a8d34d339099160918755804ce4f005f.ppt

- Количество слайдов: 33

ISO 9000 series QFD: Quality Function Deployment MST 326 lecture 4 02 February 2007 MATS 324/iso 9000 -qfd. ppt

ISO 9000 series QFD: Quality Function Deployment MST 326 lecture 4 02 February 2007 MATS 324/iso 9000 -qfd. ppt

Drivers for Quality Management • fundamental foundation for effective business practice is good customer-supplier relationships • After WWII, increasing requirement for inspection of products and documentation of procedures o defence (US MIL-Q-9858 a and NATO AQAP) o space (NASA QSR) o nuclear and power generation 02 February 2007 MATS 324/iso 9000 -qfd. ppt

Drivers for Quality Management • fundamental foundation for effective business practice is good customer-supplier relationships • After WWII, increasing requirement for inspection of products and documentation of procedures o defence (US MIL-Q-9858 a and NATO AQAP) o space (NASA QSR) o nuclear and power generation 02 February 2007 MATS 324/iso 9000 -qfd. ppt

Drivers for Quality Management • At first, each customer would audit suppliers practices and procedures • need for a widely accepted single route to company-wide certification identified • national standards for specific products define minimum specifications 02 February 2007 MATS 324/iso 9000 -qfd. ppt

Drivers for Quality Management • At first, each customer would audit suppliers practices and procedures • need for a widely accepted single route to company-wide certification identified • national standards for specific products define minimum specifications 02 February 2007 MATS 324/iso 9000 -qfd. ppt

BS 5750 (1979) • United Kingdom in 1979: BS 5750 - Quality Management and Systems • developed to permit a company to document its commitment to quality and the standard of its quality systems. 02 February 2007 MATS 324/iso 9000 -qfd. ppt

BS 5750 (1979) • United Kingdom in 1979: BS 5750 - Quality Management and Systems • developed to permit a company to document its commitment to quality and the standard of its quality systems. 02 February 2007 MATS 324/iso 9000 -qfd. ppt

ISO 9000: 1987 series • International Organisation for Standards (ISO) adopted a series of quality standards, ISO 9000: 1987 • based on BS 5750 • strongly influenced by the US Department of Defence Military Standards (MILspecs). • initial version was focused on quality control using retroactive checking and corrective actions. 02 February 2007 MATS 324/iso 9000 -qfd. ppt

ISO 9000: 1987 series • International Organisation for Standards (ISO) adopted a series of quality standards, ISO 9000: 1987 • based on BS 5750 • strongly influenced by the US Department of Defence Military Standards (MILspecs). • initial version was focused on quality control using retroactive checking and corrective actions. 02 February 2007 MATS 324/iso 9000 -qfd. ppt

ISO 9000: 1994 series • ISO 9000 was revised in 1994 • greater emphasis on quality assurance via preventive actions. • required evidence of compliance with documented procedures • tended to create a significant volume of associated procedure ("do it as you document it") manuals and bureaucracy. 02 February 2007 MATS 324/iso 9000 -qfd. ppt

ISO 9000: 1994 series • ISO 9000 was revised in 1994 • greater emphasis on quality assurance via preventive actions. • required evidence of compliance with documented procedures • tended to create a significant volume of associated procedure ("do it as you document it") manuals and bureaucracy. 02 February 2007 MATS 324/iso 9000 -qfd. ppt

QS-9000 • Ford, Chrysler, General Motors and other automotive/truck manufacturers identified deficiencies in ISO 9000: 1994 • undertook a re-interpretation and extension to develop QS-9000 • additionally addressed continuous improvement, manufacturing capability and production part approval processes. 02 February 2007 MATS 324/iso 9000 -qfd. ppt

QS-9000 • Ford, Chrysler, General Motors and other automotive/truck manufacturers identified deficiencies in ISO 9000: 1994 • undertook a re-interpretation and extension to develop QS-9000 • additionally addressed continuous improvement, manufacturing capability and production part approval processes. 02 February 2007 MATS 324/iso 9000 -qfd. ppt

ISO 9000: 2000 series • moved towards process performance metrics • reduced the need for documented procedures where clear evidence exists that the process is working well. 02 February 2007 MATS 324/iso 9000 -qfd. ppt

ISO 9000: 2000 series • moved towards process performance metrics • reduced the need for documented procedures where clear evidence exists that the process is working well. 02 February 2007 MATS 324/iso 9000 -qfd. ppt

ISO 9000: 2000 series • standards provide criteria for companies to • "certify" their quality management o recertification is required every three years • achieve "registration" by third-party auditor. • the system o verifies practice and processes o provides objective 3 rd party validation o enables benchmarking. 02 February 2007 MATS 324/iso 9000 -qfd. ppt

ISO 9000: 2000 series • standards provide criteria for companies to • "certify" their quality management o recertification is required every three years • achieve "registration" by third-party auditor. • the system o verifies practice and processes o provides objective 3 rd party validation o enables benchmarking. 02 February 2007 MATS 324/iso 9000 -qfd. ppt

ISO 9000: 2000 eight quality management principles o Customer focus o Leadership o Involvement of people o Process approach o System approach to management o Continual improvement o Factual approach to decision making o Mutually beneficial supplier relationships o The next step 02 February 2007 MATS 324/iso 9000 -qfd. ppt

ISO 9000: 2000 eight quality management principles o Customer focus o Leadership o Involvement of people o Process approach o System approach to management o Continual improvement o Factual approach to decision making o Mutually beneficial supplier relationships o The next step 02 February 2007 MATS 324/iso 9000 -qfd. ppt

ISO 9000: 2000 series • Four primary Quality Management Standards (QMS): o ISO 9000: QMS - Fundamentals and Vocabulary (recommended reading) o ISO 9001: QMS - Requirements (required standard) o ISO 9004: QMS - Guidance for Performance Improvement (recommended reading) o ISO 19011: Guidelines on Quality and Environmental Auditing 02 February 2007 MATS 324/iso 9000 -qfd. ppt

ISO 9000: 2000 series • Four primary Quality Management Standards (QMS): o ISO 9000: QMS - Fundamentals and Vocabulary (recommended reading) o ISO 9001: QMS - Requirements (required standard) o ISO 9004: QMS - Guidance for Performance Improvement (recommended reading) o ISO 19011: Guidelines on Quality and Environmental Auditing 02 February 2007 MATS 324/iso 9000 -qfd. ppt

ISO 9000: 2000 structure • Four major sections o Management Responsibility o Resource Management o Product Realisation o Measurement, Analysis and Improvement • Divided into 21 elements 02 February 2007 MATS 324/iso 9000 -qfd. ppt

ISO 9000: 2000 structure • Four major sections o Management Responsibility o Resource Management o Product Realisation o Measurement, Analysis and Improvement • Divided into 21 elements 02 February 2007 MATS 324/iso 9000 -qfd. ppt

ISO 9000 structure I Management Responsibility 1. 2. 3. 4. 5. 6. management commitment customer focus quality policy planning administration management review 02 February 2007 MATS 324/iso 9000 -qfd. ppt

ISO 9000 structure I Management Responsibility 1. 2. 3. 4. 5. 6. management commitment customer focus quality policy planning administration management review 02 February 2007 MATS 324/iso 9000 -qfd. ppt

ISO 9000 structure II Resource Management 7. provision of resources 8. human resources 9. facilities 10. work environment 02 February 2007 MATS 324/iso 9000 -qfd. ppt

ISO 9000 structure II Resource Management 7. provision of resources 8. human resources 9. facilities 10. work environment 02 February 2007 MATS 324/iso 9000 -qfd. ppt

ISO 9000 structure III Product Realisation 11. planning of realisation processes 12. customer-related processes 13. design and/or development 14. purchasing 15. production and service operations 16. control of measuring and monitoring devices 02 February 2007 MATS 324/iso 9000 -qfd. ppt

ISO 9000 structure III Product Realisation 11. planning of realisation processes 12. customer-related processes 13. design and/or development 14. purchasing 15. production and service operations 16. control of measuring and monitoring devices 02 February 2007 MATS 324/iso 9000 -qfd. ppt

ISO 9000 structure IV Measurement, Analysis and Improvement 17. planning 18. measurement and monitoring 19. control of nonconformity 20. analysis of data 21. improvement 02 February 2007 MATS 324/iso 9000 -qfd. ppt

ISO 9000 structure IV Measurement, Analysis and Improvement 17. planning 18. measurement and monitoring 19. control of nonconformity 20. analysis of data 21. improvement 02 February 2007 MATS 324/iso 9000 -qfd. ppt

QMS costs • costs of certification may be considerable. o Evans and Lindsay [page 137] suggest • registration audit may cost US$10 -40 K • training and documentation of order of US$100 K. o recording of the activities of the company can save money: the data used to • inform individual changes • underpin continuous improvement programs • invaluable as evidence in the event of litigation 02 February 2007 MATS 324/iso 9000 -qfd. ppt

QMS costs • costs of certification may be considerable. o Evans and Lindsay [page 137] suggest • registration audit may cost US$10 -40 K • training and documentation of order of US$100 K. o recording of the activities of the company can save money: the data used to • inform individual changes • underpin continuous improvement programs • invaluable as evidence in the event of litigation 02 February 2007 MATS 324/iso 9000 -qfd. ppt

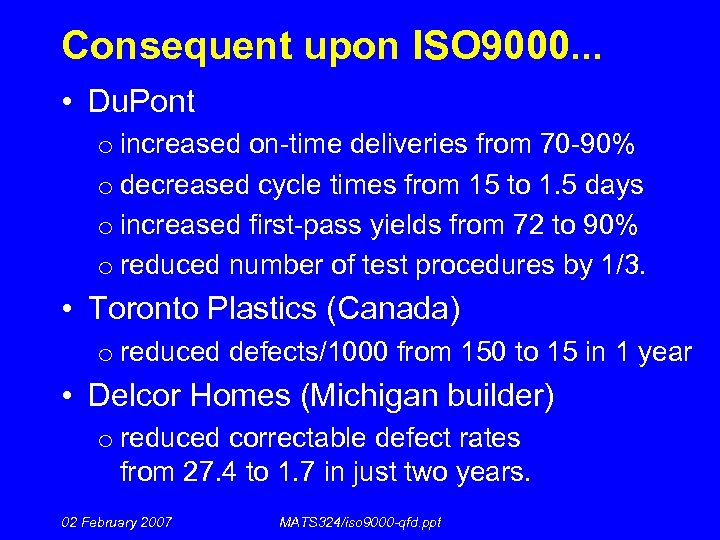

Consequent upon ISO 9000. . . • Du. Pont o increased on-time deliveries from 70 -90% o decreased cycle times from 15 to 1. 5 days o increased first-pass yields from 72 to 90% o reduced number of test procedures by 1/3. • Toronto Plastics (Canada) o reduced defects/1000 from 150 to 15 in 1 year • Delcor Homes (Michigan builder) o reduced correctable defect rates from 27. 4 to 1. 7 in just two years. 02 February 2007 MATS 324/iso 9000 -qfd. ppt

Consequent upon ISO 9000. . . • Du. Pont o increased on-time deliveries from 70 -90% o decreased cycle times from 15 to 1. 5 days o increased first-pass yields from 72 to 90% o reduced number of test procedures by 1/3. • Toronto Plastics (Canada) o reduced defects/1000 from 150 to 15 in 1 year • Delcor Homes (Michigan builder) o reduced correctable defect rates from 27. 4 to 1. 7 in just two years. 02 February 2007 MATS 324/iso 9000 -qfd. ppt

Other relevant standards I. . . • • • ISO 10006 project management ISO 10007 configuration management ISO 10012 measurement systems ISO 10013 quality documentation ISO/TR 10014 managing economics of quality • ISO 10015 training • ISO 17799 security • ISO 19011 auditing 02 February 2007 MATS 324/iso 9000 -qfd. ppt

Other relevant standards I. . . • • • ISO 10006 project management ISO 10007 configuration management ISO 10012 measurement systems ISO 10013 quality documentation ISO/TR 10014 managing economics of quality • ISO 10015 training • ISO 17799 security • ISO 19011 auditing 02 February 2007 MATS 324/iso 9000 -qfd. ppt

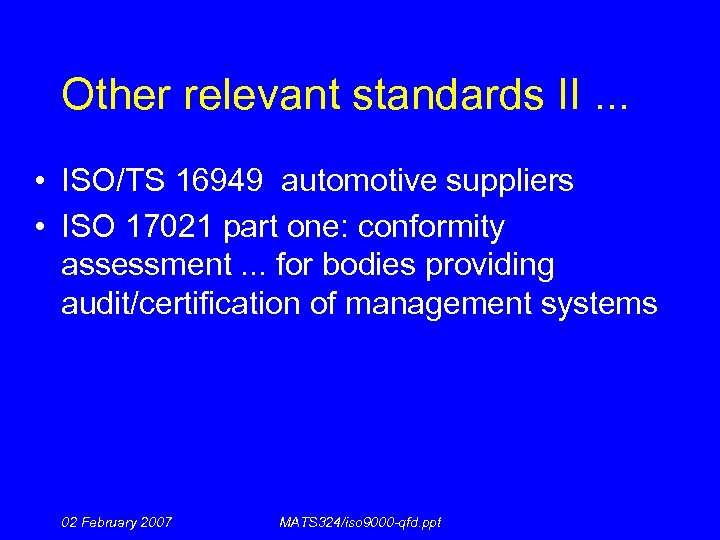

Other relevant standards II. . . • ISO/TS 16949 automotive suppliers • ISO 17021 part one: conformity assessment. . . for bodies providing audit/certification of management systems 02 February 2007 MATS 324/iso 9000 -qfd. ppt

Other relevant standards II. . . • ISO/TS 16949 automotive suppliers • ISO 17021 part one: conformity assessment. . . for bodies providing audit/certification of management systems 02 February 2007 MATS 324/iso 9000 -qfd. ppt

Other relevant standards III. . . • BS 8300: 2001 Design of buildings and their approaches to meet the needs of disabled people • BS 8887 -1: 2006 Design for manufacture, assembly, disassembly and end-of-life processing (MADE). General concepts, process and requirements 02 February 2007 MATS 324/iso 9000 -qfd. ppt

Other relevant standards III. . . • BS 8300: 2001 Design of buildings and their approaches to meet the needs of disabled people • BS 8887 -1: 2006 Design for manufacture, assembly, disassembly and end-of-life processing (MADE). General concepts, process and requirements 02 February 2007 MATS 324/iso 9000 -qfd. ppt

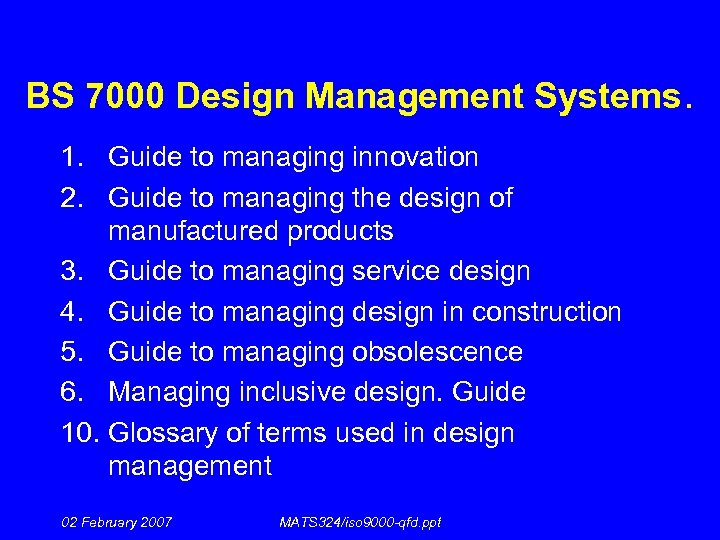

BS 7000 Design Management Systems. 1. Guide to managing innovation 2. Guide to managing the design of manufactured products 3. Guide to managing service design 4. Guide to managing design in construction 5. Guide to managing obsolescence 6. Managing inclusive design. Guide 10. Glossary of terms used in design management 02 February 2007 MATS 324/iso 9000 -qfd. ppt

BS 7000 Design Management Systems. 1. Guide to managing innovation 2. Guide to managing the design of manufactured products 3. Guide to managing service design 4. Guide to managing design in construction 5. Guide to managing obsolescence 6. Managing inclusive design. Guide 10. Glossary of terms used in design management 02 February 2007 MATS 324/iso 9000 -qfd. ppt

Product design for SMEs • BS 7373 -1: 2001 Guide to the preparation of specifications. • BS 7373 -2: 2001 Product specifications. Guide to identifying criteria for a product specification and to declaring product conformity • BS 7373 -3: 2005 Product specifications. Guide to identifying criteria for specifying a service offering 02 February 2007 MATS 324/iso 9000 -qfd. ppt

Product design for SMEs • BS 7373 -1: 2001 Guide to the preparation of specifications. • BS 7373 -2: 2001 Product specifications. Guide to identifying criteria for a product specification and to declaring product conformity • BS 7373 -3: 2005 Product specifications. Guide to identifying criteria for specifying a service offering 02 February 2007 MATS 324/iso 9000 -qfd. ppt

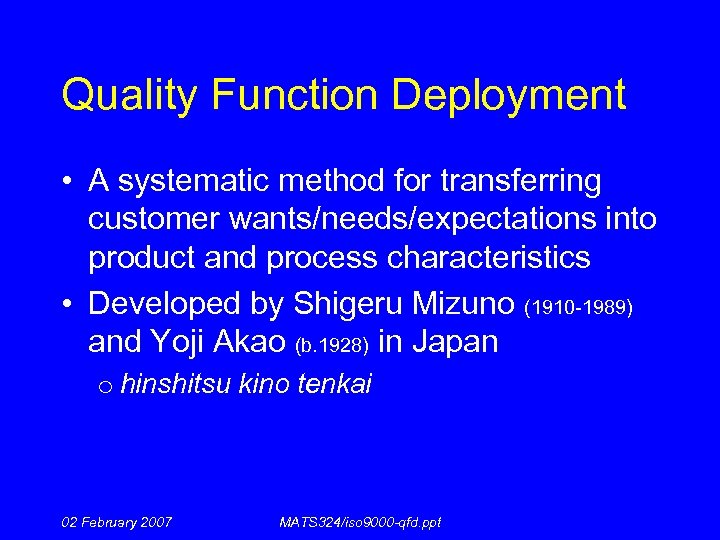

Quality Function Deployment • A systematic method for transferring customer wants/needs/expectations into product and process characteristics • Developed by Shigeru Mizuno (1910 -1989) and Yoji Akao (b. 1928) in Japan o hinshitsu kino tenkai 02 February 2007 MATS 324/iso 9000 -qfd. ppt

Quality Function Deployment • A systematic method for transferring customer wants/needs/expectations into product and process characteristics • Developed by Shigeru Mizuno (1910 -1989) and Yoji Akao (b. 1928) in Japan o hinshitsu kino tenkai 02 February 2007 MATS 324/iso 9000 -qfd. ppt

Quality Function Deployment • Excellent tool for communication between cross-functional groups • Provides a common basis for o Integrated Product Development o Simultaneous Engineering o Concurrent Engineering 02 February 2007 MATS 324/iso 9000 -qfd. ppt

Quality Function Deployment • Excellent tool for communication between cross-functional groups • Provides a common basis for o Integrated Product Development o Simultaneous Engineering o Concurrent Engineering 02 February 2007 MATS 324/iso 9000 -qfd. ppt

Quality Function Deployment • QFD work divides into four parts o market analysis to establish needs and expectations o examination of competitors abilities o identification of key factors for success o translation of key factors into product and process characteristics 02 February 2007 MATS 324/iso 9000 -qfd. ppt

Quality Function Deployment • QFD work divides into four parts o market analysis to establish needs and expectations o examination of competitors abilities o identification of key factors for success o translation of key factors into product and process characteristics 02 February 2007 MATS 324/iso 9000 -qfd. ppt

Quality Function Deployment • Conjoint Analysis (market survey) o potential customers asked to rank a number of product concepts o important factors chosen by factorial design with two levels (statistical design of experiments) • Toyota halved design costs and reduced development time by 1/3 after starting to use QFD 02 February 2007 MATS 324/iso 9000 -qfd. ppt

Quality Function Deployment • Conjoint Analysis (market survey) o potential customers asked to rank a number of product concepts o important factors chosen by factorial design with two levels (statistical design of experiments) • Toyota halved design costs and reduced development time by 1/3 after starting to use QFD 02 February 2007 MATS 324/iso 9000 -qfd. ppt

Quality Function Deployment • Analysis of competitor products should o go on continuously o subject them to same scrutiny as own company products 02 February 2007 MATS 324/iso 9000 -qfd. ppt

Quality Function Deployment • Analysis of competitor products should o go on continuously o subject them to same scrutiny as own company products 02 February 2007 MATS 324/iso 9000 -qfd. ppt

Quality Function Deployment § Product planning o house of quality § Product design o parts deployment § Process design o process planning § Production design o production planning 02 February 2007 MATS 324/iso 9000 -qfd. ppt

Quality Function Deployment § Product planning o house of quality § Product design o parts deployment § Process design o process planning § Production design o production planning 02 February 2007 MATS 324/iso 9000 -qfd. ppt

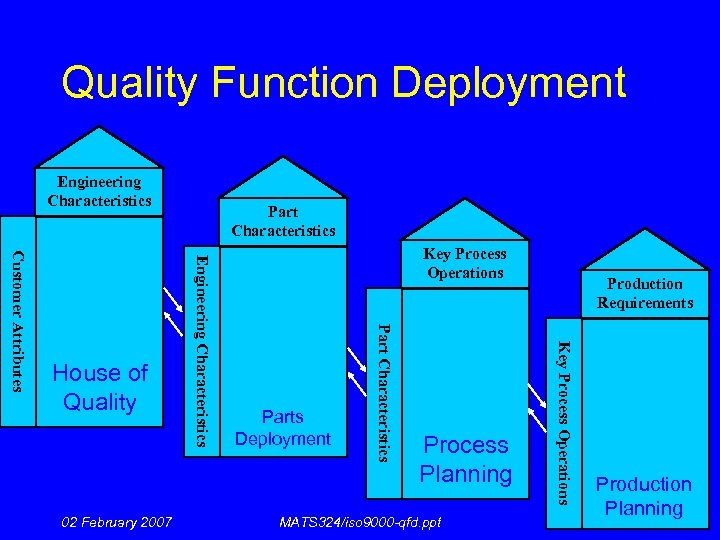

Quality Function Deployment Engineering Characteristics Key Process Operations Process Planning MATS 324/iso 9000 -qfd. ppt Production Requirements Key Process Operations Parts Deployment Part Characteristics 02 February 2007 Engineering Characteristics Customer Attributes House of Quality Part Characteristics Production Planning

Quality Function Deployment Engineering Characteristics Key Process Operations Process Planning MATS 324/iso 9000 -qfd. ppt Production Requirements Key Process Operations Parts Deployment Part Characteristics 02 February 2007 Engineering Characteristics Customer Attributes House of Quality Part Characteristics Production Planning

Quality Function Deployment • Product planning o wishes of customer transferred to product o evaluation of competitor products o identification of important properties • Product design o choose best design to fulfil targets o identify critical parts and components o further R&D if needed 02 February 2007 MATS 324/iso 9000 -qfd. ppt

Quality Function Deployment • Product planning o wishes of customer transferred to product o evaluation of competitor products o identification of important properties • Product design o choose best design to fulfil targets o identify critical parts and components o further R&D if needed 02 February 2007 MATS 324/iso 9000 -qfd. ppt

Quality Function Deployment • Process design o critical parameters identified o process control/improvement methods set • Production design o design instructions for production o define measurements, frequency and tools to be used 02 February 2007 MATS 324/iso 9000 -qfd. ppt

Quality Function Deployment • Process design o critical parameters identified o process control/improvement methods set • Production design o design instructions for production o define measurements, frequency and tools to be used 02 February 2007 MATS 324/iso 9000 -qfd. ppt

Some URLs for QFD • http: //www. qfdi. org/ • http: //www. iti-oh. com/cppd/qfd_basics. htm • http: //www. becker-associates. com/qfdwhatis. htm • http: //www. pardee-quality-methods. com/qfdis. html • http: //www. npd-solutions. com/qfd. html • http: //www. icqfd. org/ 02 February 2007 MATS 324/iso 9000 -qfd. ppt

Some URLs for QFD • http: //www. qfdi. org/ • http: //www. iti-oh. com/cppd/qfd_basics. htm • http: //www. becker-associates. com/qfdwhatis. htm • http: //www. pardee-quality-methods. com/qfdis. html • http: //www. npd-solutions. com/qfd. html • http: //www. icqfd. org/ 02 February 2007 MATS 324/iso 9000 -qfd. ppt