6825150bf312c69023314e5bd4783431.ppt

- Количество слайдов: 69

ISTANBUL TECHNICAL UNIVERSITY – TURKISH AIRLINES Operations & Logistics Management in Air Transportation Dr. David Gillen (University of British Columbia) & Dr. Benny Mantin (University of Waterloo) June 9 -14, 2014 1

LOGISTICS Learning Objectives – Key components of logistics • Order Processing, Inventory, Transportation, Sourcing, Warehousing, Materials Handling, and Packaging, integrated through a network of facilities (warehouses and distribution centers) – Logistics is integral to a firm’s strategy – Keys to managing logistics costs • Inventory management • Transportation management – Supply Chain Flexibility and Synchronization 2

WHAT IS LOGISTICS? • Logistics is the design and administration of systems to control movement and spatial positioning of factor inputs (raw materials, labor, capital, energy) work-in -process, and finished inventories at the lowest total cost. • Our focus will be on inventory management and transportation management

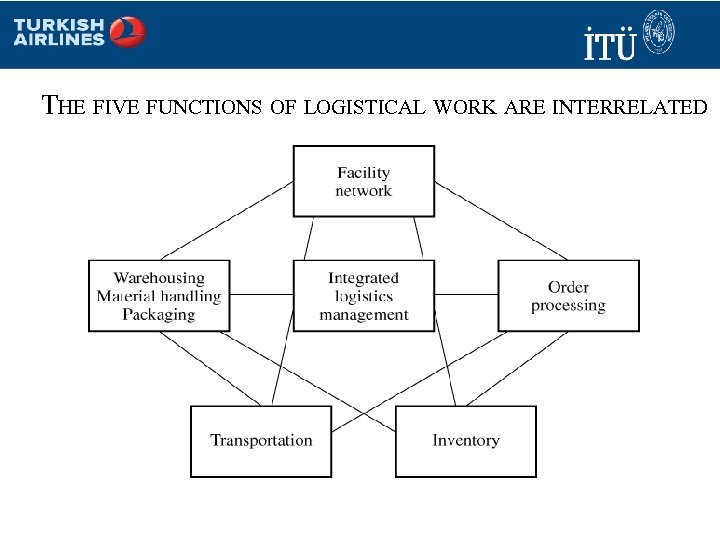

THE FIVE FUNCTIONS OF LOGISTICAL WORK ARE INTERRELATED

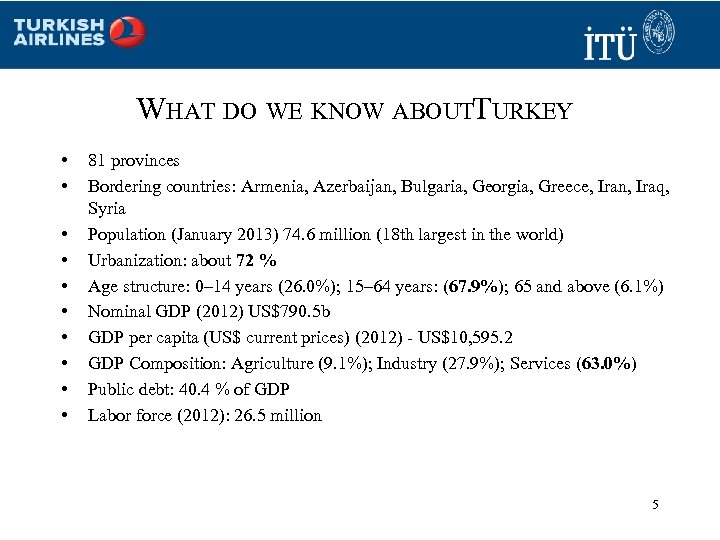

WHAT DO WE KNOW ABOUTTURKEY • • • 81 provinces Bordering countries: Armenia, Azerbaijan, Bulgaria, Georgia, Greece, Iran, Iraq, Syria Population (January 2013) 74. 6 million (18 th largest in the world) Urbanization: about 72 % Age structure: 0– 14 years (26. 0%); 15– 64 years: (67. 9%); 65 and above (6. 1%) Nominal GDP (2012) US$790. 5 b GDP per capita (US$ current prices) (2012) - US$10, 595. 2 GDP Composition: Agriculture (9. 1%); Industry (27. 9%); Services (63. 0%) Public debt: 40. 4 % of GDP Labor force (2012): 26. 5 million 5

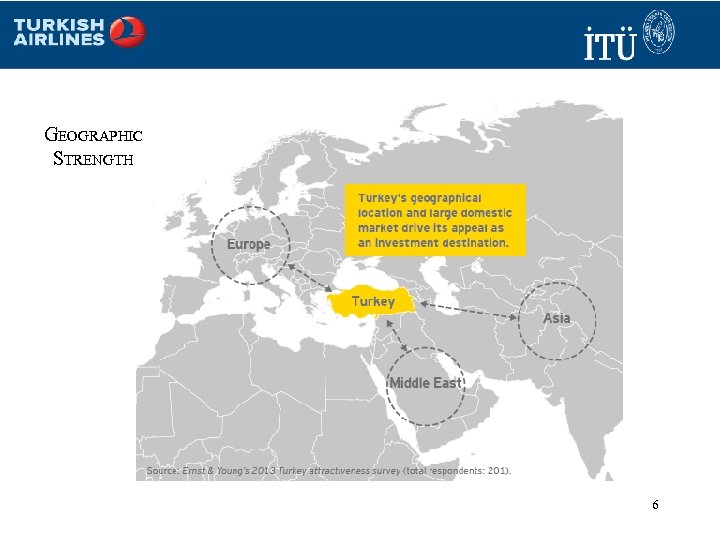

GEOGRAPHIC STRENGTH 6

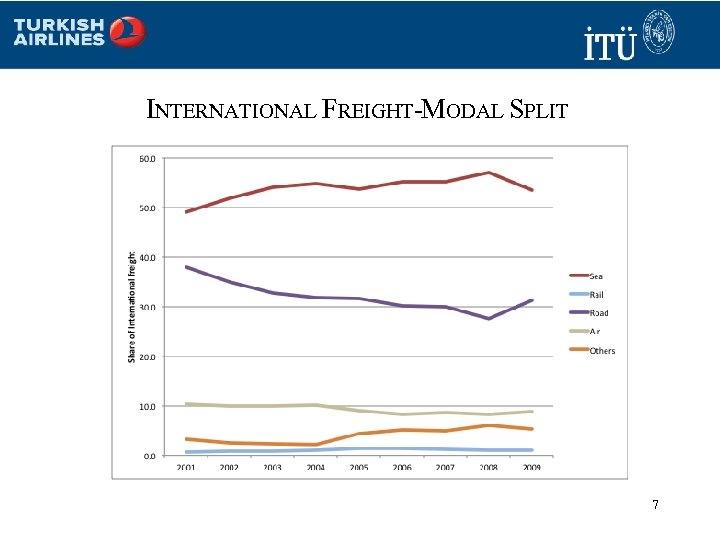

INTERNATIONAL FREIGHT-MODAL SPLIT 7

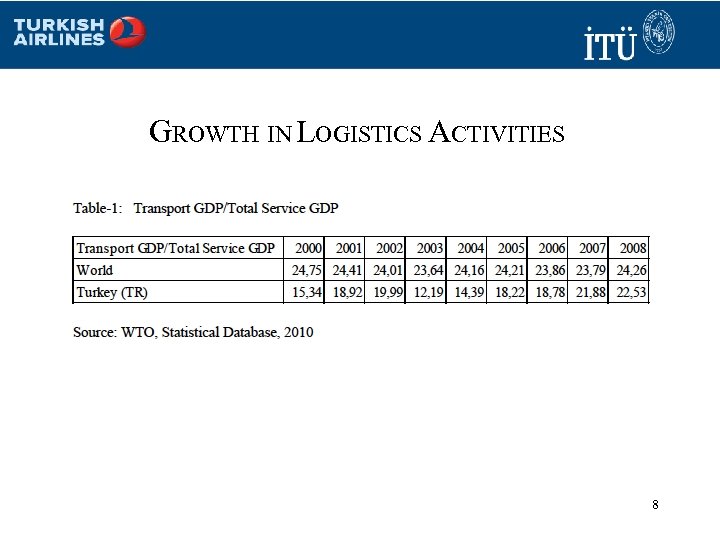

GROWTH IN LOGISTICS ACTIVITIES 8

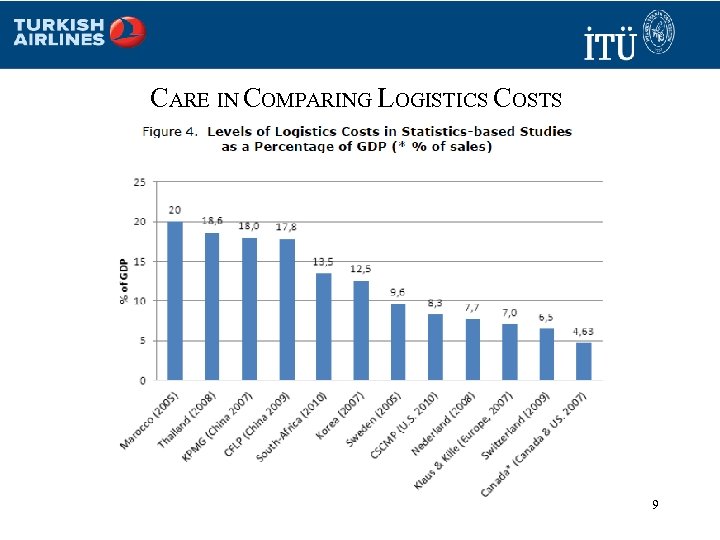

CARE IN COMPARING LOGISTICS COSTS 9

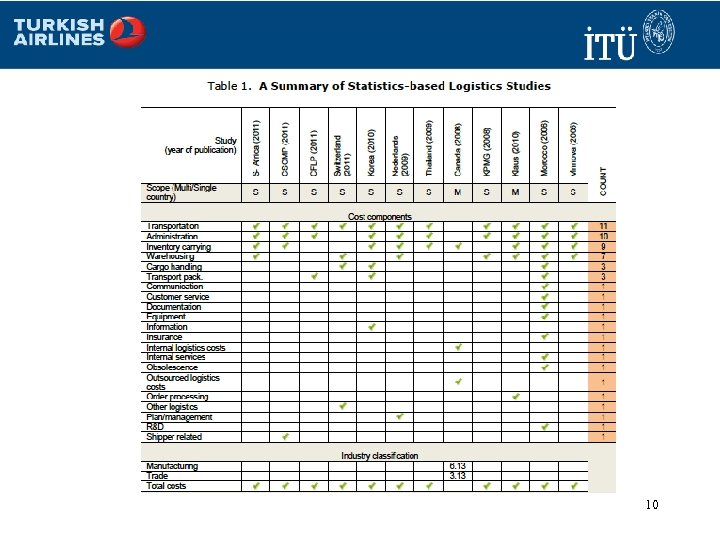

10

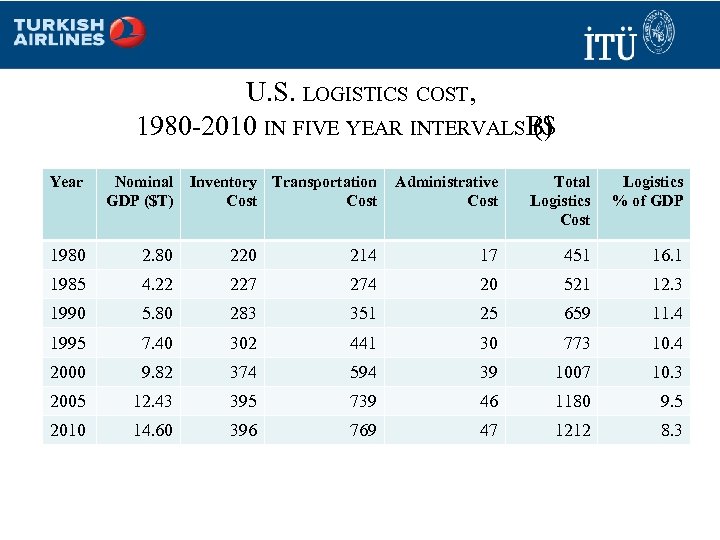

U. S. LOGISTICS COST, 1980 -2010 IN FIVE YEAR INTERVALSB) ($ Year Nominal GDP ($T) Inventory Transportation Cost Administrative Cost Total Logistics Cost Logistics % of GDP 1980 220 214 17 451 16. 1 1985 4. 22 227 274 20 521 12. 3 1990 5. 80 283 351 25 659 11. 4 1995 7. 40 302 441 30 773 10. 4 2000 9. 82 374 594 39 1007 10. 3 2005 12. 43 395 739 46 1180 9. 5 2010 14. 60 396 769 47 1212 8. 3

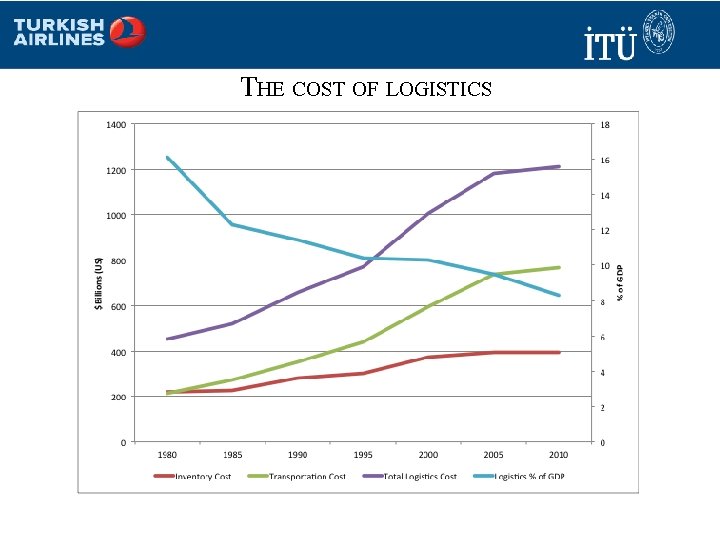

THE COST OF LOGISTICS

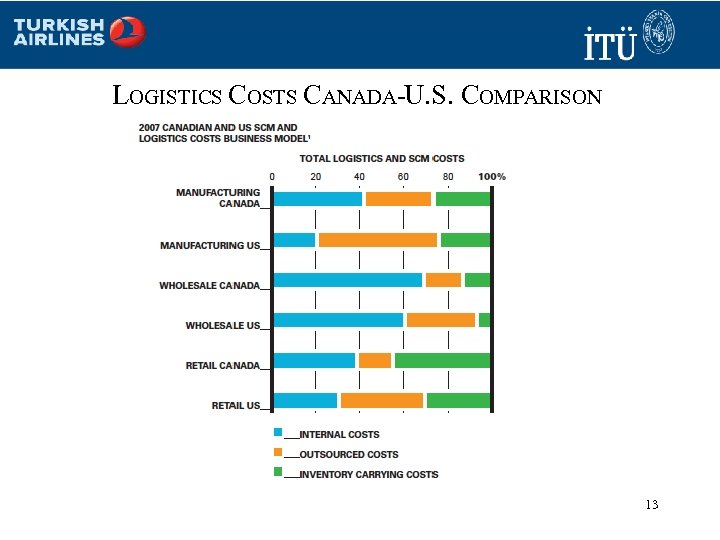

LOGISTICS COSTS CANADA-U. S. COMPARISON 13

LOGISTICS WILL CONTINUE ITS RENAISSANCE IN THE FUTURE • Information technologies will automate many of the traditionally manual logistical functions: – Automated port and rail operations – RFID tagging of materials – Advanced technologies for warehousing and inventory operations • Removal of trade barriers will continue to expand global trade and logistics • Outsourcing versus near-shoring – Implications for airlines?

LOGISTICAL VALUE PROPOSITION- ANUFACTURING & M SERVICE INDUSTRIES • Logistical value proposition consists of a commitment to key customer expectations and requirements at a minimum cost • The two elements of this value proposition are Service and Cost Minimization – Firms must make appropriate tradeoffs between service and cost for each of their key customers

SERVICE BENEFITS ARE CREATED BY LOGISTICAL PERFORMANCE IN 3 AREAS • Availability involves having inventory to consistently meet customer material or product requirements • Operational performance deals with the time required to deliver a customer’s order – Key metrics for this area involve delivery speed and consistency • Service reliability involves the quality attributes of logistics – Key to quality is accurate measurement of availability and operational performance over time

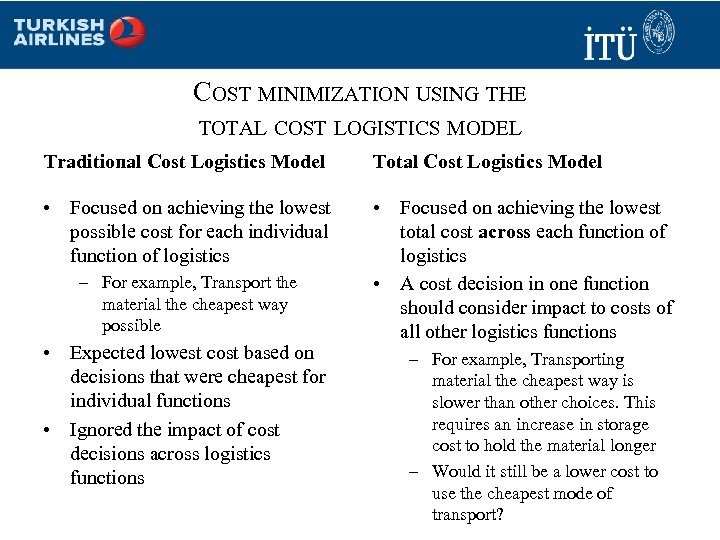

COST MINIMIZATION USING THE TOTAL COST LOGISTICS MODEL Traditional Cost Logistics Model Total Cost Logistics Model • Focused on achieving the lowest possible cost for each individual function of logistics • Focused on achieving the lowest total cost across each function of logistics • A cost decision in one function should consider impact to costs of all other logistics functions – For example, Transport the material the cheapest way possible • Expected lowest cost based on decisions that were cheapest for individual functions • Ignored the impact of cost decisions across logistics functions – For example, Transporting material the cheapest way is slower than other choices. This requires an increase in storage cost to hold the material longer – Would it still be a lower cost to use the cheapest mode of transport?

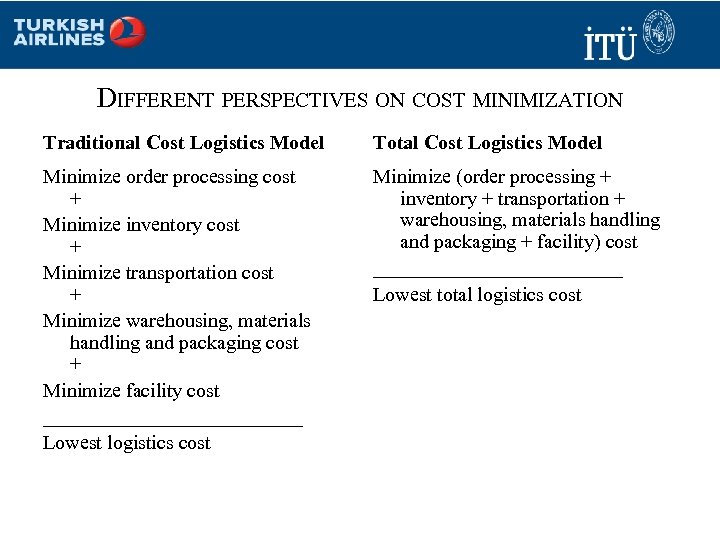

DIFFERENT PERSPECTIVES ON COST MINIMIZATION Traditional Cost Logistics Model Total Cost Logistics Model Minimize order processing cost + Minimize inventory cost + Minimize transportation cost + Minimize warehousing, materials handling and packaging cost + Minimize facility cost _____________ Lowest logistics cost Minimize (order processing + inventory + transportation + warehousing, materials handling and packaging + facility) cost _____________ Lowest total logistics cost

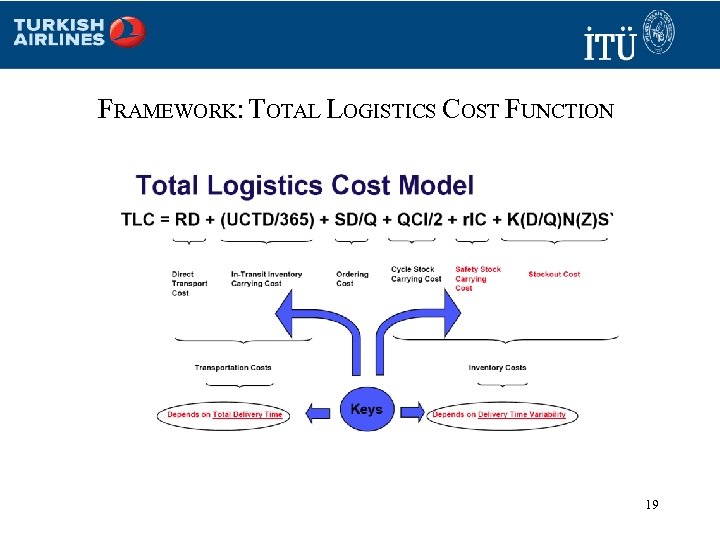

FRAMEWORK: TOTAL LOGISTICS COST FUNCTION 19

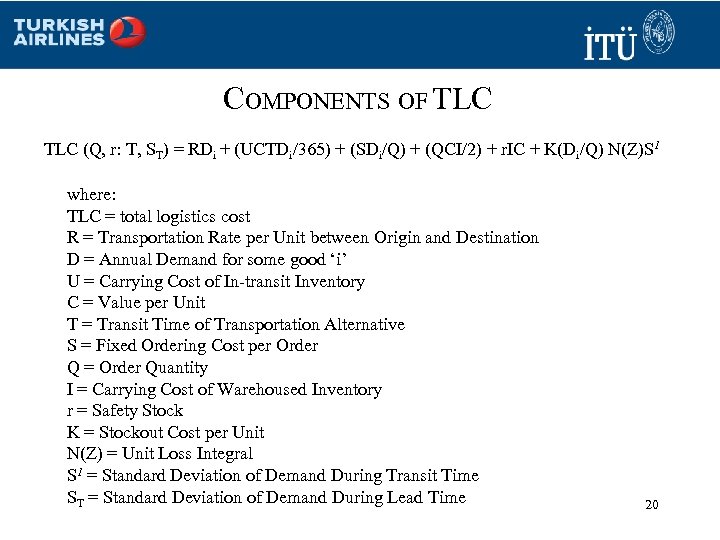

COMPONENTS OF TLC (Q, r: T, ST) = RDi + (UCTDi/365) + (SDi/Q) + (QCI/2) + r. IC + K(Di/Q) N(Z)S 1 where: TLC = total logistics cost R = Transportation Rate per Unit between Origin and Destination D = Annual Demand for some good ‘i’ U = Carrying Cost of In-transit Inventory C = Value per Unit T = Transit Time of Transportation Alternative S = Fixed Ordering Cost per Order Q = Order Quantity I = Carrying Cost of Warehoused Inventory r = Safety Stock K = Stockout Cost per Unit N(Z) = Unit Loss Integral S 1 = Standard Deviation of Demand During Transit Time ST = Standard Deviation of Demand During Lead Time 20

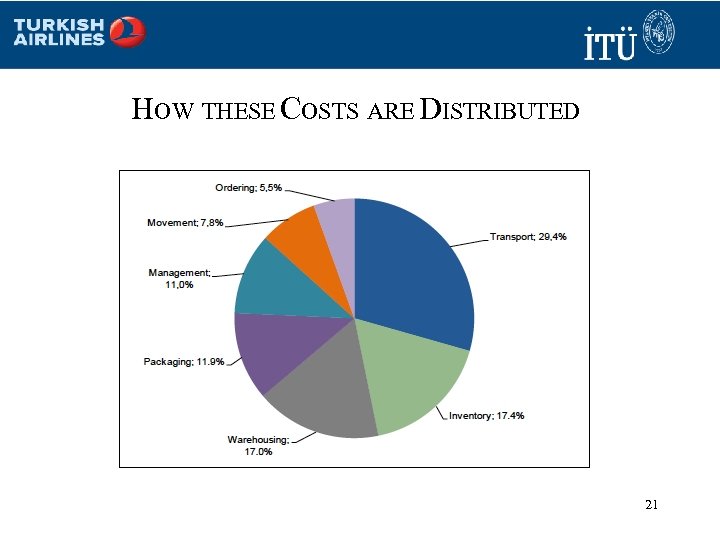

HOW THESE COSTS ARE DISTRIBUTED 21

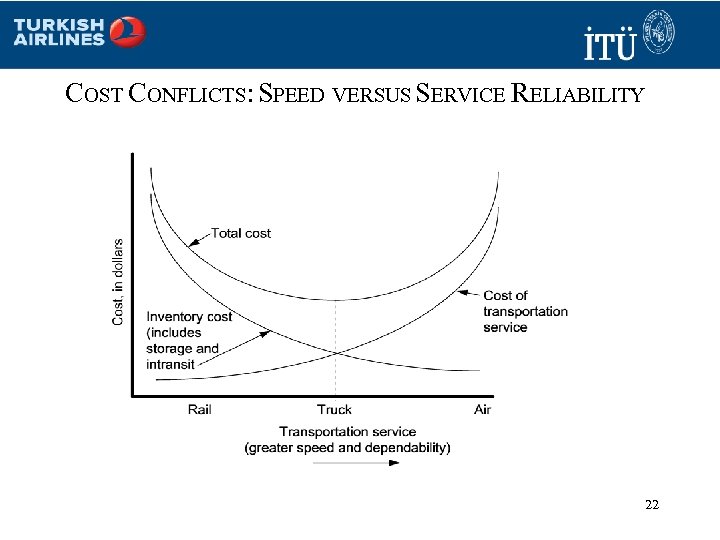

COST CONFLICTS: SPEED VERSUS SERVICE RELIABILITY 22

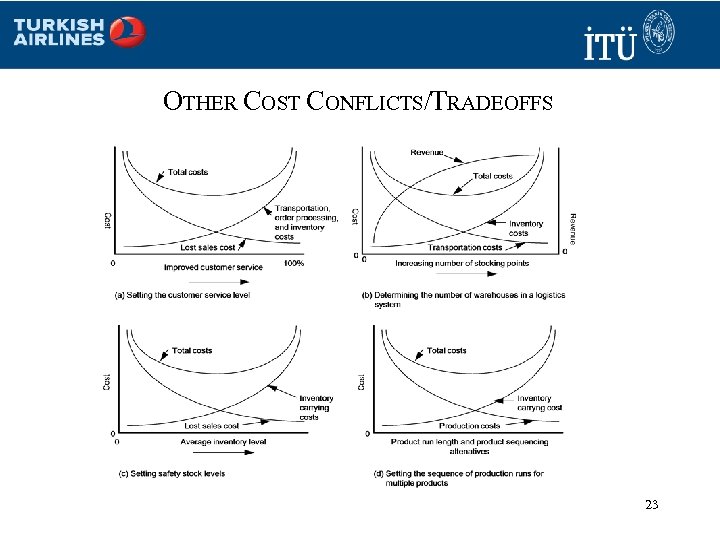

OTHER COST CONFLICTS/TRADEOFFS 23

TRANSPORTATION • Transportation is the operational area that geographically moves and positions inventory • There are three basic ways to satisfy transportation requirements – Operate a private fleet of equipment – Contract with dedicated transport specialists – Engage carriers that provide different transportation services as needed on a per shipment basis

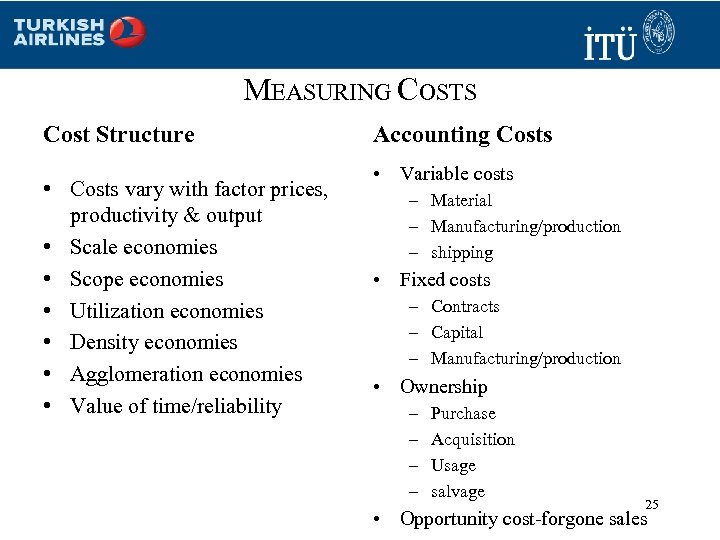

MEASURING COSTS Cost Structure • Costs vary with factor prices, productivity & output • Scale economies • Scope economies • Utilization economies • Density economies • Agglomeration economies • Value of time/reliability Accounting Costs • Variable costs – Material – Manufacturing/production – shipping • Fixed costs – Contracts – Capital – Manufacturing/production • Ownership – – Purchase Acquisition Usage salvage 25 • Opportunity cost-forgone sales

PRICING • • Concept to ‘Willingness to Pay’ Unit cost or average cost pricing Cost plus pricing Incremental cost pricing Differential Pricing (special case of Ramsey pricing) Non-linear pricing and two-part tariffs Bundling and unbundling 26

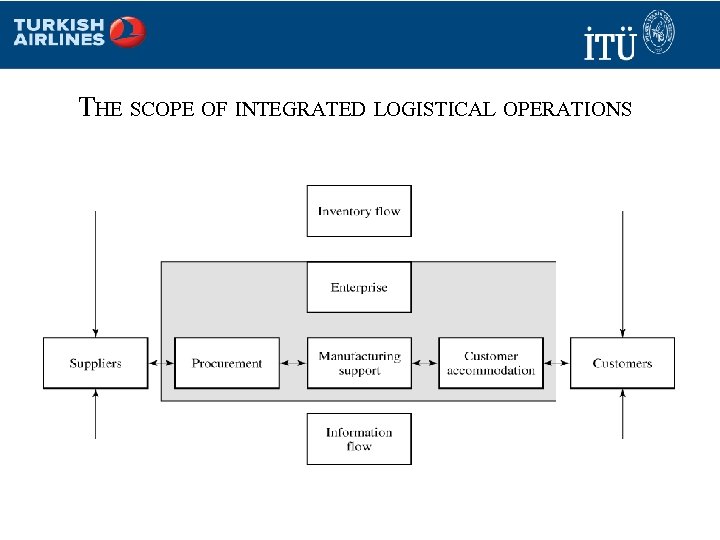

THE SCOPE OF INTEGRATED LOGISTICAL OPERATIONS

LOGISTICAL INTEGRATION REQUIRES ACHIEVING SIX OBJECTIVES SIMULTANEOUSLY ± Responsiveness ± Variance reduction ± Inventory reduction ± Shipment consolidation ± Quality ± Life cycle support

EXAMPLE SITUATIONS FOR FLEXIBLE LOGISTICS STRUCTURE • The customer-specified delivery facility might be near a point of equal logistics cost or equal delivery time from two different logistics facilities • The size of a customer’s order creates improved logistical efficiency if serviced through an alternative channel arrangement • Decision to use a selective inventory stocking strategy • Agreements between firms to move selected shipments outside the established echeloned or direct arrangements • Co-opatition (Cooperation & Competition)

SUPPLY CHAIN SYNCHRONIZATION • Supply chain synchronization is the operational integration of multiple firms across a supply chain – Seeks to coordinate the flow of materials, products and information between supply chain partners to reduce duplication of effort – Seeks to reengineer internal operations of individual firms to leverage overall supply chain capability

THE LOGISTICS PERFORMANCE CYCLE IS THE BASIC UNIT OF SUPPLY CHAIN DESIGN AND OPERATIONAL CONTROL • The performance cycle represents elements of work necessary to complete the logistics related to customer accommodation, manufacturing or procurement • A performance cycle consists of the following elements – Nodes – Links – Inventory • Base stock • Safety stock – Input and output requirements

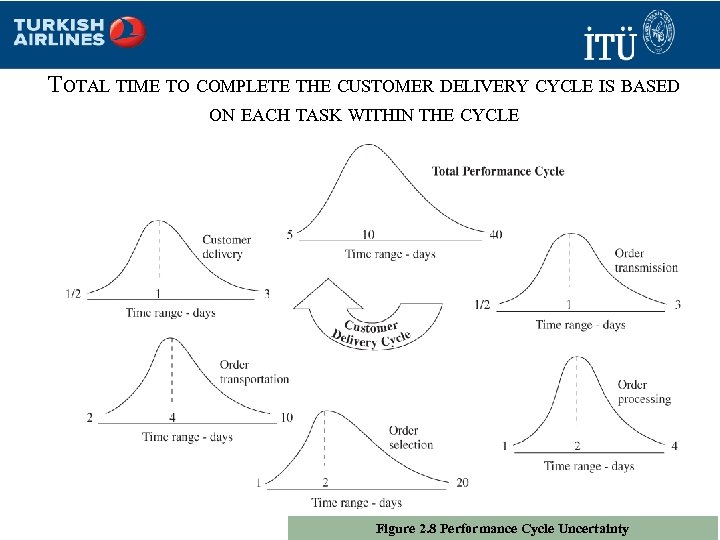

PERFORMANCE CYCLE UNCERTAINTY • Major objective of logistics in all areas is to reduce performance cycle uncertainty • Operational variance is randomly introduced during the cycle through – The structure of the performance cycle itself – Operating conditions – The quality of logistical operations

TOTAL TIME TO COMPLETE THE CUSTOMER DELIVERY CYCLE IS BASED ON EACH TASK WITHIN THE CYCLE Figure 2. 8 Performance Cycle Uncertainty

INVENTORY MANAGEMENT THE ECONOMIC ORDER QUANTITY MODEL

Knowing what you've got, Knowing what you need, Knowing what you can live without – That’s inventory control. Frank Wheeler, Revolutionary 35

INVENTORY • Definition: The stock of any item or resource used in an organization Raw Materials & Component Parts Replacement parts, tools & supplies Work-In-Process Goods in transit to warehouses or customers Finished Products 36

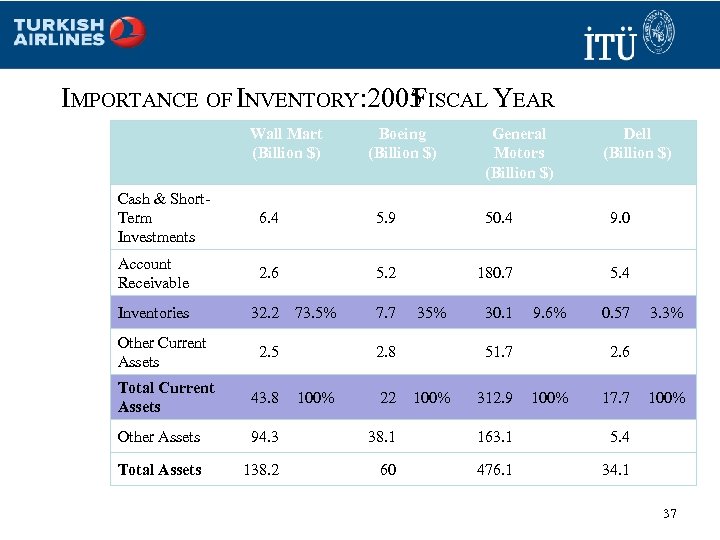

IMPORTANCE OF INVENTORY: 2005 ISCAL YEAR F Wall Mart (Billion $) Boeing (Billion $) General Motors (Billion $) Dell (Billion $) Cash & Short. Term Investments 6. 4 5. 9 50. 4 9. 0 Account Receivable 2. 6 5. 2 180. 7 5. 4 Inventories 32. 2 73. 5% 7. 7 35% 30. 1 9. 6% 0. 57 Other Current Assets 2. 5 Total Current Assets 43. 8 Other Assets 94. 3 38. 1 163. 1 5. 4 Total Assets 138. 2 60 476. 1 3. 3% 34. 1 2. 8 100% 22 51. 7 100% 312. 9 2. 6 100% 17. 7 100% 37

IMPORTANCE OF INVENTORY MANAGEMENT • . . . by 1990 Wal-Mart was already winning an important technological war that other discounters did not seem to know was on. “Wal-Mart has the most advanced inventory technology in the business and they have invested billions in it”. (New York Times, Nov. 95) • Kmart increased its inventories to $8. 3 billions in the third quarter of 2001 with an expectation of more shoppers. “But higher sales never materialized, leading to a disastrous holiday selling season. ” Kmart filed for bankruptcy on Jan. 22. (Business Week, Mar. 02) 38

IMPORTANCE OF INVENTORY MANAGEMENT MORE RECENT NEWS • San. Disk suspends production as inventories pile up for makers of computers, cell phones, and TVs … (Business Week, Dec. 08) • Natural-gas futures soared 15% Thursday after U. S. inventory data slightly eased concerns about the possibility of a storage glut (Wall Street Journal, Sept. 11, 09) • Fruit growers were blessed with excellent weather this year. But that hasn’t translated into a great year for the province’s cherry and blueberry growers, as a bumper crop has flooded the market and pushed down prices. (The Vancouver Sun, Aug. 09) • The Ford assembly plant in Oakville and 3, 000 workers will remain idle this week because of a parts shortage from a supplier in India. (Toronto Star, Oct. 27, 09) 39

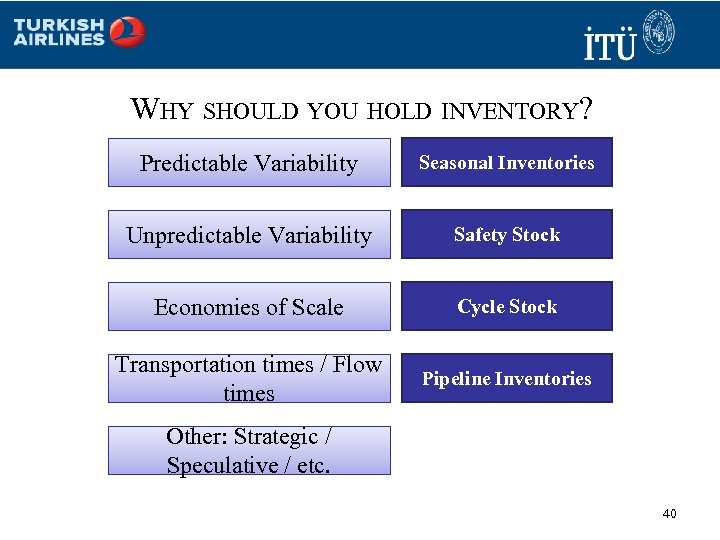

WHY SHOULD YOU HOLD INVENTORY? Predictable Variability Seasonal Inventories What are some of the inventories Safety Stock Unpredictable Variability that you have? Economies of Scale Cycle Stock Transportation times you have these Why do / Flow Pipeline Inventories times inventories? Other: Strategic / Speculative / etc. 40

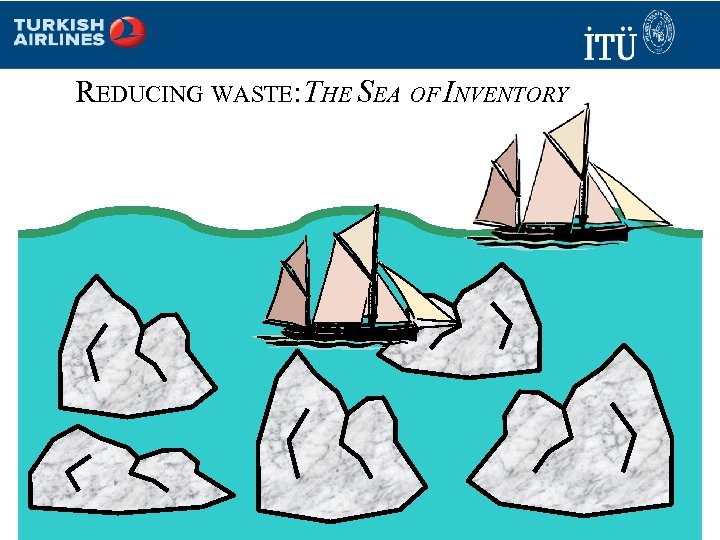

WHY SHOULD YOU NOT HOLD INVENTORY? • Inventory increases certain costs such as – – – Carrying cost Cost of customer responsiveness Cost of diluted return on investment Large-lot quality cost Cost of production problems, etc. • The Sea of Inventory hides problems … 41

REDUCING WASTE: THE SEA OF INVENTORY 42

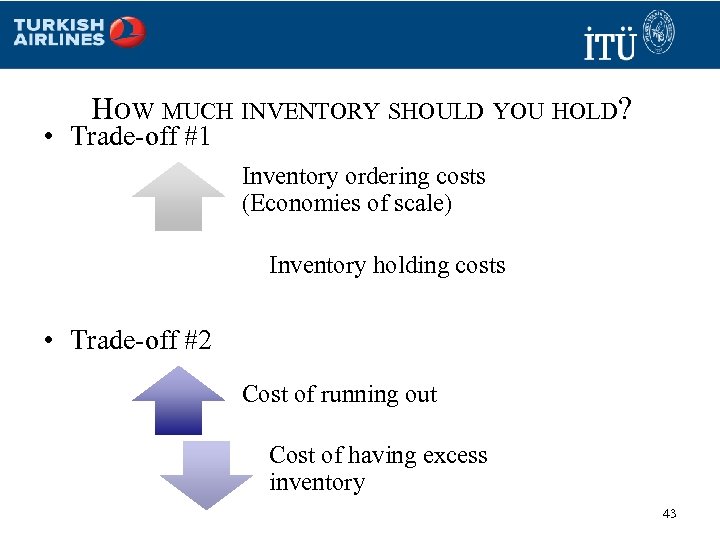

HOW MUCH INVENTORY SHOULD YOU HOLD? • Trade-off #1 Inventory ordering costs (Economies of scale) Inventory holding costs • Trade-off #2 Cost of running out Cost of having excess inventory 43

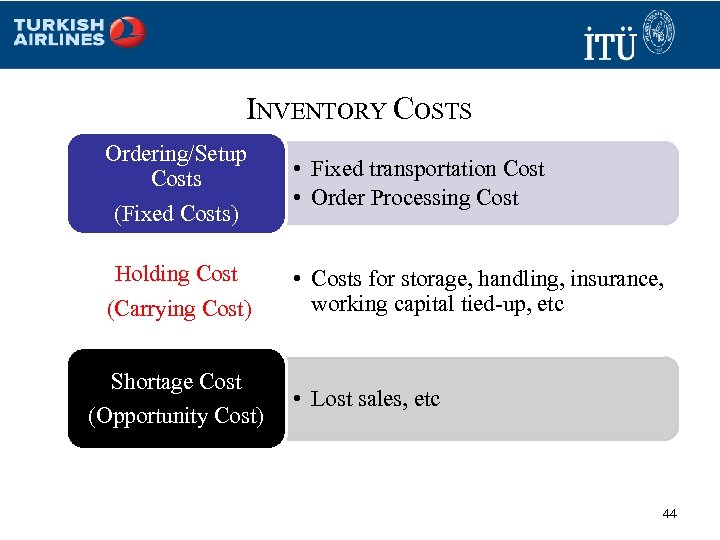

INVENTORY COSTS Ordering/Setup Costs (Fixed Costs) • Fixed transportation Cost • Order Processing Cost Holding Cost (Carrying Cost) • Costs for storage, handling, insurance, working capital tied-up, etc Shortage Cost (Opportunity Cost) • Lost sales, etc 44

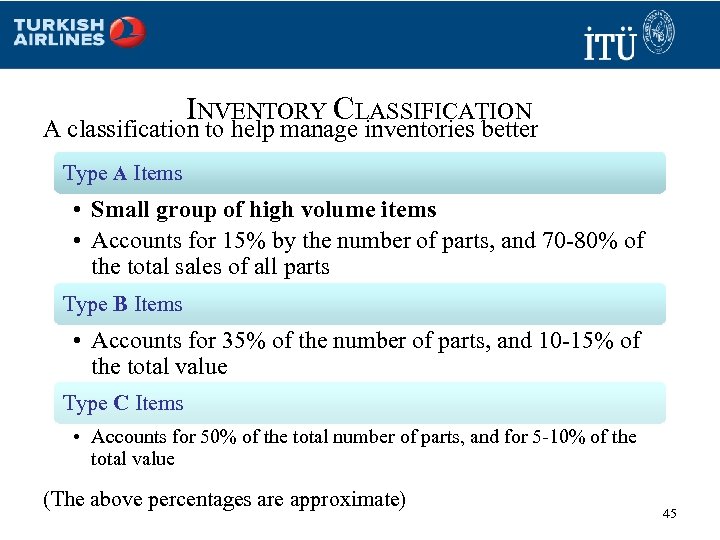

INVENTORY CLASSIFICATION A classification to help manage inventories better Type A Items • Small group of high volume items • Accounts for 15% by the number of parts, and 70 -80% of the total sales of all parts Type B Items • Accounts for 35% of the number of parts, and 10 -15% of the total value Type C Items • Accounts for 50% of the total number of parts, and for 5 -10% of the total value (The above percentages are approximate) 45

MOTIVATION: ATM • How much cash do you take out from ATM? • Why not more or less? 46

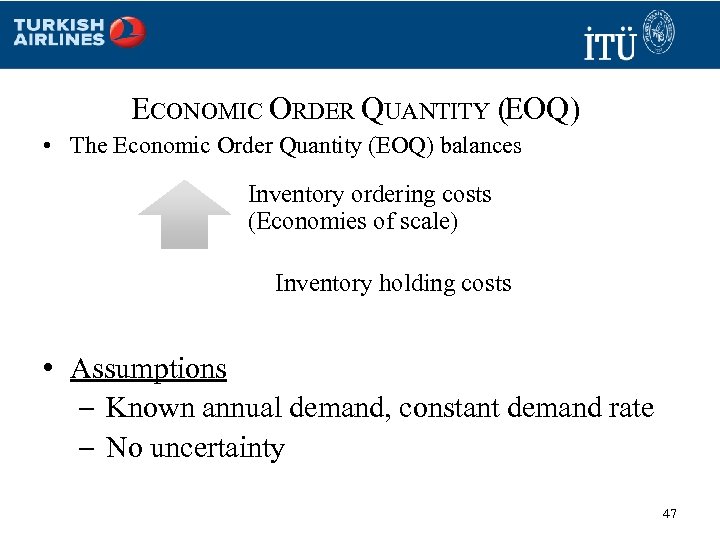

ECONOMIC ORDER QUANTITY (EOQ) • The Economic Order Quantity (EOQ) balances Inventory ordering costs (Economies of scale) Inventory holding costs • Assumptions – Known annual demand, constant demand rate – No uncertainty 47

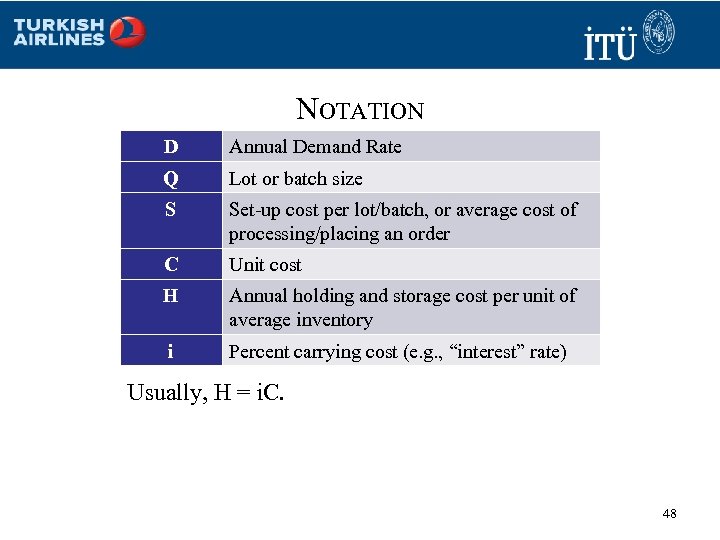

NOTATION D Annual Demand Rate Q Lot or batch size S Set-up cost per lot/batch, or average cost of processing/placing an order C Unit cost H Annual holding and storage cost per unit of average inventory i Percent carrying cost (e. g. , “interest” rate) Usually, H = i. C. 48

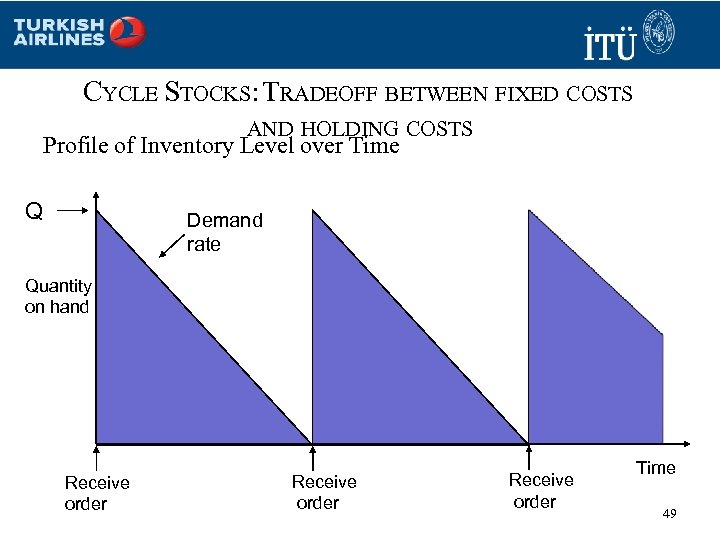

CYCLE STOCKS: TRADEOFF BETWEEN FIXED COSTS AND HOLDING COSTS Profile of Inventory Level over Time Q Demand rate Quantity on hand Receive order Time 49

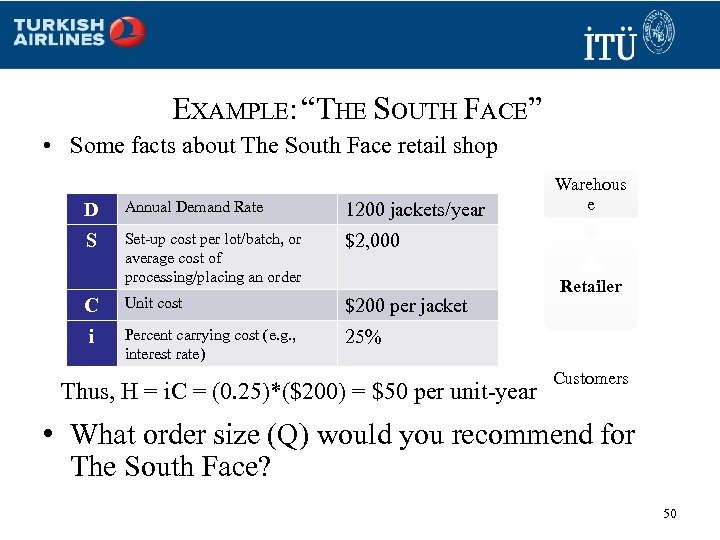

EXAMPLE: “THE SOUTH FACE” • Some facts about The South Face retail shop D Annual Demand Rate 1200 jackets/year S Set-up cost per lot/batch, or average cost of processing/placing an order $2, 000 C Unit cost $200 per jacket i Percent carrying cost (e. g. , interest rate) Warehous e 25% Thus, H = i. C = (0. 25)*($200) = $50 per unit-year Retailer Customers • What order size (Q) would you recommend for The South Face? 50

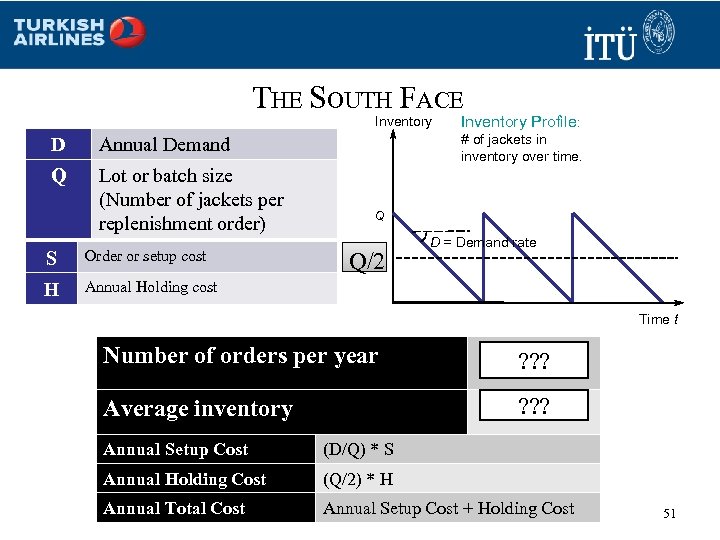

THE SOUTH FACE Inventory D Lot or batch size (Number of jackets per replenishment order) # of jackets in inventory over time. Annual Demand Q S Order or setup cost H Inventory Profile: Q D = Demand rate Annual Holding cost Q/2 Time t Number of orders per year D/Q ? ? ? Average inventory ? ? ? Q/2 Annual Setup Cost (D/Q) * S Annual Holding Cost (Q/2) * H Annual Total Cost Annual Setup Cost + Holding Cost 51

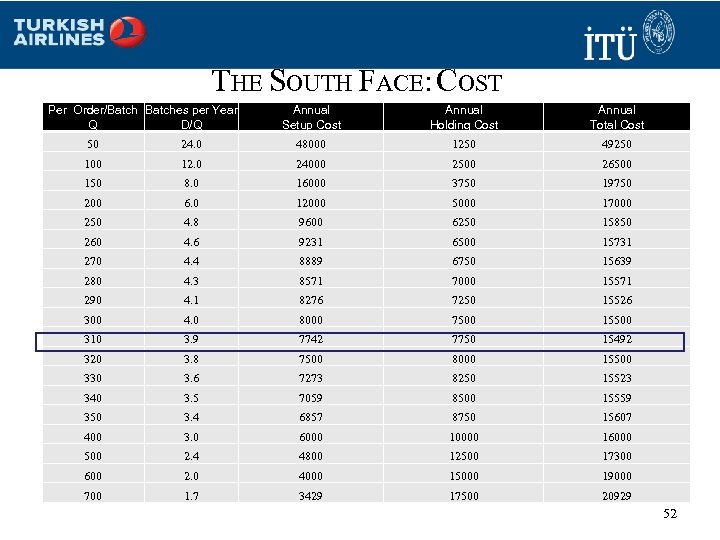

THE SOUTH FACE: COST Per Order/Batches per Year Q D/Q Annual Setup Cost Annual Holding Cost Annual Total Cost 48000 1250 49250 EOQ Model: Cost 24. 0 100 12. 0 24000 2500 26500 150 8. 0 16000 3750 19750 200 6. 0 12000 5000 17000 250 4. 8 9600 6250 15850 260 4. 6 9231 6500 15731 270 4. 4 8889 6750 15639 280 4. 3 8571 7000 15571 15000 290 4. 1 8276 7250 15526 300 4. 0 8000 7500 15500 310 3. 9 7742 7750 15492 320 3. 8 7500 8000 15500 330 3. 6 7273 8250 15523 340 5000 3. 5 7059 8500 15559 350 3. 4 6857 8750 15607 400 3. 0 6000 10000 16000 0 500 2. 4 4800 12500 17300 15000 19000 17500 20929 25000 20000 10000 600 700 110 130 150 170 190 210 230 250 270 290 310 330 350 370 390 410 430 450 470 490 510 530 550 570 590 610 630 650 670 690 710 730 750 770 790 810 830 850 870 890 910 930 950 970 990 50 30000 2. 0 1. 7 4000 Setup Cost 3429 Holding Cost Total Cost 52

Annual Cost COST MINIMIZATION GOAL Total Cost Lowest Annual Cost Inventory holding cost Ordering Costs QO (optimal order quantity) Order Quantity (Q) 53

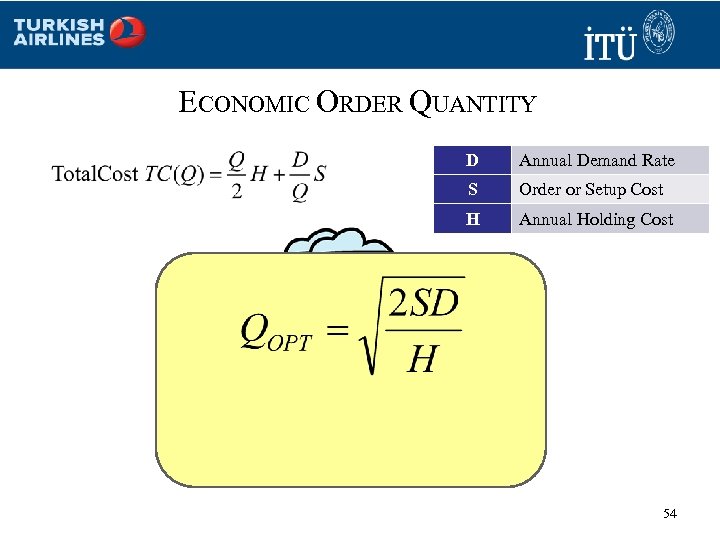

ECONOMIC ORDER QUANTITY D Annual Demand Rate S Order or Setup Cost H Annual Holding Cost 54

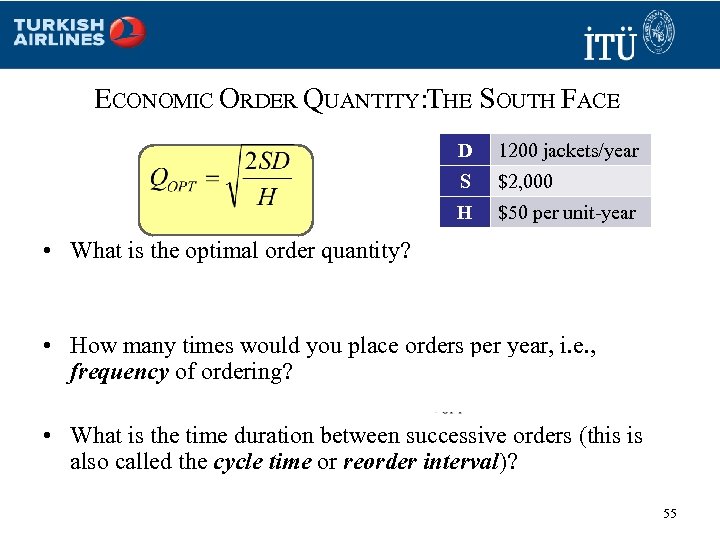

ECONOMIC ORDER QUANTITY: THE SOUTH FACE D 1200 jackets/year S $2, 000 H $50 per unit-year • What is the optimal order quantity? • How many times would you place orders per year, i. e. , frequency of ordering? • What is the time duration between successive orders (this is also called the cycle time or reorder interval)? 55

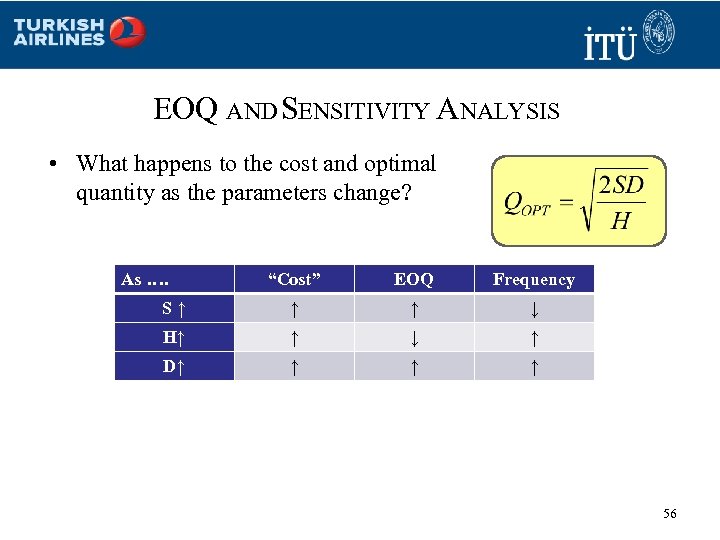

EOQ AND SENSITIVITY ANALYSIS • What happens to the cost and optimal quantity as the parameters change? As …. “Cost” EOQ Frequency S↑ ↑ ↑ ↓ H↑ ↑ ↓ ↑ D↑ ↑ 56

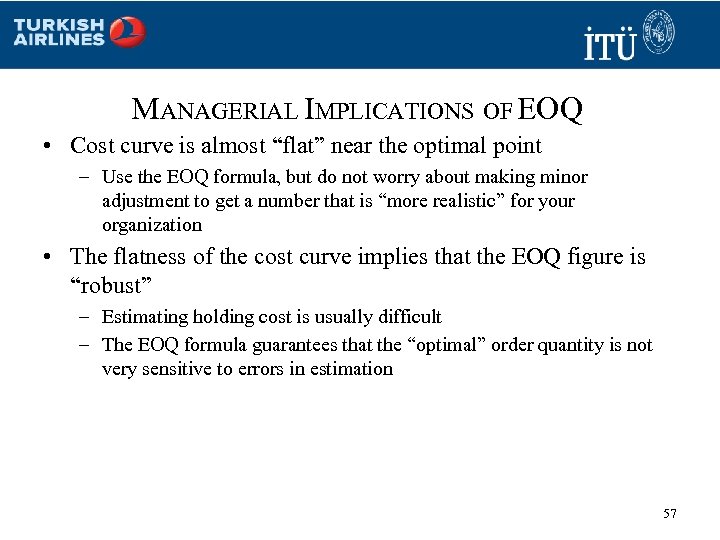

MANAGERIAL IMPLICATIONS OF EOQ Model: Cost • Cost curve is almost “flat” near the optimal point 30000 – Use the EOQ formula, but do not worry about making minor 25000 adjustment to get a number that is “more realistic” for your organization 20000 • The flatness of the cost curve implies that the EOQ figure is “robust” 15000 – Estimating holding cost is usually difficult – 10000 The EOQ formula guarantees that the “optimal” order quantity is not very sensitive to errors in estimation 5000 110 130 150 170 190 210 230 250 270 290 310 330 350 370 390 410 430 450 470 490 510 530 550 570 590 610 630 650 670 690 710 730 750 770 790 810 830 850 870 890 910 930 950 970 990 0 Setup Cost Holding Cost Total Cost 57

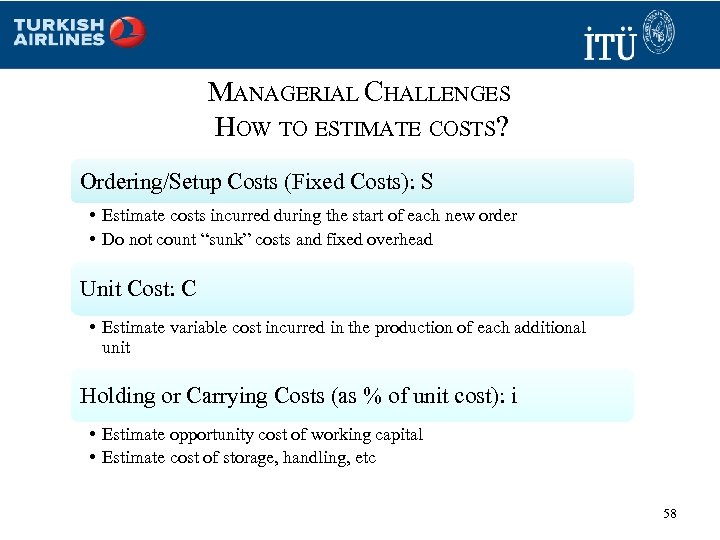

MANAGERIAL CHALLENGES HOW TO ESTIMATE COSTS? Ordering/Setup Costs (Fixed Costs): S • Estimate costs incurred during the start of each new order • Do not count “sunk” costs and fixed overhead Unit Cost: C • Estimate variable cost incurred in the production of each additional unit Holding or Carrying Costs (as % of unit cost): i • Estimate opportunity cost of working capital • Estimate cost of storage, handling, etc 58

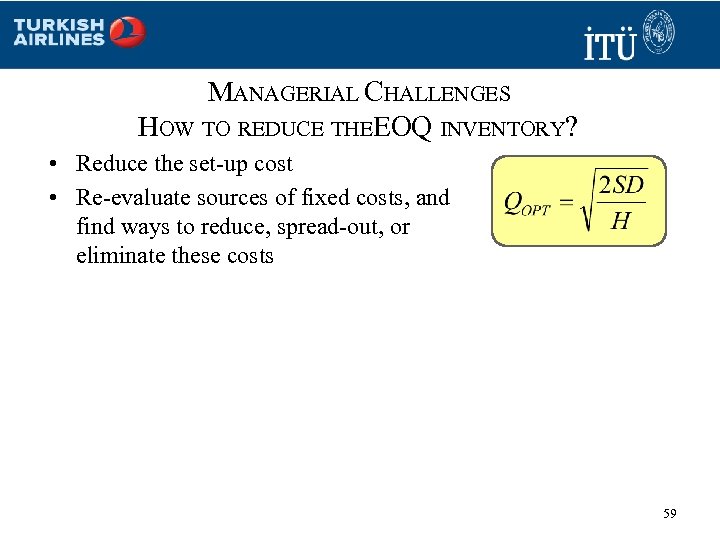

MANAGERIAL CHALLENGES HOW TO REDUCE THEEOQ INVENTORY? • Reduce the set-up cost • Re-evaluate sources of fixed costs, and find ways to reduce, spread-out, or eliminate these costs 59

APPENDIX MATERIAL 60

CONTENTS I. INTEGRATED LOGISTICS MANAGEMENT Ia. The Growth of Logistics and Its Role in the Economy A. What is Logistics? B. History of Logistics C. Role of Logistics in the Economy D. Why Logistics is gaining in importance Ib. The Integrated Logistics Management Concept A. Definition B. Logistics is concerned with questions about inventories D. Strategic profit analysis Ic. Logistics As An Element of Corporate Strategy A. A Few Logistics Facts B. Corporate Leverage From Logisitics C. Product Strategy: Innovation Phase D. Product Strategy: Cost Leadership Phase E. Product Line (Customer Service) Strategies

CONTENTS Id. Distribution Channels A. Channels: Definition, Types, Functions B. Integrated Channel Concept C. Some Logistical Implications Ie. Customer Service A. Defining Customer Service B. Measuring Customer Service C. Relationship of Customer Service to Marketing D. Optimizing Customer Service E. Stockouts F. Stockout Costs G. ABC Analysis If. International Logistics A. Importance of International Logistics B. International Strategies C. Some Additional Considerations

CONTENTS II. LOGISTICS SYSTEM ELEMENTS IIa. Inventory Management ‑ Introduction A. Financial Impact B. Reasons for Holding Inventory C. Types of Inventory D. Example of Financial Impact IIb. Inventory ‑ Carrying Costs A. General B. Capital Costs C. Other Costs D. Annual Inventory Costs E. Valuing Inventory (i. e. Value on Balance Sheet) F. Why Inventory Costs are Often Misstated IIc. Inventory ‑ Management Under Certainty (EOQ) A. Basic Inventory Cycle B. Ordering Costs C. Effect of Decrease in Cycle Time D. Total Costs E. Optimum Quantity to Order F. Quantity Discounts G. Other Cases

CONTENTS IId. Inventory ‑ Uncertainty A. Calculating Safety Stocks B. Example of Safety Stock Calculations C. The Flip Side: Reducing Cycle Variability for Your Customers D. Appendix Derivation of Formula for σc IIe. Inventory ‑ Control A. Stock Control Methods B. Inventory System Design C. Fixed Order Point D. Fixed Order Interval E. Transport Choice Case F. Items covered in readings, not in lectures G. Postscript: Inventory, Production, Marketing, Finance IIf. International Shipping A. Importance B. Technology C. Demand - Shippers (Two main market segments) D. Supply - Shipping Carriers/Owners E. Freight Rates

CONTENTS IIg. Transport ‑ Modes and Service Characteristics A. Mode Characteristics B. Costs C. Rate-Service Tradeoff IIh. Transportation: Consolidation A. Types of Consolidators B. Reasons for Consolidation C. Types of Consolidation D. Typical LTL Routing E. Containers IIi. Transportation: Traffic Management A. Traffic Management Functions B. Deregulation C. Negotiations D. Private Versus Public Carriage

CONTENTS IIj. Warehousing A. Functions of Warehousing B. Types of Warehouses C. Optimal Number of Warehouses D. Optimal Size of Warehouse E. Stock Location Methods F. Order Picking Design G. Public versus Private Warehouse Choice H. A Note on Warehouse Costs IIk. Facility Location A. Two Types of Locational Decisions B. Transport Cost Models C. Other Locational Decisions D. Tactical Location Considerations

CONTENTS IIl. Packaging A. The Two Functions of Packaging B. Unitization C. Packaging Materials D. Some Packaging Problems/Solutions E. Where/When Should Packaging Be Added? IIm. Purchasing A. Introduction B. Forward Buying C. Other Aspects of Purchasing IIn. Materials Management A. Introduction B. Materials Requirement Planning (MRP) C. Manufacturing Resource Planning (MRP II)

CONTENTS IIo. Total Quality Management A. Introduction B. TQM versus Traditional Approach C. Employee motivation D. Examples IIp. Just-in-Time Systems A. Just-In-Time-System B. Manufacturing Resource Productivity (MRP III) IIq. Production Systems IIr. Distribution Requirements Planning A. Distribution Requirements Planning (DRP) IIs. Order Processing A. The Order Cycle B. The Order Processing System C. Impact on Logistics D. Implications of Advanced Order Processing Systems

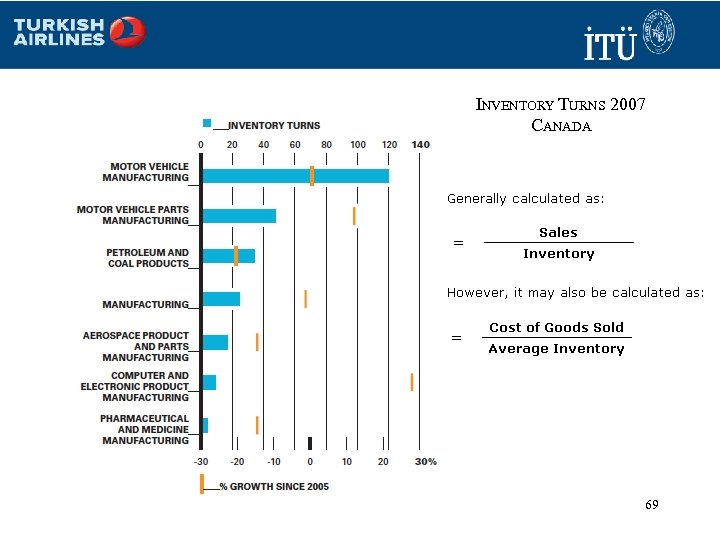

INVENTORY TURNS 2007 CANADA 69

6825150bf312c69023314e5bd4783431.ppt