caecccb3d3cc76ce44d642891105706d.ppt

- Количество слайдов: 36

Introduction to GPS and benefits for Chemical Industry Workshop on Implementation of REACH and CLP INT MARKT 52344 27 – 28 June 2013, Moscow L. Heezen

Content • ICCA SAICM commitment • Refreshment Global Product Strategy (GPS) • Product Stewardship • Why should industry participate 2

What is ICCA International Council of Chemical Associations ICCA was created in 1989 Represents chemical manufacturers and producers all over the world. Accounts for more than 75 per cent of chemical manufacturing operations. Almost 30 percent of this production is traded internationally. Promotes and co-ordinates Responsible Care and other voluntary chemical industry initiatives. Operates by coordinating the work of member associations and their member companies Main channel of communication between the industry and various international organizations, including UNEP, WTO, UNITAR and the OECD.

ICCA Global Charter The International Council of Chemical Associations (ICCA) has launched in 2005 the Responsible Care Global Charter (RCGC) as an industry contribution to the SAICM: Industry commitment to improve EHS performance Meeting and going beyond legislative and regulatory compliance Adopting voluntary initiatives with governments and other stakeholders The RCGC has 9 strategic elements

RCGC strategic elements 1. Adopt RC core principles 2. Implement fundamental features of national RC programmes 3. Commit to advancing sustainable development 4. Continuously improve and report performance 5. Enhance the management of chemicals worldwide 6. Champion and facilitate the extension of RC along chemical industry supply chain 7. Actively support national and local RC governance processes 8. Address stakeholder expectations about chemical industry activities and products 9. Provide appropriate resources to effectively implement RC

ICCA Principles of Chemicals Management systems: RCGC strategic point 5 1. Sound national policy framework, aimed at improving public confidence, avoid unnecessary costs and bureaucracy, international consistency 2. Risk based, not hazard based with scientific criteria. Benefits/costs have key role in risk mgt decisions 3. Screening of chemicals, with defined criteria for additional information 4. Leverage existing information, including alternative methods 5. Reinforce responsibility value chain for compliance and commitment to actions 6. Promote data transparency and quality. RC and RMM publicly available, protection of CBI, share information while protecting legitimate business interests.

ICCA Challenge – Global Product Strategy (GPS) GPS as an essential element of Product Stewardship performance is critical to the reputation of the chemical industry GPS was launched at the Dubai conference in Feb. 2006 to increase public confidence All major chemical companies accepted the obligation to put GPS into practice ICCA committed GPS as contribution to the UN SAICM process First positive feedback SAICM stakeholders

ICCA vision Global Product Strategy (GPS) By 2020, through a combination of voluntary and regulatory initiatives, we will have: Established a base-set of hazard and exposure information adequate to conduct safety assessments for chemicals in commerce Provided global capacity to implement best assessment practices and management procedures, especially in developing countries Shared relevant product information with co-producers, governments and the public Worked across the value chain so suppliers and customers can effectively evaluate the risks and enhance their performance Made information on chemicals publicly available (GPS IT-portal via http: //www. icca-chem. org/. )

ICCA Objective – Improve industry performance 1. Improve intelligent risk assessment processes and information gathering - Base set of information for chemicals in commerce Risk assessment for chemicals in commerce Process for sharing of relevant information Develop an inventory for chemicals in commerce 2. Continuous performance monitoring and reporting (e. g. metrics, milestones, auditing process, etc. ) 3. Ongoing capacity building to support developing regions/industries 4. Advocacy of results to governments and stakeholders

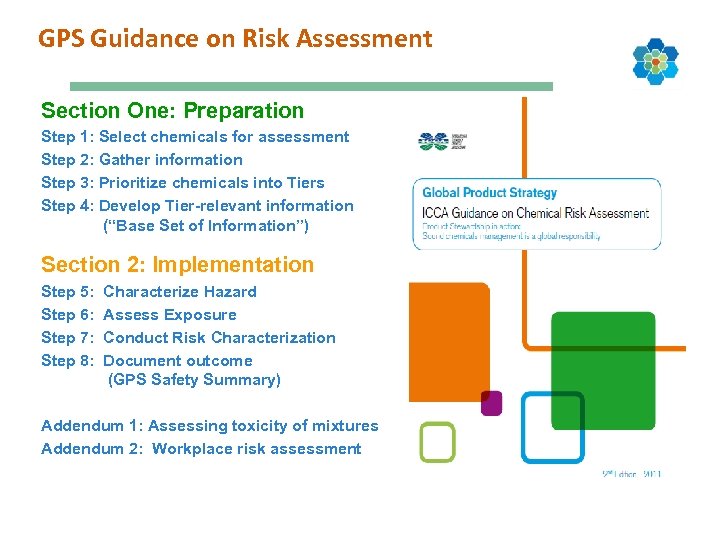

GPS Guidance on Risk Assessment Section One: Preparation Step 1: Select chemicals for assessment Step 2: Gather information Step 3: Prioritize chemicals into Tiers Step 4: Develop Tier-relevant information (“Base Set of Information”) Section 2: Implementation Step 5: Step 6: Step 7: Step 8: Characterize Hazard Assess Exposure Conduct Risk Characterization Document outcome (GPS Safety Summary) Addendum 1: Assessing toxicity of mixtures Addendum 2: Workplace risk assessment

GPS Guidance on Risk Assessment Contains best practice recommendations on how to perform risk assessment under GPS, part of a series of guidance documents aimed to help ICCA members in fulfilling their GPS commitment Intends to help define safe use conditions for chemicals and recommends best practice risk management measures so that safe use conditions can be met. Existing prioritization or risk assessment processes implemented within companies will not be affected and priority is given to processes defined by existing regulations (e. g. REACH, Ch. AMP) Pre-existing risk assessments following regulatory requirements or voluntary initiatives will be fully leveraged and will not have to be reworked.

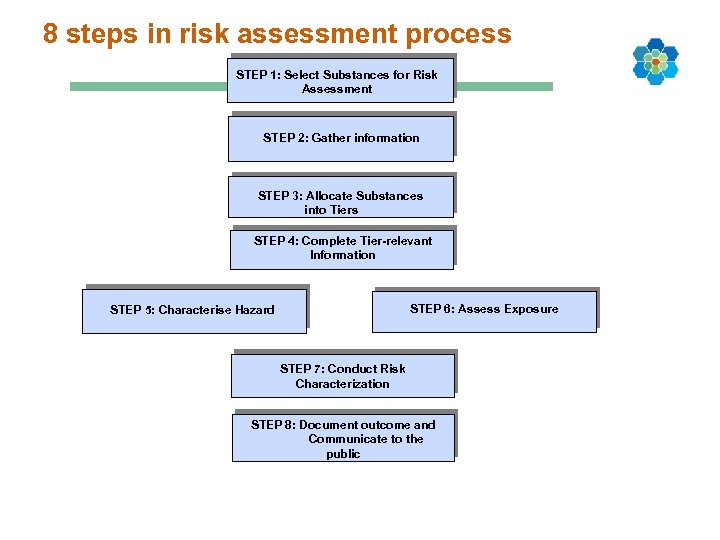

8 steps in risk assessment process STEP 1: Select Substances for Risk Assessment STEP 2: Gather information STEP 3: Allocate Substances into Tiers STEP 4: Complete Tier-relevant Information STEP 6: Assess Exposure STEP 5: Characterise Hazard STEP 7: Conduct Risk Characterization STEP 8: Document outcome and Communicate to the public

Step 1: Select substances for assessment GPS risk assessments should be performed for industrial chemicals: • Sold (“in commerce”) or transported world-wide in quantities of more than 1 metric ton per year by company and those that • Pose a major threat to human health and/or the environment (e. g. known carcinogens, etc. ) even if they are sold or transported in smaller amounts than 1 metric ton per year The inventory should be kept strictly company internal due to antitrust / competition law compliance

Step 2: Gather information on substance properties How to obtain the information: sources to access information on GHS information, Phys/Chem, Hazard and Exposure Information Evaluate the quality of the Information: Reliability, Relevance and Adequacy of data for assessment Close data gaps: As long as the information is considered reliable, alternative sources are accepted e. g

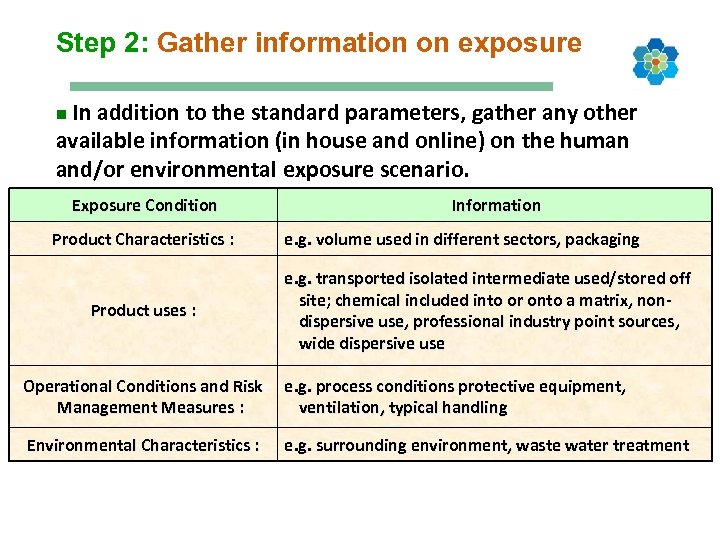

Step 2: Gather information on exposure In addition to the standard parameters, gather any other available information (in house and online) on the human and/or environmental exposure scenario. n Exposure Condition Product Characteristics : Product uses : Information e. g. volume used in different sectors, packaging e. g. transported isolated intermediate used/stored off site; chemical included into or onto a matrix, nondispersive use, professional industry point sources, wide dispersive use Operational Conditions and Risk Management Measures : e. g. process conditions protective equipment, ventilation, typical handling Environmental Characteristics : e. g. surrounding environment, waste water treatment

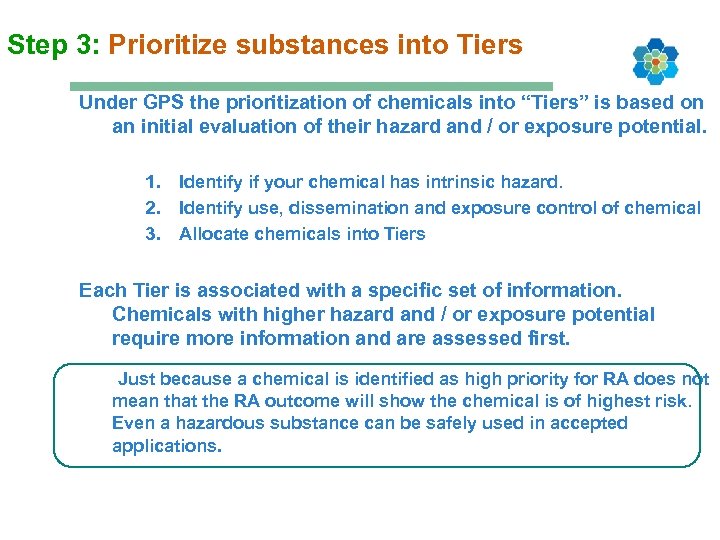

Step 3: Prioritize substances into Tiers Under GPS the prioritization of chemicals into “Tiers” is based on an initial evaluation of their hazard and / or exposure potential. 1. Identify if your chemical has intrinsic hazard. 2. Identify use, dissemination and exposure control of chemical 3. Allocate chemicals into Tiers Each Tier is associated with a specific set of information. Chemicals with higher hazard and / or exposure potential require more information and are assessed first. Just because a chemical is identified as high priority for RA does not mean that the RA outcome will show the chemical is of highest risk. Even a hazardous substance can be safely used in accepted applications.

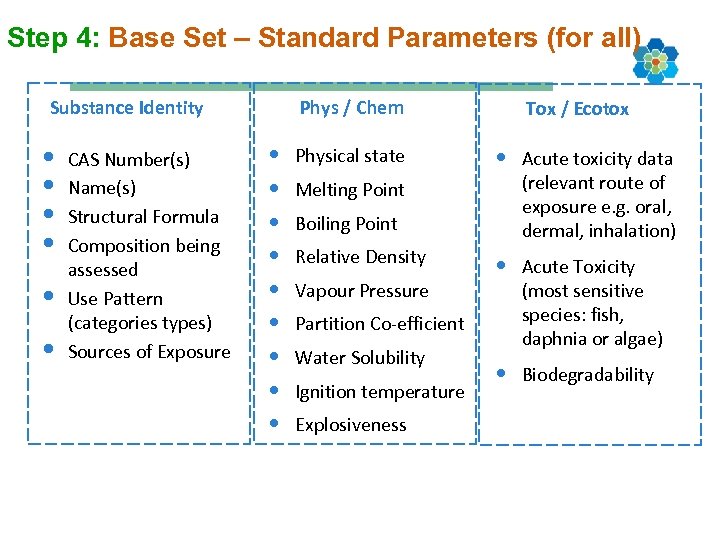

Step 4: Base Set – Standard Parameters (for all) Substance Identity • • • CAS Number(s) Name(s) Structural Formula Composition being assessed Use Pattern (categories types) Sources of Exposure Phys / Chem • • • Physical state Melting Point Boiling Point Relative Density Vapour Pressure Partition Co-efficient Water Solubility Ignition temperature Explosiveness Tox / Ecotox • Acute toxicity data (relevant route of exposure e. g. oral, dermal, inhalation) • Acute Toxicity (most sensitive species: fish, daphnia or algae) • Biodegradability

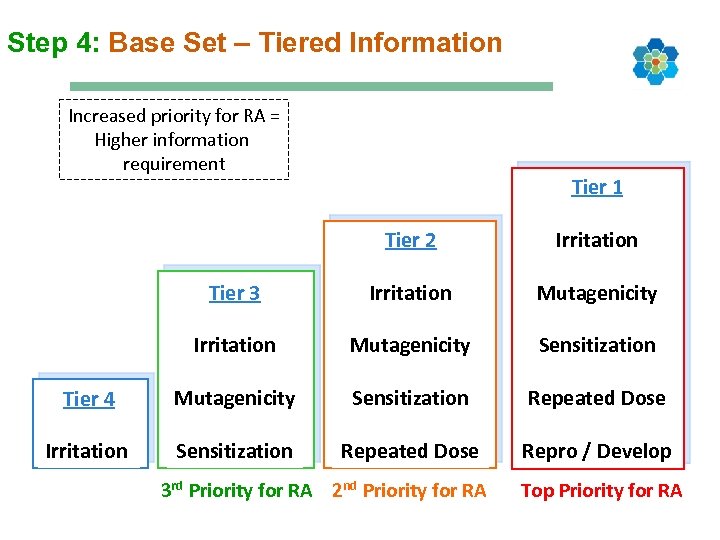

Step 4: Base Set – Tiered Information Increased priority for RA = Higher information requirement Tier 1 Tier 2 Irritation Tier 3 Irritation Mutagenicity Sensitization Tier 4 Mutagenicity Sensitization Repeated Dose Irritation Sensitization Repeated Dose Repro / Develop 3 rd Priority for RA 2 nd Priority for RA Top Priority for RA

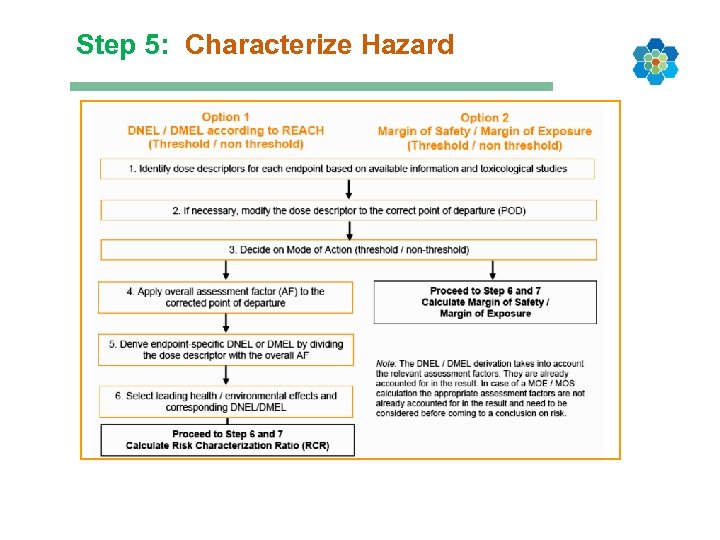

Step 5: Characterize Hazard

Step 6: Assess Exposure Step-wise process • Collect information on chemical properties • Collect information on the uses and the typical operating conditions and risk management (exposure control) measures applied • Set up an Exposure Scenario for each use • Estimate exposure for each scenario, using estimating tools (e. g. ECETOC TRA) or measured data Perform the respective assessment for: • Human Exposure - Workplace and Consumer scenarios • Environmental Exposure Assessment

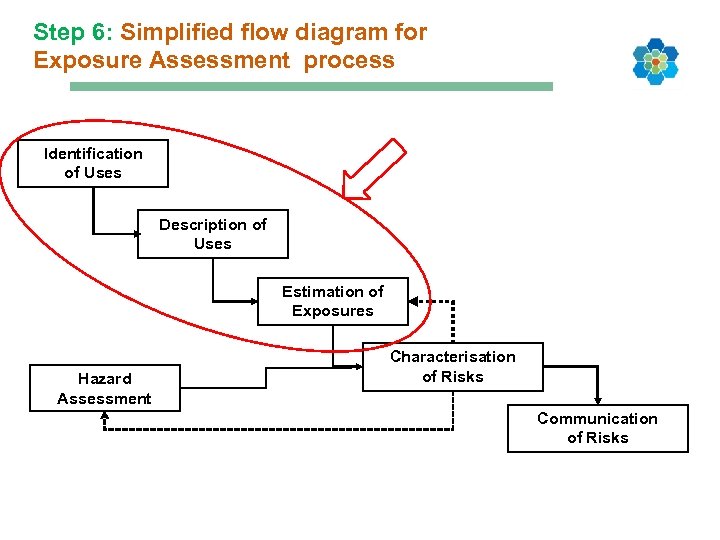

Step 6: Simplified flow diagram for Exposure Assessment process Identification of Uses Description of Uses Estimation of Exposures Hazard Assessment Characterisation of Risks Communication of Risks

Step 6: Basic Information Required for Exposure Assessment The extent of basic information for Exposure Assessment depends on the Assessment Result and additional info might be required to conclude an Assessment • Base set of information • Product Characteristics • Operational Conditions • Risk Management Measures • Environmental Characteristics • Other relevant information

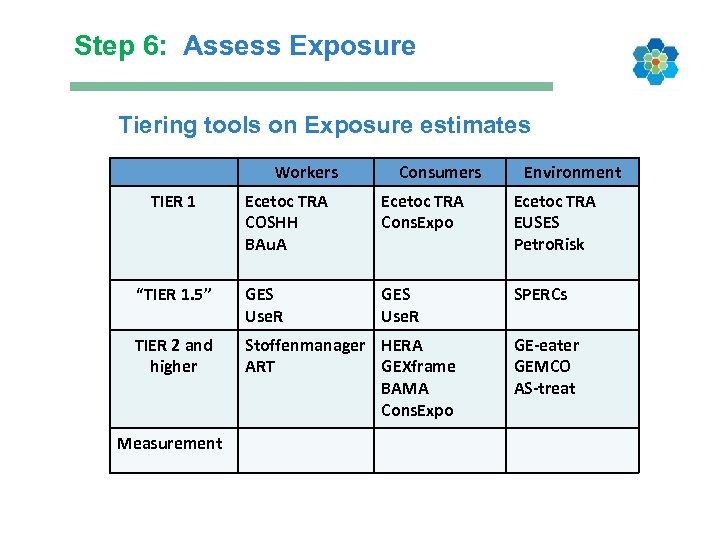

Step 6: Assess Exposure Tiering tools on Exposure estimates Workers TIER 1 Consumers Environment Ecetoc TRA COSHH BAu. A Ecetoc TRA Cons. Expo Ecetoc TRA EUSES Petro. Risk “TIER 1. 5” GES Use. R SPERCs TIER 2 and higher Stoffenmanager HERA ART GEXframe BAMA Cons. Expo Measurement GE-eater GEMCO AS-treat

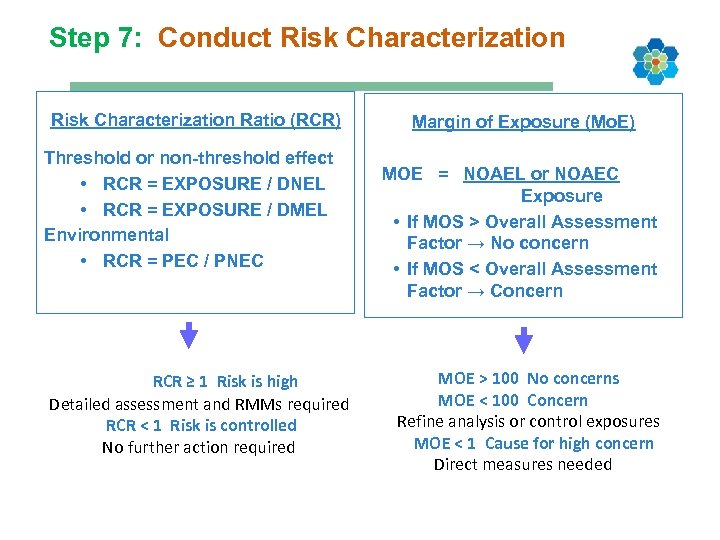

Step 7: Conduct Risk Characterization Ratio (RCR) Threshold or non-threshold effect • RCR = EXPOSURE / DNEL • RCR = EXPOSURE / DMEL Environmental • RCR = PEC / PNEC RCR ≥ 1 Risk is high Detailed assessment and RMMs required RCR < 1 Risk is controlled No further action required Margin of Exposure (Mo. E) MOE = NOAEL or NOAEC Exposure • If MOS > Overall Assessment Factor → No concern • If MOS < Overall Assessment Factor → Concern MOE > 100 No concerns MOE < 100 Concern Refine analysis or control exposures MOE < 1 Cause for high concern Direct measures needed

Step 8: Document outcome (Safety Summary) After the RA it is important to check the efficiency of the safety measures adopted, document the outcomes of the assessment and reviewing the assessment regularly to keep it updated. As this documentation will contain data of proprietary nature it will stay company internal and does not have to be shared with co-producers or the public (no mandatory exchange of dossiers). ICCA has develop a GPS specific format that can be used to communicate the essential information in a transparent way with interested stakeholders (GPS Safety Summary). • To provide the general public with a short easy to understand overview of relevant information for the chemical • Does not replace technical materials such as the (M)SDS

GPS Communication- Safety Summary The result of the risk assessment is communicated via Safety Summary The summary should be fairly basic and understood by a layman Compilation of relevant risk characterization and risk management information in an easily understandable format To be communicated to employees, downstream customers, the public and other interested parties Regional flexibility will apply in the content of the GPS Safety Summary, it is up to the company to define the relevant information and layout but should include some basic elements Currently more than 1600 GPS Safety Summaries are already available on company websites The GPS Safety Summary does not replace required technical communication documents such as the Material Safety Data Sheet (MSDS) ICCA IT portal is operational and Safety Summaries can be downloaded

27 GPS Safety Summary • The summary should be fairly basic and understood by a layman • In EU the content can be based on REACH registration dossier • The content is no fixed format. It is up to companies to decide what is in it. • Cefic Conversion Template can be used for referencing • SIEF / Consortium could be asked to draft main body GPS Safety Summary. Member companies can complete with own information.

Safety Summary – target audience § Downstream industry § SME’s and trade organisations in developing and emerging economies § Technical Instituations in Developing Countries and Emerging Economies § University Teachers / School Teachers / Students § NGO’s § Governments § Interested non-professional stakeholders § SAICM stakeholders § Healthcare professionals 28

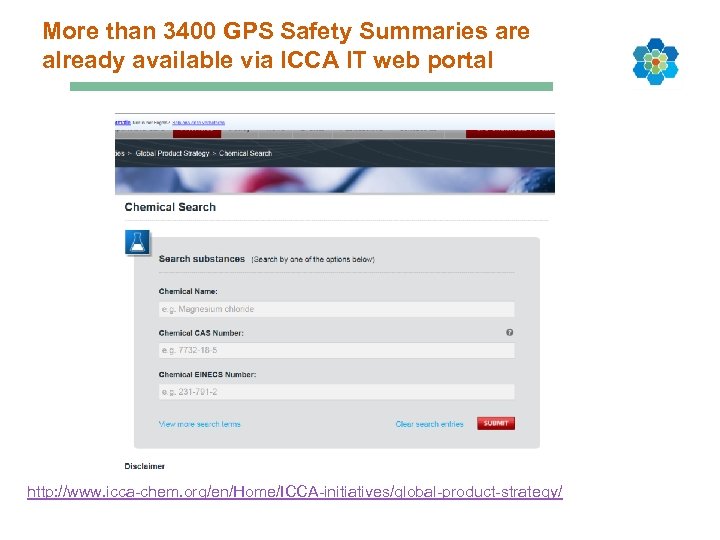

More than 3400 GPS Safety Summaries are already available via ICCA IT web portal http: //www. icca-chem. org/en/Home/ICCA-initiatives/global-product-strategy/

Examples DOW Rhodia DSM http: //www. cefic. org/Industry-support/Implementing-reach/Documents-and-Tools 1/

Product Stewardship • Product Stewardship (PS) is an integral part of Responsible Care • PS makes HSE info an integral part of the life cycle of a chemical • PS is a shared responsibility between producers, suppliers and customers • PS requires a continuous dialogue in the relevant supply chain • PS requires sharing of information to assure safe use of chemicals • PS provides a platform for companies to identify risks at an early stage and to manage them along the supply chain • PS will result in increased customer loyalty ICCA has published Product Stewardship Guidelines, to help companies setting up a PS program.

ICCA Product Stewardship Guideline: http: //www. icca-chem. org/Home/ICCA-publications/Publications-Search-Results/? topic=Product+Stewardship&p=5

Why do we need a Global Product Strategy ? The globalization of the markets call for harmonization of chemical management systems at national, regional and worldwide level. Currently chemical legislations are creating a patchwork of conflicting rules and procedures. Differences in national regulatory requirements lead to an increase in costs and time and to distortions in international competition and trade restrictions. A harmonized global standard would increase not only the safety of products but also the benefits for the consumer. ICCA views GPS as best practice example which could serve as a basis for the revision of existing (e. g. TSCA) and new regulations. GPS fulfils the requirements of a modern chemical management system.

Benefits of GPS implementation – Why should companies participate ? § Recognition for all the work done by industry in regulatory programs § Increase risk assessment expertise and occupational safety standards § Strengthen relationships with customers, authorities, public § Anticipate regulations and lower compliance costs § Influencing upcoming regulations § Global harmonization of chemicals management systems § Reduce liability issues § Secure competitive advantage 34

Why additional efforts to implement GPS? • Chemical industry committed in 2006 to GPS as our main contribution to SAICM & Sustainable Development • Raise level of chemicals management globally • Big efforts to develop GPS • Much attention - ICCA credibility & influence increased Non-delivery of GPS would mean an end to our ability to influence policy & regulations internationally 35

Thank You! Leo Heezen (reachheezen@caiway. net) 36

caecccb3d3cc76ce44d642891105706d.ppt