9662df8f5d2b6670eef3f2bc1e42806b.ppt

- Количество слайдов: 41

Inventory Control Prepared by Prof. T. K. JANA. Mechanical Engineering Haldia Institute of Technology

Inventory Control Inventory is a detailed list of items (either manufactured or procured) which are required directly or indirectly to manufacture a complete product. Direct inventory are those which finds its presence in the final product. Example: A crank shaft or a wheel of a car Indirect inventory are those which are not part of the final product, but these are necessary to facilitate the processes by which the product is manufactured. Example: A V-belt or Cutting tool of a lathe.

Classification of inventories Raw Inventories: These includes raw materials, purchased parts and semi-finished items obtained from vendors. In process Inventories: Partially completed items at different stages of manufacturing, called work-inprocess (WIP). Finished inventories: Finished-products inventories (manufacturing firms) or merchandise (retail stores). Indirect inventories: Spare parts of machineries, tools, oils etc. Pipeline inventory: Goods-in-transit to warehouses or customers.

Importance of Inventory control v Synchronize with Production process v Purchasing materials at an economical rate v To store the items at secured place and to avoid pilferage v To protect the system against stock-outs v To decouple components of the production- distribution system v To remain unperturbed against price increases v To take advantage of quantity discounts v To meet the sudden rise in demands

Inventory Control Inventory control refers to procurement of optimum quantity of materials so that the total cost will be minimum. Different cost elements associated with inventory control: 1. Procurement or Ordering Cost 2. Holding Cost or Carrying Cost 3. Shortage Cost or back order cost

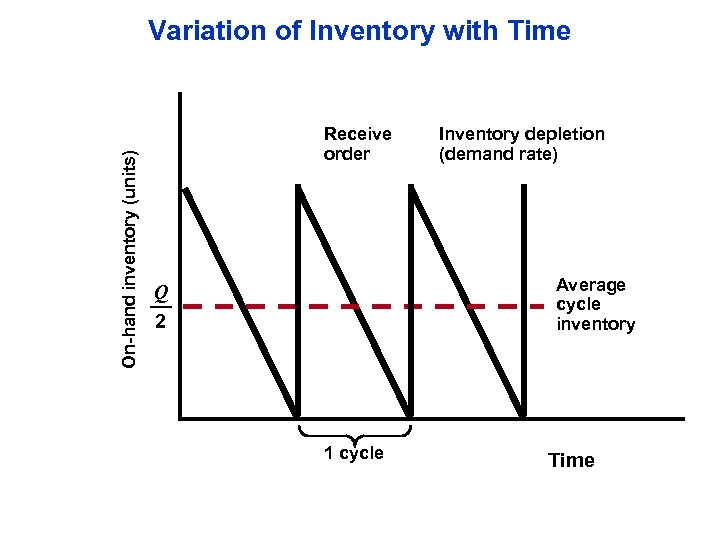

On-hand inventory (units) Variation of Inventory with Time Receive order Inventory depletion (demand rate) Average cycle inventory Q 2 1 cycle Time

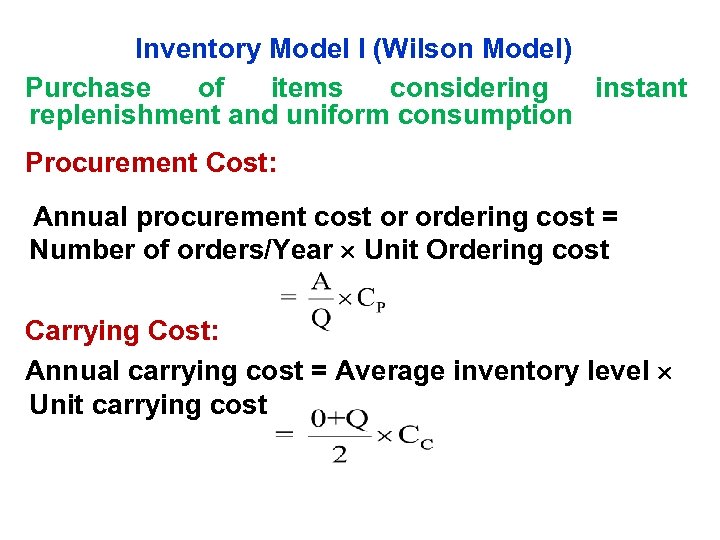

Inventory Model I (Wilson Model) Purchase of items considering instant replenishment and uniform consumption Procurement Cost: Annual procurement cost or ordering cost = Number of orders/Year Unit Ordering cost Carrying Cost: Annual carrying cost = Average inventory level Unit carrying cost

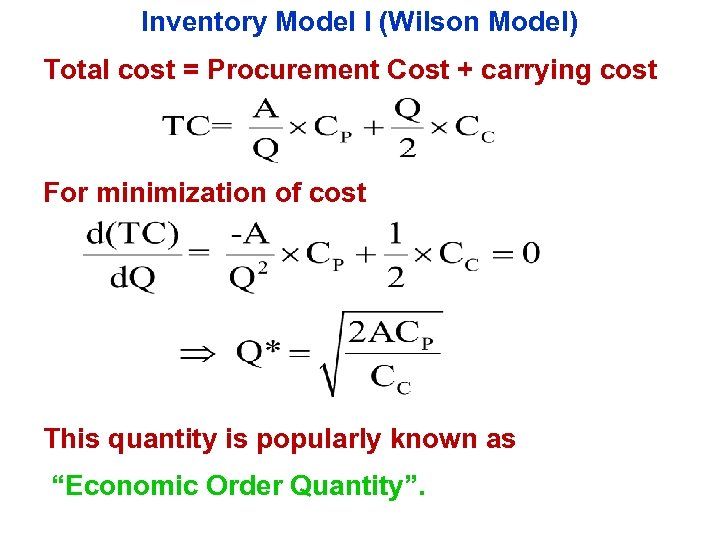

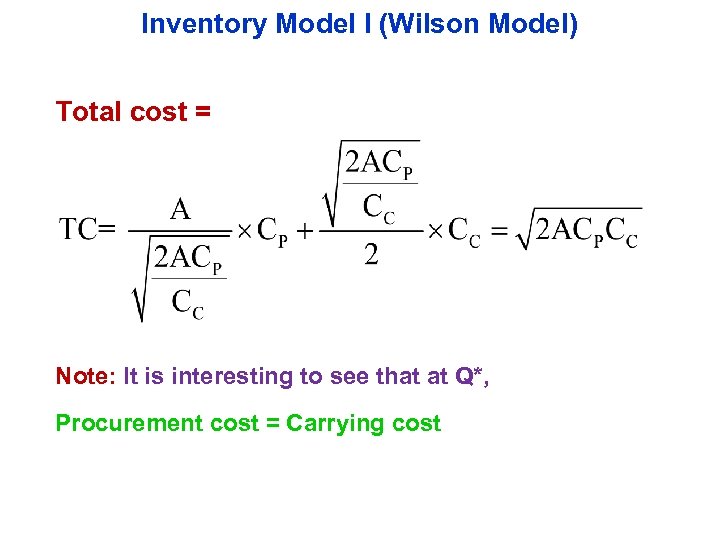

Inventory Model I (Wilson Model) Total cost = Procurement Cost + carrying cost For minimization of cost This quantity is popularly known as “Economic Order Quantity”.

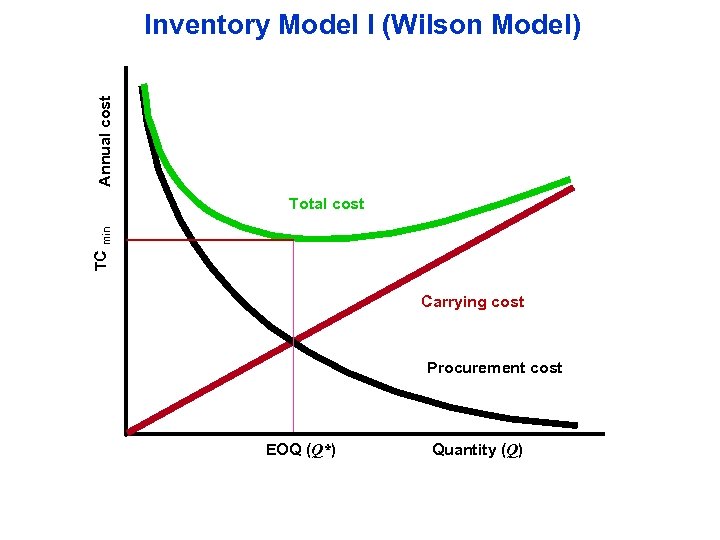

Annual cost Inventory Model I (Wilson Model) TC min Total cost Carrying cost Procurement cost EOQ (Q*) Quantity (Q)

Inventory Model I (Wilson Model) Total cost = Note: It is interesting to see that at Q*, Procurement cost = Carrying cost

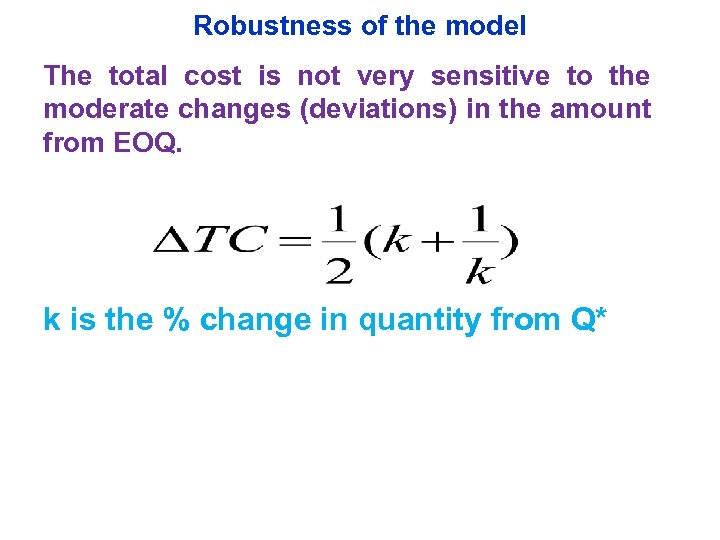

Robustness of the model The total cost is not very sensitive to the moderate changes (deviations) in the amount from EOQ. k is the % change in quantity from Q*

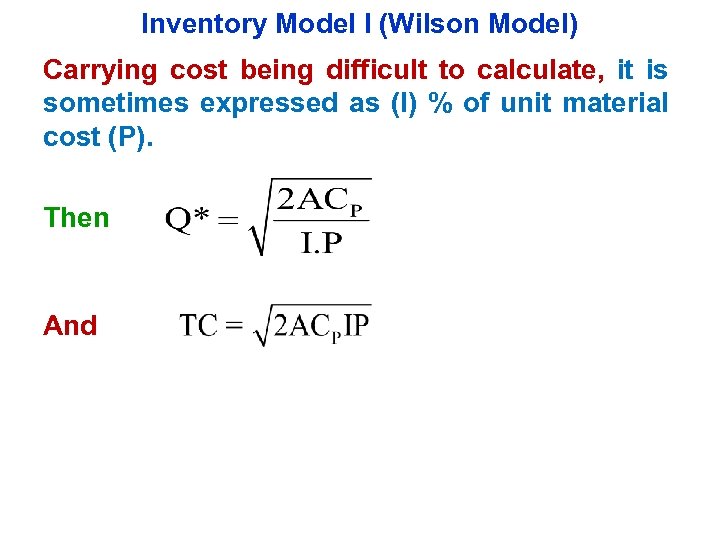

Inventory Model I (Wilson Model) Carrying cost being difficult to calculate, it is sometimes expressed as (I) % of unit material cost (P). Then And

Inventory model II (Economic Prod. Qty. )

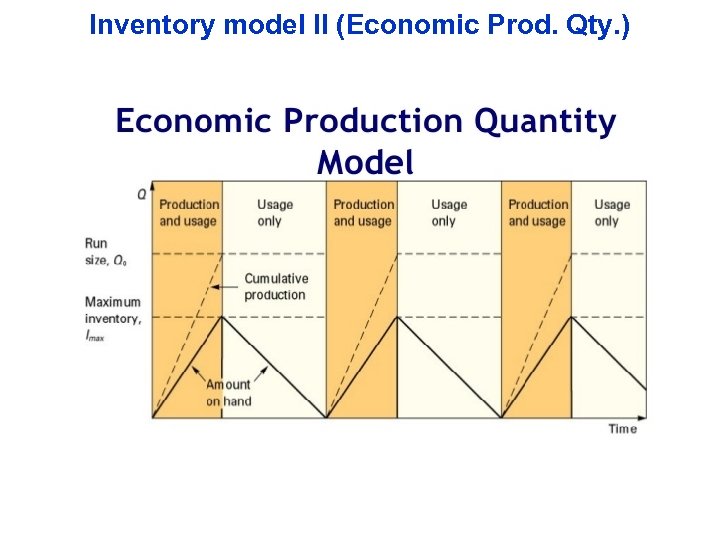

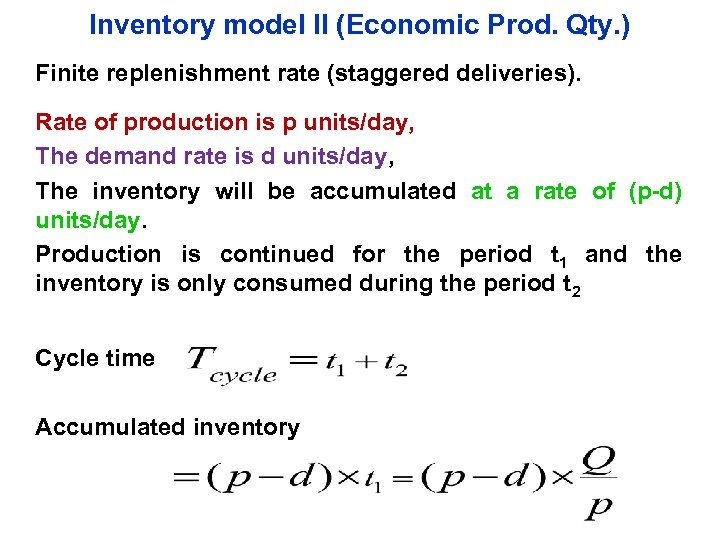

Inventory model II (Economic Prod. Qty. ) Finite replenishment rate (staggered deliveries). Rate of production is p units/day, The demand rate is d units/day, The inventory will be accumulated at a rate of (p-d) units/day. Production is continued for the period t 1 and the inventory is only consumed during the period t 2 Cycle time Accumulated inventory

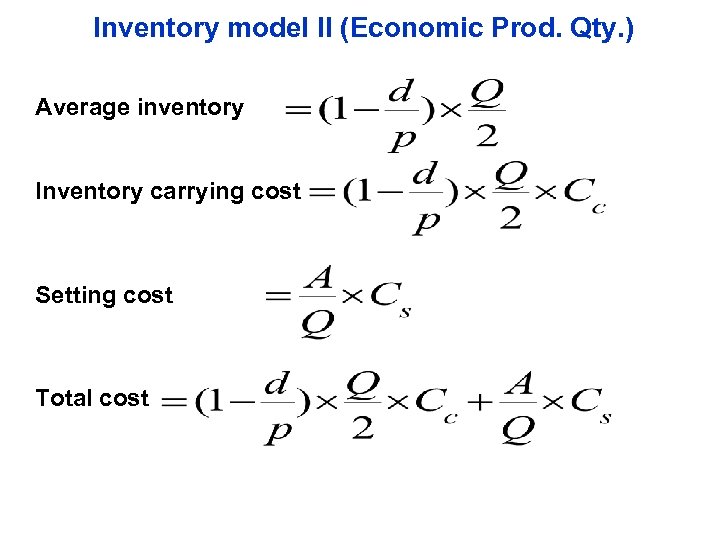

Inventory model II (Economic Prod. Qty. ) Average inventory Inventory carrying cost Setting cost Total cost

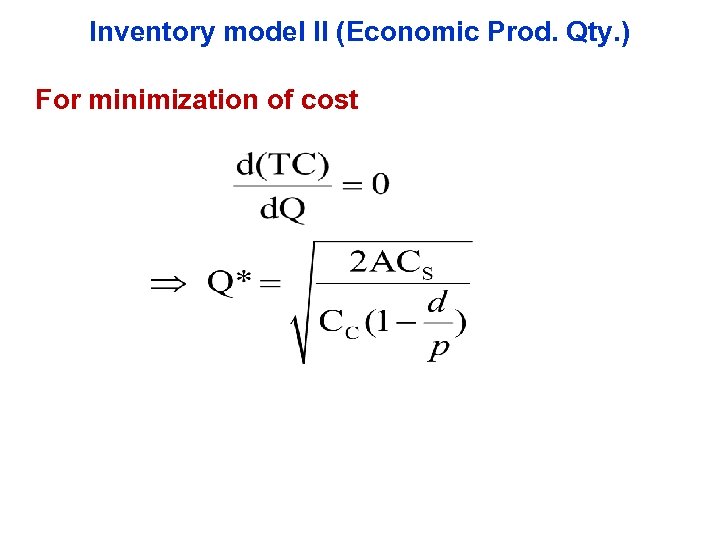

Inventory model II (Economic Prod. Qty. ) For minimization of cost

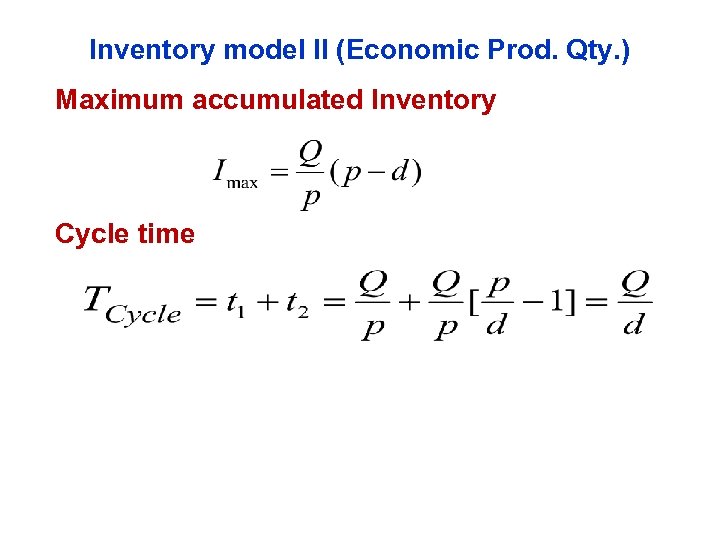

Inventory model II (Economic Prod. Qty. ) Maximum accumulated Inventory Cycle time

Inventory model III (Back order) What is back order? Due to some reasons (intentional or unintentional) the agreed quantity of materials can’t be supplied to the customer. It is therefore practiced that when the next set of materials would be available, immediately the entire backlog or due amount of material would be supplied to the customer. Failure to supply the right amount of material at right time have negative consequences on the organization.

Inventory model III (Back order) The credibility of the organization will be on the wane. The organization may opportunity in the future. loose business All these negative impacts can be converted to equivalent financial burden, popularly known as back order cost and it is considered as per unit of short supplied material.

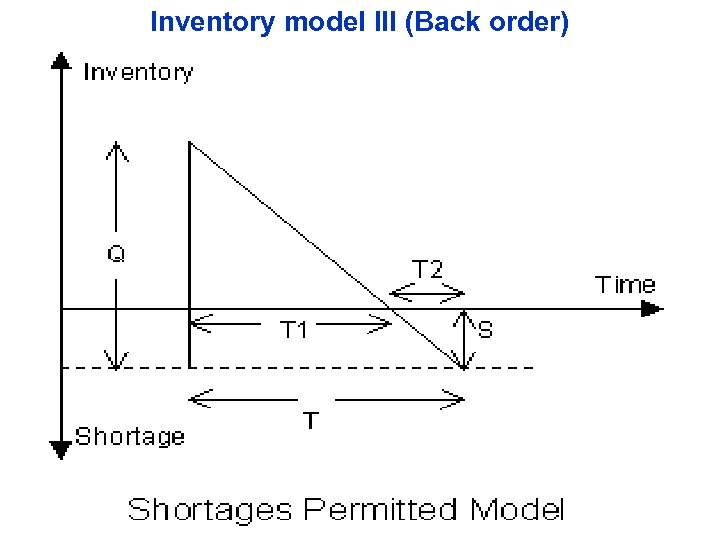

Inventory model III (Back order)

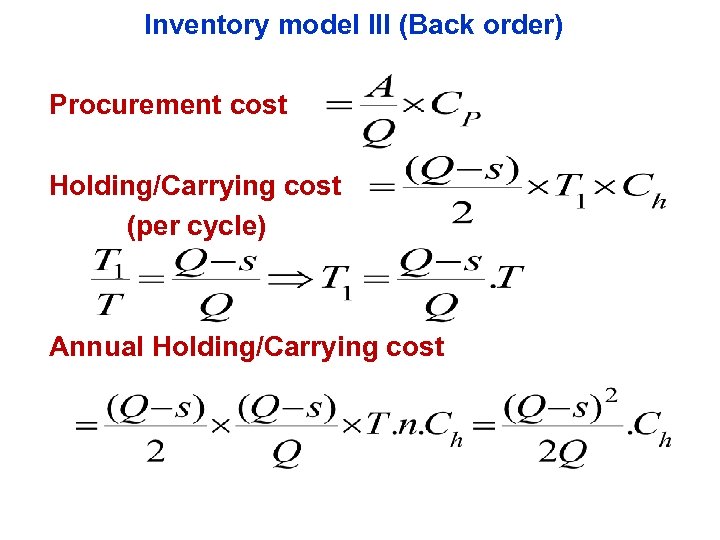

Inventory model III (Back order) Procurement cost Holding/Carrying cost (per cycle) Annual Holding/Carrying cost

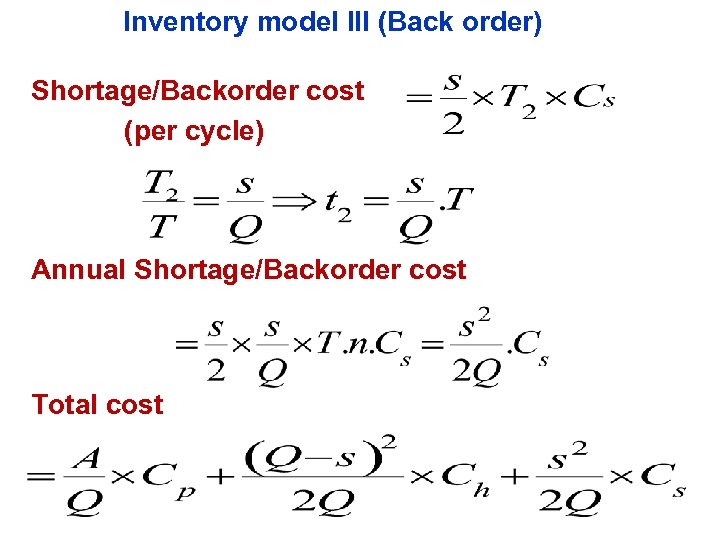

Inventory model III (Back order) Shortage/Backorder cost (per cycle) Annual Shortage/Backorder cost Total cost

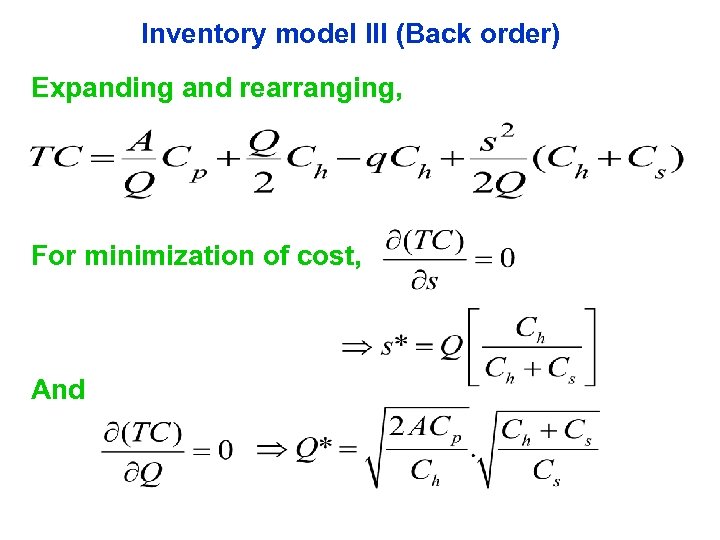

Inventory model III (Back order) Expanding and rearranging, For minimization of cost, And

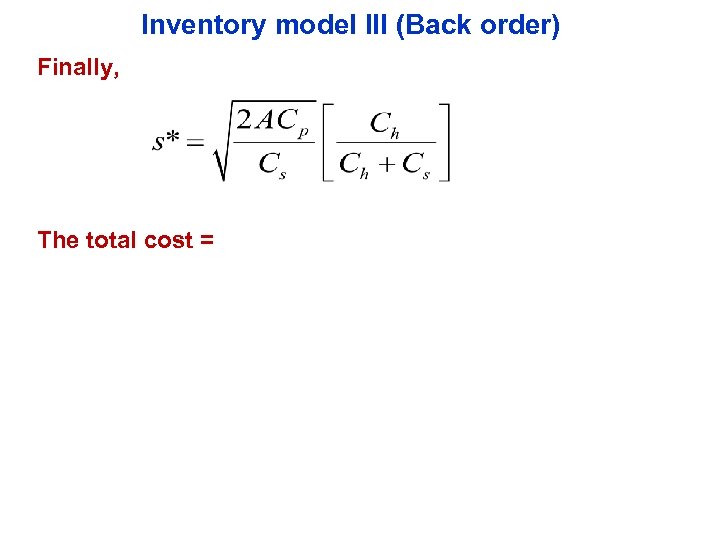

Inventory model III (Back order) Finally, The total cost =

Re-order point, Safety stock, Service level Reorder Point: It is the quantity of an item in hand drops to such an amount that the item is reordered so as to replenish the consumed item to satisfy future requirements. Lead time: It is the time frame between placing an order and getting the item. Safety Stock: Stock which is kept in excess of expected demand to satisfy fluctuations in demand rate and/or lead time. Service Level: Probability that demand will not exceed supply during lead time.

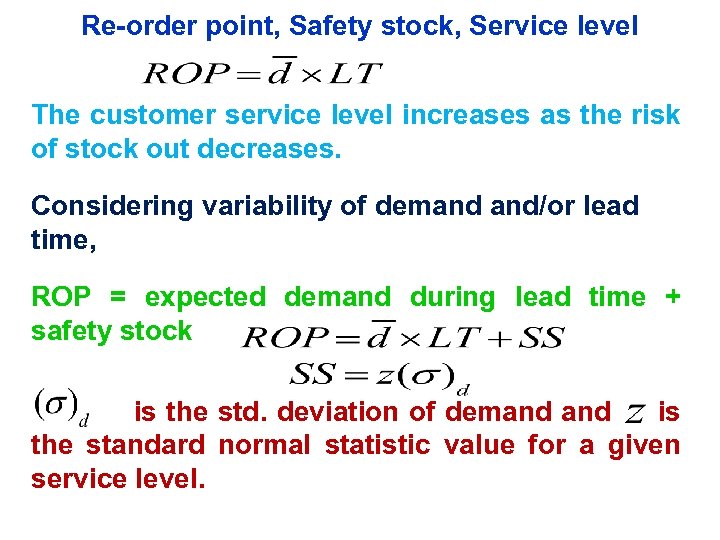

Re-order point, Safety stock, Service level The customer service level increases as the risk of stock out decreases. Considering variability of demand and/or lead time, ROP = expected demand during lead time + safety stock is the std. deviation of demand is the standard normal statistic value for a given service level.

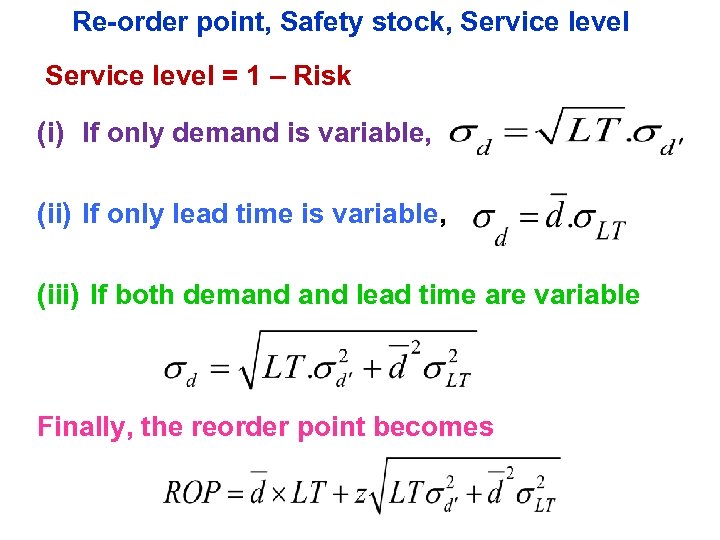

Re-order point, Safety stock, Service level = 1 – Risk (i) If only demand is variable, (ii) If only lead time is variable, (iii) If both demand lead time are variable Finally, the reorder point becomes

Classification of Purchase model A. Fixed order quantity system (Q system) In this system, an order amounting to EOQ is placed when the inventory touches the reorder level. Reorder level = d(LT) + RS + SS B. Fixed order quantity system (P system) In this system, the stock position is reviewed periodically and the order is placed.

Advantages of Q system v The frequent review of each item helps to maintain adequate stock. v If higher quantity results from fixed lot sizes, quantity discount may be availed. v Lower safety stocks reduces carrying cost.

Advantages of P system v Convenient, since items are replenished at fixed regular intervals. v Orders for multiple items can be combined together. This ensures reduction in procurement cost and transportation cost. v Stock is reviewed at fixed time, thereby streamlining the process.

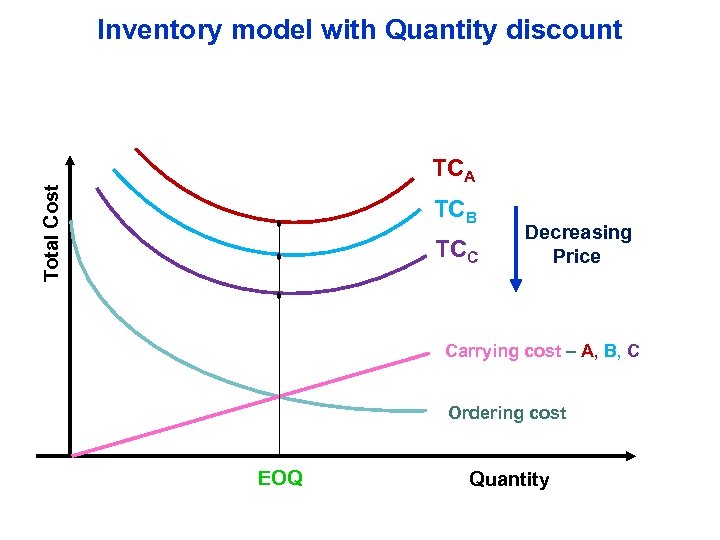

Inventory model with Quantity discounts are reduction in unit price for large orders to attract people to buy in large quantities. Usually, the price per unit decreases as order quantity is increased beyond a threshold value. Under such condition, the buyer must evaluate the potential benefits of reduced purchase price and the fewer orders resulted from large quantities purchase against the burden of increased carrying cost caused by higher average of inventories.

Inventory model with Quantity discount The objective of such analysis is to determine the order quantity that will minimize the total cost, where the total cost is the sum of Procurement cost Carrying cost, and Material cost.

Inventory model with Quantity discount Total Cost TCA TCB TCC Decreasing Price Carrying cost – A, B, C Ordering cost EOQ Quantity

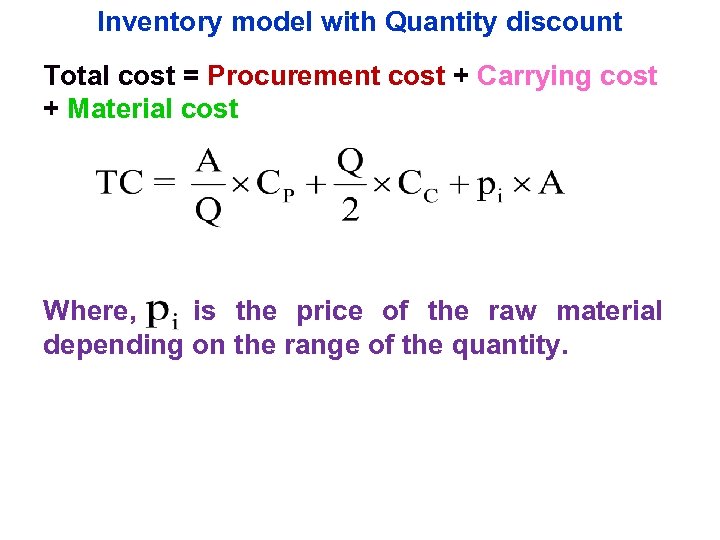

Inventory model with Quantity discount Total cost = Procurement cost + Carrying cost + Material cost Where, is the price of the raw material depending on the range of the quantity.

Inventory model with Quantity discount Solution Strategy for fixed carrying cost: 1. Compute the common minimum point by using the basic EOQ model.

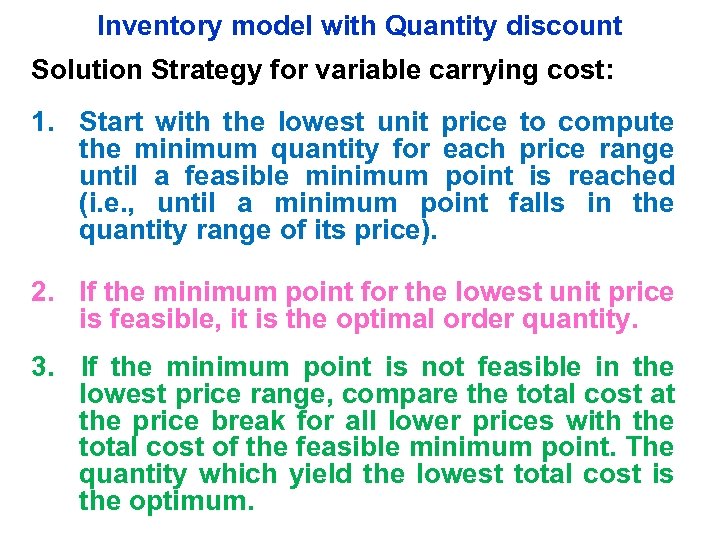

Inventory model with Quantity discount Solution Strategy for variable carrying cost: 1. Start with the lowest unit price to compute the minimum quantity for each price range until a feasible minimum point is reached (i. e. , until a minimum point falls in the quantity range of its price). 2. If the minimum point for the lowest unit price is feasible, it is the optimal order quantity. 3. If the minimum point is not feasible in the lowest price range, compare the total cost at the price break for all lower prices with the total cost of the feasible minimum point. The quantity which yield the lowest total cost is the optimum.

Selective Inventory An important aspect of inventory management is that various items held in inventory are not of equal significance in terms of monetary value, profit potential, sales or usage volume, or stock out penalties. It would be unwise to pay equal attention to each of these items. It is therefore prudent to exercise control according to the relative importance of various items in inventory. This approach is called A-B-C classification approach

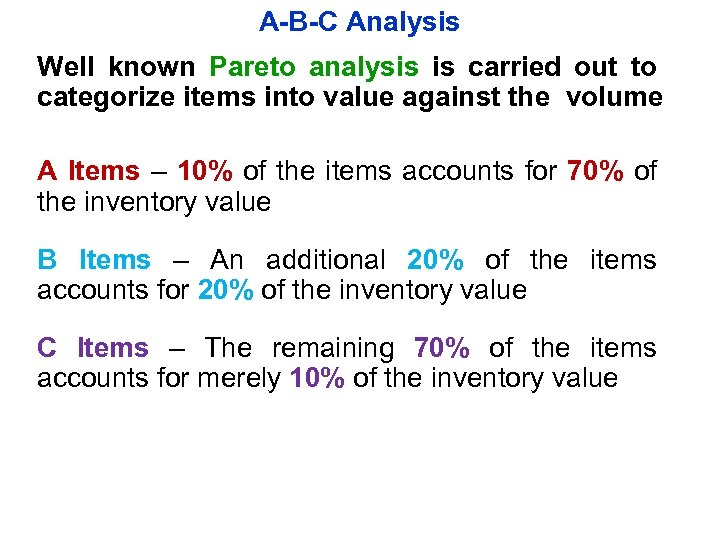

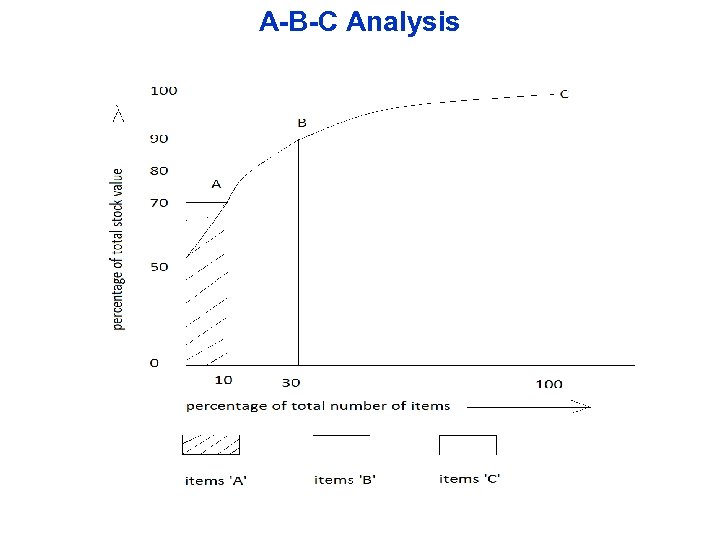

A-B-C Analysis Well known Pareto analysis is carried out to categorize items into value against the volume A Items – 10% of the items accounts for 70% of the inventory value B Items – An additional 20% of the items accounts for 20% of the inventory value C Items – The remaining 70% of the items accounts for merely 10% of the inventory value

A-B-C Analysis

Selective Inventory The basic idea of ABC analysis can be extended to apply it in other similar situations, thereby giving rise to several other titles. V-E-D Analysis: V – Vital E – Essential D – Desirable FSN Analysis: F = Fast Moving S = Slow Moving N = Non-moving HML Analysis: H = High Cost Items M = Medium Cost Items L = Low Cost Items

Thank You

9662df8f5d2b6670eef3f2bc1e42806b.ppt