27c4b8cd702e5772209e9e13daff13b0.ppt

- Количество слайдов: 55

Introduction to Supply Chain Management

Introduction to Supply Chain Management

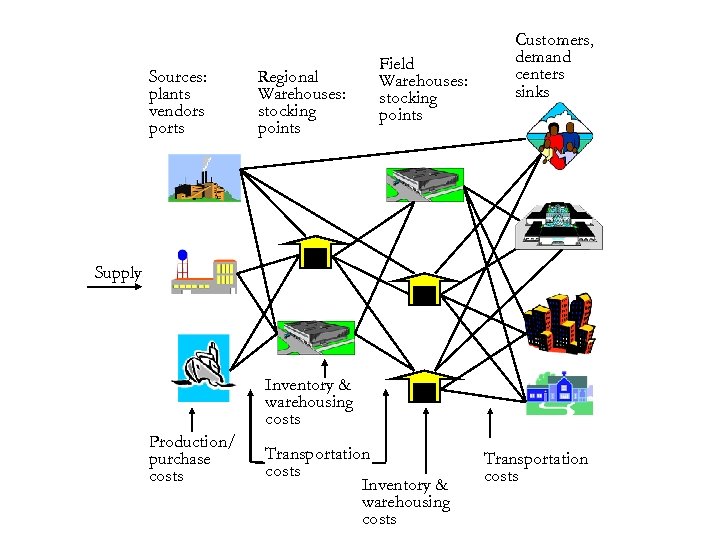

Sources: plants vendors ports Regional Warehouses: stocking points Field Warehouses: stocking points Customers, demand centers sinks Supply Inventory & warehousing costs Production/ purchase costs Transportation costs Inventory & warehousing costs Transportation costs

Sources: plants vendors ports Regional Warehouses: stocking points Field Warehouses: stocking points Customers, demand centers sinks Supply Inventory & warehousing costs Production/ purchase costs Transportation costs Inventory & warehousing costs Transportation costs

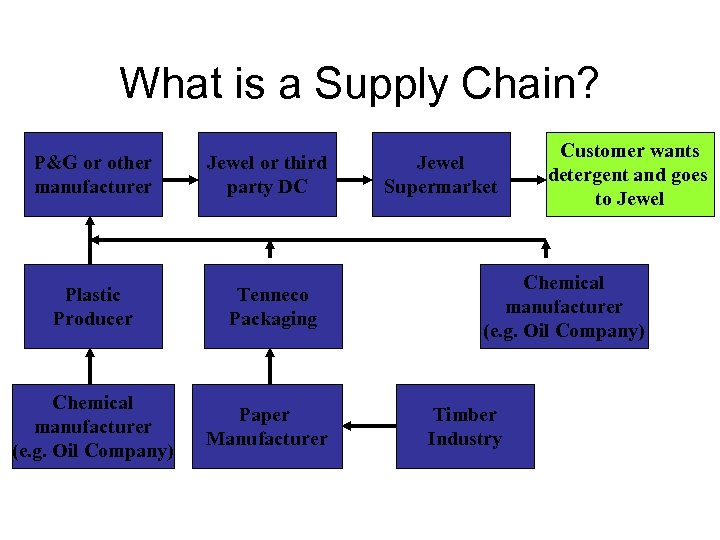

What is a Supply Chain? P&G or other manufacturer Plastic Producer Chemical manufacturer (e. g. Oil Company) Jewel or third party DC Tenneco Packaging Paper Manufacturer Jewel Supermarket Customer wants detergent and goes to Jewel Chemical manufacturer (e. g. Oil Company) Timber Industry

What is a Supply Chain? P&G or other manufacturer Plastic Producer Chemical manufacturer (e. g. Oil Company) Jewel or third party DC Tenneco Packaging Paper Manufacturer Jewel Supermarket Customer wants detergent and goes to Jewel Chemical manufacturer (e. g. Oil Company) Timber Industry

What Is A Supply Chain? • The system of suppliers, manufacturers, transportation, distributors, and vendors that exists to transform raw materials to final products and supply those products to customers. • That portion of the supply chain which comes after the manufacturing process is sometimes known as the distribution network.

What Is A Supply Chain? • The system of suppliers, manufacturers, transportation, distributors, and vendors that exists to transform raw materials to final products and supply those products to customers. • That portion of the supply chain which comes after the manufacturing process is sometimes known as the distribution network.

What Is the Goal of Supply Chain Management? • Supply chain management is concerned with the efficient integration of suppliers, factories, warehouses and stores so that merchandise is produced and distributed: – In the right quantities – To the right locations – At the right time • In order to – Minimize total system cost – Satisfy customer service requirements

What Is the Goal of Supply Chain Management? • Supply chain management is concerned with the efficient integration of suppliers, factories, warehouses and stores so that merchandise is produced and distributed: – In the right quantities – To the right locations – At the right time • In order to – Minimize total system cost – Satisfy customer service requirements

Strategies for SCM All of the advanced strategies, techniques, and approaches for Supply Chain Management focus on: –Global Optimization –Managing Uncertainty

Strategies for SCM All of the advanced strategies, techniques, and approaches for Supply Chain Management focus on: –Global Optimization –Managing Uncertainty

Tools and Strategies for Optimization • • • Decision Support Systems Inventory Control Network Design for Logistics Cross Docking

Tools and Strategies for Optimization • • • Decision Support Systems Inventory Control Network Design for Logistics Cross Docking

Global Optimization • What is it? • Why is it different/better than local optimization? • What are conflicting supply chain objectives? • What tools and approaches help with global optimization?

Global Optimization • What is it? • Why is it different/better than local optimization? • What are conflicting supply chain objectives? • What tools and approaches help with global optimization?

Sequential Optimization vs. Global Optimization Sequential Optimization Procurement Planning Manufacturing Planning Distribution Planning Demand Planning Global Optimization Supply Contracts/Collaboration/Information Systems and DSS Procurement Planning Manufacturing Planning Distribution Planning Demand Planning

Sequential Optimization vs. Global Optimization Sequential Optimization Procurement Planning Manufacturing Planning Distribution Planning Demand Planning Global Optimization Supply Contracts/Collaboration/Information Systems and DSS Procurement Planning Manufacturing Planning Distribution Planning Demand Planning

Why is Global Optimization Hard? • The supply chain is complex • Different facilities have conflicting objectives • The supply chain is a dynamic system – The power structure changes • The system varies over time

Why is Global Optimization Hard? • The supply chain is complex • Different facilities have conflicting objectives • The supply chain is a dynamic system – The power structure changes • The system varies over time

Conflicting Objectives in the Supply Chain 1. Purchasing • Stable volume requirements • Flexible delivery time • Little variation in mix • Large quantities 2. Manufacturing • Long run production • High quality • High productivity • Low production cost

Conflicting Objectives in the Supply Chain 1. Purchasing • Stable volume requirements • Flexible delivery time • Little variation in mix • Large quantities 2. Manufacturing • Long run production • High quality • High productivity • Low production cost

Conflicting Objectives in the Supply Chain 3. Warehousing • Low inventory • Reduced transportation costs • Quick replenishment capability 4. Customers • Short order lead time • High in stock • Enormous variety of products • Low prices

Conflicting Objectives in the Supply Chain 3. Warehousing • Low inventory • Reduced transportation costs • Quick replenishment capability 4. Customers • Short order lead time • High in stock • Enormous variety of products • Low prices

Uncertainty • What is variation? • What is randomness? • What tools and approaches help us to deal with these issues?

Uncertainty • What is variation? • What is randomness? • What tools and approaches help us to deal with these issues?

Can’t Forecasting Help? • Forecasting is always wrong • The longer the forecast horizon the worse the forecast • End item forecasts are even more wrong

Can’t Forecasting Help? • Forecasting is always wrong • The longer the forecast horizon the worse the forecast • End item forecasts are even more wrong

Why Is Uncertainty Hard to Deal With? • Matching supply and demand is difficult. • Forecasting doesn’t solve the problem. • Inventory and back-order levels typically fluctuate widely across the supply chain. • Demand is not the only source of uncertainty: – – – Lead times Yields Transportation times Natural Disasters Component Availability

Why Is Uncertainty Hard to Deal With? • Matching supply and demand is difficult. • Forecasting doesn’t solve the problem. • Inventory and back-order levels typically fluctuate widely across the supply chain. • Demand is not the only source of uncertainty: – – – Lead times Yields Transportation times Natural Disasters Component Availability

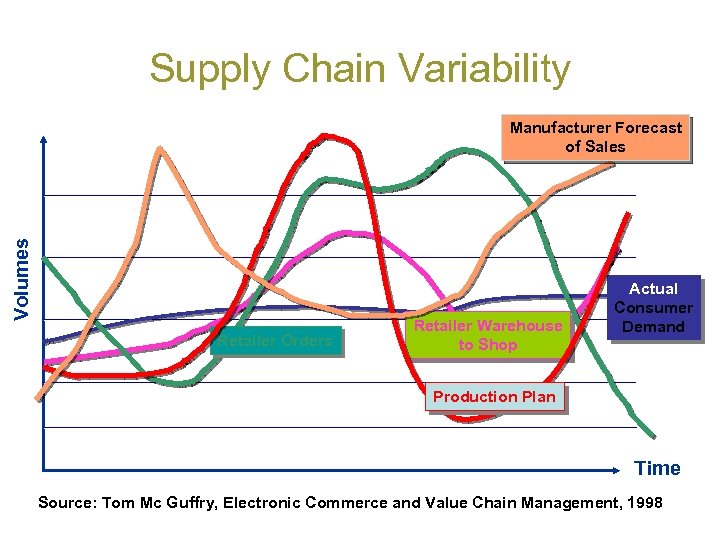

Supply Chain Variability Volumes Manufacturer Forecast of Sales Retailer Orders Retailer Warehouse to Shop Actual Consumer Demand Production Plan Time Source: Tom Mc Guffry, Electronic Commerce and Value Chain Management, 1998

Supply Chain Variability Volumes Manufacturer Forecast of Sales Retailer Orders Retailer Warehouse to Shop Actual Consumer Demand Production Plan Time Source: Tom Mc Guffry, Electronic Commerce and Value Chain Management, 1998

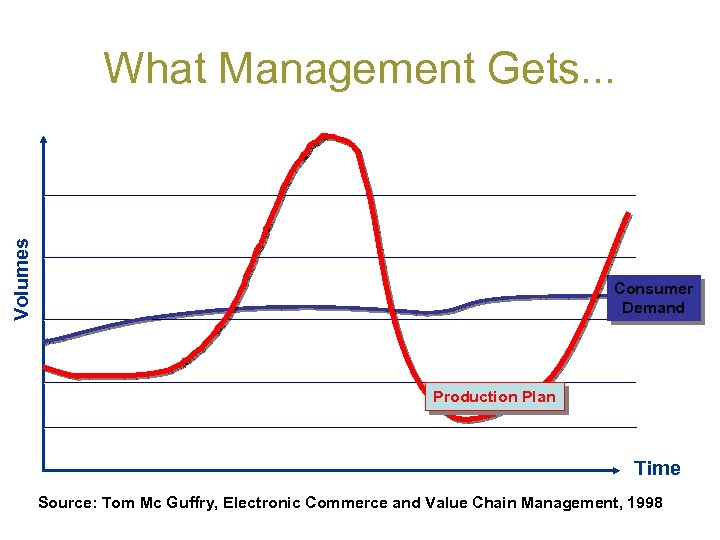

Volumes What Management Gets. . . Consumer Demand Production Plan Time Source: Tom Mc Guffry, Electronic Commerce and Value Chain Management, 1998

Volumes What Management Gets. . . Consumer Demand Production Plan Time Source: Tom Mc Guffry, Electronic Commerce and Value Chain Management, 1998

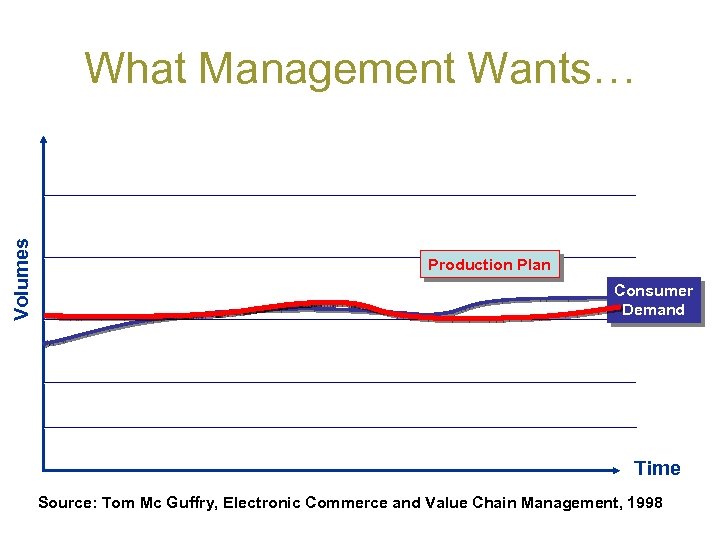

Volumes What Management Wants… Production Plan Consumer Demand Time Source: Tom Mc Guffry, Electronic Commerce and Value Chain Management, 1998

Volumes What Management Wants… Production Plan Consumer Demand Time Source: Tom Mc Guffry, Electronic Commerce and Value Chain Management, 1998

Dealing with Uncertainty • • • Pull Systems Risk Pooling Centralization Postponement Strategic Alliances Collaborative Forecasting

Dealing with Uncertainty • • • Pull Systems Risk Pooling Centralization Postponement Strategic Alliances Collaborative Forecasting

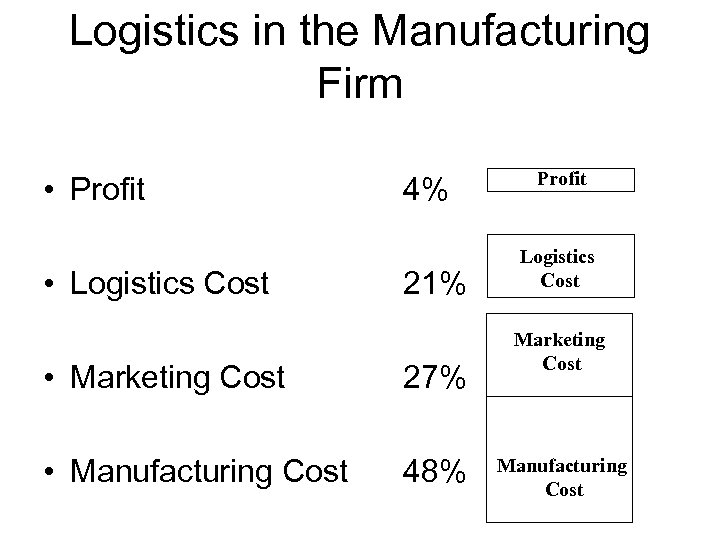

Logistics in the Manufacturing Firm • Profit • Logistics Cost 4% 21% • Marketing Cost 27% • Manufacturing Cost 48% Profit Logistics Cost Marketing Cost Manufacturing Cost

Logistics in the Manufacturing Firm • Profit • Logistics Cost 4% 21% • Marketing Cost 27% • Manufacturing Cost 48% Profit Logistics Cost Marketing Cost Manufacturing Cost

Supply Chain: The Magnitude • Compaq computer estimates it lost $500 million to $1 billion in sales in 1995 because its laptops and desktops were not available when and where customers were ready to buy them. • Boeing aircraft, one of America's leading capital goods producers, was forced to announce write downs of $2. 6 billion in October 1997, due to “Raw material shortages, internal and supplier parts shortages…”.

Supply Chain: The Magnitude • Compaq computer estimates it lost $500 million to $1 billion in sales in 1995 because its laptops and desktops were not available when and where customers were ready to buy them. • Boeing aircraft, one of America's leading capital goods producers, was forced to announce write downs of $2. 6 billion in October 1997, due to “Raw material shortages, internal and supplier parts shortages…”.

Supply Chain: The Potential • Procter & Gamble estimates that it saved retail customers $65 million through logistics gains over the past 18 months. “According to P&G, the essence of its approach lies in manufacturers and suppliers working closely together …. jointly creating business plans to eliminate the source of wasteful practices across the entire supply chain”. (Journal of business strategy, Oct. /Nov. 1997)

Supply Chain: The Potential • Procter & Gamble estimates that it saved retail customers $65 million through logistics gains over the past 18 months. “According to P&G, the essence of its approach lies in manufacturers and suppliers working closely together …. jointly creating business plans to eliminate the source of wasteful practices across the entire supply chain”. (Journal of business strategy, Oct. /Nov. 1997)

Supply Chain: the Potential • In 10 years, Wal-Mart transformed itself by changing its logistics system. It has the highest sales per square foot, inventory turnover and operating profit of any discount retailer. • Dell Computer has outperformed the competition in terms of shareholder value growth over the eight years period, 1988 -1996, by over 3, 000% (see Anderson and Lee, 1999) using – Direct business model – Build-to-order strategy.

Supply Chain: the Potential • In 10 years, Wal-Mart transformed itself by changing its logistics system. It has the highest sales per square foot, inventory turnover and operating profit of any discount retailer. • Dell Computer has outperformed the competition in terms of shareholder value growth over the eight years period, 1988 -1996, by over 3, 000% (see Anderson and Lee, 1999) using – Direct business model – Build-to-order strategy.

Supply Chain: The Complexity • National Semiconductors: – Production: • Produces chips in six different locations: four in the US, one in Britain and one in Israel • Chips are shipped to seven assembly locations in Southeast Asia. – Distribution • The final product is shipped to hundreds of facilities all over the world • 20, 000 different routes • 12 different airlines are involved • 95% of the products are delivered within 45 days • 5% are delivered within 90 days.

Supply Chain: The Complexity • National Semiconductors: – Production: • Produces chips in six different locations: four in the US, one in Britain and one in Israel • Chips are shipped to seven assembly locations in Southeast Asia. – Distribution • The final product is shipped to hundreds of facilities all over the world • 20, 000 different routes • 12 different airlines are involved • 95% of the products are delivered within 45 days • 5% are delivered within 90 days.

What’s New? • • Global competition Shorter product life cycle New, low-cost distribution channels More powerful well-informed customers • Internet and E-Business strategies

What’s New? • • Global competition Shorter product life cycle New, low-cost distribution channels More powerful well-informed customers • Internet and E-Business strategies

New Concepts • Push-Pull strategies • Direct-to-Consumer • Strategic alliances • Manufacturing postponement • Dynamic Pricing • E-Procurement

New Concepts • Push-Pull strategies • Direct-to-Consumer • Strategic alliances • Manufacturing postponement • Dynamic Pricing • E-Procurement

Process View of a Supply Chain • Cycle view: processes in a supply chain are divided into a series of cycles, each performed at the interfaces between two successive supply chain stages • Push/pull view: processes in a supply chain are divided into two categories depending on whether they are executed in response to a customer order (pull) or in anticipation of a customer order (push)

Process View of a Supply Chain • Cycle view: processes in a supply chain are divided into a series of cycles, each performed at the interfaces between two successive supply chain stages • Push/pull view: processes in a supply chain are divided into two categories depending on whether they are executed in response to a customer order (pull) or in anticipation of a customer order (push)

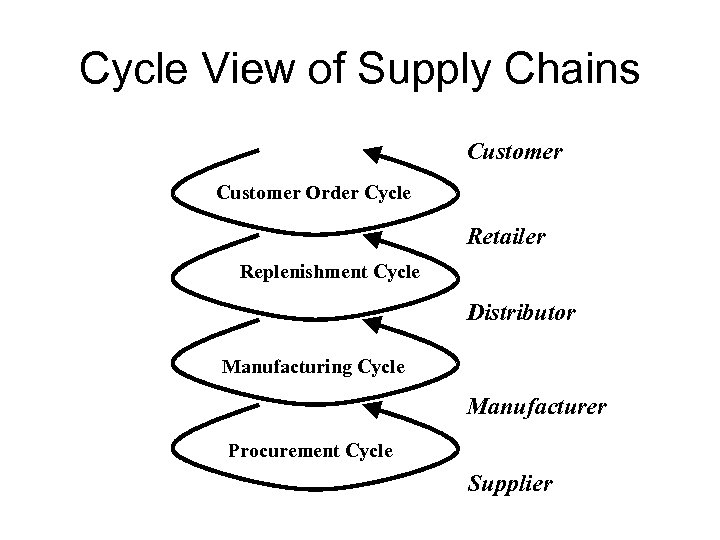

Cycle View of Supply Chains Customer Order Cycle Retailer Replenishment Cycle Distributor Manufacturing Cycle Manufacturer Procurement Cycle Supplier

Cycle View of Supply Chains Customer Order Cycle Retailer Replenishment Cycle Distributor Manufacturing Cycle Manufacturer Procurement Cycle Supplier

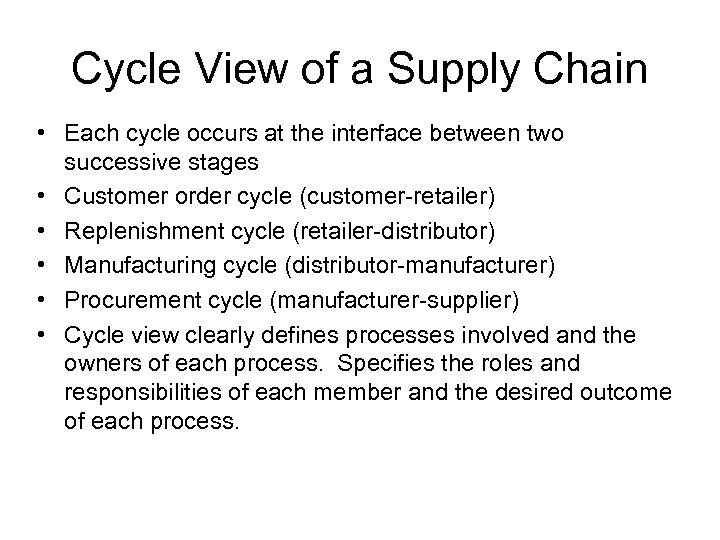

Cycle View of a Supply Chain • Each cycle occurs at the interface between two successive stages • Customer order cycle (customer-retailer) • Replenishment cycle (retailer-distributor) • Manufacturing cycle (distributor-manufacturer) • Procurement cycle (manufacturer-supplier) • Cycle view clearly defines processes involved and the owners of each process. Specifies the roles and responsibilities of each member and the desired outcome of each process.

Cycle View of a Supply Chain • Each cycle occurs at the interface between two successive stages • Customer order cycle (customer-retailer) • Replenishment cycle (retailer-distributor) • Manufacturing cycle (distributor-manufacturer) • Procurement cycle (manufacturer-supplier) • Cycle view clearly defines processes involved and the owners of each process. Specifies the roles and responsibilities of each member and the desired outcome of each process.

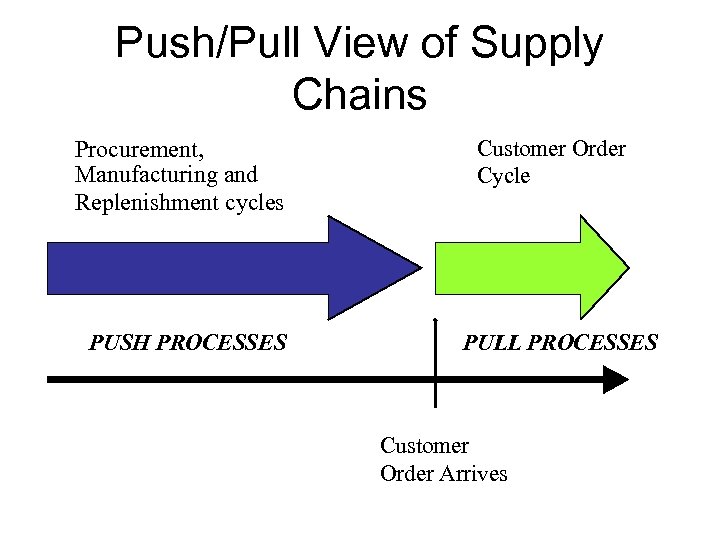

Push/Pull View of Supply Chains Procurement, Manufacturing and Replenishment cycles PUSH PROCESSES Customer Order Cycle PULL PROCESSES Customer Order Arrives

Push/Pull View of Supply Chains Procurement, Manufacturing and Replenishment cycles PUSH PROCESSES Customer Order Cycle PULL PROCESSES Customer Order Arrives

Push/Pull View of Supply Chain Processes • Supply chain processes fall into one of two categories depending on the timing of their execution relative to customer demand • Pull: execution is initiated in response to a customer order (reactive) • Push: execution is initiated in anticipation of customer orders (speculative) • Push/pull boundary separates push processes from pull processes

Push/Pull View of Supply Chain Processes • Supply chain processes fall into one of two categories depending on the timing of their execution relative to customer demand • Pull: execution is initiated in response to a customer order (reactive) • Push: execution is initiated in anticipation of customer orders (speculative) • Push/pull boundary separates push processes from pull processes

Supply Chain Performance: Achieving Strategic Fit and Scope

Supply Chain Performance: Achieving Strategic Fit and Scope

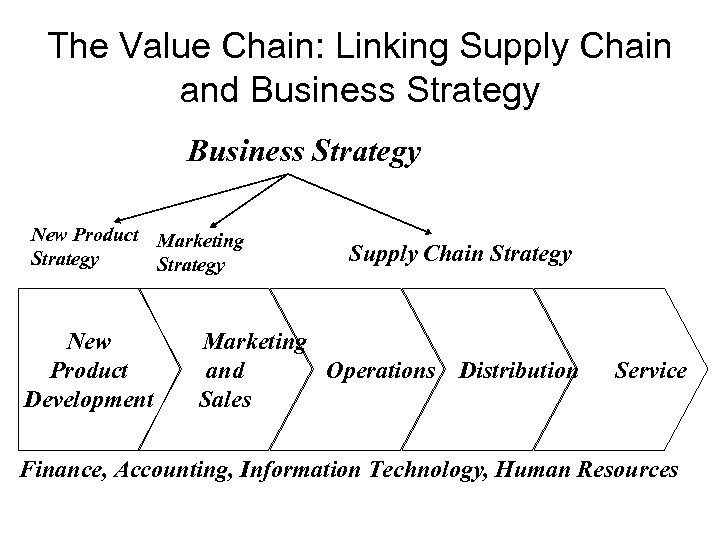

The Value Chain: Linking Supply Chain and Business Strategy New Product Marketing Strategy New Product Development Supply Chain Strategy Marketing and Operations Distribution Sales Service Finance, Accounting, Information Technology, Human Resources

The Value Chain: Linking Supply Chain and Business Strategy New Product Marketing Strategy New Product Development Supply Chain Strategy Marketing and Operations Distribution Sales Service Finance, Accounting, Information Technology, Human Resources

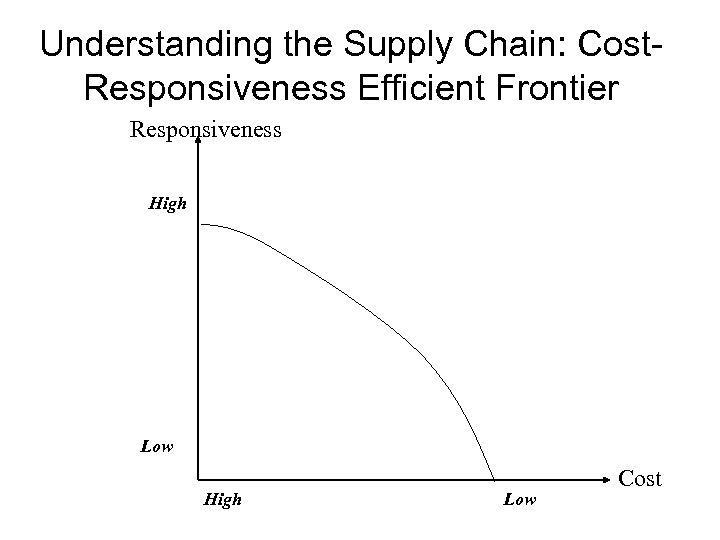

Understanding the Supply Chain: Cost. Responsiveness Efficient Frontier Responsiveness High Low Cost

Understanding the Supply Chain: Cost. Responsiveness Efficient Frontier Responsiveness High Low Cost

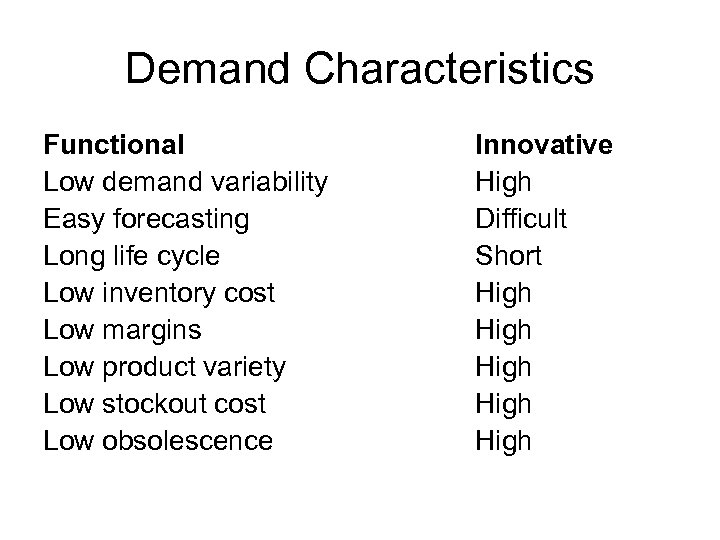

Demand Characteristics Functional Low demand variability Easy forecasting Long life cycle Low inventory cost Low margins Low product variety Low stockout cost Low obsolescence Innovative High Difficult Short High High

Demand Characteristics Functional Low demand variability Easy forecasting Long life cycle Low inventory cost Low margins Low product variety Low stockout cost Low obsolescence Innovative High Difficult Short High High

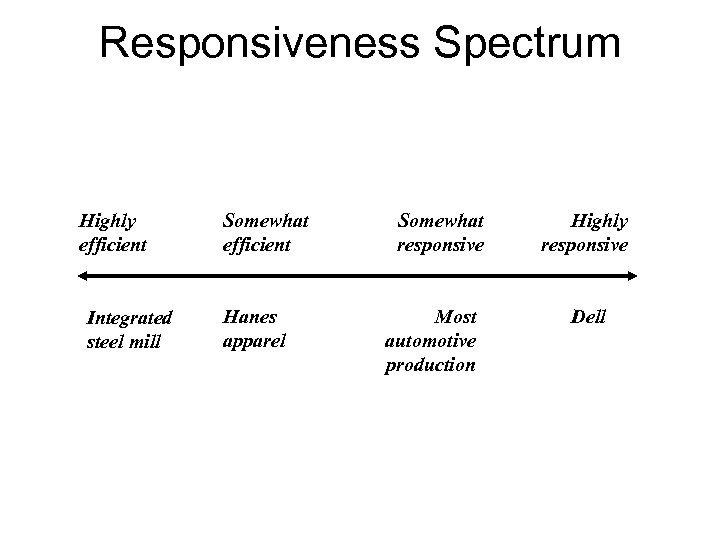

Responsiveness Spectrum Highly efficient Integrated steel mill Somewhat efficient Hanes apparel Somewhat responsive Most automotive production Highly responsive Dell

Responsiveness Spectrum Highly efficient Integrated steel mill Somewhat efficient Hanes apparel Somewhat responsive Most automotive production Highly responsive Dell

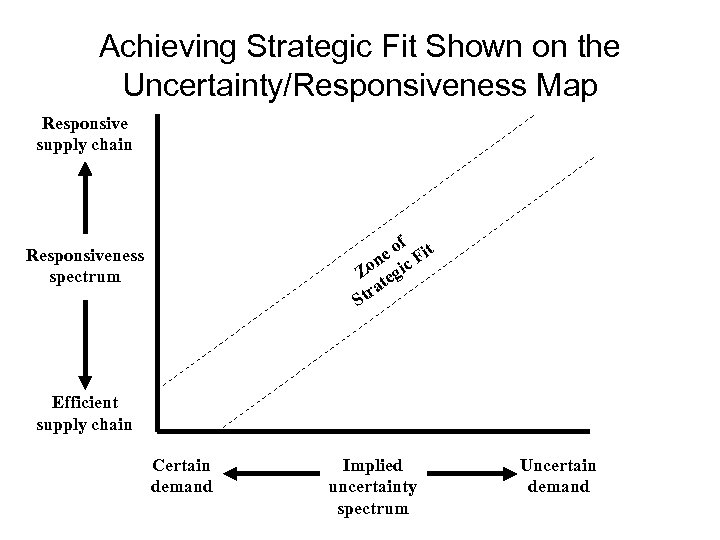

Achieving Strategic Fit Shown on the Uncertainty/Responsiveness Map Responsive supply chain f e o Fit n Zo tegic ra St Responsiveness spectrum Efficient supply chain Certain demand Implied uncertainty spectrum Uncertain demand

Achieving Strategic Fit Shown on the Uncertainty/Responsiveness Map Responsive supply chain f e o Fit n Zo tegic ra St Responsiveness spectrum Efficient supply chain Certain demand Implied uncertainty spectrum Uncertain demand

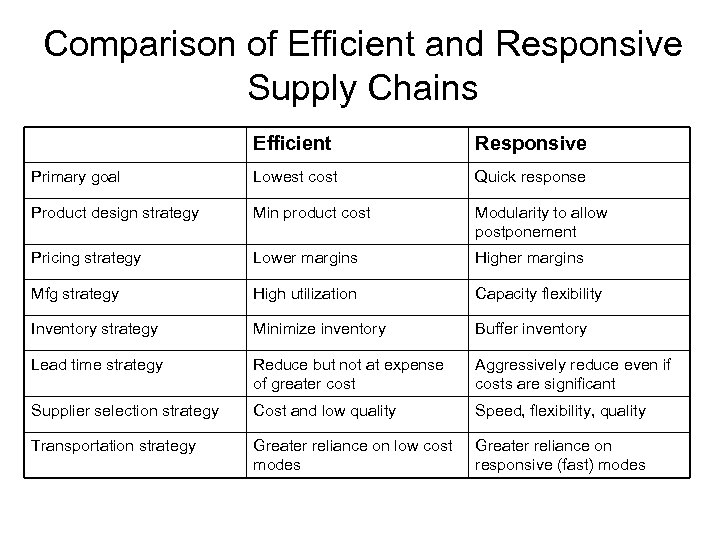

Comparison of Efficient and Responsive Supply Chains Efficient Responsive Primary goal Lowest cost Quick response Product design strategy Min product cost Modularity to allow postponement Pricing strategy Lower margins Higher margins Mfg strategy High utilization Capacity flexibility Inventory strategy Minimize inventory Buffer inventory Lead time strategy Reduce but not at expense of greater cost Aggressively reduce even if costs are significant Supplier selection strategy Cost and low quality Speed, flexibility, quality Transportation strategy Greater reliance on low cost modes Greater reliance on responsive (fast) modes

Comparison of Efficient and Responsive Supply Chains Efficient Responsive Primary goal Lowest cost Quick response Product design strategy Min product cost Modularity to allow postponement Pricing strategy Lower margins Higher margins Mfg strategy High utilization Capacity flexibility Inventory strategy Minimize inventory Buffer inventory Lead time strategy Reduce but not at expense of greater cost Aggressively reduce even if costs are significant Supplier selection strategy Cost and low quality Speed, flexibility, quality Transportation strategy Greater reliance on low cost modes Greater reliance on responsive (fast) modes

Supply Chain Drivers and Obstacles

Supply Chain Drivers and Obstacles

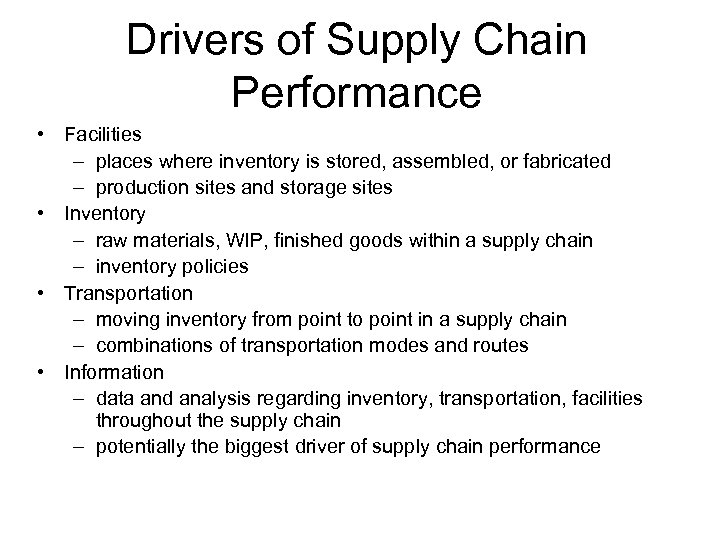

Drivers of Supply Chain Performance • Facilities – places where inventory is stored, assembled, or fabricated – production sites and storage sites • Inventory – raw materials, WIP, finished goods within a supply chain – inventory policies • Transportation – moving inventory from point to point in a supply chain – combinations of transportation modes and routes • Information – data and analysis regarding inventory, transportation, facilities throughout the supply chain – potentially the biggest driver of supply chain performance

Drivers of Supply Chain Performance • Facilities – places where inventory is stored, assembled, or fabricated – production sites and storage sites • Inventory – raw materials, WIP, finished goods within a supply chain – inventory policies • Transportation – moving inventory from point to point in a supply chain – combinations of transportation modes and routes • Information – data and analysis regarding inventory, transportation, facilities throughout the supply chain – potentially the biggest driver of supply chain performance

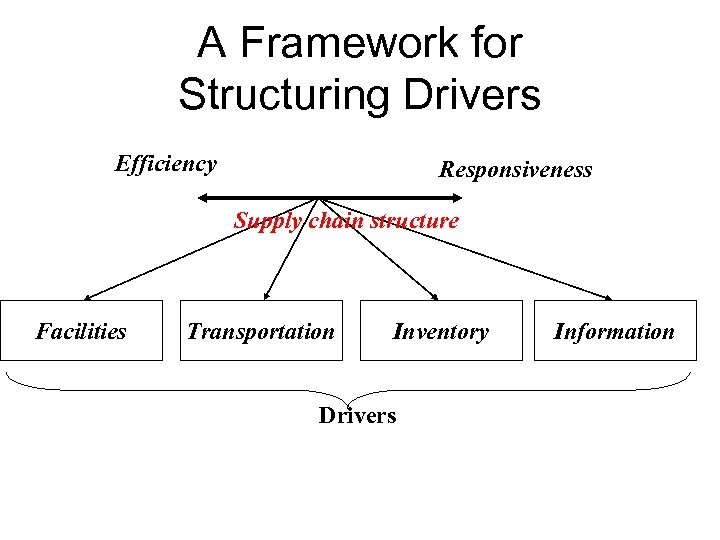

A Framework for Structuring Drivers Efficiency Responsiveness Supply chain structure Facilities Transportation Inventory Drivers Information

A Framework for Structuring Drivers Efficiency Responsiveness Supply chain structure Facilities Transportation Inventory Drivers Information

Information: Role in the Supply Chain • The connection between the various stages in the supply chain – allows coordination between stages • Crucial to daily operation of each stage in a supply chain – e. g. , production scheduling, inventory levels

Information: Role in the Supply Chain • The connection between the various stages in the supply chain – allows coordination between stages • Crucial to daily operation of each stage in a supply chain – e. g. , production scheduling, inventory levels

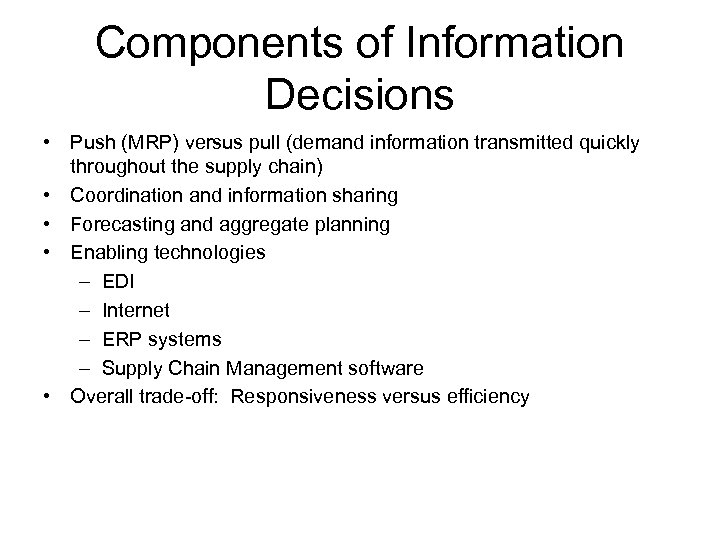

Components of Information Decisions • Push (MRP) versus pull (demand information transmitted quickly throughout the supply chain) • Coordination and information sharing • Forecasting and aggregate planning • Enabling technologies – EDI – Internet – ERP systems – Supply Chain Management software • Overall trade-off: Responsiveness versus efficiency

Components of Information Decisions • Push (MRP) versus pull (demand information transmitted quickly throughout the supply chain) • Coordination and information sharing • Forecasting and aggregate planning • Enabling technologies – EDI – Internet – ERP systems – Supply Chain Management software • Overall trade-off: Responsiveness versus efficiency

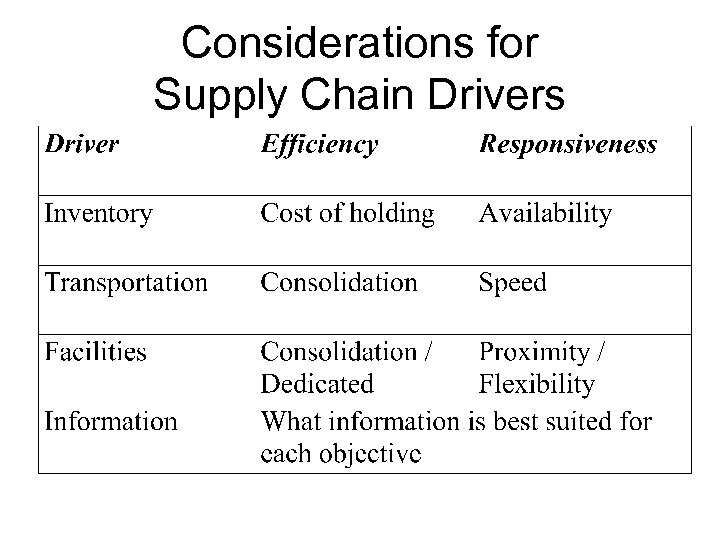

Considerations for Supply Chain Drivers

Considerations for Supply Chain Drivers

Obstacles to Achieving Strategic Fit • • • Increasing variety of products Decreasing product life cycles Increasingly demanding customers Fragmentation of supply chain ownership Globalization Difficulty executing new strategies

Obstacles to Achieving Strategic Fit • • • Increasing variety of products Decreasing product life cycles Increasingly demanding customers Fragmentation of supply chain ownership Globalization Difficulty executing new strategies

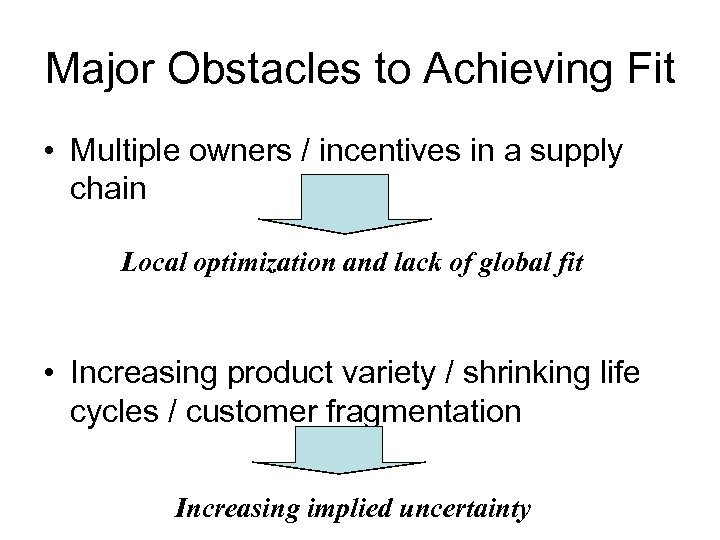

Major Obstacles to Achieving Fit • Multiple owners / incentives in a supply chain Local optimization and lack of global fit • Increasing product variety / shrinking life cycles / customer fragmentation Increasing implied uncertainty

Major Obstacles to Achieving Fit • Multiple owners / incentives in a supply chain Local optimization and lack of global fit • Increasing product variety / shrinking life cycles / customer fragmentation Increasing implied uncertainty

Summary • What are the major drivers of supply chain performance? • What is the role of each driver in creating strategic fit between supply chain strategy and competitive strategy (or between implied demand uncertainty and supply chain responsiveness)? • What are the major obstacles to achieving strategic fit? • In the remainder of the course, we will learn how to make decisions with respect to these drivers in order to achieve strategic fit and surmount these obstacles

Summary • What are the major drivers of supply chain performance? • What is the role of each driver in creating strategic fit between supply chain strategy and competitive strategy (or between implied demand uncertainty and supply chain responsiveness)? • What are the major obstacles to achieving strategic fit? • In the remainder of the course, we will learn how to make decisions with respect to these drivers in order to achieve strategic fit and surmount these obstacles

Step 1: Understanding the Customer and Supply Chain Uncertainty • • Identify the needs of the customer segment being served Quantity of product needed in each lot Response time customers will tolerate Variety of products needed Service level required Price of the product Desired rate of innovation in the product

Step 1: Understanding the Customer and Supply Chain Uncertainty • • Identify the needs of the customer segment being served Quantity of product needed in each lot Response time customers will tolerate Variety of products needed Service level required Price of the product Desired rate of innovation in the product

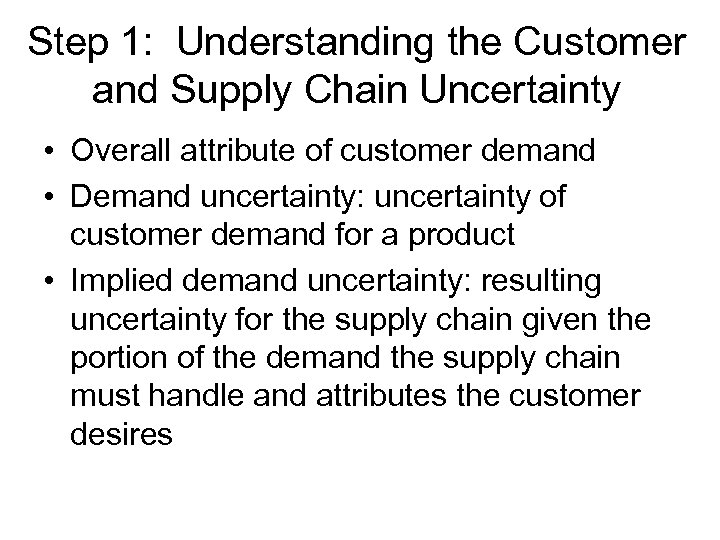

Step 1: Understanding the Customer and Supply Chain Uncertainty • Overall attribute of customer demand • Demand uncertainty: uncertainty of customer demand for a product • Implied demand uncertainty: resulting uncertainty for the supply chain given the portion of the demand the supply chain must handle and attributes the customer desires

Step 1: Understanding the Customer and Supply Chain Uncertainty • Overall attribute of customer demand • Demand uncertainty: uncertainty of customer demand for a product • Implied demand uncertainty: resulting uncertainty for the supply chain given the portion of the demand the supply chain must handle and attributes the customer desires

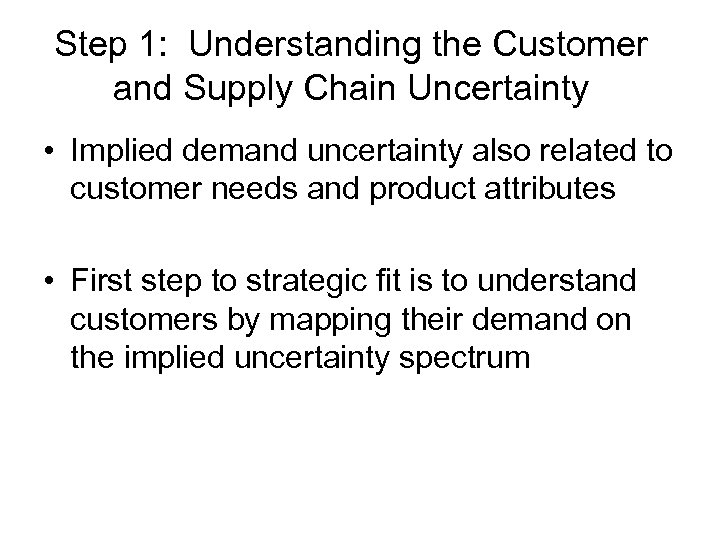

Step 1: Understanding the Customer and Supply Chain Uncertainty • Implied demand uncertainty also related to customer needs and product attributes • First step to strategic fit is to understand customers by mapping their demand on the implied uncertainty spectrum

Step 1: Understanding the Customer and Supply Chain Uncertainty • Implied demand uncertainty also related to customer needs and product attributes • First step to strategic fit is to understand customers by mapping their demand on the implied uncertainty spectrum

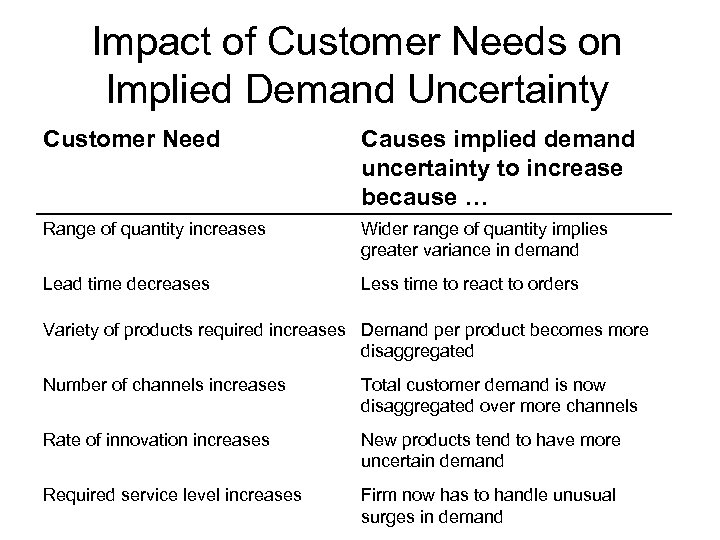

Impact of Customer Needs on Implied Demand Uncertainty Customer Need Causes implied demand uncertainty to increase because … Range of quantity increases Wider range of quantity implies greater variance in demand Lead time decreases Less time to react to orders Variety of products required increases Demand per product becomes more disaggregated Number of channels increases Total customer demand is now disaggregated over more channels Rate of innovation increases New products tend to have more uncertain demand Required service level increases Firm now has to handle unusual surges in demand

Impact of Customer Needs on Implied Demand Uncertainty Customer Need Causes implied demand uncertainty to increase because … Range of quantity increases Wider range of quantity implies greater variance in demand Lead time decreases Less time to react to orders Variety of products required increases Demand per product becomes more disaggregated Number of channels increases Total customer demand is now disaggregated over more channels Rate of innovation increases New products tend to have more uncertain demand Required service level increases Firm now has to handle unusual surges in demand

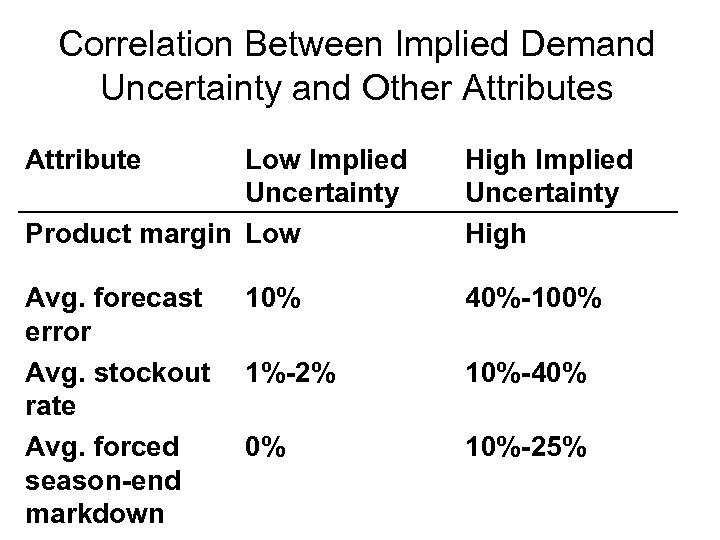

Correlation Between Implied Demand Uncertainty and Other Attributes Attribute Low Implied Uncertainty Product margin Low High Implied Uncertainty High Avg. forecast error Avg. stockout rate Avg. forced season-end markdown 10% 40%-100% 1%-2% 10%-40% 0% 10%-25%

Correlation Between Implied Demand Uncertainty and Other Attributes Attribute Low Implied Uncertainty Product margin Low High Implied Uncertainty High Avg. forecast error Avg. stockout rate Avg. forced season-end markdown 10% 40%-100% 1%-2% 10%-40% 0% 10%-25%

Step 2: Understanding the Supply Chain • How does the firm best meet demand? • Dimension describing the supply chain is supply chain responsiveness • Supply chain responsiveness -- ability to – respond to wide ranges of quantities demanded – meet short lead times – handle a large variety of products – build highly innovative products – meet a very high service level

Step 2: Understanding the Supply Chain • How does the firm best meet demand? • Dimension describing the supply chain is supply chain responsiveness • Supply chain responsiveness -- ability to – respond to wide ranges of quantities demanded – meet short lead times – handle a large variety of products – build highly innovative products – meet a very high service level

Step 2: Understanding the Supply Chain • There is a cost to achieving responsiveness • Supply chain efficiency: cost of making and delivering the product to the customer • Increasing responsiveness results in higher costs that lower efficiency • strategic fit is to map the supply chain on the responsiveness spectrum

Step 2: Understanding the Supply Chain • There is a cost to achieving responsiveness • Supply chain efficiency: cost of making and delivering the product to the customer • Increasing responsiveness results in higher costs that lower efficiency • strategic fit is to map the supply chain on the responsiveness spectrum

Step 3: Achieving Strategic Fit • Step is to ensure that what the supply chain does well is consistent with target customer’s needs • Examples: Dell, Barilla

Step 3: Achieving Strategic Fit • Step is to ensure that what the supply chain does well is consistent with target customer’s needs • Examples: Dell, Barilla