f6e6d7a75d01bff6e7147ba16cccc430.ppt

- Количество слайдов: 37

Introduction to Cost of uality presented by L. Daniel Crowley, CCP, CSTE QA Manager, IDX Seattle SASQAG Copyright DENAB Quality Sys. 1998 July 16, 1998

Cost of uality Schedule l Introduction l Principles of CQI (TQA) and Cost of Quality l Strategy for COQ l COQ Categories l Implementation of COQ Copyright DENAB Quality Sys. 1998

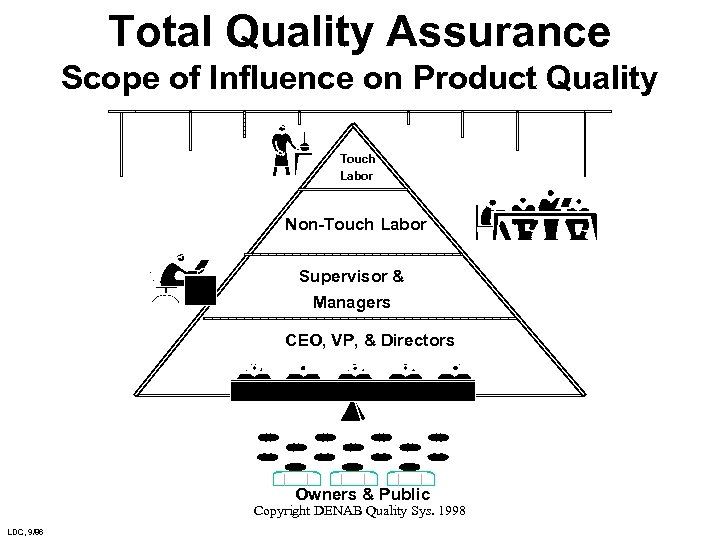

Total Quality Assurance Scope of Influence on Product Quality Touch Labor Non-Touch Labor Supervisor & Managers CEO, VP, & Directors Owners & Public Copyright DENAB Quality Sys. 1998 LDC, 9/86

Quality’s Mission ty exists to Quali improving support hroughout levels t organization an tinuously. con Copyright DENAB Quality Sys. 1998

Total Quality Management is Comprised of 3 Activities 1. Quality Control (QC) or Audit Reacting to Past Events 2. Quality Assurance (QA) Planning for Future Events 3. Quality Engineering (QE) Implementing QA Plans Copyright DENAB Quality Sys. 1998 5

TOTAL QUALITY ASSURANCE Elements for Success Quality planning Process Quality Control Problem Solving Copyright DENAB Quality Sys. 1998 LDC 10/88 Cost of Quality

Cost of uality Running a company by profit alone is like driving a car by looking in the rearview mirror. It tells you where you’ve been, not where you are going! Dr. Edward. Deming Copyright DENAB Quality Sys. 1998 7

Cost of uality Goal l The goal of a Cost of Quality system is to: Facilitate Quality Improvements that leads to operating cost reduction Opportunities. Copyright DENAB Quality Sys. 1998 ASQC, "Principles of Quality Costs", 1986

Cost of uality Definition l The cost difference between present operation and the possible operation of a business with all systems and employees at 100% performance. or l The difference between actual revenues and what revenues could be if all customers were always satisfied, that is , No Unhappy Customers. Copyright DENAB Quality Sys. 1998 LDC 10/88

Cost of uality Cost of Quality is Not: An Exact Cost. A Performance Measurement. Copyright DENAB Quality Sys. 1998

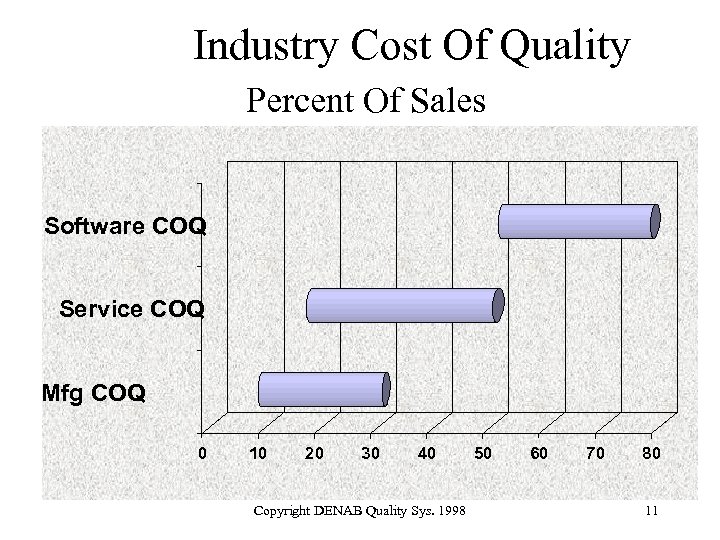

Industry Cost Of Quality Percent Of Sales Software COQ Service COQ Mfg COQ 0 10 20 30 40 Copyright DENAB Quality Sys. 1998 50 60 70 80 11

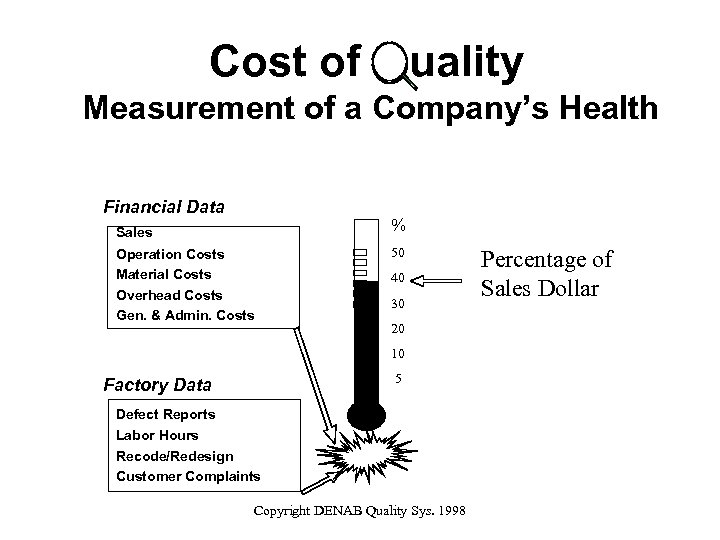

Cost of uality Measurement of a Company’s Health Financial Data % Sales Operation Costs Material Costs Overhead Costs Gen. & Admin. Costs 50 40 30 20 10 5 Factory Data Defect Reports Labor Hours Recode/Redesign Customer Complaints Copyright DENAB Quality Sys. 1998 Percentage of Sales Dollar

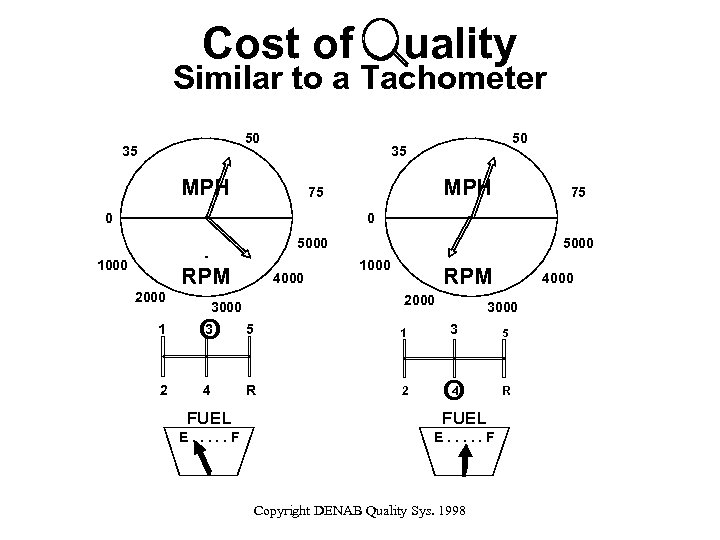

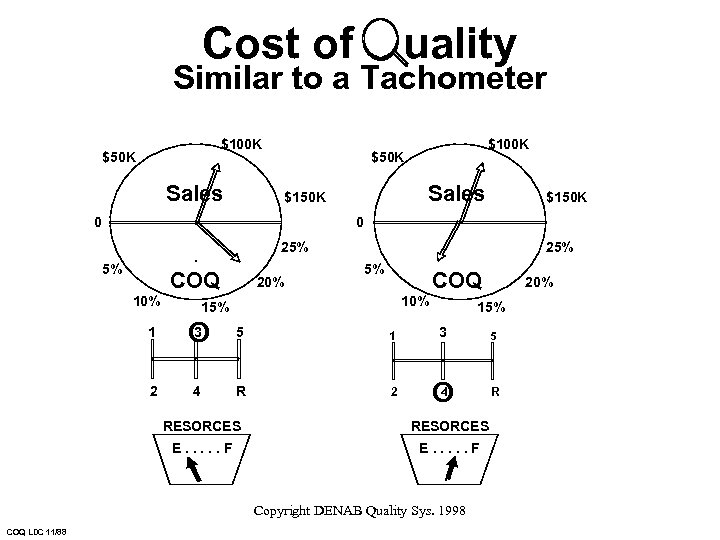

Cost of uality Similar to a Tachometer 50 35 MPH 75 0 5000 1000 RPM 2000 4000 5000 1000 RPM 2000 3000 4000 3000 1 3 O 5 1 3 5 2 4 R 2 4 O R FUEL E. . F . . Copyright DENAB Quality Sys. 1998

Cost of uality Similar to a Tachometer $100 K $50 K Sales $150 K 0 25% 5% COQ 10% 15% 20% 15% 1 3 O 5 1 3 5 2 4 R 2 4 O R RESORCES E. . F . . Copyright DENAB Quality Sys. 1998 COQ LDC 11/88

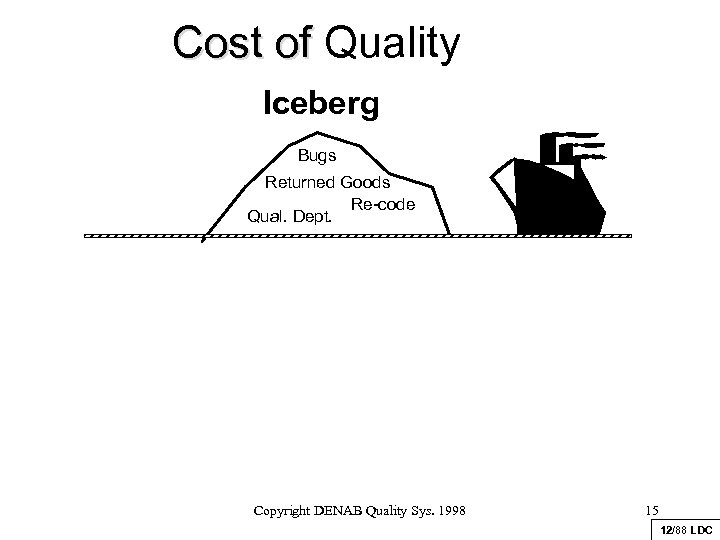

Cost of Quality Iceberg Bugs Returned Goods Re-code Qual. Dept. Copyright DENAB Quality Sys. 1998 15 12/88 LDC

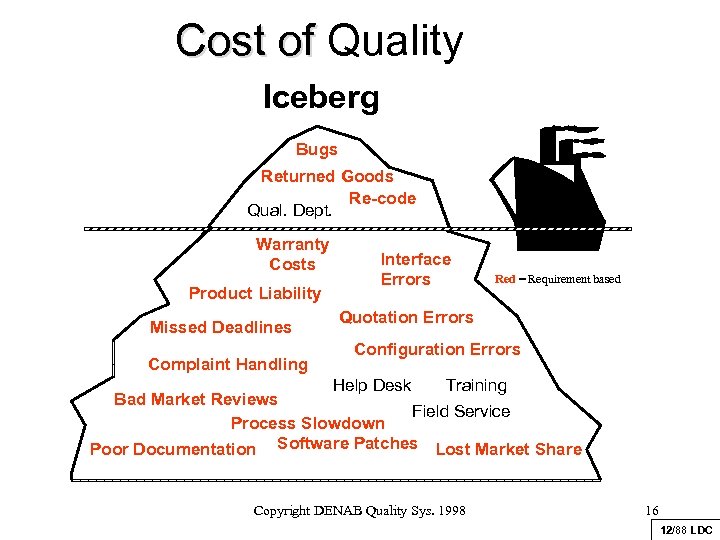

Cost of Quality Iceberg Bugs Returned Goods Re-code Qual. Dept. Warranty Costs Product Liability Missed Deadlines Complaint Handling Interface Errors Red = Requirement based Quotation Errors Configuration Errors Help Desk Training Field Service Bad Market Reviews Process Slowdown Poor Documentation Software Patches Lost Market Share Copyright DENAB Quality Sys. 1998 16 12/88 LDC

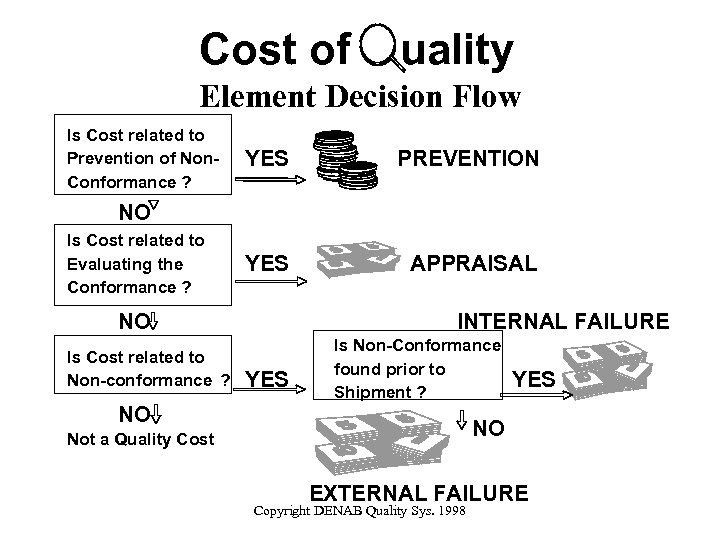

Cost of uality Element Decision Flow Is Cost related to Prevention of Non. Conformance ? YES PREVENTION YES APPRAISAL NO Is Cost related to Evaluating the Conformance ? NO Is Cost related to Non-conformance ? INTERNAL FAILURE YES Is Non-Conformance found prior to Shipment ? NO YES NO Not a Quality Cost EXTERNAL FAILURE Copyright DENAB Quality Sys. 1998

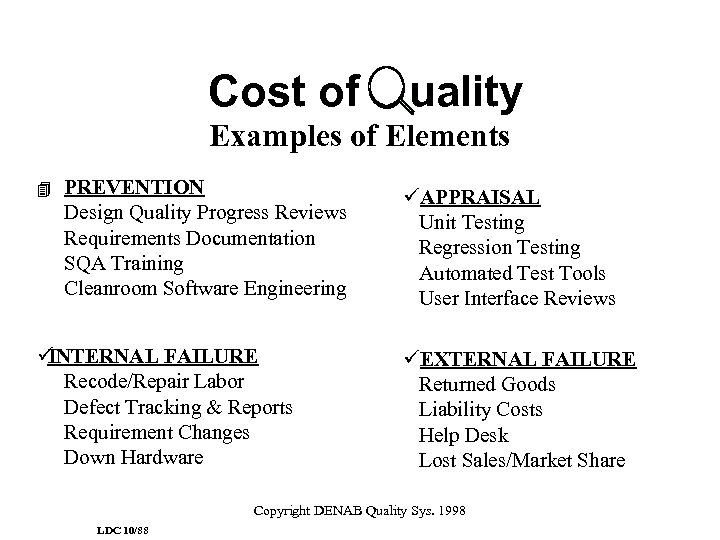

Cost of uality Examples of Elements 4 PREVENTION Design Quality Progress Reviews Requirements Documentation SQA Training Cleanroom Software Engineering ü INTERNAL FAILURE Recode/Repair Labor Defect Tracking & Reports Requirement Changes Down Hardware üAPPRAISAL Unit Testing Regression Testing Automated Test Tools User Interface Reviews üEXTERNAL FAILURE Returned Goods Liability Costs Help Desk Lost Sales/Market Share Copyright DENAB Quality Sys. 1998 LDC 10/88

Cost of uality Corrective Action vs Failure l Corrective Action is paid for Once, l Whereas Failure to take corrective action may be paid for over and over again. Copyright DENAB Quality Sys. 1998

Cost of uality Strategy Premise The Strategy is based on the premise that: l For each failure there is a root cause. l Causes are preventable. l Prevention is always cheaper. Copyright DENAB Quality Sys. 1998 ACQC, Principles of Quality Costs, 1986

Cost of uality Strategy for using Quality Costs l Take direct attack on FAILURE costs, try to drive to zero $. l Invest in the "right" PREVENTION activities to bring about improvements. l Reduce APPRAISAL costs according to results achieved. l Continuously evaluate and redirect PREVENTION efforts to gain further improvement. Copyright DENAB Quality Sys. 1998 ASQC, Principles of Quality Costs, 1986

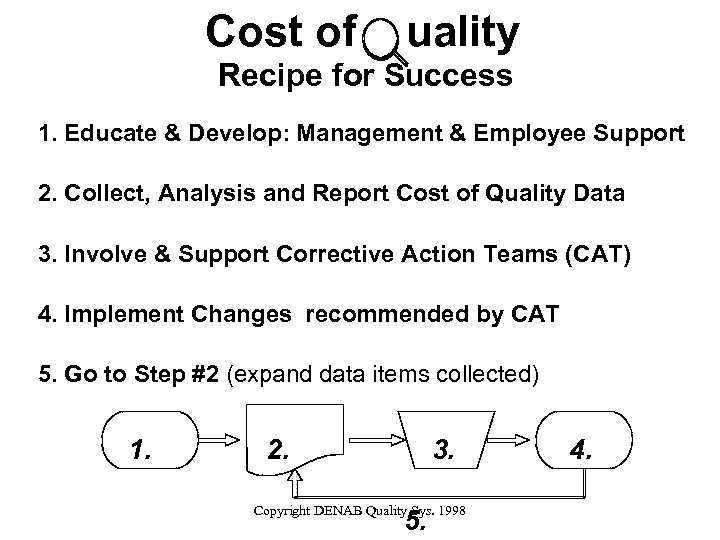

Cost of uality Recipe for Success 1. Educate & Develop: Management & Employee Support 2. Collect, Analysis and Report Cost of Quality Data 3. Involve & Support Corrective Action Teams (CAT) 4. Implement Changes recommended by CAT 5. Go to Step #2 (expand data items collected) 1. 2. 3. Copyright DENAB Quality Sys. 1998 5. 4.

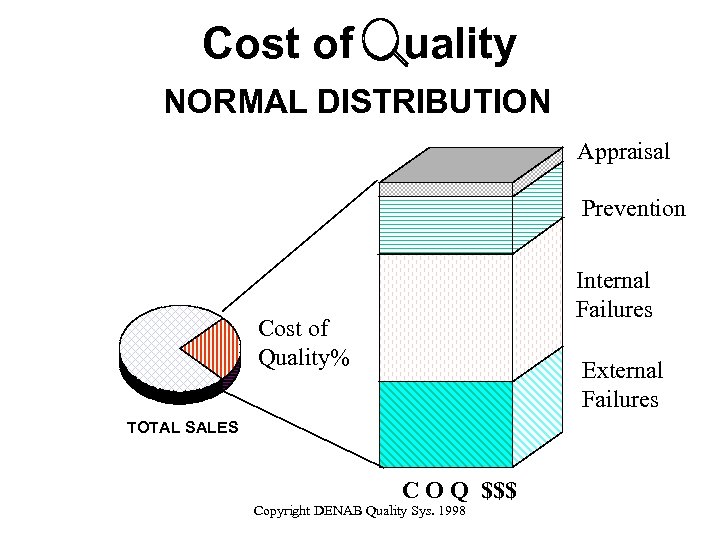

Cost of uality NORMAL DISTRIBUTION Appraisal Prevention Total Sales Internal Failures Cost of Quality% External Failures TOTAL SALES C O Q $$$ Copyright DENAB Quality Sys. 1998

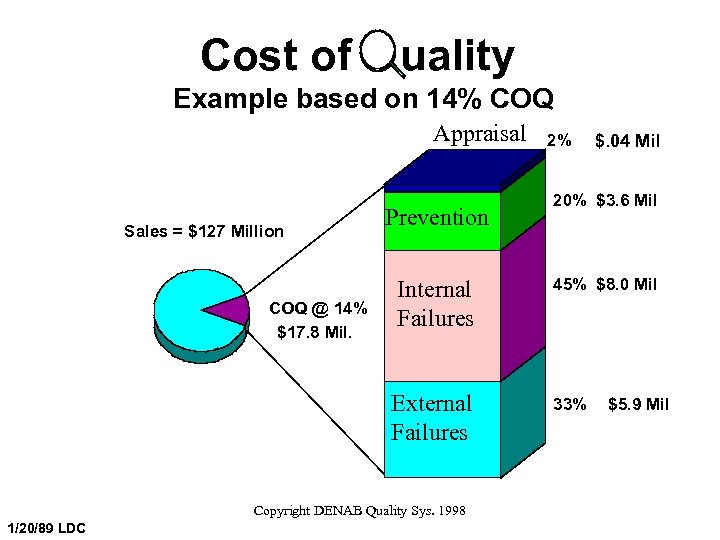

Cost of uality Example based on 14% COQ Appraisal Sales = $127 Million SALES COQ @ 14% COQ $17. 8 Mil. Prevention Internal Failures External Failures Copyright DENAB Quality Sys. 1998 1/20/89 LDC 2% $. 04 Mil 20% $3. 6 Mil 45% $8. 0 Mil 33% $5. 9 Mil

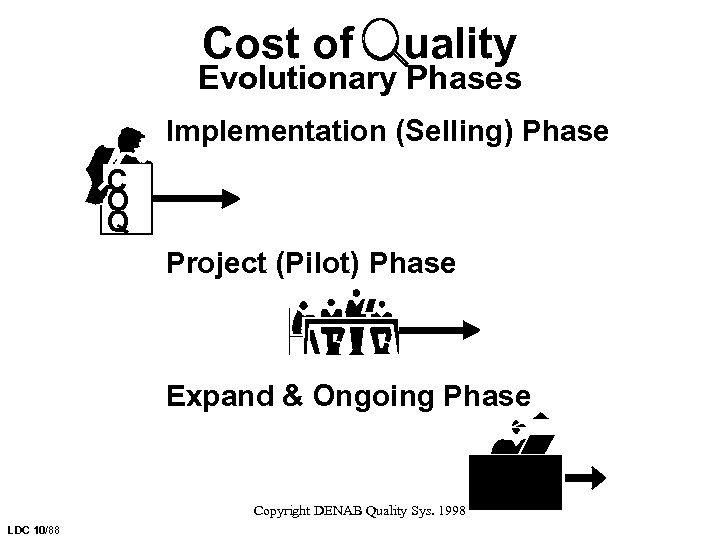

Cost of uality Evolutionary Phases Implementation (Selling) Phase C O Q Project (Pilot) Phase Expand & Ongoing Phase Copyright DENAB Quality Sys. 1998 LDC 10/88

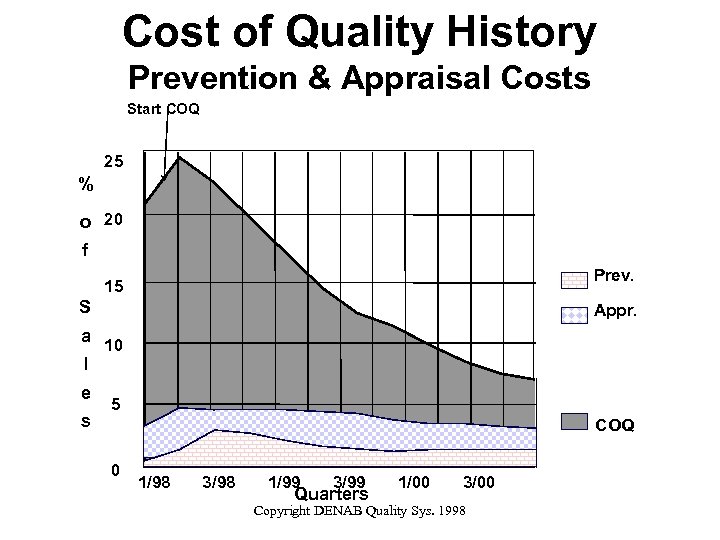

Cost of Quality History Prevention & Appraisal Costs Start COQ 25 % o 20 f Prev. 15 S a l e s Appr. 10 5 COQ 0 1/98 3/98 1/99 3/99 Quarters 1/00 3/00 Copyright DENAB Quality Sys. 1998

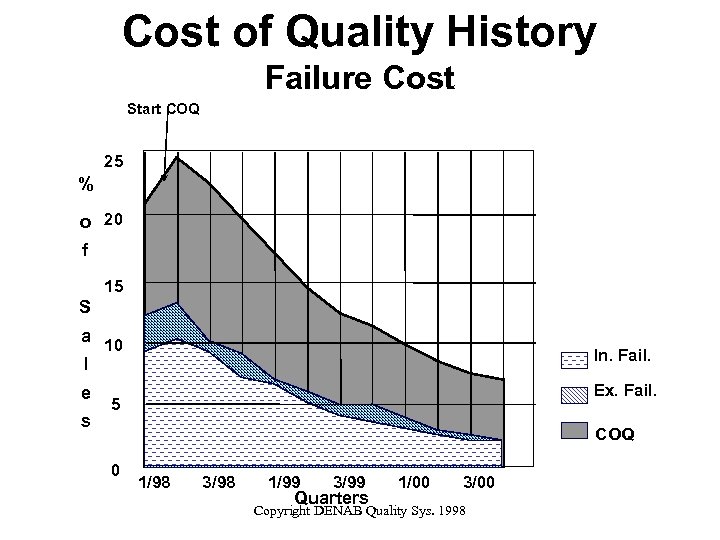

Cost of Quality History Failure Cost Start COQ 25 % o 20 f 15 S a l e s 10 In. Fail. Ex. Fail. 5 COQ 0 1/98 3/98 1/99 3/99 Quarters 1/00 3/00 Copyright DENAB Quality Sys. 1998

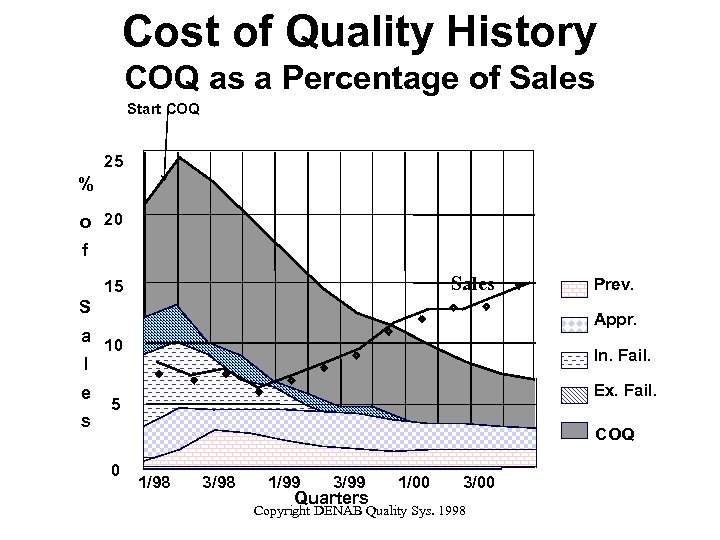

Cost of Quality History COQ as a Percentage of Sales Start COQ 25 % o 20 f Sales 15 S a l e s Prev. Appr. 10 In. Fail. Ex. Fail. 5 COQ 0 1/98 3/98 1/99 3/99 Quarters 1/00 3/00 Copyright DENAB Quality Sys. 1998

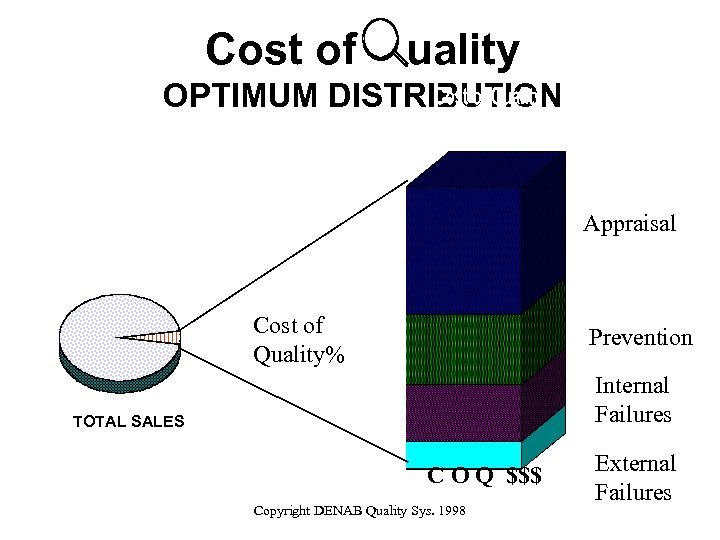

Cost of uality OPTIMUM DISTRIBUTION Appraisal Cost of Quality% Prevention Internal Failures TOTAL SALES C O Q $$$ Copyright DENAB Quality Sys. 1998 External Failures

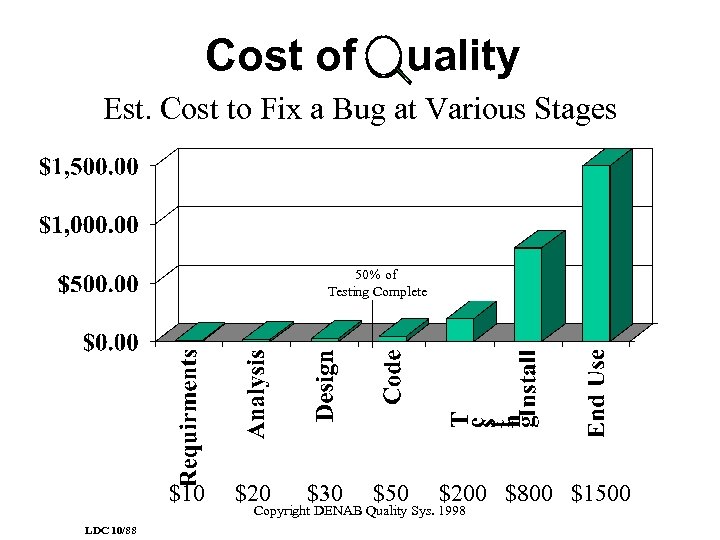

Cost of uality Est. Cost to Fix a Bug at Various Stages 50% of Testing Complete $10 LDC 10/88 $20 $30 $50 $200 $800 $1500 Copyright DENAB Quality Sys. 1998

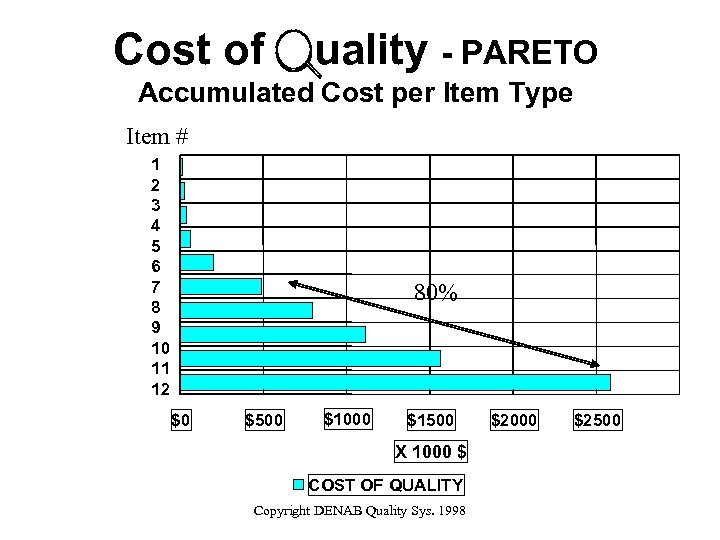

Cost of uality - PARETO Accumulated Cost per Item Type Item # 1 2 3 4 5 6 7 8 9 10 11 12 80% $0 $500 $1000 $1500 X 1000 $ COST OF QUALITY Copyright DENAB Quality Sys. 1998 $2000 $2500 $3000

Benefits of Improved Quality is a Profit Center Decreases Increases Defects Overall Costs Returned Goods Employee Turnover Customer Complaints Owner & Mgmt. Stress Decrease Legal Costs Decreased Time to Market Sales Profit Capacity Employee Satisfaction Customer Satisfaction Market Share Competitive Edge Personal Time Away Copyright DENAB Quality Sys. 1998

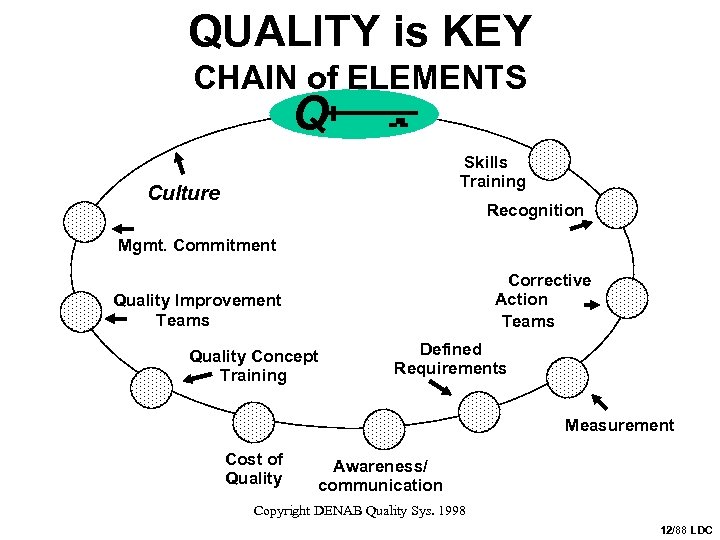

QUALITY is KEY CHAIN of ELEMENTS Q Skills Training Culture Recognition Mgmt. Commitment Corrective Action Teams Quality Improvement Teams Quality Concept Training Defined Requirements Measurement Cost of Quality Awareness/ communication Copyright DENAB Quality Sys. 1998 12/88 LDC

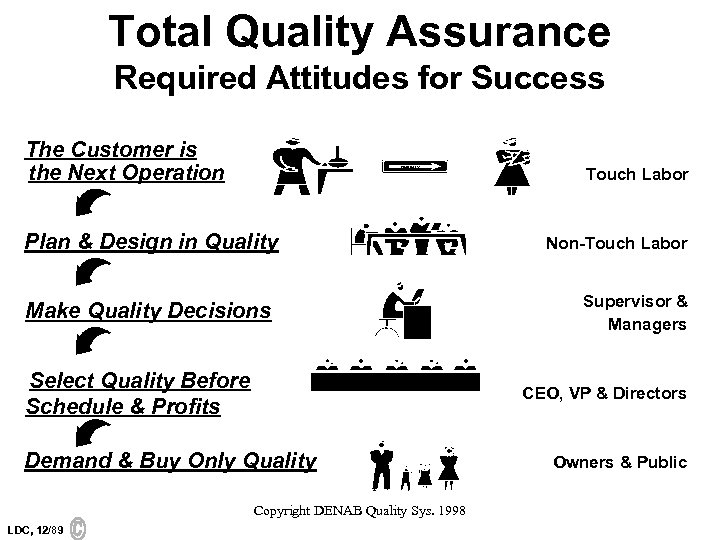

Total Quality Assurance Required Attitudes for Success The Customer is the Next Operation ONE WAY Plan & Design in Quality Make Quality Decisions Select Quality Before Schedule & Profits Non-Touch Labor Supervisor & Managers CEO, VP & Directors Demand & Buy Only Quality Copyright DENAB Quality Sys. 1998 LDC, 12/89 Touch Labor Owners & Public

How Do We Achieve Quality? • By designing products with features reflecting customer needs • By making the life-cycle more efficient and effective • By following standards, “best practices, ” tools, philosophies, methodologies, techniques and measures developed to help organizations meet Quality goals Copyright DENAB Quality Sys. 1998 35

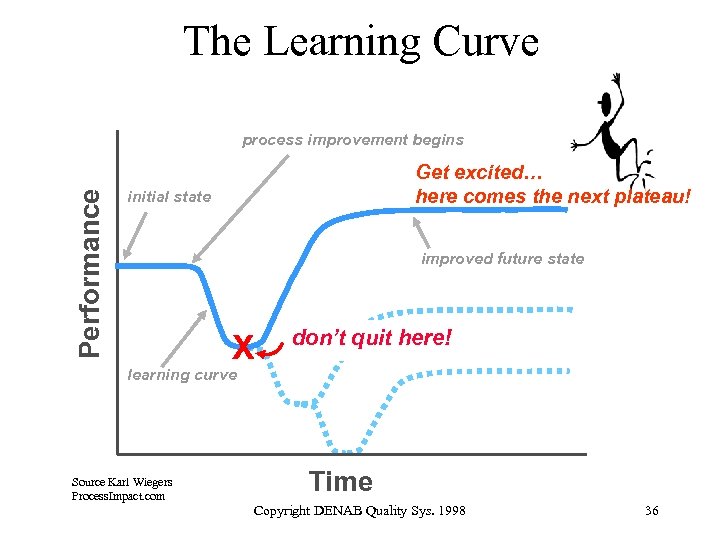

The Learning Curve Performance process improvement begins Get excited… here comes the next plateau! initial state improved future state X don’t quit here! learning curve Source Karl Wiegers Process. Impact. com Time Copyright DENAB Quality Sys. 1998 36

Thank You for Listening References: • Principles of Quality Costs (ASQ) • Guide for Reducing Quality Costs (ASQ) • Quality without Tears, Crosby • Quality Cost Analysis: Benefits & Risks, Kaner • Quality Control Handbook, Juran • Right the First Time, British Productive Council film To Contact Daniel Crowley • 206 -689 -1352 • Email Daniel_Crowley@IDX. com • L. D. Crowley@kp. org (2005) Copyright DENAB Quality Sys. 1998 37

f6e6d7a75d01bff6e7147ba16cccc430.ppt