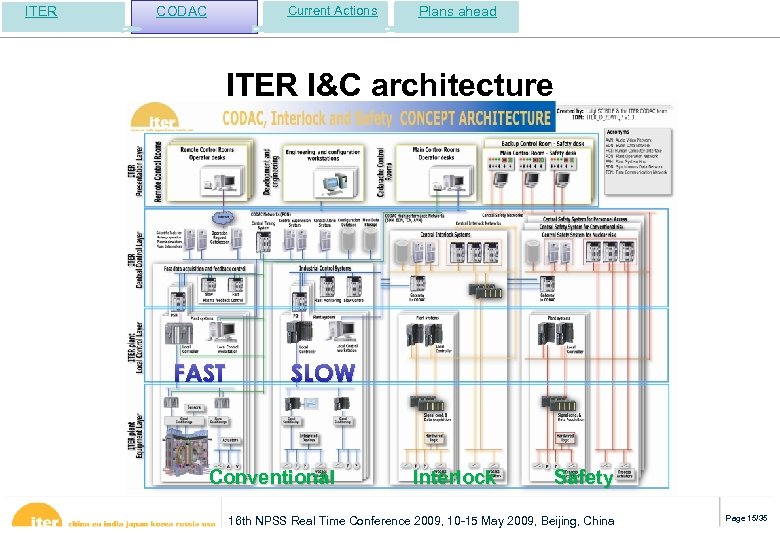

CODAC Current Actions ITER Plans ahead ITER I&C architecture FAST SLOW Conventional Interlock Safety 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 15/35

CODAC Current Actions ITER Plans ahead ITER I&C architecture FAST SLOW Conventional Interlock Safety 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 15/35

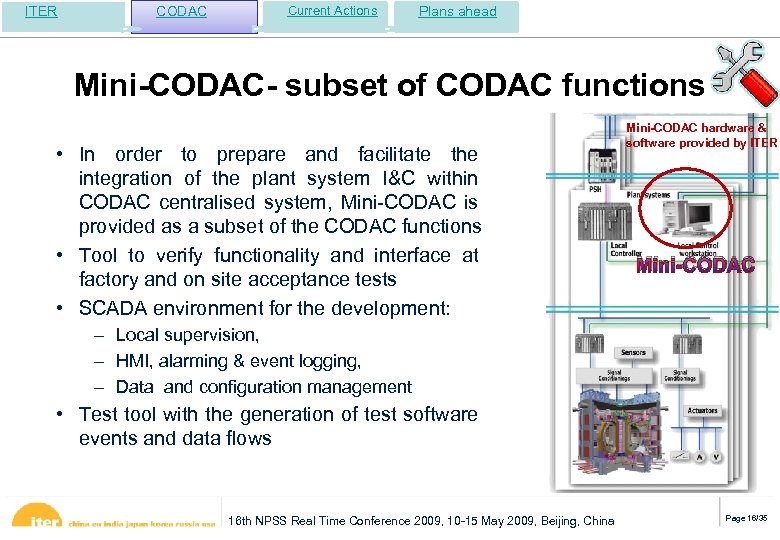

Current Actions CODAC ITER Plans ahead Mini-CODAC- subset of CODAC functions • In order to prepare and facilitate the integration of the plant system I&C within CODAC centralised system, Mini-CODAC is provided as a subset of the CODAC functions • Tool to verify functionality and interface at factory and on site acceptance tests • SCADA environment for the development: Mini-CODAC hardware & software provided by ITER Mini-CODAC – Local supervision, – HMI, alarming & event logging, – Data and configuration management • Test tool with the generation of test software events and data flows 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 16/35

Current Actions CODAC ITER Plans ahead Mini-CODAC- subset of CODAC functions • In order to prepare and facilitate the integration of the plant system I&C within CODAC centralised system, Mini-CODAC is provided as a subset of the CODAC functions • Tool to verify functionality and interface at factory and on site acceptance tests • SCADA environment for the development: Mini-CODAC hardware & software provided by ITER Mini-CODAC – Local supervision, – HMI, alarming & event logging, – Data and configuration management • Test tool with the generation of test software events and data flows 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 16/35

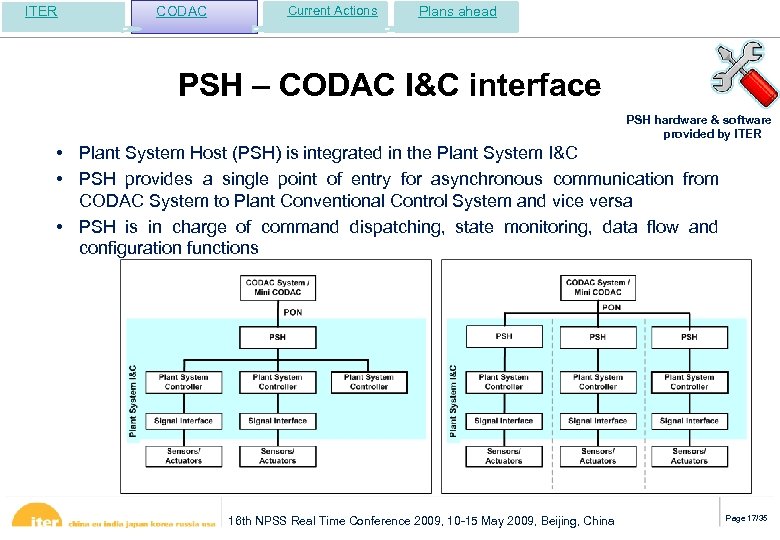

Current Actions CODAC ITER Plans ahead PSH – CODAC I&C interface PSH hardware & software provided by ITER • Plant System Host (PSH) is integrated in the Plant System I&C • PSH provides a single point of entry for asynchronous communication from CODAC System to Plant Conventional Control System and vice versa • PSH is in charge of command dispatching, state monitoring, data flow and configuration functions 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 17/35

Current Actions CODAC ITER Plans ahead PSH – CODAC I&C interface PSH hardware & software provided by ITER • Plant System Host (PSH) is integrated in the Plant System I&C • PSH provides a single point of entry for asynchronous communication from CODAC System to Plant Conventional Control System and vice versa • PSH is in charge of command dispatching, state monitoring, data flow and configuration functions 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 17/35

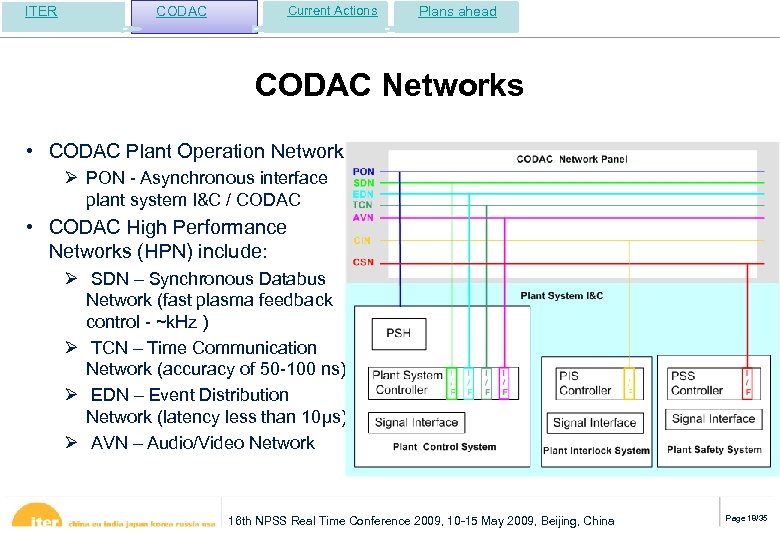

Current Actions CODAC ITER Plans ahead CODAC Networks • CODAC Plant Operation Network Ø PON - Asynchronous interface plant system I&C / CODAC • CODAC High Performance Networks (HPN) include: Ø SDN – Synchronous Databus Network (fast plasma feedback control - ~k. Hz ) Ø TCN – Time Communication Network (accuracy of 50 -100 ns) Ø EDN – Event Distribution Network (latency less than 10µs) Ø AVN – Audio/Video Network 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 18/35

Current Actions CODAC ITER Plans ahead CODAC Networks • CODAC Plant Operation Network Ø PON - Asynchronous interface plant system I&C / CODAC • CODAC High Performance Networks (HPN) include: Ø SDN – Synchronous Databus Network (fast plasma feedback control - ~k. Hz ) Ø TCN – Time Communication Network (accuracy of 50 -100 ns) Ø EDN – Event Distribution Network (latency less than 10µs) Ø AVN – Audio/Video Network 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 18/35

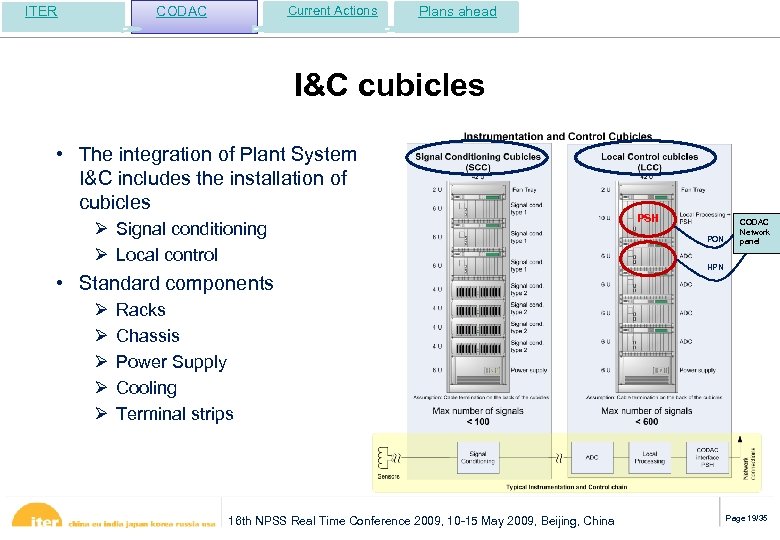

CODAC Current Actions ITER Plans ahead I&C cubicles • The integration of Plant System I&C includes the installation of cubicles Ø Signal conditioning Ø Local control • Standard components Ø Ø Ø PSH PON CODAC Network panel HPN Racks Chassis Power Supply Cooling Terminal strips 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 19/35

CODAC Current Actions ITER Plans ahead I&C cubicles • The integration of Plant System I&C includes the installation of cubicles Ø Signal conditioning Ø Local control • Standard components Ø Ø Ø PSH PON CODAC Network panel HPN Racks Chassis Power Supply Cooling Terminal strips 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 19/35

Current Actions CODAC ITER Plans ahead CODAC standardisation effort • Plant system I&C standards are essential in order to: • Integrate all plant systems I&C into one central control system • • Maintain all plant systems I&C after delivery acceptance • Contain cost by economy of scale (spare parts, expertise) • The Plant Control Design Handbook (PCDH) defines standards, specifications and interfaces applicable to all plant systems I&C • The PCDH is applicable to all ITER Procurement Arrangements which include any I&C • ITER Organization develops, supports, maintains and enforces the standards specified in the PCDH • ITER Organization will release the PCDH at regular intervals throughout the lifetime of ITER 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 20/35

Current Actions CODAC ITER Plans ahead CODAC standardisation effort • Plant system I&C standards are essential in order to: • Integrate all plant systems I&C into one central control system • • Maintain all plant systems I&C after delivery acceptance • Contain cost by economy of scale (spare parts, expertise) • The Plant Control Design Handbook (PCDH) defines standards, specifications and interfaces applicable to all plant systems I&C • The PCDH is applicable to all ITER Procurement Arrangements which include any I&C • ITER Organization develops, supports, maintains and enforces the standards specified in the PCDH • ITER Organization will release the PCDH at regular intervals throughout the lifetime of ITER 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 20/35

Current Actions CODAC ITER Plans ahead PCDH content • Deliverables and quality assurance requirements • Catalogues of standard software and hardware components • Well established industrial standards, commercial off-theshelf (COTS) and open source products are promoted • Custom-built solutions are strongly discouraged ü Design choices and the prescribed standards are based on independent market surveys, prototype activities, benchmarking and evaluations 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 21/35

Current Actions CODAC ITER Plans ahead PCDH content • Deliverables and quality assurance requirements • Catalogues of standard software and hardware components • Well established industrial standards, commercial off-theshelf (COTS) and open source products are promoted • Custom-built solutions are strongly discouraged ü Design choices and the prescribed standards are based on independent market surveys, prototype activities, benchmarking and evaluations 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 21/35

CODAC Current Actions ITER Plans ahead PCDH V 4 released end of April 2009 ü Plant System I&C Life Cycle Description and conditions ü SCADA software selection for I&C: EPICS version R 3. 14. 10 ü Software infrastructure for PSH and Mini-CODAC ü Communication middleware with Channel Access ü Siemens Simatic S 7 product line of PLC for industrial “slow” control and SIL-3 applications ü OS Linux has been preferred for PSH and Mini-CODAC ü Linux distribution shall be chosen this year ü Fast controllers ü Shall be from either PCIe families - ATCA is currently under evaluation ü Software infrastructure based on EPICS ü Real Time OS not yet decided 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 22/35

CODAC Current Actions ITER Plans ahead PCDH V 4 released end of April 2009 ü Plant System I&C Life Cycle Description and conditions ü SCADA software selection for I&C: EPICS version R 3. 14. 10 ü Software infrastructure for PSH and Mini-CODAC ü Communication middleware with Channel Access ü Siemens Simatic S 7 product line of PLC for industrial “slow” control and SIL-3 applications ü OS Linux has been preferred for PSH and Mini-CODAC ü Linux distribution shall be chosen this year ü Fast controllers ü Shall be from either PCIe families - ATCA is currently under evaluation ü Software infrastructure based on EPICS ü Real Time OS not yet decided 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 22/35

Current Actions CODAC ITER Plans ahead PSH & Mini-CODAC prototype • To support the PCDH, the CODAC team is currently active in prototyping potential technologies. The goal of these prototyping activities is to define the technologies to be used for CODAC and I&C • A task defined in Sept. 2008 aims at designing and implementing the Plant System Host (PSH) and Mini-CODAC with their technical interfaces • Requirements detailed analysis of the PSH and Mini CODAC prototypes • Interface Control Document between PSH and controllers • Case study of a “real” ITER Plant System • Mock-up of a Factory Acceptance Test (FAT) for the case study Plant System • IN (IPR) - duration of the task: 3 years 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 23/35

Current Actions CODAC ITER Plans ahead PSH & Mini-CODAC prototype • To support the PCDH, the CODAC team is currently active in prototyping potential technologies. The goal of these prototyping activities is to define the technologies to be used for CODAC and I&C • A task defined in Sept. 2008 aims at designing and implementing the Plant System Host (PSH) and Mini-CODAC with their technical interfaces • Requirements detailed analysis of the PSH and Mini CODAC prototypes • Interface Control Document between PSH and controllers • Case study of a “real” ITER Plant System • Mock-up of a Factory Acceptance Test (FAT) for the case study Plant System • IN (IPR) - duration of the task: 3 years 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 23/35

Current Actions CODAC ITER Plans ahead Plant System Simulator & Fast Control • Two types of plant system have been identified: slow control plant system based on industrial PLC technology and fast control plant system based on embedded technology for real-time requirements • A task defined in 2008 aims to design and implement: • A Plant System Simulator as test environment, • A prototype of a Fast Control Plant System (sampling rates 1 k. Hz or higher) • One major goal of this task is to explore the suitability of ATCA and μTCA technologies for ITER CODAC. It is considered urgent to have early feedback on this point • In parallel, other standard bus systems based on PCIe shall be explored and implemented • CN (ASIPP) – EU (not signed) – duration of the task: 1. 5 years 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 24/35

Current Actions CODAC ITER Plans ahead Plant System Simulator & Fast Control • Two types of plant system have been identified: slow control plant system based on industrial PLC technology and fast control plant system based on embedded technology for real-time requirements • A task defined in 2008 aims to design and implement: • A Plant System Simulator as test environment, • A prototype of a Fast Control Plant System (sampling rates 1 k. Hz or higher) • One major goal of this task is to explore the suitability of ATCA and μTCA technologies for ITER CODAC. It is considered urgent to have early feedback on this point • In parallel, other standard bus systems based on PCIe shall be explored and implemented • CN (ASIPP) – EU (not signed) – duration of the task: 1. 5 years 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 24/35

Current Actions CODAC ITER Plans ahead Operation Request Gatekeeper prototype • ITER plant will be remotely operated from all the parties • The Operation Request Gatekeeper is a crucial element to the successful remote experiment of ITER and a basic requirement of the ITER project, under the direct responsibility of CODAC • This prototyping task aims to – Develop clear structured requirements for the gatekeeper including a description of all transactions to be carried out – Provide a functional prototype to demonstrate that all security requirements for remote experiment are complete • US (General Atomics + MIT) - duration of the task: 36 weeks 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 25/35

Current Actions CODAC ITER Plans ahead Operation Request Gatekeeper prototype • ITER plant will be remotely operated from all the parties • The Operation Request Gatekeeper is a crucial element to the successful remote experiment of ITER and a basic requirement of the ITER project, under the direct responsibility of CODAC • This prototyping task aims to – Develop clear structured requirements for the gatekeeper including a description of all transactions to be carried out – Provide a functional prototype to demonstrate that all security requirements for remote experiment are complete • US (General Atomics + MIT) - duration of the task: 36 weeks 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 25/35

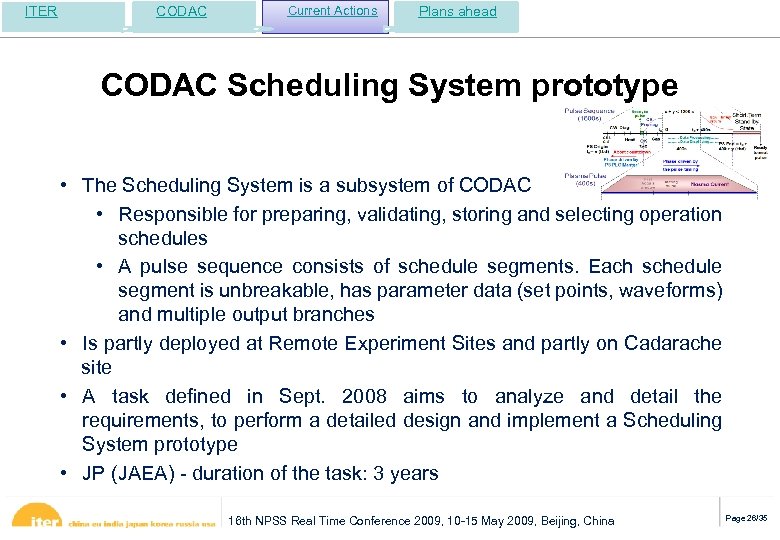

Current Actions CODAC ITER Plans ahead CODAC Scheduling System prototype • The Scheduling System is a subsystem of CODAC • Responsible for preparing, validating, storing and selecting operation schedules • A pulse sequence consists of schedule segments. Each schedule segment is unbreakable, has parameter data (set points, waveforms) and multiple output branches • Is partly deployed at Remote Experiment Sites and partly on Cadarache site • A task defined in Sept. 2008 aims to analyze and detail the requirements, to perform a detailed design and implement a Scheduling System prototype • JP (JAEA) - duration of the task: 3 years 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 26/35

Current Actions CODAC ITER Plans ahead CODAC Scheduling System prototype • The Scheduling System is a subsystem of CODAC • Responsible for preparing, validating, storing and selecting operation schedules • A pulse sequence consists of schedule segments. Each schedule segment is unbreakable, has parameter data (set points, waveforms) and multiple output branches • Is partly deployed at Remote Experiment Sites and partly on Cadarache site • A task defined in Sept. 2008 aims to analyze and detail the requirements, to perform a detailed design and implement a Scheduling System prototype • JP (JAEA) - duration of the task: 3 years 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 26/35

Current Actions CODAC ITER Plans ahead CODAC High Performance Networks survey • Some functions of CODAC require deterministic, hard realtime communication and synchronization between distributed nodes • These requirements are addressed by the CODAC High Performance Networks (HPN) • A task defined in Sept. 2008 aims to investigate potential commercial off-the-shelf technology solutions and to build small prototypes to demonstrate requirements can be met • EU (Cosylab) – US (General Atomics) - duration of the task: 25 weeks 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 27/35

Current Actions CODAC ITER Plans ahead CODAC High Performance Networks survey • Some functions of CODAC require deterministic, hard realtime communication and synchronization between distributed nodes • These requirements are addressed by the CODAC High Performance Networks (HPN) • A task defined in Sept. 2008 aims to investigate potential commercial off-the-shelf technology solutions and to build small prototypes to demonstrate requirements can be met • EU (Cosylab) – US (General Atomics) - duration of the task: 25 weeks 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 27/35

Current Actions CODAC ITER Plans ahead EPICS for Tokamak control study • A task defined in Nov. 2008 aims to leverage the experience using EPICS for Tokamak control, to capture the lessons learned, to demonstrate the use of EPICS in an existing device and to investigate a case study of integrating a plant system • Analysis of differences using EPICS in Tokamak and Particle Accelerator • Recommendation to interface a Plant System I&C and CODAC • Analysis of First Plasma Operation results to verify that an EPICSbased control system is adapted to a Tokamak configuration • KO: NFRI (KSTAR) – duration: 32 weeks 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 28/35

Current Actions CODAC ITER Plans ahead EPICS for Tokamak control study • A task defined in Nov. 2008 aims to leverage the experience using EPICS for Tokamak control, to capture the lessons learned, to demonstrate the use of EPICS in an existing device and to investigate a case study of integrating a plant system • Analysis of differences using EPICS in Tokamak and Particle Accelerator • Recommendation to interface a Plant System I&C and CODAC • Analysis of First Plasma Operation results to verify that an EPICSbased control system is adapted to a Tokamak configuration • KO: NFRI (KSTAR) – duration: 32 weeks 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 28/35

Current Actions CODAC ITER Plans ahead I&C Support contract • The operation of the ITER machine involves more than 160 plant systems I&C which are mostly procured in kind by ITER partners • The purpose of the engineering support contract is to assist IO in specifying, reviewing and following up the Plant System I&Cs along the I&C life cycle from design to integration – Support for technical specifications preparation, I&C standardization activity, Factory Acceptance Test and Site Acceptance Tests followup • The contract is scheduled to come into force this year 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 29/35

Current Actions CODAC ITER Plans ahead I&C Support contract • The operation of the ITER machine involves more than 160 plant systems I&C which are mostly procured in kind by ITER partners • The purpose of the engineering support contract is to assist IO in specifying, reviewing and following up the Plant System I&Cs along the I&C life cycle from design to integration – Support for technical specifications preparation, I&C standardization activity, Factory Acceptance Test and Site Acceptance Tests followup • The contract is scheduled to come into force this year 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 29/35

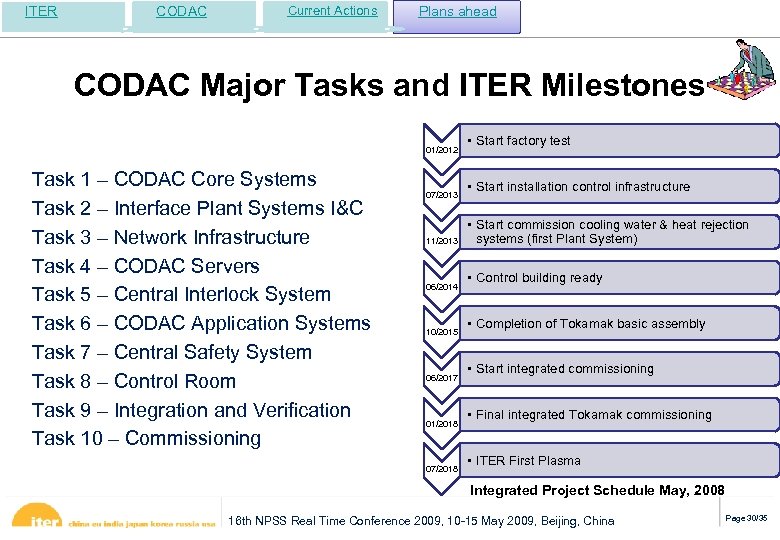

Current Actions CODAC ITER Plans ahead CODAC Major Tasks and ITER Milestones 01/2012 Task 1 – CODAC Core Systems Task 2 – Interface Plant Systems I&C Task 3 – Network Infrastructure Task 4 – CODAC Servers Task 5 – Central Interlock System Task 6 – CODAC Application Systems Task 7 – Central Safety System Task 8 – Control Room Task 9 – Integration and Verification Task 10 – Commissioning 07/2013 11/2013 06/2014 10/2015 06/2017 01/2018 07/2018 • Start factory test • Start installation control infrastructure • Start commission cooling water & heat rejection systems (first Plant System) • Control building ready • Completion of Tokamak basic assembly • Start integrated commissioning • Final integrated Tokamak commissioning • ITER First Plasma Integrated Project Schedule May, 2008 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 30/35

Current Actions CODAC ITER Plans ahead CODAC Major Tasks and ITER Milestones 01/2012 Task 1 – CODAC Core Systems Task 2 – Interface Plant Systems I&C Task 3 – Network Infrastructure Task 4 – CODAC Servers Task 5 – Central Interlock System Task 6 – CODAC Application Systems Task 7 – Central Safety System Task 8 – Control Room Task 9 – Integration and Verification Task 10 – Commissioning 07/2013 11/2013 06/2014 10/2015 06/2017 01/2018 07/2018 • Start factory test • Start installation control infrastructure • Start commission cooling water & heat rejection systems (first Plant System) • Control building ready • Completion of Tokamak basic assembly • Start integrated commissioning • Final integrated Tokamak commissioning • ITER First Plasma Integrated Project Schedule May, 2008 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 30/35

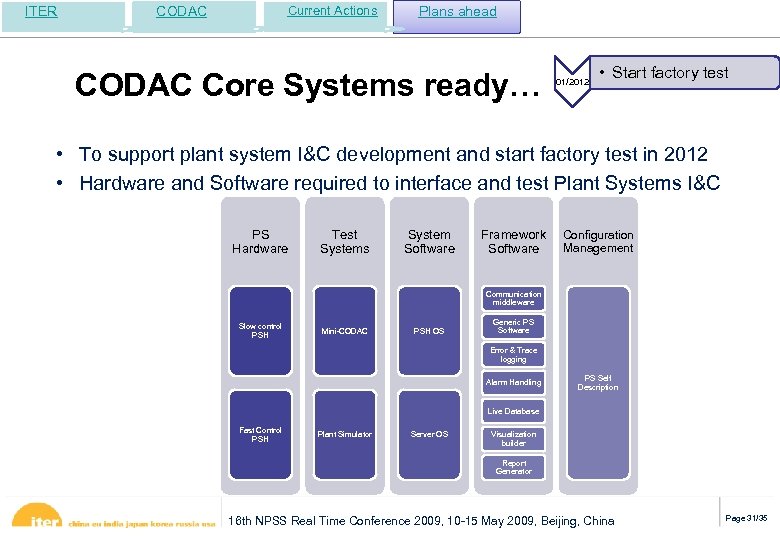

Current Actions CODAC ITER Plans ahead CODAC Core Systems ready… 01/2012 • Start factory test • To support plant system I&C development and start factory test in 2012 • Hardware and Software required to interface and test Plant Systems I&C PS Hardware Test Systems System Software Framework Configuration Management Software Communication middleware Slow control PSH Mini-CODAC PSH OS Generic PS Software Error & Trace logging Alarm Handling PS Self Description Live Database Fast Control PSH Plant Simulator Server OS Visualization builder Report Generator 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 31/35

Current Actions CODAC ITER Plans ahead CODAC Core Systems ready… 01/2012 • Start factory test • To support plant system I&C development and start factory test in 2012 • Hardware and Software required to interface and test Plant Systems I&C PS Hardware Test Systems System Software Framework Configuration Management Software Communication middleware Slow control PSH Mini-CODAC PSH OS Generic PS Software Error & Trace logging Alarm Handling PS Self Description Live Database Fast Control PSH Plant Simulator Server OS Visualization builder Report Generator 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 31/35

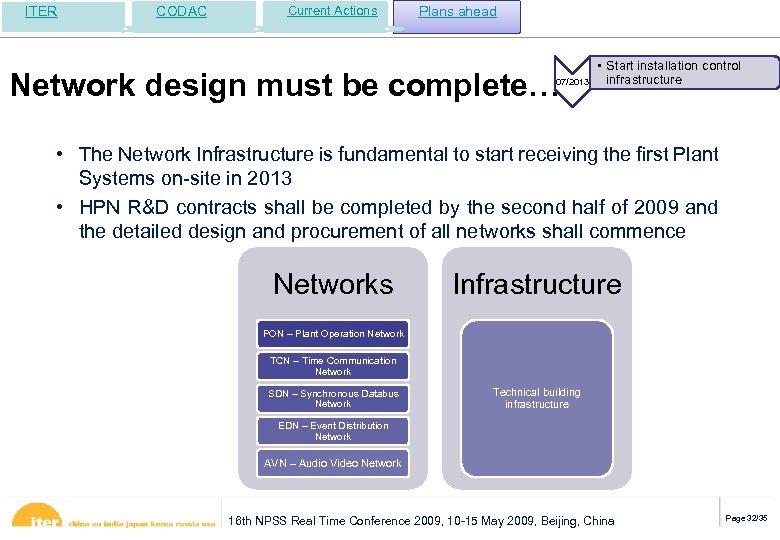

Current Actions CODAC ITER Plans ahead Network design must be complete… 07/2013 • Start installation control infrastructure • The Network Infrastructure is fundamental to start receiving the first Plant Systems on-site in 2013 • HPN R&D contracts shall be completed by the second half of 2009 and the detailed design and procurement of all networks shall commence Networks Infrastructure PON – Plant Operation Network TCN – Time Communication Network SDN – Synchronous Databus Network Technical building infrastructure EDN – Event Distribution Network AVN – Audio Video Network 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 32/35

Current Actions CODAC ITER Plans ahead Network design must be complete… 07/2013 • Start installation control infrastructure • The Network Infrastructure is fundamental to start receiving the first Plant Systems on-site in 2013 • HPN R&D contracts shall be completed by the second half of 2009 and the detailed design and procurement of all networks shall commence Networks Infrastructure PON – Plant Operation Network TCN – Time Communication Network SDN – Synchronous Databus Network Technical building infrastructure EDN – Event Distribution Network AVN – Audio Video Network 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 32/35

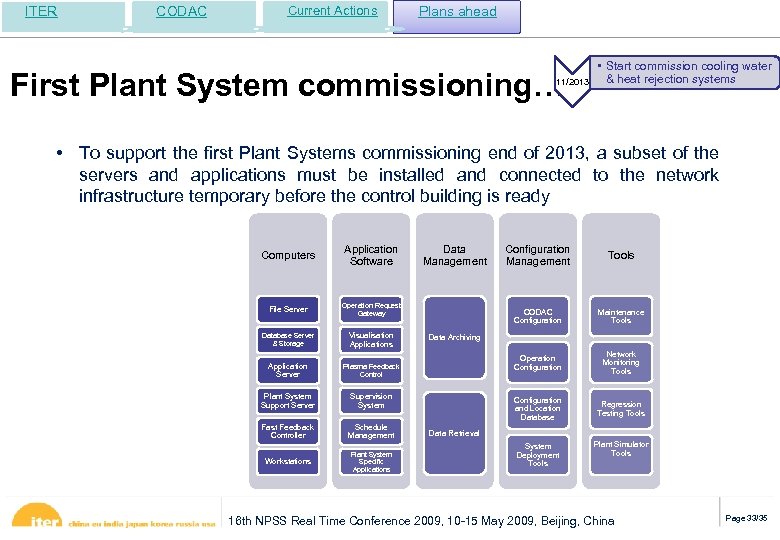

Current Actions CODAC ITER Plans ahead First Plant System commissioning… 11/2013 • Start commission cooling water & heat rejection systems • To support the first Plant Systems commissioning end of 2013, a subset of the servers and applications must be installed and connected to the network infrastructure temporary before the control building is ready Computers Application Software File Server Operation Request Gateway Database Server & Storage Visualisation Applications Application Server Plasma Feedback Control Plant System Support Server Supervision System Fast Feedback Controller Schedule Management Workstations Plant System Specific Applications Data Management Configuration Management Tools CODAC Configuration Maintenance Tools Operation Configuration Network Monitoring Tools Configuration and Location Database Regression Testing Tools Data Archiving Data Retrieval System Deployment Tools Plant Simulator Tools 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 33/35

Current Actions CODAC ITER Plans ahead First Plant System commissioning… 11/2013 • Start commission cooling water & heat rejection systems • To support the first Plant Systems commissioning end of 2013, a subset of the servers and applications must be installed and connected to the network infrastructure temporary before the control building is ready Computers Application Software File Server Operation Request Gateway Database Server & Storage Visualisation Applications Application Server Plasma Feedback Control Plant System Support Server Supervision System Fast Feedback Controller Schedule Management Workstations Plant System Specific Applications Data Management Configuration Management Tools CODAC Configuration Maintenance Tools Operation Configuration Network Monitoring Tools Configuration and Location Database Regression Testing Tools Data Archiving Data Retrieval System Deployment Tools Plant Simulator Tools 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 33/35

Current Actions CODAC ITER Plans ahead Conclusion • ITER context is quite unique and the procurement model poses enormous challenges – Impacts on CODAC architecture design – Requires a strong standardisation for better integration and future maintenance – Collaboration enhancement between IO / ITER parties through IPT • Many prototyping and survey activities leading to technology decisions have been launched in 2008 ü PCDH major version released ü Open Source SCADA (EPICS), PLC industrial controller, OS… • Plans ahead are still challenging in order to start factory test beginning 2012 and start commission in Nov. 2013 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 34/35

Current Actions CODAC ITER Plans ahead Conclusion • ITER context is quite unique and the procurement model poses enormous challenges – Impacts on CODAC architecture design – Requires a strong standardisation for better integration and future maintenance – Collaboration enhancement between IO / ITER parties through IPT • Many prototyping and survey activities leading to technology decisions have been launched in 2008 ü PCDH major version released ü Open Source SCADA (EPICS), PLC industrial controller, OS… • Plans ahead are still challenging in order to start factory test beginning 2012 and start commission in Nov. 2013 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 34/35

Current Actions Conceptual Design CODAC ITER Plans ahead Thank You… Please feel free to ask questions… 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 35/35

Current Actions Conceptual Design CODAC ITER Plans ahead Thank You… Please feel free to ask questions… 16 th NPSS Real Time Conference 2009, 10 -15 May 2009, Beijing, China Page 35/35