77dbc50db6ef3d37769dea6c128bcad6.ppt

- Количество слайдов: 45

INTRODUCTION to the DESIGN and FABRICATION of IRONDOMINATED ACCELERATOR MAGNETS Cherrill Spencer, Magnet Engineer SLAC National Accelerator Laboratory Menlo Park, California, USA Lecture # 2 of 2 Mexican Particle Accelerator School, October 2011

Overview of my Two Lectures, part 1 Lecture 1 • Purpose of my lectures on electromagnets – And steps of producing accelerator magnets • How Maxwell’s Equations help us design magnets for particle accelerators • The steps of designing a magnet • Computer modelling to make a detailed design 2 Me. PAS, Cherrill Spencer, Magnet Lecture #2 Guanajuato. 3 rd October 2011

Overview of my Two Lectures, part 2 Lecture 2 • Choice of materials and fabrication techniques – Fabricating steel yoke – Fabricating coils • Assembling the whole magnet, connecting it to power and cooling sources • Testing & magnetically measuring a magnet • Installing magnets in a beamline: alignment • Resources where you can find out much more about accelerator magnets 3 Me. PAS, Cherrill Spencer, Magnet Lecture #2 Guanajuato. 3 rd October 2011

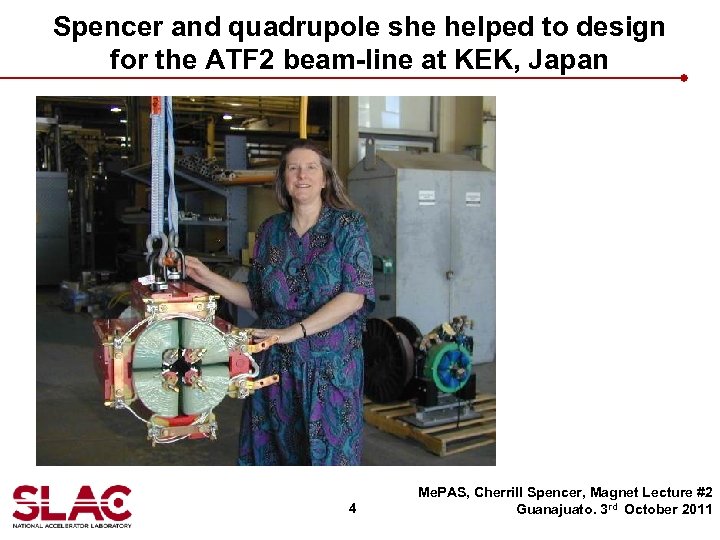

Spencer and quadrupole she helped to design for the ATF 2 beam-line at KEK, Japan 4 Me. PAS, Cherrill Spencer, Magnet Lecture #2 Guanajuato. 3 rd October 2011

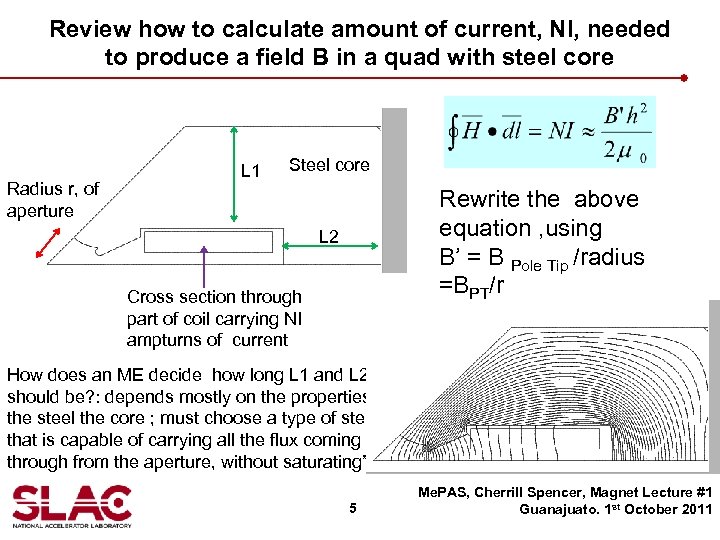

Review how to calculate amount of current, NI, needed to produce a field B in a quad with steel core Radius r, of aperture L 1 Steel core Rewrite the above equation , using B’ = B Pole Tip /radius =BPT/r NI ≈ BPT r/ 2 µ 0 L 2 Cross section through part of coil carrying NI ampturns of current How does an ME decide how long L 1 and L 2 should be? : depends mostly on the properties of the steel the core ; must choose a type of steel that is capable of carrying all the flux coming through from the aperture, without saturating” 5 Me. PAS, Cherrill Spencer, Magnet Lecture #1 Guanajuato. 1 st October 2011

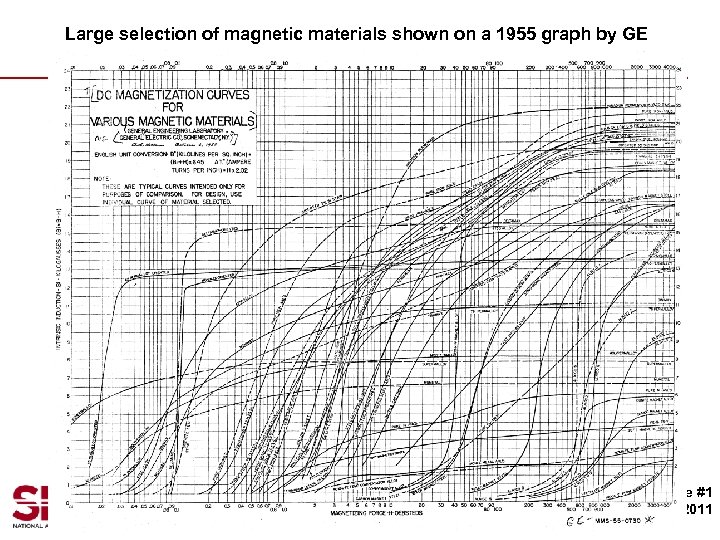

Large selection of magnetic materials shown on a 1955 graph by GE 6 Me. PAS, Cherrill Spencer, Magnet Lecture #1 Guanajuato. 1 st October 2011

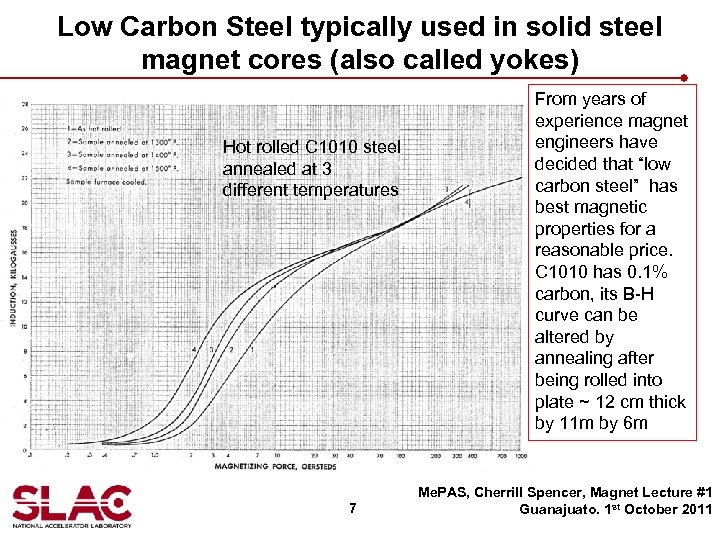

Low Carbon Steel typically used in solid steel magnet cores (also called yokes) Hot rolled C 1010 steel annealed at 3 different temperatures 7 From years of experience magnet engineers have decided that “low carbon steel” has best magnetic properties for a reasonable price. C 1010 has 0. 1% carbon, its B-H curve can be altered by annealing after being rolled into plate ~ 12 cm thick by 11 m by 6 m Me. PAS, Cherrill Spencer, Magnet Lecture #1 Guanajuato. 1 st October 2011

Steel plate can be used as solid pieces or rolled further to make very thin sheets • Low carbon steel plate can be rolled into thin sheets, from 1. 5 mm to 6 mm thick • Typically 1. 5 mm sheet used in magnets – Shape of one quadrant of a quad core is cut of sheet by a punch and die operation OR – In past few years: lasers been used to cut out laminations • Which to use depends on way magnet will be operated and relative cost of 2 methods 8 Me. PAS, Cherrill Spencer, Magnet Lecture #1 Guanajuato. 1 st October 2011

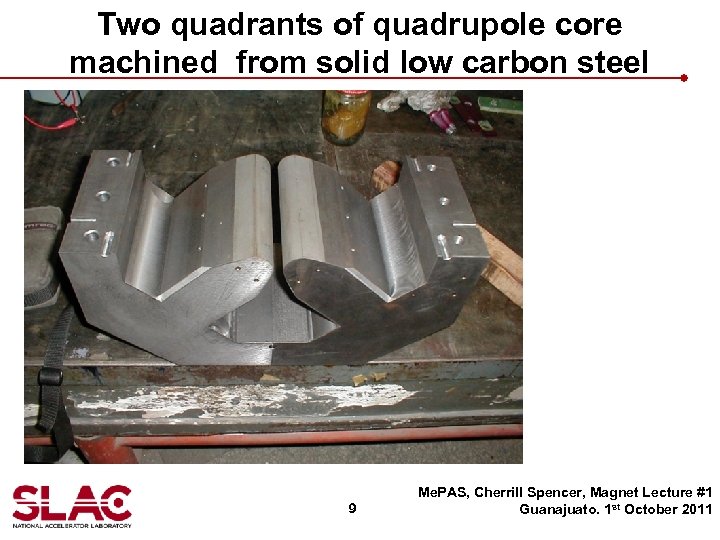

Two quadrants of quadrupole core machined from solid low carbon steel 9 Me. PAS, Cherrill Spencer, Magnet Lecture #1 Guanajuato. 1 st October 2011

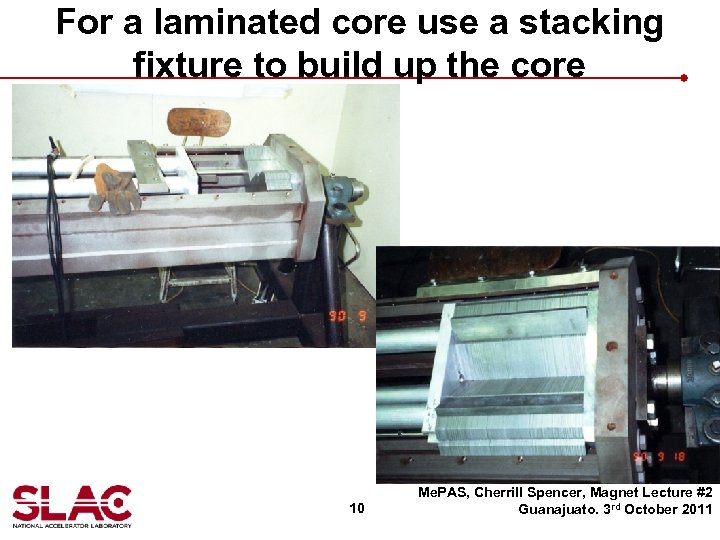

For a laminated core use a stacking fixture to build up the core 10 Me. PAS, Cherrill Spencer, Magnet Lecture #2 Guanajuato. 3 rd October 2011

Machine stacked quadrants on a planer machine: smooth split planes 11 Me. PAS, Cherrill Spencer, Magnet Lecture #2 Guanajuato. 3 rd October 2011

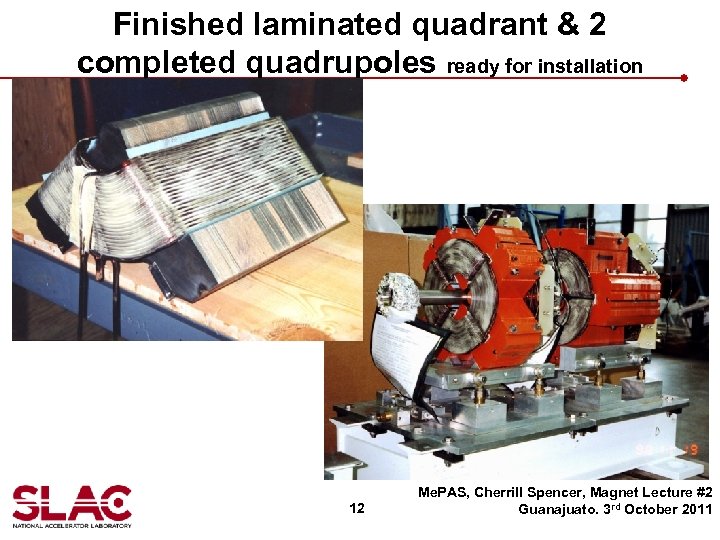

Finished laminated quadrant & 2 completed quadrupoles ready for installation 12 Me. PAS, Cherrill Spencer, Magnet Lecture #2 Guanajuato. 3 rd October 2011

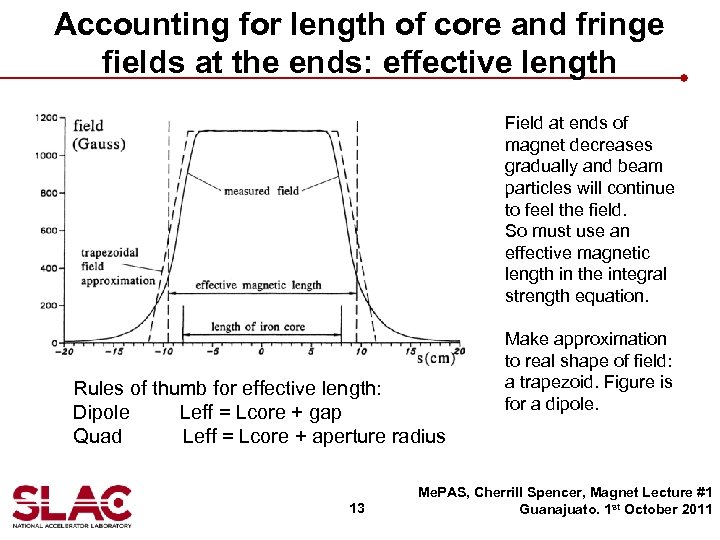

Accounting for length of core and fringe fields at the ends: effective length Field at ends of magnet decreases gradually and beam particles will continue to feel the field. So must use an effective magnetic length in the integral strength equation. Rules of thumb for effective length: Dipole Leff = Lcore + gap Quad Leff = Lcore + aperture radius 13 Make approximation to real shape of field: a trapezoid. Figure is for a dipole. Me. PAS, Cherrill Spencer, Magnet Lecture #1 Guanajuato. 1 st October 2011

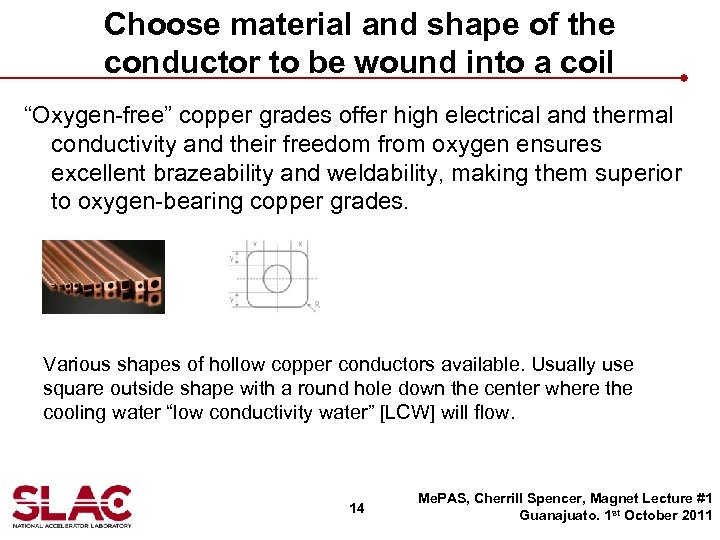

Choose material and shape of the conductor to be wound into a coil “Oxygen-free” copper grades offer high electrical and thermal conductivity and their freedom from oxygen ensures excellent brazeability and weldability, making them superior to oxygen-bearing copper grades. Various shapes of hollow copper conductors available. Usually use square outside shape with a round hole down the center where the cooling water “low conductivity water” [LCW] will flow. 14 Me. PAS, Cherrill Spencer, Magnet Lecture #1 Guanajuato. 1 st October 2011

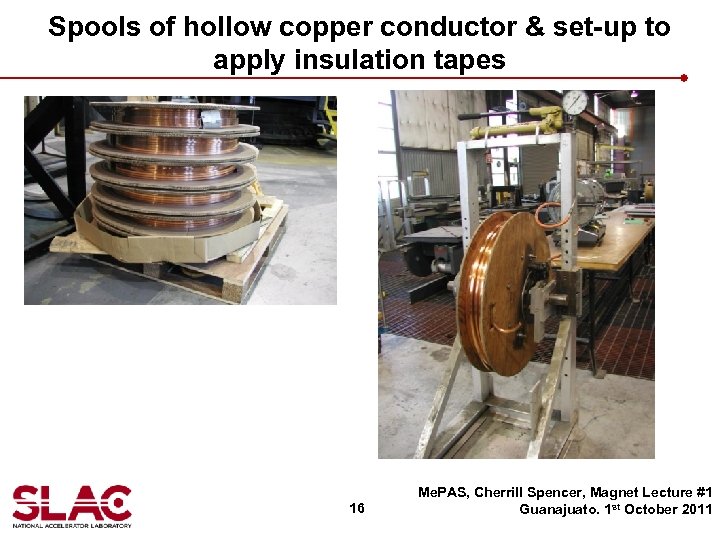

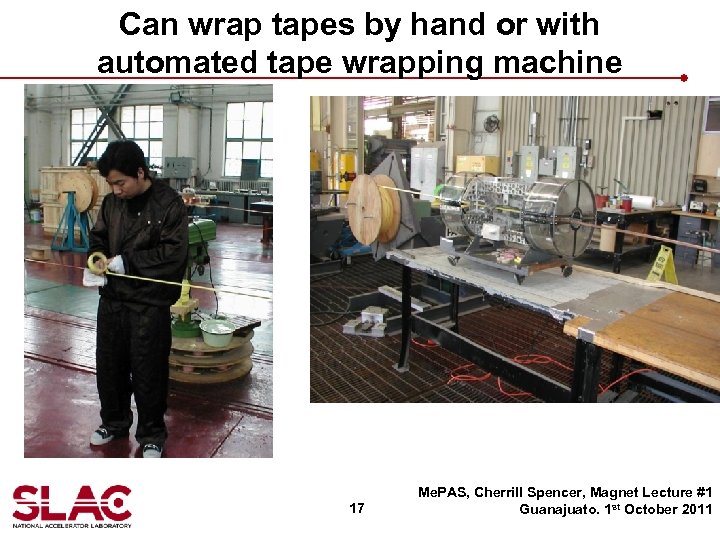

Insulate the conductor so lengths can be laid next to each other • Two insulating tapes wound around the copper conductor before it is wound into a coil: – 1 st layer e. g. Mylar tape 0. 076 mm thick x 12. 7 mm wide – 2 nd layer e. g. Glass cloth tape 0. 178 mm thick x 12. 7 mm • Wind “half-lapped” : 2 nd turn of tape around the conductor overlaps half the width of the previous turn of tape • Can have a technician do the wrapping or can invent a clever machine to use the rolls of tape and wrap the tapes • See next photos 15 Me. PAS, Cherrill Spencer, Magnet Lecture #2 Guanajuato. 3 rd October 2011

Spools of hollow copper conductor & set-up to apply insulation tapes 16 Me. PAS, Cherrill Spencer, Magnet Lecture #1 Guanajuato. 1 st October 2011

Can wrap tapes by hand or with automated tape wrapping machine 17 Me. PAS, Cherrill Spencer, Magnet Lecture #1 Guanajuato. 1 st October 2011

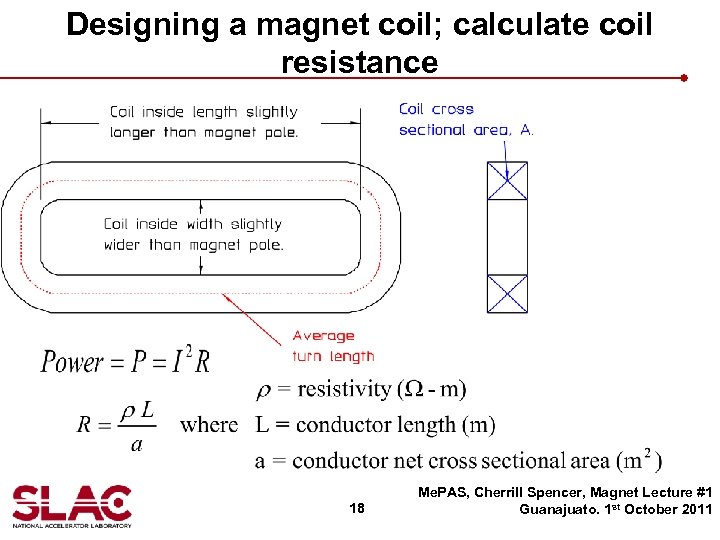

Designing a magnet coil; calculate coil resistance 18 Me. PAS, Cherrill Spencer, Magnet Lecture #1 Guanajuato. 1 st October 2011

Magnet design standards & rules • Typical current densities we use in SLAC coils: 5000 to 7500 amps per square inch: – Applying this limit determines number of turns N in a coil, because it limits I – after choosing a conductor size. • Increase in temperature of cooling water to be less than 25 ° C- application of this rule determines how many water circuits to have in a coil • NO internal brazes in a coil – most magnet failures occur at brazes and if inside coil impossible to mend. So continuous conductor between external brazes [-> length of a water circuit] 19 Me. PAS, Cherrill Spencer, Magnet Lecture #1 Guanajuato. 1 st October 2011

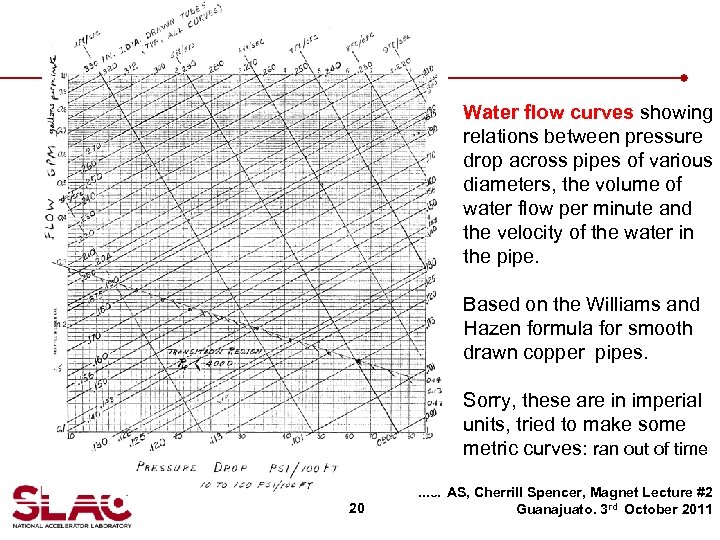

Water flow curves showing relations between pressure drop across pipes of various diameters, the volume of water flow per minute and the velocity of the water in the pipe. Based on the Williams and Hazen formula for smooth drawn copper pipes. Sorry, these are in imperial units, tried to make some metric curves: ran out of time 20 Me. PAS, Cherrill Spencer, Magnet Lecture #2 Guanajuato. 3 rd October 2011

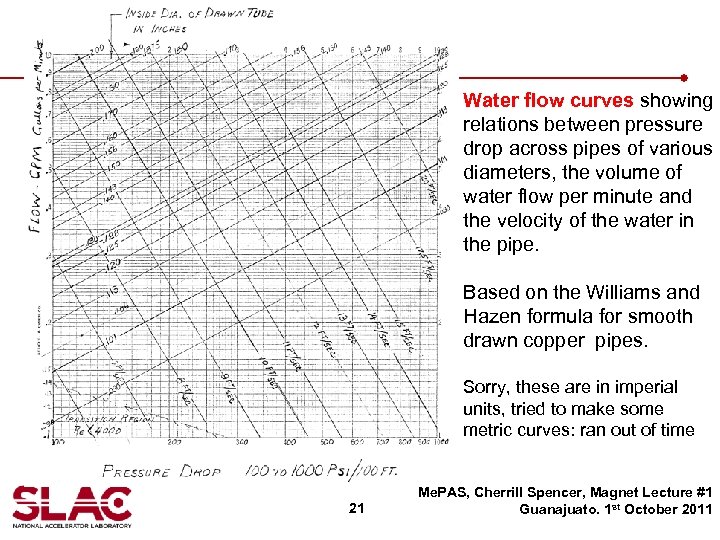

Water flow curves showing relations between pressure drop across pipes of various diameters, the volume of water flow per minute and the velocity of the water in the pipe. Based on the Williams and Hazen formula for smooth drawn copper pipes. Sorry, these are in imperial units, tried to make some metric curves: ran out of time 21 Me. PAS, Cherrill Spencer, Magnet Lecture #1 Guanajuato. 1 st October 2011

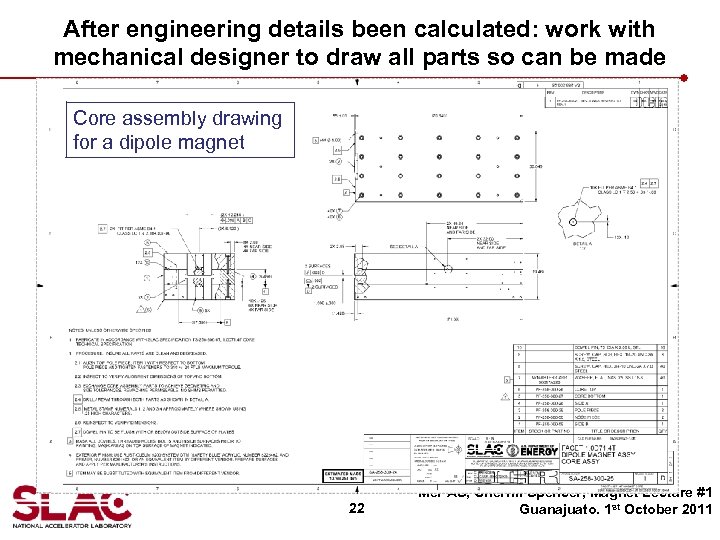

After engineering details been calculated: work with mechanical designer to draw all parts so can be made Core assembly drawing for a dipole magnet 22 Me. PAS, Cherrill Spencer, Magnet Lecture #1 Guanajuato. 1 st October 2011

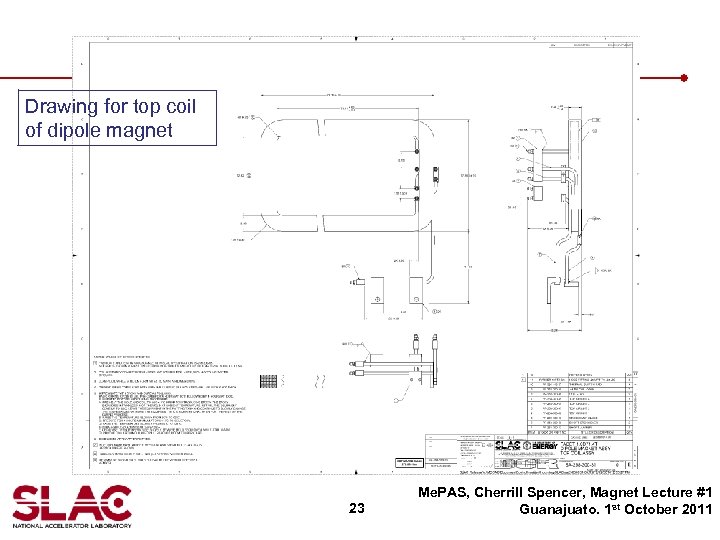

Drawing for top coil of dipole magnet 23 Me. PAS, Cherrill Spencer, Magnet Lecture #1 Guanajuato. 1 st October 2011

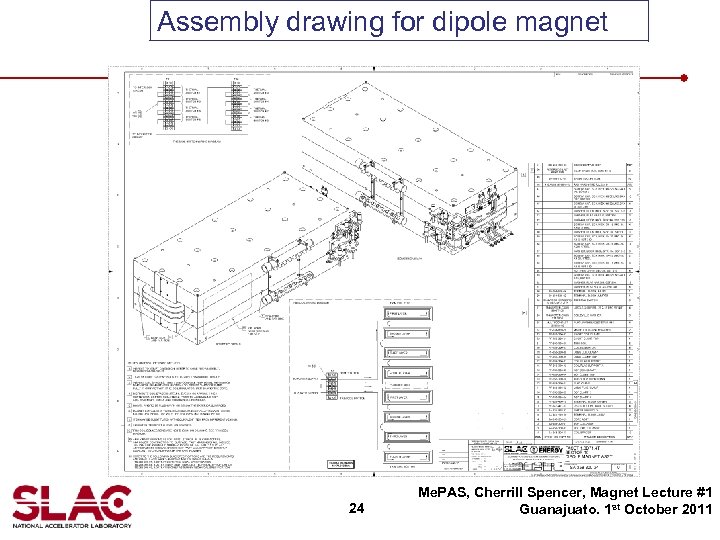

Assembly drawing for dipole magnet 24 Me. PAS, Cherrill Spencer, Magnet Lecture #1 Guanajuato. 1 st October 2011

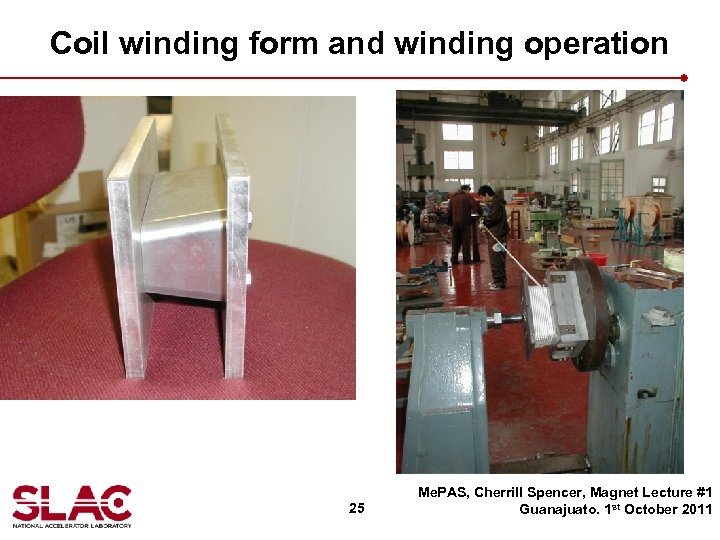

Coil winding form and winding operation 25 Me. PAS, Cherrill Spencer, Magnet Lecture #1 Guanajuato. 1 st October 2011

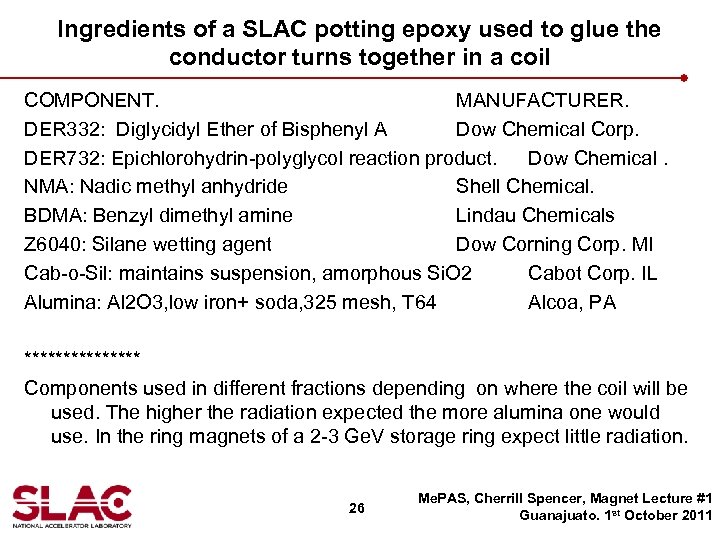

Ingredients of a SLAC potting epoxy used to glue the conductor turns together in a coil COMPONENT. MANUFACTURER. DER 332: Diglycidyl Ether of Bisphenyl A Dow Chemical Corp. DER 732: Epichlorohydrin-polyglycol reaction product. Dow Chemical. NMA: Nadic methyl anhydride Shell Chemical. BDMA: Benzyl dimethyl amine Lindau Chemicals Z 6040: Silane wetting agent Dow Corning Corp. MI Cab-o-Sil: maintains suspension, amorphous Si. O 2 Cabot Corp. IL Alumina: Al 2 O 3, low iron+ soda, 325 mesh, T 64 Alcoa, PA ******** Components used in different fractions depending on where the coil will be used. The higher the radiation expected the more alumina one would use. In the ring magnets of a 2 -3 Ge. V storage ring expect little radiation. 26 Me. PAS, Cherrill Spencer, Magnet Lecture #1 Guanajuato. 1 st October 2011

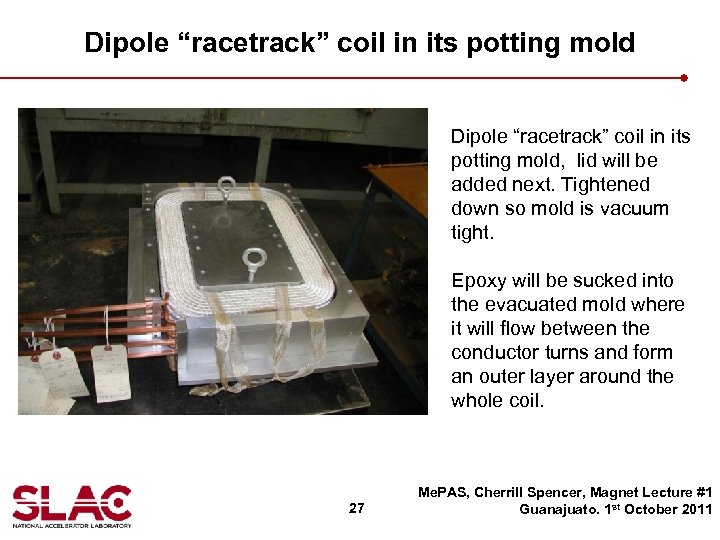

Dipole “racetrack” coil in its potting mold, lid will be added next. Tightened down so mold is vacuum tight. Epoxy will be sucked into the evacuated mold where it will flow between the conductor turns and form an outer layer around the whole coil. 27 Me. PAS, Cherrill Spencer, Magnet Lecture #1 Guanajuato. 1 st October 2011

Typical epoxy potting & curing instructions • Epoxy is a thick but will flow through tubes and into narrow spaces between the turns, getting absorbed into the insulation. Must avoid areas without any epoxy. • • Pre-heat the mold and coil to 55°C± 5°C prior to introducing epoxy. The epoxy should be introduced into the mold at ambient temperature. Raise the temperature slowly from 60°C to 90°C. Pre-cure for 4 hours minimum at 90°C ± 5°C to gel epoxy. Raise the temperature slowly from 90°C to 130°C. Cure for 4 hours at 130°C± 5°C. Decrease oven temperature slowly, remove mold from oven while still warm. • Remove coil from mold before reaches room temperature. 28 Me. PAS, Cherrill Spencer, Magnet Lecture #1 Guanajuato. 1 st October 2011

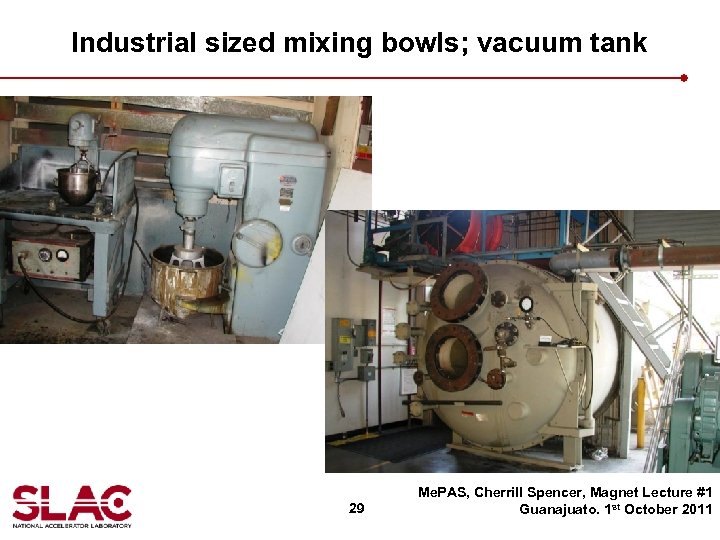

Industrial sized mixing bowls; vacuum tank 29 Me. PAS, Cherrill Spencer, Magnet Lecture #1 Guanajuato. 1 st October 2011

![Testing & measuring magnet parts during fabrication [circulate samples to students] • Most important Testing & measuring magnet parts during fabrication [circulate samples to students] • Most important](https://present5.com/presentation/77dbc50db6ef3d37769dea6c128bcad6/image-30.jpg)

Testing & measuring magnet parts during fabrication [circulate samples to students] • Most important to test the various magnet components as they are being made 30 Me. PAS, Cherrill Spencer, Magnet Lecture #1 Guanajuato. 1 st October 2011

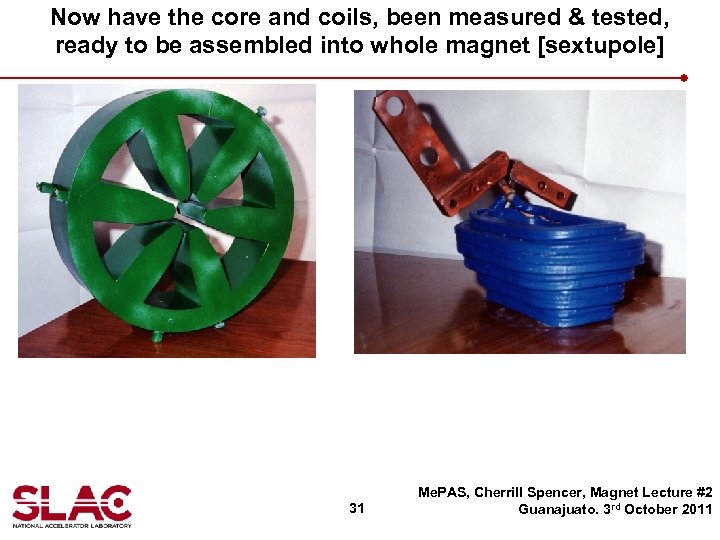

Now have the core and coils, been measured & tested, ready to be assembled into whole magnet [sextupole] 31 Me. PAS, Cherrill Spencer, Magnet Lecture #2 Guanajuato. 3 rd October 2011

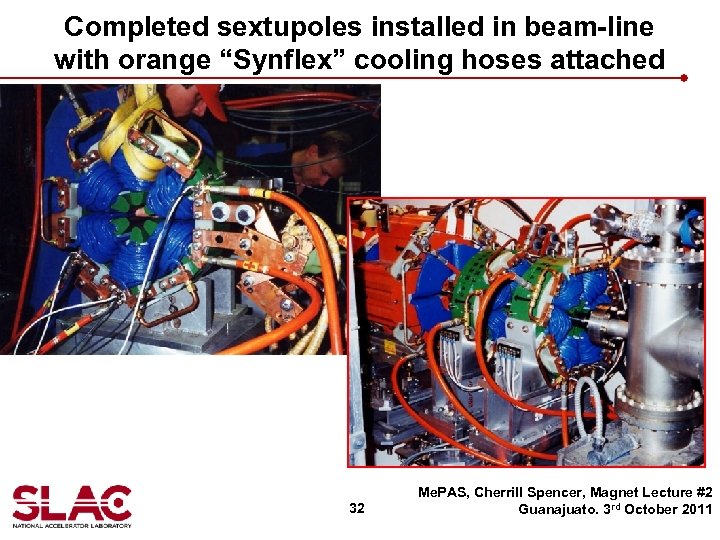

Completed sextupoles installed in beam-line with orange “Synflex” cooling hoses attached 32 Me. PAS, Cherrill Spencer, Magnet Lecture #2 Guanajuato. 3 rd October 2011

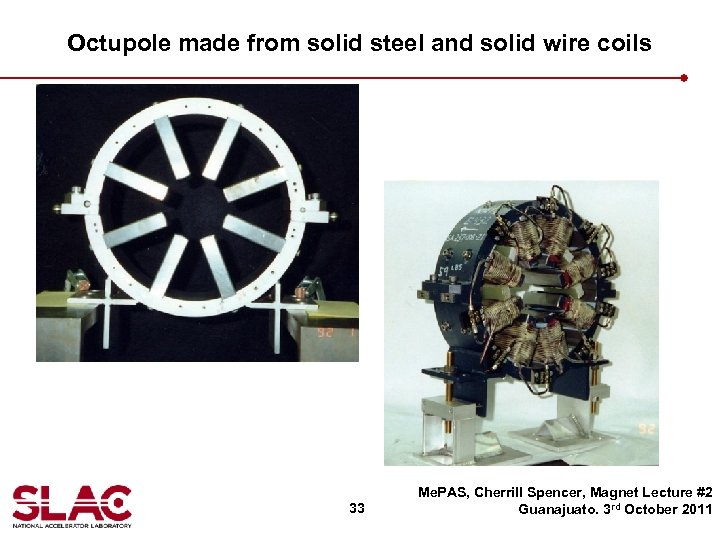

Octupole made from solid steel and solid wire coils 33 Me. PAS, Cherrill Spencer, Magnet Lecture #2 Guanajuato. 3 rd October 2011

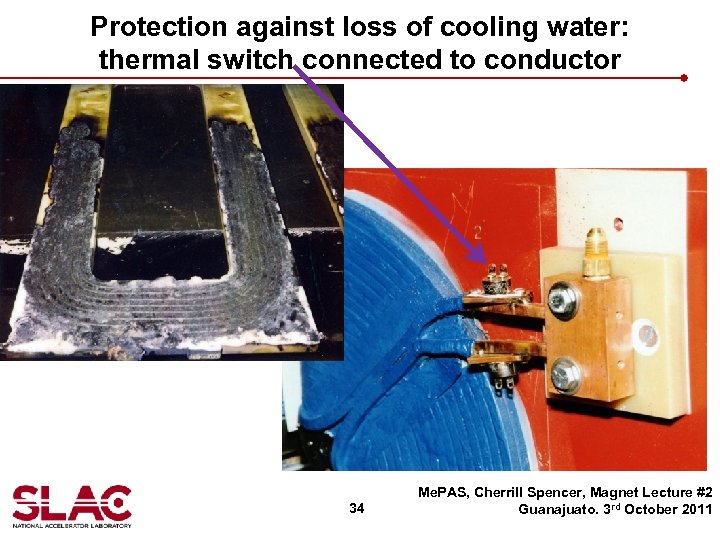

Protection against loss of cooling water: thermal switch connected to conductor 34 Me. PAS, Cherrill Spencer, Magnet Lecture #2 Guanajuato. 3 rd October 2011

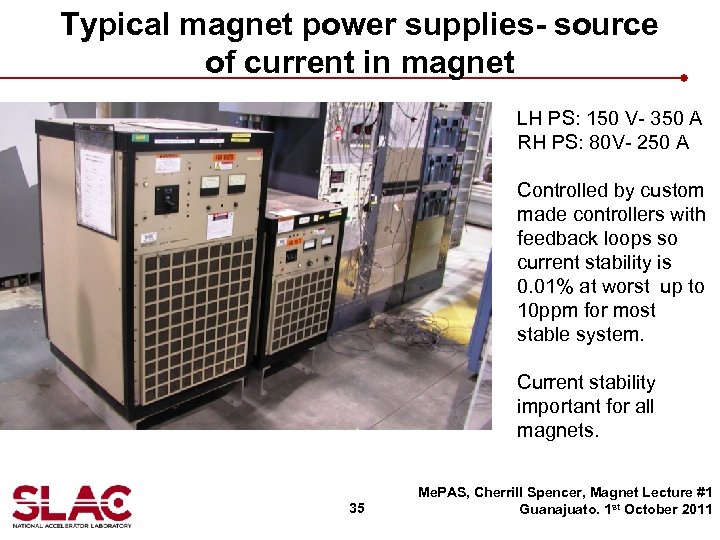

Typical magnet power supplies- source of current in magnet LH PS: 150 V- 350 A RH PS: 80 V- 250 A Controlled by custom made controllers with feedback loops so current stability is 0. 01% at worst up to 10 ppm for most stable system. Current stability important for all magnets. 35 Me. PAS, Cherrill Spencer, Magnet Lecture #1 Guanajuato. 1 st October 2011

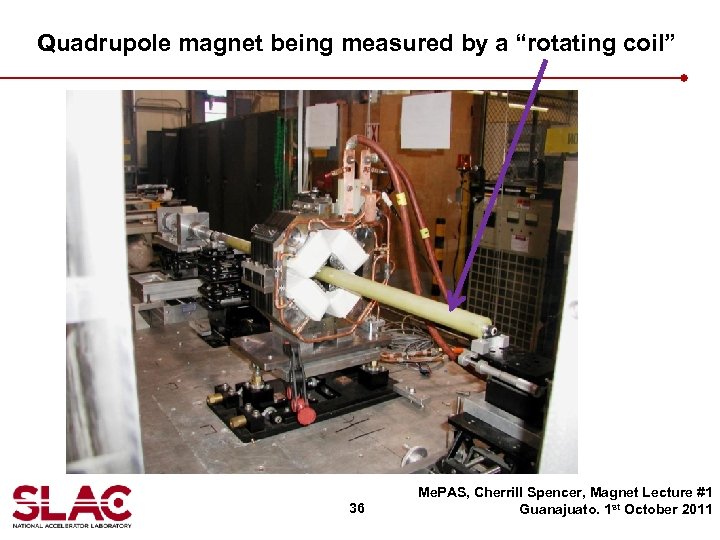

Quadrupole magnet being measured by a “rotating coil” 36 Me. PAS, Cherrill Spencer, Magnet Lecture #1 Guanajuato. 1 st October 2011

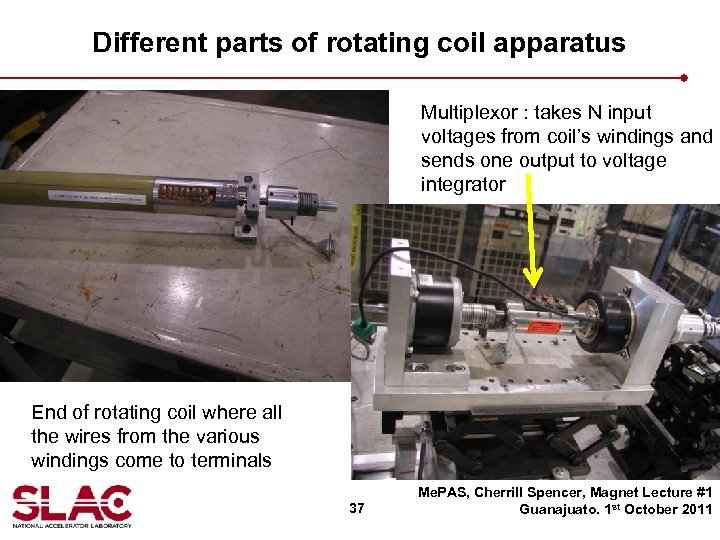

Different parts of rotating coil apparatus Multiplexor : takes N input voltages from coil’s windings and sends one output to voltage integrator End of rotating coil where all the wires from the various windings come to terminals 37 Me. PAS, Cherrill Spencer, Magnet Lecture #1 Guanajuato. 1 st October 2011

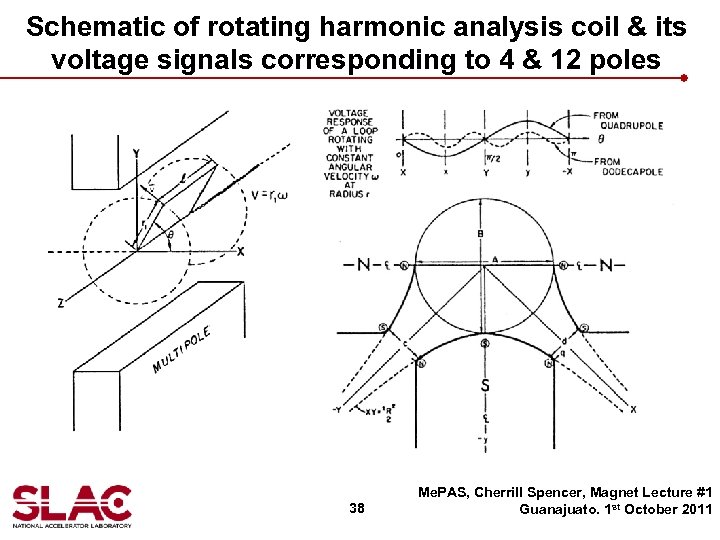

Schematic of rotating harmonic analysis coil & its voltage signals corresponding to 4 & 12 poles 38 Me. PAS, Cherrill Spencer, Magnet Lecture #1 Guanajuato. 1 st October 2011

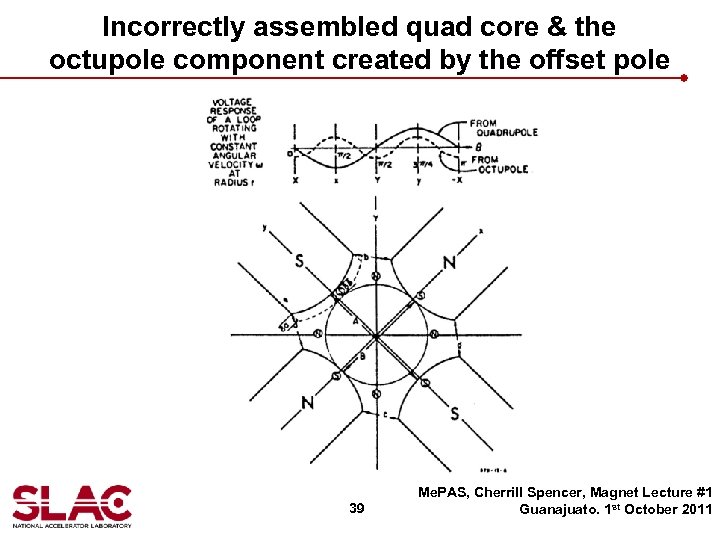

Incorrectly assembled quad core & the octupole component created by the offset pole 39 Me. PAS, Cherrill Spencer, Magnet Lecture #1 Guanajuato. 1 st October 2011

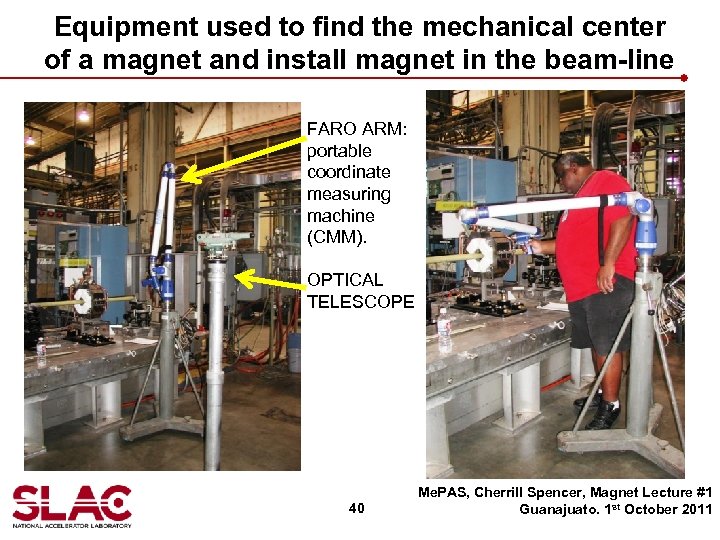

Equipment used to find the mechanical center of a magnet and install magnet in the beam-line FARO ARM: portable coordinate measuring machine (CMM). OPTICAL TELESCOPE 40 Me. PAS, Cherrill Spencer, Magnet Lecture #1 Guanajuato. 1 st October 2011

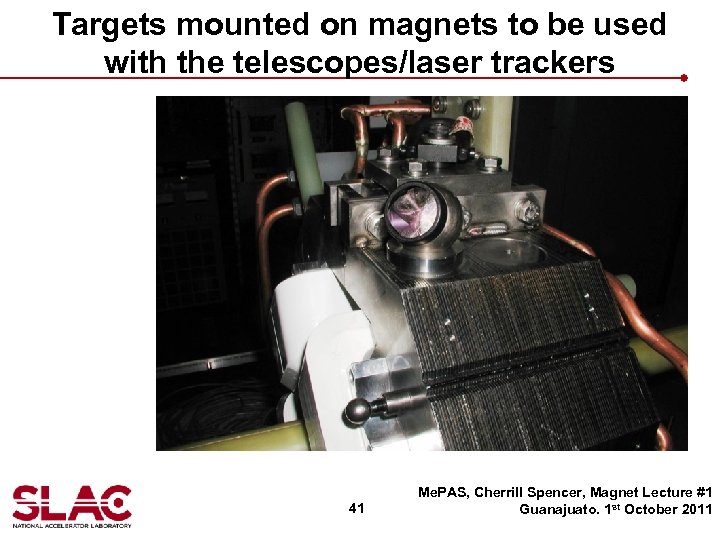

Targets mounted on magnets to be used with the telescopes/laser trackers 41 Me. PAS, Cherrill Spencer, Magnet Lecture #1 Guanajuato. 1 st October 2011

FINAL GOAL ACHIEVED: Dipole magnet successfully installed in a beam-line 42 Me. PAS, Cherrill Spencer, Magnet Lecture #1 Guanajuato. 1 st October 2011

Then an ME goes to a magnet conference and gives a paper on her work & has a nice time! Spencer at International Magnet Technology Conference MT 21 in Hefei, China. In world heritage Huangshan Mts 43 Me. PAS, Cherrill Spencer, Magnet Lecture #1 Guanajuato. 1 st October 2011

Very useful books & articles on iron-dominated magnets for those wishing to learn more • “Iron Dominated Electromagnets” by Jack T. Tanabe, book published by World Scientific • “Iron Dominated Magnets” by G. E. Fischer, SLAC-PUB-3726. Available through SPIRES search engine on the SLAC website 44 Me. PAS, Cherrill Spencer, Magnet Lecture #1 Guanajuato. 1 st October 2011

Homework problem for lecture #2 • WILL BE AVAILABLE during this afternoon! • Will be posted on the Me. PAS website 45 Me. PAS, Cherrill Spencer, Magnet Lecture #1 Guanajuato. 1 st October 2011

77dbc50db6ef3d37769dea6c128bcad6.ppt