7b6dfd89363c87acbd87539be140abeb.ppt

- Количество слайдов: 75

Introduction to Operations Management

Introduction to Operations Management

What is Operations? Operations is the production activities that go on in the organization, regardless of whether the end product is a good or a service 2

What is Operations? Operations is the production activities that go on in the organization, regardless of whether the end product is a good or a service 2

What Is Operations Management (OM)? Operations management is defined as the design, operation, and improvement of the systems that create the firm’s primary products and services Operations management is the management of systems or processes that creates value in the form of goods and services by transforming inputs into desired outputs 3

What Is Operations Management (OM)? Operations management is defined as the design, operation, and improvement of the systems that create the firm’s primary products and services Operations management is the management of systems or processes that creates value in the form of goods and services by transforming inputs into desired outputs 3

The Operations Function ü Operations as a transformation process ü Operations as a basic function ü Operations as the technical core 4

The Operations Function ü Operations as a transformation process ü Operations as a basic function ü Operations as the technical core 4

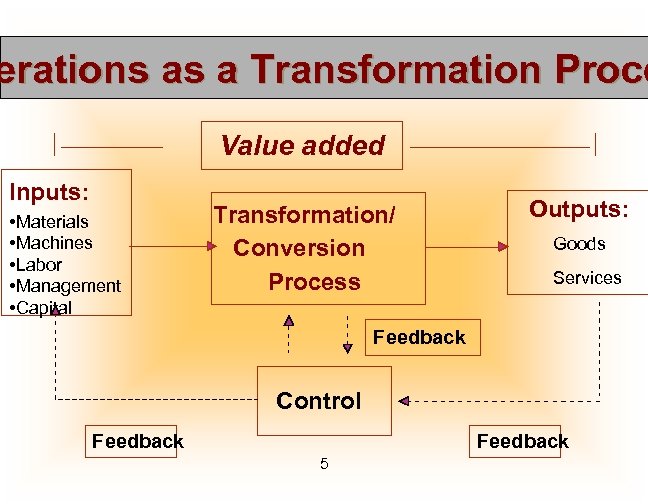

erations as a Transformation Proce Value added Inputs: • Materials • Machines • Labor • Management • Capital Transformation/ Conversion Process Outputs: Goods Services Feedback Control Feedback 5

erations as a Transformation Proce Value added Inputs: • Materials • Machines • Labor • Management • Capital Transformation/ Conversion Process Outputs: Goods Services Feedback Control Feedback 5

What is Value Added? Value added is the difference between the cost of intputs and the value or price of outputs. The essence of operations function is to add value during the transformation process

What is Value Added? Value added is the difference between the cost of intputs and the value or price of outputs. The essence of operations function is to add value during the transformation process

Firms use the money generated by value added for: ØR&D ØInvestment in new facilities and equipment ØPaying workers ØPaying for materials ØPaying for general expenses ØProfits 7

Firms use the money generated by value added for: ØR&D ØInvestment in new facilities and equipment ØPaying workers ØPaying for materials ØPaying for general expenses ØProfits 7

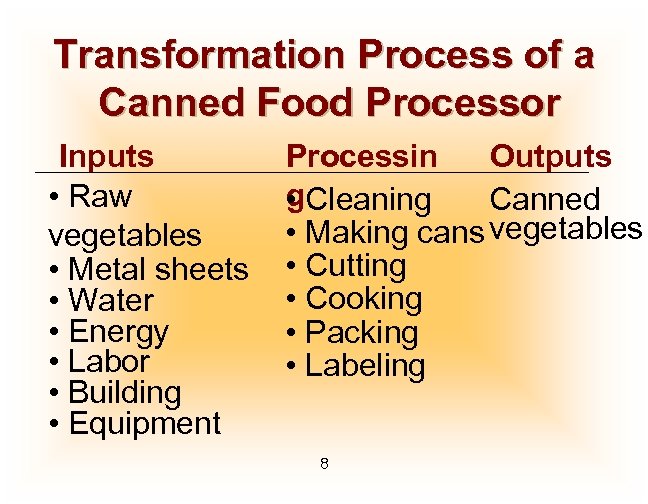

Transformation Process of a Canned Food Processor Inputs • Raw vegetables • Metal sheets • Water • Energy • Labor • Building • Equipment Processin Outputs g • Cleaning Canned • Making cans vegetables • Cutting • Cooking • Packing • Labeling 8

Transformation Process of a Canned Food Processor Inputs • Raw vegetables • Metal sheets • Water • Energy • Labor • Building • Equipment Processin Outputs g • Cleaning Canned • Making cans vegetables • Cutting • Cooking • Packing • Labeling 8

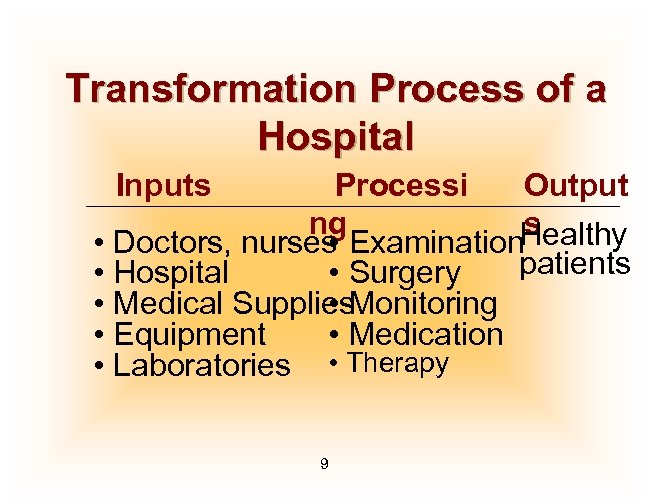

Transformation Process of a Hospital Inputs Processi Output ng s Healthy • Doctors, nurses Examination • patients • Hospital • Surgery • Medical Supplies. Monitoring • • Equipment • Medication • Laboratories • Therapy 9

Transformation Process of a Hospital Inputs Processi Output ng s Healthy • Doctors, nurses Examination • patients • Hospital • Surgery • Medical Supplies. Monitoring • • Equipment • Medication • Laboratories • Therapy 9

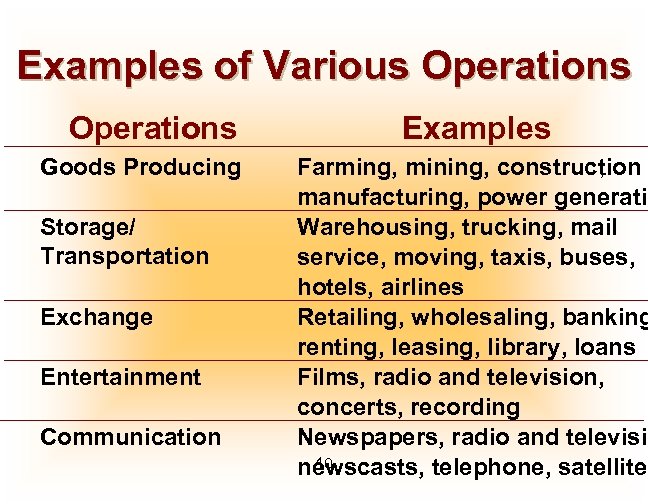

Examples of Various Operations Goods Producing Storage/ Transportation Exchange Entertainment Communication Examples Farming, mining, construction , manufacturing, power generatio Warehousing, trucking, mail service, moving, taxis, buses, hotels, airlines Retailing, wholesaling, banking renting, leasing, library, loans Films, radio and television, concerts, recording Newspapers, radio and televisio 10 newscasts, telephone, satellites

Examples of Various Operations Goods Producing Storage/ Transportation Exchange Entertainment Communication Examples Farming, mining, construction , manufacturing, power generatio Warehousing, trucking, mail service, moving, taxis, buses, hotels, airlines Retailing, wholesaling, banking renting, leasing, library, loans Films, radio and television, concerts, recording Newspapers, radio and televisio 10 newscasts, telephone, satellites

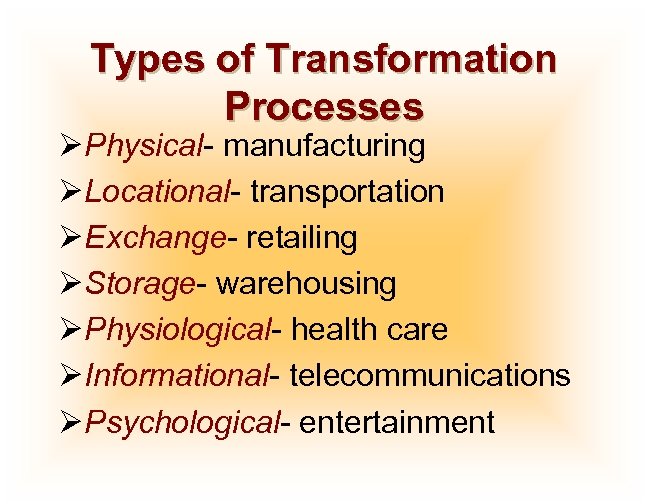

Types of Transformation Processes ØPhysical- manufacturing ØLocational- transportation ØExchange- retailing ØStorage- warehousing ØPhysiological- health care ØInformational- telecommunications ØPsychological- entertainment

Types of Transformation Processes ØPhysical- manufacturing ØLocational- transportation ØExchange- retailing ØStorage- warehousing ØPhysiological- health care ØInformational- telecommunications ØPsychological- entertainment

Operations as a Basic Function Ø Marketing Ø Generates demand gets customers Ø Operations Ø creates product or service Ø Finance/Accounti ng Obtains funds 12 Ø Tracks organizational performance Ø

Operations as a Basic Function Ø Marketing Ø Generates demand gets customers Ø Operations Ø creates product or service Ø Finance/Accounti ng Obtains funds 12 Ø Tracks organizational performance Ø

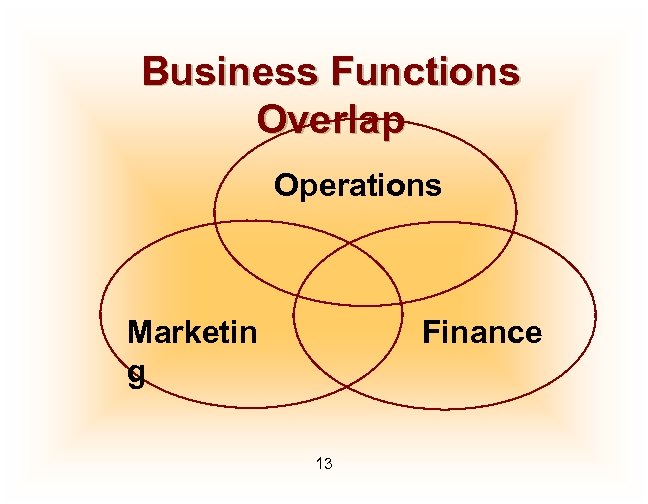

Business Functions Overlap Operations Marketin g Finance 13

Business Functions Overlap Operations Marketin g Finance 13

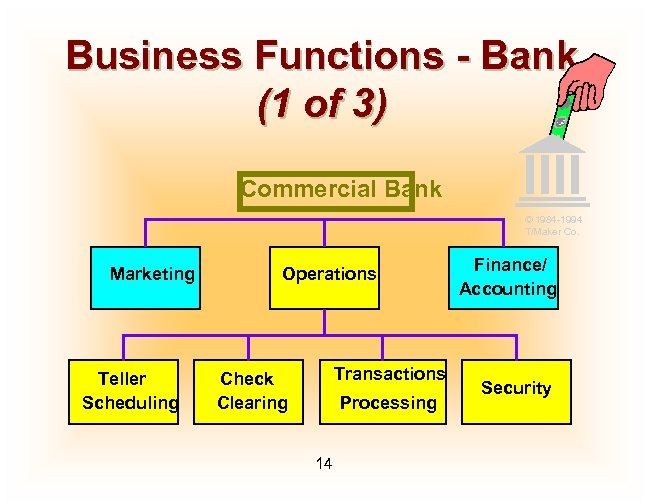

Business Functions - Bank (1 of 3) Commercial Bank © 1984 -1994 T/Maker Co. Marketing Teller Scheduling Operations Transactions Check Clearing Processing 14 Finance/ Accounting Security

Business Functions - Bank (1 of 3) Commercial Bank © 1984 -1994 T/Maker Co. Marketing Teller Scheduling Operations Transactions Check Clearing Processing 14 Finance/ Accounting Security

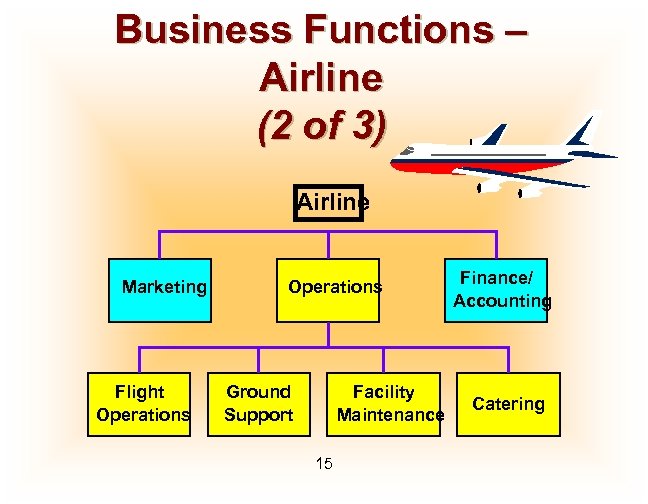

Business Functions – Airline (2 of 3) Airline Marketing Flight Operations Ground Support Facility Maintenance 15 Finance/ Accounting Catering

Business Functions – Airline (2 of 3) Airline Marketing Flight Operations Ground Support Facility Maintenance 15 Finance/ Accounting Catering

Business Functions – Manufacturer (3 of 3) Manufacturing Marketing Manufacturing Operations Production Control 16 Quality Control Finance/ Accounting Purchasing

Business Functions – Manufacturer (3 of 3) Manufacturing Marketing Manufacturing Operations Production Control 16 Quality Control Finance/ Accounting Purchasing

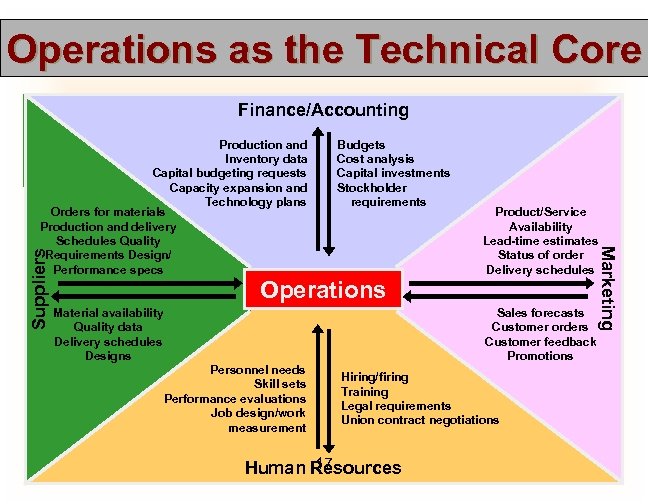

Operations as the Technical Core Finance/Accounting Suppliers Budgets Cost analysis Capital investments Stockholder requirements Product/Service Availability Lead-time estimates Status of order Delivery schedules Operations Material availability Quality data Delivery schedules Designs Sales forecasts Customer orders Customer feedback Promotions Personnel needs Skill sets Performance evaluations Job design/work measurement Hiring/firing Training Legal requirements Union contract negotiations 17 Human Resources Marketing Production and Inventory data Capital budgeting requests Capacity expansion and Technology plans Orders for materials Production and delivery Schedules Quality Requirements Design/ Performance specs

Operations as the Technical Core Finance/Accounting Suppliers Budgets Cost analysis Capital investments Stockholder requirements Product/Service Availability Lead-time estimates Status of order Delivery schedules Operations Material availability Quality data Delivery schedules Designs Sales forecasts Customer orders Customer feedback Promotions Personnel needs Skill sets Performance evaluations Job design/work measurement Hiring/firing Training Legal requirements Union contract negotiations 17 Human Resources Marketing Production and Inventory data Capital budgeting requests Capacity expansion and Technology plans Orders for materials Production and delivery Schedules Quality Requirements Design/ Performance specs

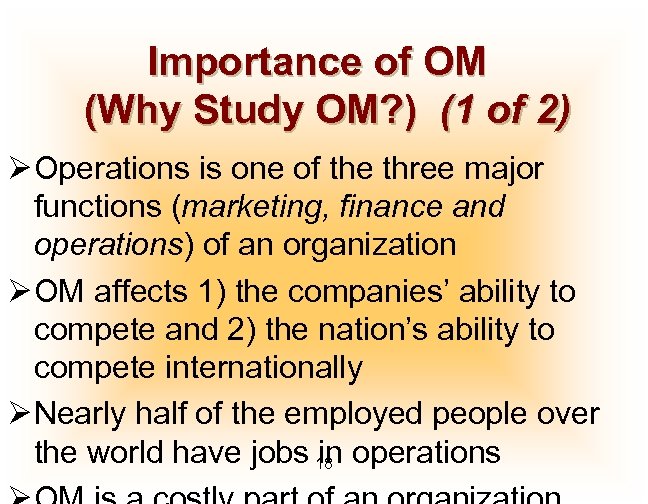

Importance of OM (Why Study OM? ) (1 of 2) Ø Operations is one of the three major functions (marketing, finance and operations) of an organization Ø OM affects 1) the companies’ ability to compete and 2) the nation’s ability to compete internationally Ø Nearly half of the employed people over the world have jobs 18 operations in

Importance of OM (Why Study OM? ) (1 of 2) Ø Operations is one of the three major functions (marketing, finance and operations) of an organization Ø OM affects 1) the companies’ ability to compete and 2) the nation’s ability to compete internationally Ø Nearly half of the employed people over the world have jobs 18 operations in

Importance of OM (Why Study OM? ) – (2 of 2) Ø Offers a major opportunity for an organization to improve its productivity and profitability Ø The OM function is responsible for a major portion of the assets of most organizations Ø The concepts, tools and techniques of OM are widely used in managing other 19 functions.

Importance of OM (Why Study OM? ) – (2 of 2) Ø Offers a major opportunity for an organization to improve its productivity and profitability Ø The OM function is responsible for a major portion of the assets of most organizations Ø The concepts, tools and techniques of OM are widely used in managing other 19 functions.

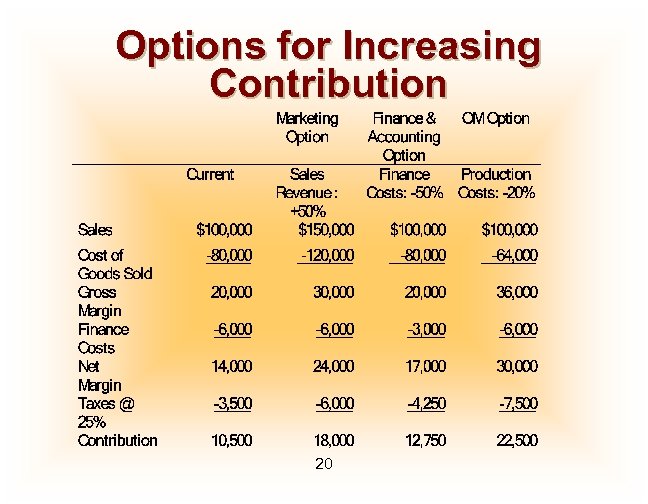

Options for Increasing Contribution 20

Options for Increasing Contribution 20

Production of Goods vs. Delivery of Services 21

Production of Goods vs. Delivery of Services 21

Manufacturing or Service Tangible Act 22

Manufacturing or Service Tangible Act 22

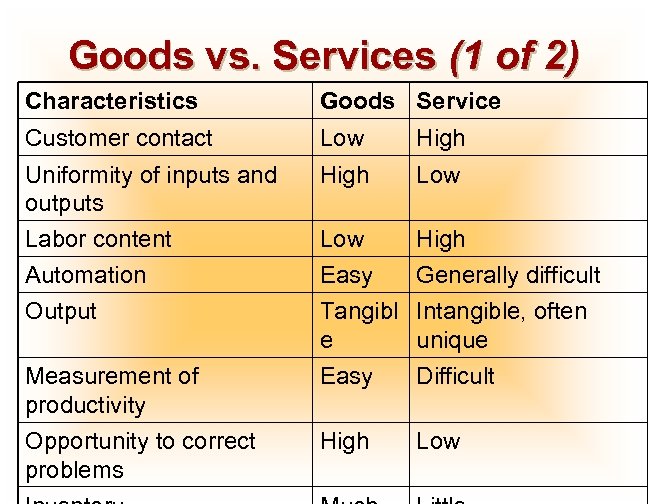

Goods vs. Services (1 of 2) Characteristics Goods Service Customer contact Low High Uniformity of inputs and outputs High Low Labor content Automation Output Low Easy Tangibl e High Generally difficult Intangible, often unique Measurement of productivity Opportunity to correct problems Easy Difficult High Low

Goods vs. Services (1 of 2) Characteristics Goods Service Customer contact Low High Uniformity of inputs and outputs High Low Labor content Automation Output Low Easy Tangibl e High Generally difficult Intangible, often unique Measurement of productivity Opportunity to correct problems Easy Difficult High Low

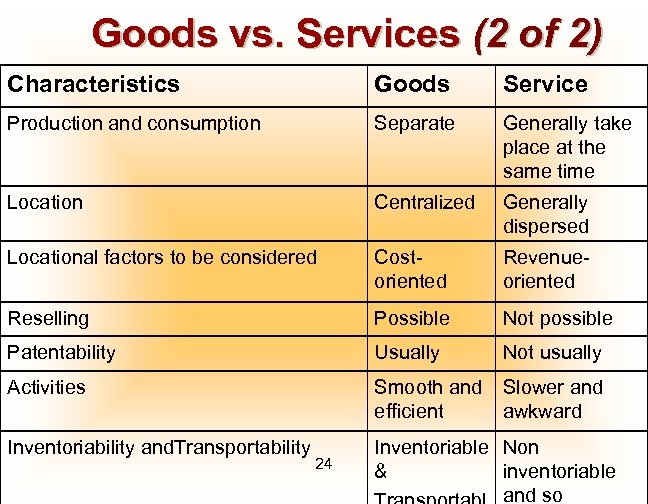

Goods vs. Services (2 of 2) Characteristics Goods Service Production and consumption Separate Generally take place at the same time Location Centralized Generally dispersed Locational factors to be considered Costoriented Revenueoriented Reselling Possible Not possible Patentability Usually Not usually Activities Smooth and efficient Slower and awkward Inventoriability and. Transportability Inventoriable Non & inventoriable and so 24

Goods vs. Services (2 of 2) Characteristics Goods Service Production and consumption Separate Generally take place at the same time Location Centralized Generally dispersed Locational factors to be considered Costoriented Revenueoriented Reselling Possible Not possible Patentability Usually Not usually Activities Smooth and efficient Slower and awkward Inventoriability and. Transportability Inventoriable Non & inventoriable and so 24

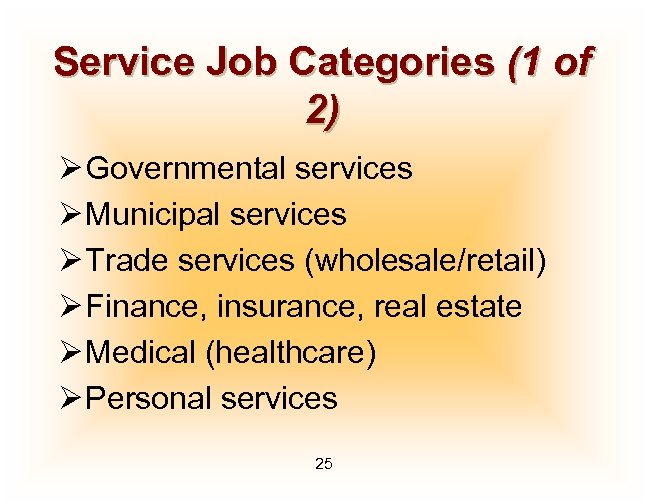

Service Job Categories (1 of 2) Ø Governmental services Ø Municipal services Ø Trade services (wholesale/retail) Ø Finance, insurance, real estate Ø Medical (healthcare) Ø Personal services 25

Service Job Categories (1 of 2) Ø Governmental services Ø Municipal services Ø Trade services (wholesale/retail) Ø Finance, insurance, real estate Ø Medical (healthcare) Ø Personal services 25

Service Job Categories (2 of 2) Ø Business services Ø Education Ø Food, lodging and entertainment Ø Utilities and transportation Ø Legal, consulting Ø Repair 26

Service Job Categories (2 of 2) Ø Business services Ø Education Ø Food, lodging and entertainment Ø Utilities and transportation Ø Legal, consulting Ø Repair 26

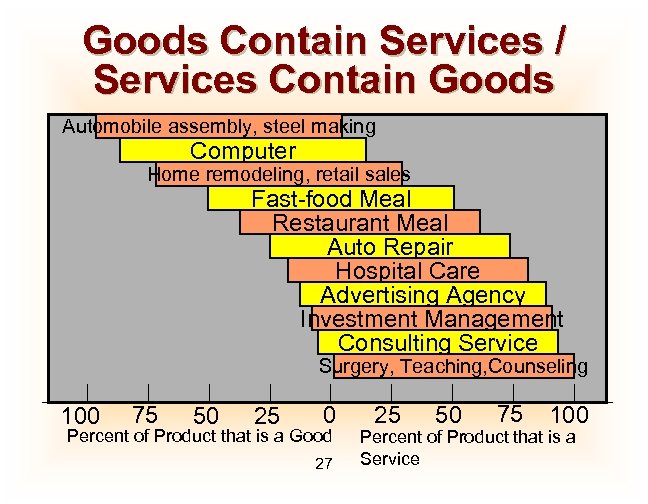

Goods Contain Services / Services Contain Goods Automobile assembly, steel making Computer Home remodeling, retail sales Fast-food Meal Restaurant Meal Auto Repair Hospital Care Advertising Agency Investment Management Consulting Service Surgery, Teaching, Counseling 100 75 50 25 0 Percent of Product that is a Good 27 25 50 75 100 Percent of Product that is a Service

Goods Contain Services / Services Contain Goods Automobile assembly, steel making Computer Home remodeling, retail sales Fast-food Meal Restaurant Meal Auto Repair Hospital Care Advertising Agency Investment Management Consulting Service Surgery, Teaching, Counseling 100 75 50 25 0 Percent of Product that is a Good 27 25 50 75 100 Percent of Product that is a Service

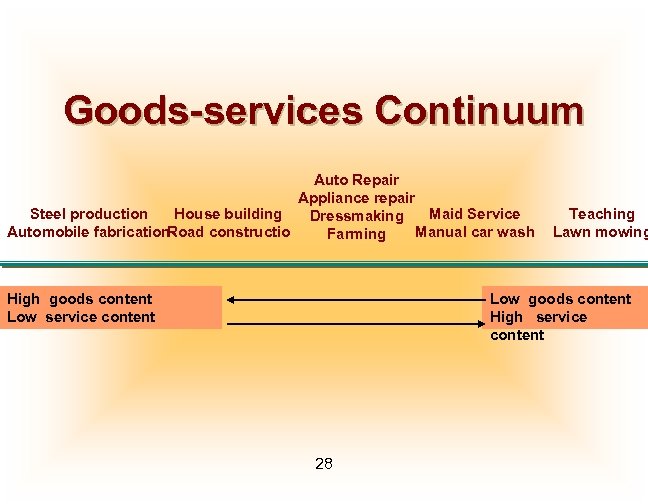

Goods-services Continuum Auto Repair Appliance repair Steel production House building Maid Service Dressmaking Automobile fabrication Road constructio Manual car wash Farming High goods content Low service content Teaching Lawn mowing Low goods content High service content 28

Goods-services Continuum Auto Repair Appliance repair Steel production House building Maid Service Dressmaking Automobile fabrication Road constructio Manual car wash Farming High goods content Low service content Teaching Lawn mowing Low goods content High service content 28

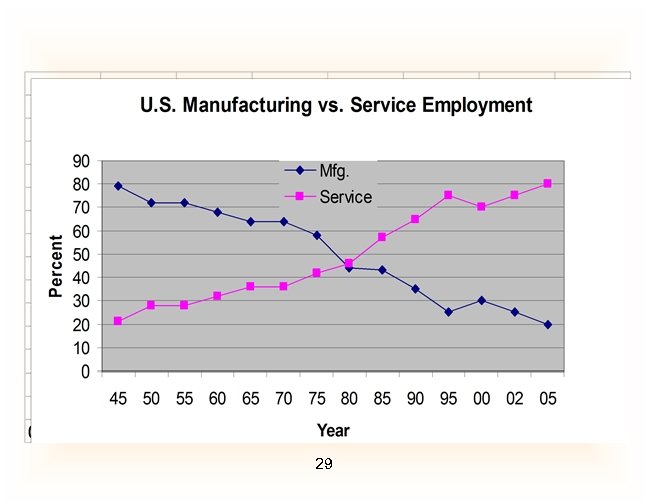

29

29

Decline in Manufacturing Jobs Ø Productivity Ø Increasing productivity allows companies to maintain or increase their output using fewer workers Ø Outsourcing Ø Some manufacturing work has been outsourced to more productive companies 30

Decline in Manufacturing Jobs Ø Productivity Ø Increasing productivity allows companies to maintain or increase their output using fewer workers Ø Outsourcing Ø Some manufacturing work has been outsourced to more productive companies 30

Challenges of Managing Services Ø Service jobs are often less structured than manufacturing jobs Ø Customer contact is higher Ø Worker skill levels are lower Ø Services hire many low-skill, entry-level workers Ø Employee turnover is higher Ø Input variability is higher 31 Ø Service performance can be affected by

Challenges of Managing Services Ø Service jobs are often less structured than manufacturing jobs Ø Customer contact is higher Ø Worker skill levels are lower Ø Services hire many low-skill, entry-level workers Ø Employee turnover is higher Ø Input variability is higher 31 Ø Service performance can be affected by

Services in Manufacturing In manufacturing, services can be divided into two groups: ØCore Services ØValue-added Services

Services in Manufacturing In manufacturing, services can be divided into two groups: ØCore Services ØValue-added Services

Core services are basic things that Services customers want from products they purchase 33

Core services are basic things that Services customers want from products they purchase 33

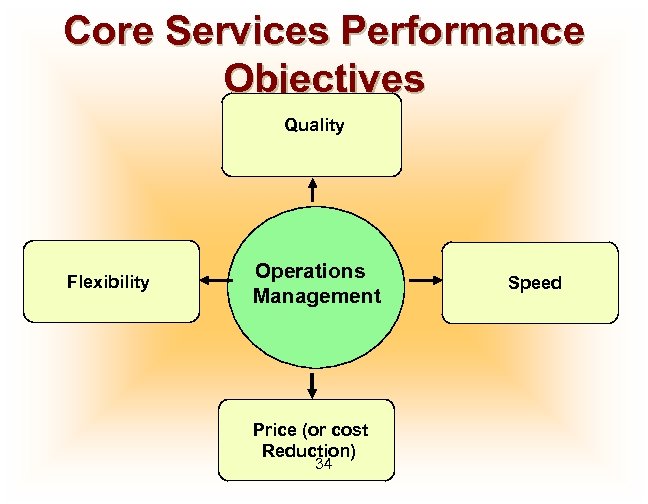

Core Services Performance Objectives Quality Flexibility Operations Management Price (or cost Reduction) 34 Speed

Core Services Performance Objectives Quality Flexibility Operations Management Price (or cost Reduction) 34 Speed

Value-Added Services differentiate the Value-added services organization from competitors and build relationships that bind customers to the firm in a positive way 35

Value-Added Services differentiate the Value-added services organization from competitors and build relationships that bind customers to the firm in a positive way 35

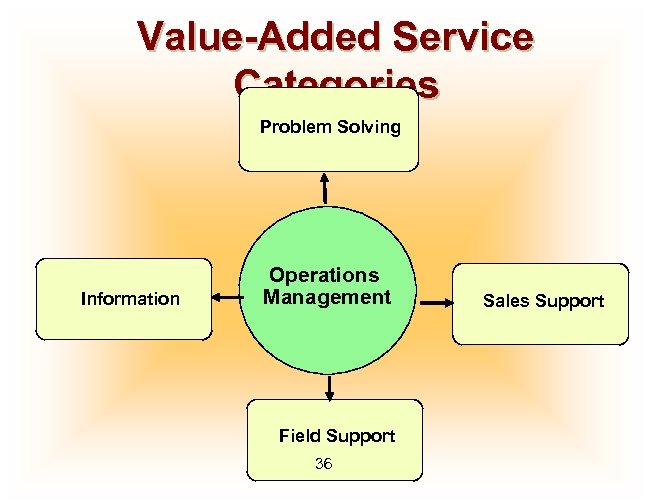

Value-Added Service Categories Problem Solving Information Operations Management Field Support 36 Sales Support

Value-Added Service Categories Problem Solving Information Operations Management Field Support 36 Sales Support

The Scope of OM: What Operations Managers Do? Plan - Organize - Staff - Lead Control 37

The Scope of OM: What Operations Managers Do? Plan - Organize - Staff - Lead Control 37

Critical OM Decisions 38

Critical OM Decisions 38

Critical OM Decisions Ø Service, product design Ø Process, capacity design Ø Planning of the technology Ø Location Ø Layout design Ø Human resources, job design Ø Production planning and scheduling Ø Supply chain management Ø Inventory management Ø Maintenance 39 Ø Quality management

Critical OM Decisions Ø Service, product design Ø Process, capacity design Ø Planning of the technology Ø Location Ø Layout design Ø Human resources, job design Ø Production planning and scheduling Ø Supply chain management Ø Inventory management Ø Maintenance 39 Ø Quality management

Operations Management and Decision Making Ø Models Ø Quantitative approaches Ø Analysis of tradeoffs Ø Systems approach Ø Establishing priorities

Operations Management and Decision Making Ø Models Ø Quantitative approaches Ø Analysis of tradeoffs Ø Systems approach Ø Establishing priorities

Models A model is an abstraction of reality. Types of models: – Physical – Schematic – Mathematical 41

Models A model is an abstraction of reality. Types of models: – Physical – Schematic – Mathematical 41

Why Models are Beneficial? ØEasy to use, less expensive ØRequire users to organize information ØSystematic approach to problem solving ØIncrease understanding of the problem ØEnable “what if” questions ØSpecific objectives

Why Models are Beneficial? ØEasy to use, less expensive ØRequire users to organize information ØSystematic approach to problem solving ØIncrease understanding of the problem ØEnable “what if” questions ØSpecific objectives

Limitations of Models: ØQuantitative information may be emphasized at the expense of qualitative information ØMay be incorrectly applied and results may be misinterpreted

Limitations of Models: ØQuantitative information may be emphasized at the expense of qualitative information ØMay be incorrectly applied and results may be misinterpreted

Quantitative Approaches (Analytical Tools used in OM) ØLinear programming ØQueuing techniques ØInventory models ØProject models ØStatistical models ØSimulation ØDecision analysis

Quantitative Approaches (Analytical Tools used in OM) ØLinear programming ØQueuing techniques ØInventory models ØProject models ØStatistical models ØSimulation ØDecision analysis

Tradeoffs Decision on the amount of inventory to stock Increased cost of holding inventory vs. Level of customer service 45

Tradeoffs Decision on the amount of inventory to stock Increased cost of holding inventory vs. Level of customer service 45

Systems Approach “The whole is greater than the sum of the parts. ” Suboptimization 46

Systems Approach “The whole is greater than the sum of the parts. ” Suboptimization 46

Establishing Priorities: Pareto Phenomenon ØA few factors account for a high percentage of the occurrence of some event(s) Ø 80/20 Rule - 80% of problems are caused by 20% of the activities. How do we identify the vital few? 47

Establishing Priorities: Pareto Phenomenon ØA few factors account for a high percentage of the occurrence of some event(s) Ø 80/20 Rule - 80% of problems are caused by 20% of the activities. How do we identify the vital few? 47

The Historical Evolution of Operations Management 48

The Historical Evolution of Operations Management 48

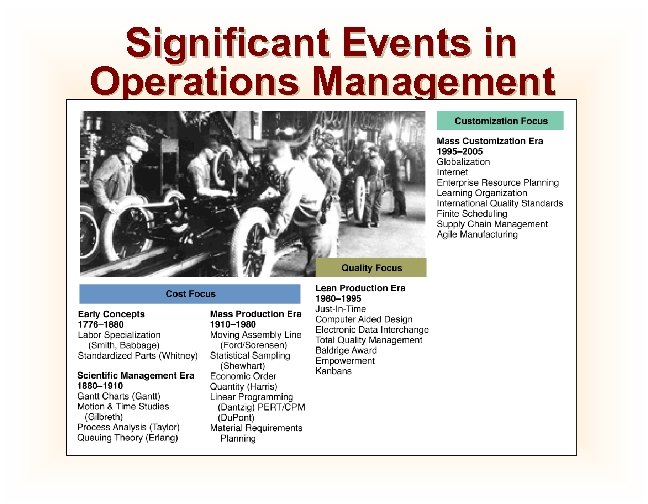

Significant Events in Operations Management

Significant Events in Operations Management

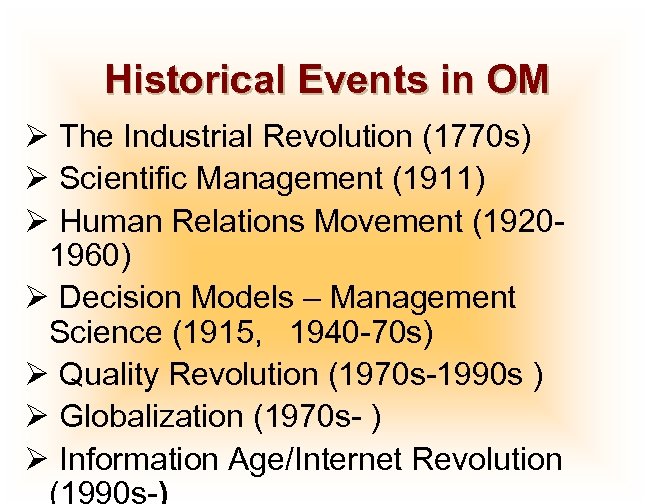

Historical Events in OM Ø The Industrial Revolution (1770 s) Ø Scientific Management (1911) Ø Human Relations Movement (19201960) Ø Decision Models – Management Science (1915, 1940 -70 s) Ø Quality Revolution (1970 s-1990 s ) Ø Globalization (1970 s- ) Ø Information Age/Internet Revolution

Historical Events in OM Ø The Industrial Revolution (1770 s) Ø Scientific Management (1911) Ø Human Relations Movement (19201960) Ø Decision Models – Management Science (1915, 1940 -70 s) Ø Quality Revolution (1970 s-1990 s ) Ø Globalization (1970 s- ) Ø Information Age/Internet Revolution

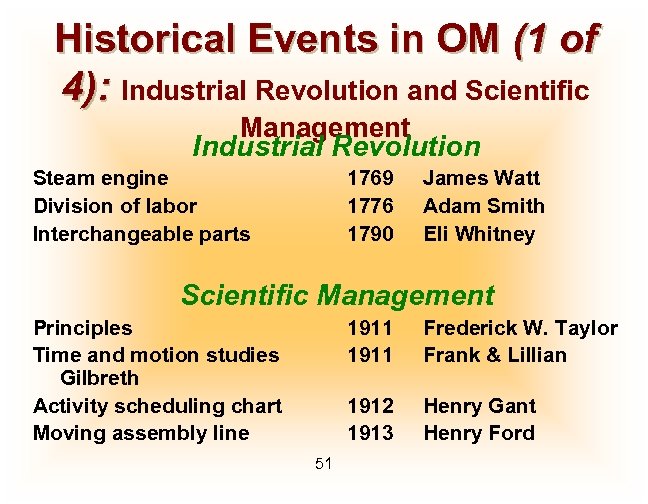

Historical Events in OM (1 of 4): Industrial Revolution and Scientific Management Industrial Revolution Steam engine Division of labor Interchangeable parts 1769 1776 1790 James Watt Adam Smith Eli Whitney Scientific Management Principles Time and motion studies Gilbreth Activity scheduling chart Moving assembly line 1911 1912 1913 51 Frederick W. Taylor Frank & Lillian Henry Gant Henry Ford

Historical Events in OM (1 of 4): Industrial Revolution and Scientific Management Industrial Revolution Steam engine Division of labor Interchangeable parts 1769 1776 1790 James Watt Adam Smith Eli Whitney Scientific Management Principles Time and motion studies Gilbreth Activity scheduling chart Moving assembly line 1911 1912 1913 51 Frederick W. Taylor Frank & Lillian Henry Gant Henry Ford

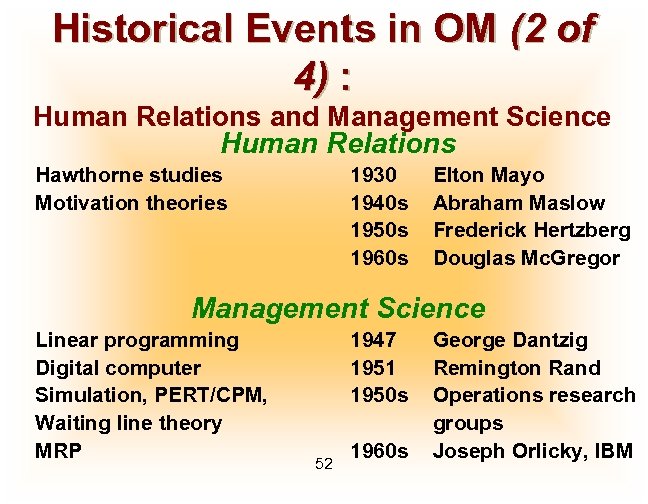

Historical Events in OM (2 of 4) : Human Relations and Management Science Human Relations Hawthorne studies Motivation theories 1930 1940 s 1950 s 1960 s Elton Mayo Abraham Maslow Frederick Hertzberg Douglas Mc. Gregor Management Science Linear programming Digital computer Simulation, PERT/CPM, Waiting line theory MRP 1947 1951 1950 s 52 1960 s George Dantzig Remington Rand Operations research groups Joseph Orlicky, IBM

Historical Events in OM (2 of 4) : Human Relations and Management Science Human Relations Hawthorne studies Motivation theories 1930 1940 s 1950 s 1960 s Elton Mayo Abraham Maslow Frederick Hertzberg Douglas Mc. Gregor Management Science Linear programming Digital computer Simulation, PERT/CPM, Waiting line theory MRP 1947 1951 1950 s 52 1960 s George Dantzig Remington Rand Operations research groups Joseph Orlicky, IBM

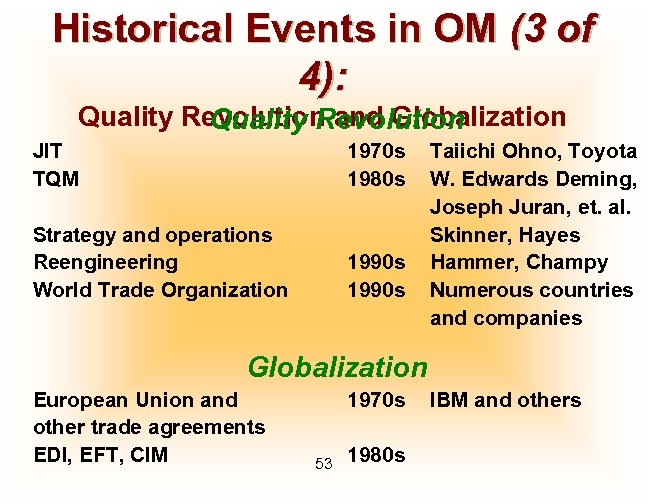

Historical Events in OM (3 of 4): Quality Revolution and Globalization Quality Revolution JIT TQM 1970 s 1980 s Strategy and operations Reengineering World Trade Organization 1990 s Taiichi Ohno, Toyota W. Edwards Deming, Joseph Juran, et. al. Skinner, Hayes Hammer, Champy Numerous countries and companies Globalization European Union and other trade agreements EDI, EFT, CIM 1970 s 53 1980 s IBM and others

Historical Events in OM (3 of 4): Quality Revolution and Globalization Quality Revolution JIT TQM 1970 s 1980 s Strategy and operations Reengineering World Trade Organization 1990 s Taiichi Ohno, Toyota W. Edwards Deming, Joseph Juran, et. al. Skinner, Hayes Hammer, Champy Numerous countries and companies Globalization European Union and other trade agreements EDI, EFT, CIM 1970 s 53 1980 s IBM and others

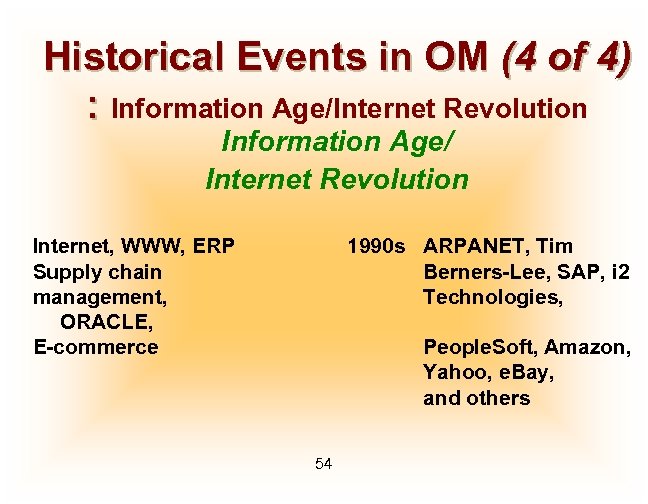

Historical Events in OM (4 of 4) : Information Age/Internet Revolution Information Age/ Internet Revolution Internet, WWW, ERP Supply chain management, ORACLE, E-commerce 1990 s ARPANET, Tim Berners-Lee, SAP, i 2 Technologies, People. Soft, Amazon, Yahoo, e. Bay, and others 54

Historical Events in OM (4 of 4) : Information Age/Internet Revolution Information Age/ Internet Revolution Internet, WWW, ERP Supply chain management, ORACLE, E-commerce 1990 s ARPANET, Tim Berners-Lee, SAP, i 2 Technologies, People. Soft, Amazon, Yahoo, e. Bay, and others 54

Exciting New Challenges in Operations Management 55

Exciting New Challenges in Operations Management 55

New Concepts and Trends in OM ØMass Customization ØSupply Chain Management ØOutsourcing ØLean manufacturing ØAgility ØElectronic Commerce

New Concepts and Trends in OM ØMass Customization ØSupply Chain Management ØOutsourcing ØLean manufacturing ØAgility ØElectronic Commerce

New Concepts and Trends(1 of 6): Mass Customization The rapid, low cost production of goods and services that fulfill constantly changing and increasingly unique customer desires.

New Concepts and Trends(1 of 6): Mass Customization The rapid, low cost production of goods and services that fulfill constantly changing and increasingly unique customer desires.

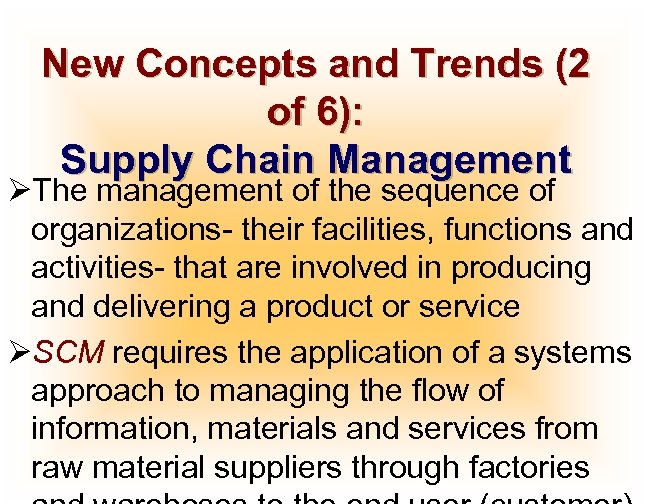

New Concepts and Trends (2 of 6): Supply Chain Management ØThe management of the sequence of organizations- their facilities, functions and activities- that are involved in producing and delivering a product or service ØSCM requires the application of a systems approach to managing the flow of information, materials and services from raw material suppliers through factories

New Concepts and Trends (2 of 6): Supply Chain Management ØThe management of the sequence of organizations- their facilities, functions and activities- that are involved in producing and delivering a product or service ØSCM requires the application of a systems approach to managing the flow of information, materials and services from raw material suppliers through factories

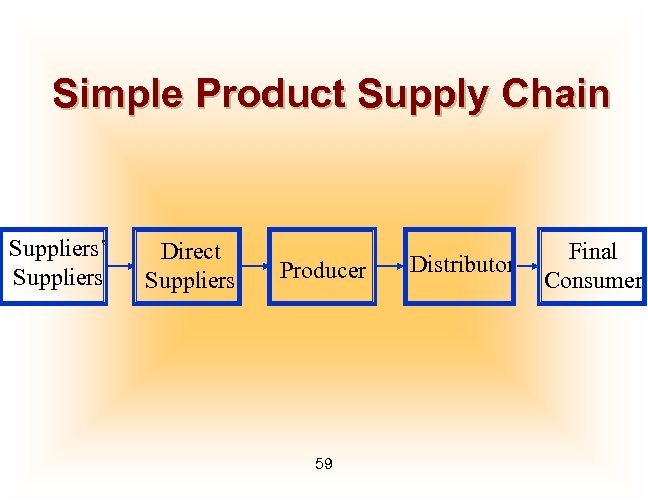

Simple Product Supply Chain Suppliers’ Suppliers Direct Suppliers Producer 59 Distributor Final Consumer

Simple Product Supply Chain Suppliers’ Suppliers Direct Suppliers Producer 59 Distributor Final Consumer

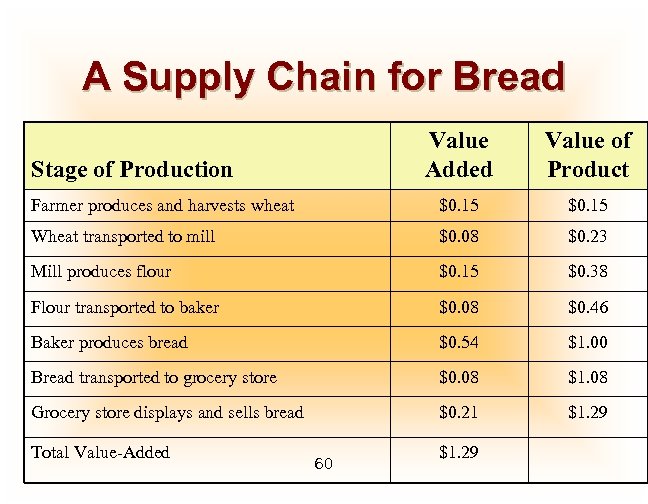

A Supply Chain for Bread Value Added Value of Product Farmer produces and harvests wheat $0. 15 Wheat transported to mill $0. 08 $0. 23 Mill produces flour $0. 15 $0. 38 Flour transported to baker $0. 08 $0. 46 Baker produces bread $0. 54 $1. 00 Bread transported to grocery store $0. 08 $1. 08 Grocery store displays and sells bread $0. 21 $1. 29 Stage of Production Total Value-Added 60 $1. 29

A Supply Chain for Bread Value Added Value of Product Farmer produces and harvests wheat $0. 15 Wheat transported to mill $0. 08 $0. 23 Mill produces flour $0. 15 $0. 38 Flour transported to baker $0. 08 $0. 46 Baker produces bread $0. 54 $1. 00 Bread transported to grocery store $0. 08 $1. 08 Grocery store displays and sells bread $0. 21 $1. 29 Stage of Production Total Value-Added 60 $1. 29

New Concepts and Trends (3 of 6) : Outsourcing Buying goods or services rather than producing goods or performing services within the organization 61

New Concepts and Trends (3 of 6) : Outsourcing Buying goods or services rather than producing goods or performing services within the organization 61

New Concepts and Trends (4 of 6): Lean Manufacturing ØSystems that use minimal amounts of resources - less space, less inventory, fewer workers, fewer levels of management- to produce a high volume of high-quality goods with some variety ØAn adaptation of mass production that prizes quality and flexibility ØIncorporates advantages of mass production (high volume, low unit cost) and

New Concepts and Trends (4 of 6): Lean Manufacturing ØSystems that use minimal amounts of resources - less space, less inventory, fewer workers, fewer levels of management- to produce a high volume of high-quality goods with some variety ØAn adaptation of mass production that prizes quality and flexibility ØIncorporates advantages of mass production (high volume, low unit cost) and

New Concepts and Trends (5 of 6): Agility The ability of an organization to respond quickly to demands or opportunities. Involves maintaining a flexible system that can quickly respond to changes in either the volume of demand or changes in product/service offerings 63

New Concepts and Trends (5 of 6): Agility The ability of an organization to respond quickly to demands or opportunities. Involves maintaining a flexible system that can quickly respond to changes in either the volume of demand or changes in product/service offerings 63

New Concepts and Trends (6 of 6): Electronic Commerce The use of computer networks, primarily the internet, to buy and sell products, services, and information.

New Concepts and Trends (6 of 6): Electronic Commerce The use of computer networks, primarily the internet, to buy and sell products, services, and information.

Other Trends (1 of 2) ØEnhancing Value-Added Services ØManagement of Technology ØEmphasis on Operations Strategy ØIncreasing Emphasis on Cost Control and Productivity Improvement ØQuality and Process Improvements ØIncreasing emphasis on business and social responsibility

Other Trends (1 of 2) ØEnhancing Value-Added Services ØManagement of Technology ØEmphasis on Operations Strategy ØIncreasing Emphasis on Cost Control and Productivity Improvement ØQuality and Process Improvements ØIncreasing emphasis on business and social responsibility

Other Trends (2 of 2) ØDeveloping flexible supply chains to enable mass customization of products and services Ø Achieving the Service Factory 66

Other Trends (2 of 2) ØDeveloping flexible supply chains to enable mass customization of products and services Ø Achieving the Service Factory 66

Globalization 67

Globalization 67

Globalization can take the form of: Ø Selling in foreign markets Ø Producing in foreign lands Ø Purchasing from foreign suppliers Ø Partnering with foreign firms 68

Globalization can take the form of: Ø Selling in foreign markets Ø Producing in foreign lands Ø Purchasing from foreign suppliers Ø Partnering with foreign firms 68

Reasons to Globalize Operations (1 of 2) ØTo take advantage of favorable costs ØTo gain access to and attract international markets ØTo build reliable sources of supply ØTo improve the supply chain ØTo be more responsive to changes in demand

Reasons to Globalize Operations (1 of 2) ØTo take advantage of favorable costs ØTo gain access to and attract international markets ØTo build reliable sources of supply ØTo improve the supply chain ØTo be more responsive to changes in demand

Reasons to Globalize Operations (2 of 2) Ø To provide better goods and services Ø To learn to improve operations Ø To attract and retain global talent Ø To keep abreast of the latest trends and technologies 70

Reasons to Globalize Operations (2 of 2) Ø To provide better goods and services Ø To learn to improve operations Ø To attract and retain global talent Ø To keep abreast of the latest trends and technologies 70

Examples of Global Strategies ØBoeing – both sales and production are worldwide. ØBenetton – moves inventory to stores around the world faster than its competitor by building flexibility into design, production, and distribution ØSony – purchases components from suppliers in Thailand, Malaysia, and around the world 71 ØGM is building four similar plants in

Examples of Global Strategies ØBoeing – both sales and production are worldwide. ØBenetton – moves inventory to stores around the world faster than its competitor by building flexibility into design, production, and distribution ØSony – purchases components from suppliers in Thailand, Malaysia, and around the world 71 ØGM is building four similar plants in

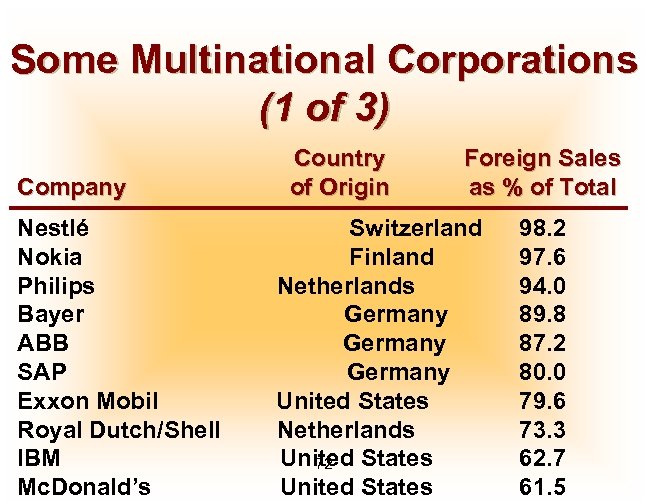

Some Multinational Corporations (1 of 3) Company Nestlé Nokia Philips Bayer ABB SAP Exxon Mobil Royal Dutch/Shell IBM Mc. Donald’s Country of Origin Foreign Sales as % of Total Switzerland Finland Netherlands Germany United States Netherlands United States 72 United States 98. 2 97. 6 94. 0 89. 8 87. 2 80. 0 79. 6 73. 3 62. 7 61. 5

Some Multinational Corporations (1 of 3) Company Nestlé Nokia Philips Bayer ABB SAP Exxon Mobil Royal Dutch/Shell IBM Mc. Donald’s Country of Origin Foreign Sales as % of Total Switzerland Finland Netherlands Germany United States Netherlands United States 72 United States 98. 2 97. 6 94. 0 89. 8 87. 2 80. 0 79. 6 73. 3 62. 7 61. 5

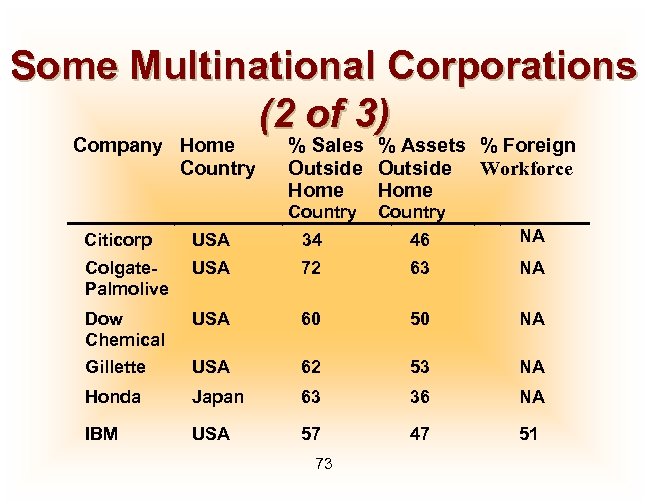

Some Multinational Corporations (2 of 3) Company Home Country % Sales % Assets % Foreign Outside Workforce Home Country Citicorp USA 34 46 NA Colgate. Palmolive USA 72 63 NA Dow Chemical Gillette USA 60 50 NA USA 62 53 NA Honda Japan 63 36 NA IBM USA 57 47 51 73

Some Multinational Corporations (2 of 3) Company Home Country % Sales % Assets % Foreign Outside Workforce Home Country Citicorp USA 34 46 NA Colgate. Palmolive USA 72 63 NA Dow Chemical Gillette USA 60 50 NA USA 62 53 NA Honda Japan 63 36 NA IBM USA 57 47 51 73

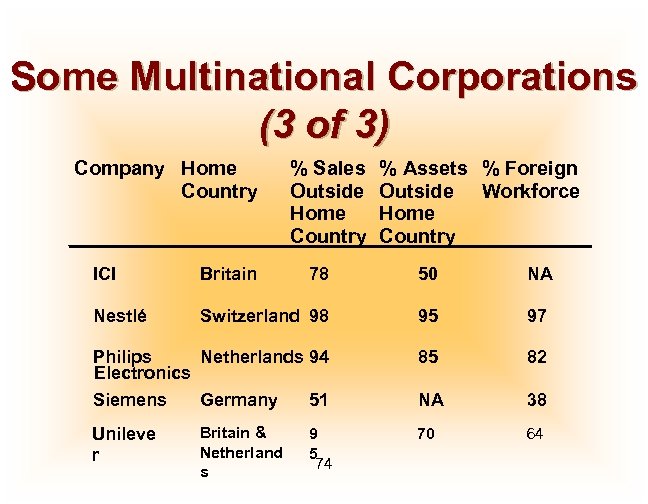

Some Multinational Corporations (3 of 3) Company Home Country % Sales Outside Home Country % Assets % Foreign Outside Workforce Home Country ICI Britain 78 50 NA Nestlé Switzerland 98 95 97 Philips Netherlands 94 Electronics Siemens Germany 51 85 82 NA 38 Unileve r 70 64 Britain & Netherland s 9 5 74

Some Multinational Corporations (3 of 3) Company Home Country % Sales Outside Home Country % Assets % Foreign Outside Workforce Home Country ICI Britain 78 50 NA Nestlé Switzerland 98 95 97 Philips Netherlands 94 Electronics Siemens Germany 51 85 82 NA 38 Unileve r 70 64 Britain & Netherland s 9 5 74

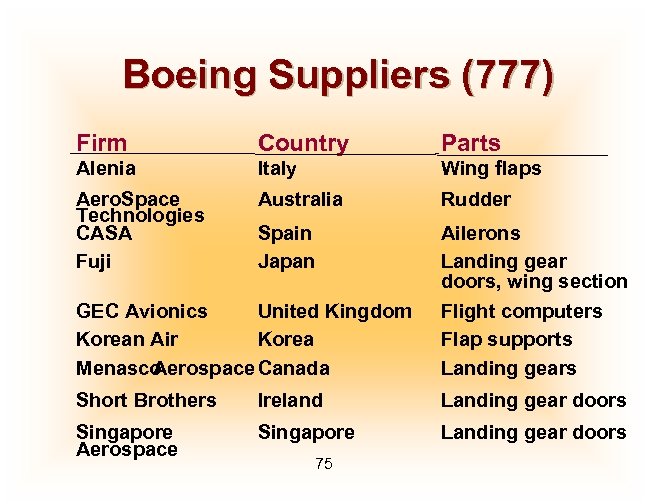

Boeing Suppliers (777) Firm Country Parts Alenia Italy Wing flaps Aero. Space Technologies CASA Fuji Australia Rudder Spain Japan Ailerons Landing gear doors, wing section GEC Avionics United Kingdom Korean Air Korea Aerospace Canada Menasco Flight computers Flap supports Landing gears Short Brothers Ireland Landing gear doors Singapore Aerospace Singapore Landing gear doors 75

Boeing Suppliers (777) Firm Country Parts Alenia Italy Wing flaps Aero. Space Technologies CASA Fuji Australia Rudder Spain Japan Ailerons Landing gear doors, wing section GEC Avionics United Kingdom Korean Air Korea Aerospace Canada Menasco Flight computers Flap supports Landing gears Short Brothers Ireland Landing gear doors Singapore Aerospace Singapore Landing gear doors 75