1ae3c3bf2074a14db87f50c5f78a97ec.ppt

- Количество слайдов: 23

IT In Manufacturing Industries : R&D and Application SULISTYO Direktorat Teknologi Informasi dan Elektronika Badan Pengkajian dan Penerapan Teknologi Seminar Sehari Aplikasi Internet Di Era Milenium Ketiga Gedung Fakultas Teknik Universitas Pancasila Jakarta , 21 September 2000

IT In Manufacturing Industries : R&D and Application SULISTYO Direktorat Teknologi Informasi dan Elektronika Badan Pengkajian dan Penerapan Teknologi Seminar Sehari Aplikasi Internet Di Era Milenium Ketiga Gedung Fakultas Teknik Universitas Pancasila Jakarta , 21 September 2000

Agenda v. Background v. Outline, Subjects and Cooperation v. IT in Manufacturing (Automobile & Parts; Electronics & Parts ; Textile & Apparel ) v. Future Activities (SCM & EC) v. Conclusion

Agenda v. Background v. Outline, Subjects and Cooperation v. IT in Manufacturing (Automobile & Parts; Electronics & Parts ; Textile & Apparel ) v. Future Activities (SCM & EC) v. Conclusion

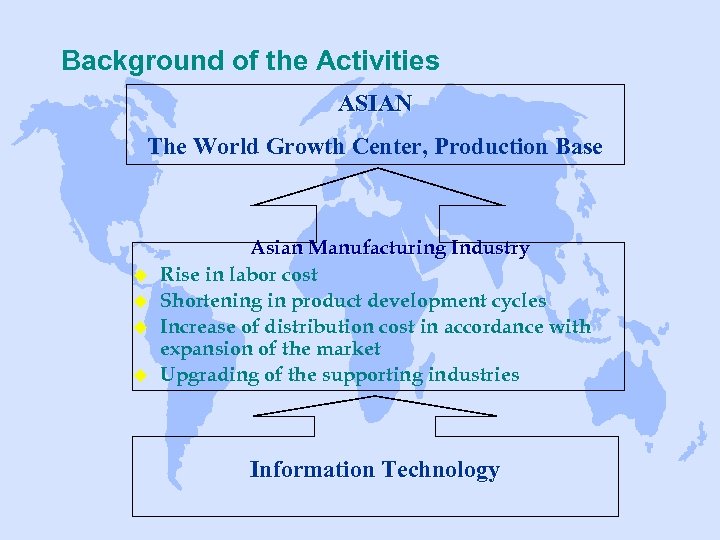

Background of the Activities ASIAN The World Growth Center, Production Base u u Asian Manufacturing Industry Rise in labor cost Shortening in product development cycles Increase of distribution cost in accordance with expansion of the market Upgrading of the supporting industries Information Technology

Background of the Activities ASIAN The World Growth Center, Production Base u u Asian Manufacturing Industry Rise in labor cost Shortening in product development cycles Increase of distribution cost in accordance with expansion of the market Upgrading of the supporting industries Information Technology

Activities Outline u Mission International cooperative research and development of integrated information system to support the manufacturing process from design to production through international network in order to upgrade the manufacturing and supporting industries in Asian countries

Activities Outline u Mission International cooperative research and development of integrated information system to support the manufacturing process from design to production through international network in order to upgrade the manufacturing and supporting industries in Asian countries

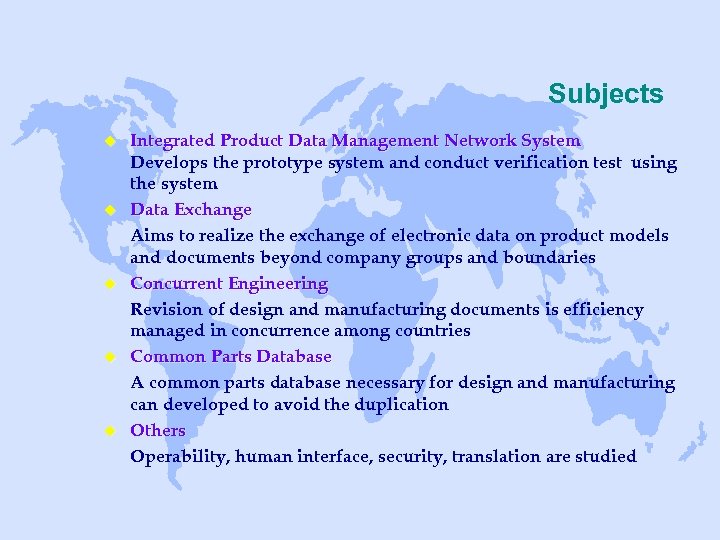

Subjects u u u Integrated Product Data Management Network System Develops the prototype system and conduct verification test using the system Data Exchange Aims to realize the exchange of electronic data on product models and documents beyond company groups and boundaries Concurrent Engineering Revision of design and manufacturing documents is efficiency managed in concurrence among countries Common Parts Database A common parts database necessary for design and manufacturing can developed to avoid the duplication Others Operability, human interface, security, translation are studied

Subjects u u u Integrated Product Data Management Network System Develops the prototype system and conduct verification test using the system Data Exchange Aims to realize the exchange of electronic data on product models and documents beyond company groups and boundaries Concurrent Engineering Revision of design and manufacturing documents is efficiency managed in concurrence among countries Common Parts Database A common parts database necessary for design and manufacturing can developed to avoid the duplication Others Operability, human interface, security, translation are studied

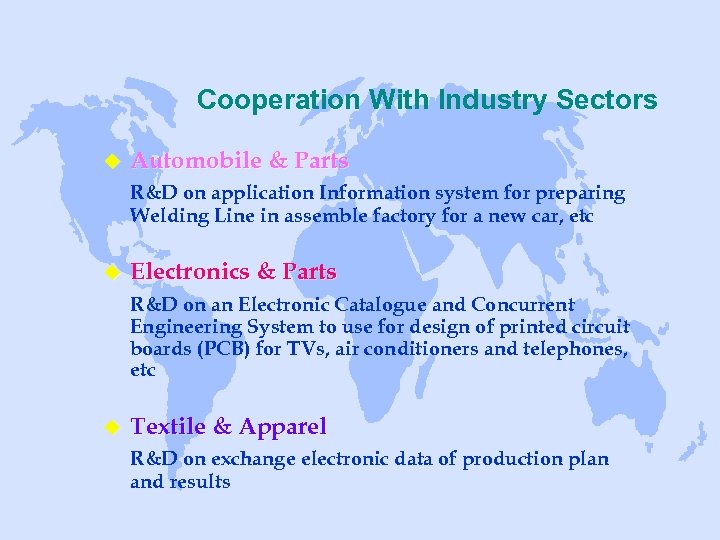

Cooperation With Industry Sectors u Automobile & Parts R&D on application Information system for preparing Welding Line in assemble factory for a new car, etc u Electronics & Parts R&D on an Electronic Catalogue and Concurrent Engineering System to use for design of printed circuit boards (PCB) for TVs, air conditioners and telephones, etc u Textile & Apparel R&D on exchange electronic data of production plan and results

Cooperation With Industry Sectors u Automobile & Parts R&D on application Information system for preparing Welding Line in assemble factory for a new car, etc u Electronics & Parts R&D on an Electronic Catalogue and Concurrent Engineering System to use for design of printed circuit boards (PCB) for TVs, air conditioners and telephones, etc u Textile & Apparel R&D on exchange electronic data of production plan and results

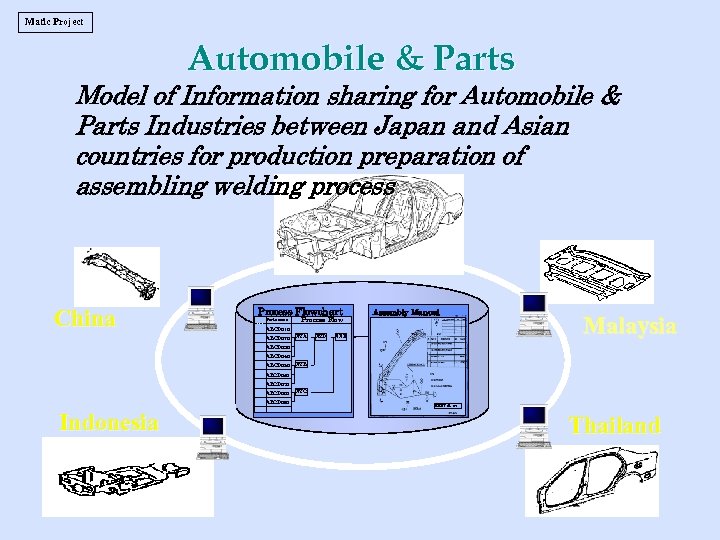

Matic Project Automobile & Parts Model of Information sharing for Automobile & Parts Industries between Japan and Asian countries for production preparation of assembling welding process China Process Flowchart Process Flow. . . Assembly Manual Parts name ABCD 010 ABCD 020 XYA XZD XXE Malaysia ABCD 030 ABCD 040 ABCD 050 XYB ABCD 060 ABCD 070 ABCD 080 ABCD 090 Indonesia XYC PROCESS NO. XYA Thailand

Matic Project Automobile & Parts Model of Information sharing for Automobile & Parts Industries between Japan and Asian countries for production preparation of assembling welding process China Process Flowchart Process Flow. . . Assembly Manual Parts name ABCD 010 ABCD 020 XYA XZD XXE Malaysia ABCD 030 ABCD 040 ABCD 050 XYB ABCD 060 ABCD 070 ABCD 080 ABCD 090 Indonesia XYC PROCESS NO. XYA Thailand

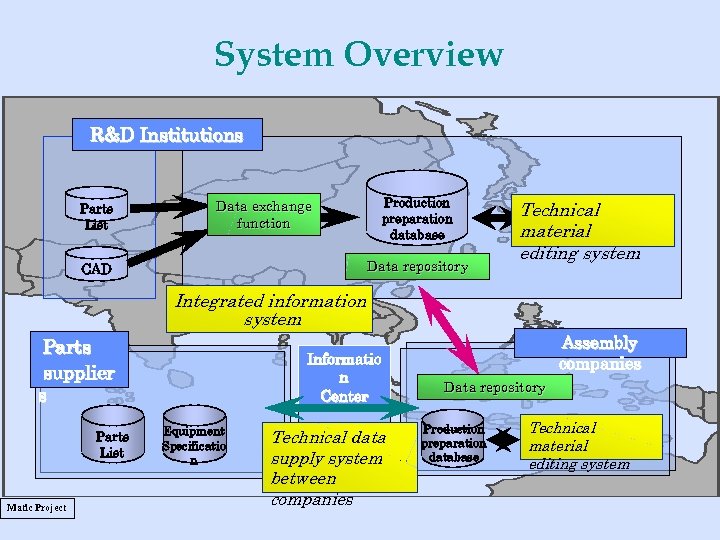

System Overview R&D Institutions Parts List Production preparation database Data exchange function Data repository CAD Technical material editing system Integrated information system Parts supplier s Parts List Matic Project Informatio n Center Equipment Specificatio n Technical data supply system between companies Assembly companies Data repository Production preparation database Technical material editing system

System Overview R&D Institutions Parts List Production preparation database Data exchange function Data repository CAD Technical material editing system Integrated information system Parts supplier s Parts List Matic Project Informatio n Center Equipment Specificatio n Technical data supply system between companies Assembly companies Data repository Production preparation database Technical material editing system

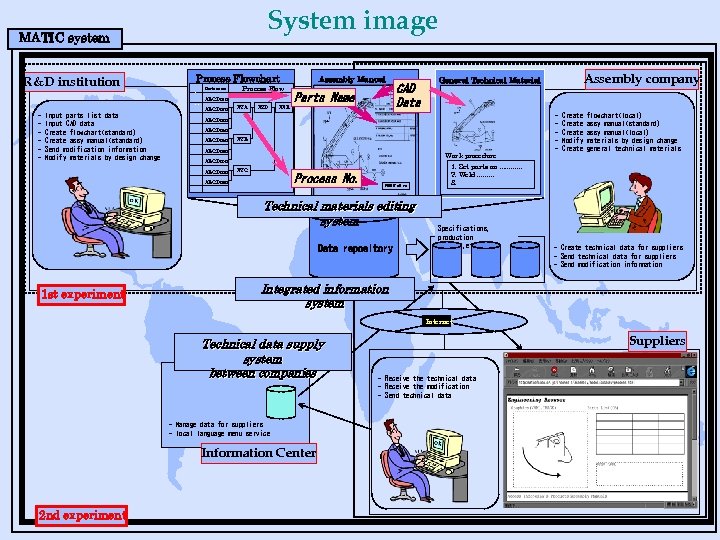

System image MATIC system R&D institution - Input parts list data Input CAD data Create flowchart(standard) Create assy manual(standard) Send modification information Modify materials by design change Process Flowchart Process Flow. ABCD 010. . XYA XZD XXE Assembly Manual Parts name Parts Name ABCD 020 CAD Data ABCD 030 ABCD 040 ABCD 050 XYB ABCD 060 ABCD 070 ABCD 080 XYC Process No. ABCD 090 PROCESS NO. XYA Technical materials editing system Data repository 1 st experiment Assembly company General Technical Material Work procedure 1. Set parts on. . . 2. Weld. . 3. Specifications, production drawing, etc. - Create Modify Create flowchart(local) assy manual(standard) assy manual(local) materials by design change general technical materials - Create technical data for suppliers - Send modification information Integrated information system Internet Technical data supply system between companies - Manage data for suppliers - local language menu service Information Center 2 nd experiment Suppliers - Receive the technical data - Receive the modification - Send technical data

System image MATIC system R&D institution - Input parts list data Input CAD data Create flowchart(standard) Create assy manual(standard) Send modification information Modify materials by design change Process Flowchart Process Flow. ABCD 010. . XYA XZD XXE Assembly Manual Parts name Parts Name ABCD 020 CAD Data ABCD 030 ABCD 040 ABCD 050 XYB ABCD 060 ABCD 070 ABCD 080 XYC Process No. ABCD 090 PROCESS NO. XYA Technical materials editing system Data repository 1 st experiment Assembly company General Technical Material Work procedure 1. Set parts on. . . 2. Weld. . 3. Specifications, production drawing, etc. - Create Modify Create flowchart(local) assy manual(standard) assy manual(local) materials by design change general technical materials - Create technical data for suppliers - Send modification information Integrated information system Internet Technical data supply system between companies - Manage data for suppliers - local language menu service Information Center 2 nd experiment Suppliers - Receive the technical data - Receive the modification - Send technical data

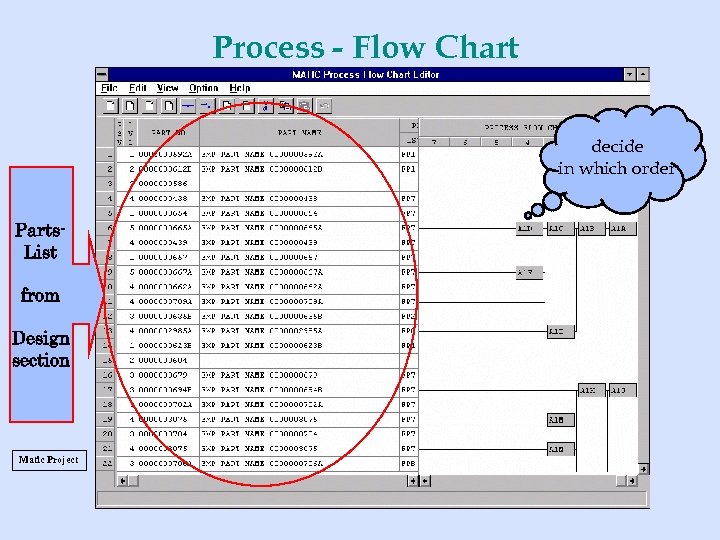

Process - Flow Chart decide in which order Parts. List from Design section Matic Project

Process - Flow Chart decide in which order Parts. List from Design section Matic Project

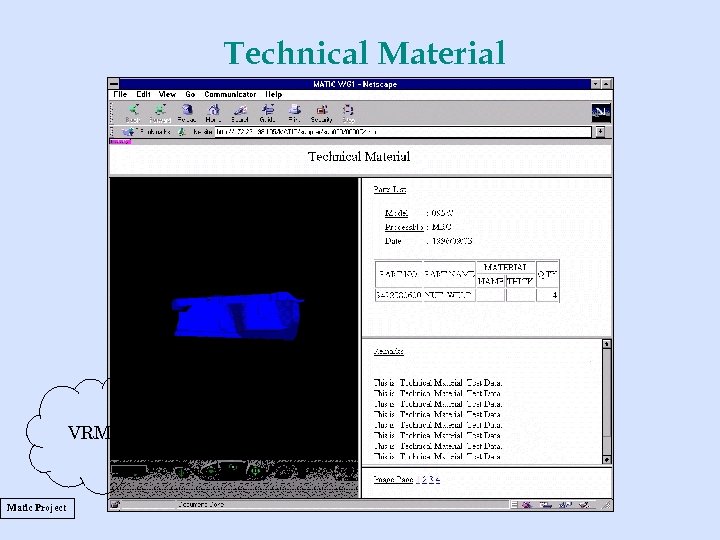

Technical Material VRML Matic Project

Technical Material VRML Matic Project

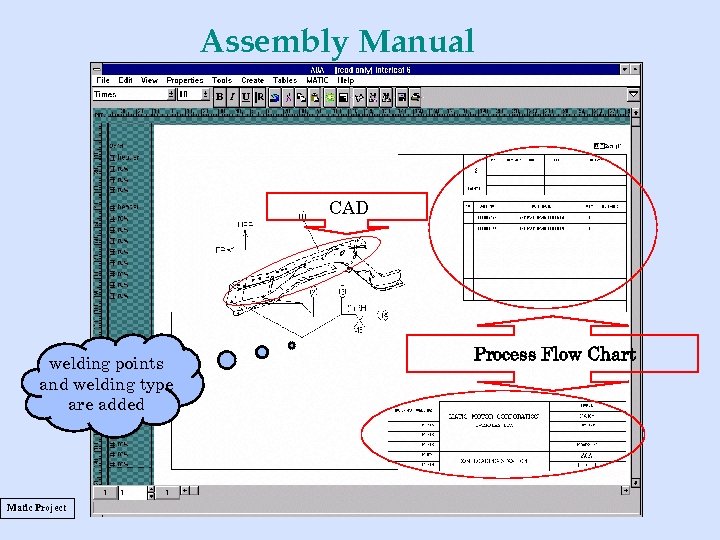

Assembly Manual CAD welding points and welding type are added Matic Project Process Flow Chart

Assembly Manual CAD welding points and welding type are added Matic Project Process Flow Chart

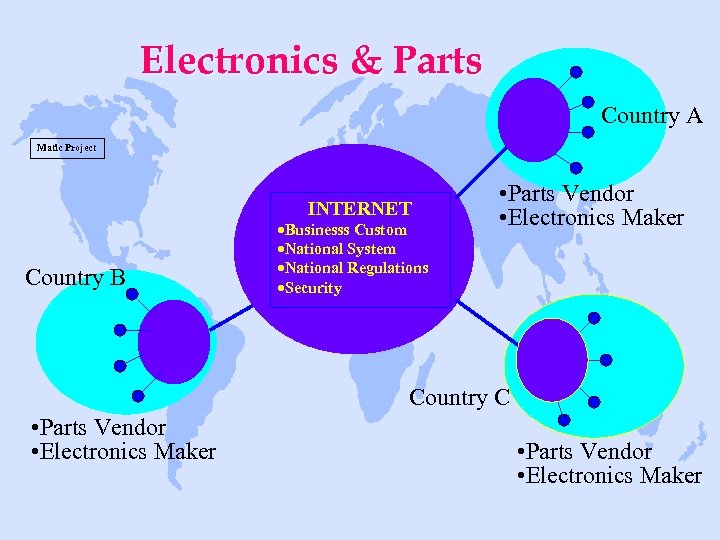

Electronics & Parts Country A Matic Project INTERNET Country B ·Businesss Custom ·National System ·National Regulations ·Security • Parts Vendor • Electronics Maker Country C • Parts Vendor • Electronics Maker

Electronics & Parts Country A Matic Project INTERNET Country B ·Businesss Custom ·National System ·National Regulations ·Security • Parts Vendor • Electronics Maker Country C • Parts Vendor • Electronics Maker

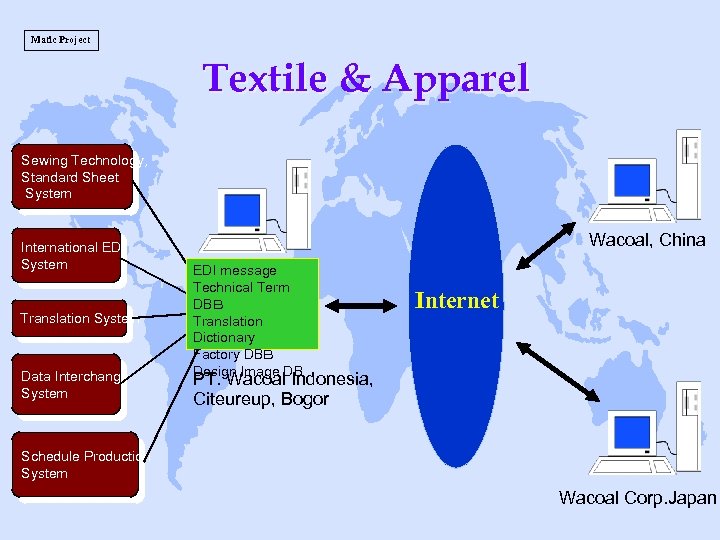

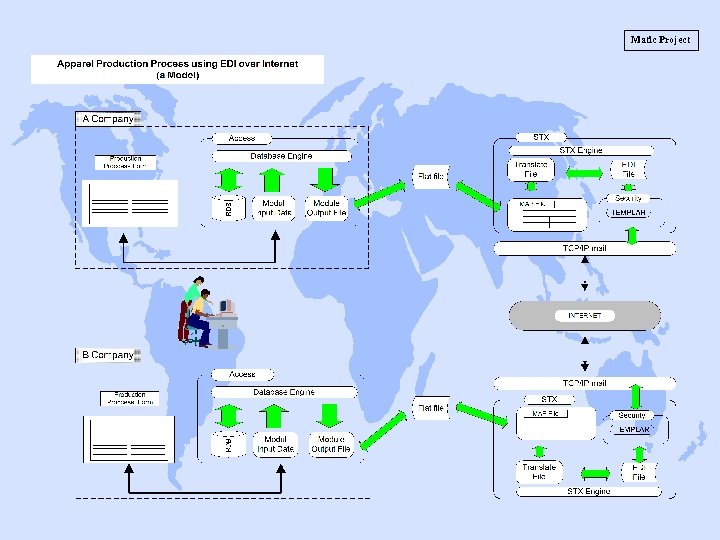

Matic Project Textile & Apparel Sewing Technology, Standard Sheet System International EDI System Translation System Data Interchange System Wacoal, China EDI message Technical Term DBB Translation Dictionary Factory DBB Design Image DB Internet PT. Wacoal Indonesia, Citeureup, Bogor Schedule Production System Wacoal Corp. Japan

Matic Project Textile & Apparel Sewing Technology, Standard Sheet System International EDI System Translation System Data Interchange System Wacoal, China EDI message Technical Term DBB Translation Dictionary Factory DBB Design Image DB Internet PT. Wacoal Indonesia, Citeureup, Bogor Schedule Production System Wacoal Corp. Japan

Matic Project

Matic Project

Matic Project

Matic Project

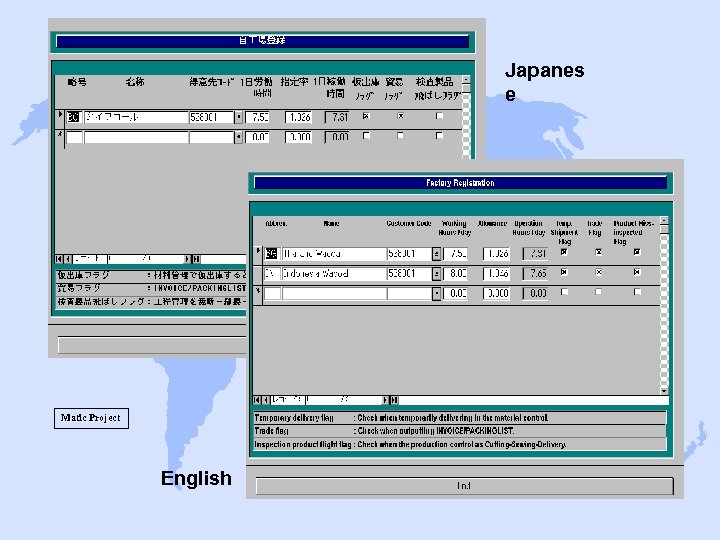

Japanes e Matic Project English

Japanes e Matic Project English

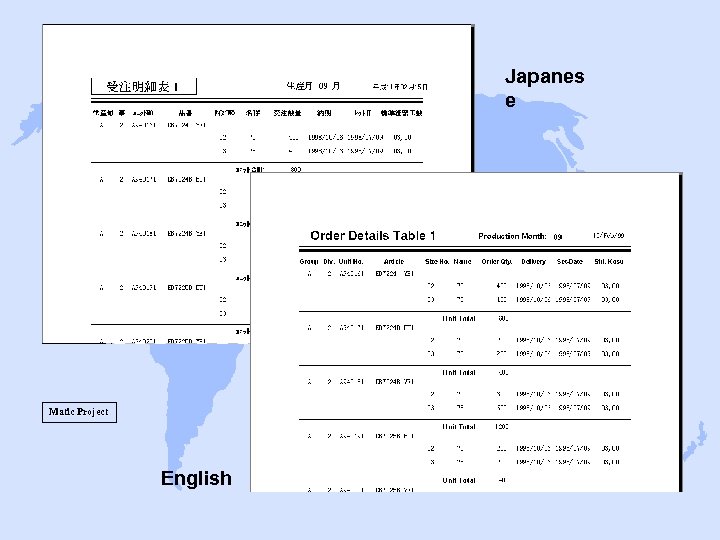

Japanes e Matic Project English

Japanes e Matic Project English

Future Plan Activity • Material Supply-Chain Management & E-Commerce Development SCM : value delivery to customers through co-ordination: u u Order generation; order taking Order fulfilment; distribution of products, services, information E-C : value delivery to customers through coordination/integration: u u Electronic exchange of goods (products, services, information) Supporting functions (banking, insurance, etc. )

Future Plan Activity • Material Supply-Chain Management & E-Commerce Development SCM : value delivery to customers through co-ordination: u u Order generation; order taking Order fulfilment; distribution of products, services, information E-C : value delivery to customers through coordination/integration: u u Electronic exchange of goods (products, services, information) Supporting functions (banking, insurance, etc. )

SCM aims to satisfy. . . Supplier Demands • • Payment options Forecasting Timeliness Inventory management Tracking Sales performance Feedback Customer Demands • Quality and consistency of • • • service Customisation / convenience Selection options Payment options Availability information Distribution information Interaction Internal Demands • Reduced costs • Increased revenues • Branding / customer loyalty

SCM aims to satisfy. . . Supplier Demands • • Payment options Forecasting Timeliness Inventory management Tracking Sales performance Feedback Customer Demands • Quality and consistency of • • • service Customisation / convenience Selection options Payment options Availability information Distribution information Interaction Internal Demands • Reduced costs • Increased revenues • Branding / customer loyalty

Can E-Commerce Help ? u Inventory Management / Customisation F F F u Provides customised supply catalogues on customers’ intranets Customers save from purchase-order processing costs Can offer add-on and customised services Selection Options F F F Deal directly with suppliers to receive multiple bids for parts Save $500 - $700 M off purchasing costs over 3 years Cut purchasing cycle times by 50%

Can E-Commerce Help ? u Inventory Management / Customisation F F F u Provides customised supply catalogues on customers’ intranets Customers save from purchase-order processing costs Can offer add-on and customised services Selection Options F F F Deal directly with suppliers to receive multiple bids for parts Save $500 - $700 M off purchasing costs over 3 years Cut purchasing cycle times by 50%

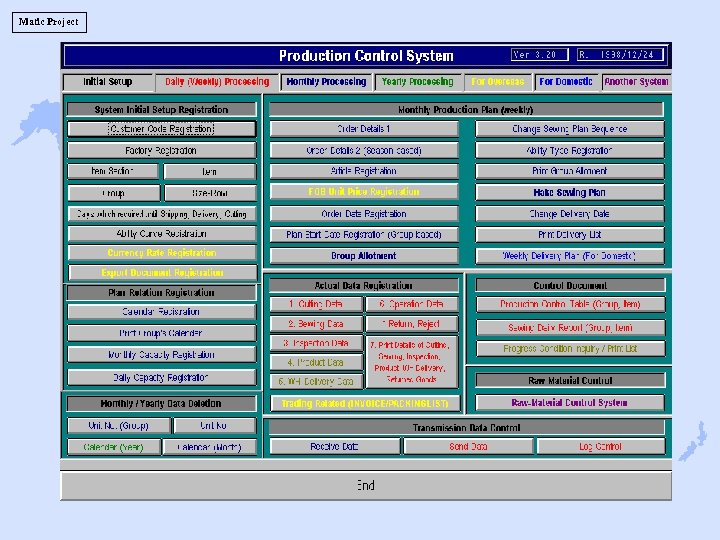

Conclusion • General Achievement Ø IT application in manufacturing industry Ø Production Control System Database Ø Process scheduling production Ø Security system, etc. • Future Activities Ø SCM & EC Development Ø Web Connected System Development Ø Promote to Industries Association

Conclusion • General Achievement Ø IT application in manufacturing industry Ø Production Control System Database Ø Process scheduling production Ø Security system, etc. • Future Activities Ø SCM & EC Development Ø Web Connected System Development Ø Promote to Industries Association

Badan Pengkajian dan Penerpan Teknologi Direktorat Teknologi Informasi dan Elektronika Sulistyo Tel: +62 -21 -316 -9805/13 Fax: +62 -21 -316 -9811 E-M: sulis@inn. bppt. go. id Gd. II BPPT Lt. 21 Jl. Thamrin No. 8 Jakarta 10340 http: // www. dtie. bppt. go. id

Badan Pengkajian dan Penerpan Teknologi Direktorat Teknologi Informasi dan Elektronika Sulistyo Tel: +62 -21 -316 -9805/13 Fax: +62 -21 -316 -9811 E-M: sulis@inn. bppt. go. id Gd. II BPPT Lt. 21 Jl. Thamrin No. 8 Jakarta 10340 http: // www. dtie. bppt. go. id