1ac7f53777e1d8735b82085dea299236.ppt

- Количество слайдов: 52

ISO STEP-AP 233 Transition Development to Enablement Harold P. Frisch – NASA Emeritus, AP 233 co-lead Charlie Stirk - Cost. Vision Inc. With special thanks to David Price & Phil Spiby at Eurostep

Agenda • Development – Background on AP 233 and SE standards – Relationship to other STEP standards – AP 233 detail @ executive level • Enablement – Implementation approaches • UML/Sys. ML based • STEP/EXPRESS based – New implementations possibilities

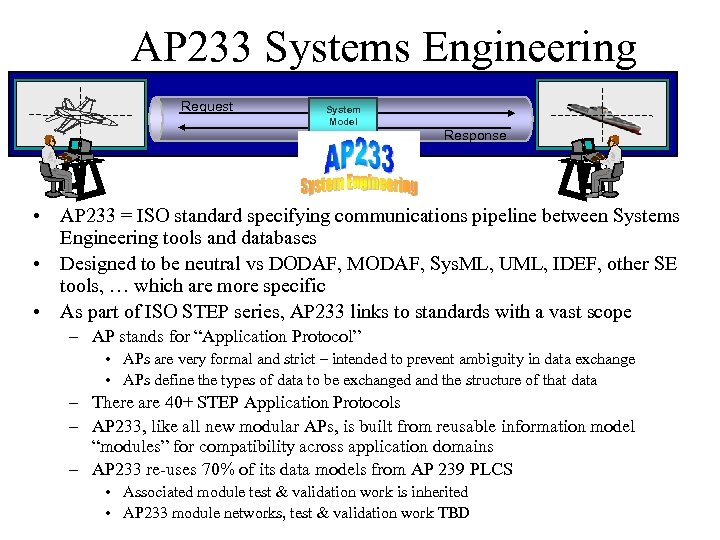

AP 233 Systems Engineering • System-of-systems engineering requires Request System • Greater collaboration and tool interoperability, and … Model Response • Using robust modeling techniques for describing systems architectures • AP 233 = ISO standard specifying communications pipeline between Systems Engineering tools and databases • Designed to be neutral vs DODAF, MODAF, Sys. ML, UML, IDEF, other SE tools, … which are more specific • As part of ISO STEP series, AP 233 links to standards with a vast scope – AP stands for “Application Protocol” • APs are very formal and strict – intended to prevent ambiguity in data exchange • APs define the types of data to be exchanged and the structure of that data – There are 40+ STEP Application Protocols – AP 233, like all new modular APs, is built from reusable information model “modules” for compatibility across application domains – AP 233 re-uses 70% of its data models from AP 239 PLCS • Associated module test & validation work is inherited • AP 233 module networks, test & validation work TBD

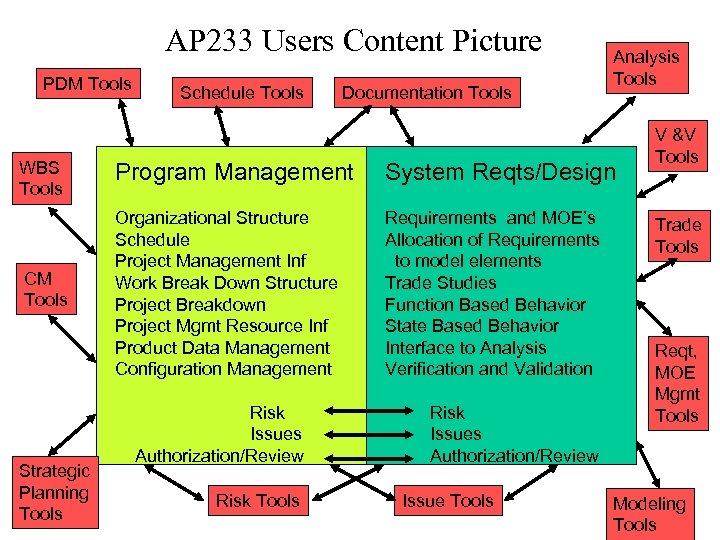

AP 233 Users Content Picture PDM Tools Schedule Tools Documentation Tools Analysis Tools WBS Tools Program Management System Reqts/Design CM Tools Organizational Structure Schedule Project Management Inf Work Break Down Structure Project Breakdown Project Mgmt Resource Inf Product Data Management Configuration Management Requirements and MOE’s Allocation of Requirements to model elements Trade Studies Function Based Behavior State Based Behavior Interface to Analysis Verification and Validation Strategic Planning Tools Risk Issues Authorization/Review Risk Tools Risk Issues Authorization/Review Issue Tools V &V Tools Trade Tools Reqt, MOE Mgmt Tools Modeling Tools

AP 233 Participants • Over the course of the project, numerous organizations have helped with AP 233

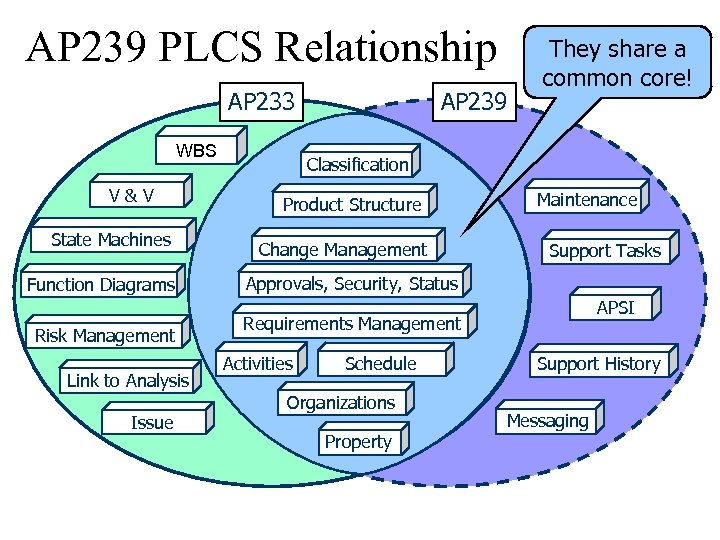

AP 239 PLCS Relationship AP 233 WBS V&V State Machines Function Diagrams Risk Management Link to Analysis Issue AP 239 They share a common core! Classification Product Structure Change Management Maintenance Support Tasks Approvals, Security, Status APSI Requirements Management Activities Schedule Organizations Property Support History Messaging

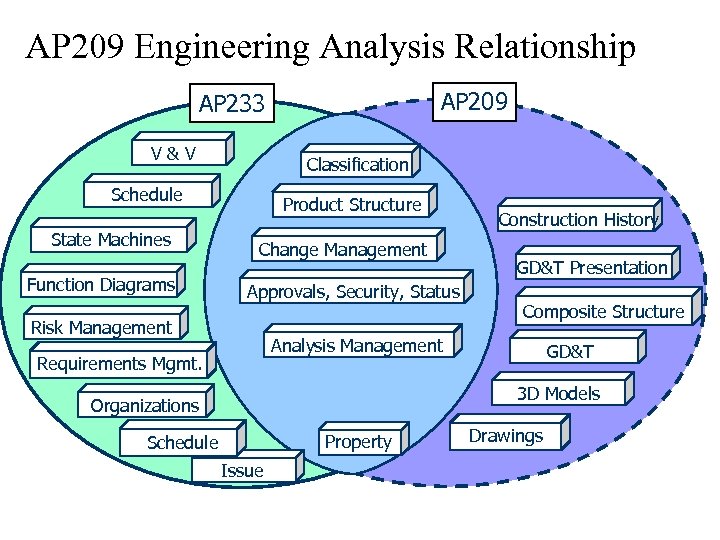

AP 209 Engineering Analysis Relationship AP 209 AP 233 V&V Classification Schedule State Machines Function Diagrams Product Structure Change Management Approvals, Security, Status Risk Management Construction History GD&T Presentation Composite Structure Analysis Management Requirements Mgmt. GD&T 3 D Models Organizations Property Schedule Issue Drawings

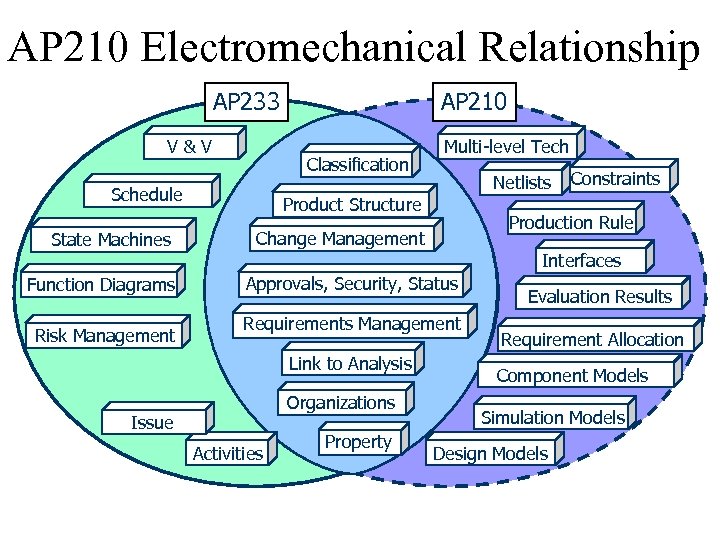

AP 210 Electromechanical Relationship AP 233 V&V Classification Schedule State Machines Function Diagrams Risk Management AP 210 Multi-level Tech Netlists Product Structure Production Rule Change Management Interfaces Approvals, Security, Status Requirements Management Link to Analysis Organizations Issue Activities Property Constraints Evaluation Results Requirement Allocation Component Models Simulation Models Design Models

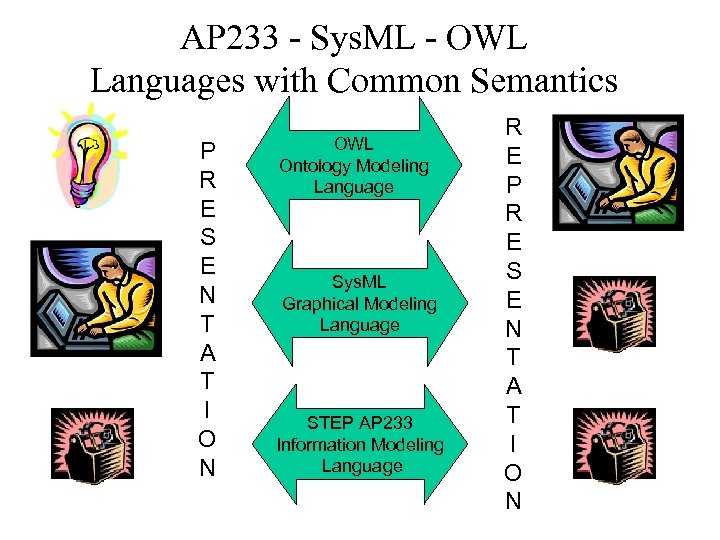

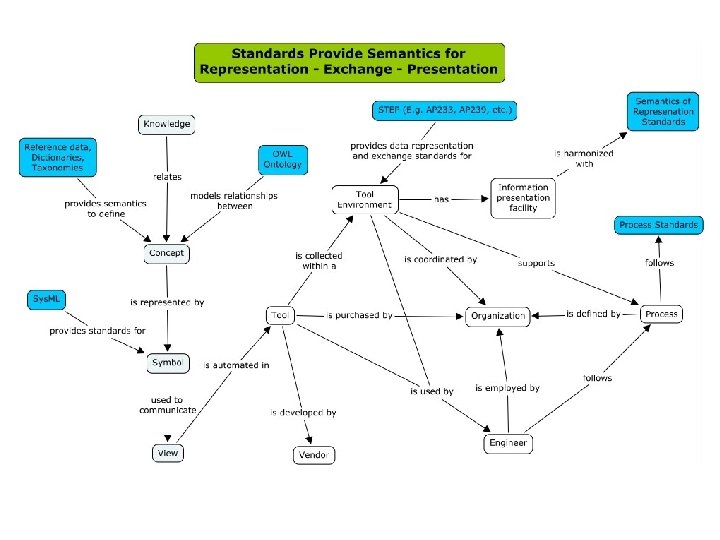

AP 233 - Sys. ML - OWL Languages with Common Semantics P R E S E N T A T I O N OWL Ontology Modeling Language Sys. ML Graphical Modeling Language STEP AP 233 Information Modeling Language R E P R E S E N T A T I O N

Do. D and ISO 10303 STEP • Kenneth Krieg, US Under Secretary of Defense for Acquisition, Technology and Logistics (Do. D USD ATL) • Memorandum “Standard for the Exchange of. Product Model Data (STEP) --- ISO 10303”, June 23, 2005 • Recommends: – Implementing an approach for managing digital product/technical data across DOD – Ensure product model data meets ISO STEP requirements – Adoption of ISO 10303 to enhance interoperability – Ensure procuring activities plan, purchase and accept delivery of product/technical data only in digital formats specified by the guidance on contracts awarded

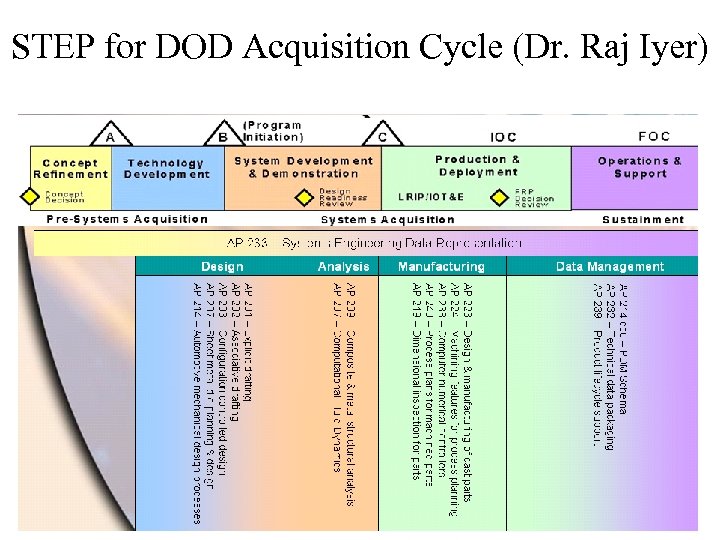

STEP for DOD Acquisition Cycle (Dr. Raj Iyer)

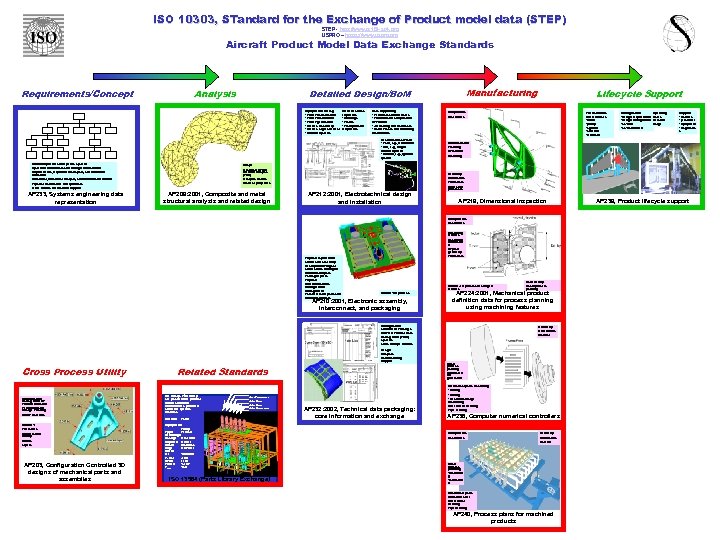

ISO 10303, STandard for the Exchange of Product model data (STEP) STEP - http: //www. tc 184 -sc 4. org USPRO – https: //www. uspro. org Aircraft Product Model Data Exchange Standards Requirements/Concept Analysis Equipment Coverage • Power-transmission • Power-distribution • Power-generation • Electric Machinery • Electric Light and Heat • Control Systems Electrotechnica l Systems • Buildings • Plants • Transportatio n Systems Data Supporting • Terminals and Interfaces • Functional Decomposition AP 233, Systems engineering data representation Shape Associated Finite Element Analysis (FEA) Analysis results material properties AP 209: 2001, Composite and metal structural analysis and related design Lifecycle Support Components Assemblies Work activities and resources • define • justify • approve • schedule • feedback of Product • 3 D Cabling and Harnesses • Cable Tracks and Mounting Instructions Electrotechnical Plant • Plant, e. g. , Automobile • Unit, e. g. , Engine Control System • Subunit, e. g. , Ignition System Conformity to the concept of a system System definition data and configuration control Requirements, requirement analysis, and functional allocation Functional, functional analysis, and functional behaviour Physical architecture and synthesis Trade studies for decision support Manufacturing Detailed Design/Bo. M Geometry Dimensions Tolerances Inspection processes AP 212: 2001, Electrotechnical design and installation Physical layout of the circuit card assembly Description of logical connections among the functional objects Packaged parts Physical interconnections Configuration management Parameters for parts and functional objects AP 219, Dimensional inspection Machining features Assembly informatio n Explicit geometry Tolerances Edition 3 in process to add gear features Edition 2 in process AP 210: 2001, Electronic assembly, interconnect, and packaging Design Analysis Manufacturing Support Related Standards All six pumps are the identical component in the library. When they are placed in the product model additional information is provided about the specific instance. Attribute Edition 2 Tolerances Construction history Colors Layers AP 203, Configuration Controlled 3 D designs of mechanical parts and assemblies FW LT Pump (Spare) FW HT Pump (Spare) Value Equipment: Pump Type: Vertical Centrifugal Casing: Cast Iron Impeller: Bronze Shaft: Stainless Mfg: Allweiler Marine Q: 200 m 3/h Ps bar 3 bar RPM: 1750 Power: 23 kw TMAX 250 ISO 13584 (Parts Library Exchange) AP 232: 2002, Technical data packaging: core information and exchange Make or buy Macro process planning AP 224: 2001, Mechanical product definition data for process planning using machining features Configuration controlled exchanges between Product Data Management (PDM) systems Links multiple formats Configuration Management of Product Structure Versioning and Change Tracking Bill of Materials Support • facilities • personnel • equipment • diagnostic s Administration Planning Execution Archiving Components Assemblies Cross Process Utility Configuration Operating • design requirements states • design configuration Behavior • as-built Usage • as-maintained Geometry Dimensions Material Mirco process planning Automated NC generation Mechanical parts machining • milling • turning • electro discharge machining Sheet metal bending Pipe bending AP 238, Computer numerical controllers Components Assemblies Geometry Dimensions Material Maco process planning • machinin g • fabricatio n Mechanical parts Structural steel Sheet metal bending Pipe bending AP 240, Process plans for machined products AP 239, Product lifecycle support

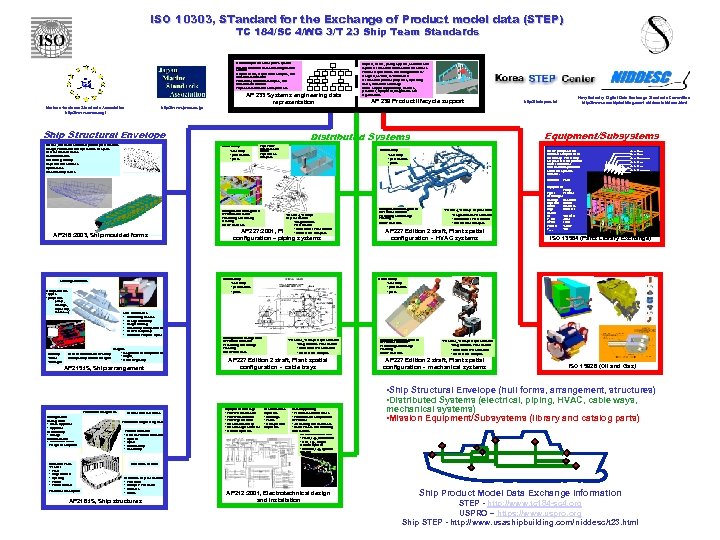

ISO 10303, STandard for the Exchange of Product model data (STEP) TC 184/SC 4/WG 3/T 23 Ship Team Standards Conformity to the concept of a system System definition data and configuration control Requirements, requirement analysis, and functional allocation Functional, functional analysis, and functional behaviour Physical architecture and synthesis AP 233 Systems engineering data representation Marine e-business Standards Association http: //www. emsa. org/ Request, define, justify, approve, schedule and capture feedback on work activities/resources. Product requirements and configuration asdesigned, as-built, as-maintained Feedback on product properties, operating states, behaviour and usage Define support opportunity, facilities, personnel, equipment, diagnostics and organizations AP 239 Product lifecycle support Ship Structural Envelope Surface, wireframe and offset point representations Design, Production and Operations lifecycles General characteristics Main dimensions Hull form geometry Major internal surfaces Hydrostatics Intact Stability tables Equipment/Subsystems Distributed Systems Connectivity • assembly • penetrations • ports Pipe Flow Analysis and Sizing Pipe Stress Analysis Connectivity • assembly • penetrations • ports All six pumps are the identical component in the library. When they are placed in the product model additional information is provided about the specific instance. Attribute Configuration Management of Product Structure Versioning and Change Tracking Bill of Materials AP 216: 2003, Ship moulded forms Stability • intact • damaged 2 -D and 3_-D Shape Representation • Diagrammatic Presentation • Solid Model Presentation • Interference Analysis AP 227: 2001, Plant spatial configuration – piping systems Connectivity • assembly • penetrations • ports Loading conditions Compartments • types • properties (shape, coatings, adjacency, access…. ) Navy/Industry Digital Data Exchange Standards Committee http: //www. usashipbuilding. com/ niddesc/niddesc. html http: //kstep. or. kr/ http: //www. jmsa. or. jp Configuration Management of Product Structure Versioning and Change Tracking Bill of Materials 2 -D and 3_-D Shape Representation • Diagrammatic Presentation • Solid Model Presentation • Interference Analysis AP 227 Edition 2: draft, Plant spatial configuration - HVAC systems FW LT Pump (Spare) FW HT Pump (Spare) Value Equipment: Pump Type: Vertical Centrifugal Casing: Cast Iron Impeller: Bronze Shaft: Stainless Mfg: Allweiler Marine Q: 200 m 3/h Ps bar 3 bar RPM: 1750 Power: 23 kw TMAX 250 ISO 13584 (Parts Library Exchange) Connectivity • assembly • penetrations • ports Zone Boundaries • Controlling Access • Design Authority • Cargo Stowage • Machinery Compartments • Crew Occupancy • Common Purpose Spaces Cargoes • assignment to compartments General Subdivision of a Ship • weight, into Spatially Bounded Regions • centre of gravity AP 215: IS, Ship arrangement Configuration Management of Product Structure Versioning and Change Tracking Bill of Materials 2 -D and 3_-D Shape Representation • Diagrammatic Presentation • Solid Model Presentation • Interference Analysis AP 227 Edition 2: draft, Plant spatial configuration - cable trays Configuration Management of Product Structure Versioning and Change Tracking Bill of Materials 2 -D and 3_-D Shape Representation • Diagrammatic Presentation • Solid Model Presentation • Interference Analysis AP 227 Edition 2: draft, Plant spatial configuration - mechanical systems ISO 15926 (Oil and Gas) • Ship Structural Envelope (hull forms, arrangement, structures) • Distributed Systems (electrical, piping, HVAC, cable ways, Production Design Data Configuration Management • Class Approval • Approval Relationship • Change Administration • Promotion Status Weight Description Structural Parts • Feature • Plate • Edge Content • Opening • Profile Endcut Technical Description General Characteristics Production Engineering Data Product Structure • Generic Product Structure • System • Space • Connectivity • Assembly Equipment Coverage • Power-transmission • Power-distribution • Power-generation • Electric Machinery • Electric Light and Heat • Control Systems Electrotechnica l Systems • Buildings • Plants • Transportatio n Systems Data Supporting • Terminals and Interfaces • Functional Decomposition of Product • 3 D Cabling and Harnesses • Cable Tracks and Mounting Instructions Electrotechnical Plant • Plant, e. g. , Automobile • Unit, e. g. , Engine Control System • Subunit, e. g. , Ignition System mechanical systems) • Mission Equipment/Subsystems (library and catalog parts) Hull Cross Section Geometric Representations • Wireframe • Complex Wireframe • Surfaces • Solids AP 218: IS, Ship structures AP 212: 2001, Electrotechnical design and installation Ship Product Model Data Exchange Information STEP - http: //www. tc 184 -sc 4. org USPRO – https: //www. uspro. org Ship STEP - http: //www. usashipbuilding. com/niddesc/t 23. html

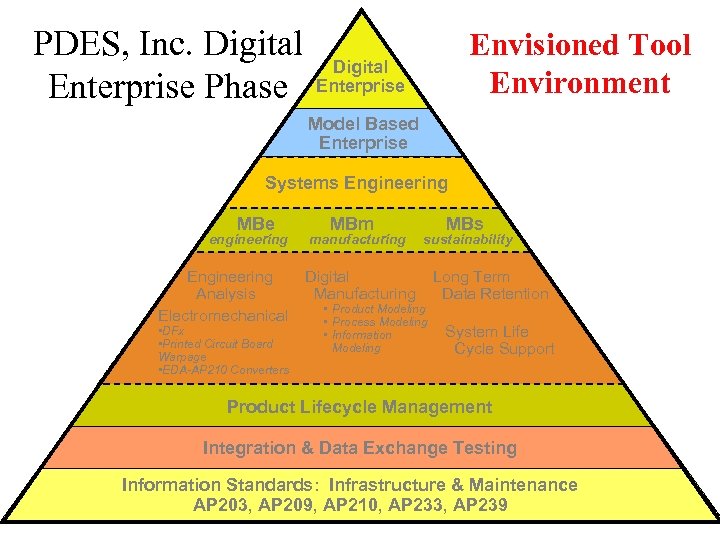

PDES, Inc. Digital Enterprise Phase Enterprise Envisioned Tool Environment Model Based Enterprise Systems Engineering MBe engineering Engineering Analysis Electromechanical • DFx • Printed Circuit Board Warpage • EDA-AP 210 Converters MBm manufacturing Digital Manufacturing MBs sustainability • Product Modeling • Process Modeling • Information Modeling Long Term Data Retention System Life Cycle Support Product Lifecycle Management Integration & Data Exchange Testing Information Standards: Infrastructure & Maintenance AP 203, AP 209, AP 210, AP 233, AP 239

AP 233 Enablement Phase No open technical issues Development team transitioning to a support and maintenance role. Enablement activities will test and validate capabilities while AP 233 is in the ballot resolution and Draft International Standard (DIS) preparation process.

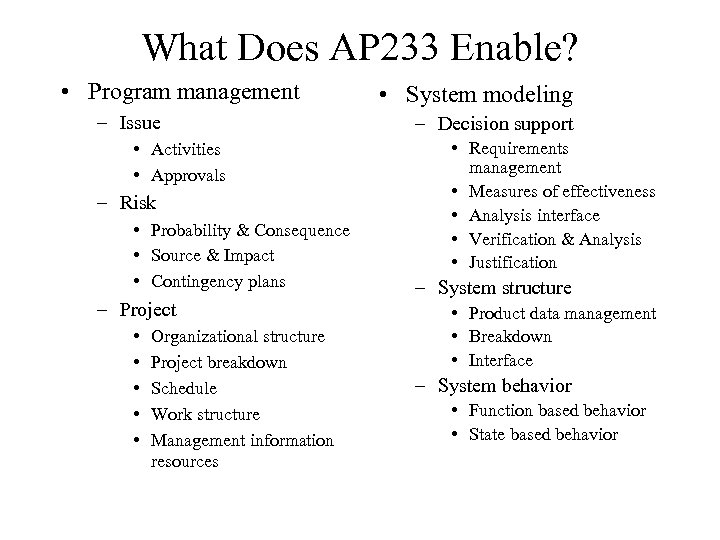

What Does AP 233 Enable? • Program management – Issue • Activities • Approvals – Risk • Probability & Consequence • Source & Impact • Contingency plans – Project • • • Organizational structure Project breakdown Schedule Work structure Management information resources • System modeling – Decision support • Requirements management • Measures of effectiveness • Analysis interface • Verification & Analysis • Justification – System structure • Product data management • Breakdown • Interface – System behavior • Function based behavior • State based behavior

AP 233 Extendibility • Through External_class references to External_class_library • Adds semantics to basic schema concepts • Can tailor to specific domain or business • Can standardize the external libraries

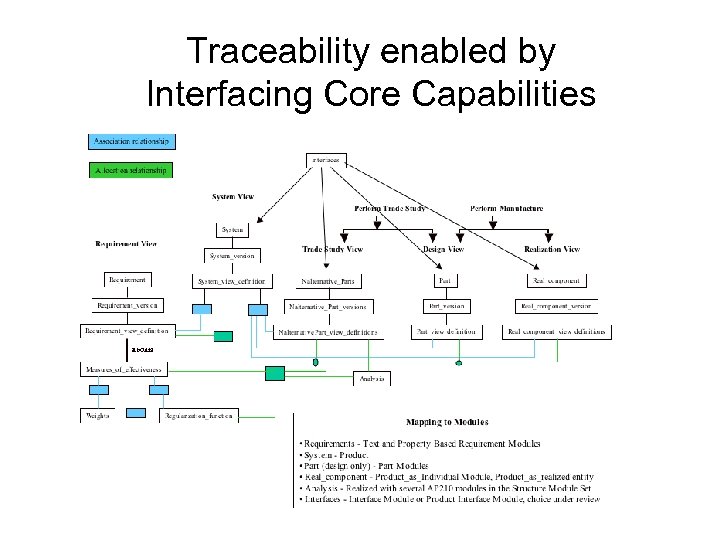

Traceability enabled by Interfacing Core Capabilities

Approaches to Implementation • Representation AP 233 in UML – Generate XMI file from UML – Transform XMI to STEP XML file (Part 28) • Development of Data Exchange Sets (DEX) – Like AP 239 Product Life Cycle Support – Standardization through OASIS • Both use OWL for external classes

Representation Using UML Pilots • Sys. ML-AP 233 Converter Demo – Eurostep: David Price & Phil Spiby – Artisan: Alan Moore – Presented at INCOSE July 2005 • Do. DAF/CADM-AP 233 Mapping – Eurostep: David Price – Presented at OSJTF So. S Architecture Modeling Meeting in 2006

Sys. ML–AP 233 Conclusions • AP 233 supports – Core Sys. ML Requirements concepts – Core Sys. ML System concepts • AP 233 -specific extensions should broaden Sys. ML coverage • Sys. ML/AP 233 translator implementation can support industry needs, yet be simple and inexpensive if we: – “stay out of the weeds” in STEP-land – use widespread technology

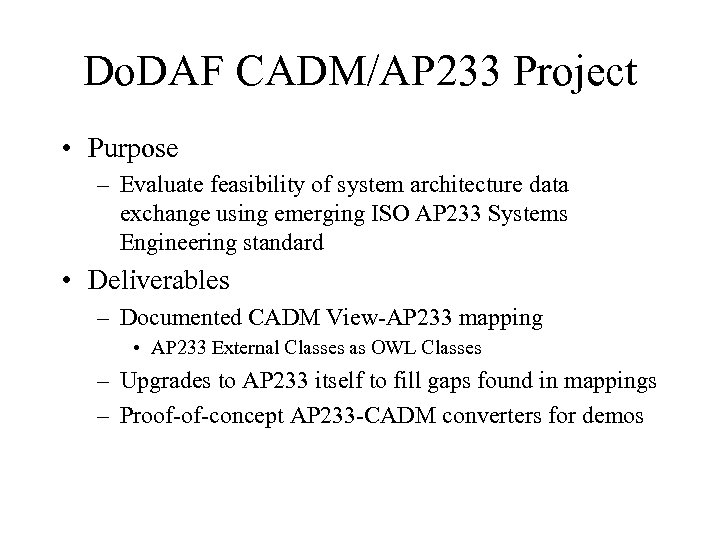

Do. DAF CADM/AP 233 Project • Purpose – Evaluate feasibility of system architecture data exchange using emerging ISO AP 233 Systems Engineering standard • Deliverables – Documented CADM View-AP 233 mapping • AP 233 External Classes as OWL Classes – Upgrades to AP 233 itself to fill gaps found in mappings – Proof-of-concept AP 233 -CADM converters for demos

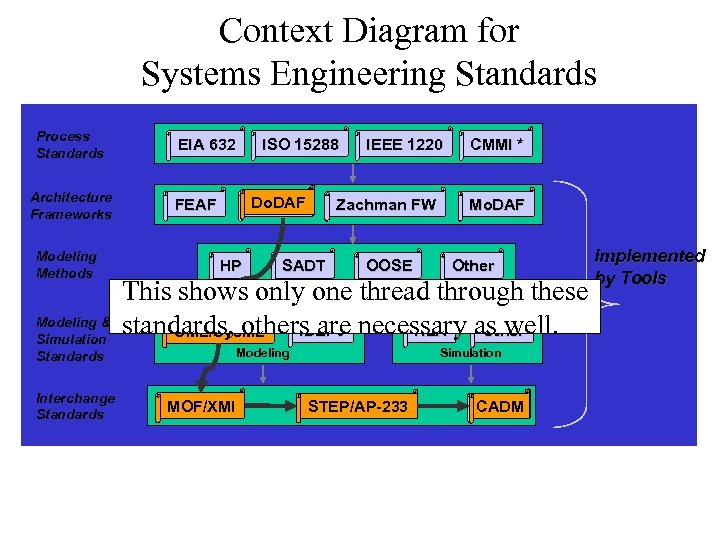

Context Diagram for Systems Engineering Standards Process Standards Architecture Frameworks Modeling Methods Modeling & Simulation Standards Interchange Standards EIA 632 ISO 15288 Do. DAF FEAF HP IEEE 1220 Zachman FW SADT OOSE CMMI * Mo. DAF Other Implemented by Tools This shows only one thread through these standards, others are necessary as well. UML/Sys. ML IDEF 0 HLA Other Modeling MOF/XMI Simulation STEP/AP-233 Other CADM

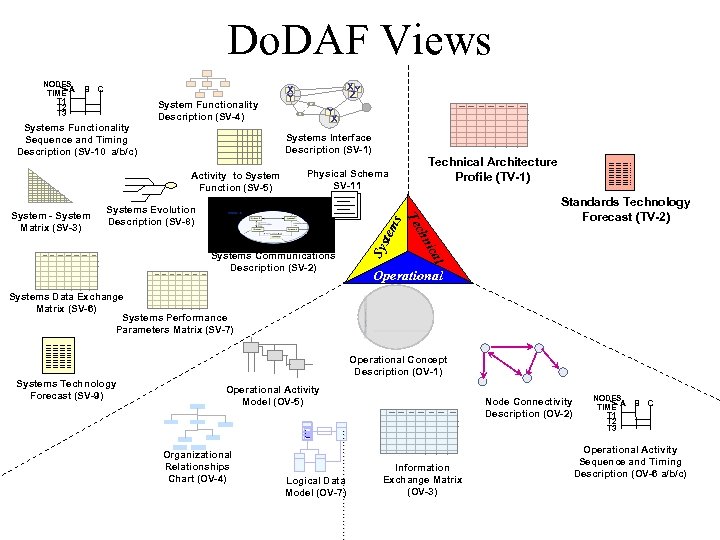

Do. DAF Views B C System Functionality Description (SV-4) Systems Functionality Sequence and Timing Description (SV-10 a/b/c) Y X Systems Interface Description (SV-1) Activity to System Function (SV-5) Physical Schema SV-11 tem s Systems Evolution Description (SV-8) Standards Technology Forecast (TV-2) l ica Systems Communications Description (SV-2) Technical Architecture Profile (TV-1) chn Te System - System Matrix (SV-3) XY Z X Y Sys NODES TIME A T 1 T 2 T 3 Operational Systems Data Exchange Matrix (SV-6) Systems Performance Parameters Matrix (SV-7) Operational Concept Description (OV-1) Systems Technology Forecast (SV-9) Operational Activity Model (OV-5) • . . . Organizational Relationships Chart (OV-4) Node Connectivity Description (OV-2) • - Logical Data Model (OV-7) Information Exchange Matrix (OV-3) NODES TIME A T 1 T 2 T 3 B C Operational Activity Sequence and Timing Description (OV-6 a/b/c)

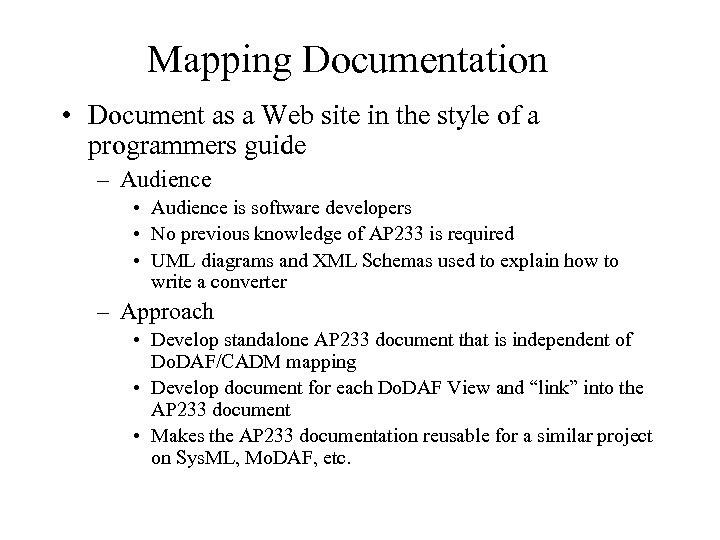

Mapping Documentation • Document as a Web site in the style of a programmers guide – Audience • Audience is software developers • No previous knowledge of AP 233 is required • UML diagrams and XML Schemas used to explain how to write a converter – Approach • Develop standalone AP 233 document that is independent of Do. DAF/CADM mapping • Develop document for each Do. DAF View and “link” into the AP 233 document • Makes the AP 233 documentation reusable for a similar project on Sys. ML, Mo. DAF, etc.

Published Deliverable • Web site documenting AP 233 and CADM/AP 233 mapping http: //www. exff. org/ap 233

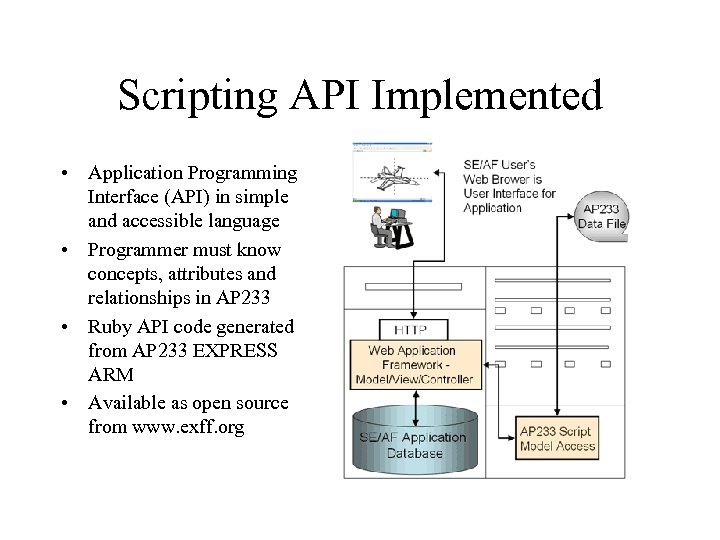

Scripting API Implemented • Application Programming Interface (API) in simple and accessible language • Programmer must know concepts, attributes and relationships in AP 233 • Ruby API code generated from AP 233 EXPRESS ARM • Available as open source from www. exff. org

CADM-AP 233 Conclusions • Proved that AP 233 can support Architecture Framework tool integration – All DODAF views supported – Mappings based on CADM Version 1. 02 and AP 233 Working Draft 2 (with fixes) • Improved AP 233 itself by filling gaps identified during the project • Open source documentation, methods, tools, API

AP 239 Product Life Cycle Support • PLCS is STEP AP 239 • PLCS became ISO standard 9/01/2005 – Funding and implementation led by NATO allies – Many early AP 233 models were incorporated into PLCS (e. g. Requirements) • Extending through DEX • Web Services Definition Language (WSDL) interface developed for PLCS (www. plcs-resources. org)

PLCS enables requirement management through life • AP 239 shares common modules with AP 233 – Systems Engineering • Aim is to support requirements trace from predesign through to maintenance and disposal • UK MOD has funded demonstration project for this capability with BAE Systems

PLCS provides full history to support optimization and change over time • In the PLCS models it is assumed that any value supplied – E. g. a property such as mean time to perform a task • • may have multiple values over time where each value could have been: – – – supplied at different times by different people subject to approval subject to security classification associated to a justification/probability/risk • This requirement has been recognised from the start of modelling • Improve CM of support information by use of “single source” Assured Product and Support Information (APSI)

PLCS - Life Cycle PDM Capability (1) • PDM Schema already supports automated exchange of – – Part id and properties Associated documents and files (incl. CAx) Product structure Product (and document) approval status • This is already in production use by – US Aerospace and Defence prime contractors (via AP 203) – German/Swedish/French Automotive sector (via AP 214 cc 6) – Eurofighter Typhoon PDM partners • . . A powerful and proven capability for Configuration Management of a complex product design

PLCS - Life Cycle PDM Capability (2) • AP 239 has added: – Classification, supported by reference data libraries – Product_as_individual (planned and realized) - UID – Product breakdowns (system, physical, functional, zonal and hybrid) – Text based requirements (from AP 233) – Extended property capability – Interfaces – Attachment_slot – Message, Envelope (similar to ENGDAT) – Information Rights v… A powerful capability for Life Cycle Configuration Management of Assured Product and Support Information

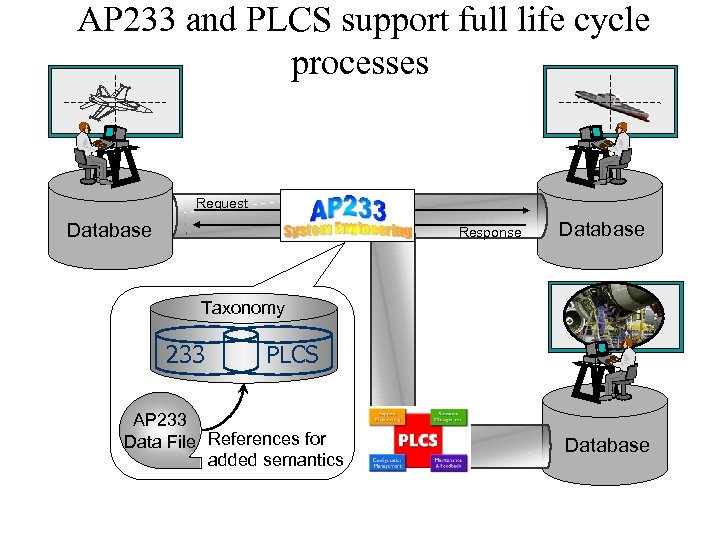

AP 233 and PLCS support full life cycle processes Request Database Response Database Taxonomy 233 PLCS AP 233 Data File References for added semantics Database

PLCS - Reference data • What is it? – Values for attributes that are agreed and defined in advance of use – E. g types of task, grades of people, types of products, types of document – E. g. NATO Stock Number – classifications • Why use it? – Because it improves reliability and effectiveness of exchange – Because it can be extended: • To add to the scope of the standard • To provide project specific functions – Because it supports re-use of values from existing standards • Idea proven in Oil and Gas industry

PLCS – Data Exchange Sets • DEXs are: – – Subsets of the AP 239 Information model Selected to meet a specific data exchange need Built from relevant modules Supported by Usage Guidance, population rules and Reference data – Can be refined from other DEXs • DEXs may be standardized at any level (work group, company, project, organization, national, international) • DEXs enable – Consistent implementation of AP 239 – Data consolidation through time

Current PLCS DEX developments • • Product as individual Product breakdown for support Maintenance plan Task set Operational feedback Fault states Work Package Definition Work Package Reporting • Plus a range of developments which apply additional constraints and reference data based on generic DEX

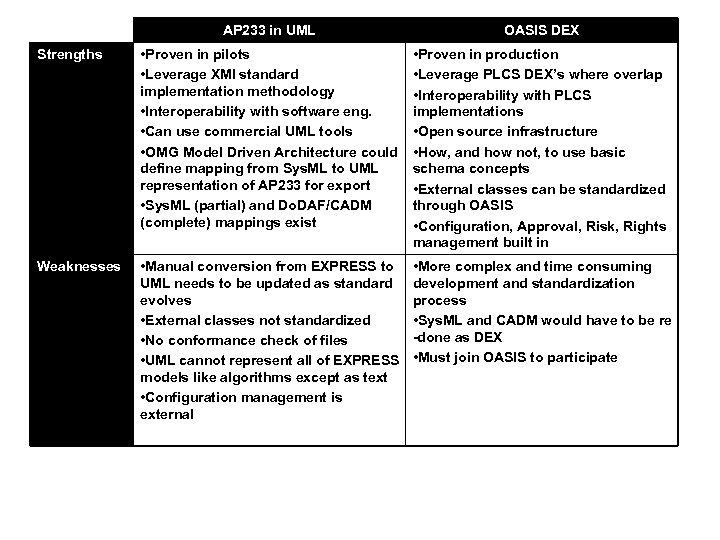

AP 233 in UML OASIS DEX Strengths • Proven in pilots • Leverage XMI standard implementation methodology • Interoperability with software eng. • Can use commercial UML tools • OMG Model Driven Architecture could define mapping from Sys. ML to UML representation of AP 233 for export • Sys. ML (partial) and Do. DAF/CADM (complete) mappings exist • Proven in production • Leverage PLCS DEX’s where overlap • Interoperability with PLCS implementations • Open source infrastructure • How, and how not, to use basic schema concepts • External classes can be standardized through OASIS • Configuration, Approval, Risk, Rights management built in Weaknesses • Manual conversion from EXPRESS to UML needs to be updated as standard evolves • External classes not standardized • No conformance check of files • UML cannot represent all of EXPRESS models like algorithms except as text • Configuration management is external • More complex and time consuming development and standardization process • Sys. ML and CADM would have to be re -done as DEX • Must join OASIS to participate

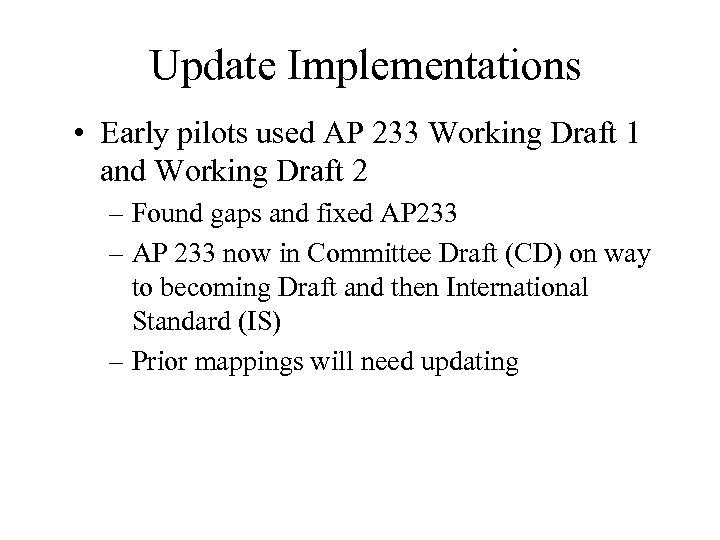

Update Implementations • Early pilots used AP 233 Working Draft 1 and Working Draft 2 – Found gaps and fixed AP 233 – AP 233 now in Committee Draft (CD) on way to becoming Draft and then International Standard (IS) – Prior mappings will need updating

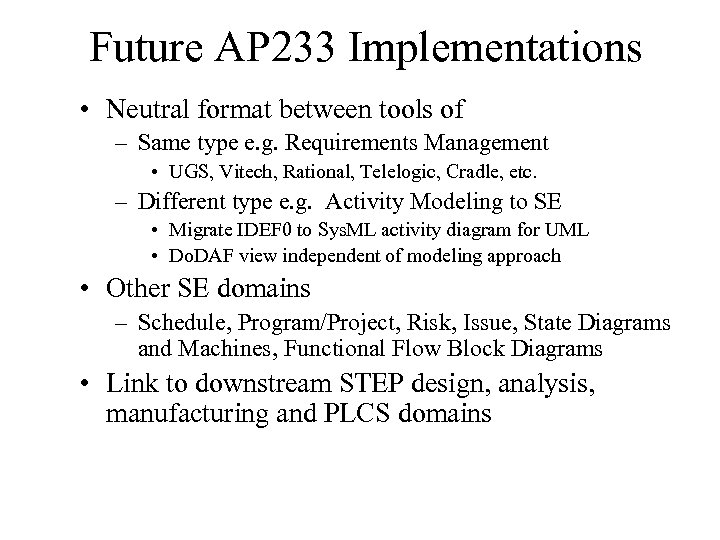

Future AP 233 Implementations • Neutral format between tools of – Same type e. g. Requirements Management • UGS, Vitech, Rational, Telelogic, Cradle, etc. – Different type e. g. Activity Modeling to SE • Migrate IDEF 0 to Sys. ML activity diagram for UML • Do. DAF view independent of modeling approach • Other SE domains – Schedule, Program/Project, Risk, Issue, State Diagrams and Machines, Functional Flow Block Diagrams • Link to downstream STEP design, analysis, manufacturing and PLCS domains

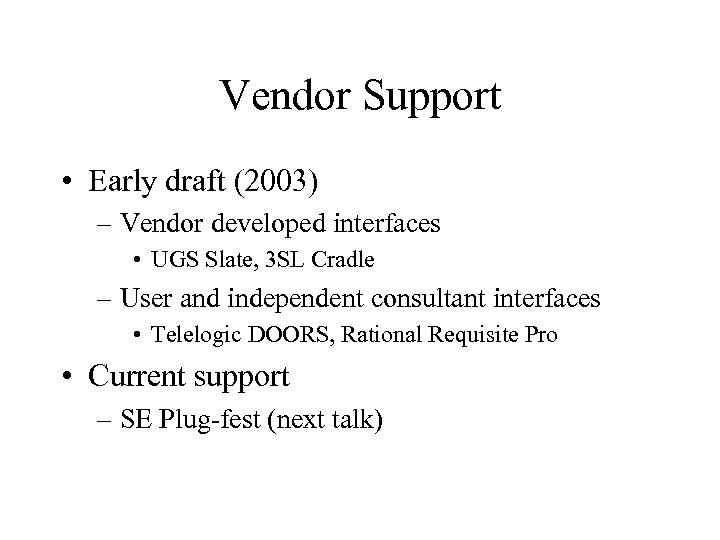

Vendor Support • Early draft (2003) – Vendor developed interfaces • UGS Slate, 3 SL Cradle – User and independent consultant interfaces • Telelogic DOORS, Rational Requisite Pro • Current support – SE Plug-fest (next talk)

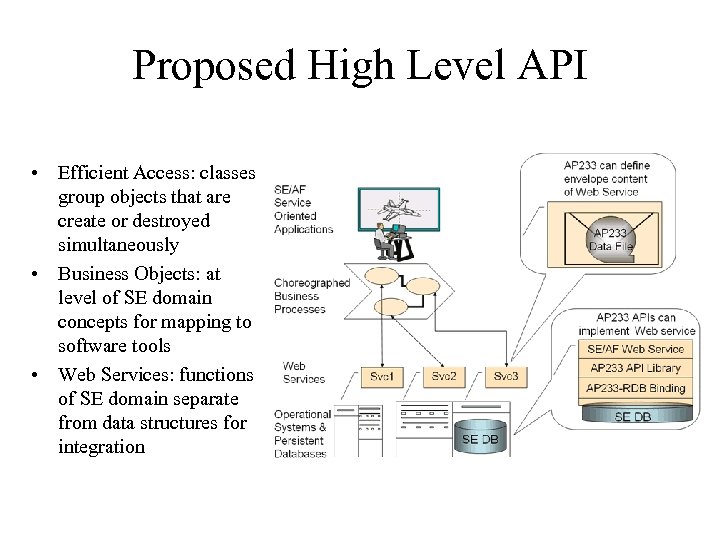

Proposed High Level API • Efficient Access: classes group objects that are create or destroyed simultaneously • Business Objects: at level of SE domain concepts for mapping to software tools • Web Services: functions of SE domain separate from data structures for integration

Summary • AP 233 is designed to – support integration of Systems Engineering tools – provide a “front end” to PLCS-based Support Engineering tools – link with detailed design, PDM, analysis, etc. through other STEP protocols – align with OMG Sys. ML – enable INCOSE vision of Model-Based Systems Engineering

Backup Slides

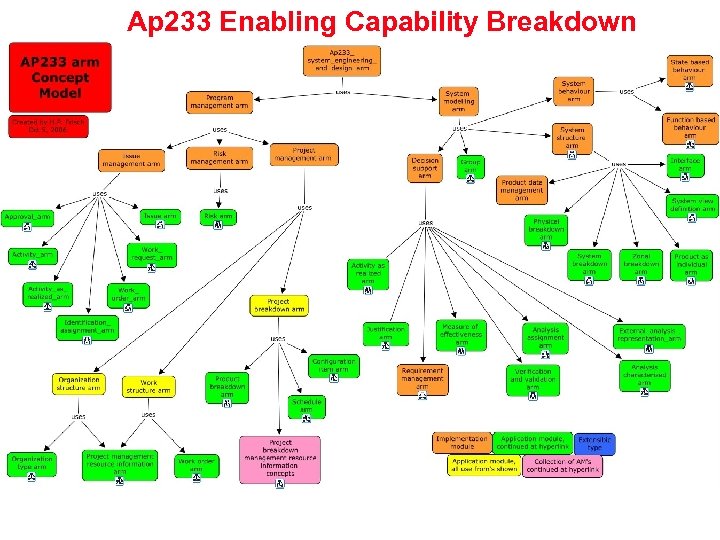

Ap 233 Enabling Capability Breakdown

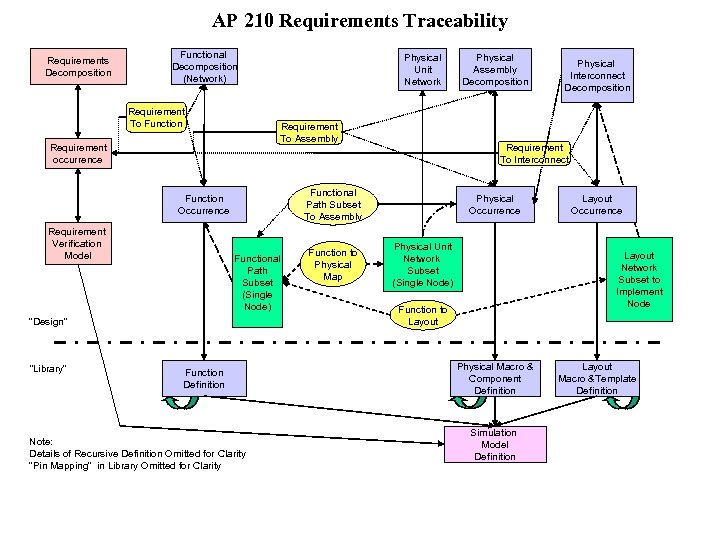

AP 210 Requirements Traceability Requirements Decomposition Functional Decomposition (Network) Requirement To Function Physical Unit Network Requirement To Assembly Requirement occurrence Requirement Verification Model Functional Path Subset (Single Node) “Design” “Library” Function Definition Note: Details of Recursive Definition Omitted for Clarity “Pin Mapping” in Library Omitted for Clarity Function to Physical Map Physical Interconnect Decomposition Requirement To Interconnect Functional Path Subset To Assembly Function Occurrence Physical Assembly Decomposition Physical Occurrence Physical Unit Network Subset (Single Node) Layout Occurrence Layout Network Subset to Implement Node Function to Layout Physical Macro & Component Definition Simulation Model Definition Layout Macro &Template Definition

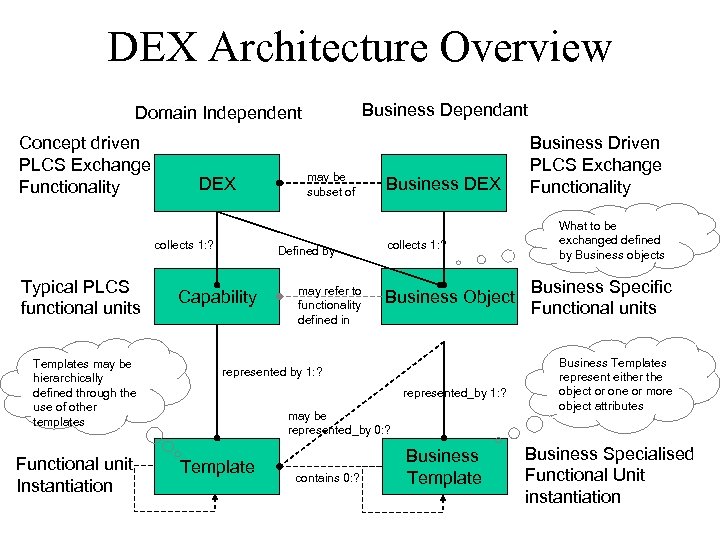

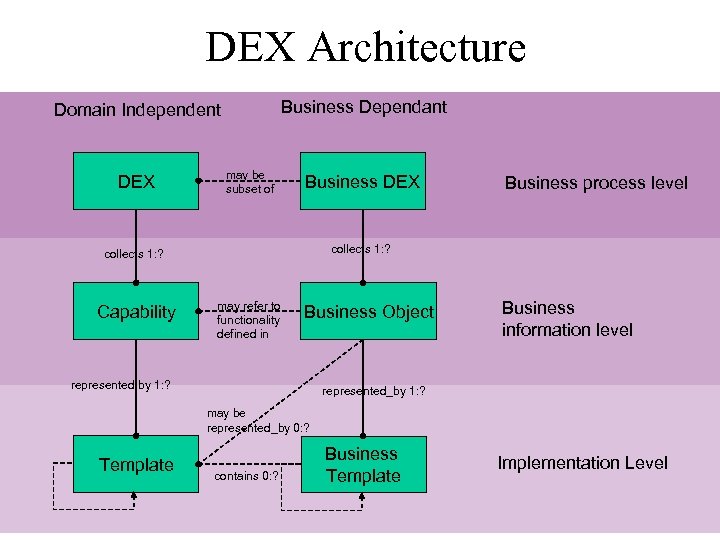

DEX Architecture Overview Business Dependant Domain Independent Concept driven PLCS Exchange Functionality DEX collects 1: ? Typical PLCS functional units Templates may be hierarchically defined through the use of other templates Functional unit Instantiation may be subset of Defined by Capability may refer to functionality defined in Business DEX collects 1: ? Business Object represented by 1: ? represented_by 1: ? may be represented_by 0: ? Template contains 0: ? Business Template Business Driven PLCS Exchange Functionality What to be exchanged defined by Business objects Business Specific Functional units Business Templates represent either the object or one or more object attributes Business Specialised Functional Unit instantiation

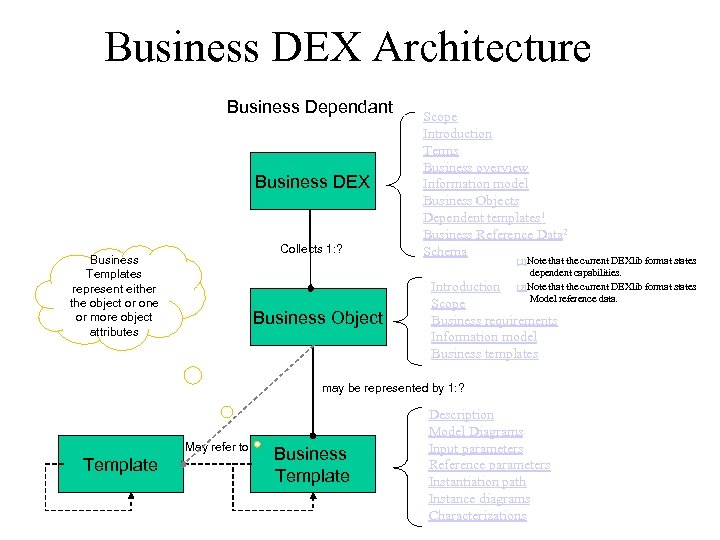

Business DEX Architecture Business Dependant Business DEX Collects 1: ? Business Templates represent either the object or one or more object attributes Scope Introduction Terms Business overview Information model Business Objects Dependent templates 1 Business Reference Data 2 Schema [1]Note that the current DEXlib format states dependent capabilities. [2]Note that the current DEXlib format states Model reference data. Business Object Introduction Scope Business requirements Information model Business templates may be represented by 1: ? May refer to Template Business Template Description Model Diagrams Input parameters Reference parameters Instantiation path Instance diagrams Characterizations

DEX Architecture Business Dependant Domain Independent DEX may be subset of Business DEX collects 1: ? Capability Business process level may refer to functionality defined in Business Object represented by 1: ? Business information level represented_by 1: ? may be represented_by 0: ? Template contains 0: ? Business Template Implementation Level

Current PLCS Implementations • Visby Corvette • Gripen pilot project • Norwegian frigate – Extending to other NDLO programmes – Being promoted actively for JSF • Eurostep Share-A-Space • BAE Systems Land Systems Hagglunds • UK MOD pilots for RAF LITS and Navy UMMS – Logistics Coherence project • US Do. D ELITE project for UH-60 helicopter – Extending to other service linked to UID – Plans for HMMWV and Bradley

Deployments of Web Services Eurostep – – PLCS-PLM services implemented on top of Share-A-space SDK/JDKs provided for implementing clients Eurostep / Acando – develop a SAP-adapter wrapping up SAP as PLCS web services and deployed inside the SAPXI environment – PLCS-PLM services used with Share-A-space and Opus for spare optimization FMV BAE Systems Hägglunds – PLCS-PLM services implemented on top of in house PDM system Ericsson – PLCS-PLM services + Share-A-space being used to integrate PDM systems. E. g. In house systems + multiple Windchill installations Motorola – PLCS-PLM services + Share-A-space used to integrate DOORS / Requisite Pro requirements management systems Volvo Penta – PLCS-PLM services used with Share-A-space and in house systems for producing spare parts lists VIVACE – PLCS-PLM services used to integrate PDM data (Share-A-space ), engineering analysis and process flow software (Fiper)

1ac7f53777e1d8735b82085dea299236.ppt