e20428b1105aded7b1bc1c04f7543da9.ppt

- Количество слайдов: 27

IR&D Studies of Light Weight Ablator for Future Reentry Capsule Heatshield IHI AEROSPACE Co. , Ltd. Kenichi HIRAI 2012. 6. 21 JAXA Yuichi ISHIDA, Toshio OGASAWARA, Takuya AOKI, Tetsuya YAMADA, Kazuhisa FUJITA, Toshiyuki SUZUKI

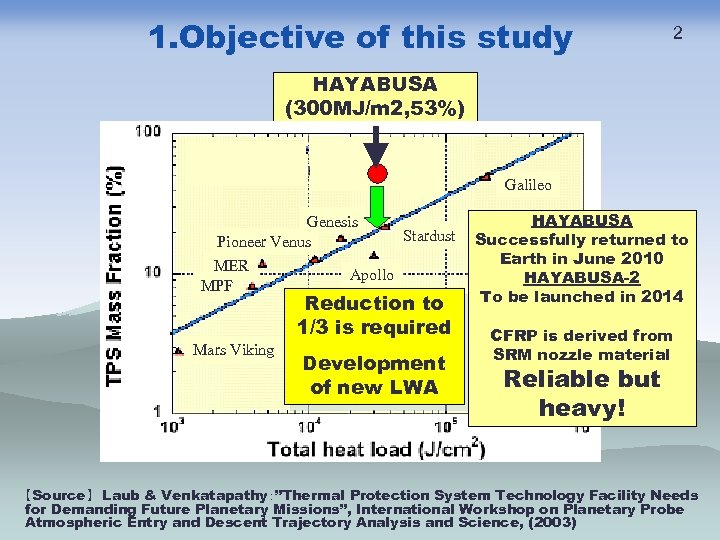

1. Objective of this study 2 HAYABUSA (300 MJ/m 2, 53%) Galileo Genesis Stardust Pioneer Venus MER Apollo MPF Reduction to 1/3 is required Mars Viking Development of new LWA HAYABUSA Successfully returned to Earth in June 2010 HAYABUSA-2 To be launched in 2014 CFRP is derived from SRM nozzle material Reliable but heavy! 【Source】 Laub & Venkatapathy:”Thermal Protection System Technology Facility Needs for Demanding Future Planetary Missions”, International Workshop on Planetary Probe Atmospheric Entry and Descent Trajectory Analysis and Science, (2003)

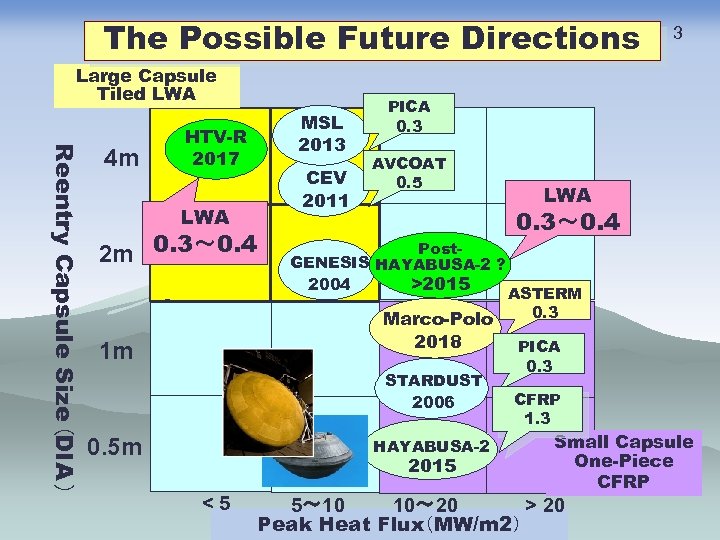

The Possible Future Directions Large Capsule Tiled LWA Reentry Capsule Size (DIA ) 4 m HTV-R 2017 LWA 2 m 0. 3~ 0. 4 MSL 2013 CEV 2011 3 PICA 0. 3 AVCOAT 0. 5 Post. GENESIS HAYABUSA-2 ? 2004 >2015 LWA 0. 3~ 0. 4 ASTERM 0. 3 Marco-Polo 2018 1 m STARDUST 2006 0. 5 m HAYABUSA-2 2015 <5 PICA 0. 3 CFRP 1. 3 Small Capsule One-Piece CFRP 5~ 10 10~ 20 > 20 Peak Heat Flux(MW/m 2)

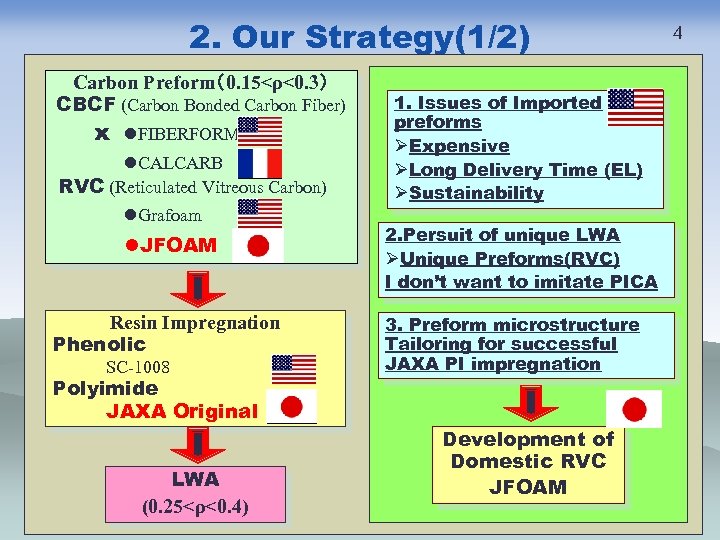

2. Our Strategy(1/2) Carbon Preform(0. 15<ρ<0. 3) CBCF (Carbon Bonded Carbon Fiber) x l. FIBERFORM l. CALCARB RVC (Reticulated Vitreous Carbon) l. Grafoam l. JFOAM Resin Impregnation Phenolic SC-1008 Polyimide JAXA Original LWA (0. 25<ρ<0. 4) 1. Issues of Imported preforms ØExpensive ØLong Delivery Time (EL) ØSustainability 2. Persuit of unique LWA ØUnique Preforms(RVC) I don’t want to imitate PICA 3. Preform microstructure Tailoring for successful JAXA PI impregnation Development of Domestic RVC JFOAM 4

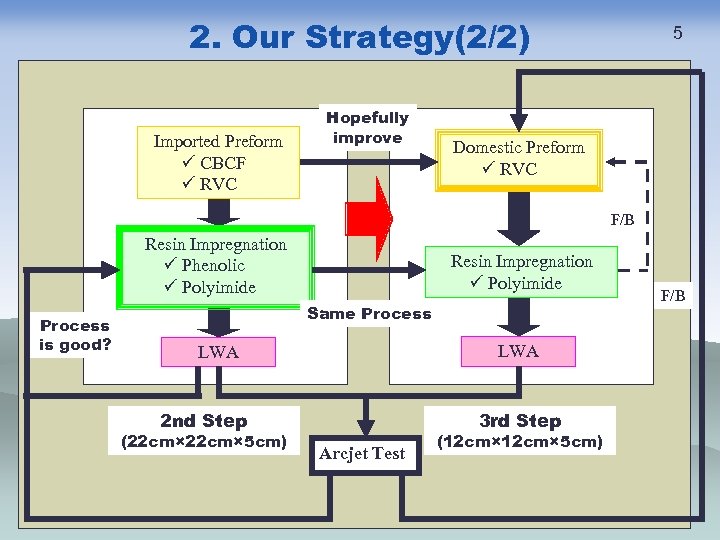

2. Our Strategy(2/2) Imported Preform ü CBCF ü RVC Hopefully improve 5 Domestic Preform ü RVC F/B Resin Impregnation ü Phenolic ü Polyimide Process is good? Resin Impregnation ü Polyimide Same Process LWA 2 nd Step (22 cm× 5 cm) 3 rd Step Arcjet Test (12 cm× 5 cm) F/B

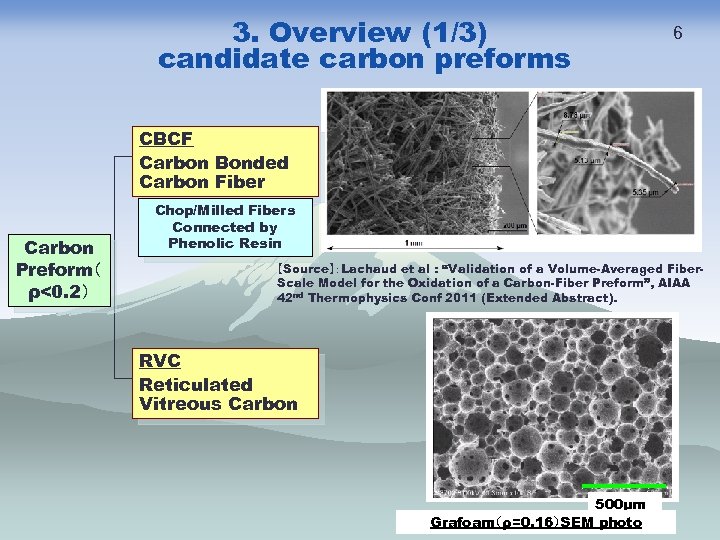

3. Overview (1/3) candidate carbon preforms 6 CBCF Carbon Bonded Carbon Fiber Carbon Preform( ρ<0. 2) Chop/Milled Fibers Connected by Phenolic Resin 【Source】:Lachaud et al : “Validation of a Volume-Averaged Fiber. Scale Model for the Oxidation of a Carbon-Fiber Preform”, AIAA 42 nd Thermophysics Conf 2011 (Extended Abstract). RVC Reticulated Vitreous Carbon 500μm Grafoam(ρ=0. 16)SEM photo

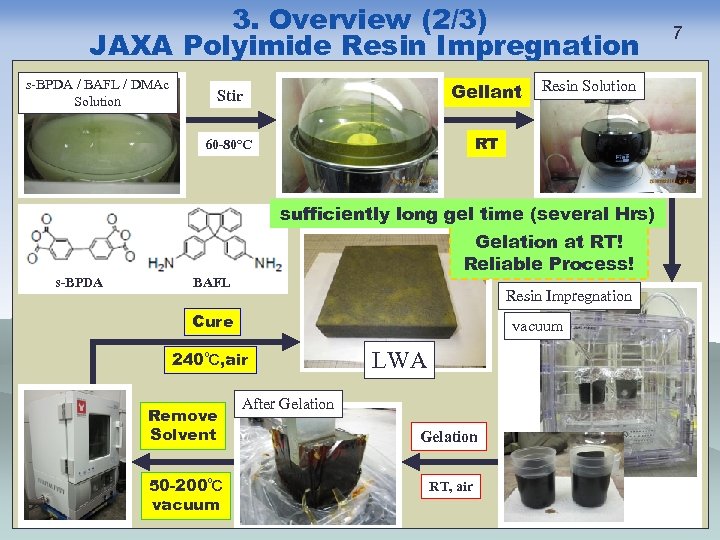

3. Overview (2/3) JAXA Polyimide Resin Impregnation s-BPDA / BAFL / DMAc Solution Stir Gellant 60 -80℃ Resin Solution RT sufficiently long gel time (several Hrs) s-BPDA Gelation at RT! Reliable Process! BAFL Resin Impregnation Cure vacuum 240℃, air Remove Solvent 50 -200℃ vacuum LWA After Gelation RT, air 7

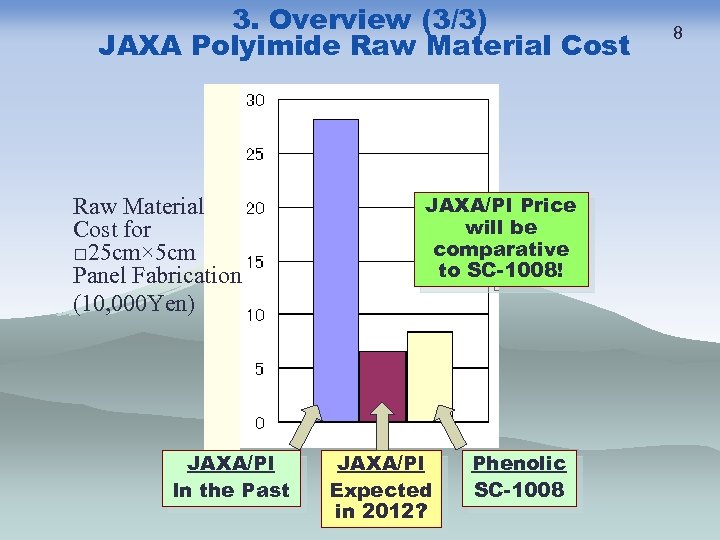

3. Overview (3/3) JAXA Polyimide Raw Material Cost for □ 25 cm× 5 cm Panel Fabrication (10, 000 Yen) JAXA/PI In the Past JAXA/PI Price will be comparative to SC-1008! JAXA/PI Expected in 2012? Phenolic SC-1008 8

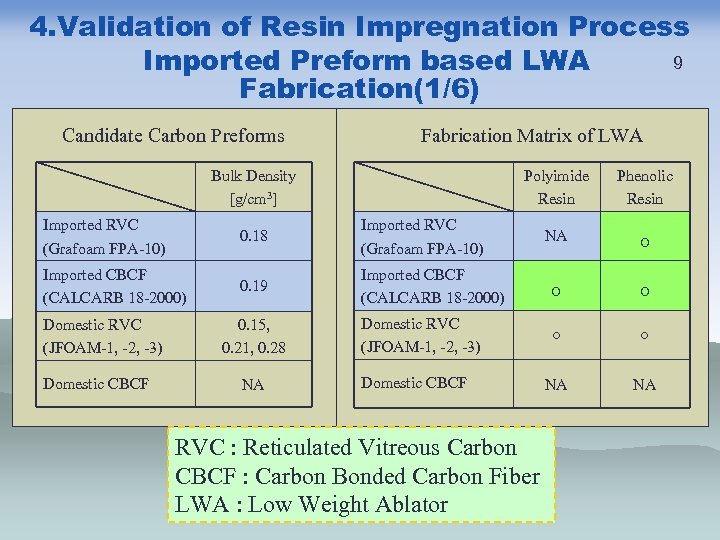

4. Validation of Resin Impregnation Process 9 Imported Preform based LWA Fabrication(1/6) Candidate Carbon Preforms Fabrication Matrix of LWA Bulk Density [g/cm 3] Polyimide Resin Phenolic Resin NA ○ Imported RVC (Grafoam FPA-10) 0. 18 Imported RVC (Grafoam FPA-10) Imported CBCF (CALCARB 18 -2000) 0. 19 Imported CBCF (CALCARB 18 -2000) ○ ○ Domestic RVC (JFOAM-1, -2, -3) ○ ○ NA NA Domestic RVC (JFOAM-1, -2, -3) Domestic CBCF 0. 15, 0. 21, 0. 28 NA Domestic CBCF RVC : Reticulated Vitreous Carbon CBCF : Carbon Bonded Carbon Fiber LWA : Low Weight Ablator

4. Validation of Resin Impregnation Process Imported Preform based LWA 10 Fabrication(2/6) CBCF/Preform Size : 22 cm× 5 cm Weight : 473. 4 g Bulk Density : 0. 196 g/cm 3 CBCF/PI LWA Size : 21. 98× 21. 99× 4. 65 cm Weight : 799. 7 g Bulk Density : 0. 356 g/cm 3

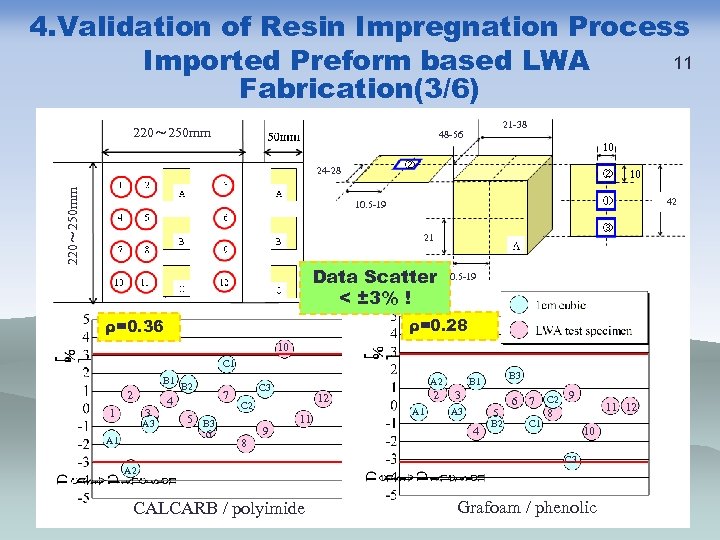

4. Validation of Resin Impregnation Process 11 Imported Preform based LWA Fabrication(3/6) 220~ 250 mm 21 -38 48 -56 220~ 250 mm 24 -28 42 10. 5 -19 21 Data Scatter < ± 3% ! 10. 5 -19 ρ=0. 28 ρ=0. 36 10 C 1 B 1 2 1 3 A 1 B 2 4 5 B 3 6 7 A 2 C 3 8 9 2 12 C 2 11 A 2 CALCARB / polyimide A 1 B 3 B 1 3 A 3 5 4 B 2 6 7 C 1 C 2 9 11 12 8 10 C 3 Grafoam / phenolic

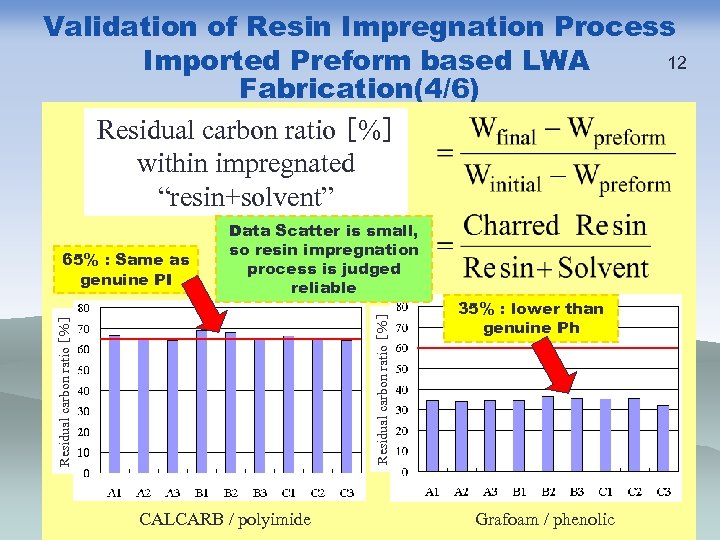

Validation of Resin Impregnation Process 12 Imported Preform based LWA Fabrication(4/6) Residual carbon ratio [%] within impregnated “resin+solvent” Residual carbon ratio [%] 65% : Same as genuine PI Data Scatter is small, so resin impregnation process is judged reliable CALCARB / polyimide 35% : lower than genuine Ph Grafoam / phenolic

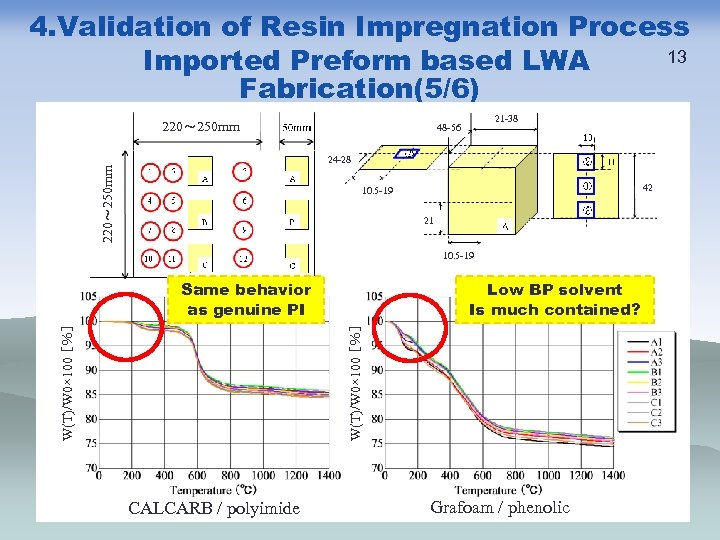

4. Validation of Resin Impregnation Process 13 Imported Preform based LWA Fabrication(5/6) 220~ 250 mm 21 -38 48 -56 220~ 250 mm 24 -28 42 10. 5 -19 21 10. 5 -19 Low BP solvent Is much contained? W(T)/W 0× 100 [%] Same behavior as genuine PI CALCARB / polyimide Grafoam / phenolic

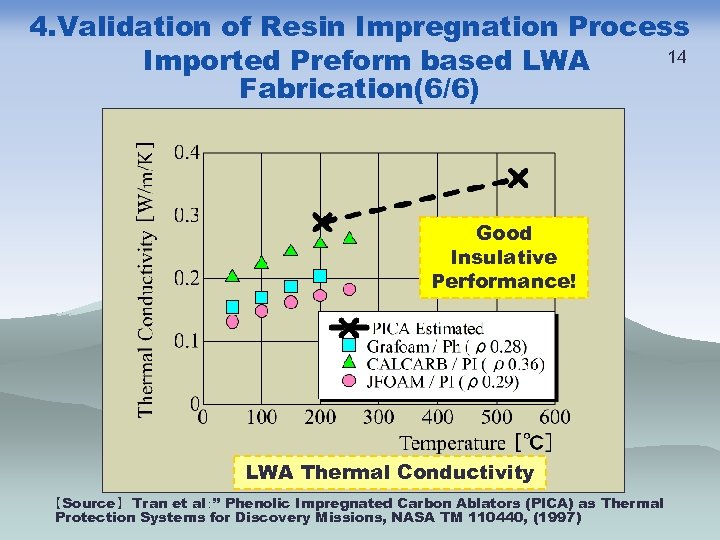

4. Validation of Resin Impregnation Process 14 Imported Preform based LWA Fabrication(6/6) Good Insulative Performance! LWA Thermal Conductivity 【Source】 Tran et al:” Phenolic Impregnated Carbon Ablators (PICA) as Thermal Protection Systems for Discovery Missions, NASA TM 110440, (1997)

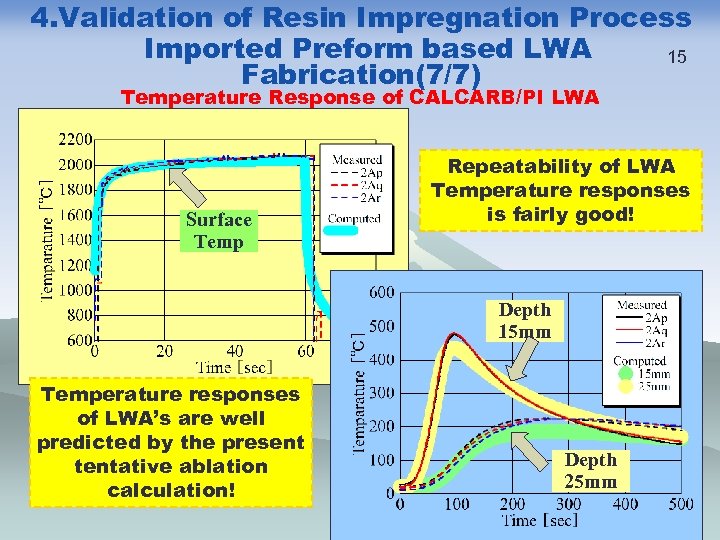

4. Validation of Resin Impregnation Process Imported Preform based LWA 15 Fabrication(7/7) Temperature Response of CALCARB/PI LWA Surface Temp Repeatability of LWA Temperature responses is fairly good! Depth 15 mm Temperature responses of LWA’s are well predicted by the present tentative ablation calculation! Depth 25 mm

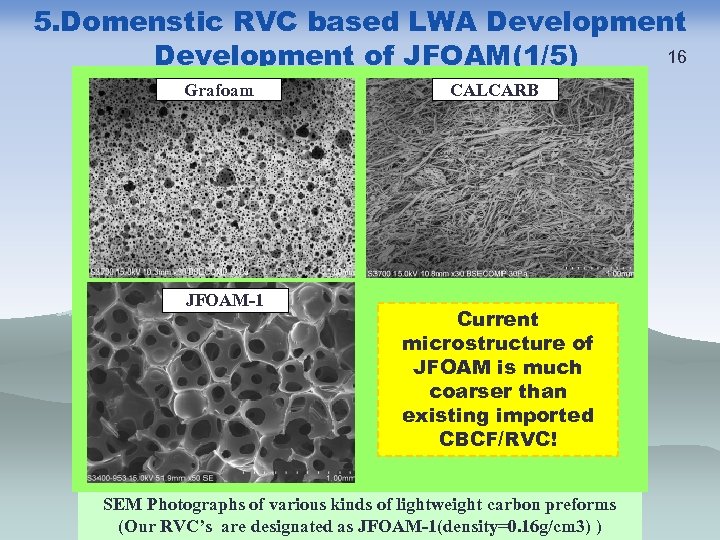

5. Domenstic RVC based LWA Development 16 Development of JFOAM(1/5) Grafoam JFOAM-1 CALCARB Current microstructure of JFOAM is much coarser than existing imported CBCF/RVC! SEM Photographs of various kinds of lightweight carbon preforms (Our RVC’s are designated as JFOAM-1(density=0. 16 g/cm 3) )

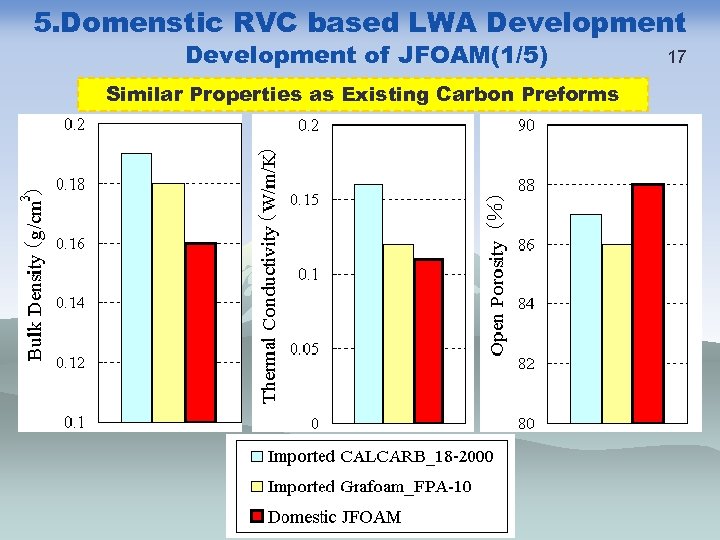

5. Domenstic RVC based LWA Development of JFOAM(1/5) Similar Properties as Existing Carbon Preforms 17

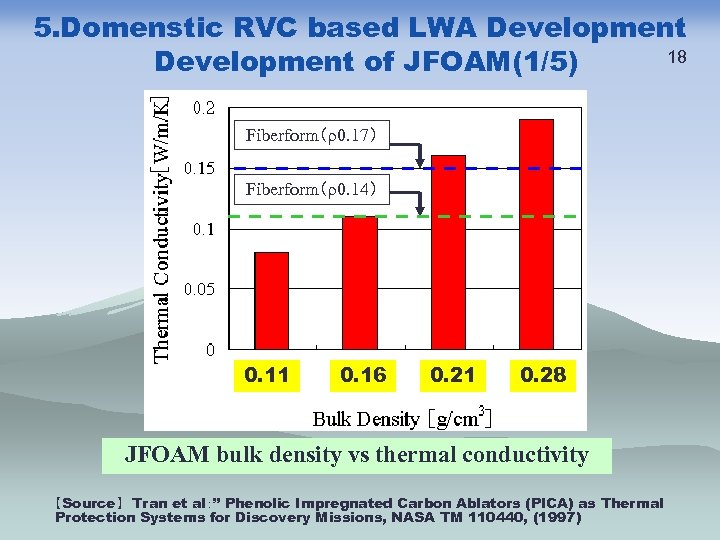

5. Domenstic RVC based LWA Development 18 Development of JFOAM(1/5) Fiberform(ρ0. 17) Fiberform(ρ0. 14) 0. 11 0. 16 0. 21 0. 28 JFOAM bulk density vs thermal conductivity 【Source】 Tran et al:” Phenolic Impregnated Carbon Ablators (PICA) as Thermal Protection Systems for Discovery Missions, NASA TM 110440, (1997)

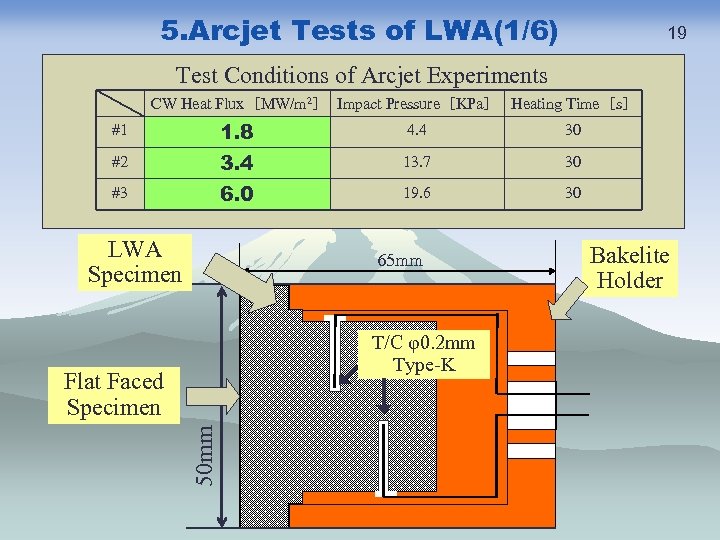

5. Arcjet Tests of LWA(1/6) 19 Test Conditions of Arcjet Experiments CW Heat Flux [MW/m 2] Impact Pressure [KPa] Heating Time [s] #1 1. 8 4. 4 30 #2 3. 4 13. 7 30 #3 6. 0 19. 6 30 LWA Specimen 65 mm T/C φ0. 2 mm Type-K 50 mm Flat Faced Specimen Bakelite Holder

5. Arcjet Tests of LWA(2/6) JFOAM/PI Before Test JFOAM-3/PI After Test: 3. 4 MW/m 2 x 30 s JFOAM-3/PI After Test: 6 MW/m 2 x 30 s 20

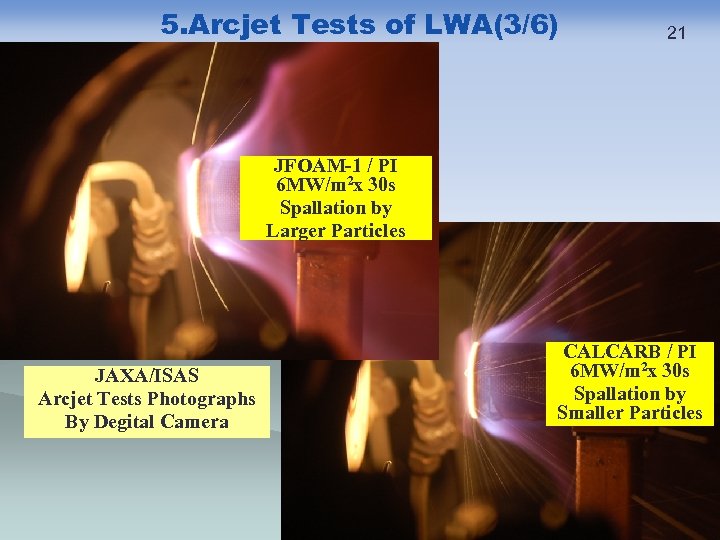

5. Arcjet Tests of LWA(3/6) 21 JFOAM-1 / PI 6 MW/m 2 x 30 s Spallation by Larger Particles (a) JAXA/ISAS Arcjet Tests Photographs By Degital Camera CALCARB / PI 6 MW/m 2 x 30 s Spallation by Smaller Particles

![Y(Recession Rate) [mm/s] 5. Arcjet Tests of LWA(4/6) PICA Recession Characteristics Y=0. 2326 X Y(Recession Rate) [mm/s] 5. Arcjet Tests of LWA(4/6) PICA Recession Characteristics Y=0. 2326 X](https://present5.com/presentation/e20428b1105aded7b1bc1c04f7543da9/image-22.jpg)

Y(Recession Rate) [mm/s] 5. Arcjet Tests of LWA(4/6) PICA Recession Characteristics Y=0. 2326 X P: pressure(KPa) q: heat flux(W/cm 2) X(p 0. 33×exp(-5. 93/q 0. 25)) Empirical Expression for Surface Recession Rate of PICA Hwang, et al. , Race Towards Launch: Qualifying the Mars Science Laboratory Heatshield in under Ten Months, ICCE-17(17 th International Conference on Composite/ NANO Engineering, (2009) 22

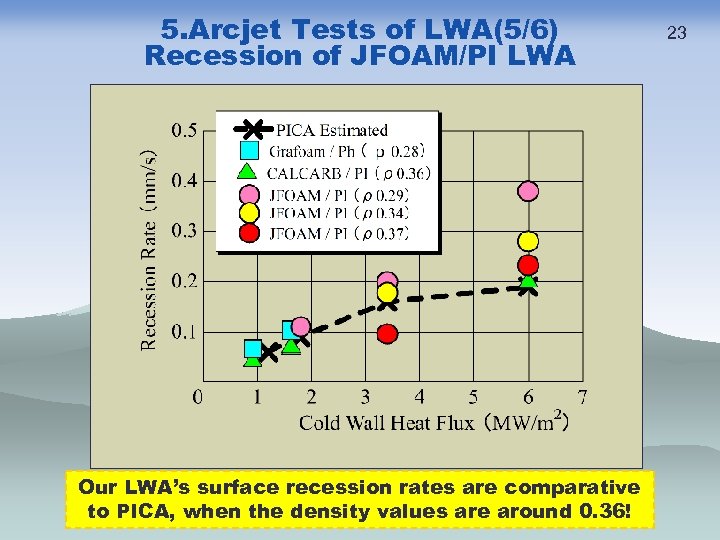

5. Arcjet Tests of LWA(5/6) Recession of JFOAM/PI LWA Our LWA’s surface recession rates are comparative to PICA, when the density values are around 0. 36! 23

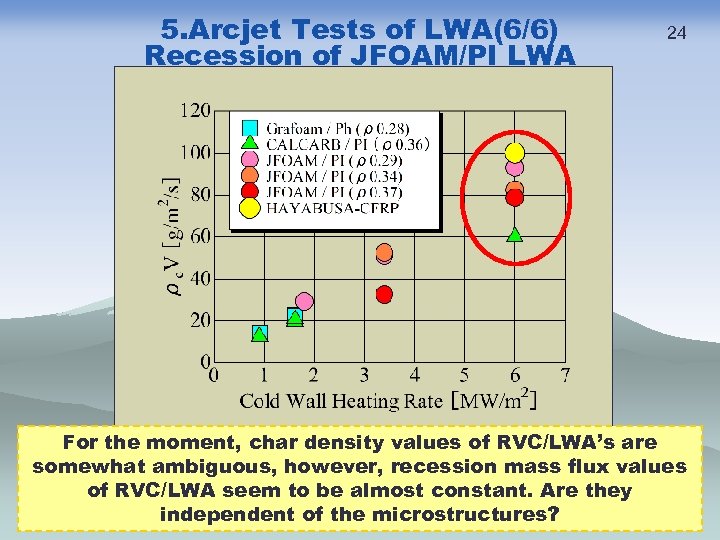

5. Arcjet Tests of LWA(6/6) Recession of JFOAM/PI LWA 24 For the moment, char density values of RVC/LWA’s are somewhat ambiguous, however, recession mass flux values of RVC/LWA seem to be almost constant. Are they independent of the microstructures?

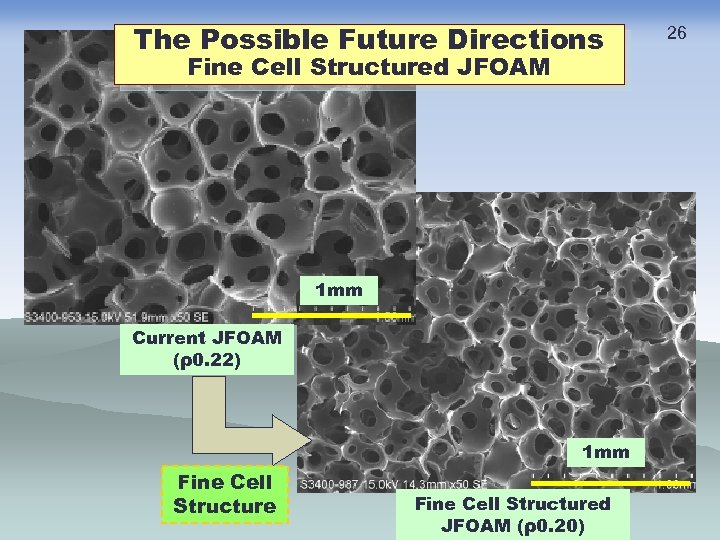

5. Conclusions & Future Works u u We are currently conducting IR&D activity towards domestic RVC/LWA with density 0. 3 -0. 4 g/cm 3 for future reentry missions. From the experiences of fabricating LWA panels of 22 cm x 5 cm and density measurements, we have confirmed that our resinimpregnation process for LWA is quite stable and reliable. Ø CALCARB/PI <± 3% Ø u u u 25 Grafoam/Ph <± 3% The insulative peformance of current LWA’s is judged acceptable. But the Arcjet tests revealed signs of spallation-driven recession especially for our domestic RVC/LWA, which may be attributed to the coarse microstructures peculiar to our current RVC’s. Therefore, further modifications for our RVC are currently underway in order to improve recession resistance. Ø Fine Cell Structures

The Possible Future Directions Fine Cell Structured JFOAM 1 mm Current JFOAM (ρ0. 22) 1 mm Fine Cell Structured JFOAM (ρ0. 20) 26

Thank You for Your Attention! Any Questions?

e20428b1105aded7b1bc1c04f7543da9.ppt