938bcfe59aa08d88ff7e46e13b1546af.ppt

- Количество слайдов: 13

IS CAN Bus – Ci. A WD 103 Update Low Cost, Intrinsically Safe Transducer Bus Enabling Ne. SSI Gen II Rick Ales and Doug Nordstrom Swagelok Company © 2006 Swagelok Company.

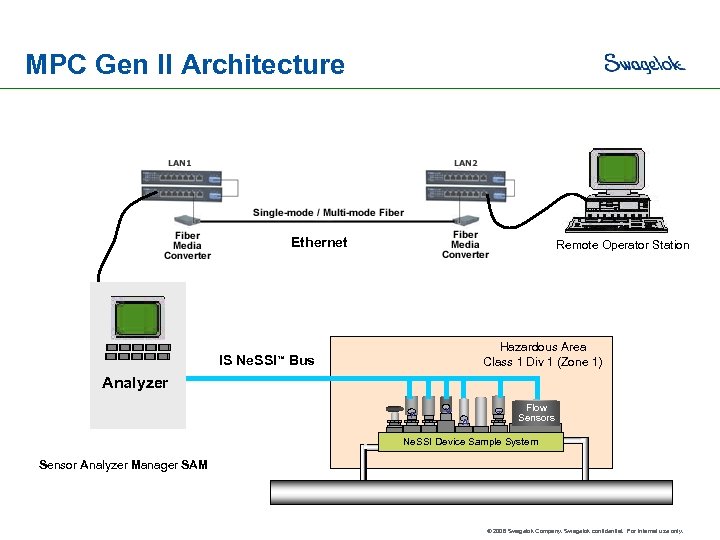

MPC Gen II Architecture Ethernet Remote Operator Station Hazardous Area Class 1 Div 1 (Zone 1) IS Ne. SSI Bus ™ Analyzer P V A T Flow Sensors Ne. SSI Device Sample System Sensor Analyzer Manager SAM © 2006 Swagelok Company. Swagelok confidential. For internal use only.

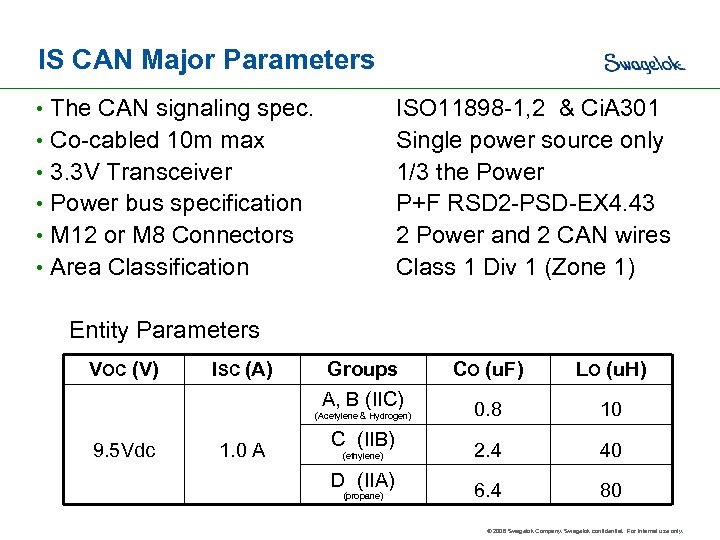

IS CAN Major Parameters • The CAN signaling spec. • Co-cabled 10 m max • 3. 3 V Transceiver • Power bus specification • M 12 or M 8 Connectors • Area Classification ISO 11898 -1, 2 & Ci. A 301 Single power source only 1/3 the Power P+F RSD 2 -PSD-EX 4. 43 2 Power and 2 CAN wires Class 1 Div 1 (Zone 1) Entity Parameters VOC (V) ISC (A) 9. 5 Vdc 1. 0 A Groups CO (u. F) A, B (IIC) 0. 8 (Acetylene & Hydrogen) C (IIB) (ethylene) D (IIA) (propane) LO (u. H) 10 2. 4 40 6. 4 80 © 2006 Swagelok Company. Swagelok confidential. For internal use only.

Ci. A WD 103 Organization • Joshua Pearl • Reiner Zitzmann • Swagelok • ABB • Siemens • Texas Instruments • Pepperl + Fuchs • Turck • Parker Hannifin • Circor IXXAT Co. CAN in Automation Chairman Secretary www. smartshs. org © 2006 Swagelok Company. Swagelok confidential. For internal use only.

CIRCOR Tech Ne. SSi™ Product Development & Market Snapshot Patrick Lowery IFPAC 2007, 1. 29. 07 Complete, Modular, Ready Today www. circortech. com

Progress At present, CIRCOR Tech has built and lab tested several different categories of sample system devices based on the Siemens I 2 C Maxum™ GC Digital Bus Ø § § § § Pressure Sensor Solenoid Pilot Valve Fluid temperature probe Pressure, flow combination sensors 2 nd iteration with IS design circuits are in process for All the above components, plus Multi-variable sensor (Pressure, temp, flow) Low-powered combi-valve for closed loop, IS (Zone 1, Div 1), flow and pressure control Filter monitoring modules Maxum™ is a trademark of Siemens Energy and Automation Complete, Modular, Ready Today www. circortech. com

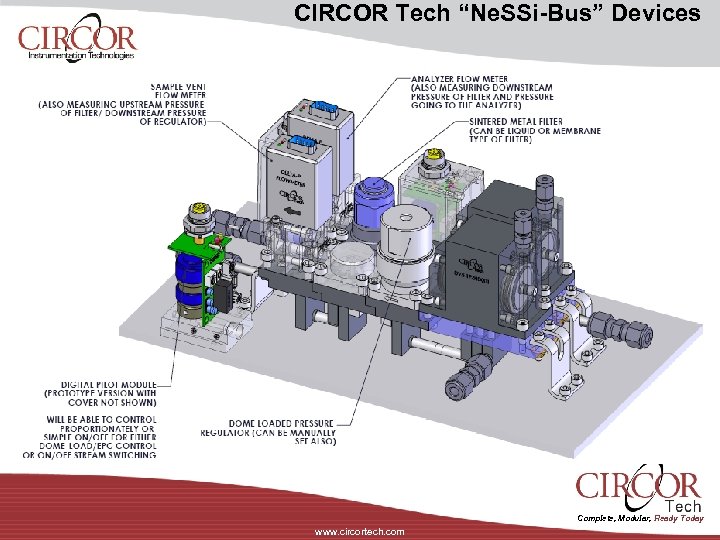

CIRCOR Tech “Ne. SSi-Bus” Devices Complete, Modular, Ready Today www. circortech. com

Progress Ø Ø In addition, preparations are being made to test power supply schemes for low powered CAN Bus as per the Ci. A (CAN in Automation) Intrinsically Safe CAN Bus Working Group Working network of sensors, valves, and control devices will be online in late Feb according to proposed IS power supply and communication scheme CIRCOR Tech Core sensing and control modules will have different bus flavors available according to end user or analyzer OEM preference (I 2 C, CAN Bus, Modbus, RS 485) Will be working with CAN and other PLC and/or hybrid controller companies to bring control solutions for retrofit activity outside of smart GC’s Complete, Modular, Ready Today www. circortech. com

What’s Next? Ø Mainstream customers will not adopt a “discontinuous” technology without: § Having the “whole product concept” fulfilled ü Having the entire core product (s) augmented by EVERYTHING that is needed for the customer to have a compelling reason to buy ü Distributors or sales people skilled in the new technology ü Good warranty, strong company, and strong support ü 2 nd Sources and a Competitive Marketplace § This includes the product (s) along with training, support, manuals, cables, connectors, accessories, additional hardware and software, etc. § Example: One cannot implement an IS CAN Bus solution without a certified IS Power Supply, an IS CAN Bus Isolator Repeater, Special Cabling, Wiring Documentation, and Config. Software Complete, Modular, Ready Today www. circortech. com

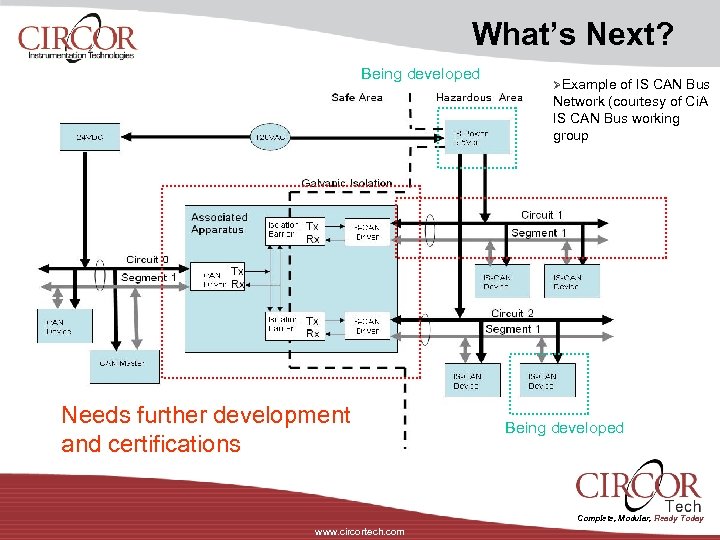

What’s Next? Being developed ØExample of IS CAN Bus Network (courtesy of Ci. A IS CAN Bus working group Needs further development and certifications Being developed Complete, Modular, Ready Today www. circortech. com

What’s Next? Ø What is still needed to fulfill the Whole Product Concept for Digital Bus? § More power supply components § Repeaters, Isolators, and Barriers § Connectors and Cabling § Configuration Management Software § A Standalone SAM (Sensor Actuator Manager) for non-GC analyzer applications with HMI Ø What is needed for overall Ne. SSi system success? § End users must “change behavior” in order to adopt a discontinuous technology innovation § At a certain point, innovation must cease to allow customer to digest what is currently being offered. Otherwise, they are waiting on the next revision Complete, Modular, Ready Today www. circortech. com

What’s Next? Ø Examples of what to expect § Digital bus system maintenance will require software and hardware interaction between analyzer and sample system § Could get stuck in information overload mode if streaming data is provided rather than mission critical decision making information § Sample system purge systems go away, potentially exposing the digital devices to concentrated chemical vapors continuously § Compromises may have to be made to make digital bus sensors cost effective in these extreme environments ü ü ü IP 65 ratings a necessity, corrosive resistance a must, 85 deg C operation Hot Swap, Plug and play, C 1 D 1, Zone 1 (possibly Zone 0) certifications become necessary Digital devices must be field addressable rather than “software addressable” which means that windows, access ports, must be available Some sort of visual indication of system health would be desirable rather than going back and forth between SHS and analyzer CAN IT ALL BE ACHIEVED COST EFFECTIVELY? ? ? Complete, Modular, Ready Today www. circortech. com

What’s Next? Ø Examples of what to expect, cont. § Energy budgets will become important due to the relatively high cost § § per milliwatt of special IS power supplies Terms like “average cost per node”, and “average power per node”, will used to as a technical selling advantages for smart digitally controlled sample systems Multi-function, multi-variable devices will be leveraged to gather multiple pieces of information with a single bus node, minimizing connection cost Digital bus node functionality and failure modes (FMEA) will have to be taken into account when performing system design and safety reviews of smart sample systems Will integrators adopt this responsibility quickly? Complete, Modular, Ready Today www. circortech. com

938bcfe59aa08d88ff7e46e13b1546af.ppt