ff69c64ebd6425ee0e6e7825c7e1c210.ppt

- Количество слайдов: 93

Is CHP Right for Me? New York State Energy R & D Authority Addressing Energy, Economic, and Environmental Priorities

Is CHP Right for Me? New York State Energy R & D Authority Addressing Energy, Economic, and Environmental Priorities

Overview • What is DG? • What is CHP? • Benefits of DG/CHP. • Available technologies/equipment. • Issues/hurdles for implementation.

Overview • What is DG? • What is CHP? • Benefits of DG/CHP. • Available technologies/equipment. • Issues/hurdles for implementation.

What is Distributed Generation? Electric power generation close to the load. • Small-scale relative to central-plants. • Can use fossil fuel – natural gas, diesel, propane…, or renewable energy – solar, wind, landfill/digester gas…

What is Distributed Generation? Electric power generation close to the load. • Small-scale relative to central-plants. • Can use fossil fuel – natural gas, diesel, propane…, or renewable energy – solar, wind, landfill/digester gas…

DG Applications • Premium Power – reliability, power quality. • Backup Power – reliability. • Peak Shaving – peak demand reduction. • Base Load/CHP – cost reduction.

DG Applications • Premium Power – reliability, power quality. • Backup Power – reliability. • Peak Shaving – peak demand reduction. • Base Load/CHP – cost reduction.

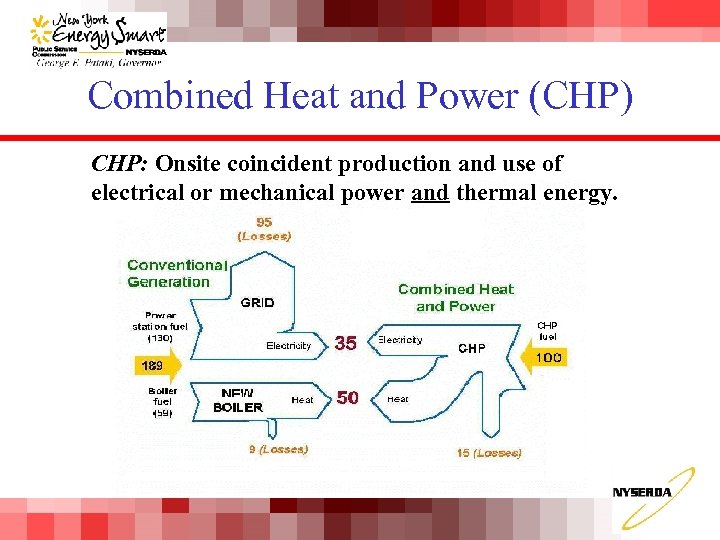

Combined Heat and Power (CHP) CHP: Onsite coincident production and use of electrical or mechanical power and thermal energy.

Combined Heat and Power (CHP) CHP: Onsite coincident production and use of electrical or mechanical power and thermal energy.

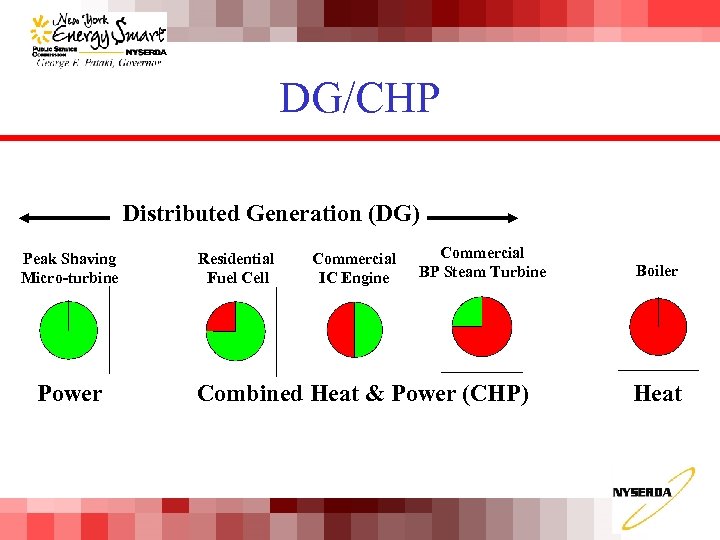

DG/CHP Distributed Generation (DG) Peak Shaving Micro-turbine Power Residential Fuel Cell Commercial IC Engine Commercial BP Steam Turbine Combined Heat & Power (CHP) Boiler Heat

DG/CHP Distributed Generation (DG) Peak Shaving Micro-turbine Power Residential Fuel Cell Commercial IC Engine Commercial BP Steam Turbine Combined Heat & Power (CHP) Boiler Heat

Where Does DG/CHP Make Sense? • Capacity constrained, high electric demands. • High thermal (steam, hot water, direct heat, cooling) demands. • Coincident thermal and electric demands. • Extended operating hours. • Access to fuels (byproducts, natural gas).

Where Does DG/CHP Make Sense? • Capacity constrained, high electric demands. • High thermal (steam, hot water, direct heat, cooling) demands. • Coincident thermal and electric demands. • Extended operating hours. • Access to fuels (byproducts, natural gas).

Benefits of DG/CHP • Fuel “in” at one place, multiple benefits “out” yields financial savings. • Diversification of energy supply sources yields greater reliability ====> Energy Security. • Return on investment: DG/CHP ====> every day. Emergency generator ====> sporadically.

Benefits of DG/CHP • Fuel “in” at one place, multiple benefits “out” yields financial savings. • Diversification of energy supply sources yields greater reliability ====> Energy Security. • Return on investment: DG/CHP ====> every day. Emergency generator ====> sporadically.

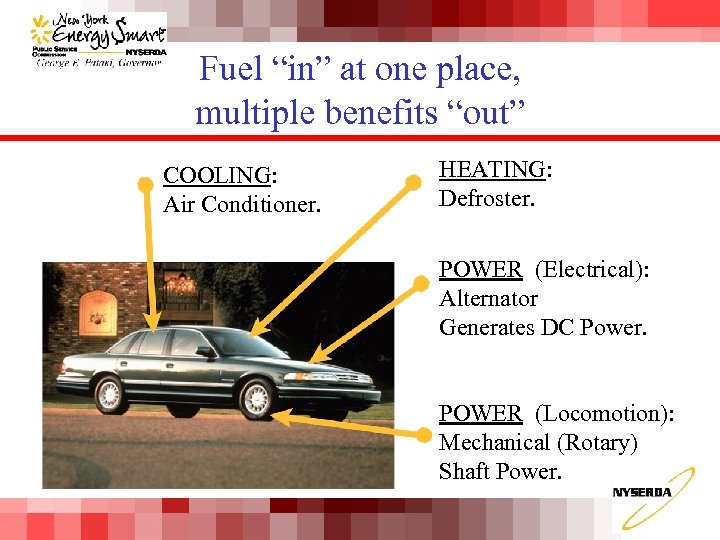

Fuel “in” at one place, multiple benefits “out” COOLING: Air Conditioner. HEATING: Defroster. POWER (Electrical): Alternator Generates DC Power. POWER (Locomotion): Mechanical (Rotary) Shaft Power.

Fuel “in” at one place, multiple benefits “out” COOLING: Air Conditioner. HEATING: Defroster. POWER (Electrical): Alternator Generates DC Power. POWER (Locomotion): Mechanical (Rotary) Shaft Power.

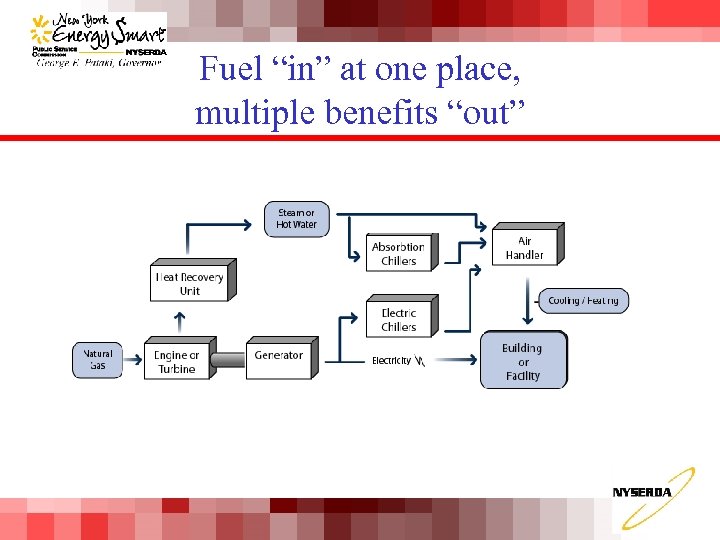

Fuel “in” at one place, multiple benefits “out”

Fuel “in” at one place, multiple benefits “out”

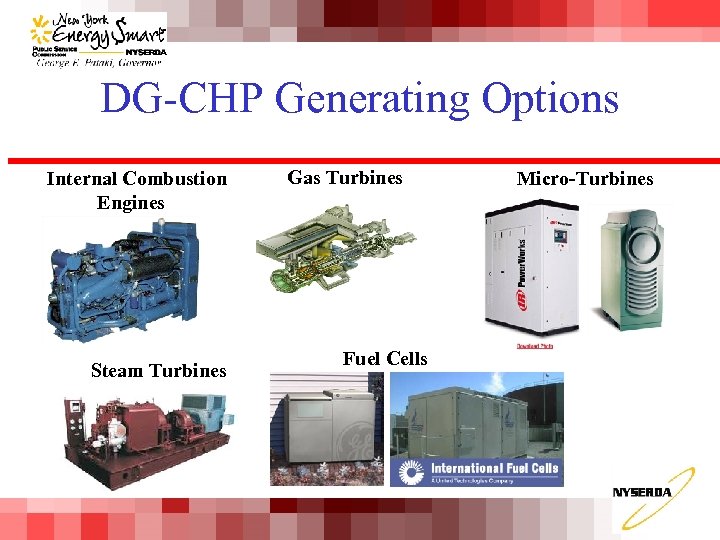

DG-CHP Generating Options Internal Combustion Engines Gas Turbines Steam Turbines Fuel Cells Micro-Turbines

DG-CHP Generating Options Internal Combustion Engines Gas Turbines Steam Turbines Fuel Cells Micro-Turbines

Choice of Equipment • First: identify your electric & thermal needs. • Next: match needs to a type of technology. Example: Engine - versus - Microturbine Electrical efficiency: Engine ~ 35%, Microturbine ~25% Byproduct heat: Engine high- & low-grade, Microturbine all high-grade Other considerations: familiarity of technology, dump radiator, emissions • Finally: select an equipment vendor.

Choice of Equipment • First: identify your electric & thermal needs. • Next: match needs to a type of technology. Example: Engine - versus - Microturbine Electrical efficiency: Engine ~ 35%, Microturbine ~25% Byproduct heat: Engine high- & low-grade, Microturbine all high-grade Other considerations: familiarity of technology, dump radiator, emissions • Finally: select an equipment vendor.

Evolving Equipment • Pre-engineered skid-mounted systems. • A fully-integrated car produced on an assembly line is likely to be more reliable, less expensive, and “running” sooner than buying the individual parts and having someone assemble it for you. • Likewise with CHP (not quite “plug-and-play” yet). • Major efforts by USDOE recently.

Evolving Equipment • Pre-engineered skid-mounted systems. • A fully-integrated car produced on an assembly line is likely to be more reliable, less expensive, and “running” sooner than buying the individual parts and having someone assemble it for you. • Likewise with CHP (not quite “plug-and-play” yet). • Major efforts by USDOE recently.

DG/CHP Issues/Hurdles • Interconnection with utility grid/tariffs. • Synchronous - versus - Induction. • Air permit. • Footprint/available space. • Financing.

DG/CHP Issues/Hurdles • Interconnection with utility grid/tariffs. • Synchronous - versus - Induction. • Air permit. • Footprint/available space. • Financing.

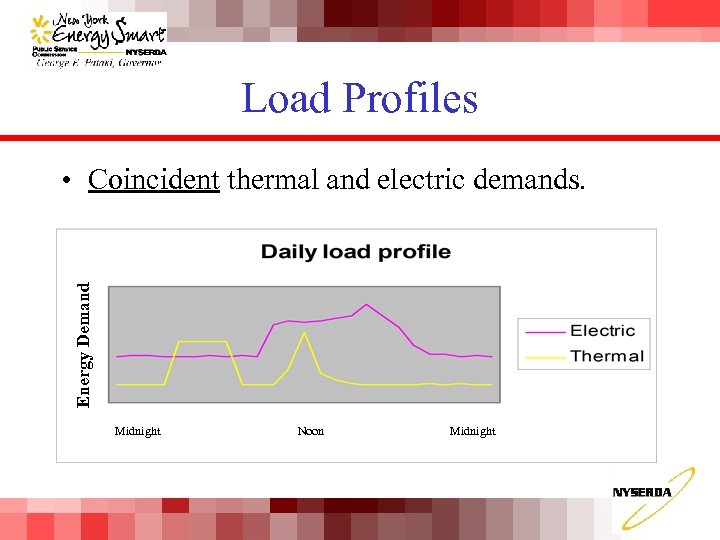

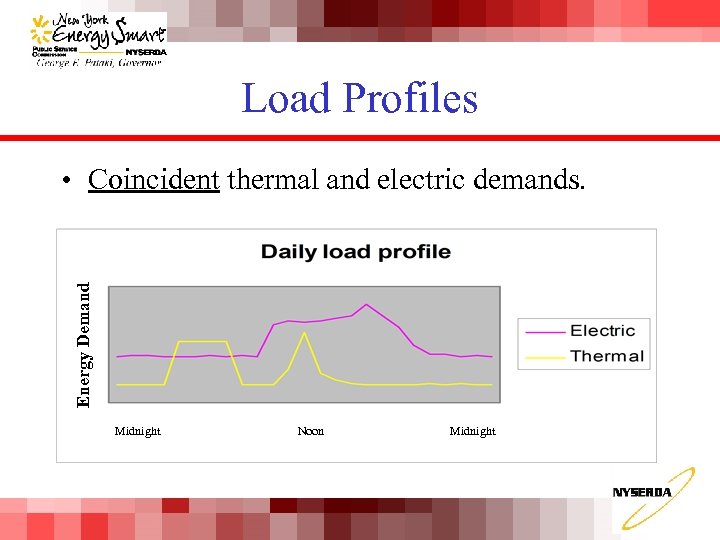

Load Profiles Energy Demand • Coincident thermal and electric demands. Midnight Noon Midnight

Load Profiles Energy Demand • Coincident thermal and electric demands. Midnight Noon Midnight

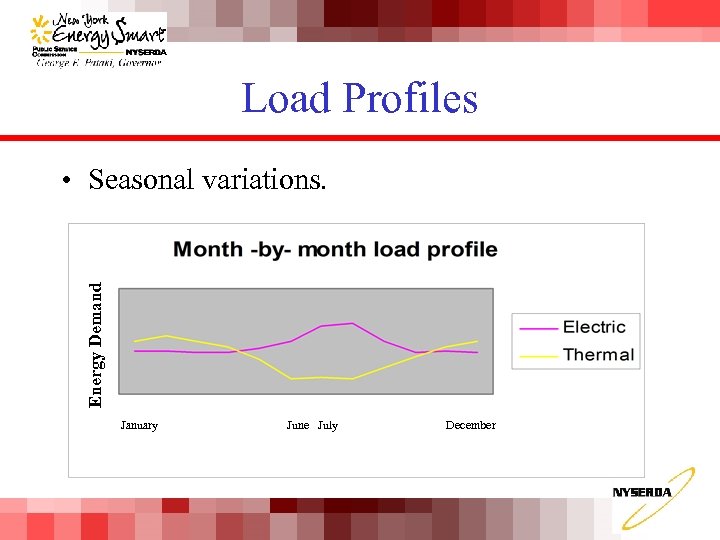

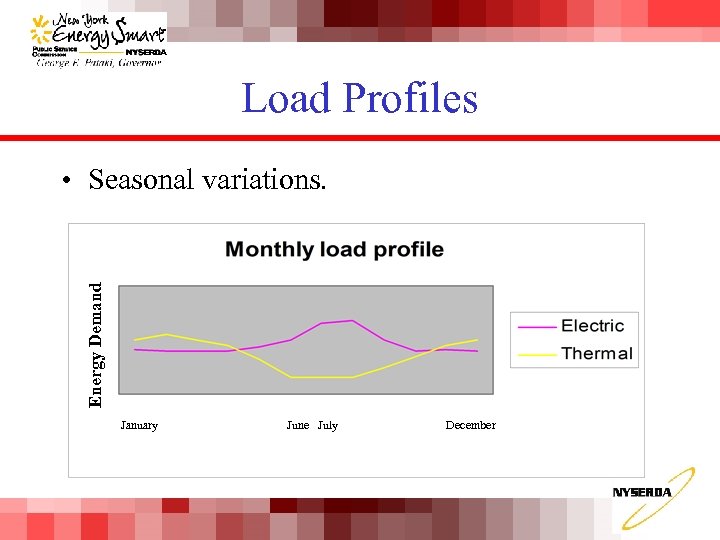

Load Profiles Energy Demand • Seasonal variations. January June July December

Load Profiles Energy Demand • Seasonal variations. January June July December

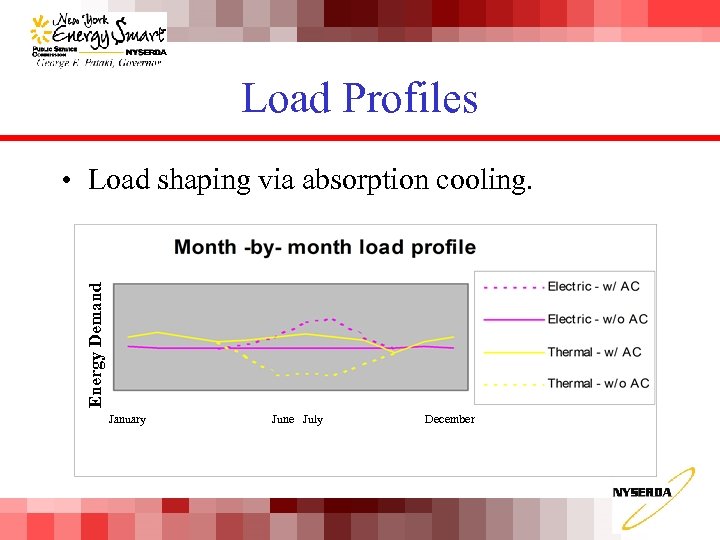

Load Profiles Energy Demand • Load shaping via absorption cooling. January June July December

Load Profiles Energy Demand • Load shaping via absorption cooling. January June July December

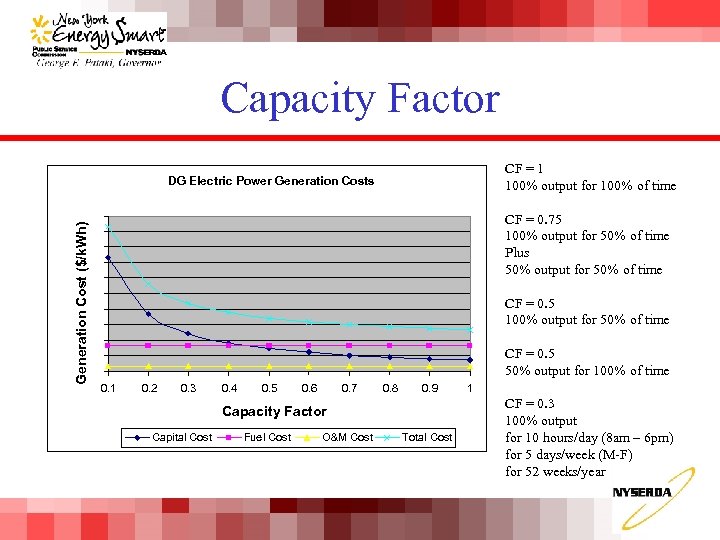

Capacity Factor CF = 1 100% output for 100% of time Generation Cost ($/k. Wh) DG Electric Power Generation Costs CF = 0. 75 100% output for 50% of time Plus 50% output for 50% of time CF = 0. 5 100% output for 50% of time CF = 0. 5 50% output for 100% of time 0. 1 0. 2 0. 3 0. 4 0. 5 0. 6 0. 7 0. 8 0. 9 Capacity Factor Capital Cost Fuel Cost O&M Cost Total Cost 1 CF = 0. 3 100% output for 10 hours/day (8 am – 6 pm) for 5 days/week (M-F) for 52 weeks/year

Capacity Factor CF = 1 100% output for 100% of time Generation Cost ($/k. Wh) DG Electric Power Generation Costs CF = 0. 75 100% output for 50% of time Plus 50% output for 50% of time CF = 0. 5 100% output for 50% of time CF = 0. 5 50% output for 100% of time 0. 1 0. 2 0. 3 0. 4 0. 5 0. 6 0. 7 0. 8 0. 9 Capacity Factor Capital Cost Fuel Cost O&M Cost Total Cost 1 CF = 0. 3 100% output for 10 hours/day (8 am – 6 pm) for 5 days/week (M-F) for 52 weeks/year

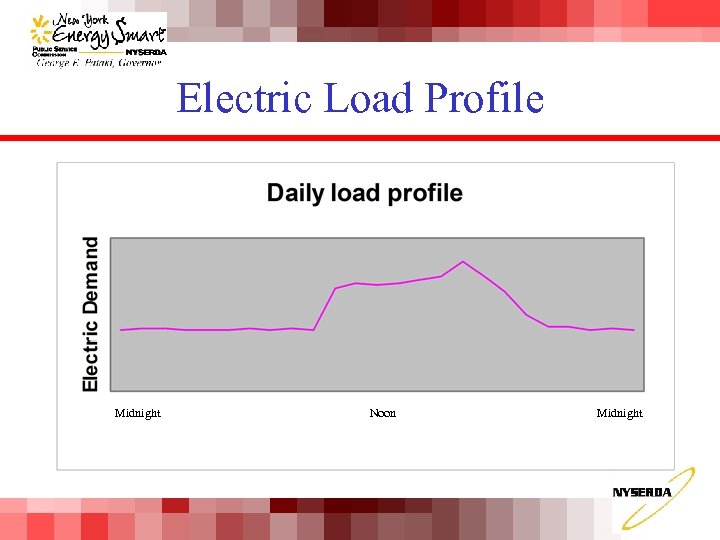

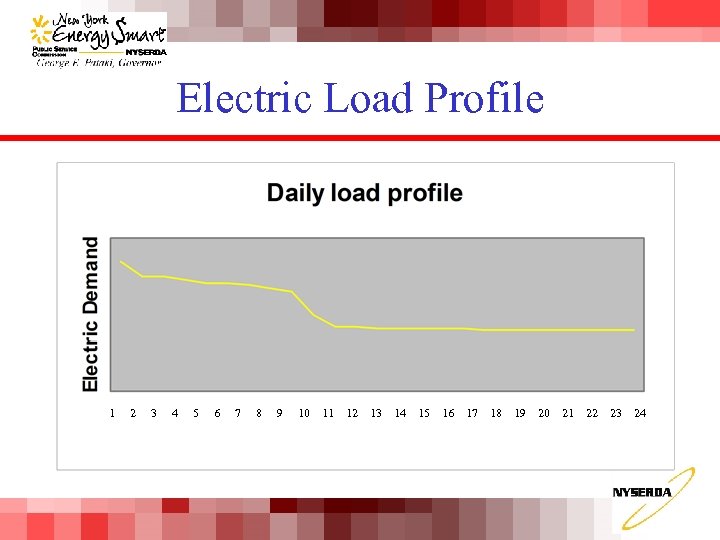

Electric Load Profile Midnight Noon Midnight

Electric Load Profile Midnight Noon Midnight

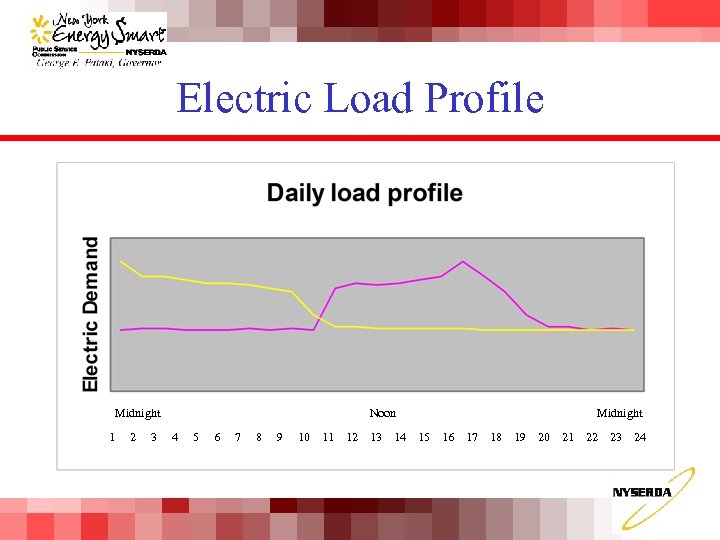

Electric Load Profile Midnight Noon Midnight 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

Electric Load Profile Midnight Noon Midnight 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

Electric Load Profile 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

Electric Load Profile 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

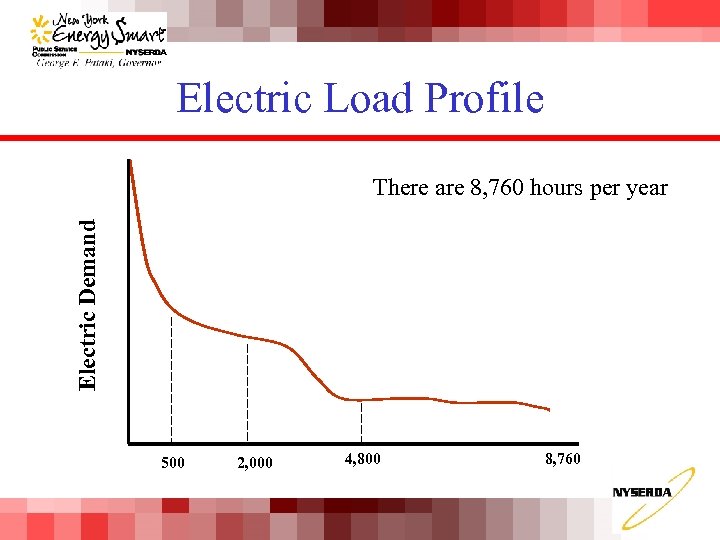

Electric Load Profile Electric Demand There are 8, 760 hours per year 500 2, 000 4, 800 8, 760

Electric Load Profile Electric Demand There are 8, 760 hours per year 500 2, 000 4, 800 8, 760

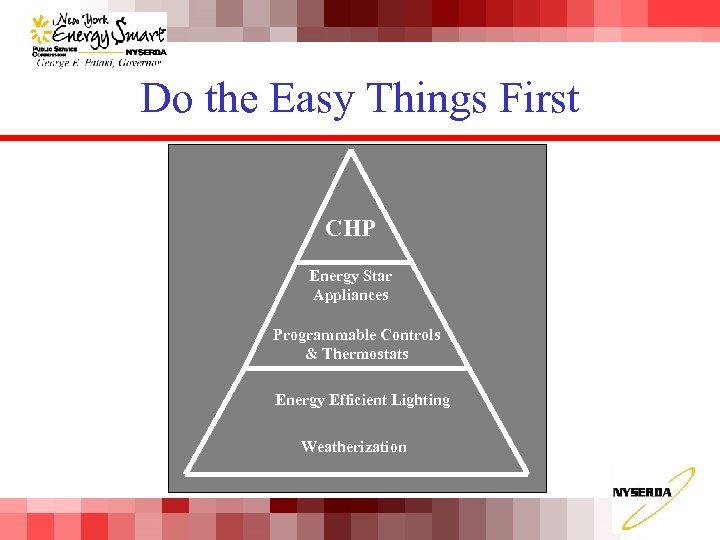

Do the Easy Things First CHP Energy Star Appliances Programmable Controls & Thermostats Energy Efficient Lighting Weatherization

Do the Easy Things First CHP Energy Star Appliances Programmable Controls & Thermostats Energy Efficient Lighting Weatherization

NYSERDA Funding Programs • Energy Audits which include ‘quick screen’ for CHP. • Site-specific CHP feasibility studies. • CHP hardware installation.

NYSERDA Funding Programs • Energy Audits which include ‘quick screen’ for CHP. • Site-specific CHP feasibility studies. • CHP hardware installation.

Quick Screening for CHP • There are various quick screening tools in development or use by NYSERDA, local gas utilities, & UMASS Amherst. • The NYSERDA tools are typically incorporated into a more comprehensive energy efficient scope of work. • Generally they analyze the cost-effectiveness of CHP to determine whether a building should pursue a detailed feasibility study.

Quick Screening for CHP • There are various quick screening tools in development or use by NYSERDA, local gas utilities, & UMASS Amherst. • The NYSERDA tools are typically incorporated into a more comprehensive energy efficient scope of work. • Generally they analyze the cost-effectiveness of CHP to determine whether a building should pursue a detailed feasibility study.

R&D to Implementation - AMP • The Assisted Multifamily Program provides whole-building energy efficiency to low- to moderate-income properties of > 4 units. • AMP provides a complete energy assessment, financial packaging including a NYSERDA grant, & construction oversight, in addition to 3 -year monitoring & consumption analysis.

R&D to Implementation - AMP • The Assisted Multifamily Program provides whole-building energy efficiency to low- to moderate-income properties of > 4 units. • AMP provides a complete energy assessment, financial packaging including a NYSERDA grant, & construction oversight, in addition to 3 -year monitoring & consumption analysis.

R&D to Implementation - AMP • CHP must be considered by the auditor as a program requirement using the quick screening tool. • If the analysis warrants it, the cost for a feasibility study AND an installed CHP system are packaged into the overall deal.

R&D to Implementation - AMP • CHP must be considered by the auditor as a program requirement using the quick screening tool. • If the analysis warrants it, the cost for a feasibility study AND an installed CHP system are packaged into the overall deal.

R&D to Implementation - AMP • If a viable financial package cannot be reached, AMP will consider additional funding from the CHP PON administered by R&D, otherwise the costs are borne by the owner and AMP. • AMP typically packages deals at a 4: 1 ratio of owner investment to NYSERDA funds.

R&D to Implementation - AMP • If a viable financial package cannot be reached, AMP will consider additional funding from the CHP PON administered by R&D, otherwise the costs are borne by the owner and AMP. • AMP typically packages deals at a 4: 1 ratio of owner investment to NYSERDA funds.

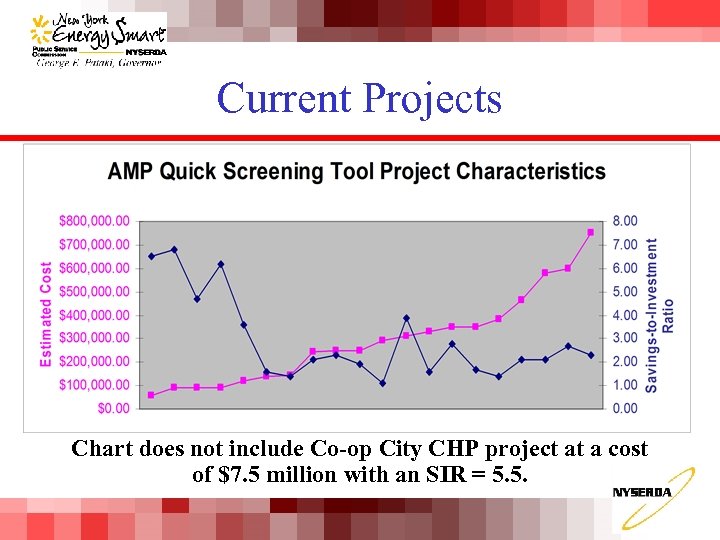

Current Projects Chart does not include Co-op City CHP project at a cost of $7. 5 million with an SIR = 5. 5.

Current Projects Chart does not include Co-op City CHP project at a cost of $7. 5 million with an SIR = 5. 5.

Current Projects • Systems are sized to maximize needs & restrictions related to the electric peak & baseload as well as the daily peak DHW load using additional DHW storage if necessary. • Estimated savings range from 9, 232 to 52, 000 k. Wh annually. • Majority of systems are 30 -60 k. W systems.

Current Projects • Systems are sized to maximize needs & restrictions related to the electric peak & baseload as well as the daily peak DHW load using additional DHW storage if necessary. • Estimated savings range from 9, 232 to 52, 000 k. Wh annually. • Majority of systems are 30 -60 k. W systems.

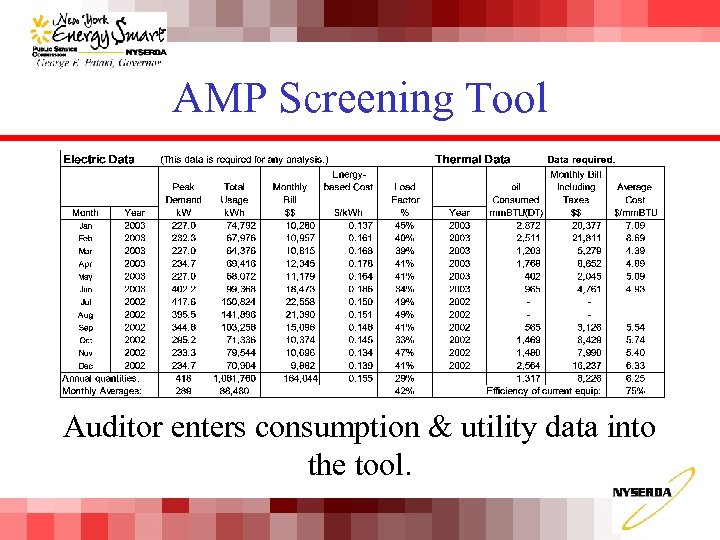

AMP Screening Tool Auditor enters consumption & utility data into the tool.

AMP Screening Tool Auditor enters consumption & utility data into the tool.

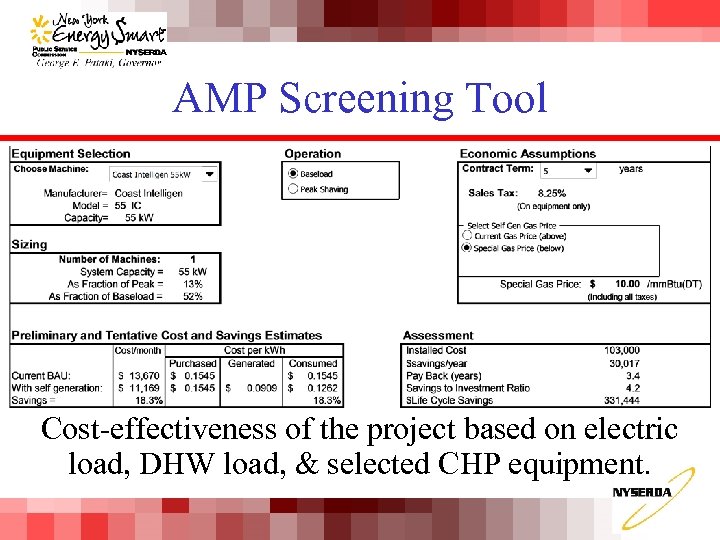

AMP Screening Tool Cost-effectiveness of the project based on electric load, DHW load, & selected CHP equipment.

AMP Screening Tool Cost-effectiveness of the project based on electric load, DHW load, & selected CHP equipment.

Testing & Verification • The current AMP quick screening tool is being applied retroactively to some of our multifamily CHP projects to test its accuracy. • A continuing analysis will be conducted in each AMP project to compare the tool’s projections to those of the eventual feasibility study and ultimately to actual performance of installed projects.

Testing & Verification • The current AMP quick screening tool is being applied retroactively to some of our multifamily CHP projects to test its accuracy. • A continuing analysis will be conducted in each AMP project to compare the tool’s projections to those of the eventual feasibility study and ultimately to actual performance of installed projects.

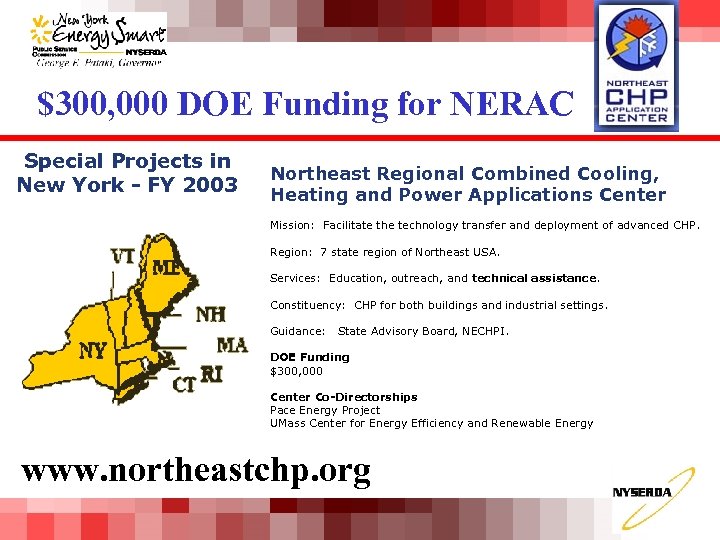

$300, 000 DOE Funding for NERAC Special Projects in New York - FY 2003 Northeast Regional Combined Cooling, Heating and Power Applications Center Mission: Facilitate the technology transfer and deployment of advanced CHP. Region: 7 state region of Northeast USA. Services: Education, outreach, and technical assistance. Constituency: CHP for both buildings and industrial settings. Guidance: State Advisory Board, NECHPI. DOE Funding $300, 000 Center Co-Directorships Pace Energy Project UMass Center for Energy Efficiency and Renewable Energy www. northeastchp. org

$300, 000 DOE Funding for NERAC Special Projects in New York - FY 2003 Northeast Regional Combined Cooling, Heating and Power Applications Center Mission: Facilitate the technology transfer and deployment of advanced CHP. Region: 7 state region of Northeast USA. Services: Education, outreach, and technical assistance. Constituency: CHP for both buildings and industrial settings. Guidance: State Advisory Board, NECHPI. DOE Funding $300, 000 Center Co-Directorships Pace Energy Project UMass Center for Energy Efficiency and Renewable Energy www. northeastchp. org

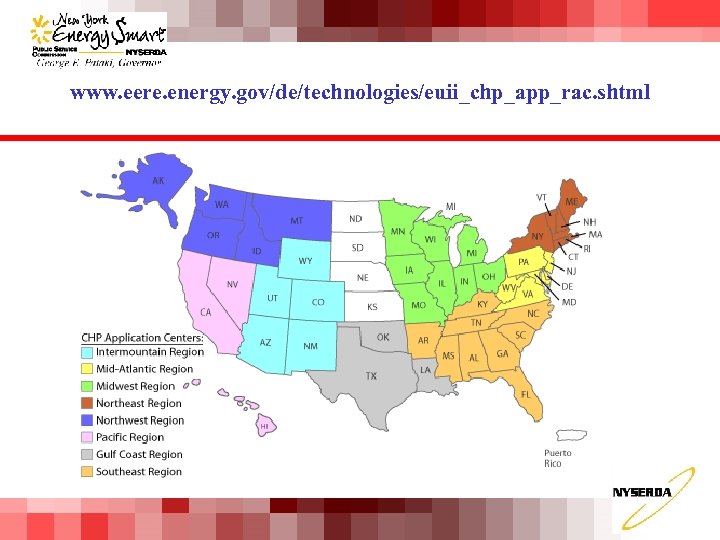

www. eere. energy. gov/de/technologies/euii_chp_app_rac. shtml

www. eere. energy. gov/de/technologies/euii_chp_app_rac. shtml

NYSERDA Funding Programs • Energy Audits which include ‘quick screen’ for CHP. • Site-specific CHP feasibility studies. • CHP hardware installation.

NYSERDA Funding Programs • Energy Audits which include ‘quick screen’ for CHP. • Site-specific CHP feasibility studies. • CHP hardware installation.

PON 831 CHP & Renewable Generation Technical Assistance • • Competitive Solicitation $250, 000 in available funding 50% cost share up to $50, 000 December 1, 2004 Deadline

PON 831 CHP & Renewable Generation Technical Assistance • • Competitive Solicitation $250, 000 in available funding 50% cost share up to $50, 000 December 1, 2004 Deadline

Limitations • Study must include heat recovery • At minimum, 75% of electricity generated would be used on-site • 20 MW capacity for CHP applications

Limitations • Study must include heat recovery • At minimum, 75% of electricity generated would be used on-site • 20 MW capacity for CHP applications

Study Components • • Load profile analysis Determination of CHP efficiency Site information Economic evaluation Tariff impacts and interconnection issues Permitting Reliability

Study Components • • Load profile analysis Determination of CHP efficiency Site information Economic evaluation Tariff impacts and interconnection issues Permitting Reliability

Load Profile • Detailed analysis of load profiles – What are thermal demands of the heat sinks? – When is the heat used? – Are thermal and electrical loads coincidental?

Load Profile • Detailed analysis of load profiles – What are thermal demands of the heat sinks? – When is the heat used? – Are thermal and electrical loads coincidental?

Load Profiles Energy Demand • Seasonal variations. January June July December

Load Profiles Energy Demand • Seasonal variations. January June July December

Load Profiles Energy Demand • Coincident thermal and electric demands. Midnight Noon Midnight

Load Profiles Energy Demand • Coincident thermal and electric demands. Midnight Noon Midnight

System Efficiency • Annual Thermal utilization • Annual fuel conversion efficiency Heat recovered + Electricity generated Fuel input • NYSERDA target is 60%

System Efficiency • Annual Thermal utilization • Annual fuel conversion efficiency Heat recovered + Electricity generated Fuel input • NYSERDA target is 60%

Site Information • • Floor Plan Fuel requirements/ availability Construction schedule Existing air permit

Site Information • • Floor Plan Fuel requirements/ availability Construction schedule Existing air permit

Economic Evaluation • Life Cycle Cost analysis • Operational costs – Maintenance – Tariff impacts • Detailed capital cost breakdown

Economic Evaluation • Life Cycle Cost analysis • Operational costs – Maintenance – Tariff impacts • Detailed capital cost breakdown

Tariff Impacts & Interconnection • Impact of CHP on existing tariffs – For example CHP exemption in Con. Ed territory • Detailed discussion of any new applicable tariff impacts • Grid interconnection issues – Standard interconnection under 300 k. Va

Tariff Impacts & Interconnection • Impact of CHP on existing tariffs – For example CHP exemption in Con. Ed territory • Detailed discussion of any new applicable tariff impacts • Grid interconnection issues – Standard interconnection under 300 k. Va

Permitting • Environmental permits – EPA – DEP – DEC • Detailed emission inventory • Building permits – Special fuel line requirements

Permitting • Environmental permits – EPA – DEP – DEC • Detailed emission inventory • Building permits – Special fuel line requirements

Reliability & Availability • Estimated downtime – Scheduled – Unplanned • Affect on customer’s core business

Reliability & Availability • Estimated downtime – Scheduled – Unplanned • Affect on customer’s core business

Example • • • Large NYC hospital 7. 5 MW gas turbine $4, 000 annual savings $20, 000 estimated installation cost 75% Annual Fuel Conversion Efficiency 37, 500 pound reduction of NOx

Example • • • Large NYC hospital 7. 5 MW gas turbine $4, 000 annual savings $20, 000 estimated installation cost 75% Annual Fuel Conversion Efficiency 37, 500 pound reduction of NOx

NYSERDA Funding Programs • Energy Audits which include ‘quick screen’ for CHP. • Site-specific CHP feasibility studies. • CHP hardware installation.

NYSERDA Funding Programs • Energy Audits which include ‘quick screen’ for CHP. • Site-specific CHP feasibility studies. • CHP hardware installation.

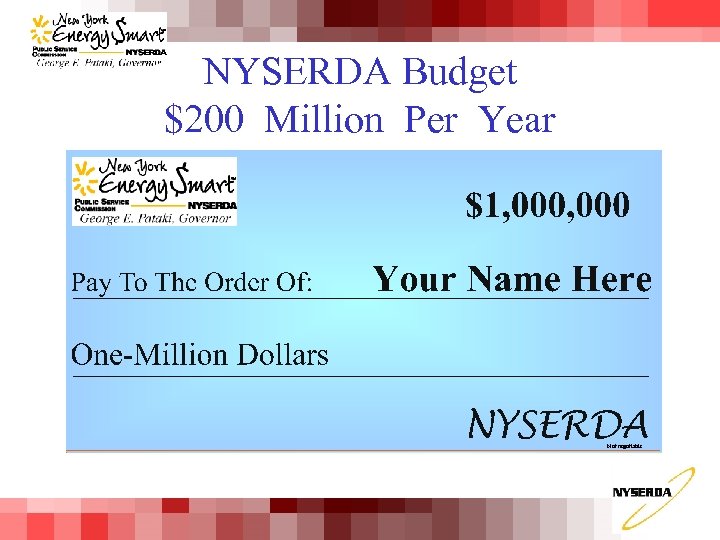

NYSERDA Budget $200 Million Per Year Not negotiable

NYSERDA Budget $200 Million Per Year Not negotiable

Objectives of DG/CHP Program • Support CHP to bolster NYS economy. • Encourage clean and efficient systems. • Establish a broad portfolio various technologies, various end-use sectors. Document hurdles and lessons learned: • Identify “Role Model” systems ====> replicate: faster, better, cheaper.

Objectives of DG/CHP Program • Support CHP to bolster NYS economy. • Encourage clean and efficient systems. • Establish a broad portfolio various technologies, various end-use sectors. Document hurdles and lessons learned: • Identify “Role Model” systems ====> replicate: faster, better, cheaper.

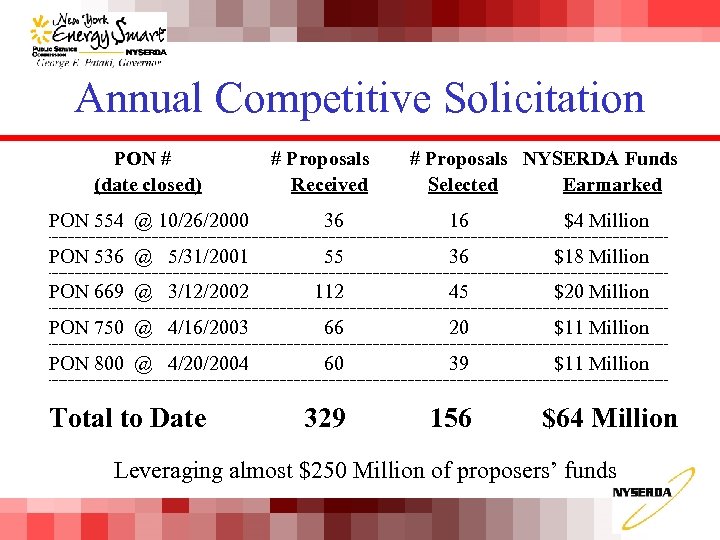

Annual Competitive Solicitation PON # (date closed) # Proposals Received # Proposals NYSERDA Funds Selected Earmarked PON 554 @ 10/26/2000 36 16 $4 Million ------------------------------------------------------------------------------------------------------------------------------------- PON 536 @ 5/31/2001 55 36 $18 Million ------------------------------------------------------------------------------------------------------------------------------------- PON 669 @ 3/12/2002 112 45 $20 Million ------------------------------------------------------------------------------------------------------------------------------------- PON 750 @ 4/16/2003 66 20 $11 Million ------------------------------------------------------------------------------------------------------------------------------------- PON 800 @ 4/20/2004 60 39 $11 Million ------------------------------------------------------------------------------------------------------------------------------------- Total to Date 329 156 $64 Million Leveraging almost $250 Million of proposers’ funds

Annual Competitive Solicitation PON # (date closed) # Proposals Received # Proposals NYSERDA Funds Selected Earmarked PON 554 @ 10/26/2000 36 16 $4 Million ------------------------------------------------------------------------------------------------------------------------------------- PON 536 @ 5/31/2001 55 36 $18 Million ------------------------------------------------------------------------------------------------------------------------------------- PON 669 @ 3/12/2002 112 45 $20 Million ------------------------------------------------------------------------------------------------------------------------------------- PON 750 @ 4/16/2003 66 20 $11 Million ------------------------------------------------------------------------------------------------------------------------------------- PON 800 @ 4/20/2004 60 39 $11 Million ------------------------------------------------------------------------------------------------------------------------------------- Total to Date 329 156 $64 Million Leveraging almost $250 Million of proposers’ funds

Competitive Selection $

Competitive Selection $

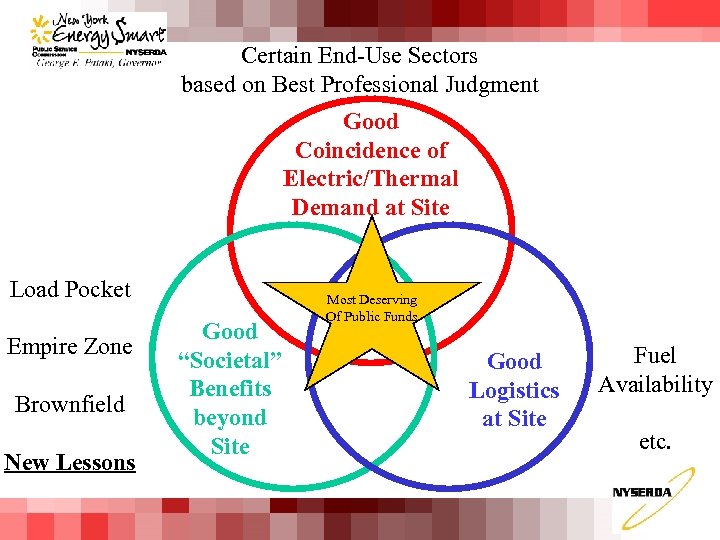

Certain End-Use Sectors based on Best Professional Judgment Good Coincidence of Electric/Thermal Demand at Site Load Pocket Empire Zone Brownfield New Lessons Good “Societal” Benefits beyond Site Most Deserving Of Public Funds Good Logistics at Site Fuel Availability etc.

Certain End-Use Sectors based on Best Professional Judgment Good Coincidence of Electric/Thermal Demand at Site Load Pocket Empire Zone Brownfield New Lessons Good “Societal” Benefits beyond Site Most Deserving Of Public Funds Good Logistics at Site Fuel Availability etc.

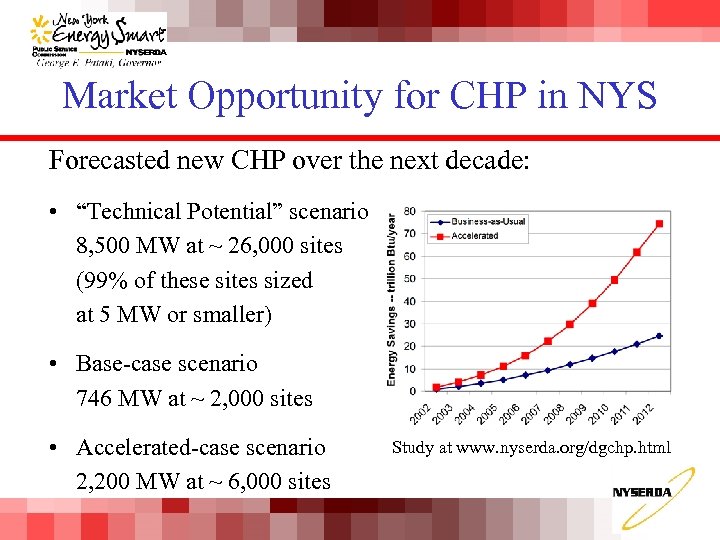

Market Opportunity for CHP in NYS Forecasted new CHP over the next decade: • “Technical Potential” scenario 8, 500 MW at ~ 26, 000 sites (99% of these sites sized at 5 MW or smaller) • Base-case scenario 746 MW at ~ 2, 000 sites • Accelerated-case scenario 2, 200 MW at ~ 6, 000 sites Study at www. nyserda. org/dgchp. html

Market Opportunity for CHP in NYS Forecasted new CHP over the next decade: • “Technical Potential” scenario 8, 500 MW at ~ 26, 000 sites (99% of these sites sized at 5 MW or smaller) • Base-case scenario 746 MW at ~ 2, 000 sites • Accelerated-case scenario 2, 200 MW at ~ 6, 000 sites Study at www. nyserda. org/dgchp. html

DG/CHP Case Studies • Residential buildings: Brooklyn, Manhattan • Commercial building: Waldbaums Supermarket

DG/CHP Case Studies • Residential buildings: Brooklyn, Manhattan • Commercial building: Waldbaums Supermarket

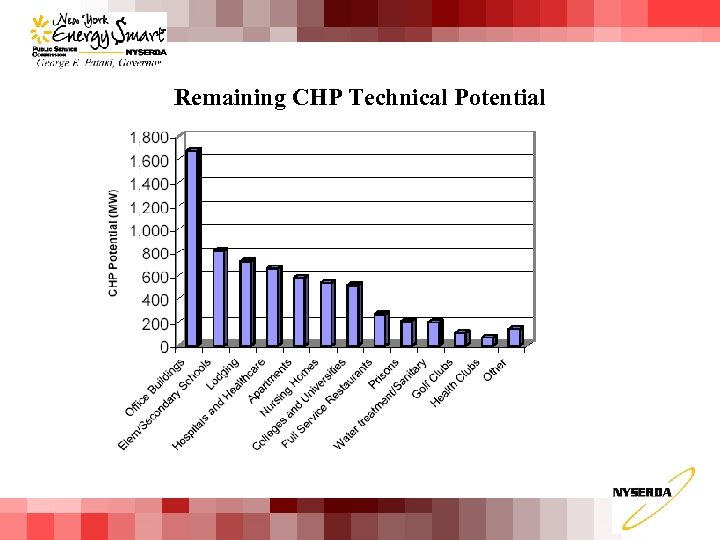

Remaining CHP Technical Potential

Remaining CHP Technical Potential

Challenges • Multiple Stakeholders – Building Owner / Cooperative (Board), Tenants, Utility, Design Engineer, Developer, Oversight Agencies, Local Code Enforcement, Financing Institution. • Large Base of Existing Older Buildings – Limited space within the building – Usually located in a densely populated area – 2/3 of all apartments in NY State are in NYC – Residents more sensitive to noise, vibration and service interruptions.

Challenges • Multiple Stakeholders – Building Owner / Cooperative (Board), Tenants, Utility, Design Engineer, Developer, Oversight Agencies, Local Code Enforcement, Financing Institution. • Large Base of Existing Older Buildings – Limited space within the building – Usually located in a densely populated area – 2/3 of all apartments in NY State are in NYC – Residents more sensitive to noise, vibration and service interruptions.

Metering and Cogeneration ðDirect Metered – Each apartment in the building has a electric utility meter, and the individual purchases and pays for their own electricity. • Promotes energy efficiency as consumers incur the cost associated with their energy use. • Load is not available to being supplied by on-site generation and hence limits the application of CHP. ðMastered Metered – One electric utility meter for the entire residential building. • Entire building’s electric load is available to Cogeneration. • Tenants less likely to be energy conscious. ð Sub-Metered Master Building – Tenants pay for the electricity they use and the entire building’s electric load is available to cogeneration.

Metering and Cogeneration ðDirect Metered – Each apartment in the building has a electric utility meter, and the individual purchases and pays for their own electricity. • Promotes energy efficiency as consumers incur the cost associated with their energy use. • Load is not available to being supplied by on-site generation and hence limits the application of CHP. ðMastered Metered – One electric utility meter for the entire residential building. • Entire building’s electric load is available to Cogeneration. • Tenants less likely to be energy conscious. ð Sub-Metered Master Building – Tenants pay for the electricity they use and the entire building’s electric load is available to cogeneration.

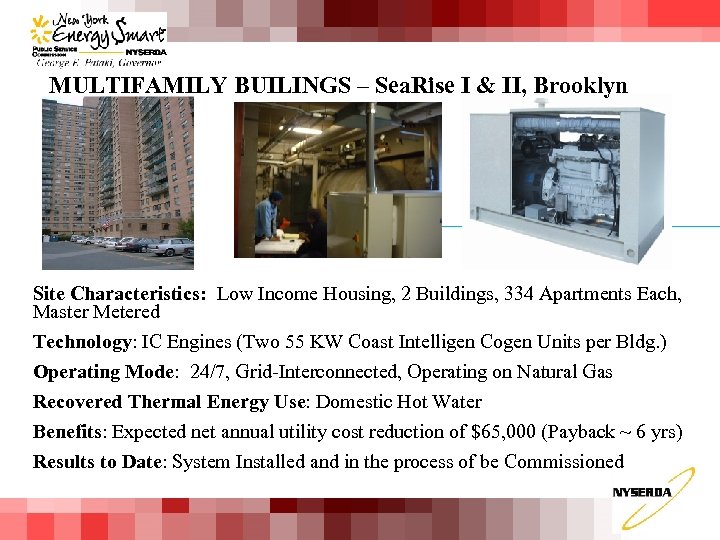

MULTIFAMILY BUILINGS – Sea. Rise I & II, Brooklyn Site Characteristics: Low Income Housing, 2 Buildings, 334 Apartments Each, Master Metered Technology: IC Engines (Two 55 KW Coast Intelligen Cogen Units per Bldg. ) Operating Mode: 24/7, Grid-Interconnected, Operating on Natural Gas Recovered Thermal Energy Use: Domestic Hot Water Benefits: Expected net annual utility cost reduction of $65, 000 (Payback ~ 6 yrs) Results to Date: System Installed and in the process of be Commissioned

MULTIFAMILY BUILINGS – Sea. Rise I & II, Brooklyn Site Characteristics: Low Income Housing, 2 Buildings, 334 Apartments Each, Master Metered Technology: IC Engines (Two 55 KW Coast Intelligen Cogen Units per Bldg. ) Operating Mode: 24/7, Grid-Interconnected, Operating on Natural Gas Recovered Thermal Energy Use: Domestic Hot Water Benefits: Expected net annual utility cost reduction of $65, 000 (Payback ~ 6 yrs) Results to Date: System Installed and in the process of be Commissioned

Site History ð 1987 Sea. Rise I & II installs Cogeneration System • IC Engine 145 k. W (restricted to 120 k. W), thermal output 830, 000 Btu/Hr, thermal storage – 1200 gallons, operating strategy – thermal, thermal load – DHW ð Experienced reduced operation due to low thermal demand (no dump radiator). ð Extended outages • Engine failure due to poor unit reliability • Equipment manufacturer filing for bankruptcy • Lack of a maintenance contractor • Local personnel had little or no involvement with the units other than to inform maintenance contractor when unit was out of service.

Site History ð 1987 Sea. Rise I & II installs Cogeneration System • IC Engine 145 k. W (restricted to 120 k. W), thermal output 830, 000 Btu/Hr, thermal storage – 1200 gallons, operating strategy – thermal, thermal load – DHW ð Experienced reduced operation due to low thermal demand (no dump radiator). ð Extended outages • Engine failure due to poor unit reliability • Equipment manufacturer filing for bankruptcy • Lack of a maintenance contractor • Local personnel had little or no involvement with the units other than to inform maintenance contractor when unit was out of service.

Lessons Learned ð Instrumentation should be installed to measure electric and thermal loads before sizing the cogeneration system; ðUnits sized to meet 50 to 75 percent of the peak DHW thermal load with appropriately sized thermal storage will achieve nearcontinuous operation. Dump radiators, if economically justified, will also improve unit operations and reliability in some cases;

Lessons Learned ð Instrumentation should be installed to measure electric and thermal loads before sizing the cogeneration system; ðUnits sized to meet 50 to 75 percent of the peak DHW thermal load with appropriately sized thermal storage will achieve nearcontinuous operation. Dump radiators, if economically justified, will also improve unit operations and reliability in some cases;

Lessons Learned (continued) ðSizing cogenerators to supply both DHW heating and significant portions of site space heating will result in grossly oversized unit during the five to six months when space heating is minimal. Multiple unit installations and/or dump radiators can be used to reduce unit start/stop cycling if they can be economically justified;

Lessons Learned (continued) ðSizing cogenerators to supply both DHW heating and significant portions of site space heating will result in grossly oversized unit during the five to six months when space heating is minimal. Multiple unit installations and/or dump radiators can be used to reduce unit start/stop cycling if they can be economically justified;

Lessons Learned (continued) ð Cogenerators should be specified that have proven track records for dependable operation. Consideration should be given to the manufacturer’s support staff and facilities that will be available to support the unit after installation; ð Installation of a remote monitoring system is recommended to provide automatic notification of the system outages and to assist in troubleshooting cogenerator problems;

Lessons Learned (continued) ð Cogenerators should be specified that have proven track records for dependable operation. Consideration should be given to the manufacturer’s support staff and facilities that will be available to support the unit after installation; ð Installation of a remote monitoring system is recommended to provide automatic notification of the system outages and to assist in troubleshooting cogenerator problems;

Lessons Learned (continued) ð Effective use of on-site personnel in the daily operation of the cogenerator results in reduced outage time; ð Service agreements covering both cogenerator and balance of plant equipment should be in place at the time of installation. If possible, a single contractor should be responsible for maintaining both cogenerator and balance of plant equipment.

Lessons Learned (continued) ð Effective use of on-site personnel in the daily operation of the cogenerator results in reduced outage time; ð Service agreements covering both cogenerator and balance of plant equipment should be in place at the time of installation. If possible, a single contractor should be responsible for maintaining both cogenerator and balance of plant equipment.

MULTIFAMILY BUILINGS – 10 West 66 Street, Manhattan Site Characteristics: Electrically heated and cooled multifamily (256 units) residential cooperative building, gas fired hot water system, Master Metered w/ sub-metering. Technology: one 70 k. W Ingersoll-Rand Microturbine + 100 k. W Gas Recip Engine Standby/Backup DG unit Operating Mode: 24/7, Grid-Interconnected, Operating on Natural Gas Recovered Thermal Energy Use: Domestic Hot Water Benefits: Expected net annual utility cost reduction of $36, 000 (Payback ~ 9 yrs) Results to Date: System Installed and Running

MULTIFAMILY BUILINGS – 10 West 66 Street, Manhattan Site Characteristics: Electrically heated and cooled multifamily (256 units) residential cooperative building, gas fired hot water system, Master Metered w/ sub-metering. Technology: one 70 k. W Ingersoll-Rand Microturbine + 100 k. W Gas Recip Engine Standby/Backup DG unit Operating Mode: 24/7, Grid-Interconnected, Operating on Natural Gas Recovered Thermal Energy Use: Domestic Hot Water Benefits: Expected net annual utility cost reduction of $36, 000 (Payback ~ 9 yrs) Results to Date: System Installed and Running

MULTIFAMILY BUILINGS – 205 West End Avenue, Manhattan Site Characteristics: 540 unit Cooperative, Heating & Hot Water Con Ed Steam, Master Metered w/ Sub-metering Technology: 2 – 150 KW Waukesha VSG 11 GSID continuous duty reciprocating engines Operating Mode: 24/7, Grid-Interconnected, Operating on Natural Gas Recovered Thermal Energy Use: Domestic Hot Water, Comfort Heating Benefits: Expected net annual utility cost reduction of $319, 500 (Payback ~ 2. 2 yrs) Results to Date: System Installed and Running

MULTIFAMILY BUILINGS – 205 West End Avenue, Manhattan Site Characteristics: 540 unit Cooperative, Heating & Hot Water Con Ed Steam, Master Metered w/ Sub-metering Technology: 2 – 150 KW Waukesha VSG 11 GSID continuous duty reciprocating engines Operating Mode: 24/7, Grid-Interconnected, Operating on Natural Gas Recovered Thermal Energy Use: Domestic Hot Water, Comfort Heating Benefits: Expected net annual utility cost reduction of $319, 500 (Payback ~ 2. 2 yrs) Results to Date: System Installed and Running

Suggestions for Minimizing Risk ð Unbiased Feasibility / Engineering Study • Technology, Size and System Operation matches the facility characteristics and needs. ð Verify Contractor and Equipment Performance ð Staged Implementation for Projects with Multiply Buildings within a Complex • Get the bugs out before replicating.

Suggestions for Minimizing Risk ð Unbiased Feasibility / Engineering Study • Technology, Size and System Operation matches the facility characteristics and needs. ð Verify Contractor and Equipment Performance ð Staged Implementation for Projects with Multiply Buildings within a Complex • Get the bugs out before replicating.

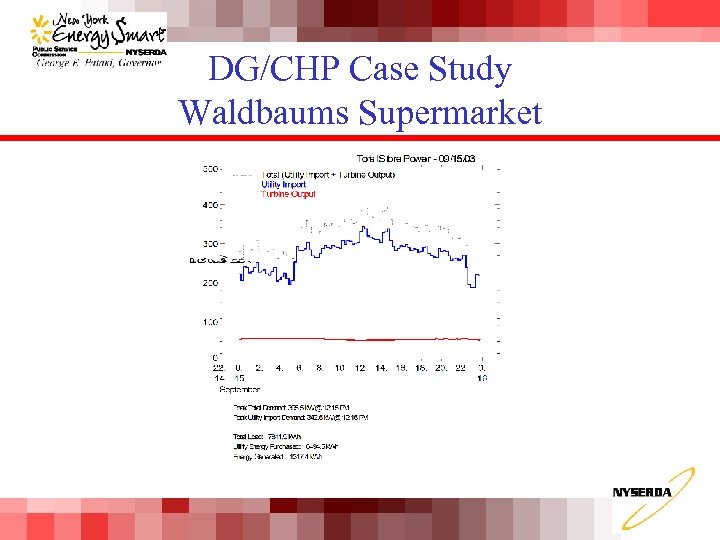

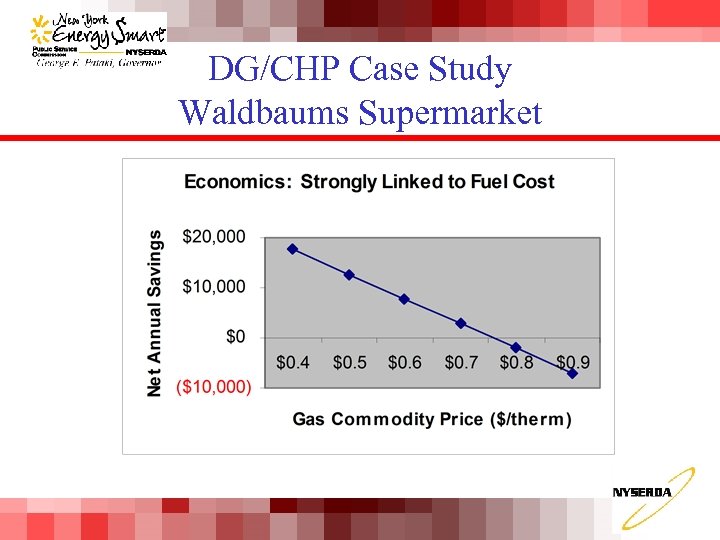

DG/CHP Case Study Waldbaums Supermarket

DG/CHP Case Study Waldbaums Supermarket

DG/CHP Case Study Waldbaums Supermarket

DG/CHP Case Study Waldbaums Supermarket

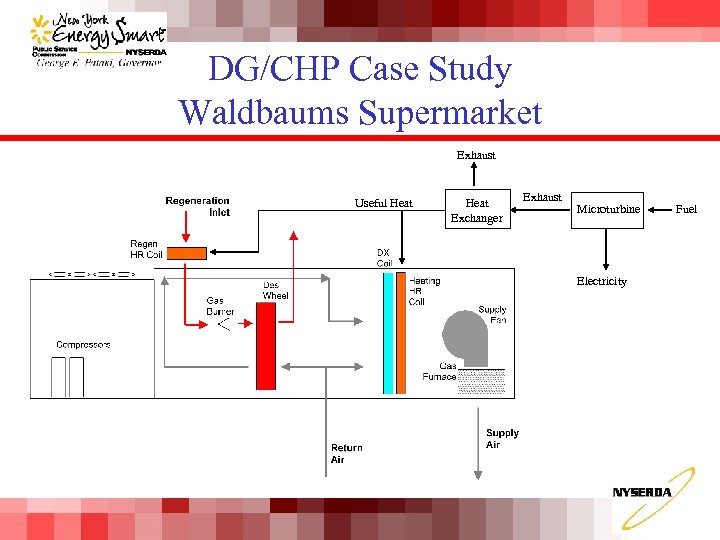

DG/CHP Case Study Waldbaums Supermarket Exhaust Useful Heat Exchanger Exhaust Microturbine Electricity Fuel

DG/CHP Case Study Waldbaums Supermarket Exhaust Useful Heat Exchanger Exhaust Microturbine Electricity Fuel

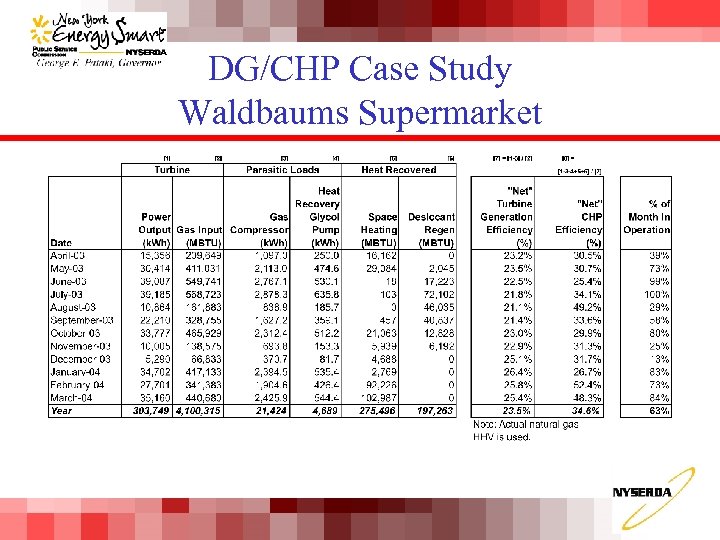

DG/CHP Case Study Waldbaums Supermarket

DG/CHP Case Study Waldbaums Supermarket

DG/CHP Case Study Waldbaums Supermarket

DG/CHP Case Study Waldbaums Supermarket

Financing • NYC Economic Development Corp Energy Cost Savings Program (ECSP). • Cash value of Emission Reduction Credits (ERCs). • Business practices – Performance Contracting.

Financing • NYC Economic Development Corp Energy Cost Savings Program (ECSP). • Cash value of Emission Reduction Credits (ERCs). • Business practices – Performance Contracting.

Financing http: //www. newyorkbiz. com/Business_Incentives/Energy/ECSPProgram. pdf Benefits are available to businesses that generate their own electricity through distributed generation. Rebate on “delivery charge” for natural gas used in CHP. Rebate on “delivery charge” for grid-supplied electricity. Rebate up to 4. 44 cents per k. Wh self-generated via CHP.

Financing http: //www. newyorkbiz. com/Business_Incentives/Energy/ECSPProgram. pdf Benefits are available to businesses that generate their own electricity through distributed generation. Rebate on “delivery charge” for natural gas used in CHP. Rebate on “delivery charge” for grid-supplied electricity. Rebate up to 4. 44 cents per k. Wh self-generated via CHP.

Financing national fuel DG Partnership Pilot Program Approved by NYPSC on March 20, 2003. • Permits NFG to give customer funding to buydown cost of CHP equipment, lowering payback. • Pilot program with initial term of 3 years. Annual cap of $1 million/year, total of $3 million. • Proposed typical buydowns range $50, 000 - $150, 000. Actual buydown based on incremental margin per project. • Customer must sign a performance contract with term of up to 6 years. May also be required to provide security.

Financing national fuel DG Partnership Pilot Program Approved by NYPSC on March 20, 2003. • Permits NFG to give customer funding to buydown cost of CHP equipment, lowering payback. • Pilot program with initial term of 3 years. Annual cap of $1 million/year, total of $3 million. • Proposed typical buydowns range $50, 000 - $150, 000. Actual buydown based on incremental margin per project. • Customer must sign a performance contract with term of up to 6 years. May also be required to provide security.

Financing • NYC Economic Development Corp Energy Cost Savings Program (ECSP). • Cash value of Emission Reduction Credits (ERCs). • Business practices – Performance Contracting.

Financing • NYC Economic Development Corp Energy Cost Savings Program (ECSP). • Cash value of Emission Reduction Credits (ERCs). • Business practices – Performance Contracting.

Emission at the Central Power Plant Emission from Conventional Heating

Emission at the Central Power Plant Emission from Conventional Heating

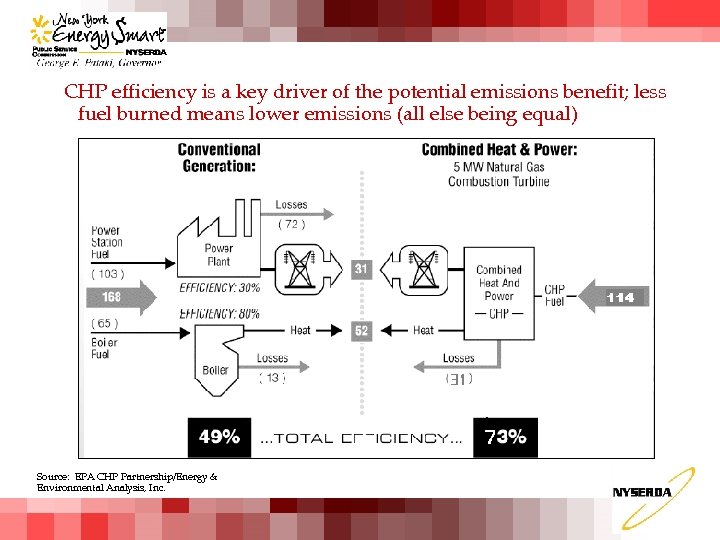

CHP efficiency is a key driver of the potential emissions benefit; less fuel burned means lower emissions (all else being equal) Source: EPA CHP Partnership/Energy & Environmental Analysis, Inc.

CHP efficiency is a key driver of the potential emissions benefit; less fuel burned means lower emissions (all else being equal) Source: EPA CHP Partnership/Energy & Environmental Analysis, Inc.

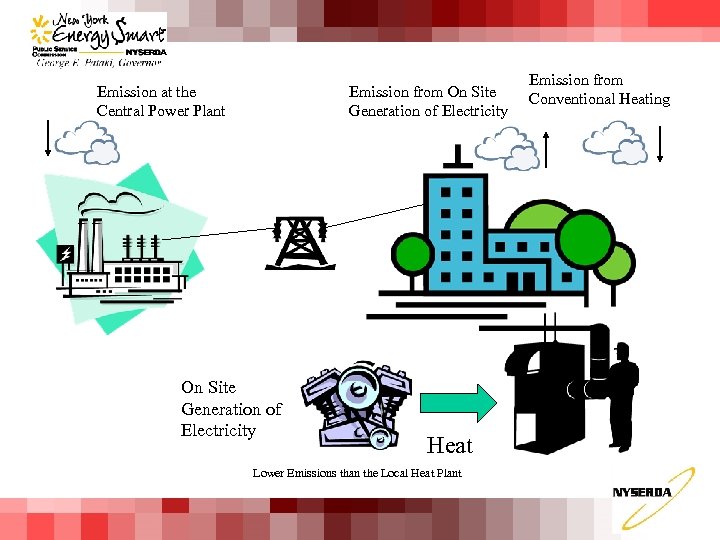

Emission at the Central Power Plant Emission from On Site Generation of Electricity Heat Lower Emissions than the Local Heat Plant Emission from Conventional Heating

Emission at the Central Power Plant Emission from On Site Generation of Electricity Heat Lower Emissions than the Local Heat Plant Emission from Conventional Heating

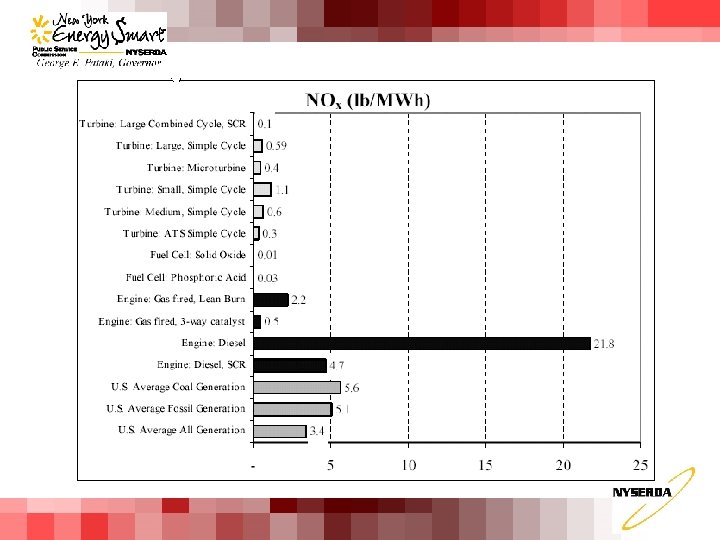

Does CHP Lead to Reduced Emissions? It Depends. Emissions impacts for CHP depend on: (1) the CHP unit emissions, (2) the displaced/avoided grid emissions, (3) the retired/displaced on-site boiler, and (4) avoided T&D losses CHP vs. Conventional Generation emission comparisons can be viewed from three perspectives: Total emissions: The total emissions of CHP vs. Conventional Generation to serve equivalent end-use needs (includes T&D losses). Electric sector emissions: Comparison of the electric side emissions of CHP vs. Central Power Plant (includes T&D losses) Thermal load emissions: Comparison of thermal side of CHP vs. thermal side of Conventional Thermal Generation (i. e. , the old boiler)

Does CHP Lead to Reduced Emissions? It Depends. Emissions impacts for CHP depend on: (1) the CHP unit emissions, (2) the displaced/avoided grid emissions, (3) the retired/displaced on-site boiler, and (4) avoided T&D losses CHP vs. Conventional Generation emission comparisons can be viewed from three perspectives: Total emissions: The total emissions of CHP vs. Conventional Generation to serve equivalent end-use needs (includes T&D losses). Electric sector emissions: Comparison of the electric side emissions of CHP vs. Central Power Plant (includes T&D losses) Thermal load emissions: Comparison of thermal side of CHP vs. thermal side of Conventional Thermal Generation (i. e. , the old boiler)

ERC Definitions per NYCRR 231. 2(b)(14) Emission reduction credit (ERC). Any decrease in emissions of a nonattainment contaminant in tons per year, occurring on or after November 15, 1990: (i) which is surplus, quantifiable, permanent, and enforceable; and (ii) which results from a physical change in, or a change in the method of operation of an emission unit subject to Part 201 of this Title; and (a) is quantified as the difference between prior actual annual emissions or prior allowable annual emissions, whichever is less, and the subsequent maximum annual potential; and (b) is certified in accordance with the provisions of section 231 -2. 6 of this Subpart; or (iii) which results from a physical change in, or a change in the method of operation of an air contamination source not subject to Part 201 of this Title, and is certified in accordance with the provisions of section 231 -2. 6 of this Subpart.

ERC Definitions per NYCRR 231. 2(b)(14) Emission reduction credit (ERC). Any decrease in emissions of a nonattainment contaminant in tons per year, occurring on or after November 15, 1990: (i) which is surplus, quantifiable, permanent, and enforceable; and (ii) which results from a physical change in, or a change in the method of operation of an emission unit subject to Part 201 of this Title; and (a) is quantified as the difference between prior actual annual emissions or prior allowable annual emissions, whichever is less, and the subsequent maximum annual potential; and (b) is certified in accordance with the provisions of section 231 -2. 6 of this Subpart; or (iii) which results from a physical change in, or a change in the method of operation of an air contamination source not subject to Part 201 of this Title, and is certified in accordance with the provisions of section 231 -2. 6 of this Subpart.

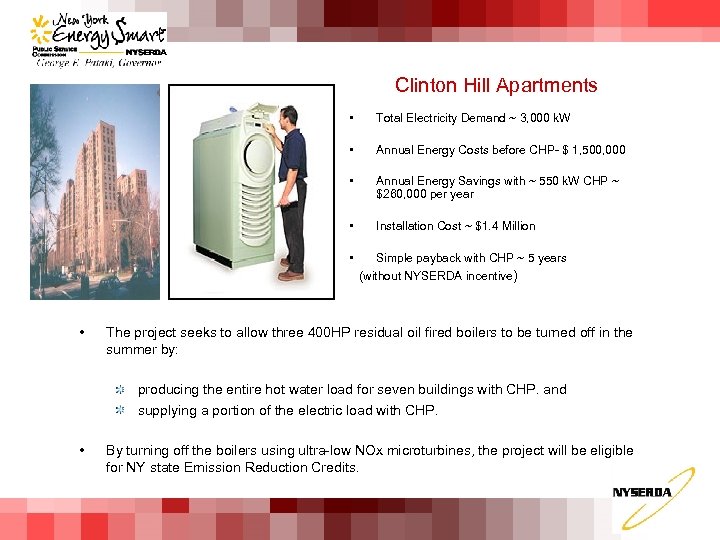

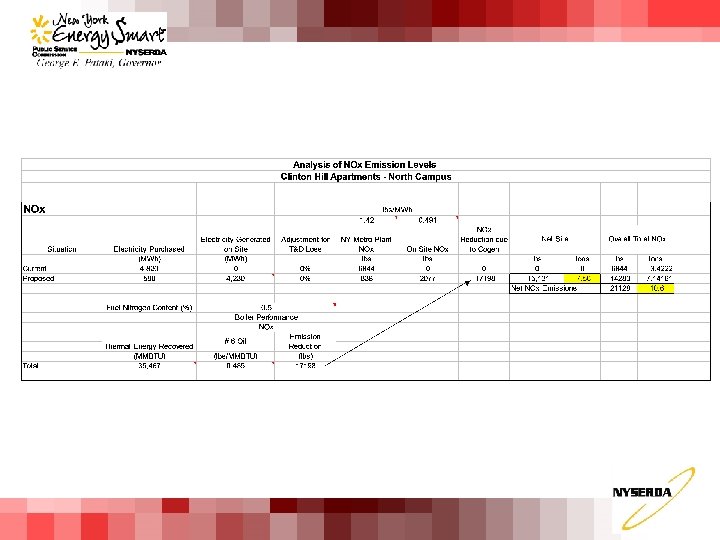

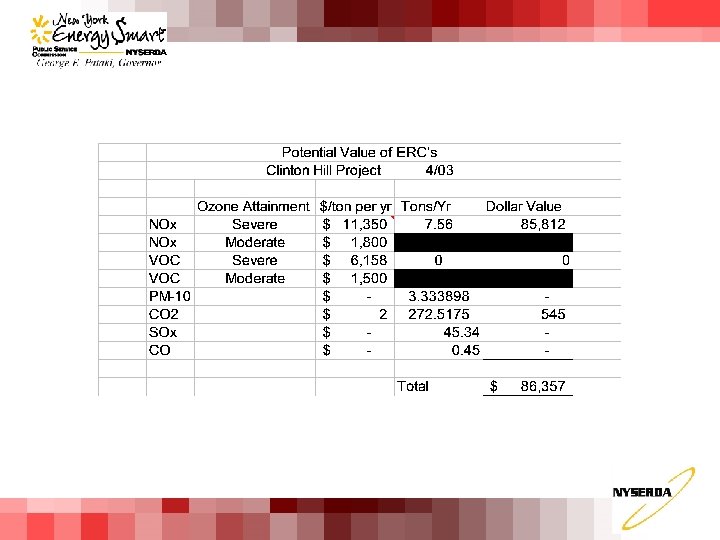

Clinton Hill Apartments • Total Electricity Demand ~ 3, 000 k. W • Annual Energy Costs before CHP- $ 1, 500, 000 • Annual Energy Savings with ~ 550 k. W CHP ~ $260, 000 per year • Installation Cost ~ $1. 4 Million • Simple payback with CHP ~ 5 years (without NYSERDA incentive) • The project seeks to allow three 400 HP residual oil fired boilers to be turned off in the summer by: producing the entire hot water load for seven buildings with CHP. and supplying a portion of the electric load with CHP. • By turning off the boilers using ultra-low NOx microturbines, the project will be eligible for NY state Emission Reduction Credits.

Clinton Hill Apartments • Total Electricity Demand ~ 3, 000 k. W • Annual Energy Costs before CHP- $ 1, 500, 000 • Annual Energy Savings with ~ 550 k. W CHP ~ $260, 000 per year • Installation Cost ~ $1. 4 Million • Simple payback with CHP ~ 5 years (without NYSERDA incentive) • The project seeks to allow three 400 HP residual oil fired boilers to be turned off in the summer by: producing the entire hot water load for seven buildings with CHP. and supplying a portion of the electric load with CHP. • By turning off the boilers using ultra-low NOx microturbines, the project will be eligible for NY state Emission Reduction Credits.

Financing • NYC Economic Development Corp Energy Cost Savings Program (ECSP). • Cash value of Emission Reduction Credits (ERCs). • Business practices – Performance Contracting.

Financing • NYC Economic Development Corp Energy Cost Savings Program (ECSP). • Cash value of Emission Reduction Credits (ERCs). • Business practices – Performance Contracting.

Financing Performance Contracting • Someone else pays for the equipment! • You buy the “output” electricity and heat at a slightly reduced price than from elsewhere. • Performance Contractor takes the financial risk, but reaps the majority of financial reward. • Often, long-term contracts required.

Financing Performance Contracting • Someone else pays for the equipment! • You buy the “output” electricity and heat at a slightly reduced price than from elsewhere. • Performance Contractor takes the financial risk, but reaps the majority of financial reward. • Often, long-term contracts required.

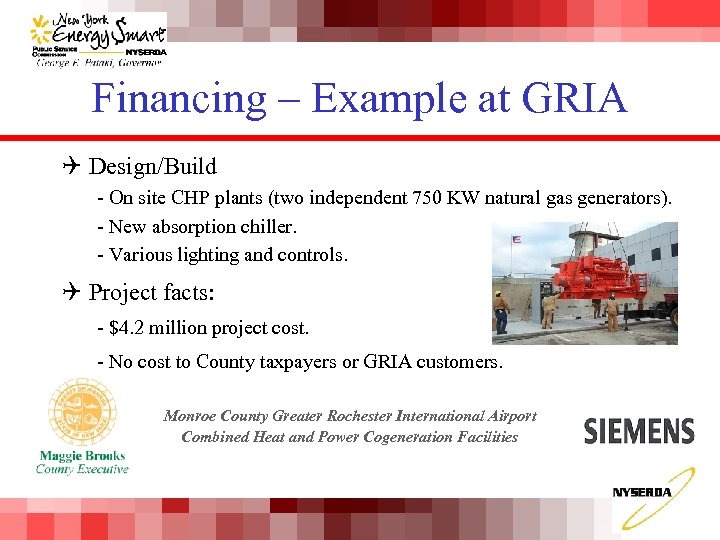

Financing – Example at GRIA Q Design/Build - On site CHP plants (two independent 750 KW natural gas generators). - New absorption chiller. - Various lighting and controls. Q Project facts: - $4. 2 million project cost. - No cost to County taxpayers or GRIA customers. Monroe County Greater Rochester International Airport Combined Heat and Power Cogeneration Facilities

Financing – Example at GRIA Q Design/Build - On site CHP plants (two independent 750 KW natural gas generators). - New absorption chiller. - Various lighting and controls. Q Project facts: - $4. 2 million project cost. - No cost to County taxpayers or GRIA customers. Monroe County Greater Rochester International Airport Combined Heat and Power Cogeneration Facilities

Financing Performance Contracting Posted on: 08/21/2004 Publication date: 08/23/2004 Fitness Facility Uses Cogeneration WALTHAM, Mass. — American. DG has agreed to supply low-cost energy to the Westfield Area YMCA in Westfield, N. J. The facility will receive a substantial portion of its electricity and hot water directly from an on-site, 150 -k. W cogeneration facility operated by American. DG. The system uses natural gasdriven cogeneration modules from Tecogen. Jim Lenox, director of facilities at the Y, stated, “Not having to make any capital equipment expenditure was an important factor in our decision. ”

Financing Performance Contracting Posted on: 08/21/2004 Publication date: 08/23/2004 Fitness Facility Uses Cogeneration WALTHAM, Mass. — American. DG has agreed to supply low-cost energy to the Westfield Area YMCA in Westfield, N. J. The facility will receive a substantial portion of its electricity and hot water directly from an on-site, 150 -k. W cogeneration facility operated by American. DG. The system uses natural gasdriven cogeneration modules from Tecogen. Jim Lenox, director of facilities at the Y, stated, “Not having to make any capital equipment expenditure was an important factor in our decision. ”

Contact Us Dana Levy Joseph Borowiec DLL@nyserda. org (518) 862 -1090 ext. 3377 JCB@nyserda. org (518) 862 -1090 ext. 3381 Mark Gundrum Mike Colgrove MRG@nyserda. org (518) 862 -1090 ext. 3256 MTC@nyserda. org (212) 971 -5342 ext. 3006

Contact Us Dana Levy Joseph Borowiec DLL@nyserda. org (518) 862 -1090 ext. 3377 JCB@nyserda. org (518) 862 -1090 ext. 3381 Mark Gundrum Mike Colgrove MRG@nyserda. org (518) 862 -1090 ext. 3256 MTC@nyserda. org (212) 971 -5342 ext. 3006

www. nyserda. org George E. Pataki Governor Hot Topics • Governor Announces $15 million for Clean Energy Projects Vincent A. De. Iorio, Esq. Chairman Peter R. Smith President Programs • Agricultural • Commercial/Industrial • Communities • Demand Response • Economic Development • Energy & the Environment • Hospitals/Institutions • Municipal • Renewables New York State • Residential Energy Research & Development Authority • Schools 17 Columbia Circle • Small Business Albany, NY 12203 -6399 • State Government Toll-Free: 1 -866 -NYSERDA • Transportation • Other New York City and Buffalo Regional Offices

www. nyserda. org George E. Pataki Governor Hot Topics • Governor Announces $15 million for Clean Energy Projects Vincent A. De. Iorio, Esq. Chairman Peter R. Smith President Programs • Agricultural • Commercial/Industrial • Communities • Demand Response • Economic Development • Energy & the Environment • Hospitals/Institutions • Municipal • Renewables New York State • Residential Energy Research & Development Authority • Schools 17 Columbia Circle • Small Business Albany, NY 12203 -6399 • State Government Toll-Free: 1 -866 -NYSERDA • Transportation • Other New York City and Buffalo Regional Offices