817acab58c3a2ff60b3f0e452c983e42.ppt

- Количество слайдов: 20

IRRIGATION SYSTEM ME 414: Team 4 Chris Cook Matt Griffey Jason Colgan Breanne Walters Jeremy Johnson

IRRIGATION SYSTEM ME 414: Team 4 Chris Cook Matt Griffey Jason Colgan Breanne Walters Jeremy Johnson

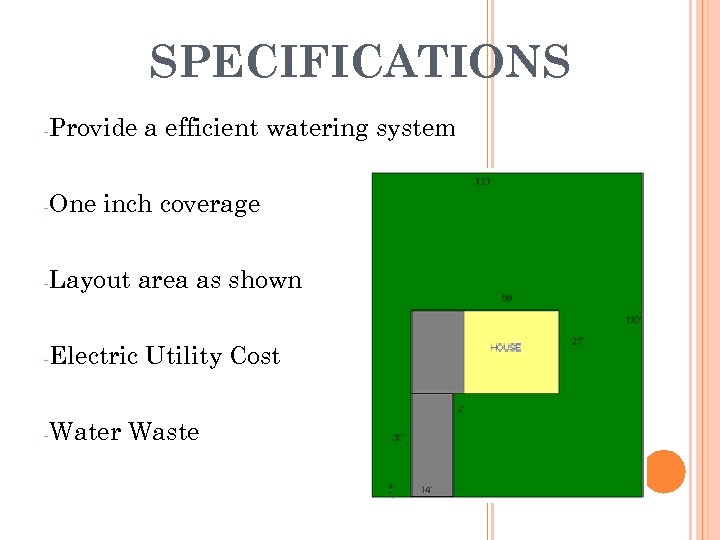

SPECIFICATIONS -Provide -One a efficient watering system inch coverage -Layout area as shown -Electric -Water Utility Cost Waste

SPECIFICATIONS -Provide -One a efficient watering system inch coverage -Layout area as shown -Electric -Water Utility Cost Waste

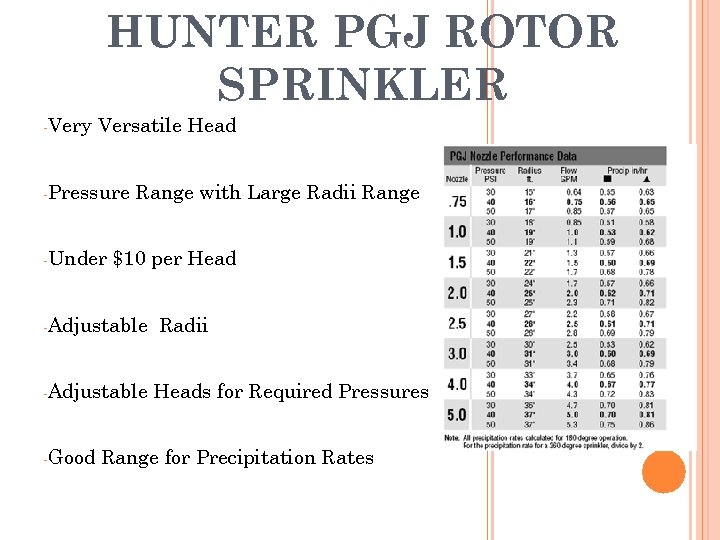

HUNTER PGJ ROTOR SPRINKLER -Very Versatile Head -Pressure -Under Range with Large Radii Range $10 per Head -Adjustable -Good Radii Heads for Required Pressures Range for Precipitation Rates

HUNTER PGJ ROTOR SPRINKLER -Very Versatile Head -Pressure -Under Range with Large Radii Range $10 per Head -Adjustable -Good Radii Heads for Required Pressures Range for Precipitation Rates

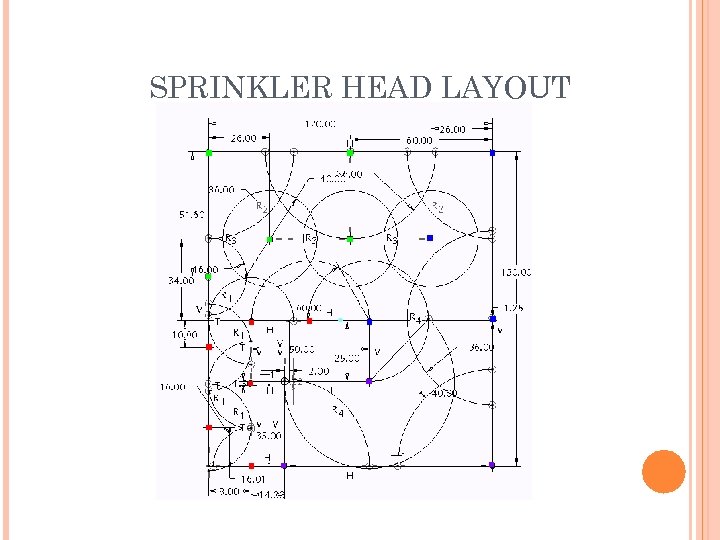

SPRINKLER HEAD LAYOUT

SPRINKLER HEAD LAYOUT

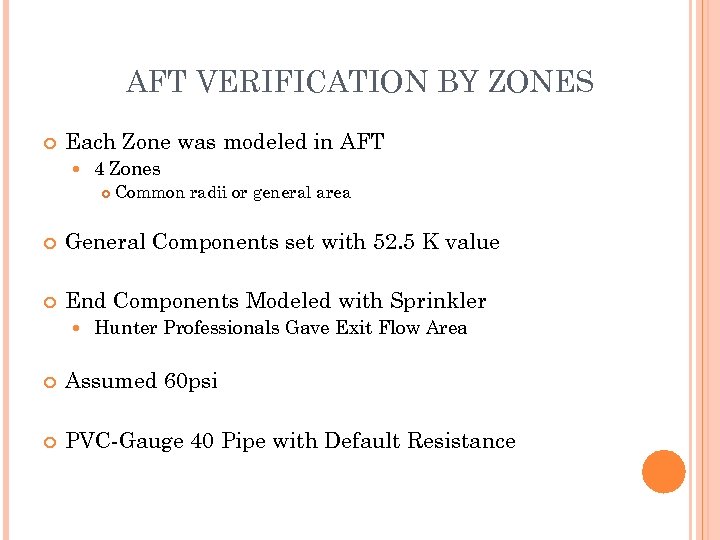

AFT VERIFICATION BY ZONES Each Zone was modeled in AFT 4 Zones Common radii or general area General Components set with 52. 5 K value End Components Modeled with Sprinkler Hunter Professionals Gave Exit Flow Area Assumed 60 psi PVC-Gauge 40 Pipe with Default Resistance

AFT VERIFICATION BY ZONES Each Zone was modeled in AFT 4 Zones Common radii or general area General Components set with 52. 5 K value End Components Modeled with Sprinkler Hunter Professionals Gave Exit Flow Area Assumed 60 psi PVC-Gauge 40 Pipe with Default Resistance

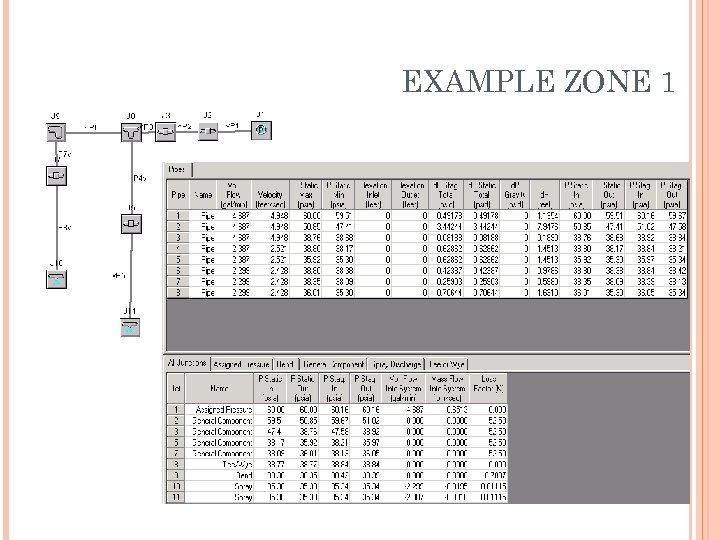

EXAMPLE ZONE 1

EXAMPLE ZONE 1

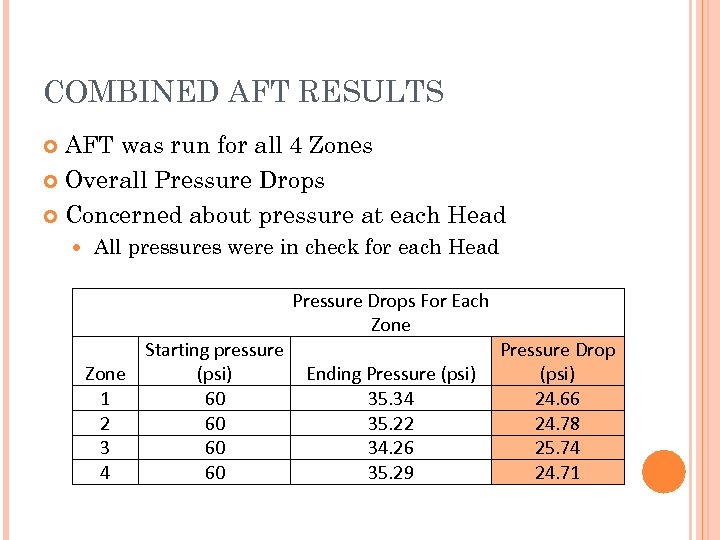

COMBINED AFT RESULTS AFT was run for all 4 Zones Overall Pressure Drops Concerned about pressure at each Head All pressures were in check for each Head Pressure Drops For Each Zone Starting pressure Zone (psi) Ending Pressure (psi) 1 60 35. 34 2 60 35. 22 3 60 34. 26 4 60 35. 29 Pressure Drop (psi) 24. 66 24. 78 25. 74 24. 71

COMBINED AFT RESULTS AFT was run for all 4 Zones Overall Pressure Drops Concerned about pressure at each Head All pressures were in check for each Head Pressure Drops For Each Zone Starting pressure Zone (psi) Ending Pressure (psi) 1 60 35. 34 2 60 35. 22 3 60 34. 26 4 60 35. 29 Pressure Drop (psi) 24. 66 24. 78 25. 74 24. 71

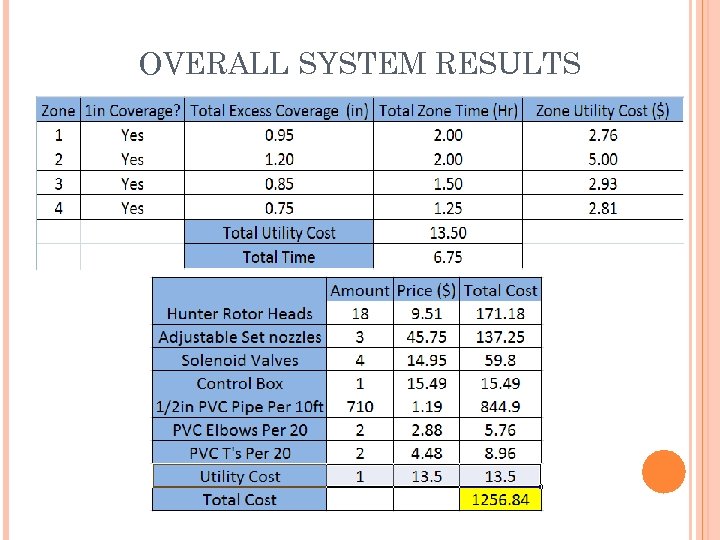

OVERALL SYSTEM RESULTS

OVERALL SYSTEM RESULTS

QUESTIONS

QUESTIONS

ME 414: PROJECT 2: TUBE AND SHELL HEAT EXCHANGER DESIGN Jason Colgan, Chris Cook, Matt Griffey, Jeremy Johnson, Breanne Walters

ME 414: PROJECT 2: TUBE AND SHELL HEAT EXCHANGER DESIGN Jason Colgan, Chris Cook, Matt Griffey, Jeremy Johnson, Breanne Walters

DESIGN PARAMETERS Remove 1. 2 Megawatts of power Process Water Inlet 90ºC Outlet 40ºC City water Inlet during summer 25ºC Optimal Length 4 -6 meters

DESIGN PARAMETERS Remove 1. 2 Megawatts of power Process Water Inlet 90ºC Outlet 40ºC City water Inlet during summer 25ºC Optimal Length 4 -6 meters

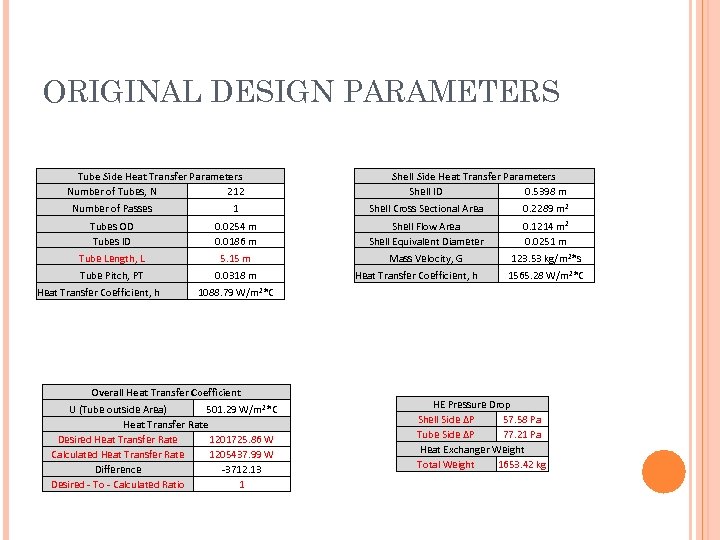

ORIGINAL DESIGN PARAMETERS Tube Side Heat Transfer Parameters Number of Tubes, N 212 Shell Side Heat Transfer Parameters Shell ID 0. 5398 m Number of Passes 1 Shell Cross Sectional Area 0. 2289 m 2 Tubes OD Tubes ID 0. 0254 m 0. 0186 m Shell Flow Area Shell Equivalent Diameter 0. 1214 m 2 0. 0251 m Tube Length, L 5. 15 m Mass Velocity, G 123. 53 kg/m 2*s Tube Pitch, PT 0. 0318 m Heat Transfer Coefficient, h 1565. 28 W/m 2*C 1088. 79 W/m 2*C Overall Heat Transfer Coefficient U (Tube outside Area) 501. 29 W/m 2*C Heat Transfer Rate Desired Heat Transfer Rate 1201725. 86 W Calculated Heat Transfer Rate 1205437. 99 W Difference -3712. 13 Desired - To - Calculated Ratio 1 HE Pressure Drop Shell Side ∆P 57. 58 Pa Tube Side ∆P 77. 21 Pa Heat Exchanger Weight Total Weight 1653. 42 kg

ORIGINAL DESIGN PARAMETERS Tube Side Heat Transfer Parameters Number of Tubes, N 212 Shell Side Heat Transfer Parameters Shell ID 0. 5398 m Number of Passes 1 Shell Cross Sectional Area 0. 2289 m 2 Tubes OD Tubes ID 0. 0254 m 0. 0186 m Shell Flow Area Shell Equivalent Diameter 0. 1214 m 2 0. 0251 m Tube Length, L 5. 15 m Mass Velocity, G 123. 53 kg/m 2*s Tube Pitch, PT 0. 0318 m Heat Transfer Coefficient, h 1565. 28 W/m 2*C 1088. 79 W/m 2*C Overall Heat Transfer Coefficient U (Tube outside Area) 501. 29 W/m 2*C Heat Transfer Rate Desired Heat Transfer Rate 1201725. 86 W Calculated Heat Transfer Rate 1205437. 99 W Difference -3712. 13 Desired - To - Calculated Ratio 1 HE Pressure Drop Shell Side ∆P 57. 58 Pa Tube Side ∆P 77. 21 Pa Heat Exchanger Weight Total Weight 1653. 42 kg

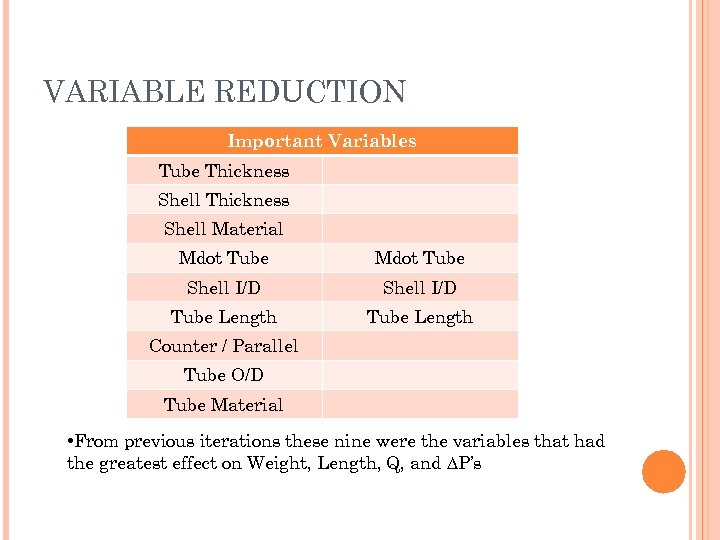

VARIABLE REDUCTION Important Variables Tube Thickness Shell Material Mdot Tube Shell I/D Tube Length Counter / Parallel Tube O/D Tube Material • From previous iterations these nine were the variables that had the greatest effect on Weight, Length, Q, and ∆P’s

VARIABLE REDUCTION Important Variables Tube Thickness Shell Material Mdot Tube Shell I/D Tube Length Counter / Parallel Tube O/D Tube Material • From previous iterations these nine were the variables that had the greatest effect on Weight, Length, Q, and ∆P’s

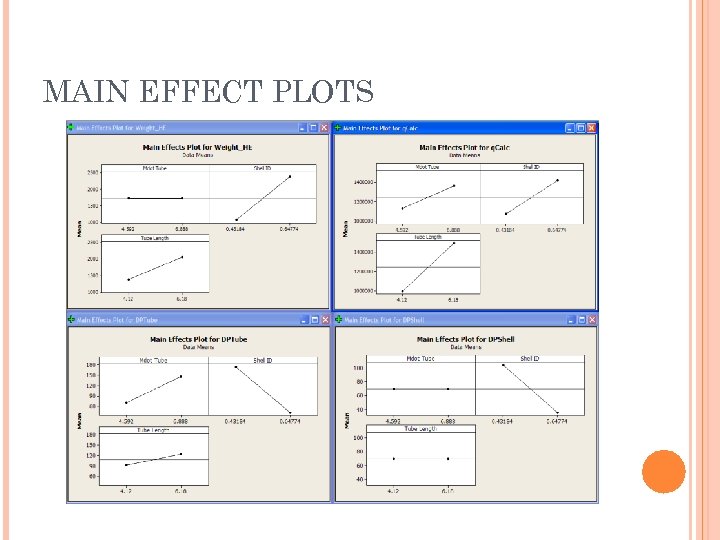

MAIN EFFECT PLOTS

MAIN EFFECT PLOTS

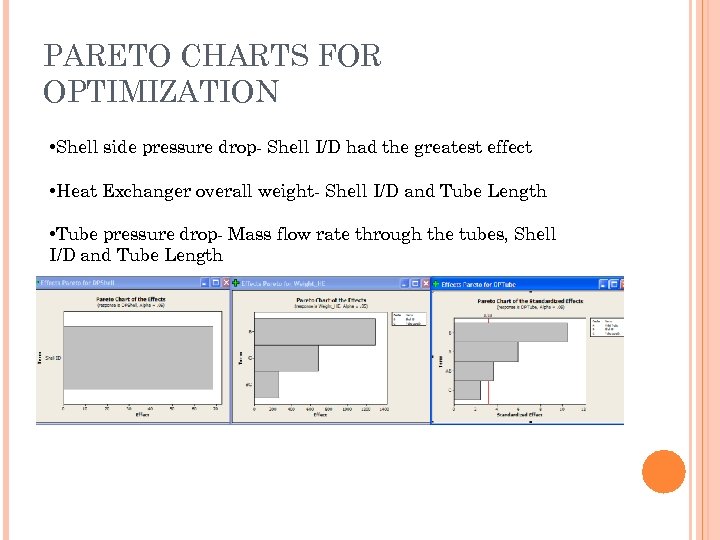

PARETO CHARTS FOR OPTIMIZATION • Shell side pressure drop- Shell I/D had the greatest effect • Heat Exchanger overall weight- Shell I/D and Tube Length • Tube pressure drop- Mass flow rate through the tubes, Shell I/D and Tube Length

PARETO CHARTS FOR OPTIMIZATION • Shell side pressure drop- Shell I/D had the greatest effect • Heat Exchanger overall weight- Shell I/D and Tube Length • Tube pressure drop- Mass flow rate through the tubes, Shell I/D and Tube Length

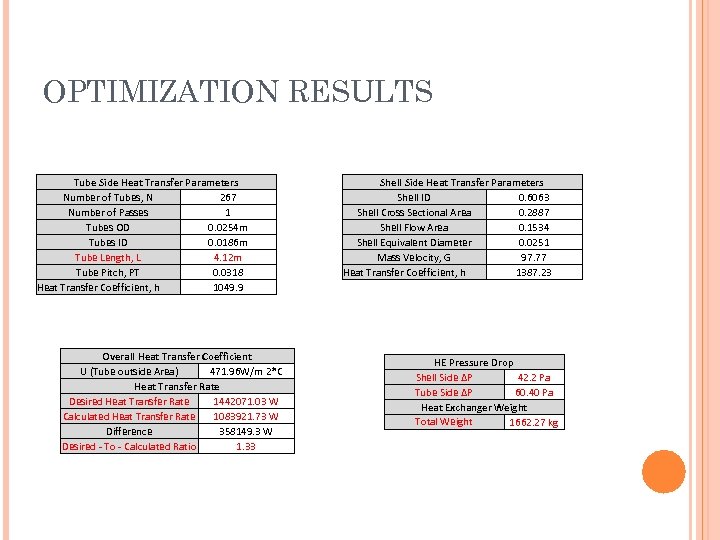

OPTIMIZATION RESULTS Tube Side Heat Transfer Parameters Number of Tubes, N 267 Number of Passes 1 Tubes OD 0. 0254 m Tubes ID 0. 0186 m Tube Length, L 4. 12 m Tube Pitch, PT 0. 0318 Heat Transfer Coefficient, h 1049. 9 Overall Heat Transfer Coefficient U (Tube outside Area) 471. 96 W/m 2*C Heat Transfer Rate Desired Heat Transfer Rate 1442071. 03 W Calculated Heat Transfer Rate 1083921. 73 W Difference 358149. 3 W Desired - To - Calculated Ratio 1. 33 Shell Side Heat Transfer Parameters Shell ID 0. 6063 Shell Cross Sectional Area 0. 2887 Shell Flow Area 0. 1534 Shell Equivalent Diameter 0. 0251 Mass Velocity, G 97. 77 Heat Transfer Coefficient, h 1387. 23 HE Pressure Drop Shell Side ∆P 42. 2 Pa Tube Side ∆P 60. 40 Pa Heat Exchanger Weight Total Weight 1662. 27 kg

OPTIMIZATION RESULTS Tube Side Heat Transfer Parameters Number of Tubes, N 267 Number of Passes 1 Tubes OD 0. 0254 m Tubes ID 0. 0186 m Tube Length, L 4. 12 m Tube Pitch, PT 0. 0318 Heat Transfer Coefficient, h 1049. 9 Overall Heat Transfer Coefficient U (Tube outside Area) 471. 96 W/m 2*C Heat Transfer Rate Desired Heat Transfer Rate 1442071. 03 W Calculated Heat Transfer Rate 1083921. 73 W Difference 358149. 3 W Desired - To - Calculated Ratio 1. 33 Shell Side Heat Transfer Parameters Shell ID 0. 6063 Shell Cross Sectional Area 0. 2887 Shell Flow Area 0. 1534 Shell Equivalent Diameter 0. 0251 Mass Velocity, G 97. 77 Heat Transfer Coefficient, h 1387. 23 HE Pressure Drop Shell Side ∆P 42. 2 Pa Tube Side ∆P 60. 40 Pa Heat Exchanger Weight Total Weight 1662. 27 kg

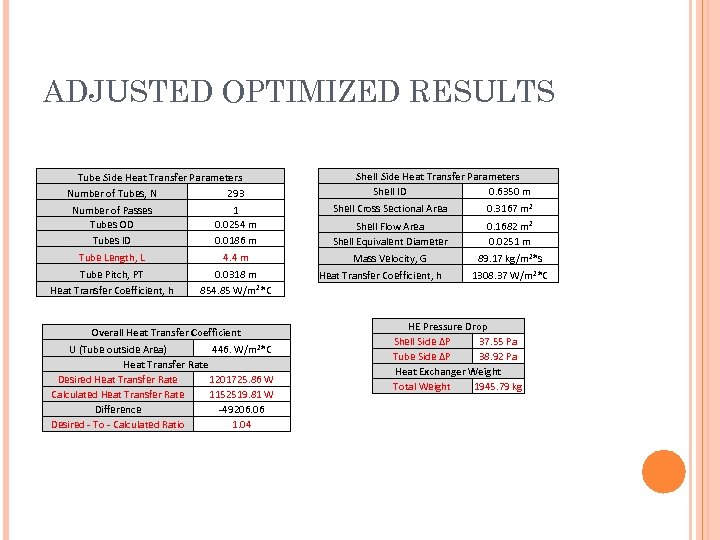

ADJUSTED OPTIMIZED RESULTS Tube Side Heat Transfer Parameters Number of Tubes, N 293 Shell Side Heat Transfer Parameters Shell ID 0. 6350 m Number of Passes Tubes OD Tubes ID 1 0. 0254 m 0. 0186 m Shell Cross Sectional Area 0. 3167 m 2 Shell Flow Area Shell Equivalent Diameter 0. 1682 m 2 0. 0251 m Tube Length, L 4. 4 m Mass Velocity, G 89. 17 kg/m 2*s Tube Pitch, PT Heat Transfer Coefficient, h 0. 0318 m 854. 85 W/m 2*C Overall Heat Transfer Coefficient U (Tube outside Area) 446. W/m 2*C Heat Transfer Rate Desired Heat Transfer Rate 1201725. 86 W Calculated Heat Transfer Rate 1152519. 81 W Difference -49206. 06 Desired - To - Calculated Ratio 1. 04 Heat Transfer Coefficient, h 1308. 37 W/m 2*C HE Pressure Drop Shell Side ∆P 37. 55 Pa Tube Side ∆P 38. 92 Pa Heat Exchanger Weight Total Weight 1945. 79 kg

ADJUSTED OPTIMIZED RESULTS Tube Side Heat Transfer Parameters Number of Tubes, N 293 Shell Side Heat Transfer Parameters Shell ID 0. 6350 m Number of Passes Tubes OD Tubes ID 1 0. 0254 m 0. 0186 m Shell Cross Sectional Area 0. 3167 m 2 Shell Flow Area Shell Equivalent Diameter 0. 1682 m 2 0. 0251 m Tube Length, L 4. 4 m Mass Velocity, G 89. 17 kg/m 2*s Tube Pitch, PT Heat Transfer Coefficient, h 0. 0318 m 854. 85 W/m 2*C Overall Heat Transfer Coefficient U (Tube outside Area) 446. W/m 2*C Heat Transfer Rate Desired Heat Transfer Rate 1201725. 86 W Calculated Heat Transfer Rate 1152519. 81 W Difference -49206. 06 Desired - To - Calculated Ratio 1. 04 Heat Transfer Coefficient, h 1308. 37 W/m 2*C HE Pressure Drop Shell Side ∆P 37. 55 Pa Tube Side ∆P 38. 92 Pa Heat Exchanger Weight Total Weight 1945. 79 kg

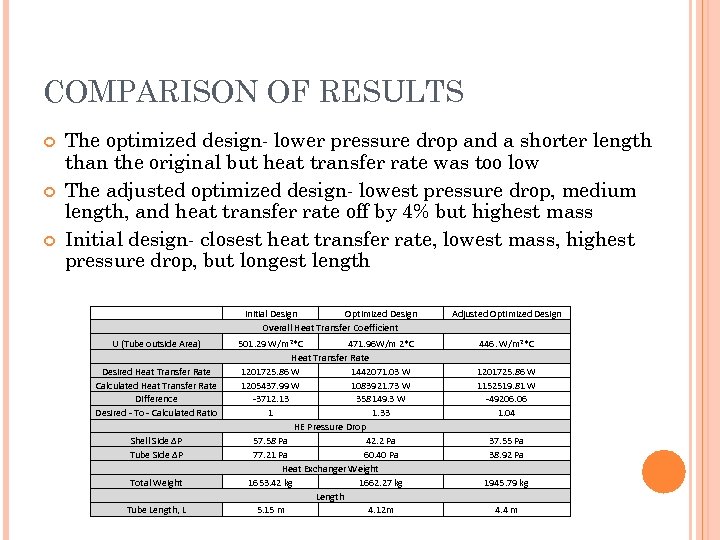

COMPARISON OF RESULTS The optimized design- lower pressure drop and a shorter length than the original but heat transfer rate was too low The adjusted optimized design- lowest pressure drop, medium length, and heat transfer rate off by 4% but highest mass Initial design- closest heat transfer rate, lowest mass, highest pressure drop, but longest length U (Tube outside Area) Desired Heat Transfer Rate Calculated Heat Transfer Rate Difference Desired - To - Calculated Ratio Shell Side ∆P Tube Side ∆P Total Weight Tube Length, L Optimized Design Initial Design Overall Heat Transfer Coefficient 501. 29 W/m 2*C 471. 96 W/m 2*C Heat Transfer Rate 1201725. 86 W 1442071. 03 W 1205437. 99 W 1083921. 73 W -3712. 13 358149. 3 W 1 1. 33 HE Pressure Drop 57. 58 Pa 42. 2 Pa 77. 21 Pa 60. 40 Pa Heat Exchanger Weight 1653. 42 kg 1662. 27 kg Length 5. 15 m 4. 12 m Adjusted Optimized Design 446. W/m 2*C 1201725. 86 W 1152519. 81 W -49206. 06 1. 04 37. 55 Pa 38. 92 Pa 1945. 79 kg 4. 4 m

COMPARISON OF RESULTS The optimized design- lower pressure drop and a shorter length than the original but heat transfer rate was too low The adjusted optimized design- lowest pressure drop, medium length, and heat transfer rate off by 4% but highest mass Initial design- closest heat transfer rate, lowest mass, highest pressure drop, but longest length U (Tube outside Area) Desired Heat Transfer Rate Calculated Heat Transfer Rate Difference Desired - To - Calculated Ratio Shell Side ∆P Tube Side ∆P Total Weight Tube Length, L Optimized Design Initial Design Overall Heat Transfer Coefficient 501. 29 W/m 2*C 471. 96 W/m 2*C Heat Transfer Rate 1201725. 86 W 1442071. 03 W 1205437. 99 W 1083921. 73 W -3712. 13 358149. 3 W 1 1. 33 HE Pressure Drop 57. 58 Pa 42. 2 Pa 77. 21 Pa 60. 40 Pa Heat Exchanger Weight 1653. 42 kg 1662. 27 kg Length 5. 15 m 4. 12 m Adjusted Optimized Design 446. W/m 2*C 1201725. 86 W 1152519. 81 W -49206. 06 1. 04 37. 55 Pa 38. 92 Pa 1945. 79 kg 4. 4 m

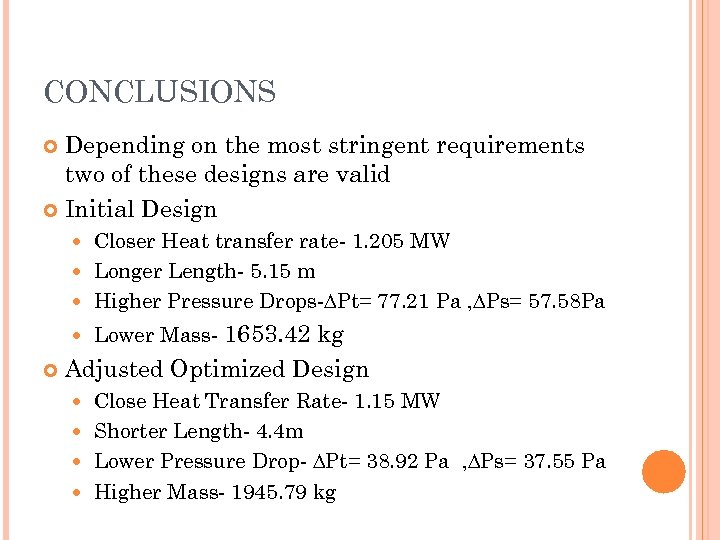

CONCLUSIONS Depending on the most stringent requirements two of these designs are valid Initial Design Closer Heat transfer rate- 1. 205 MW Longer Length- 5. 15 m Higher Pressure Drops-∆Pt= 77. 21 Pa , ∆Ps= 57. 58 Pa Lower Mass- 1653. 42 kg Adjusted Optimized Design Close Heat Transfer Rate- 1. 15 MW Shorter Length- 4. 4 m Lower Pressure Drop- ∆Pt= 38. 92 Pa , ∆Ps= 37. 55 Pa Higher Mass- 1945. 79 kg

CONCLUSIONS Depending on the most stringent requirements two of these designs are valid Initial Design Closer Heat transfer rate- 1. 205 MW Longer Length- 5. 15 m Higher Pressure Drops-∆Pt= 77. 21 Pa , ∆Ps= 57. 58 Pa Lower Mass- 1653. 42 kg Adjusted Optimized Design Close Heat Transfer Rate- 1. 15 MW Shorter Length- 4. 4 m Lower Pressure Drop- ∆Pt= 38. 92 Pa , ∆Ps= 37. 55 Pa Higher Mass- 1945. 79 kg

QUESTIONS ?

QUESTIONS ?